Patents

Literature

116results about "Removable covers for furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

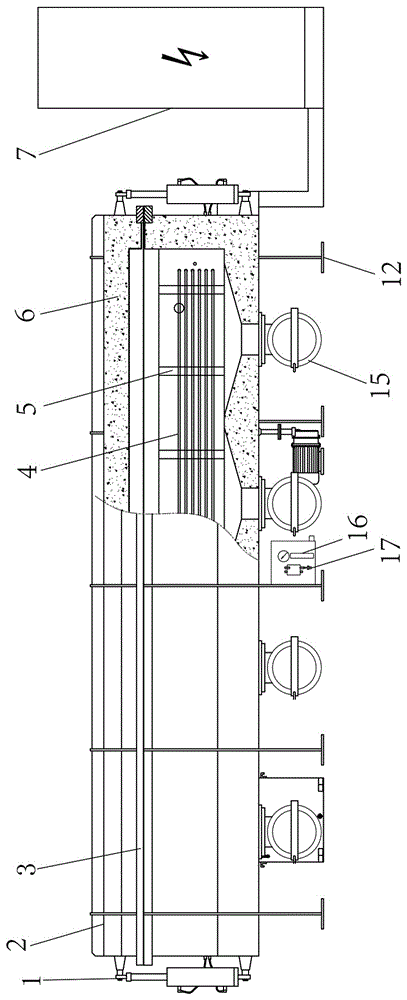

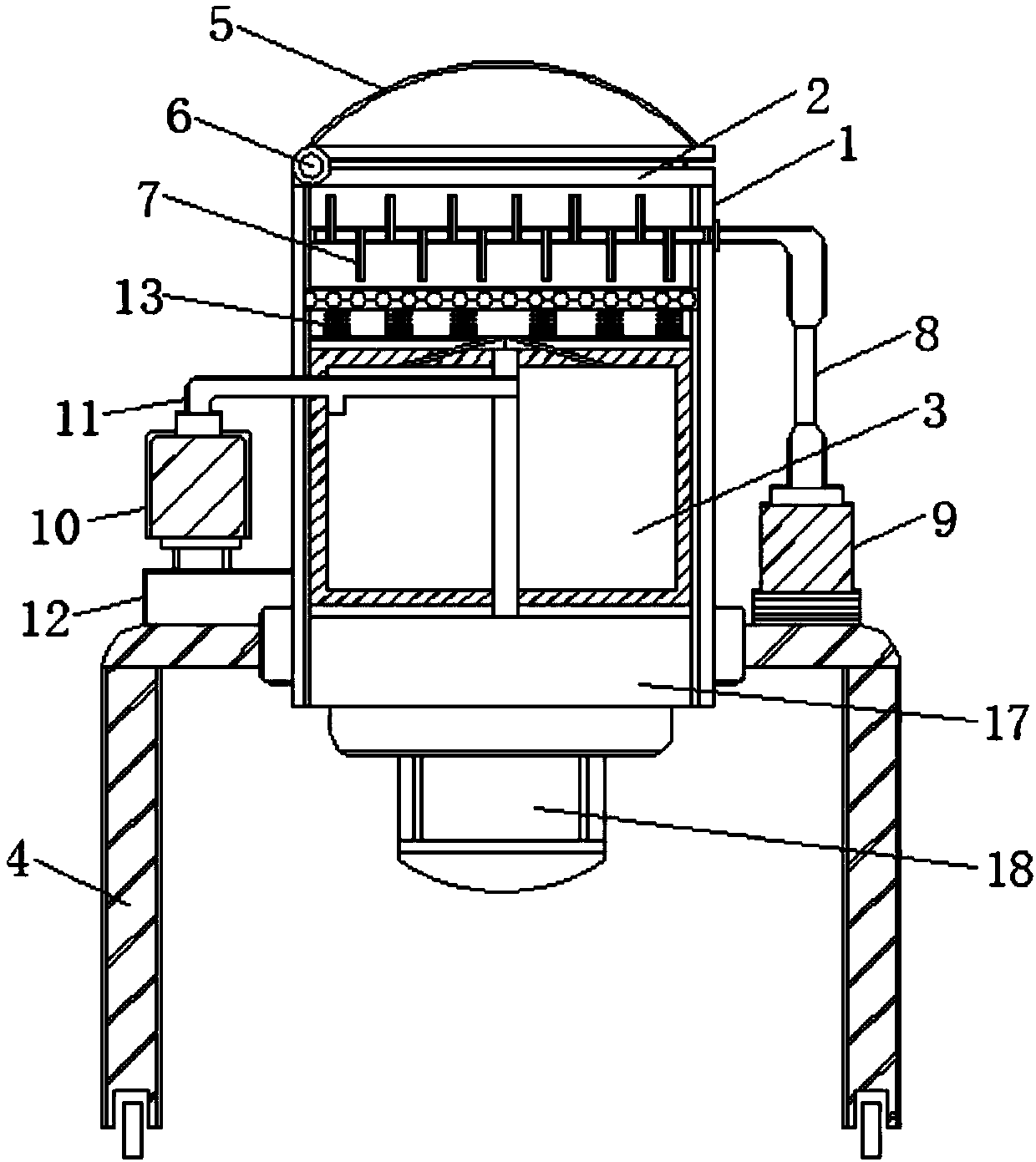

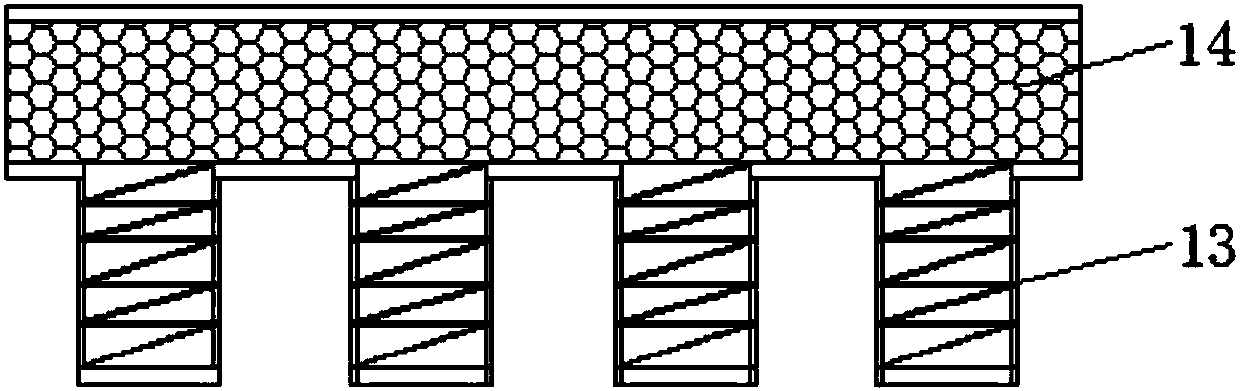

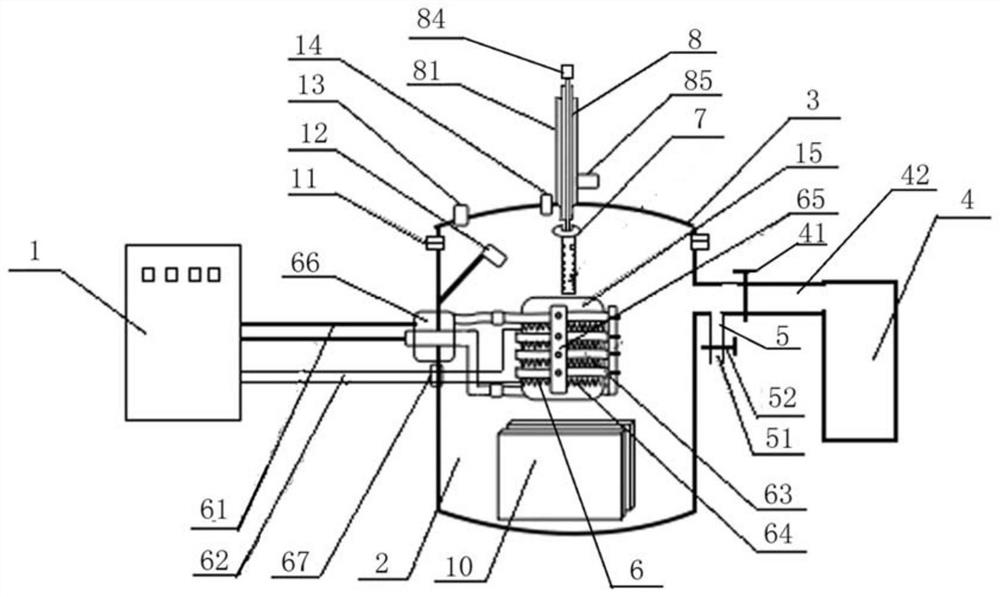

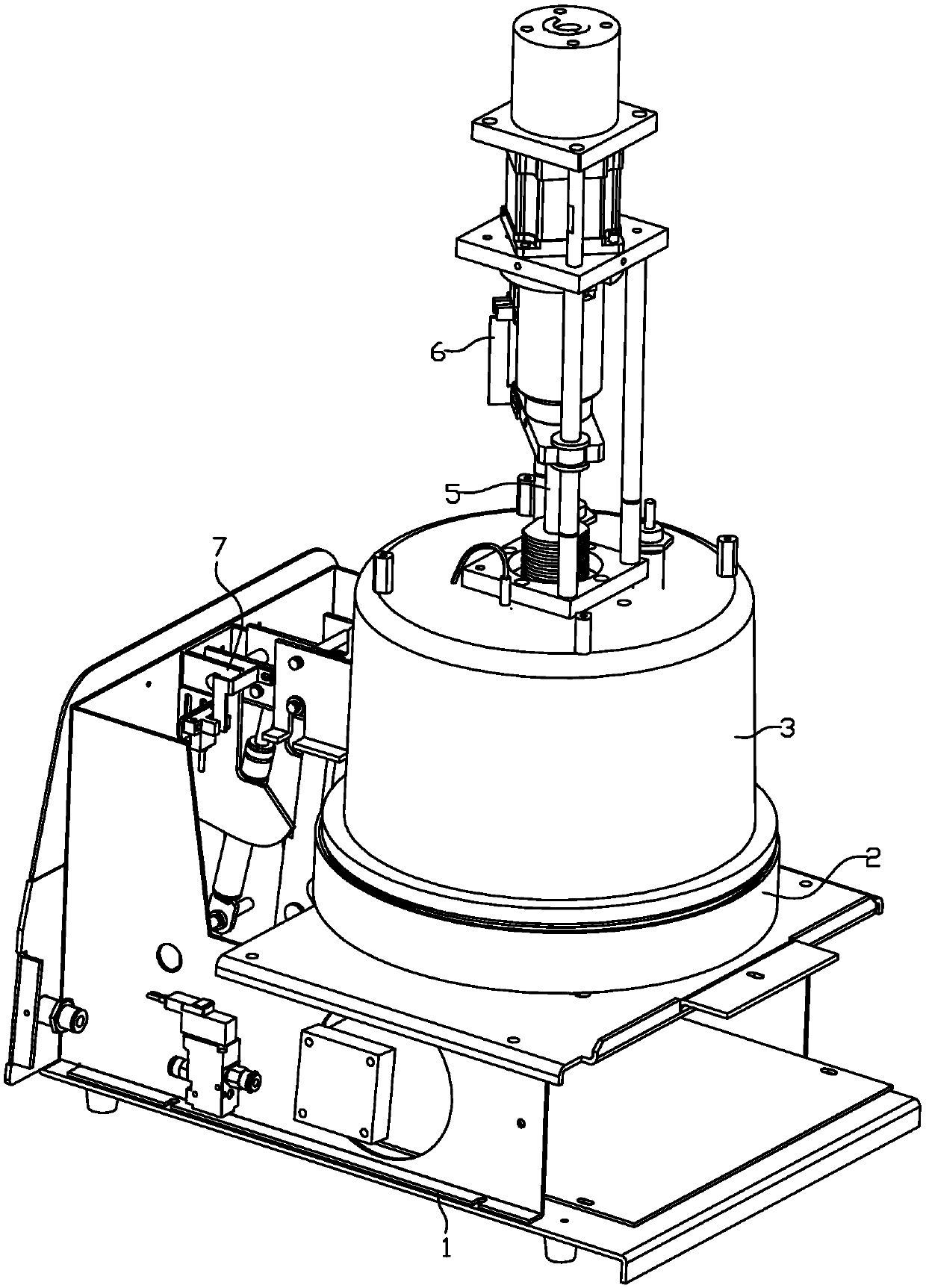

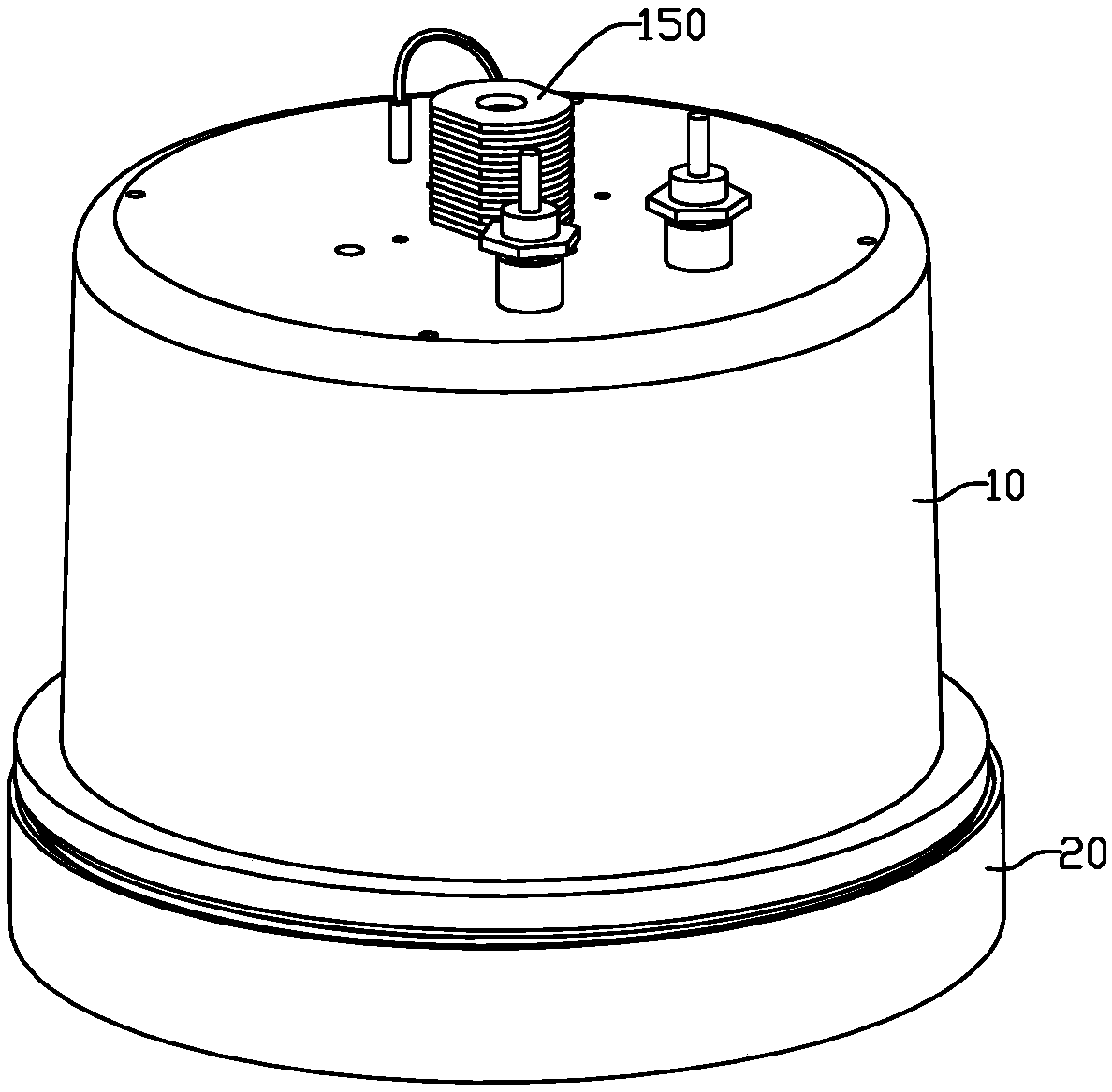

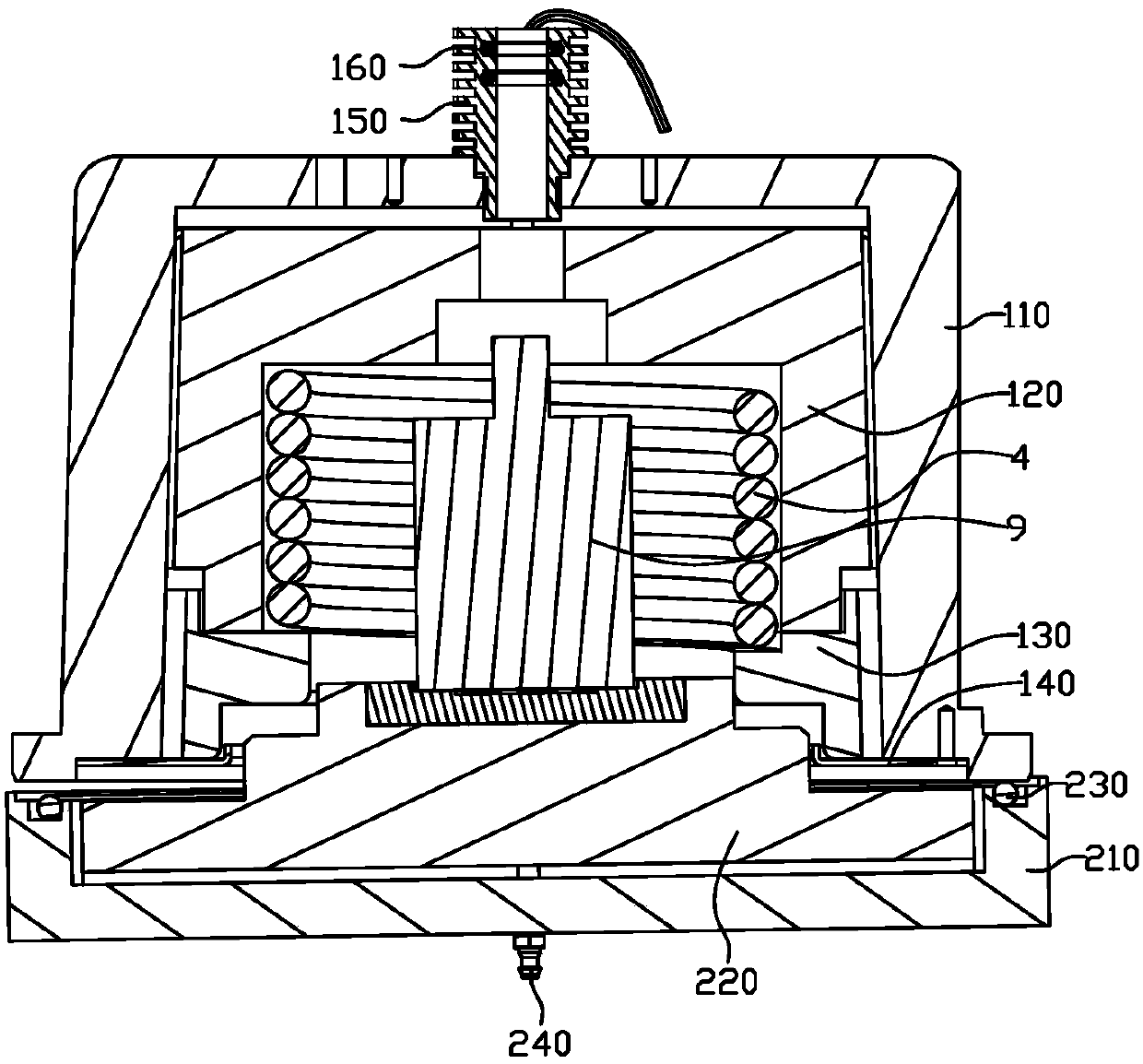

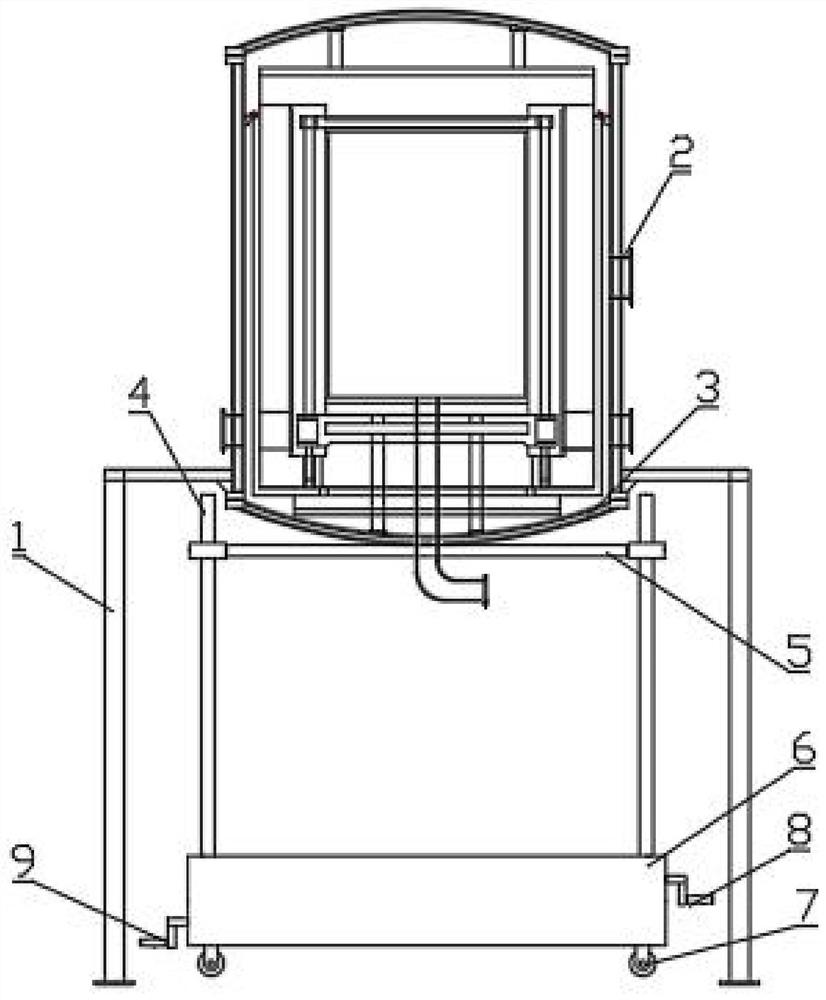

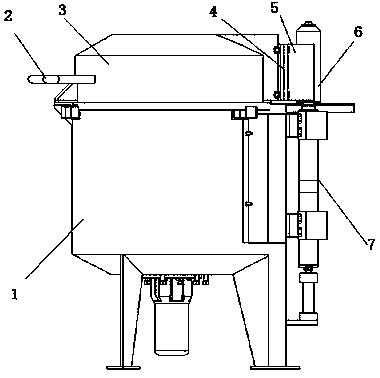

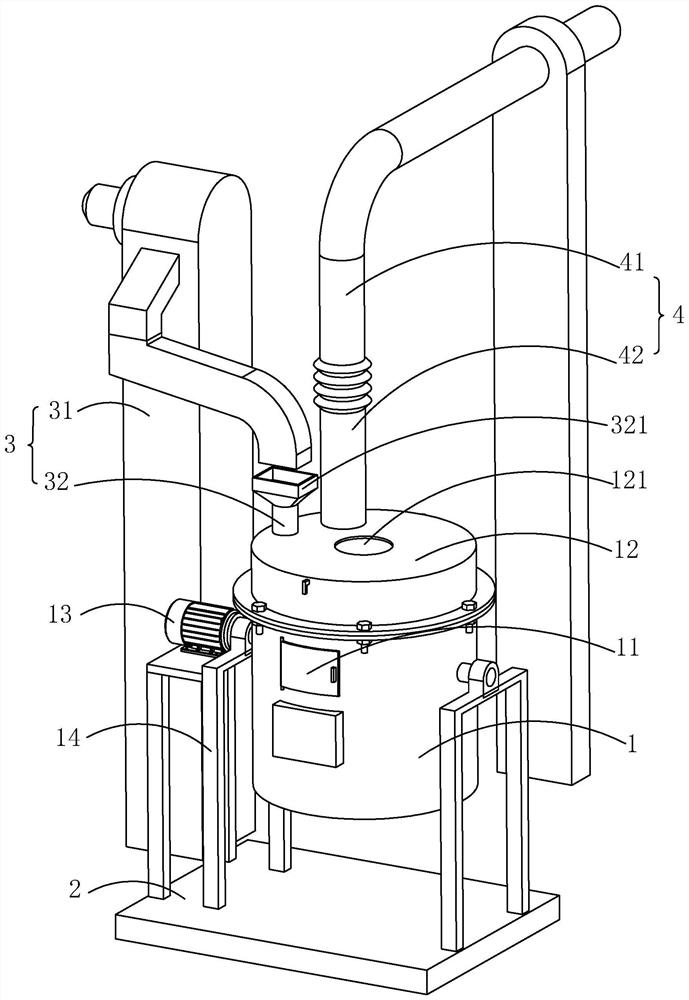

Vacuum incinerator device and operating method thereof

ActiveCN106091689AGuaranteed stabilityEasy to collectRemovable covers for furnacesSpinnerette packsTemperature controlControl system

The invention discloses a vacuum incinerator. The vacuum incinerator is a JZK-C well type vacuum incinerator and comprises a vacuum hearth, an incinerator cover opening and closing device, electric heating pipes, a waste collecting system, a vacuum pipeline anti-blocking device, a water spraying device, a water ring vacuum pump, a water backflow preventing device, a gas-water separator, a control system, a water circuit, an air circuit and the like, wherein the vacuum hearth is horizontally placed with an incinerator opening facing upwards and composed of an incinerator cover and a work room used for storing cleaned parts. The waste collecting system mainly comprises a waste collecting tank which is installed on the lower portion of the hearth. A hopper-shaped tray is arranged at the bottom of an inner cavity of the vacuum hearth. A discharging port of the tray is located over the waste collecting tank. Compared with the prior art, the vacuum incinerator is compact in structure, good in sealing performance and large in work space; the incinerator cover is opened and closed through two oil cylinders, the cover opening angle is larger than 90 degrees, and the opening and closing stability of the incinerator cover is guaranteed; waste can be collected conveniently, incineration and cleaning are conducted efficiently, and the situation of water backflow can be effectively prevented; and the automation level is high, temperature control is accurate, the working efficiency is improved, and the labor intensity is relieved.

