Method for recycling nitrogen gas and sulfur dioxide from calcining iron pyrite burner gas through variable-voltage variable-frequency adsorption

A technology of sulfur dioxide and pressure swing adsorption, which is applied in the direction of chemical instruments and methods, sulfur compounds, separation methods, etc., can solve the problems of large amount of slag output, large equipment investment, and low production cost, so as to avoid difficult disposal and engineering Green effect of investment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

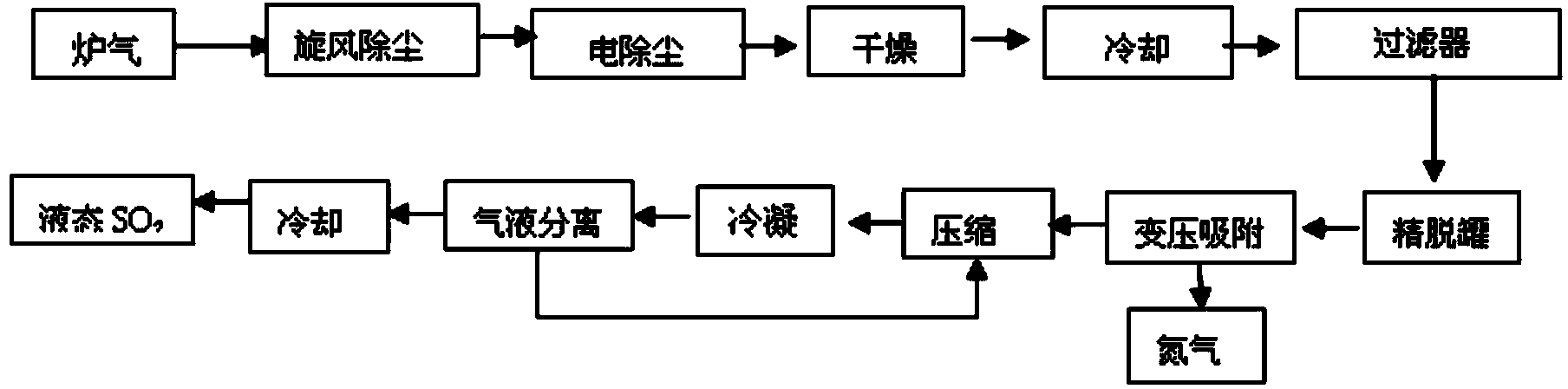

[0036] The furnace gas from the fluidized bed furnace for roasting pyrite is recovered by the high-temperature waste heat boiler, the medium temperature and low temperature cooling purification after cyclone dust removal and electric dust removal, dust removal and sulfur trioxide, drying and cooling. At this time, the temperature of the furnace gas is 35°C , with a mass ratio of sulfur dioxide of 12%, CO 2 and O 2 The content of N2 is less than 1%, and N2 is 87%; then the dust particles and rust entrained in the mixed gas are removed through a refined sulfuric acid furnace gas filter made of 200-mesh polytetrafluoroethylene, and then adsorbed by a fine extraction tank loaded with combined carbon molecular sieves Remove traces of water and O in the mixed furnace gas 2 and CO 2 , at this time, the water content in the mixed furnace gas is reduced to 2.1mg / kg, the content of sulfur dioxide is about 12.5%, and the N 2 The content is about 87.5%; then compressed by the compresso...

Embodiment 2

[0042] The sulfur dioxide-containing furnace gas from the fluidized bed furnace for roasting pyrite is recovered by the high-temperature waste heat boiler, and after the cyclone dust removal and electric dust removal, the medium temperature cooling purification and low temperature cooling purification, dust removal and sulfur trioxide removal, drying and cooling, at this time, Furnace gas temperature is 40°C, sulfur dioxide content is 7%, CO 2 and O 2 content of less than 1%, N 2 92%; and then through a 200-mesh polytetrafluoroethylene refined sulfuric acid furnace gas filter to remove dust particles and rust entrained in the mixed gas, fine desorption tank adsorption to remove trace water and O in the mixed furnace gas 2 and CO 2 , at this time, the water content in the mixed furnace gas is reduced to 3.2mg / kg, the content of sulfur dioxide is about 7.5%, and the content of N2 is about 92.5%; The exhaust pressure is 0.55MPa, and the exhaust temperature is about 41°C at nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com