Owner:JIANGSU XINLONG CHEM FIBER MACHINERY

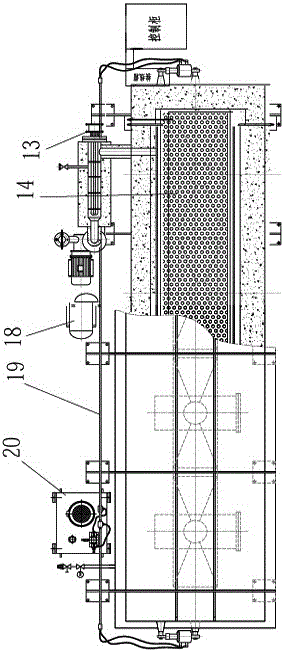

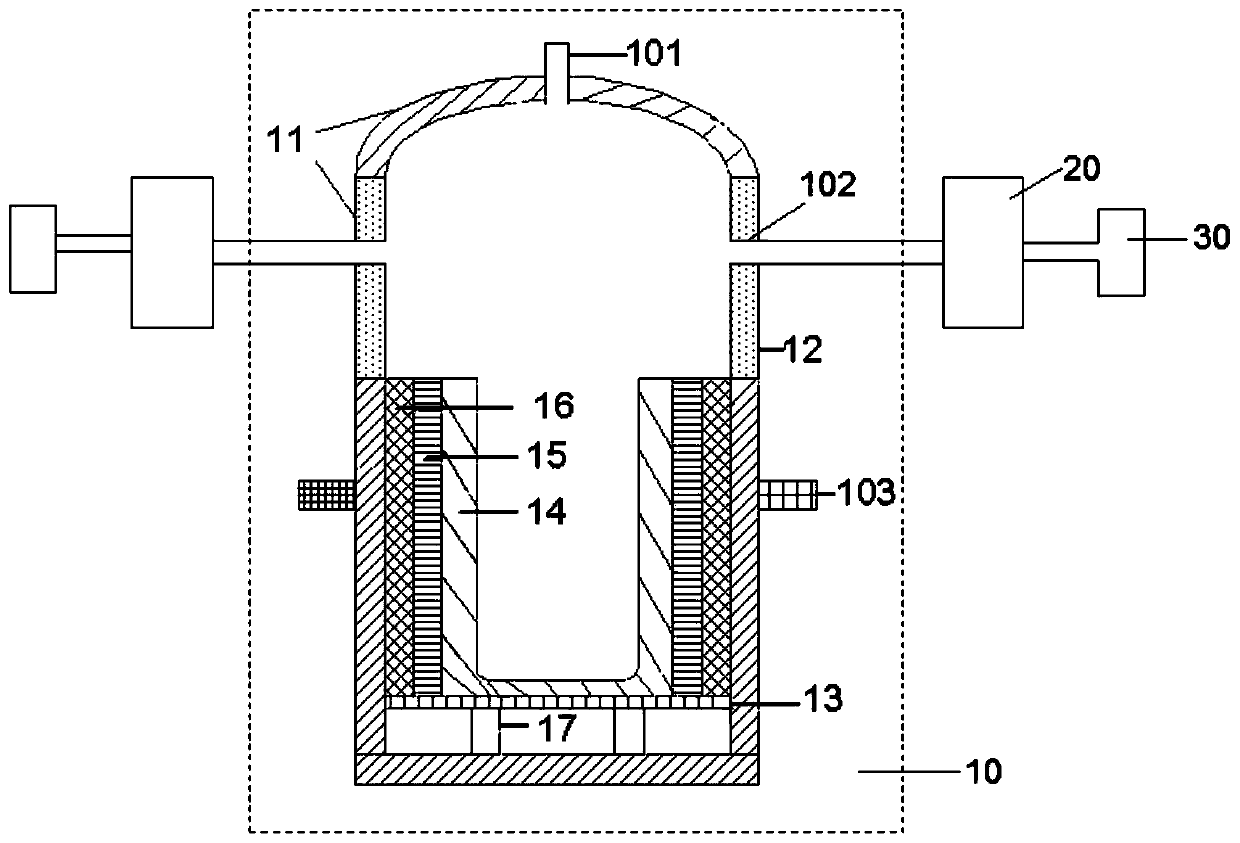

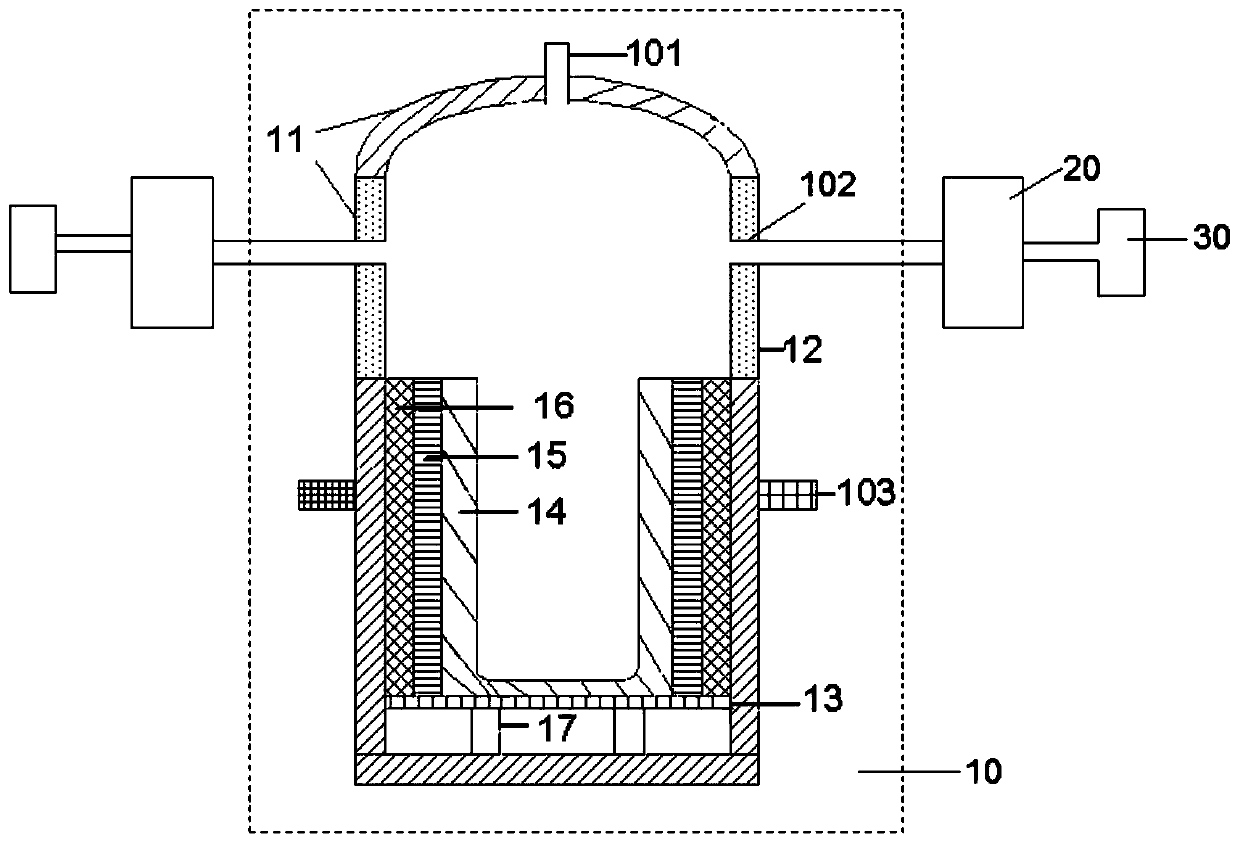

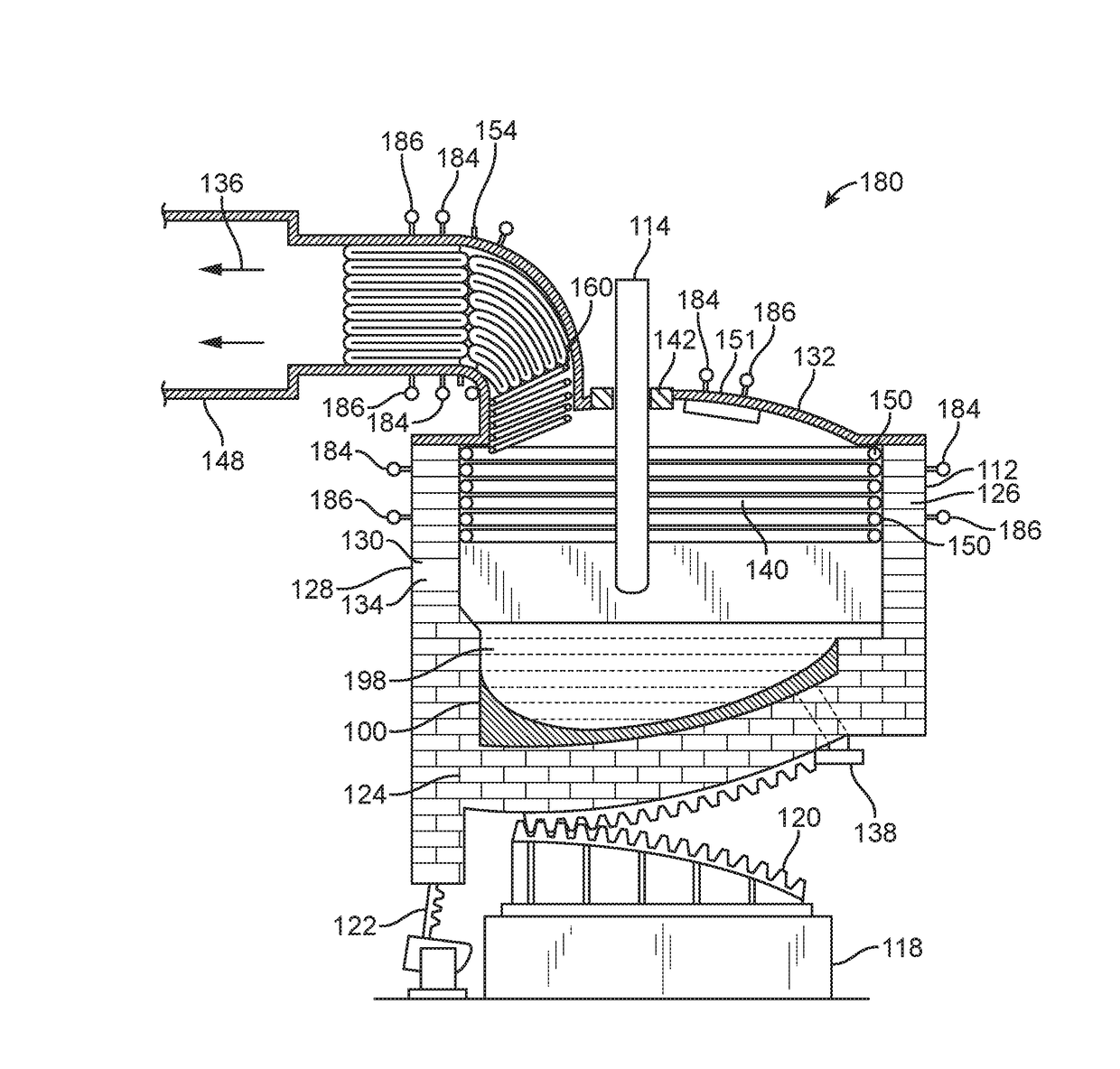

Recovery of metal from dross and apparatus therefore

InactiveUS6159269AEliminate disadvantagesPrevent heat lossRemovable covers for furnacesRotary drum furnacesOxygenDross

PCT No. PCT / CA97 / 00242 Sec. 371 Date Sep. 29, 1998 Sec. 102(e) Date Sep. 29, 1998 PCT Filed Apr. 10, 1997 PCT Pub. No. WO97 / 39155 PCT Pub. Date Oct. 23, 1997A process and an apparatus are disclosed for improved recovery of metal from dross, wherein a dross treating furnace is provided with a refractory wall or lining with good capacity to store and conduct heat. This furnace is preheated to a desired temperature by injection of oxygen to burn non-recoverable metal remaining in the residue after tapping of the recoverable metal contained in the dross. When dross is treated in such preheated furnace, the heat emanating by conduction from the furnace wall is sufficient to melt and separate the recoverable metal contained in the dross, without addition of an external heat source, such as fuel or gas burners, plasma torches or electric arcs.

Owner:PYROGENESIS CANADA INC

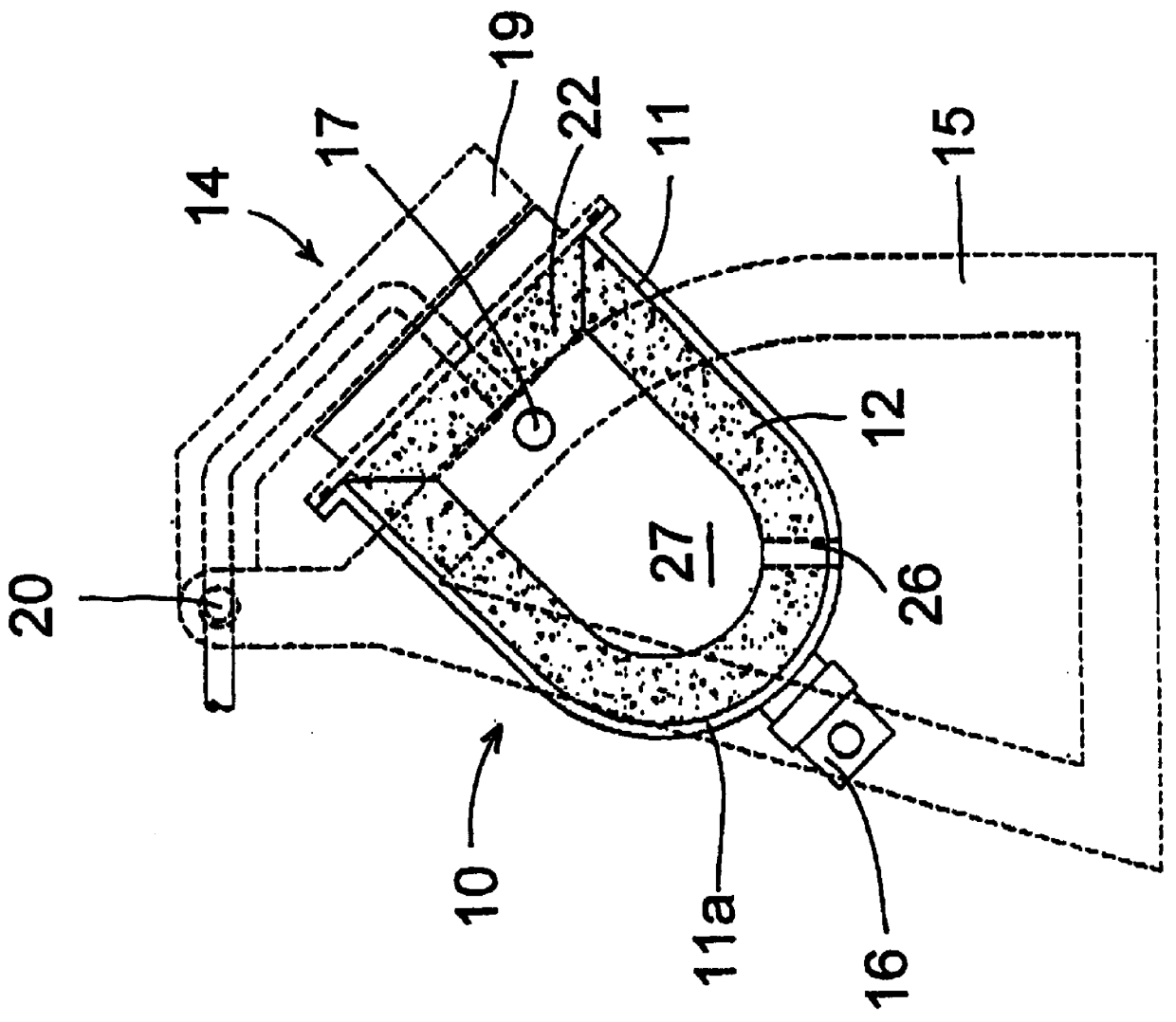

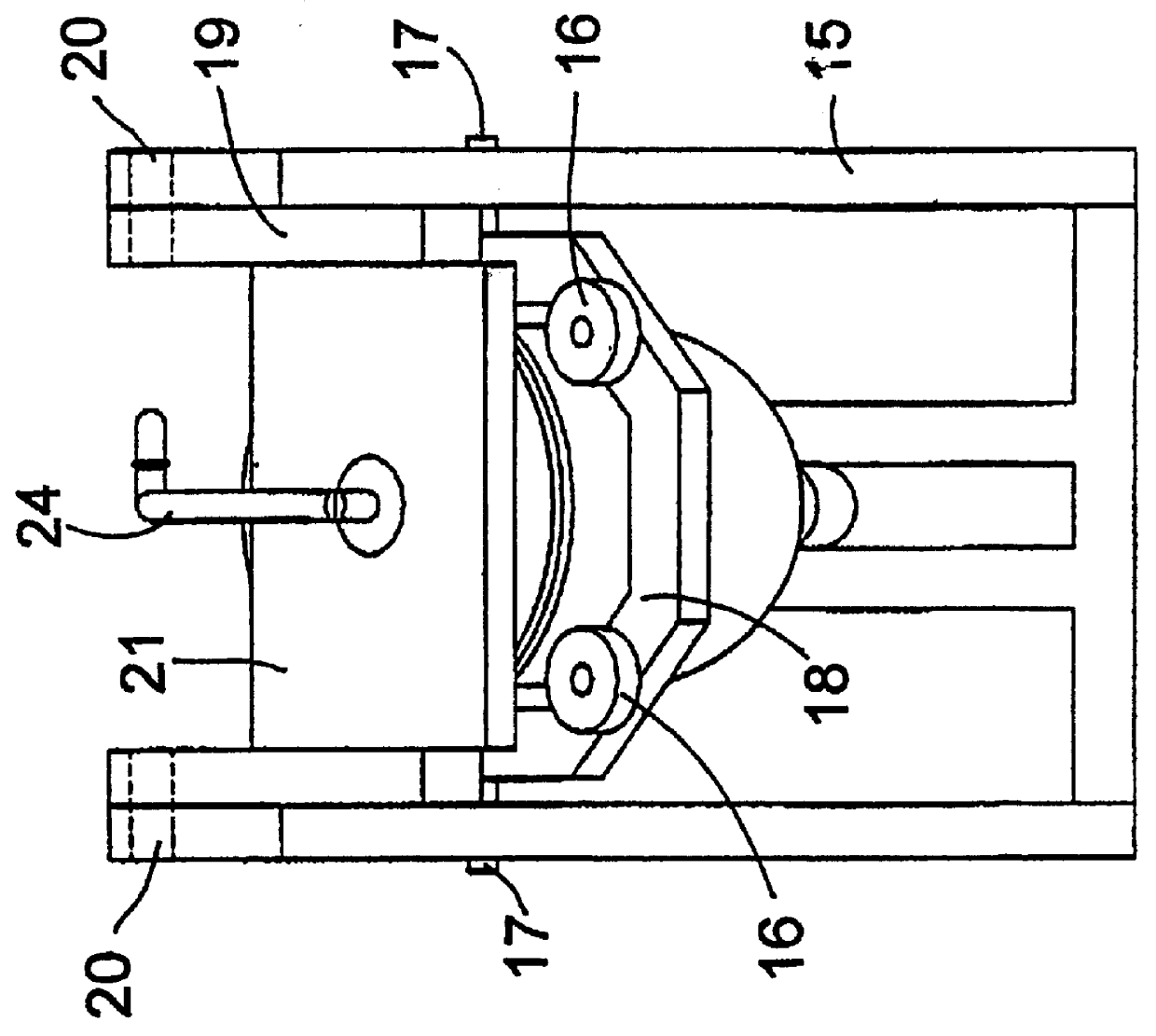

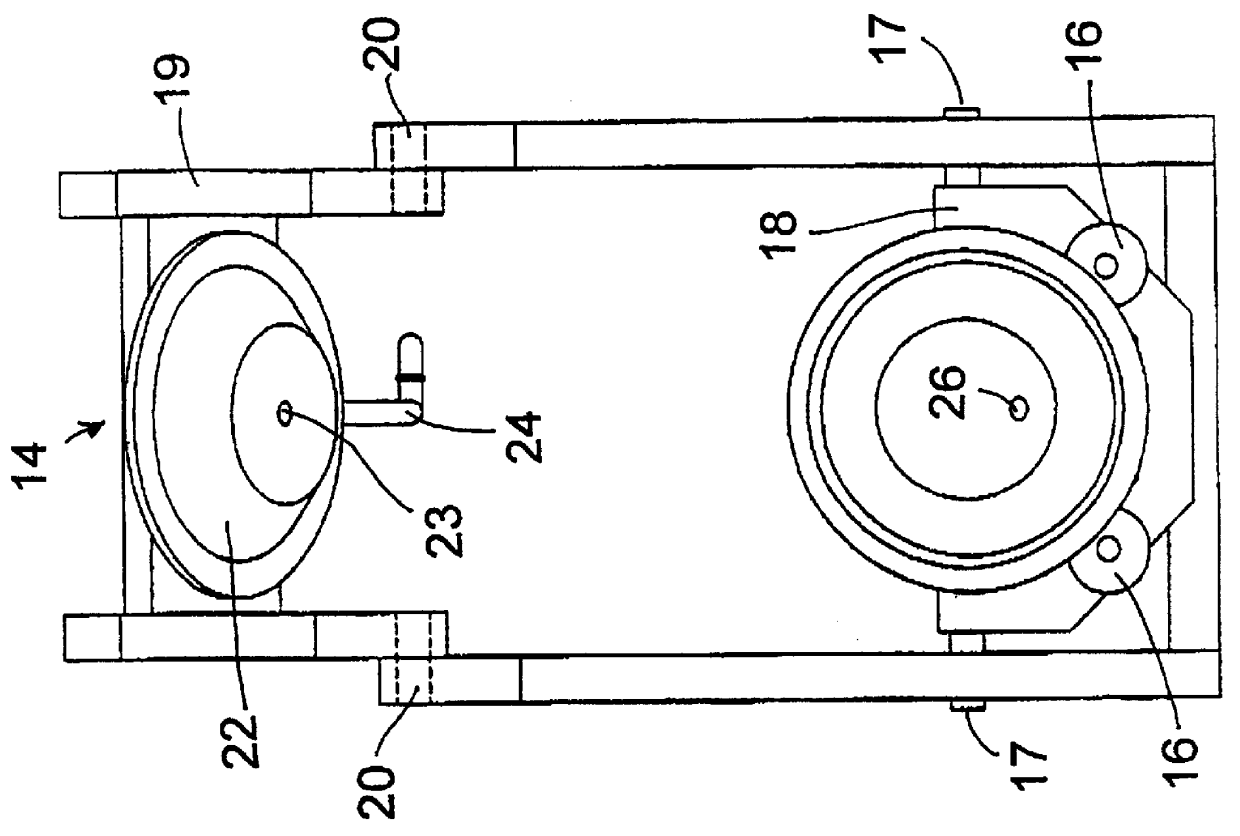

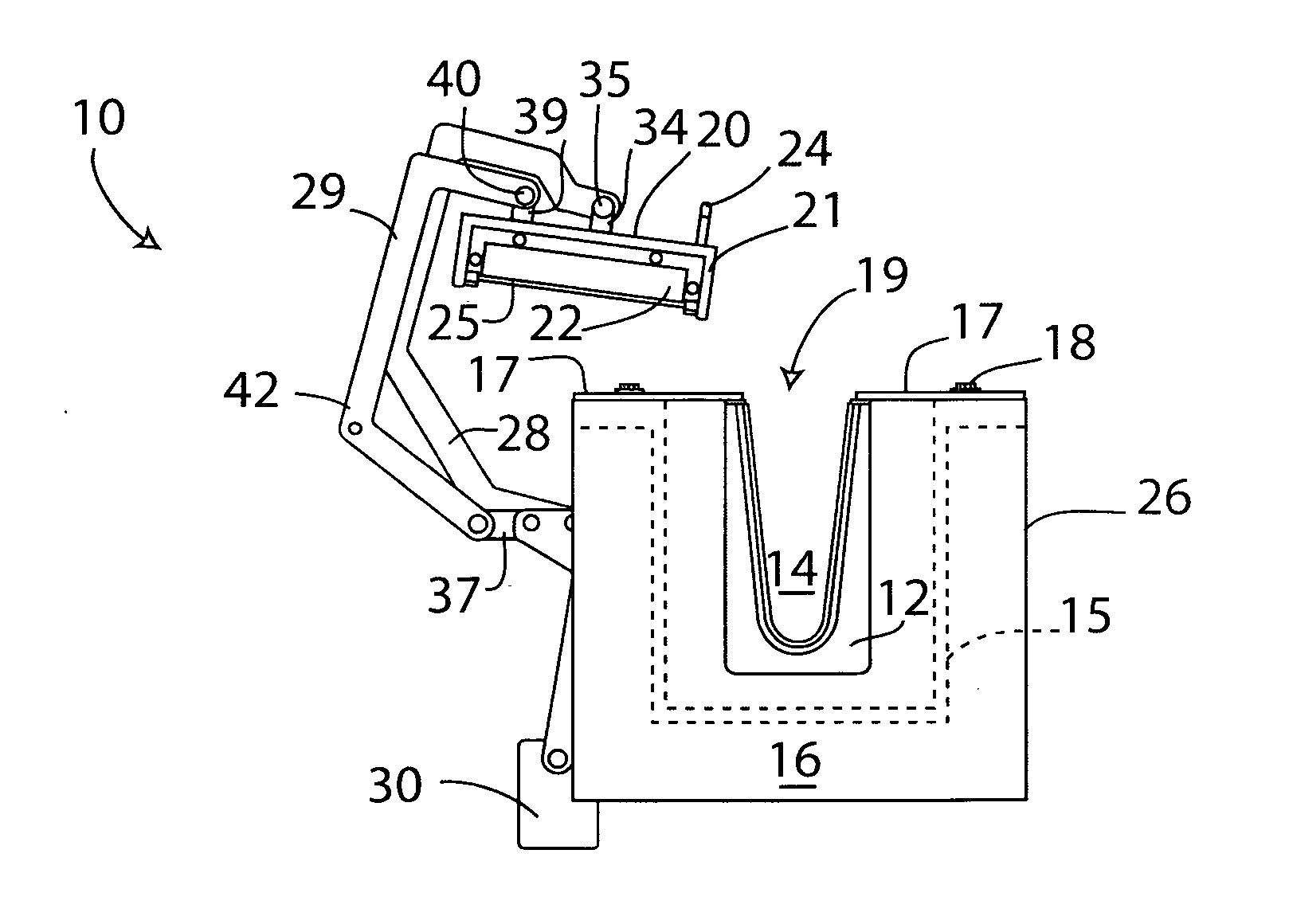

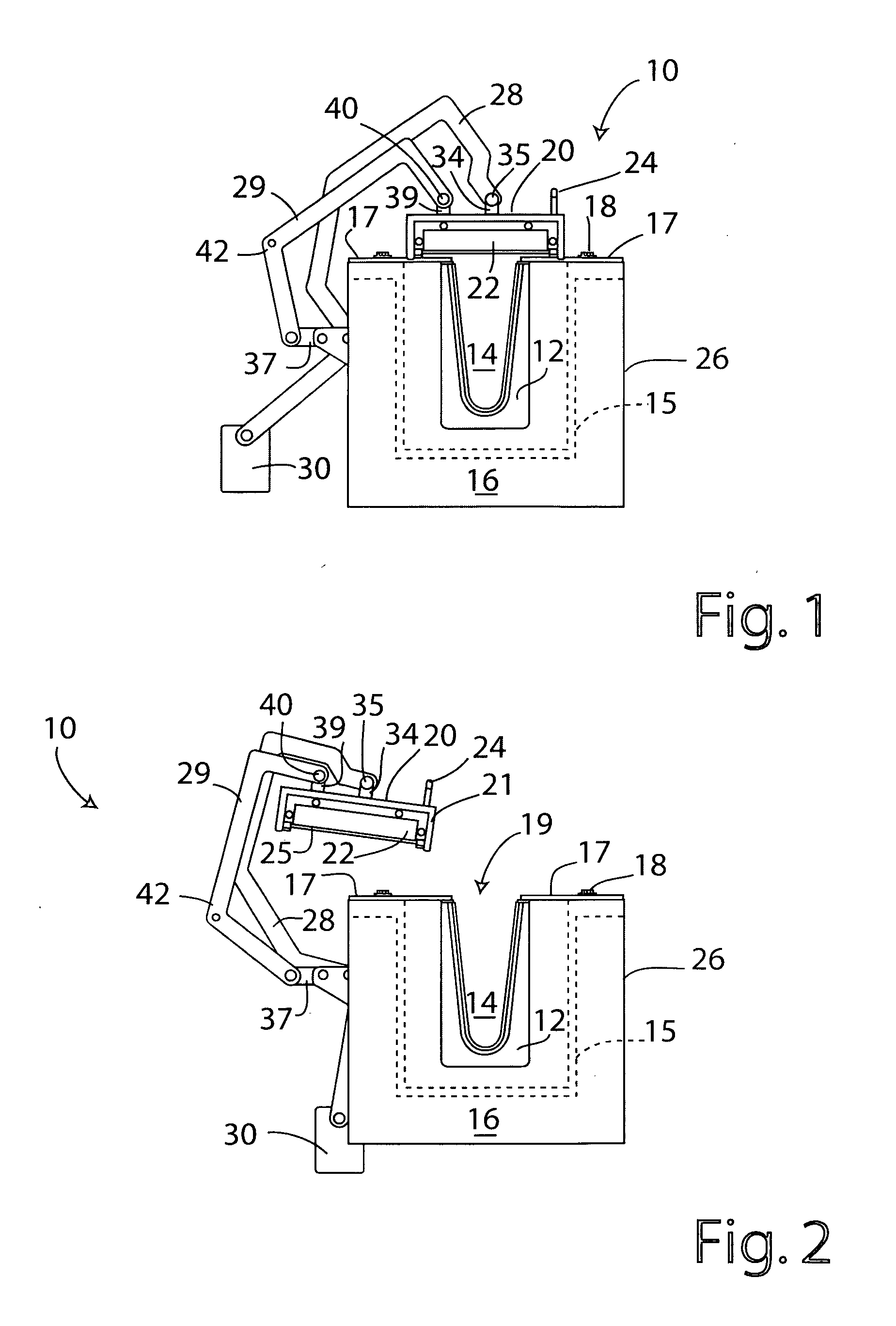

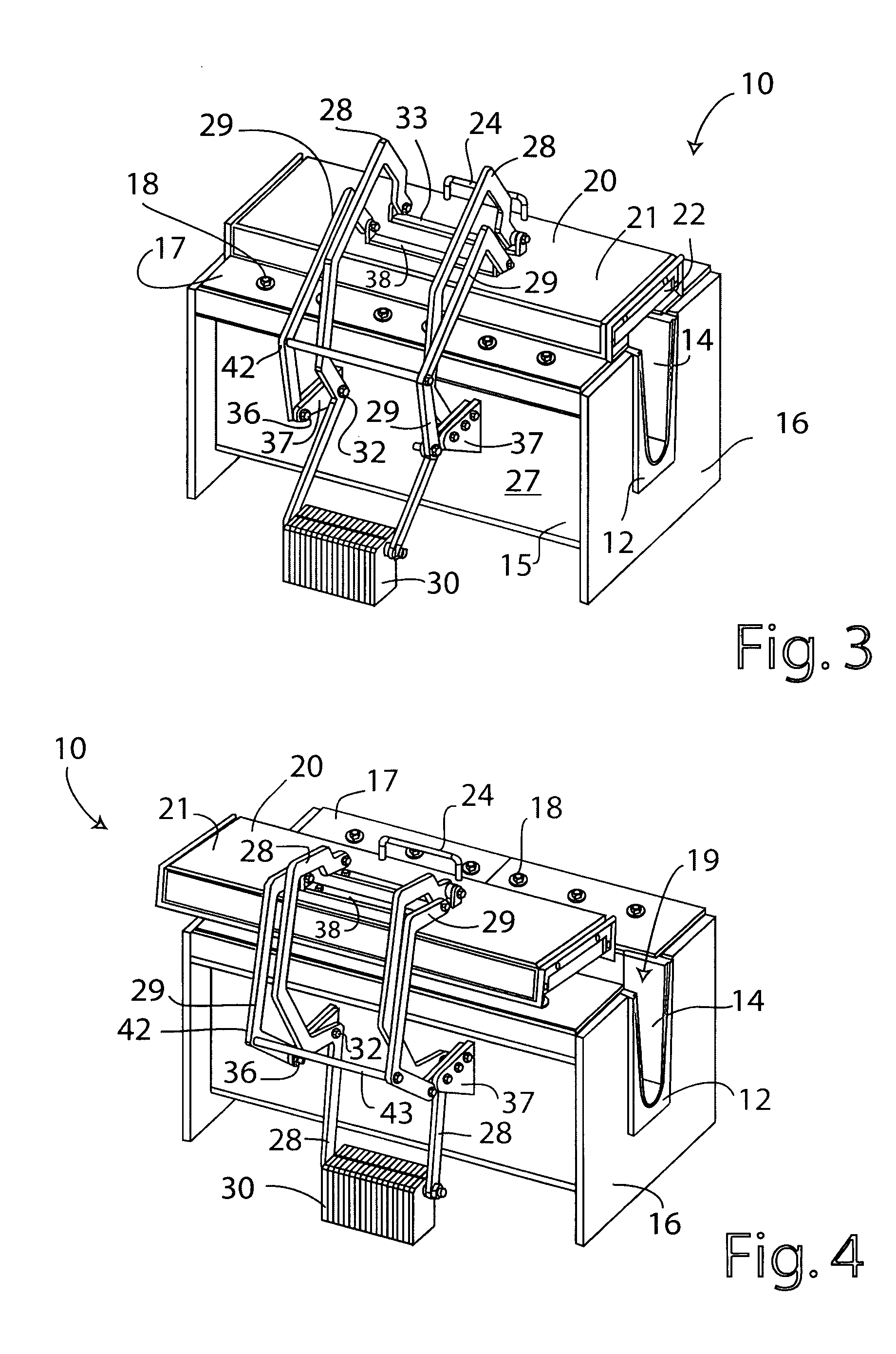

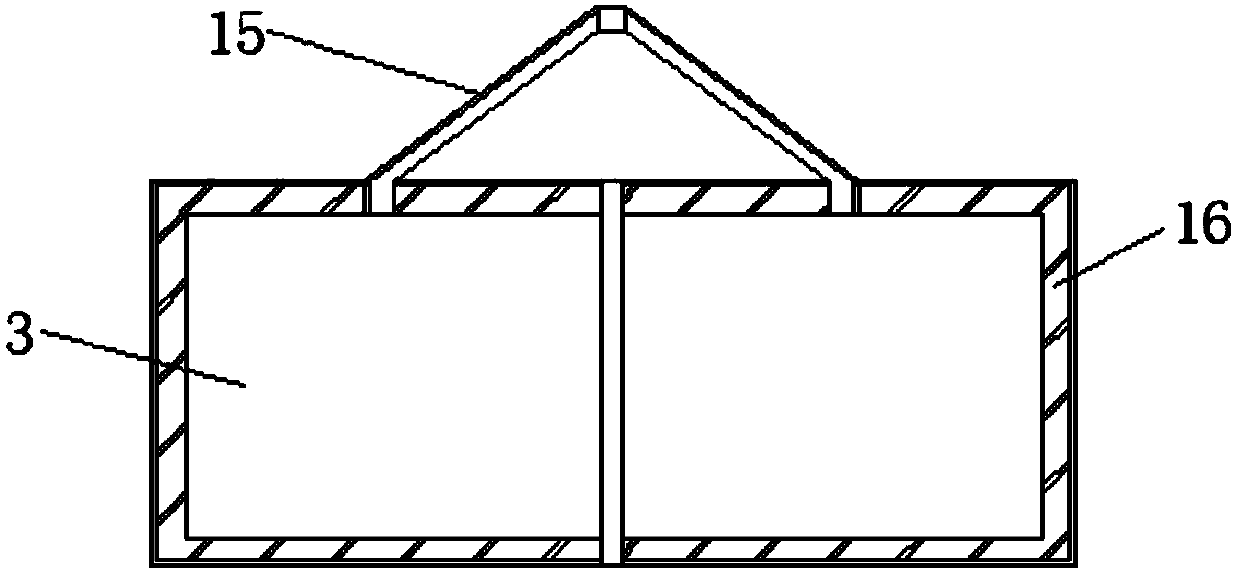

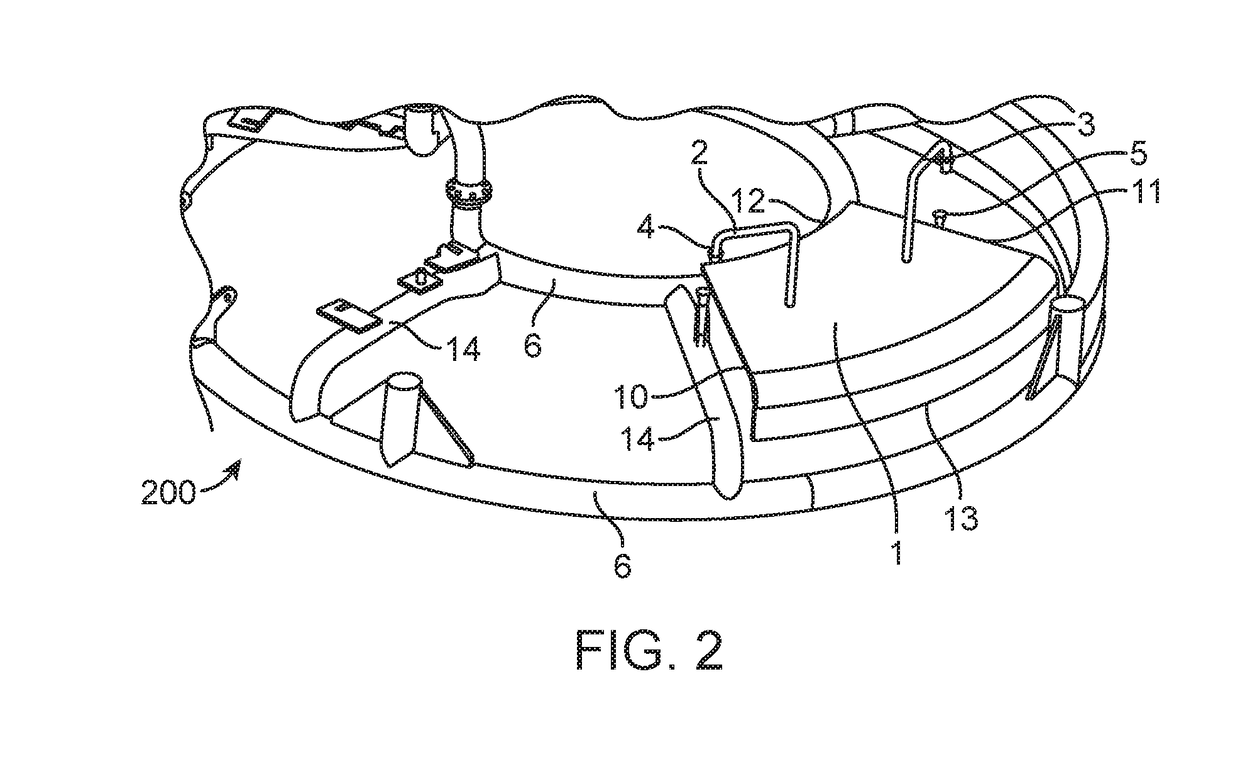

Molten metal containment structure having movable cover

An exemplary embodiment of the invention provides a molten metal containment structure, including a vessel having an internal volume for containing molten metal and an open upper end. The structure further includes a cover for the vessel having an underside facing the internal volume, the cover being movable between a closed position, covering the open upper end of the vessel with the underside of the cover, and an open position in which the cover is remote from the open upper end of the vessel to allow access to the internal volume from one side of the structure. The cover is attached to at least one lifting arm (preferably two or more) and at least on rotation control arm (preferably two or more). The lifting arm(s) operates to guide the cover from the open position to the closed position, and vice versa. The rotation control arm(s) operates to control pivoting of the cover during movement from the closed position to the open position, and vice versa, to prevent exposure of the underside of the cover, which in operation is very hot, to a person positioned adjacent to the structure at the aforesaid one side thereof. The lifting arm(s) and / or rotation control arm(s) provide a force that at least partially counterbalances a weight of the cover.

Owner:NOVELIS INC

Non-ferrous metal smelting furnace

InactiveCN107764063AImprove smelting effectImprove efficiencyRemovable covers for furnacesCharge manipulationDrive shaftNon-ferrous extractive metallurgy

The invention discloses a non-ferrous metal smelting furnace, which comprises a furnace body, a feeding port, a smelting chamber and a bracket. At the lower end of the furnace body, an exhaust fan is arranged on one side of the furnace body, an exhaust pipe is connected to the upper end of the exhaust fan, and the exhaust fan is connected to the smelting chamber through the exhaust pipe, and a motor is installed on the other side of the furnace body. , one end of the motor is connected with a transmission shaft. In the present invention, an exhaust fan is arranged on one side of the furnace body to extract dust and toxic and harmful gases, thereby improving the smelting effect of non-ferrous metals. By setting a crushing shaft under the feeding port, the volume of the solid metal is more uniform after crushing. It is convenient for smelting operation. By setting a mesh screen at the lower end of the crushing shaft and connecting a vibrating spring at the lower end of the mesh screen, the mesh screen can be used to select different standards of screening, so that the non-ferrous metal smelting is more sufficient.

Owner:WUXI SANZHONG MOLD CO LTD

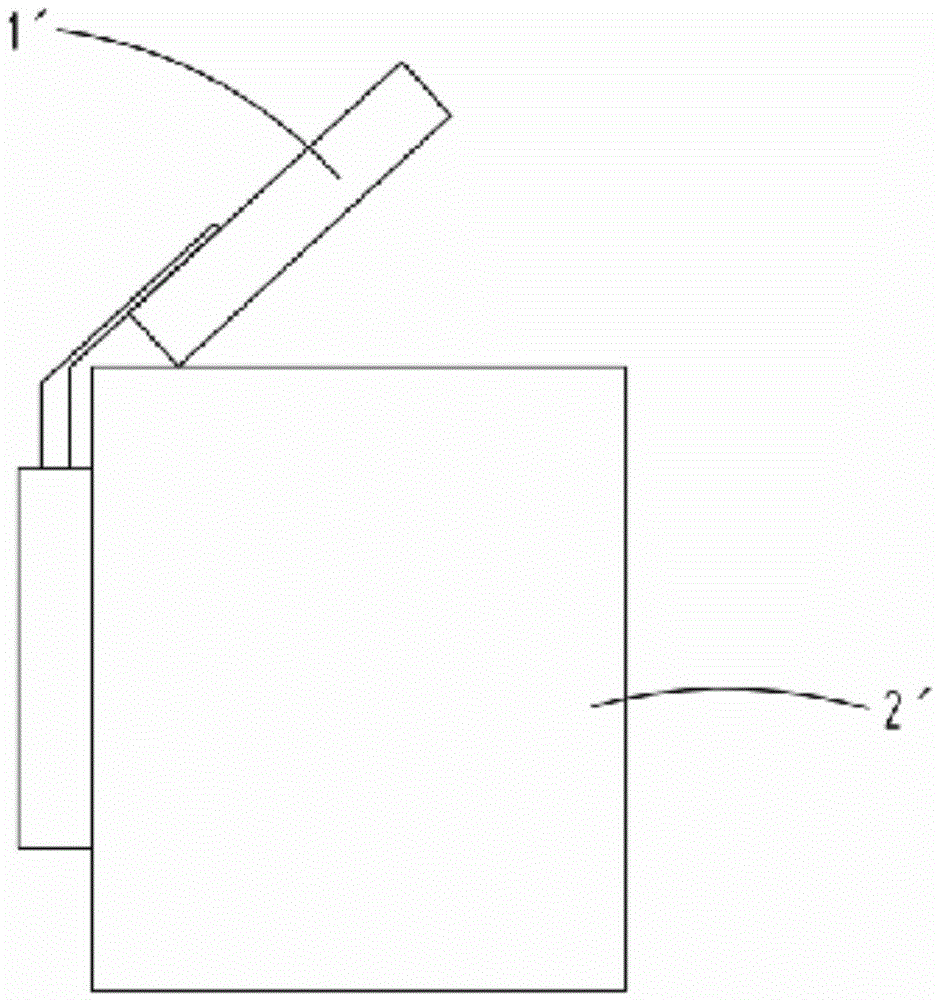

Covering and uncovering device of LF furnace

InactiveCN105779693ASignificant energy saving benefitsReduced radiant heat dissipationRemovable covers for furnacesFixed frameEngineering

The invention discloses a covering and uncovering device of an LF furnace. The covering and uncovering device of the LF furnace comprises an inverted-T-shaped fork tooth in the shape of an inverted T, a reversing device controlling the inverted-T-shaped fork tooth to swing, a fork tooth trolley installing the inverted-T-shaped fork tooth, a fixing frame and an electric-hydraulic pusher driving the fork tooth trolley to move along a running track, and the inverted-T-shaped fork tooth is formed by arranging a plurality of fork teeth forming a certain position front and back. The reversing device is arranged on the fixing frame through bolts. The inverted-T-shaped fork tooth is arranged under the reversing device, and the reversing device is parallel to the fork tooth trolley. The fork tooth trolley and the electric-hydraulic pusher are arranged on the fixing frame. The electric-hydraulic pusher is arranged over the fork tooth trolley. By means of stretching out or contracting back of the electric-hydraulic pusher, the fork tooth trolley is driven to move along the running track, the inverted-T-shaped fork tooth is driven to vertically swing along the angle of the reversing device, and the adjustment of the included angle between the fork tooth and the horizontal plane and covering / uncovering are achieved.

Owner:JIANGSU DISA MACHINERY

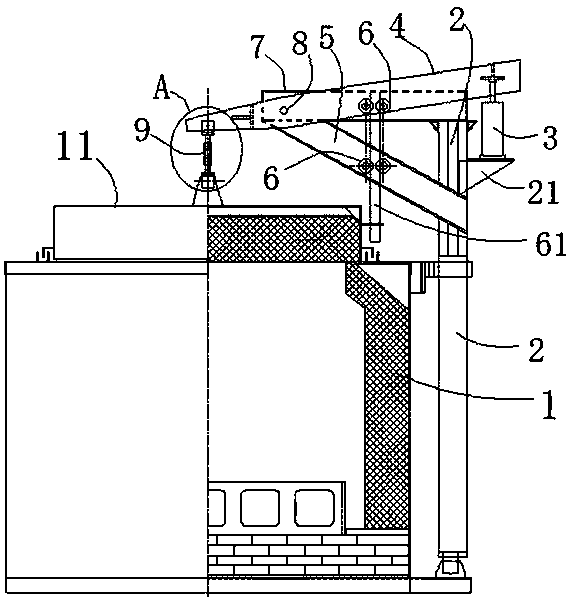

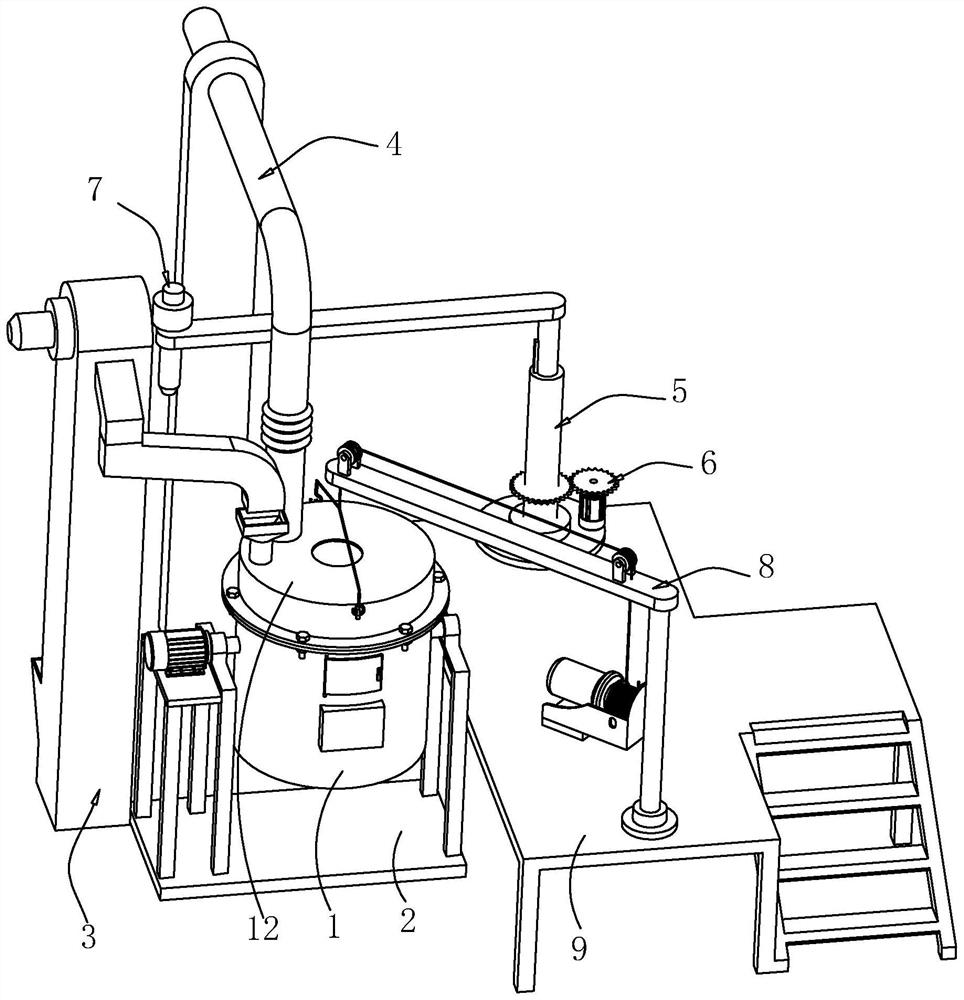

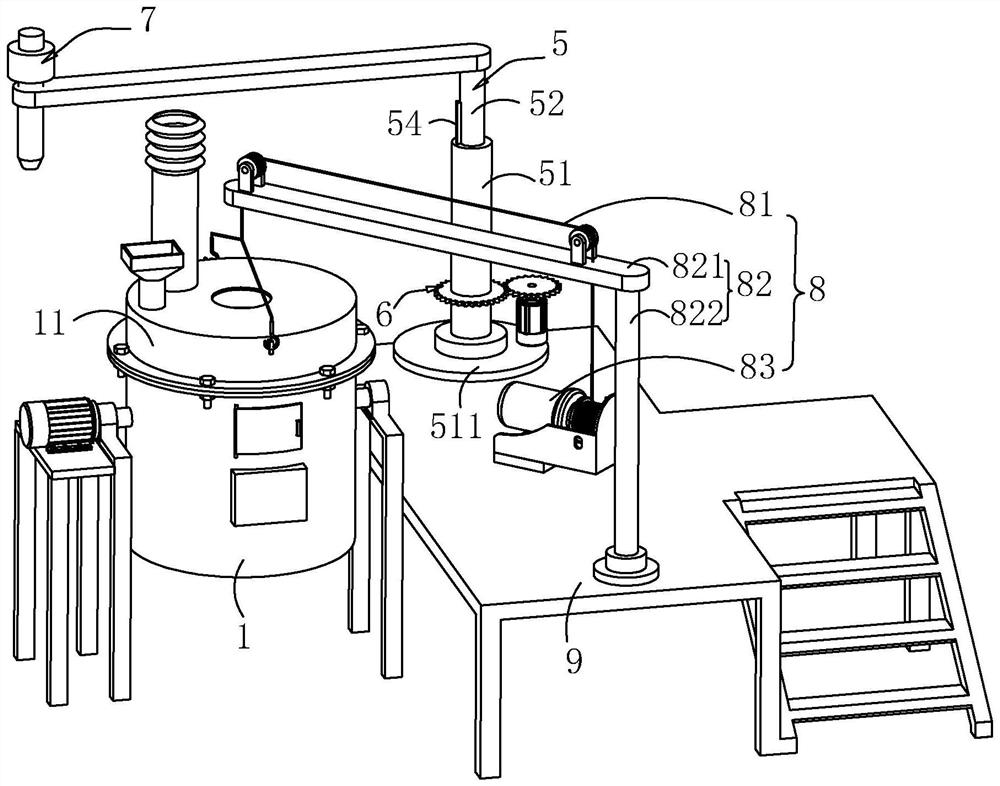

Furnace lid for rare earth alloy smelting furnace, smelting furnace and method

PendingCN112484491AGood dispersionPlay a stirring roleRemovable covers for furnacesStirring devicesProduction cycleSmelting

The invention discloses a furnace lid for a rare earth alloy smelting furnace, the smelting furnace and a method. The furnace lid for the rare earth alloy smelting furnace comprises a cover body and araw material rotary lifting device. The raw material rotary lifting device comprises a rotating rod, a rotating rod outer cylinder, a rotating motor, a fixed outer cylinder, a lifting motor, a connecting rod, a gear, a rack and a metal raw material clamping disc. According to the rare earth alloy smelting furnace, the yield of alloy products with large component melting point differences can be increased, and the production period can be shortened.

Owner:BAOTOU RES INST OF RARE EARTHS +2

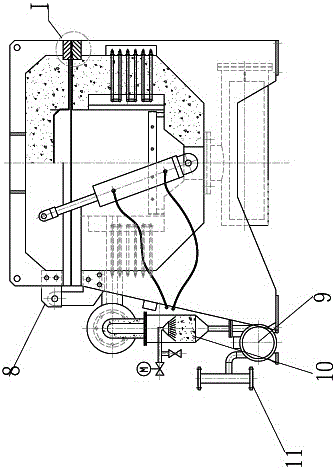

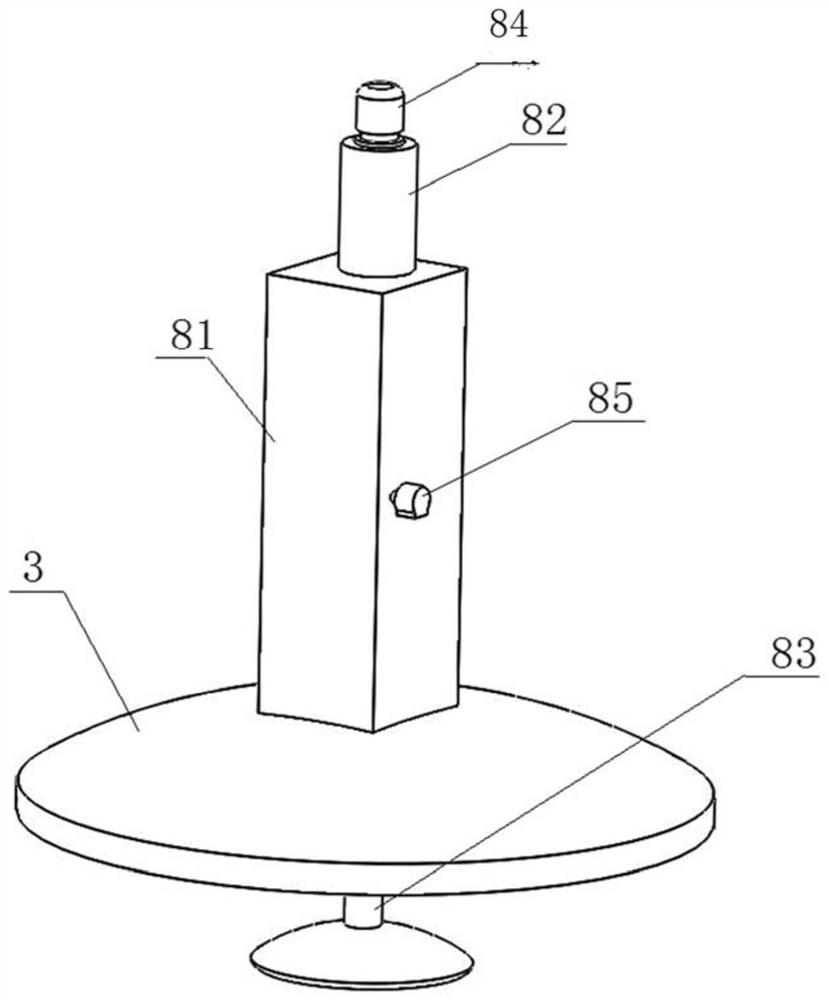

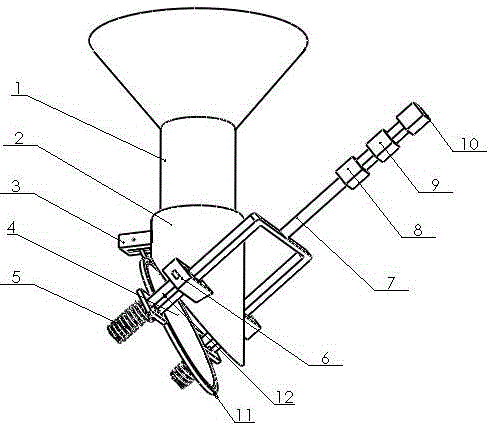

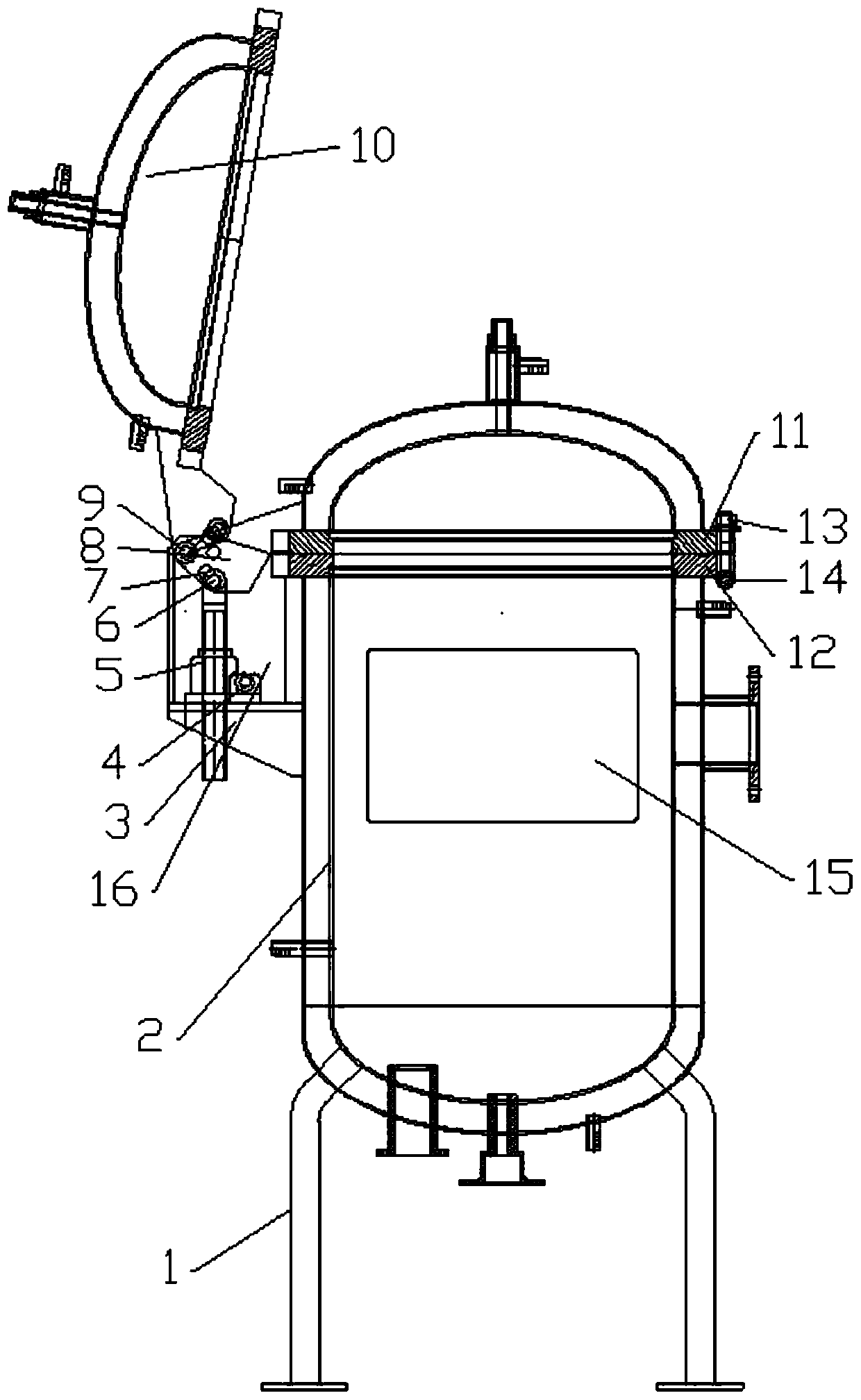

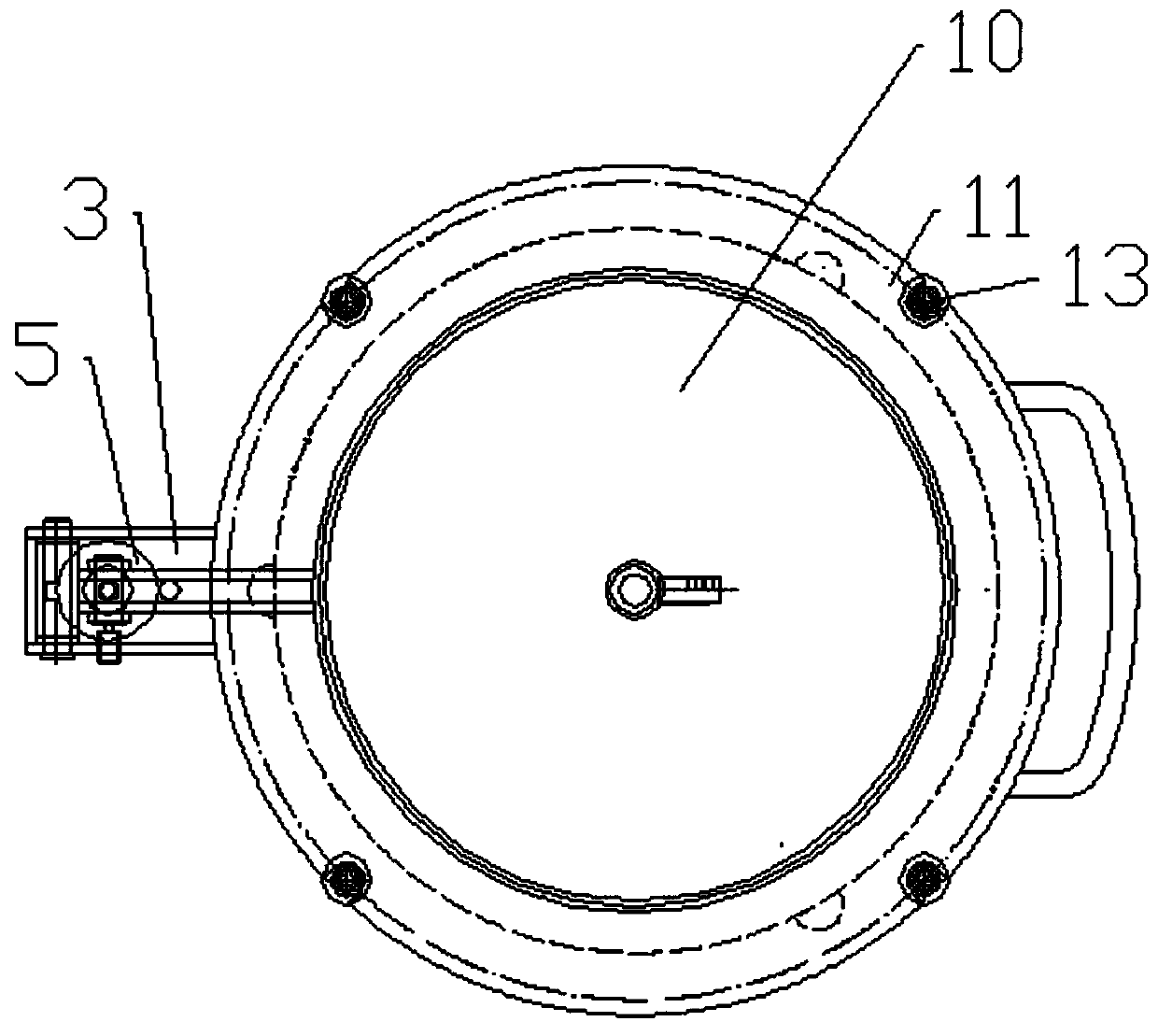

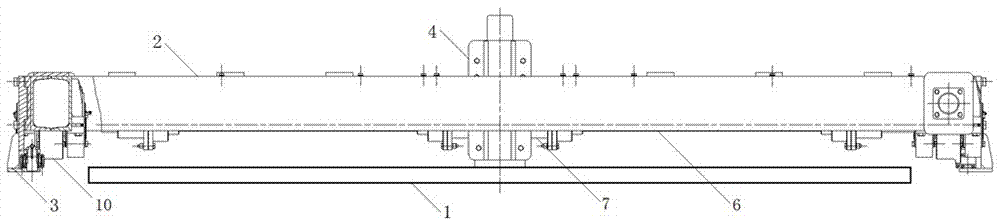

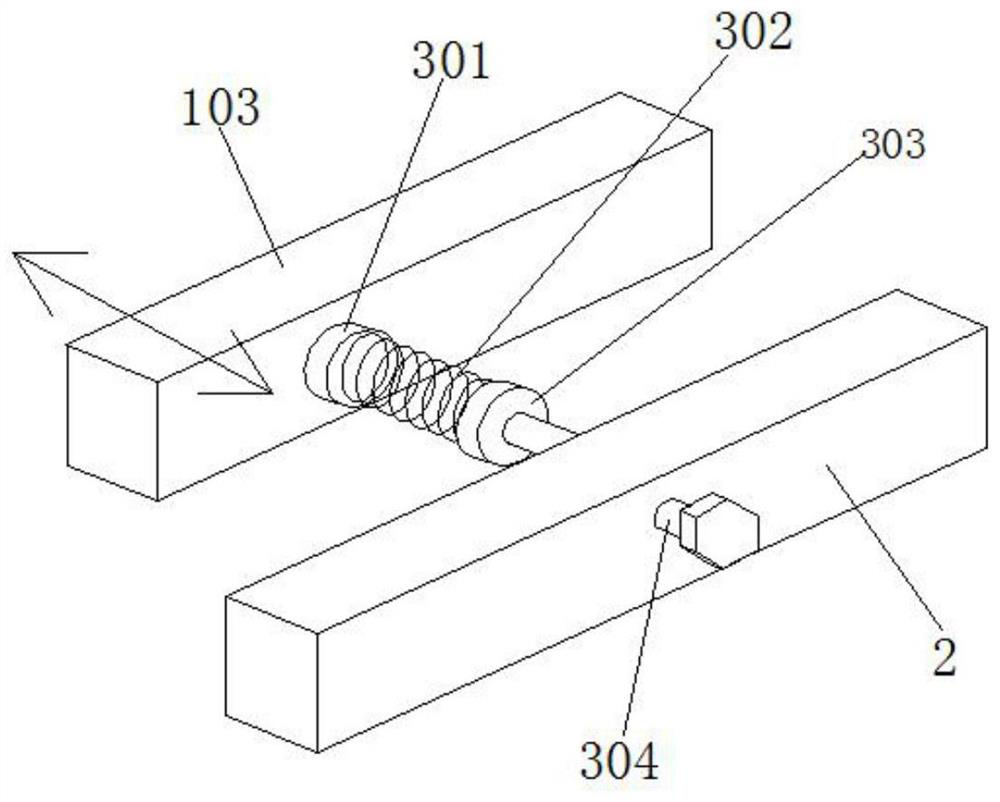

Opening device for deslagging bottom cover of smelting furnace

ActiveCN106247804ANot easy to pile upMeet the needs of blankingRemovable covers for furnacesCharge manipulationReduction driveReducer

The invention relates to an automatic opening device for a deslagging bottom cover of a smelting furnace, and belongs to the field of smelting furnace processing. The automatic opening device comprises a furnace mouth 1 of the smelting furnace, a boiler sleeve 2, a supporting block 3, the bottom cover 4, a limiting supporting block 6, a connecting rod 7, a speed reducer 8 and a motor 10; the supporting block 3 and the limiting supporting block 6 are fixedly arranged on the boiler sleeve 2; one end of the bottom cover 4 is movably connected to the supporting block 3; through holes are formed in two sides of each of the limiting supporting block 6 and the bottom cover 4; the connecting rod 7 comprises a central rod and two parallel side rods connected to the central rod; one end of the central rod is connected to the speed reducer 8; the other end of the speed reducer 8 is connected to the motor 10; the two side rods of the connecting rod 7 separately pass through the through holes in the two sides of each of the limiting supporting block 6 and the bottom cover 4; and the connecting rod 7 is driven by the speed reducer 8 and the motor 10 to push the bottom cover 4 to open or cover an opening of the boiler sleeve 2. The automatic opening device can meet material-dropping needs, and has the characteristics of being simple in structure, convenient to manufacture, stable in performance, high in degree of automation and the like.

Owner:KUNMING UNIV OF SCI & TECH

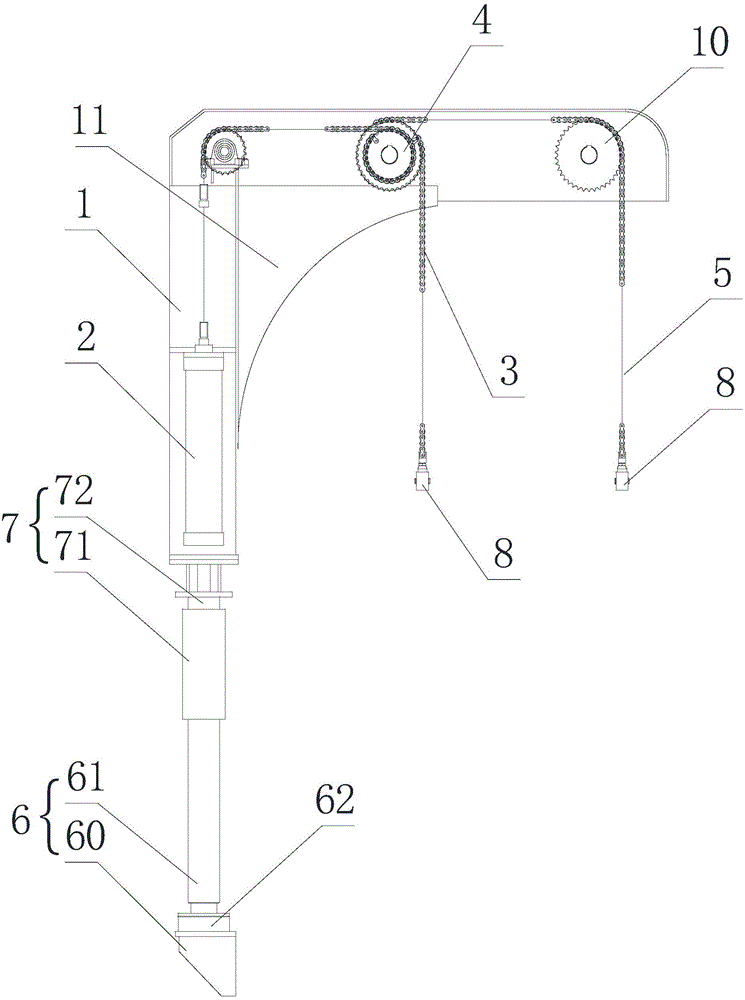

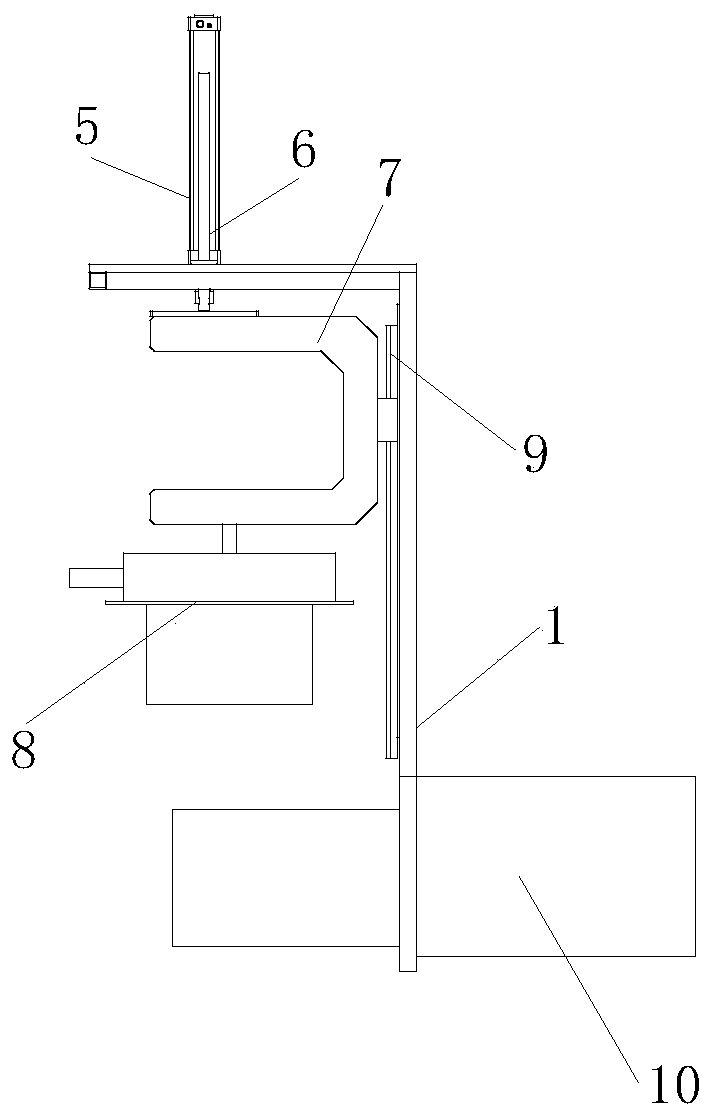

Furnace cover lifting device for tempering furnace

InactiveCN104651576AImprove stabilityGuaranteed stabilityRemovable covers for furnacesIndustrial engineering

The invention relates to a furnace cover lifting device for a tempering furnace, which comprises a machine frame, a lifting cylinder, a first chain and a chain wheel component, wherein the chain wheel component is provided with a second chain; the bottom end of the machine frame is provided with a rotator; the rotator is provided with a regulating component; and the first chain and second chain are respectively provided with a suspension rod. The lifting device has the following advantages: the suspension rods arranged on the first chain and second chain are utilized to lift the furnace cover; the lifting cylinder is utilized to implement transmission of the first chain and second chain; the first chain and second chain are arranged symmetrically, thereby ensuring the stability of the furnace cover in the furnace cover ascending or descending process; in the descending process of the lifted furnace cover, the rotator is utilized to implement rotation of the machine frame so as to adapt to the lifting of the furnace cover at different angles, thereby facilitating the placement of the workpiece, reducing the injuries to the operating personnel in the workpiece placement process and being beneficial to the discharge and feed of the workpiece; and the regulating component is utilized to regulate the position of the machine frame on the rotator, thereby adapting to different workpieces.

Owner:浙江省长兴精工电炉制造有限公司

Industrial furnace opening seal device convenient to replace

InactiveCN111551034AEasy to replaceWill not affect normal workRemovable covers for furnacesElectric machineEngineering

The invention discloses an industrial furnace opening seal device convenient to replace. The device comprises a moving clamping mechanism, a clamping mechanism is mounted on the upper end of the moving clamping mechanism, a motor drives a screw to rotate, the screw drives a rotating block to move towards the back end, a moving block drives a seal ring to clamp and fix the edge of a furnace cover through a connecting plate, the advantages of secondary seal of a furnace cover and increasing of seal of the furnace cover are achieved, an ejecting supporting mechanism is mounted on the upper end ofthe moving clamping mechanism, when the moving block moves, a second swing rod can be driven to swing, a pushing block drives a seal clamping block to fix the right ends of two seal rings through a push rod, and the advantage of increasing the clamping stability of the seal rings can be achieved. A moving mechanism is mounted on the upper end of the moving clamping mechanism, a second air cylinder is pushed towards the left end, the clamping mechanism and the ejecting supporting mechanism move to the connecting position of the furnace cover and a furnace opening, and the advantage of rapidlydriving the clamping mechanism and the ejecting supporting mechanism to move is achieved.

Owner:汪祺富

Antimony concentrate vacuum smelting device

PendingCN111156820AIncrease generation speedHigh recovery rateRemovable covers for furnacesCharge treatment typeTemperature controlProcess engineering

The invention provides an antimony concentrate vacuum smelting device. The antimony concentrate vacuum smelting device comprises a shell, a program temperature control device and a pressure control device, wherein a smelting cavity, a charging port and a pressure control port are arranged in the shell, and the charging port and the pressure control port communicate with the smelting cavity; the charging port is used for adding stibnite, reducing fuel and an alkaline additive; the program temperature control device is used for controlling the temperature in the smelting cavity in stages; and the pressure control device communicates with the pressure control port and is used for controlling the vacuum degree in the smelting cavity. By adopting the vacuum smelting device to extract metallic antimony from the stibnite, the recovery rate of the metallic antimony is greatly improved, the process flow is simplified, and the recovery cost is reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

Casting porcelain furnace

PendingCN108050842ARealize industrial productionImprove reliabilityRemovable covers for furnacesCharge composition/statePunching

The invention relates to the field of dental equipment, and discloses a casting porcelain furnace. The casting porcelain furnace includes a base which is used as a bearing structure, a furnace cover,a furnace seat, a heating device, a punching rod and a punching rod driving assembly. The furnace cover is sealed with the furnace base to form an insulated furnace chamber, and a through hole, in communication with the furnace chamber, is formed in the furnace cover. The furnace seat and / or the furnace seat are provided with an air exhausting hole which is in communication with the furnace chamber. The heating device is used to heat the furnace chamber. The punching rod is inserted in the through hole in a sealed mode. The punching rod can exert pressure on material which is to be processed under the driving of the punch rod driving assembly. The high temperature and vacuum environment can be provided in the casting process through the coordination of the furnace seat, the furnace cover,the heating device, the punching rod and the punching rod driving assembly. At the same time, a casting material can be exerted pressure, so that the industrialized production of cast porcelain teethis achieved. The casting porcelain furnace is convenient to use and high in reliability.

Owner:SHENZHEN SHENGSHI INTELLIGENT EQUIP

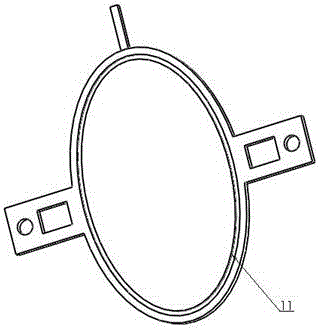

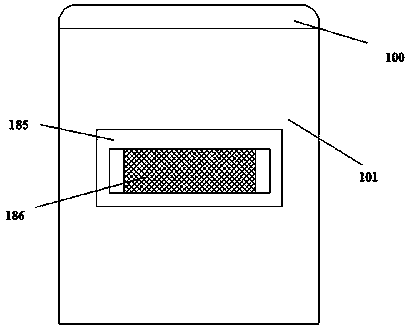

Closable type automatic material throwing copper furnace cover used for continuous casting of copper and aluminum composite materials

ActiveCN106643172AImprove airtightnessReduce dehydrogenationRemovable covers for furnacesElectrical controlCopper

This invention provides a closable type automatic material throwing copper furnace cover used for continuous casting of copper and aluminum composite materials. The closable type automatic material throwing copper furnace cover used for continuous casting of the copper and aluminum composite materials comprises a sealing cover which is provided with a sealing device; the sealing device comprises a melting furnace cover and a heat preserving furnace cover; and the sealing cover is provided with an automatic material throwing device which is controlled by an electrical control device. The closable type automatic material throwing copper furnace cover used for continuous casting of the copper and aluminum composite materials is good in sealing performance, good in heat preservation effect, low in energy consumption, capable of achieving automatic material throwing, convenient to operate and high in safety. When a copper plate is added, a worker mainly performs operation through a switch on a remote controller, the labor force is saved, the production efficiency is improved, an electrical mechanism is controlled through a cylinder, and cost is low; and besides, a furnace cover material adding port is small, the material adding position is low, copper liquid cannot be splashed out easily, and safety is high.

Owner:YANTAI FISEND BIMETAL

Top loading roof for electric arc, metallurgical or refining furnaces and system thereof

ActiveUS20180216888A1Development of quick changingExtended service lifeRemovable covers for furnacesLinings repairElectric arc furnaceEngineering

A method of quickly changing a portion of the roof of an electric arc furnace having a top loading roof system comprising providing at least one pie-shaped water cooled panel supported below the roof support beams and located to protect the underside hot face of the roof support beams, providing at least one quick water disconnect for connecting the at least one pie-shaped water cooled panel to a water supply, raising and removing the at least one pie-shaped water cooled roof panel, replacing the at least one pie-shaped water cooled roof panel with another pie-shaped water cooled panel or repairing the at least one pie-shaped water cooled roof panel, and continuing operation of the furnace.

Owner:AMERIFAB INC

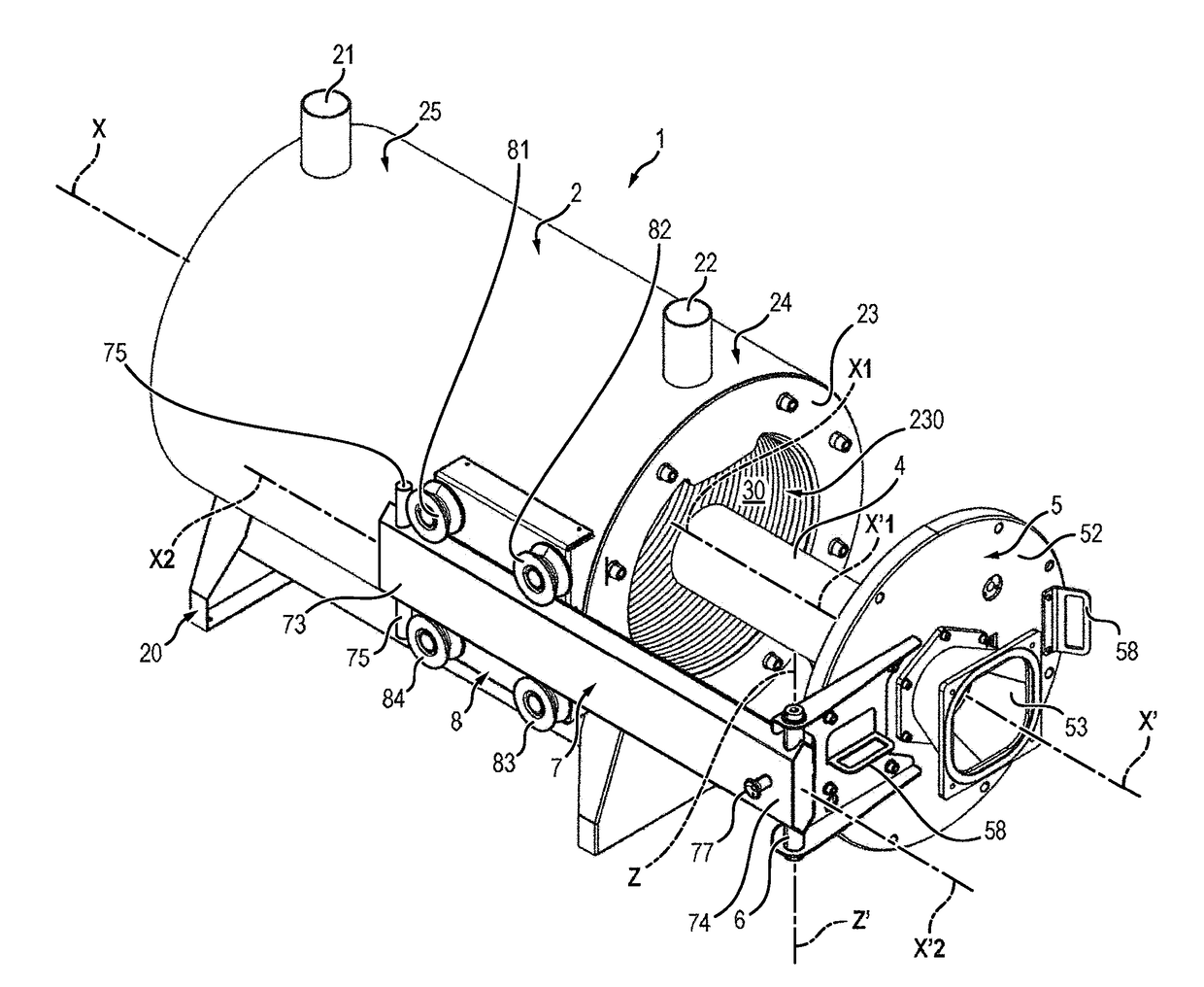

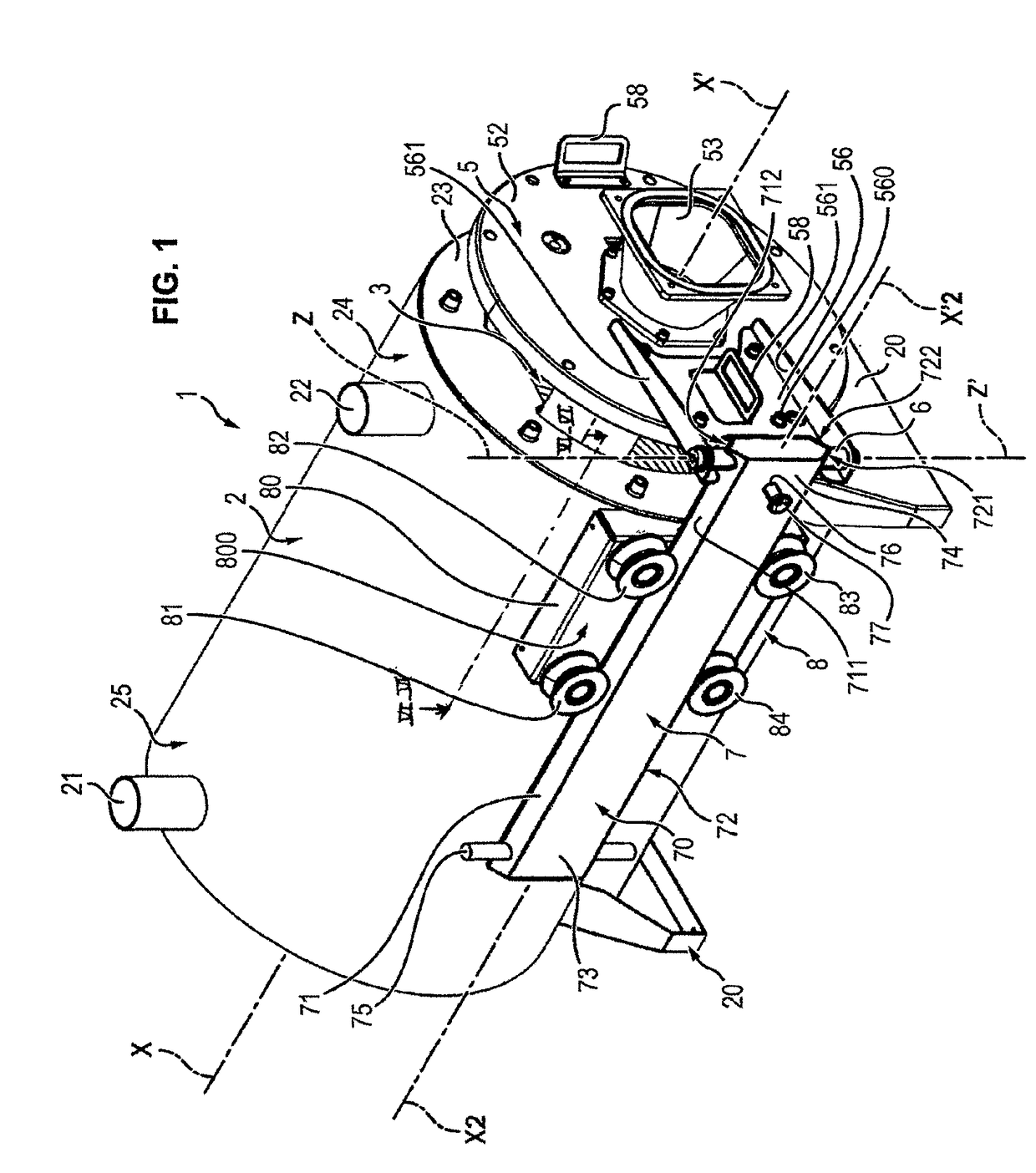

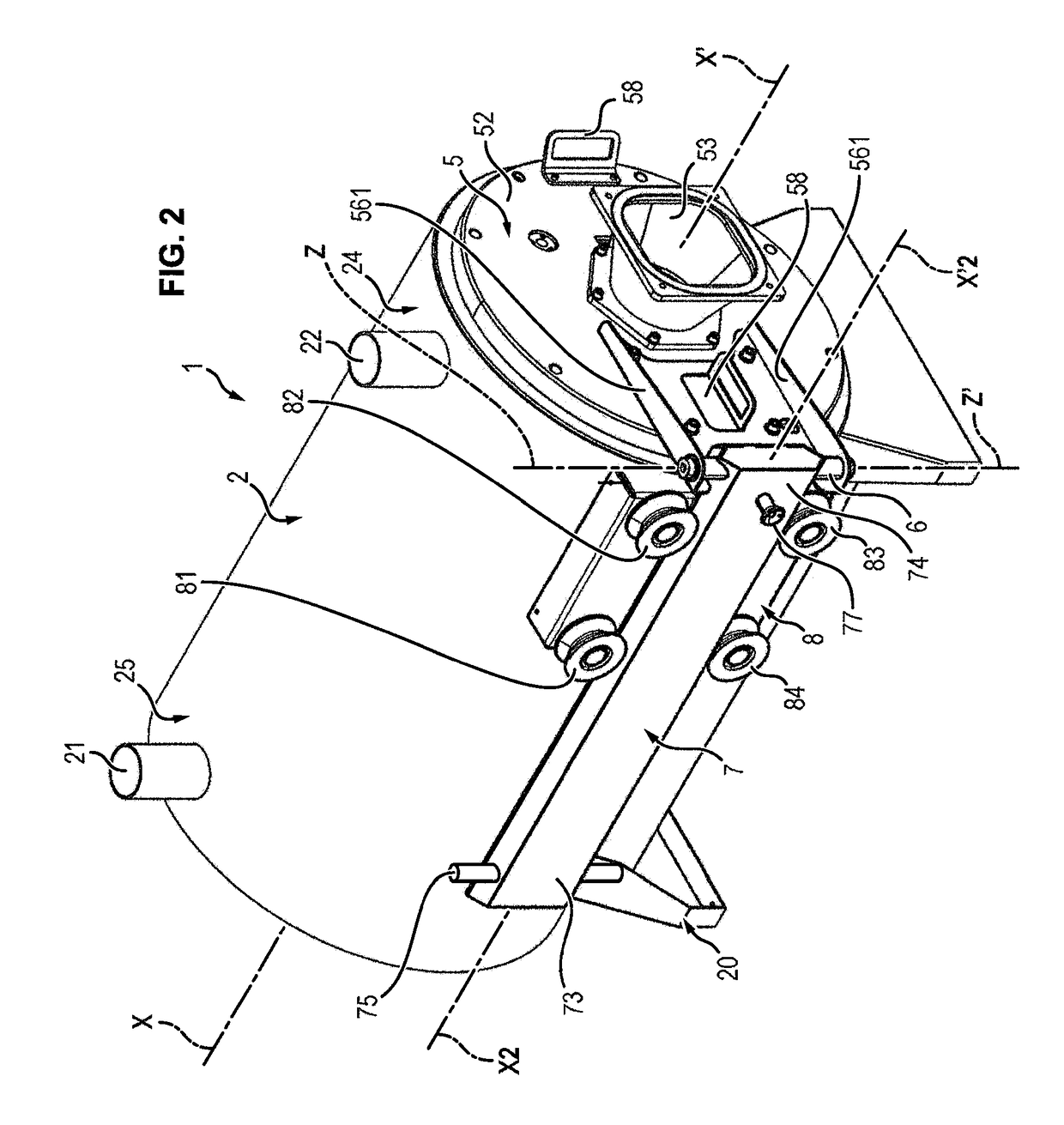

Heat exchanger

InactiveUS20180216815A1Easy to cleanGuaranteed normal exchangeRemovable covers for furnacesBurnersCombustion chamberCombustor

The invention relates to a heat exchanger (1) comprising a shell (2) containing a heat exchange device (3) and delimiting a combustion chamber (30), said shell (2) being provided with an access opening and with a door (5) provided on its inner face with a burner (4).It is remarkable in that said door (5) is mounted pivotally around a pivot (6) attached to the end of a slide (7), in that said shell (2) is provided on its exterior surface with axial guide means (8) of said slide (7) along a displacement axis X2-X′2 which extends parallel to the longitudinal axis X-X′ of said shell (2), in that the pivot (6) extends along an axis Z-Z′ perpendicular to said displacement axis X2-X′2, the travel of said slide (7) being greater than the length of the burner (4).

Owner:SERMETA

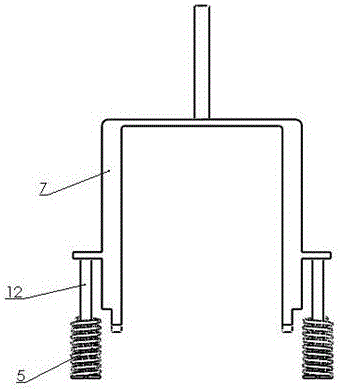

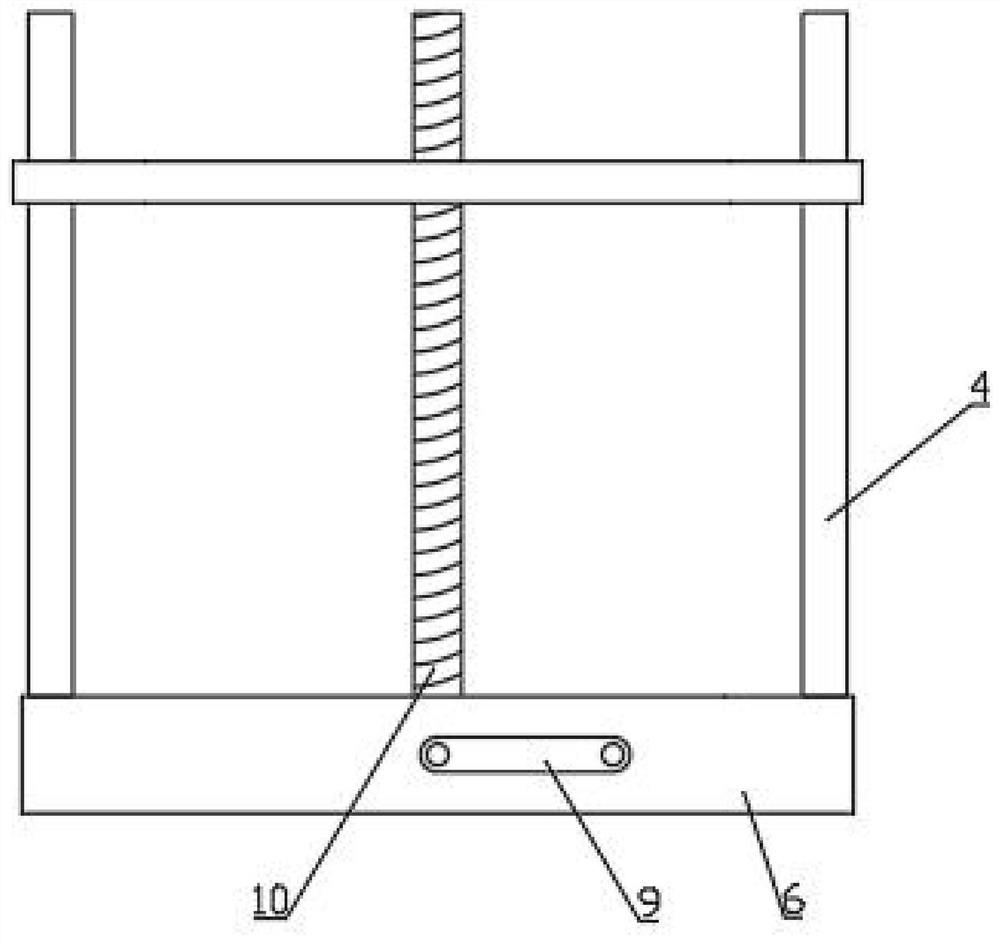

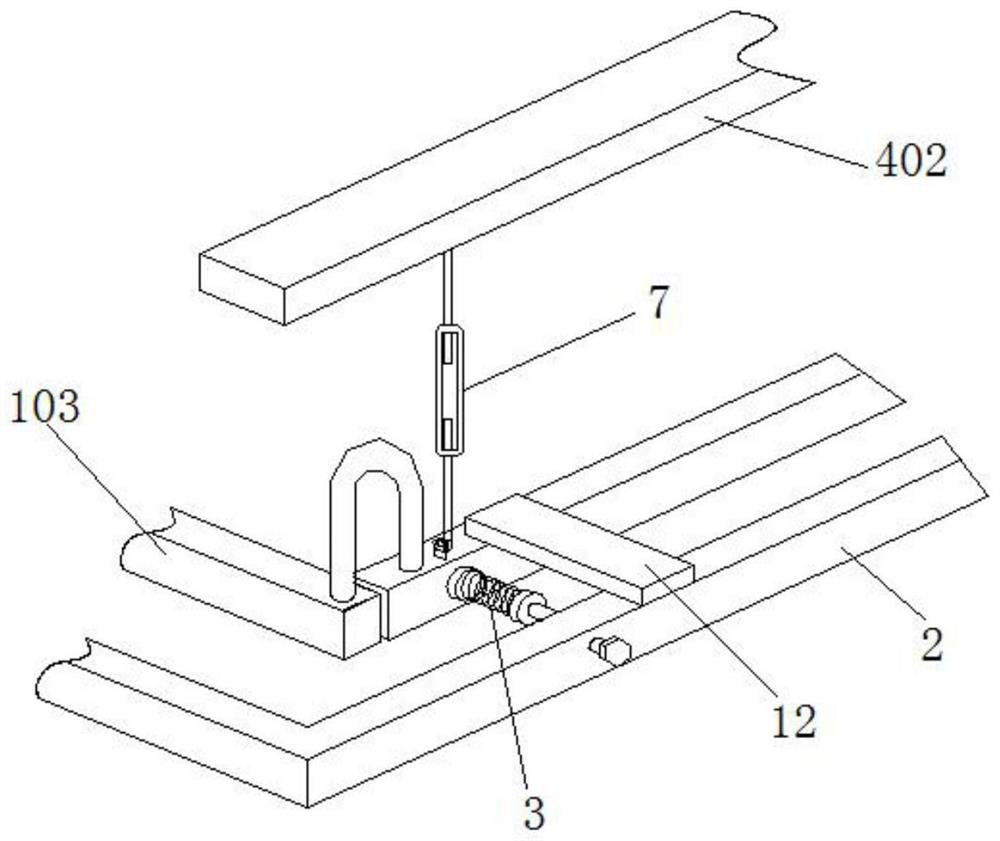

Sintering furnace bottom cover lifting and pressing mechanism

PendingCN111637748AEasy to moveEasy to fixRemovable covers for furnacesCharge treatment typeStructural engineeringBevel gear

The invention discloses a sintering furnace bottom cover lifting and pressing mechanism. The sintering furnace bottom cover lifting and pressing mechanism comprises a sintering furnace body, a furnacebottom cover and a lifting and pressing mechanism body, wherein the sintering furnace body is arranged on a support, the furnace bottom cover is arranged at the bottom of the sintering furnace body,the lifting and pressing mechanism body is arranged on the furnace bottom cover, guide rods are vertically arranged on the periphery of the top face of the base, the guide rods are sleeved with a supporting table and are in sliding connection with the supporting table, the furnace bottom cover is fixedly installed on the supporting table, the bottom ends of first screw rods extend into the base and are rotationally connected with the base, the bottoms of the first screw rods are connected with driven bevel gears, the driven bevel gears are in engaged connection with driving bevel gears, two sets of driving bevel gears sleeve the two sides of a connecting shaft, and one end of the connecting shaft is rotationally installed on the inner wall of the base, and the other end of the connecting shaft extends to the outer side of the base and is connected with a first handle. According to the sintering furnace bottom cover lifting and pressing mechanism, by means of the lifting and pressing mechanism body, the furnace bottom cover and the sintering furnace body can be conveniently pressed and closed, and therefore the working efficiency of installation of the furnace bottom cover is greatly improved.

Owner:安徽迪维斯冶金装备有限公司

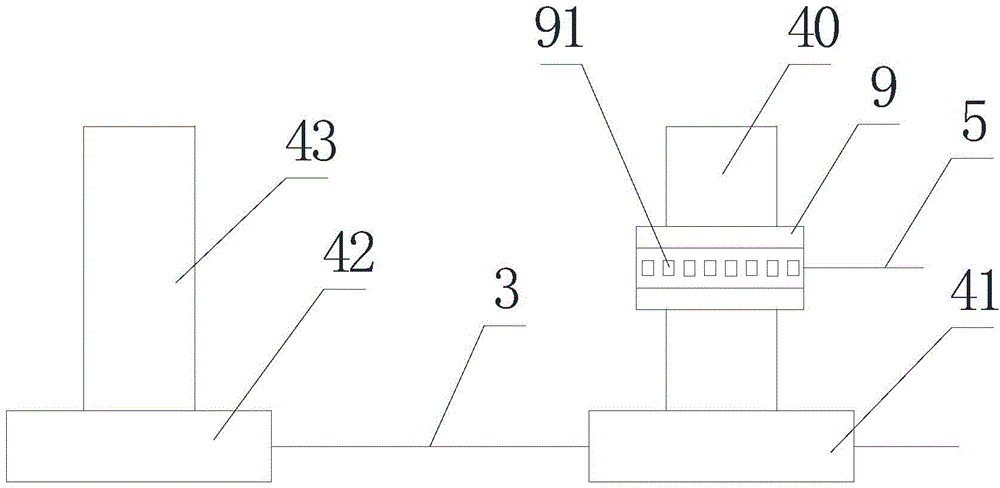

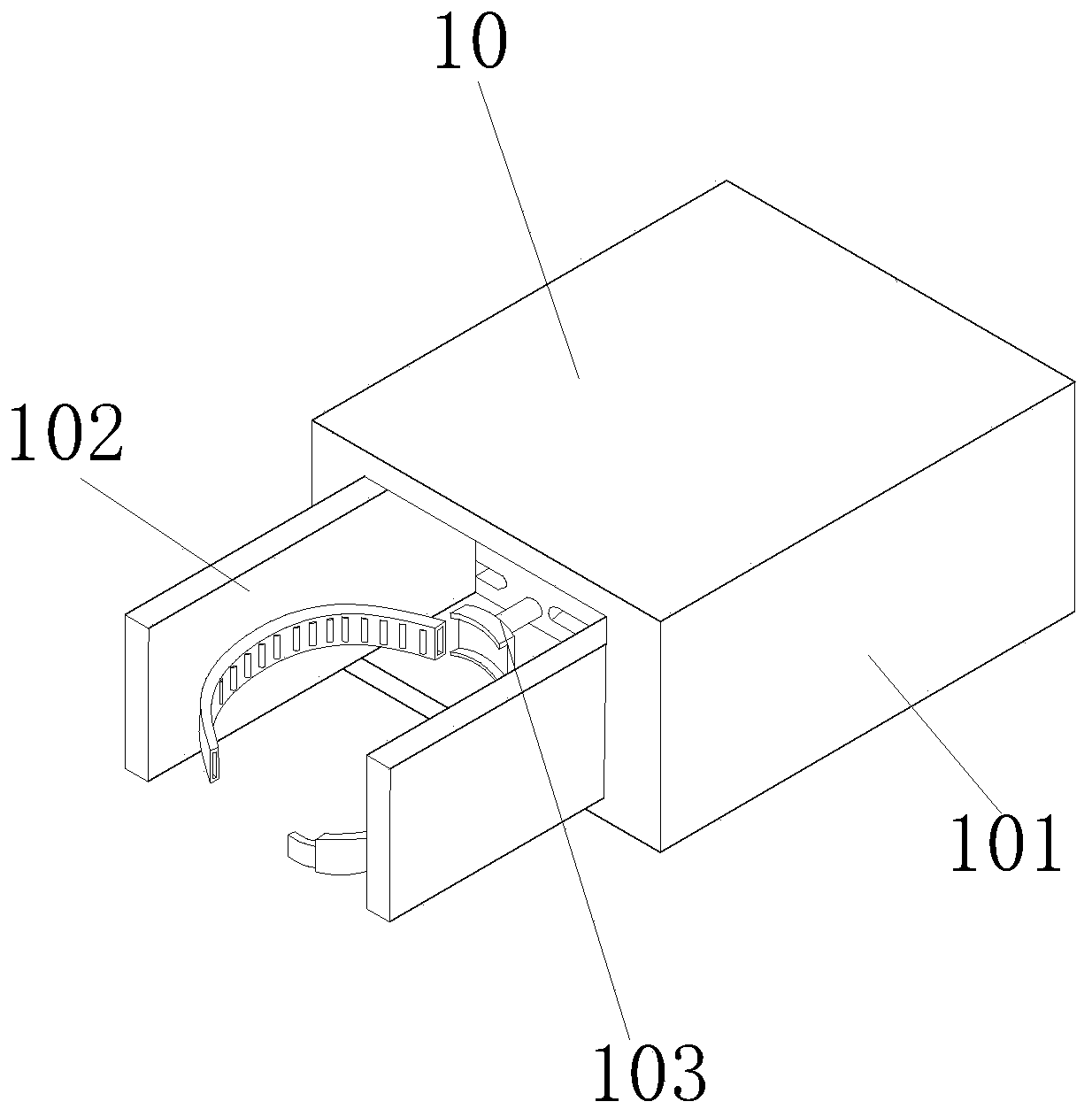

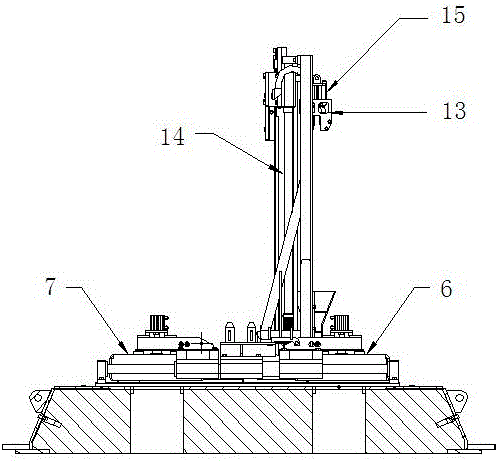

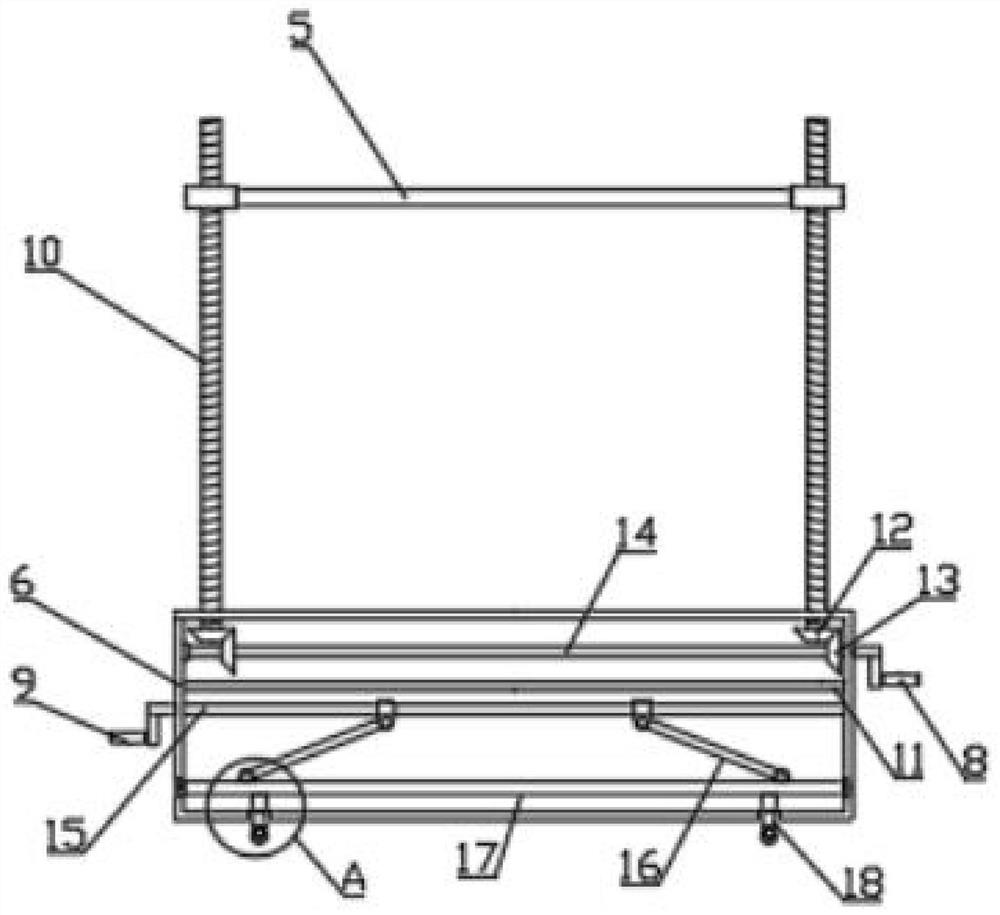

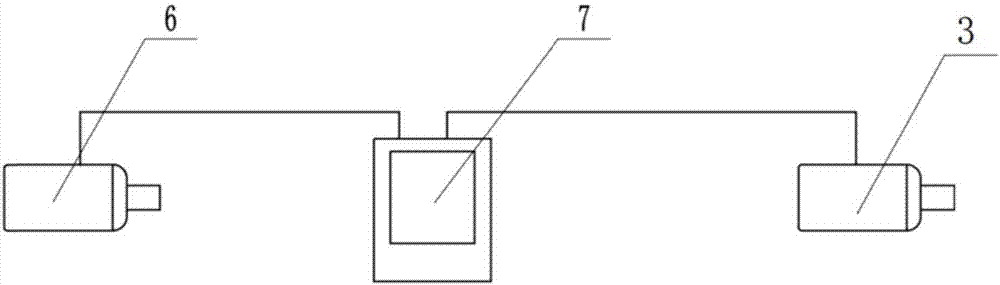

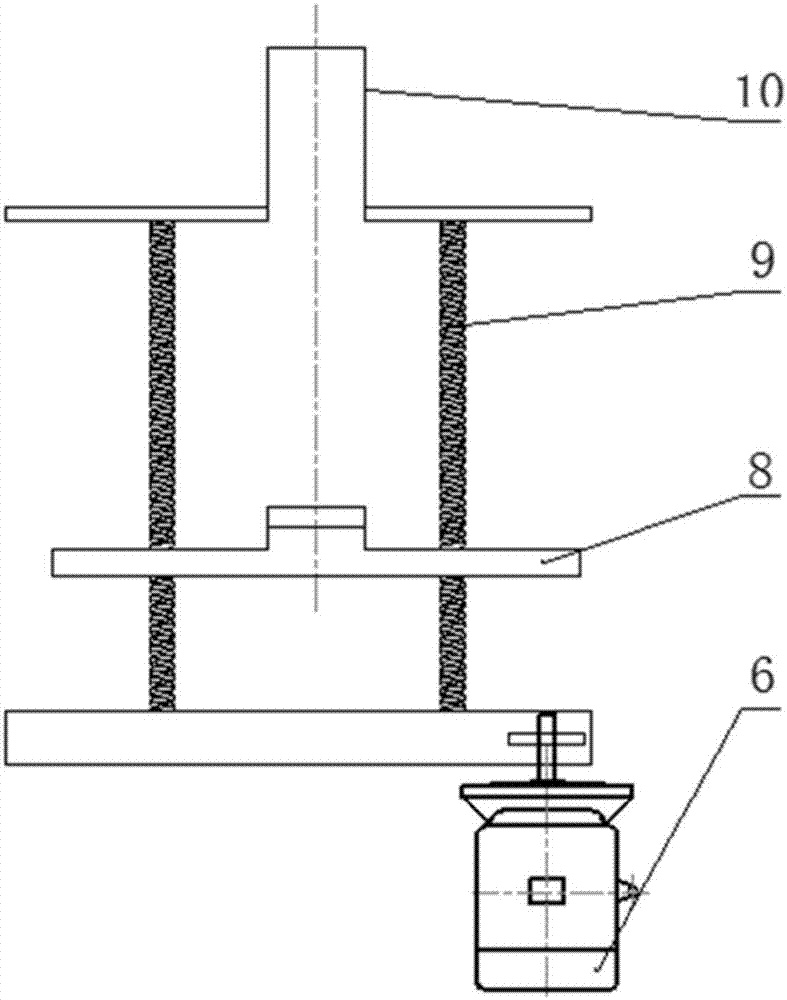

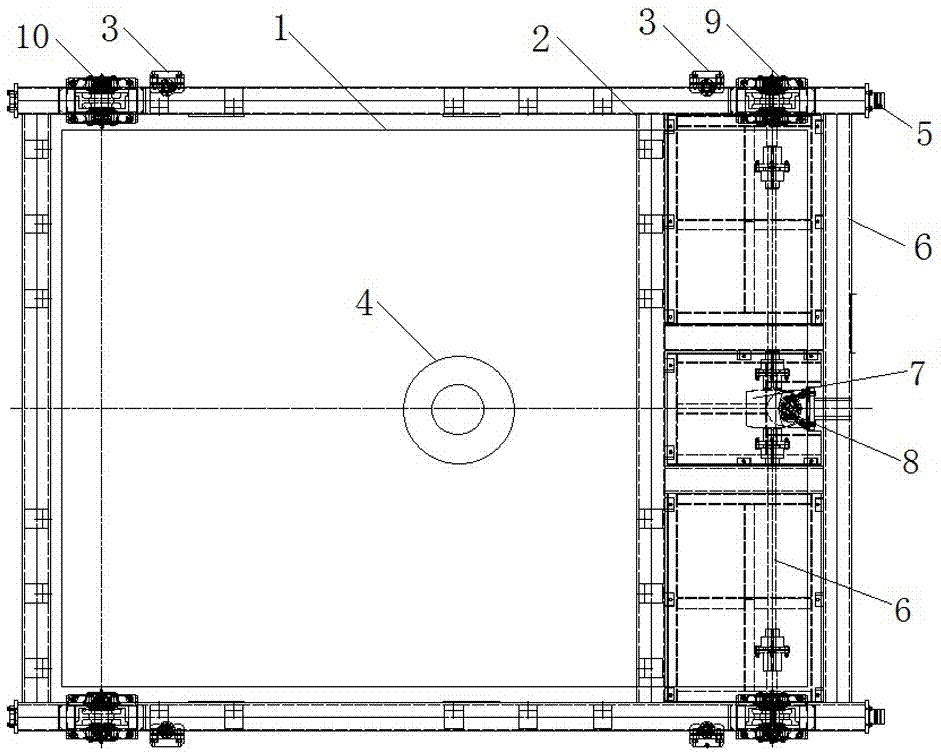

MOX batch sintering furnace synchronous lifting device

ActiveCN107514911ARealize synchronous lifting functionAccurate response to lifting statusRemovable covers for furnacesControl devices for furnacesLaser rangingSynchronous motor

An MOX batch sintering furnace synchronous lifting device comprises a synchronous lifting device, a synchronous circuit and a furnace bottom raising device. The furnace bottom raising device comprises a lifting motor 6, a furnace bottom cover 8, a lead screw 9 and a furnace body 10. The lifting motor 6 drives the lead screw 9 to rotate. The lead screw 9 enables the furnace bottom cover 8 to rise so as to be close to the furnace body 10. The synchronous lifting device comprises a threaded lead screw 1, a guide rod 2, a synchronous motor 3, a simulation sintering furnace bottom 4 and a laser ranging sensor 5. The synchronous motor 3 drives the threaded lead screw 1 to rotate, so that the simulation sintering furnace bottom 4 on the threaded lead screw 1 and the guide rod 2 are made to rise. Besides, the laser ranging sensor 5 is installed on the simulation sintering furnace bottom 4. In a synchronous circuit, the lifting motor 6 and the synchronous motor 3 are both connected with a signal detection and control circuit 7, the control circuit 7 can reduce the rotation speed of the lifting motor 6 and then transmits the rotation speed electrical signal to the synchronous motor 3, and therefore the lifting motor 6 and the synchronous motor 3 can synchronously conduct ascending and descending. The distance or lifting height of the furnace bottom cover 8 can be judged.

Owner:中核四0四成都核技术工程设计研究院有限公司

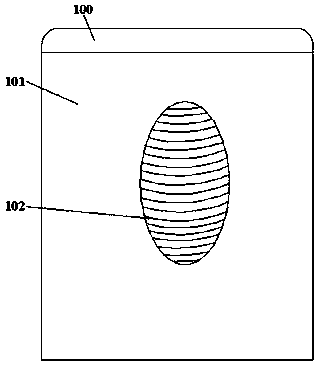

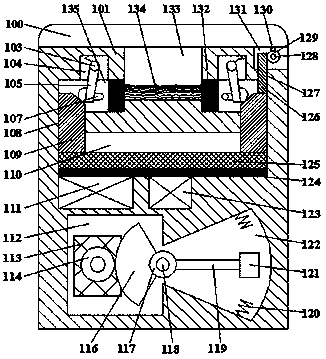

Wireless remote control automatic cover turning vacuum furnace

InactiveCN110926213AAvoid unsafe hazardsReduce labor intensityRemovable covers for furnacesControl devices for furnacesWireless controlRemote control

The invention discloses a wireless remote control automatic cover turning vacuum furnace. The wireless remote control automatic cover turning vacuum furnace comprises a furnace body and a furnace cover, wherein the furnace body is supported on supporting legs, a support is connected to the side surface, close to the upper end, of the furnace body, a motor and a screw rod lifter are installed on the support, the upper part of the screw rod lifter is hinged to a connecting seat, and the connecting seat is fixedly connected with the furnace cover; and supporting plates are further arranged on thetwo sides of the screw rod lifter, and the connecting seat is hinged to the supporting plates. The wireless remote control automatic cover turning vacuum furnace has the beneficial effects that the TRSS turbine screw rod lifter and the 24V motor are adopted, the furnace cover can be opened and closed by starting wireless control of a remote controller, the working stability is good, the safety ishigh, the potential safety hazard of cover opening is solved, the labor intensity of workers is reduced, the working efficiency is improved, the service life of equipment is prolonged, and the intelligence of the whole process of cover opening and closing is realized.

Owner:湘潭市汇丰设备制造有限公司

Double-opening seal top cover structure of industrial kiln

The invention discloses a double-opening seal top cover structure of an industrial kiln. The structure comprises a kiln body, a top cover, a top cover outlet and a seal cover, wherein the top cover isarranged at the right end of the kiln body and is of a bottle cap structure. The top cover is arranged on the kiln, the seal cover is arranged at the top cover outlet, the double-opening kiln can beused according to actual requirements, the top cover does not need to be opened every time, and use is convenient; the top cover is sealed by a No. 1 sealing ring, a No. 2 sealing ring and a double sealing structure, and mutually meshed tooth grooves are formed in joint surfaces of the No. 1 sealing ring and the No. 2 sealing ring; the top cover is also pressed by an electric push rod, good seal conditions are ensured, the service life is longer, and normal operation of the kiln is facilitated; the seal cover is matched with a fixing sleeve through a telescopic rod, and is convenient to open and close and not easy to fall off, the fixing structure is stable, good seal performance is also ensured by the seal cover, and the structure is suitable for popularization.

Owner:熊秀秀

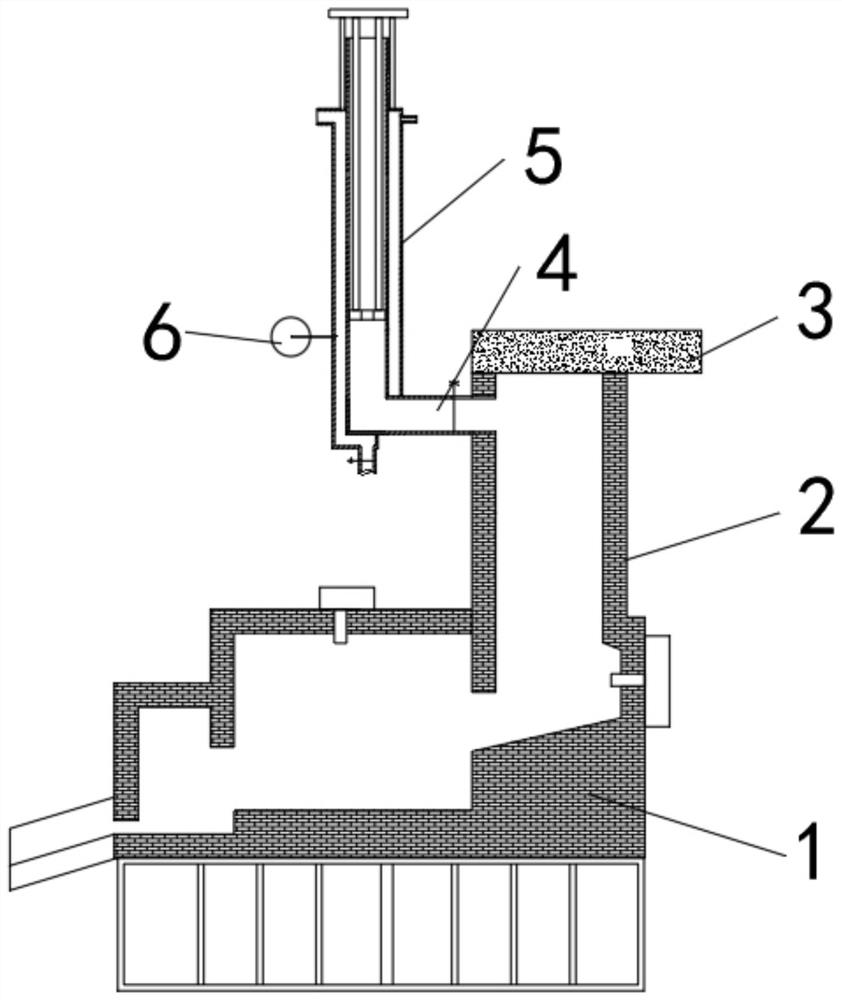

Aluminum alloy continuous melting furnace utilizing waste heat to regenerate resin sand

PendingCN113203284AIncrease profitReach the purpose of recyclingRemovable covers for furnacesCharge composition/stateFlueWaste heat

The invention discloses an aluminum alloy continuous melting furnace utilizing waste heat to regenerate resin sand, and relates to a melting furnace. The aluminum alloy continuous melting furnace specifically comprises a furnace body and a feeding tower installed at the top of the furnace body, a furnace cover is fixed at the top of the feeding tower, and the side face of the top end of the feeding tower is fixedly connected with one end of an L-shaped discharge flue. A sleeve fixedly sleeves the vertical part of the discharge flue, a sand inlet is formed in the side face of the top end of the sleeve, a discharge port is formed in the bottom of the sleeve, reclaimed sand is discharged through the discharge port, and an extraction opening is formed in the top of the sleeve. According to the aluminum alloy continuous melting furnace utilizing the waste heat to regenerate the resin sand, the waste heat of the melting furnace is utilized, so that the heat utilization rate of the melting furnace is effectively increased, additional resin sand heating equipment is not needed, the purpose of recycling the resin sand is achieved, and the production cost of an enterprise is reduced.

Owner:江苏迅隆铝业有限公司

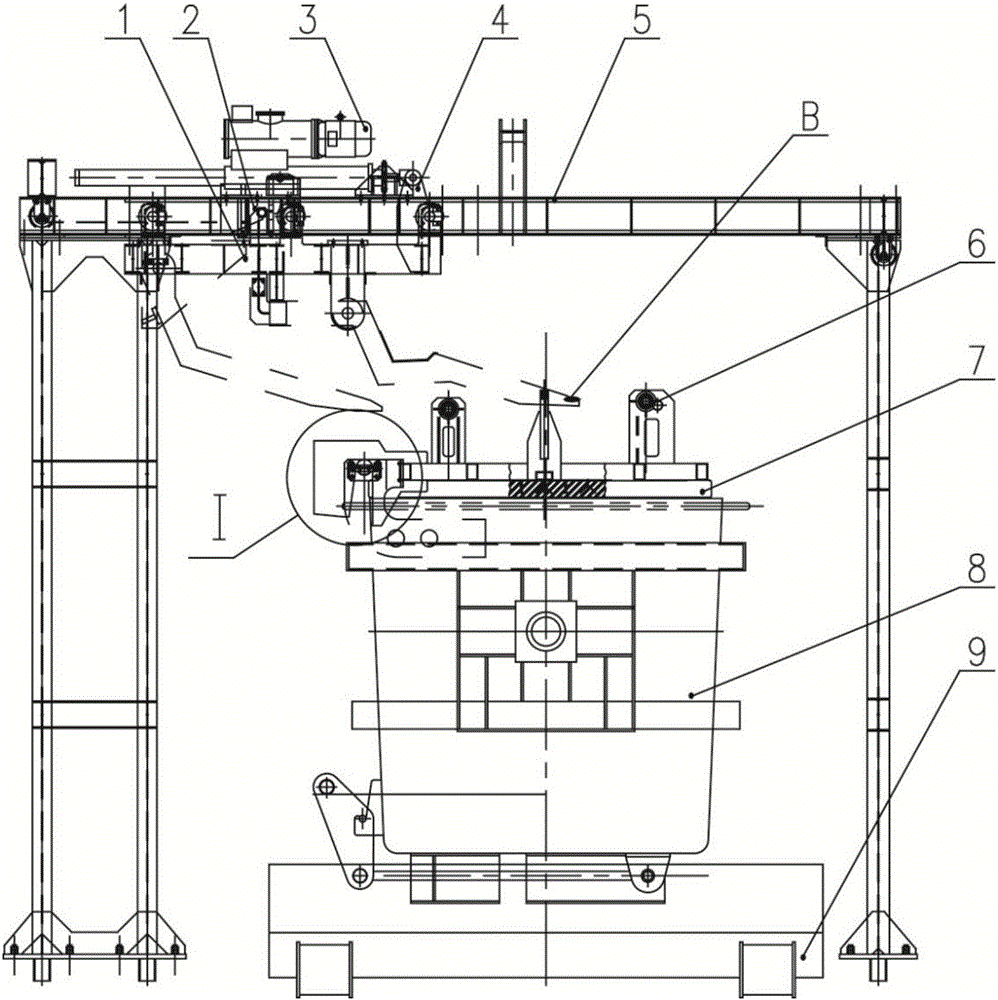

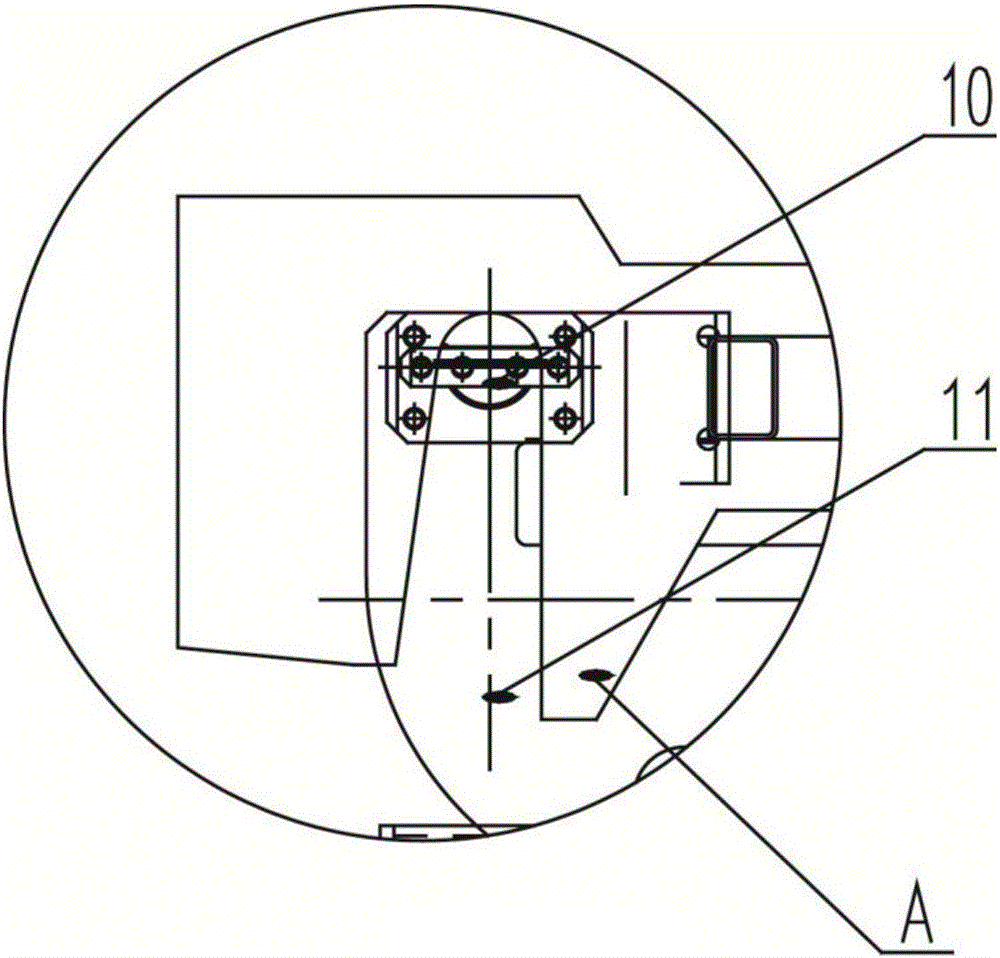

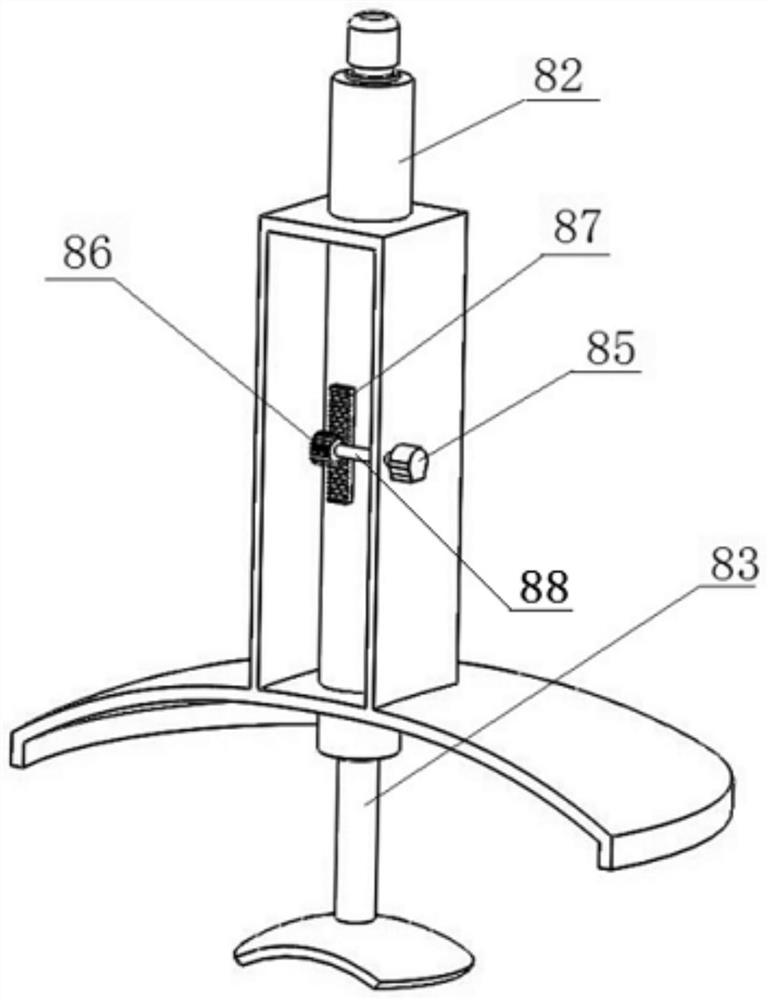

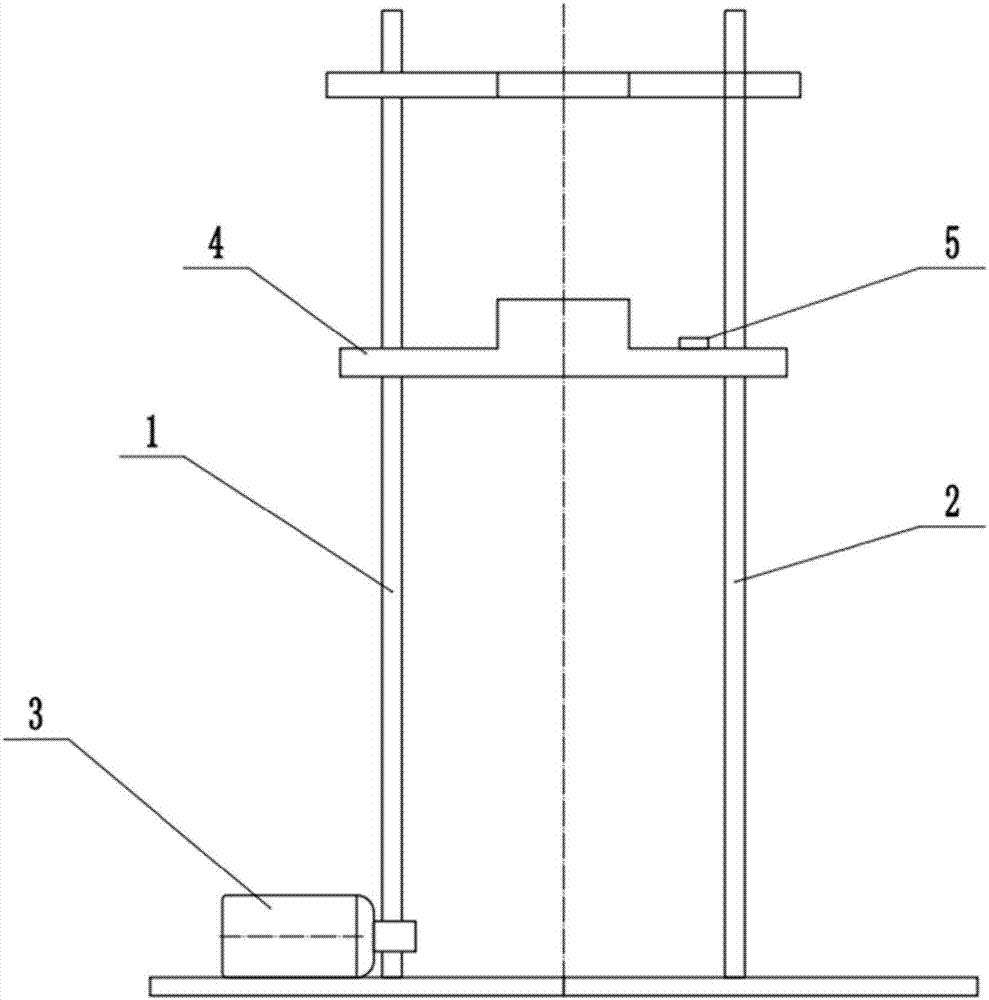

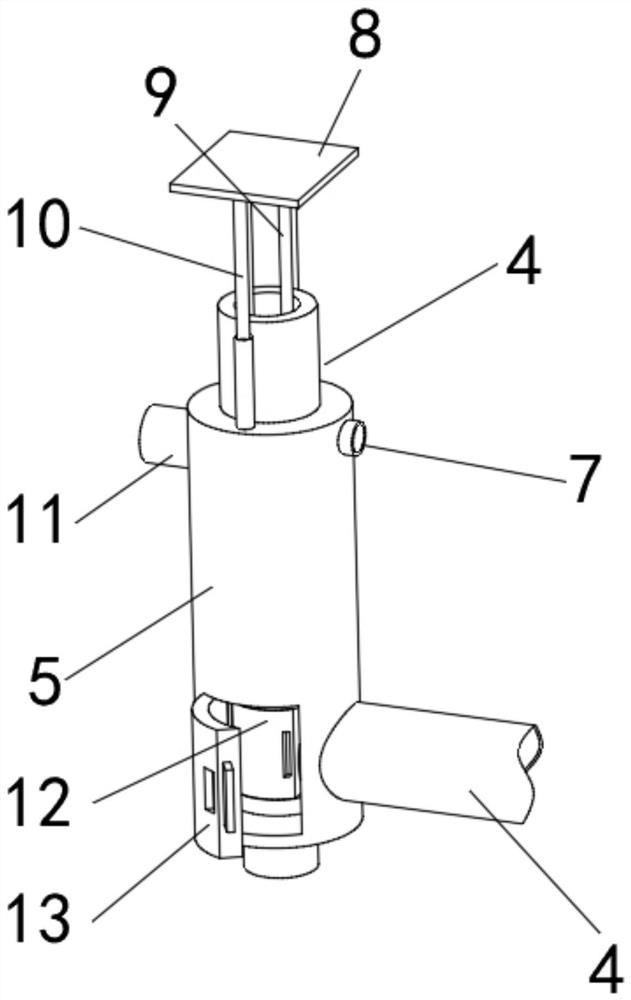

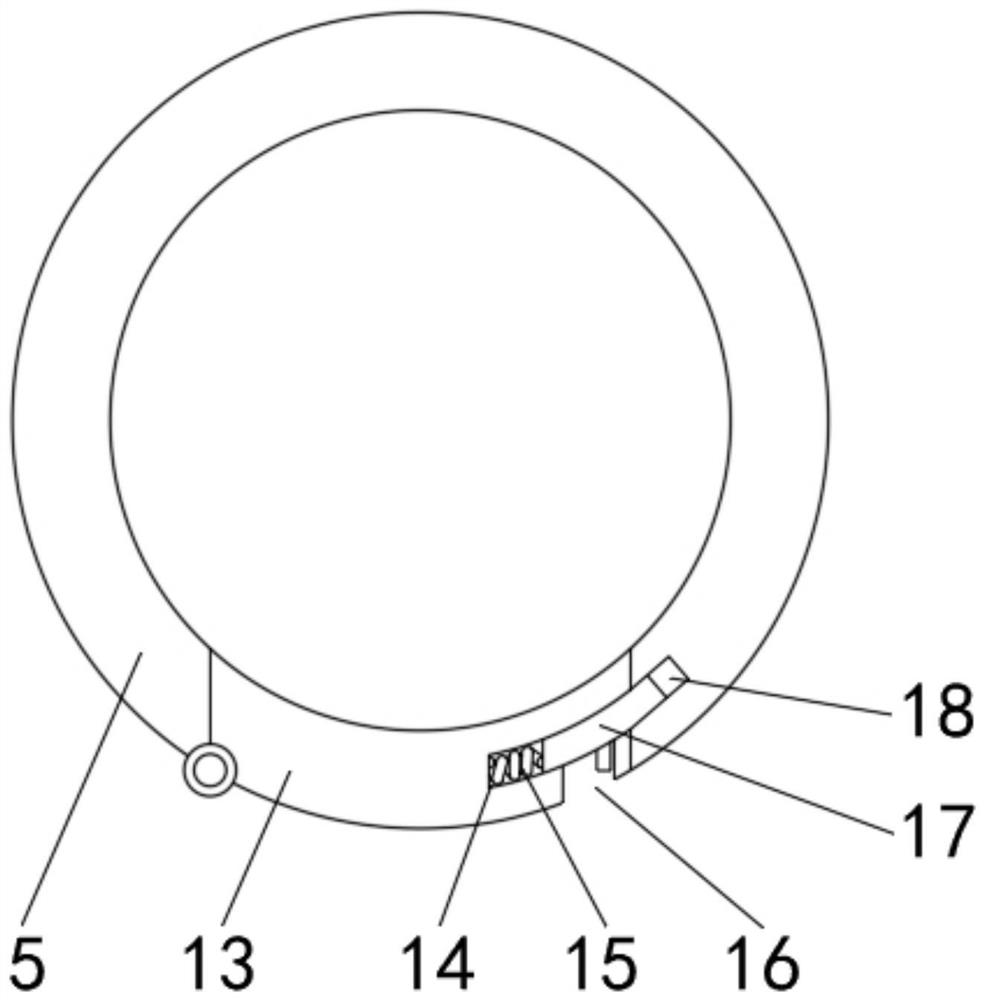

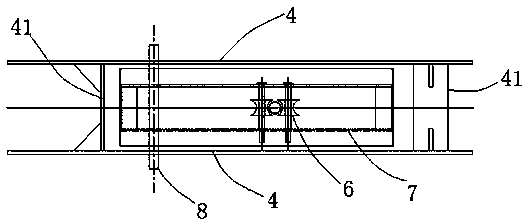

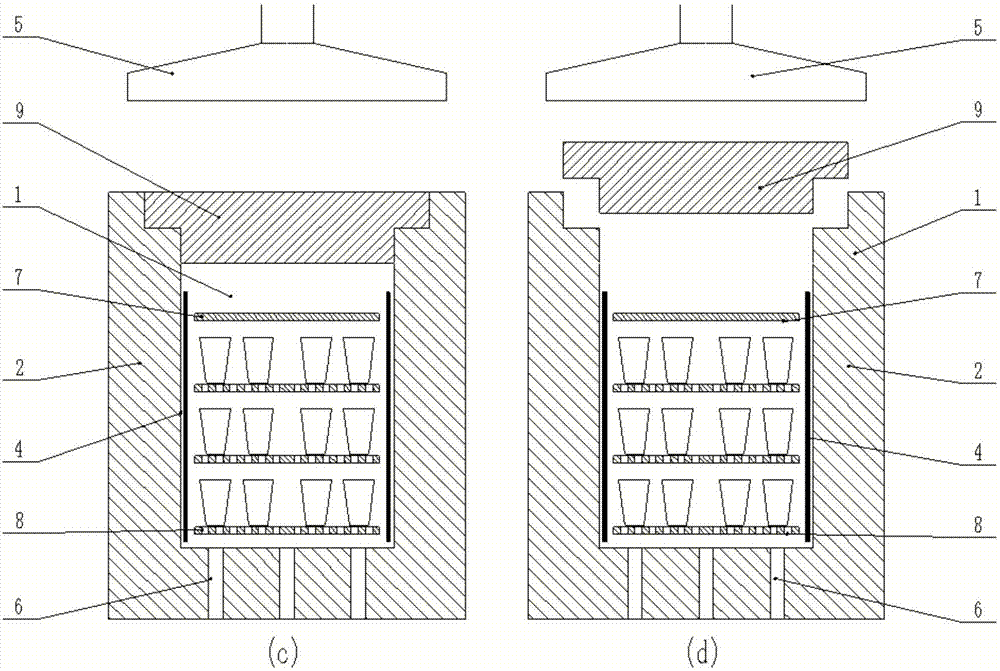

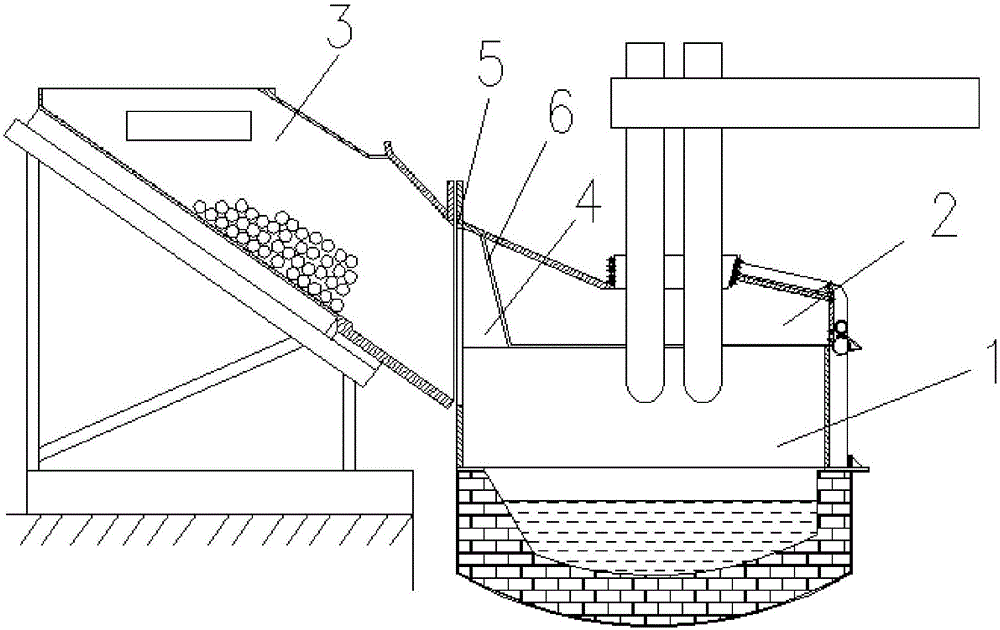

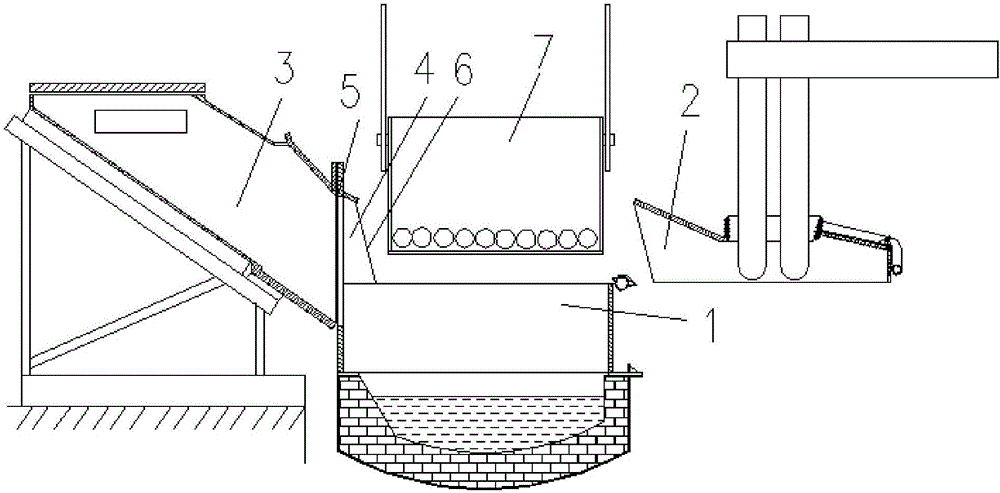

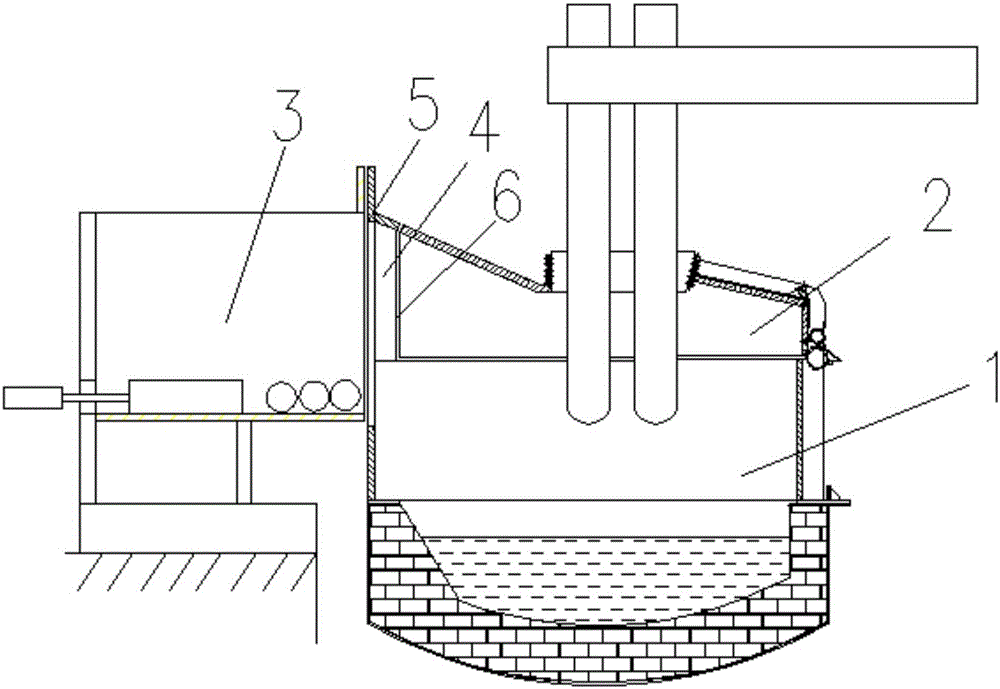

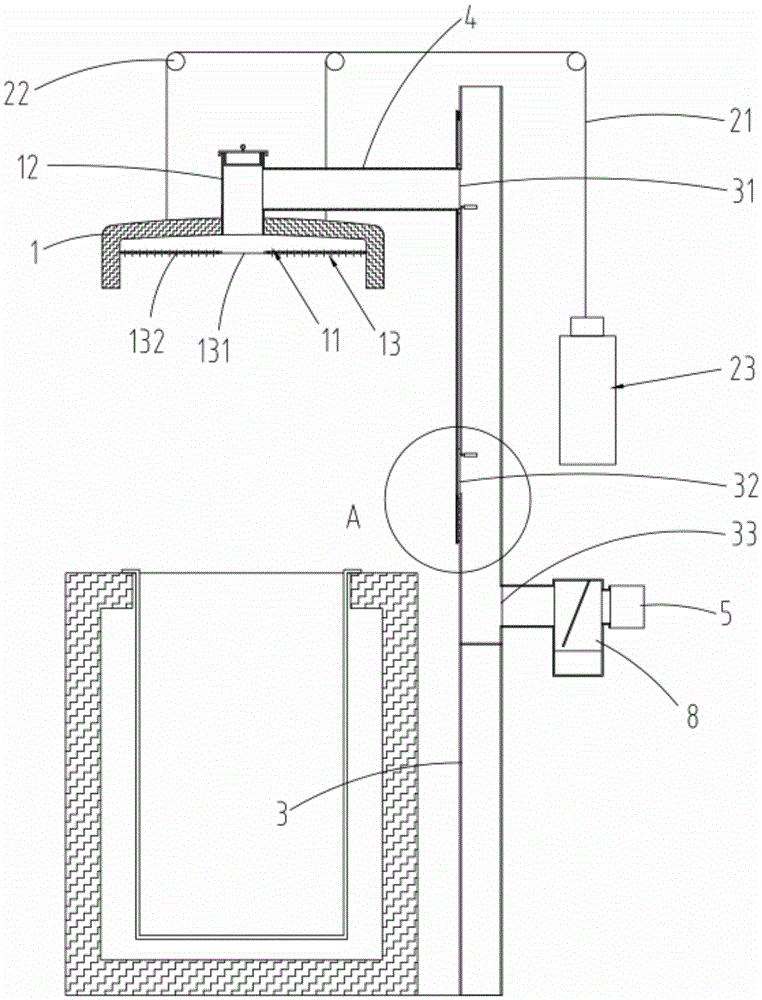

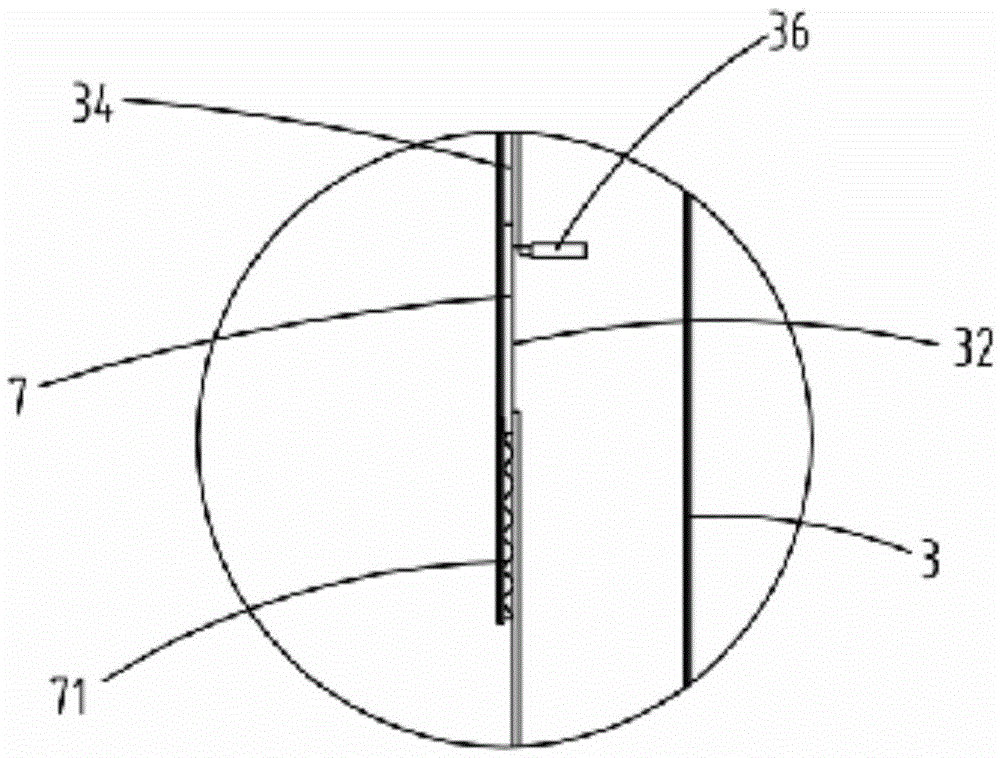

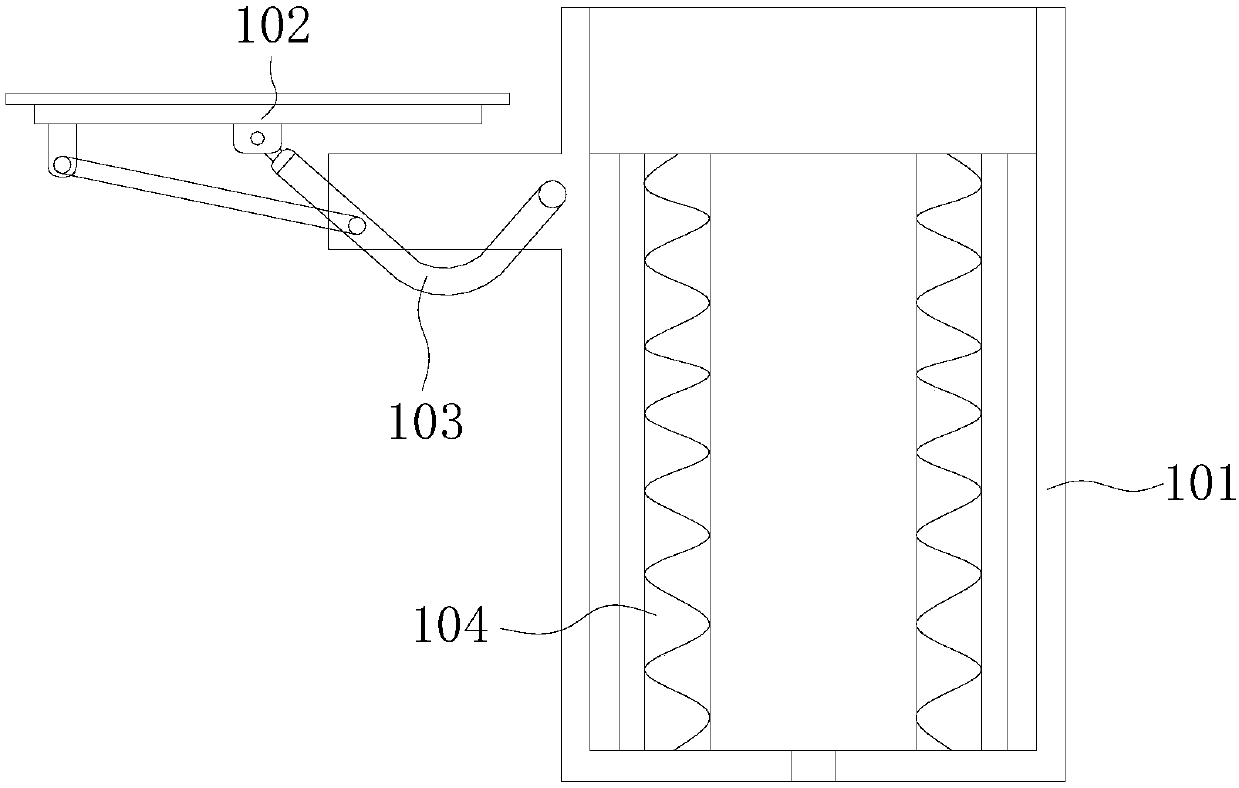

Pit type furnace opening device

InactiveCN107664410AOptimize the opening methodSmall footprintRemovable covers for furnacesVertical furnacesHydraulic cylinderEngineering

A well-type furnace opening device. The purpose of the invention is to design a well-type furnace opening device with reasonable structure and good use effect. The technical solution of the present invention is a well-type furnace opening device, which includes a furnace body, a hydraulic cylinder is installed on one side of the furnace body, a hydraulic rod is installed in the hydraulic cylinder, the end of the hydraulic rod is fixedly connected with the rotating seat, and the rotating seat A rotating shaft is arranged on the furnace cover, and the furnace cover is fixedly connected with the sleeve sleeved on the rotating shaft, and a handle is provided on the furnace cover. The furnace cover is made of alloy material. The invention has the beneficial effects of effectively improving the opening mode of the well-type furnace, reducing the occupied area of the well-type furnace, and improving the processing efficiency of the well-type furnace.

Owner:HENAN TIANLI THERMOTECHNICAL EQUIP CO LTD

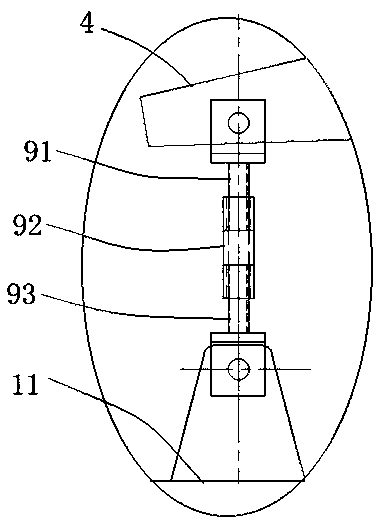

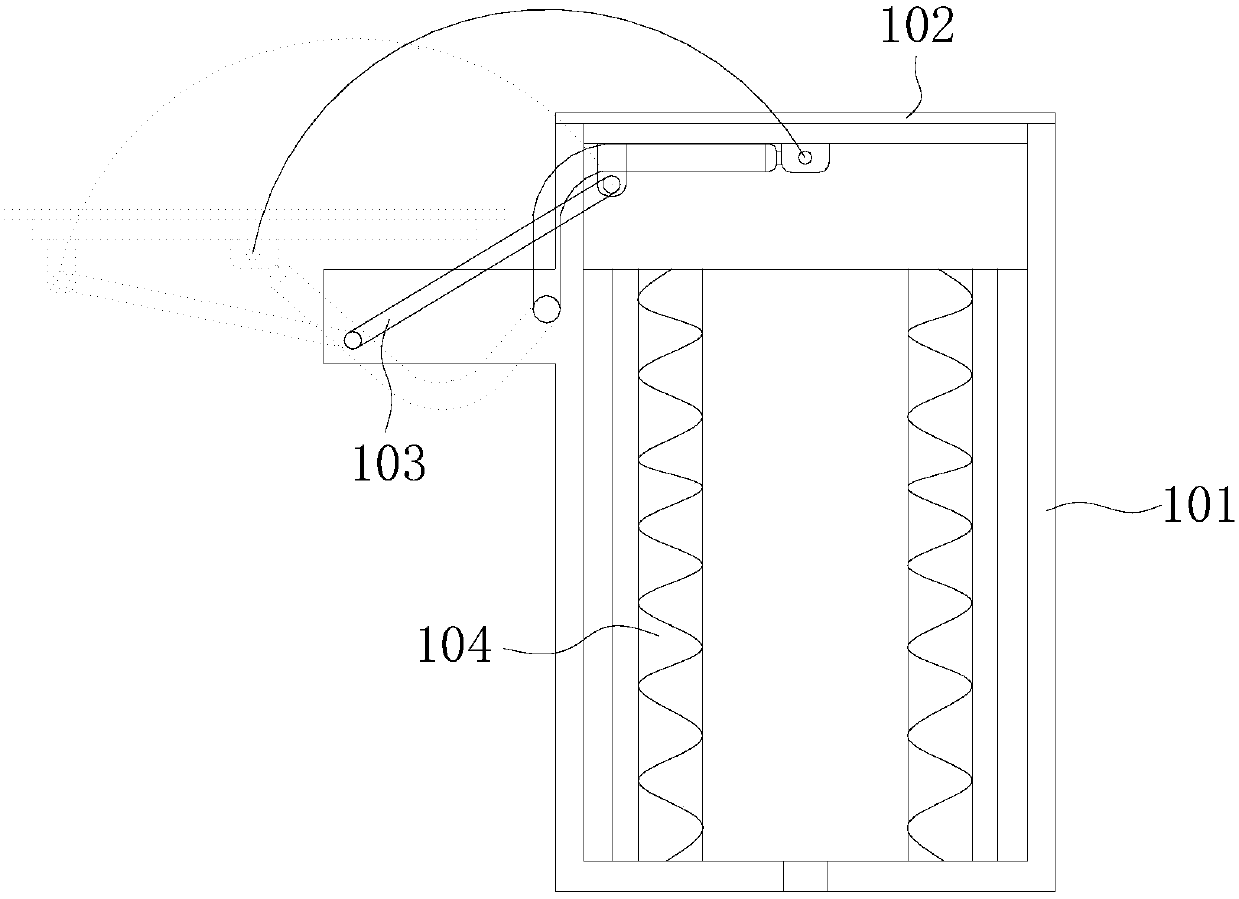

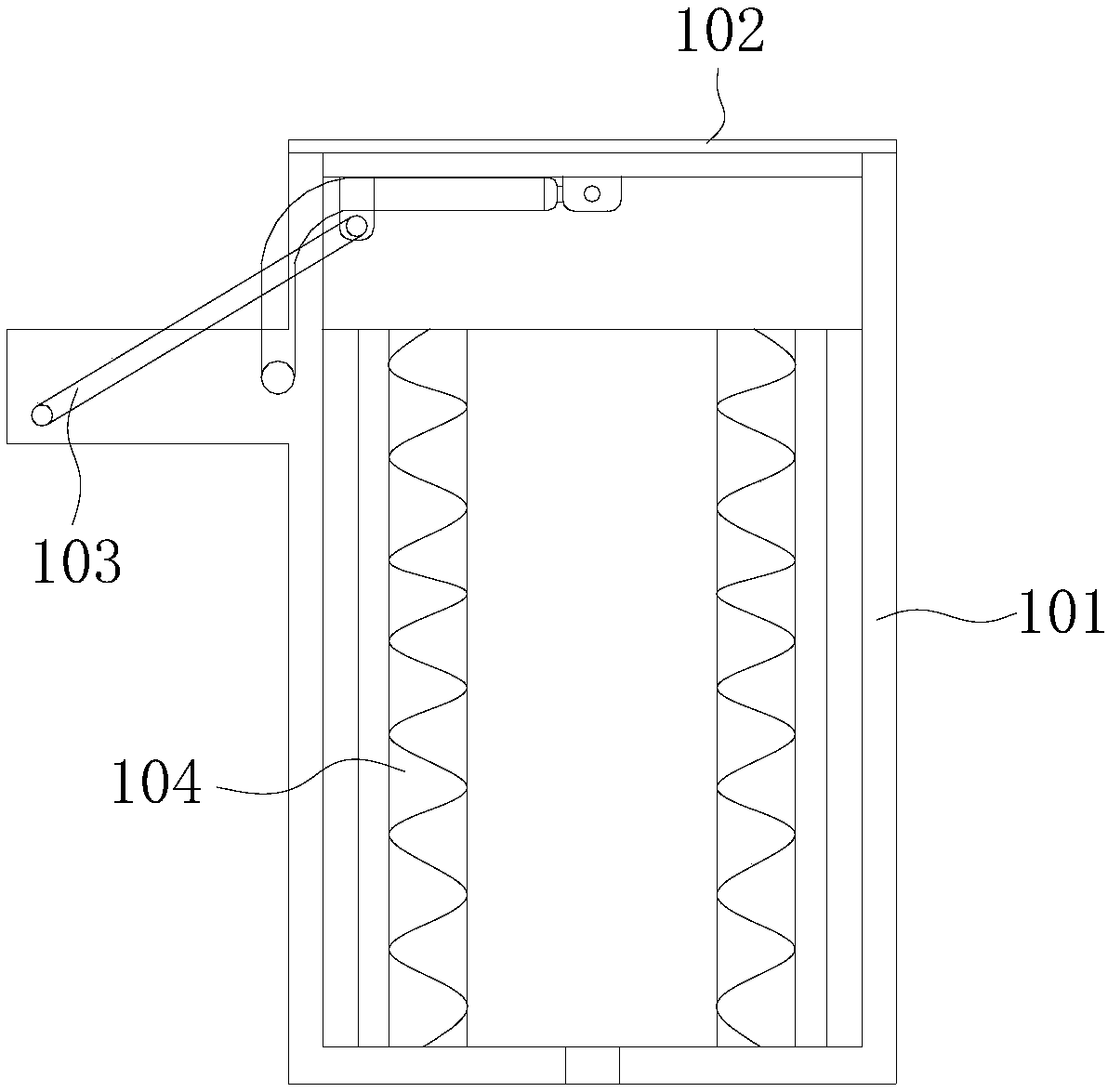

Furnace cover lifting structure of pit furnace

PendingCN110108127ASmall driving forceFew structural partsRemovable covers for furnacesEngineeringMechanical engineering

Owner:HENAN TIANLI THERMOTECHNICAL EQUIP CO LTD

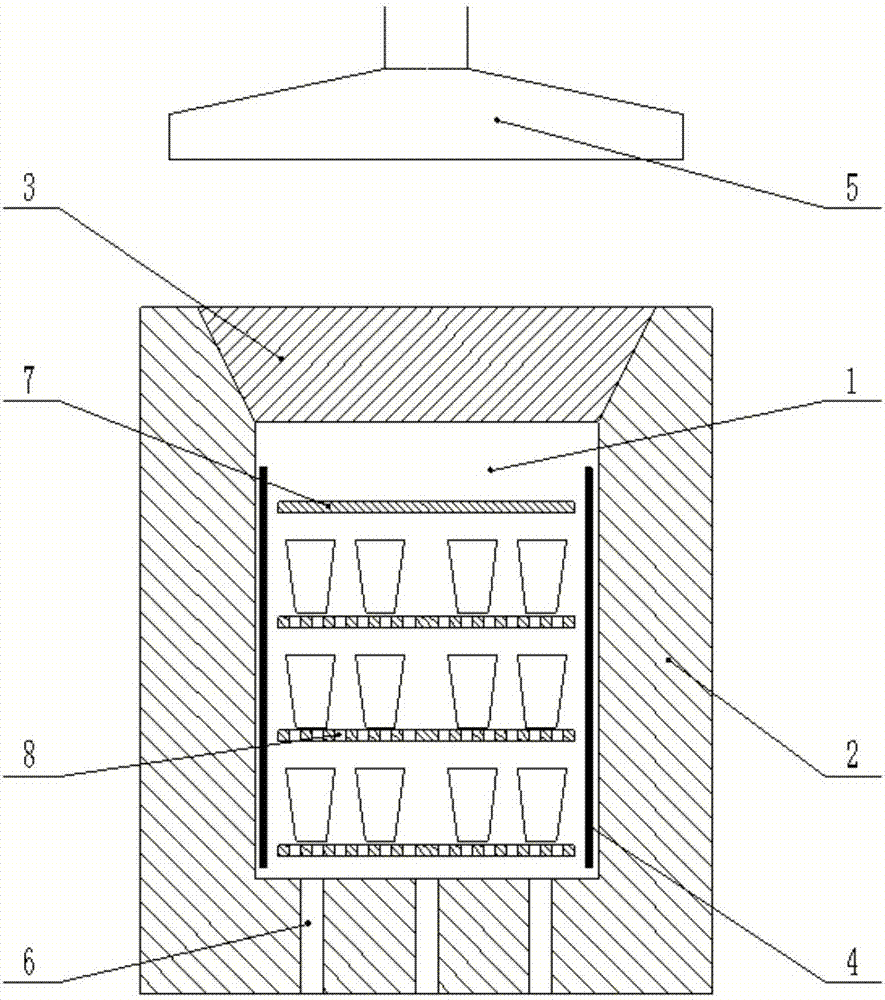

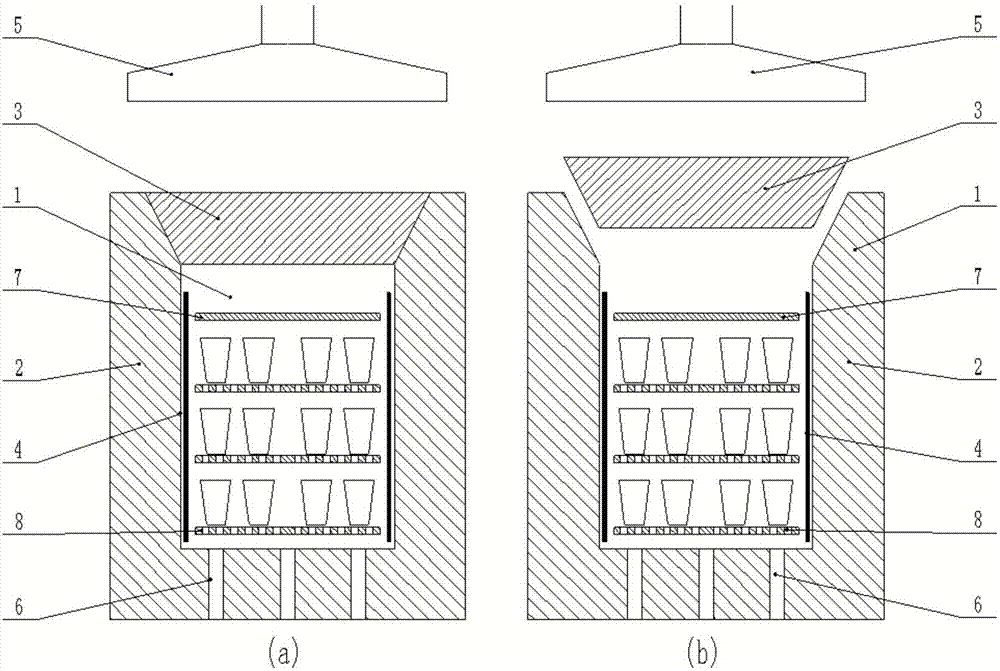

Ceramic kiln with cooling control structure

InactiveCN106885469ASolve the problem of extremely uneven temperature fieldReduced strengthRemovable covers for furnacesCharge composition/stateNatural convectionTop cap

The invention relates to a ceramic kiln with a cooling control structure, and belongs to the technical field of ceramic firing. The ceramic kiln comprises a hearth, a hearth outer wall, a liftable top cap, heaters, a smoke exhaust hood, a controlled air inlet pipeline, a soaking refractory slab and perforated ventilating refractory slabs, wherein the heaters are arranged on the walls of the hearth, and the perforated ventilating refractory slabs are arranged in the hearth longitudinally; a green body to be fired is arranged on the perforated ventilating refractory slabs, and the soaking refractory slab is located above the green body to be fired; the lower part of the hearth is provided with the controlled air inlet pipeline, and the upper part of the hearth is provided with the liftable top cap; the smoke exhaust hood is arranged above the top cap. The temperature in the ceramic kiln provided by the invention is controlled and reduced through controlling radiation quantity and natural convection quantity, and the liftable top cap is controlled; air enters from the bottom, and smoke is collected and exhausted from the top; a temperature field of a ceramic firing cooling stage and atmosphere uniformity are ensured. The ceramic kiln provided by the invention has the advantages of strong practicability and broad application prospect, and the ceramic production efficiency and the rate of finished products can be improved effectively.

Owner:杭州志在材料科技有限公司 +1

Explosion-proof cover mechanism on smelting furnace

InactiveCN111578713AAutomatic shutdownRemovable covers for furnacesFurnace safety devicesEngineeringStructural engineering

The invention discloses an explosion-proof cover mechanism on a smelting furnace. The explosion-proof cover mechanism comprises a furnace body; a pressure relief hole is formed in the furnace body; anexplosion-proof pipe is formed on the outer wall of the furnace body; an explosion-proof cover is inserted into the explosion-proof pipe; a guide column is formed on the explosion-proof cover; a positioning plate is inserted into the explosion-proof pipe; a guide hole is formed in the center of the positioning plate; the guide column is inserted into the guide hole; the guide column is sleeved with a first compression spring in an inserted manner; a pressure relief groove is formed in the side wall of the explosion-proof pipe; a limiting hole is formed in the side wall of the guide column; anaccommodating groove is formed in the inner wall of the guide hole; a telescopic rod is inserted into the accommodating groove; the telescopic rod consists of several joint pipes; the adjacent jointpipes are inserted together; an iron block is fixed to the leftmost joint pipe of the telescopic rod; a first electromagnet is fixed to the inner wall of the accommodating groove; the telescopic rod is sleeved with a second compression spring in an inserted manner; the two ends of the second compression spring abut against the leftmost joint pipe of the telescopic rod and a support correspondingly; and a second electromagnet is fixed in the limiting hole. According to the invention, the explosion-proof cover after explosion-proof pressure relief can be automatically closed.

Owner:嵊州旧竹机械有限公司

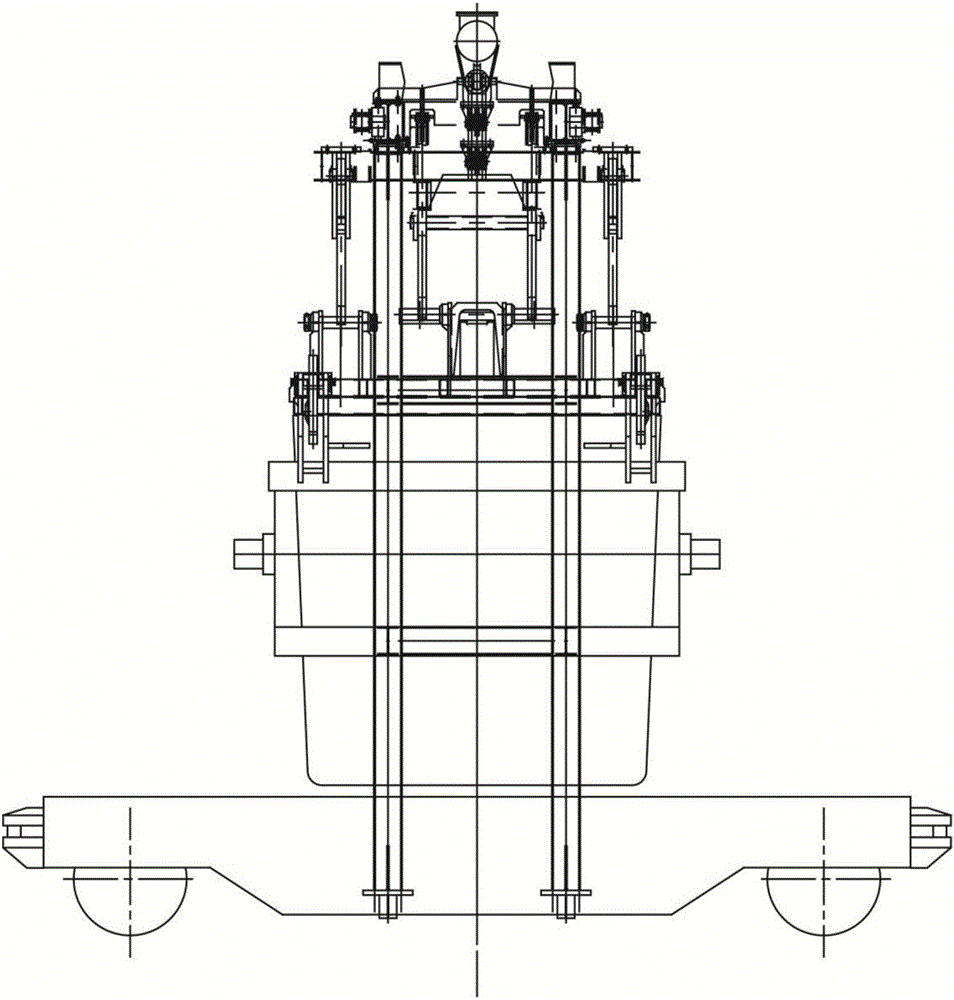

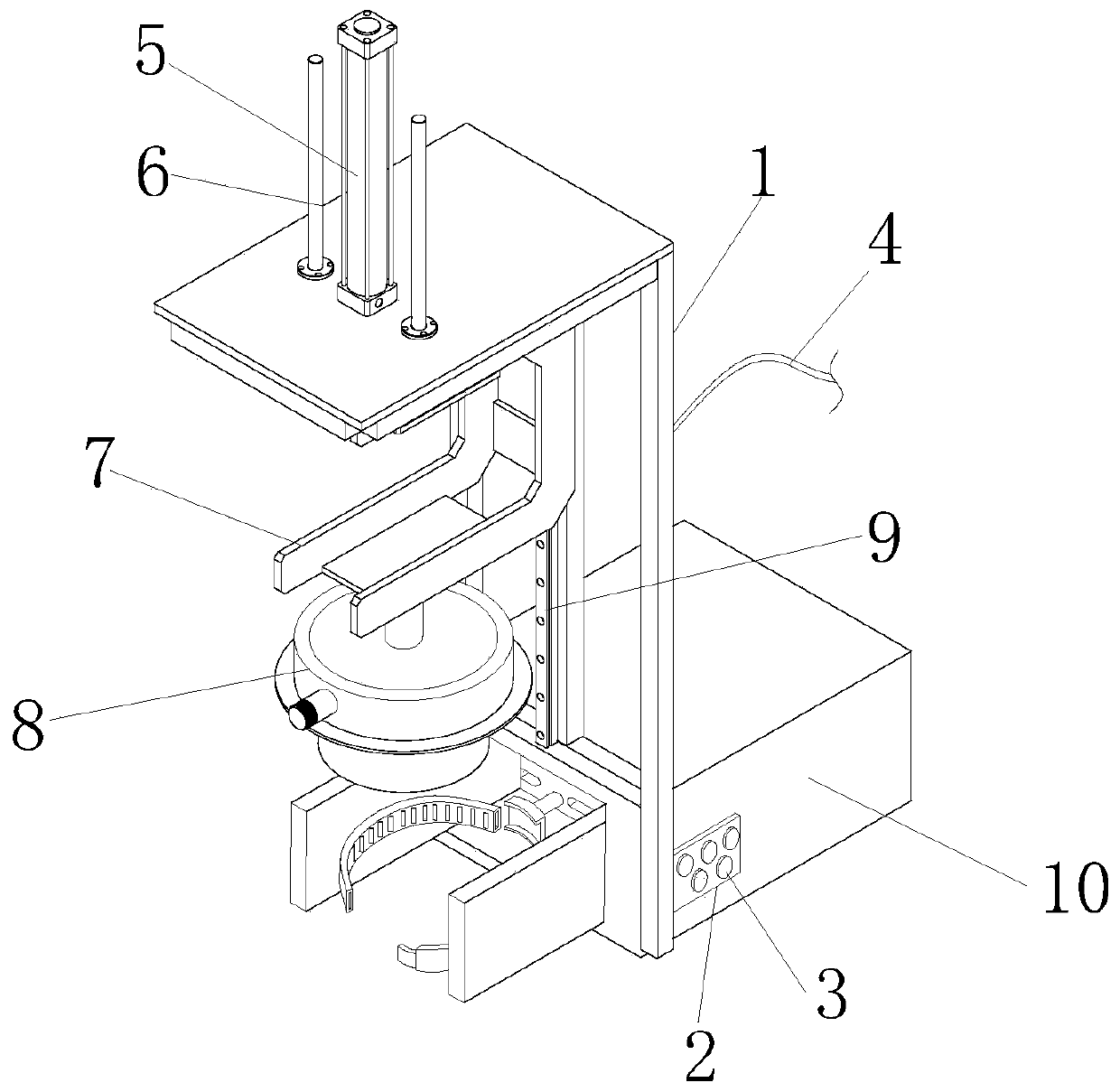

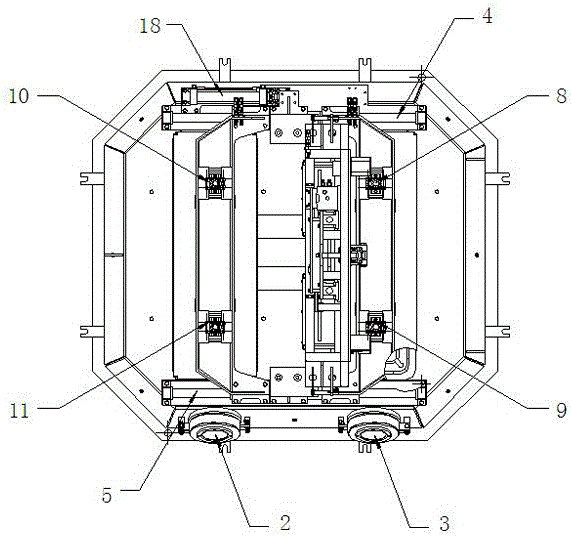

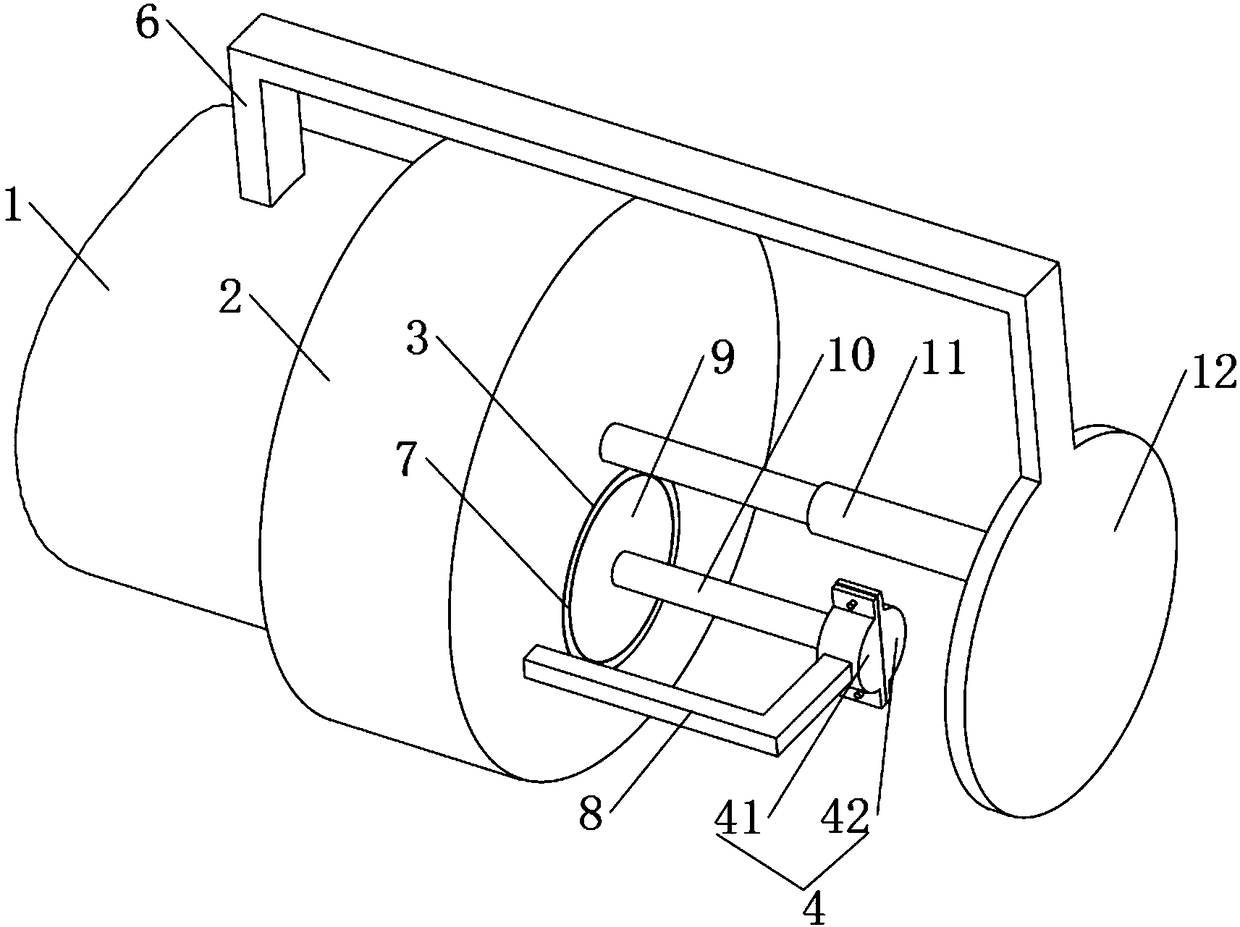

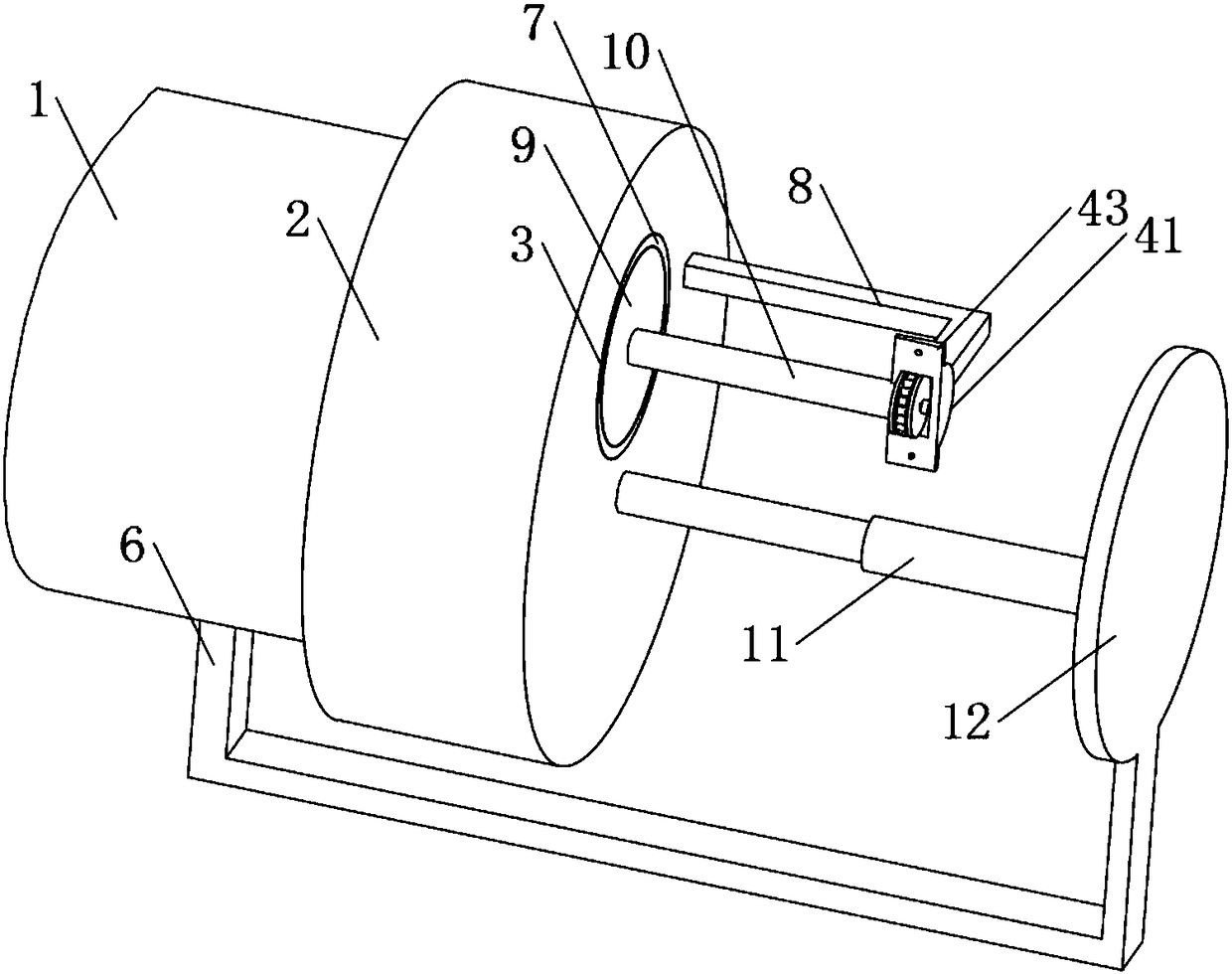

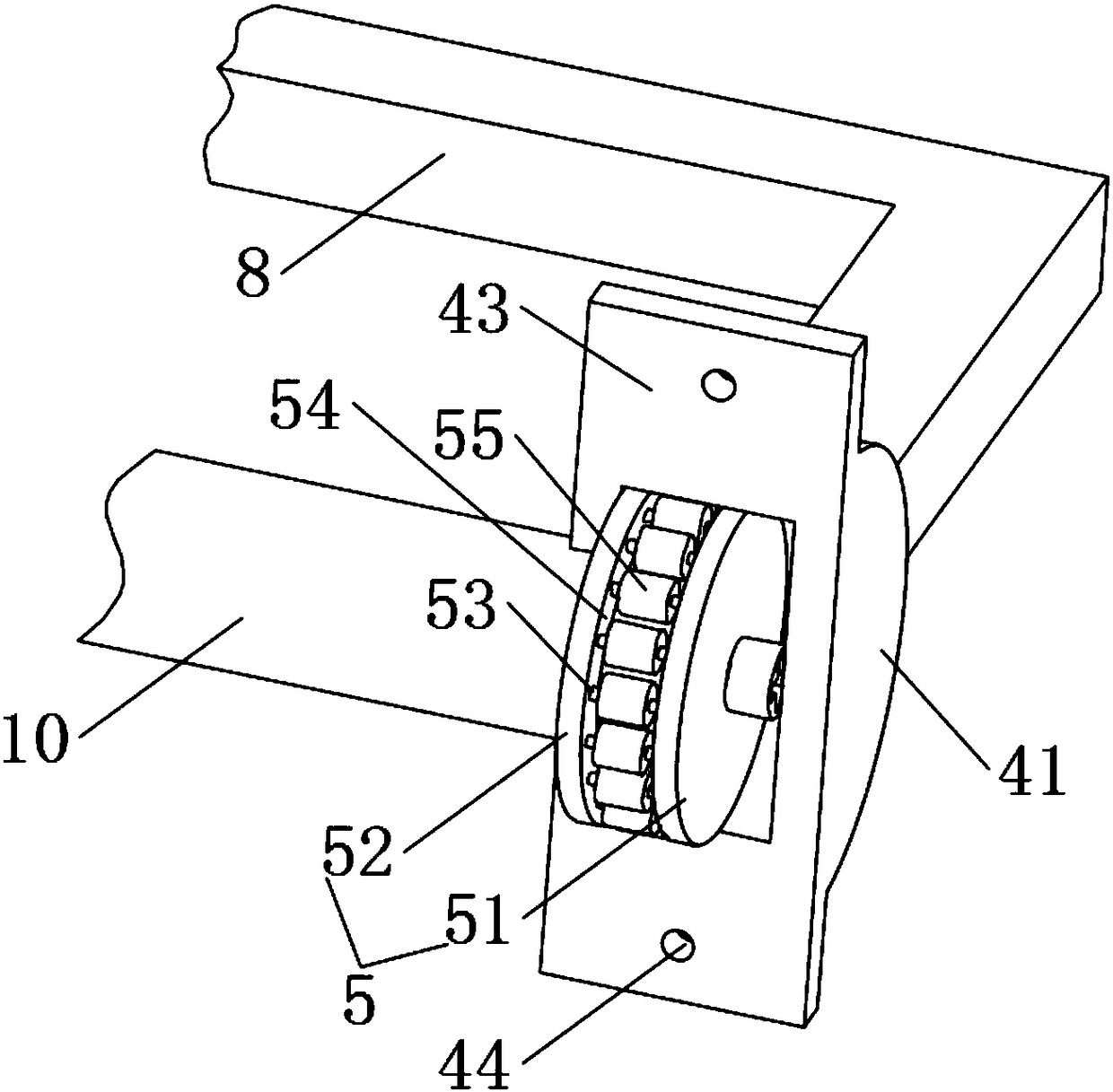

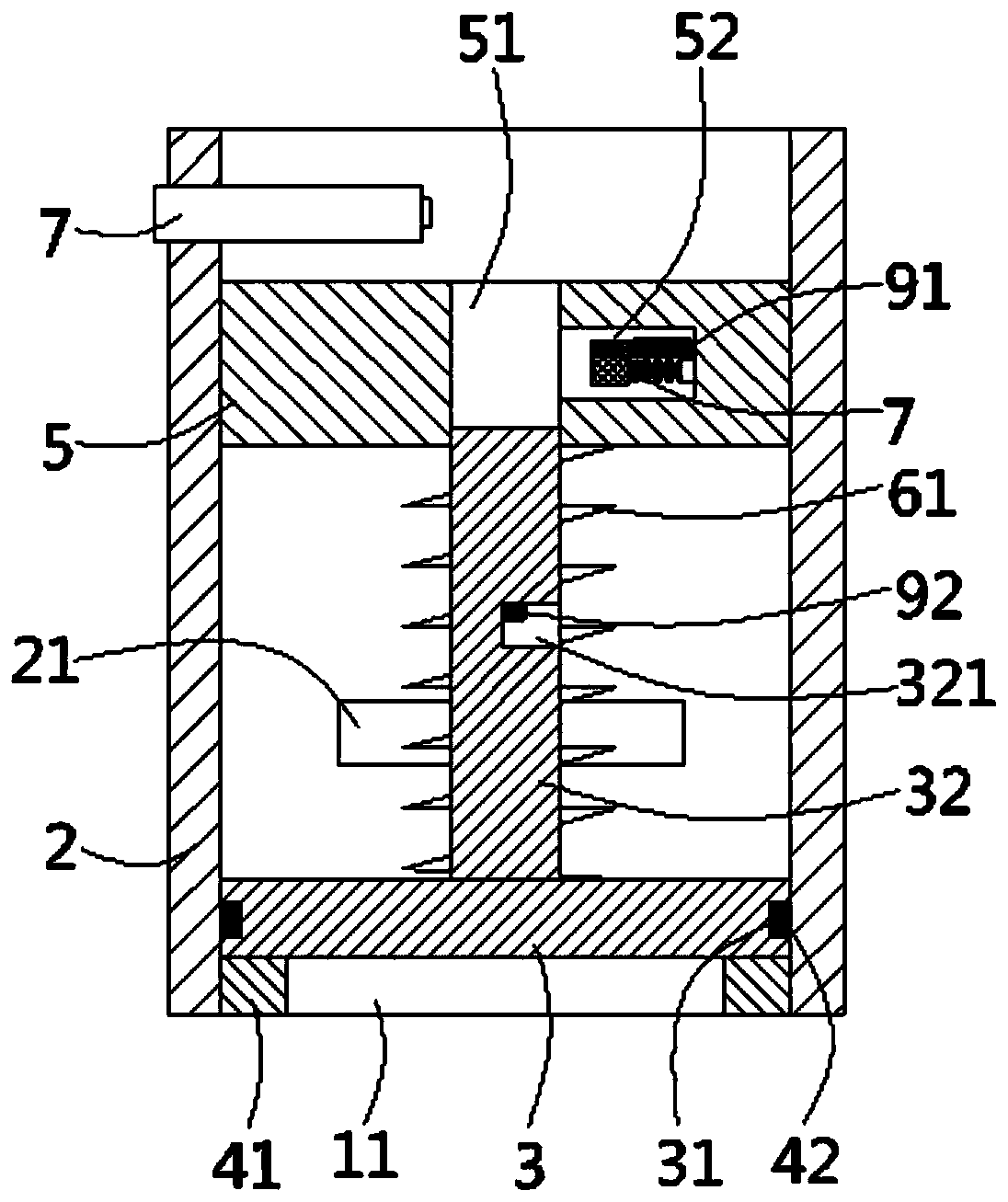

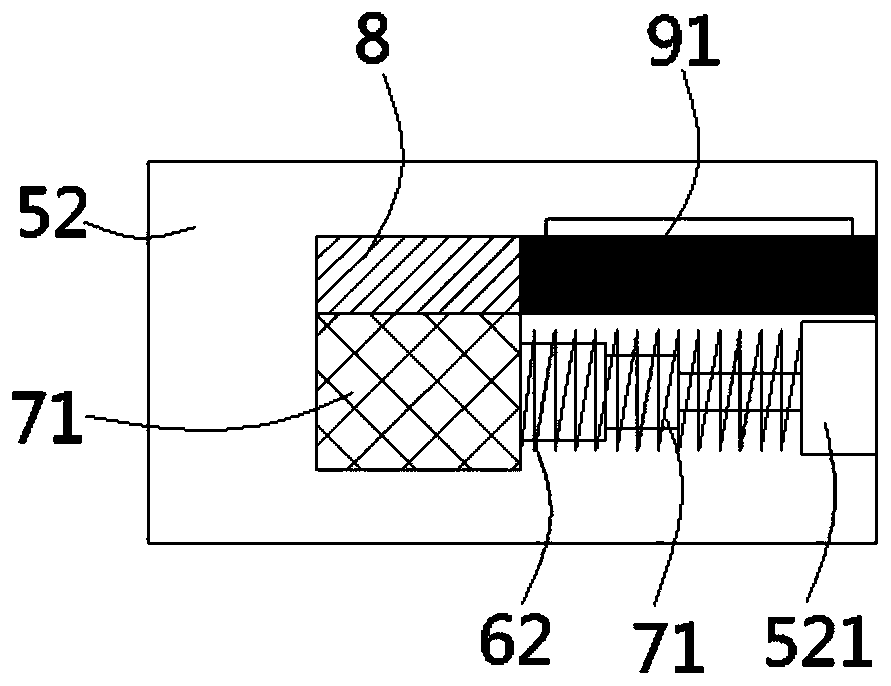

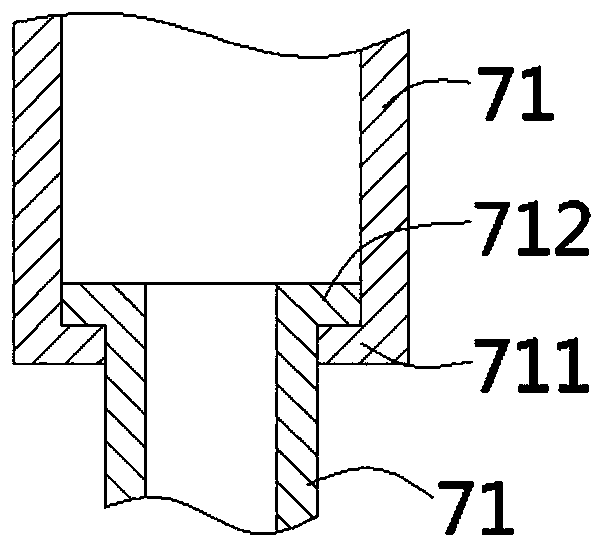

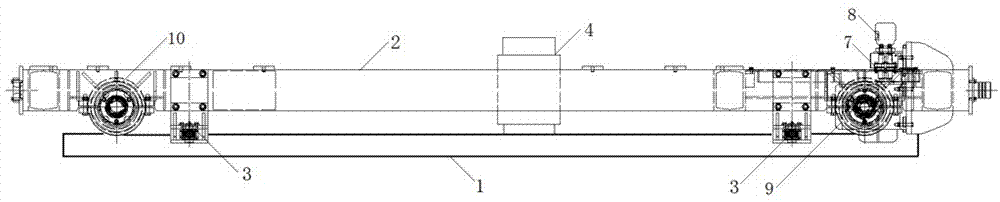

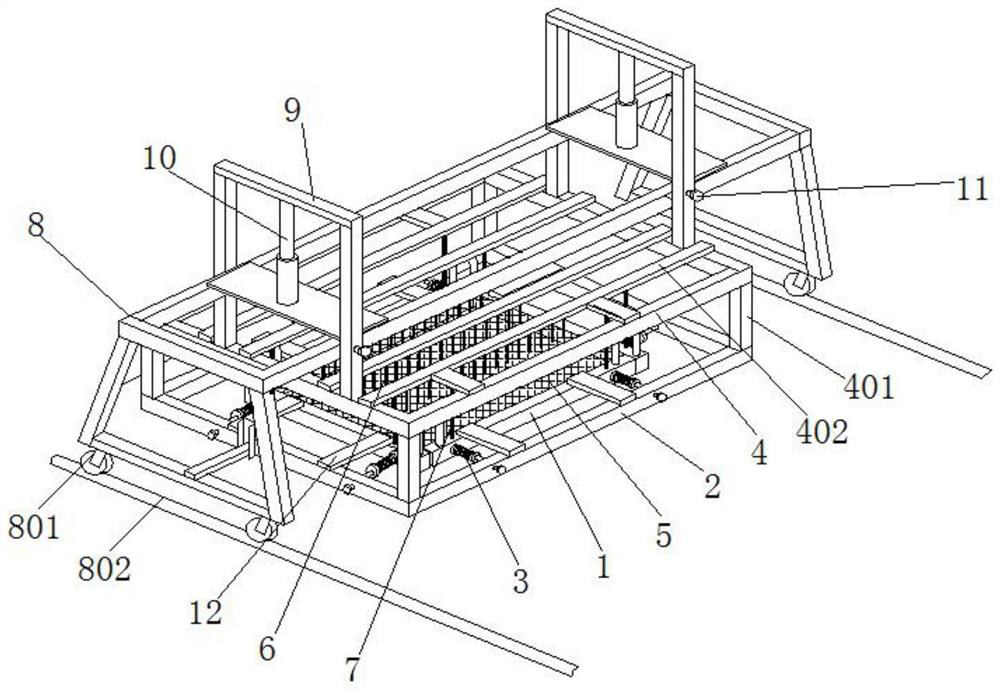

Automatic furnace cover closing device suitable for vacuum melting furnace

PendingCN106895701AReliable performanceExtended service lifeRemovable covers for furnacesCharge treatment typeDrive wheelVehicle frame

The invention discloses an automatic furnace cover closing device suitable for a vacuum melting furnace. The automatic furnace cover closing device comprises a furnace cover body, a moving device and a control device. The moving device comprises a trolley frame, a driving wheel set, a driven wheel set, a rectifying mechanism, a lifting mechanism and a power mechanism. The driving wheel set and a power mechanism are arranged at one end of the trolley frame. The power mechanism is in transmission connection with the driving wheel set. The other end of the trolley frame is provided with the driven wheel set. The portion, between the driving wheel set and the driven wheel set, of the trolley frame is provided with the rectifying mechanism. The lifting mechanism is arranged in the center portion of the trolley frame. A furnace cover is arranged below the lifting mechanism. The lifting mechanism is movably matched with the furnace cover. The lifting mechanism and the power mechanism are both electrically connected with the control device. The automatic furnace cover closing device is stable and reliable in operation performance, long in service life, convenient and fast to repair and maintain and low in fault rate, the technical defects that existing equipment cannot work stably in the high-intensity magnetic field, and is unstable in operation, and inconvenient and not fast to repair and maintain are overcome, requirements of practical production are met, the production efficiency is effectively improved, and production cost is reduced.

Owner:YUNNAN HEAVY EQUIP MFG GRP

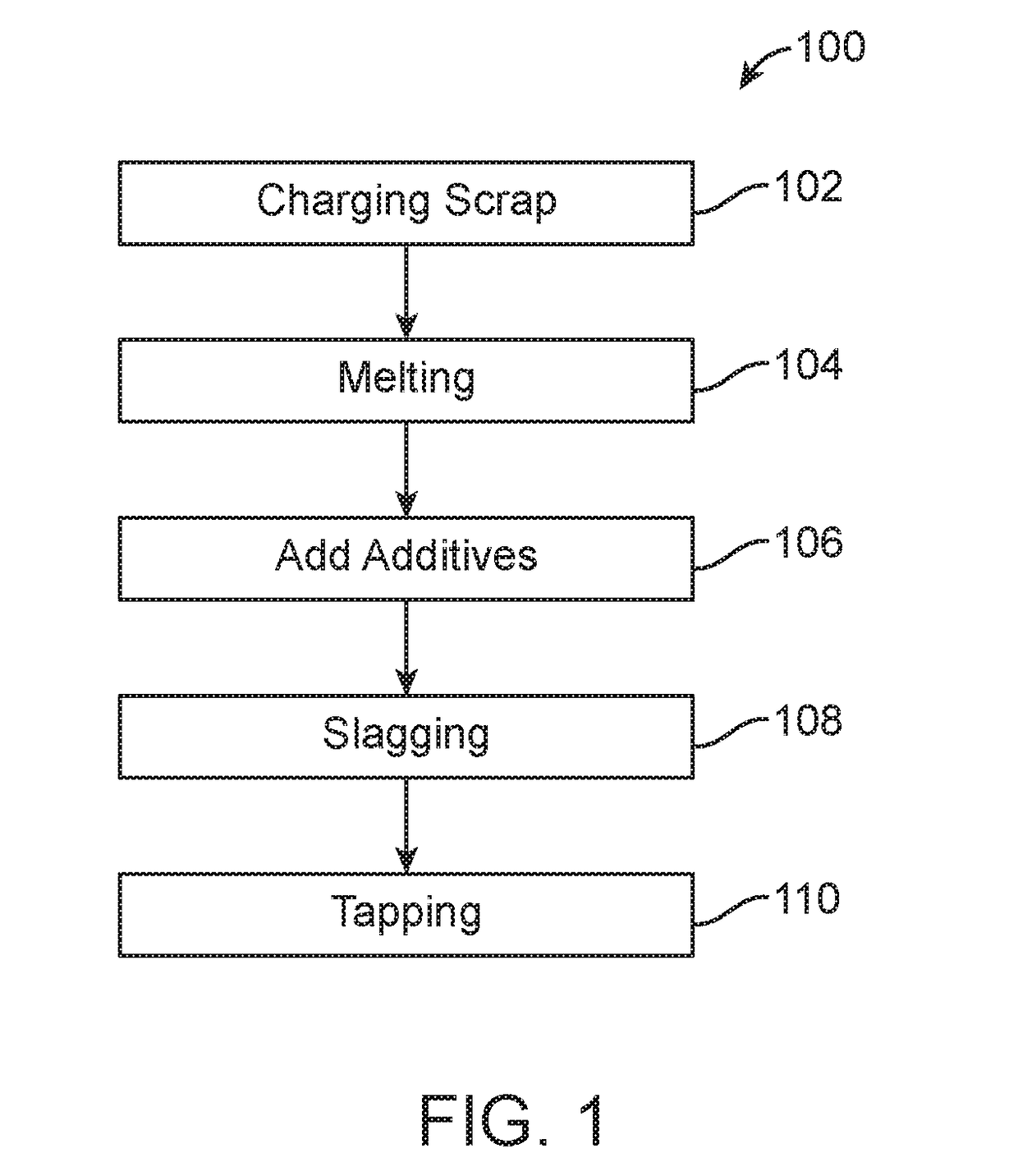

Automatic metal smelting equipment and smelting process thereof

PendingCN114562878AAvoid the phenomenon of too low purityAvoid wastingRemovable covers for furnacesMaintainance of heating chambersSmelting processEngineering

The invention relates to automatic metal smelting equipment and a smelting process thereof, and relates to the field of metal smelting, the automatic metal smelting equipment comprises a melting furnace, a furnace cover is detachably connected to the melting furnace, a material spraying opening is formed in the furnace cover, and a metering scale is connected to the lower portion of the melting furnace; a spray gun is arranged above the melting furnace and comprises an inner rotating cylinder and an outer rotating cylinder, a driving assembly for driving the inner rotating cylinder to rotate relative to the outer rotating cylinder is connected to the inner rotating cylinder, and the inner rotating cylinder and the outer rotating cylinder rotate relative to each other and are used for adjusting the amount of sprayed reducing gas. The device has the beneficial effects that a worker judges the amount of reducing gas needing to be sprayed into the melting furnace according to the weight of metal in the melting furnace, so that accurate amount control is achieved, waste of the reducing gas is avoided, and meanwhile the phenomenon that the purity of the metal obtained through reduction is too low is avoided.

Owner:洛南环亚源铜业有限公司

Furnace cover structure of kiln

PendingCN114046660ASo as not to damageImprove performanceRemovable covers for furnacesFurnace cooling arrangementsStructural engineeringMechanical engineering

The invention discloses a furnace cover structure of a kiln. The furnace cover structure comprises a furnace top frame, a bottom frame and a top frame, wherein a furnace top is arranged in an area defined by the furnace top frame, the furnace top frame is defined by a plurality of peripheral pipe bodies, a gap is reserved between the ends of any two adjacent peripheral pipe bodies, the bottom frame surrounds the outer side of the furnace top frame, a plurality of elastic supporting devices are arranged in an area between the bottom frame and the furnace top frame, a plurality of pressing plates are arranged above the bottom frame, one ends of the pressing plates are fixed to the bottom frame, the other ends of the pressing plates abut against the furnace top frame, the top frame is located above the bottom frame, the top frame is connected with the bottom frame through a plurality of supporting columns, a hanging frame is arranged in an area defined by the top frame, the furnace top is connected with the hanging frame through a plurality of steel wires, and each peripheral pipe body is connected with the hanging frame through a plurality of pulling pieces. According to the invention, the furnace top frame can move towards the periphery along with heating expansion of the furnace top, the furnace top cannot be damaged due to extrusion, and the whole furnace top is stable in performance and more reliable in structure.

Owner:唐山市科硕特种陶瓷制造有限公司

Cover opening structure of waste steel preheating arc furnace

ActiveCN106524767AAny tiltEasy to openRemovable covers for furnacesElectric arc furnaceVertical plane

The invention discloses a cover opening structure of a waste steel preheating arc furnace, and belongs to the technical field of steel refining. The cover opening structure comprises a furnace body, a furnace cover, a waste steel preheating device and a ring body; the ring body is arranged above the furnace body, and is fixedly connected with the furnace body to form a waste steel charging joint; the waste steel charging joint is connected with the waste steel preheating device; the waste steel charging joint has a vertical plane perpendicular to the tilting axis of the furnace body for adapting to any tilting operation of the furnace body; a sealing surface matched with the furnace cover is arranged on one side, deviated from the waste steel preheating device, of the ring body for adapting to the rotary swing operation of the furnace cover; and when the furnace cover is closed, the furnace cover and the ring body form tight combination through the sealing surface. The cover opening structure can keep closed arc surface when the sealing surface closes the furnace cover, is convenient to open and close the furnace cover, is tight in matching between the furnace cover and the furnace body, and is excellent in tightness of the whole arc furnace.

Owner:CISDI ENG CO LTD

Heating equipment

InactiveCN108534551ASimple structureEasy to operateRemovable covers for furnacesBatteries circuit arrangementsBiochemical engineering

Owner:何正和

Industrial furnace with liftable dust-collecting furnace cover

ActiveCN105546992AAvoid interferenceImprove the environmentRemovable covers for furnacesWaste heat treatmentCrucibleFlue gas

The invention relates to an industrial furnace with a liftable dust-collecting furnace cover. The industrial furnace comprises a furnace body, the furnace cover, and a lifting mechanism for lifting the furnace cover, wherein a semienclosed cavity is formed on the inner wall of the furnace cover; a salt adding passage is formed in the top of the furnace cover; a first flue gas inlet, a second flue gas inlet and a flue gas outlet which are communicated with the inside of a fixed flue gas pipeline are formed in the fixed flue gas pipeline; the flue gas outlet is connected with a flue gas pumping device; the end part of a movable flue gas pipeline can move up and down along the outer wall of the fixed flue gas pipeline; the salt adding passage is communicated with the first flue gas inlet or the second flue gas inlet through the movable flue gas pipeline; a crucible is arranged at the inner part of the furnace body; the height difference of the first flue gas inlet and the second flue gas inlet meets the condition that when the furnace cover is opened, a workpiece to be processed can be hung into the crucible. The condition of interference generated in materials and the furnace cover when the workpiece is hung into the furnace body is avoided, flue gas dispersed in the furnace body can be concentrated and pumped no matter whether the furnace cover is opened or closed, the workshop environment can be improved, and the health of workers are benefited.

Owner:嘉兴乐创紧固件科技有限公司

Aluminum alloy smelting furnace and smelting device

PendingCN107860232AAvoid influenceJob impactRemovable covers for furnacesMaintainance of heating chambersHigh frequencyMetal

The invention provides an aluminum alloy smelting furnace and a smelting device and belongs to the technical field of metal smelting. The aluminum alloy smelting furnace comprises a furnace body, a cover body, a control device and the smelting device. The cover body is connected with the furnace body through the control device. The control device controls the cover body to move relative to the furnace body in a translational mode. The cover body and the furnace body constitute a furnace hearth. The end, far from the cover body, of the furnace body is provided with an outlet. The outlet communicates with the furnace hearth. The smelting device is located in the furnace hearth. The smelting device comprises a high-frequency heating device, a heat collection device and a reflecting layer which are arranged in sequence. The reflecting layer is connected with the furnace body. The reflecting layer is located between the high-frequency heating device and the furnace body. The smelting devicecomprises the aluminum alloy smelting furnace. The aluminum alloy smelting furnace provided by the invention is provided with the control device; the cover body and the furnace body can be opened andclosed just through translational motion so that the influence of opening and closing of a shell on a suction device can be effectively avoided.

Owner:重庆顺博铝合金股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com