Automatic furnace cover closing device suitable for vacuum melting furnace

A vacuum melting furnace, automatic closing technology, applied in the direction of movable furnace cover, furnace, charge, etc., can solve the problems of inconvenient maintenance, unstable work, unstable operation, etc., achieve stable and reliable operation performance, and improve production Efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

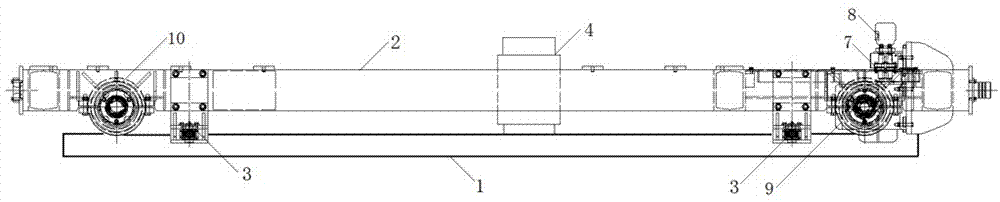

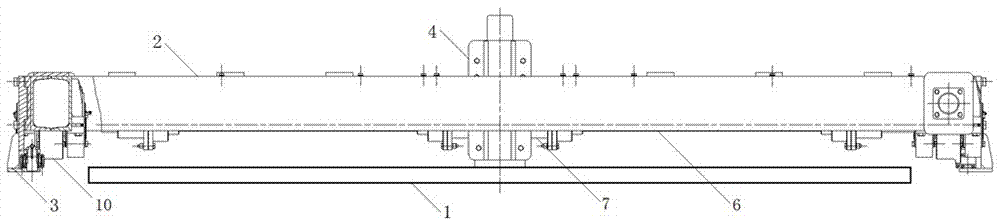

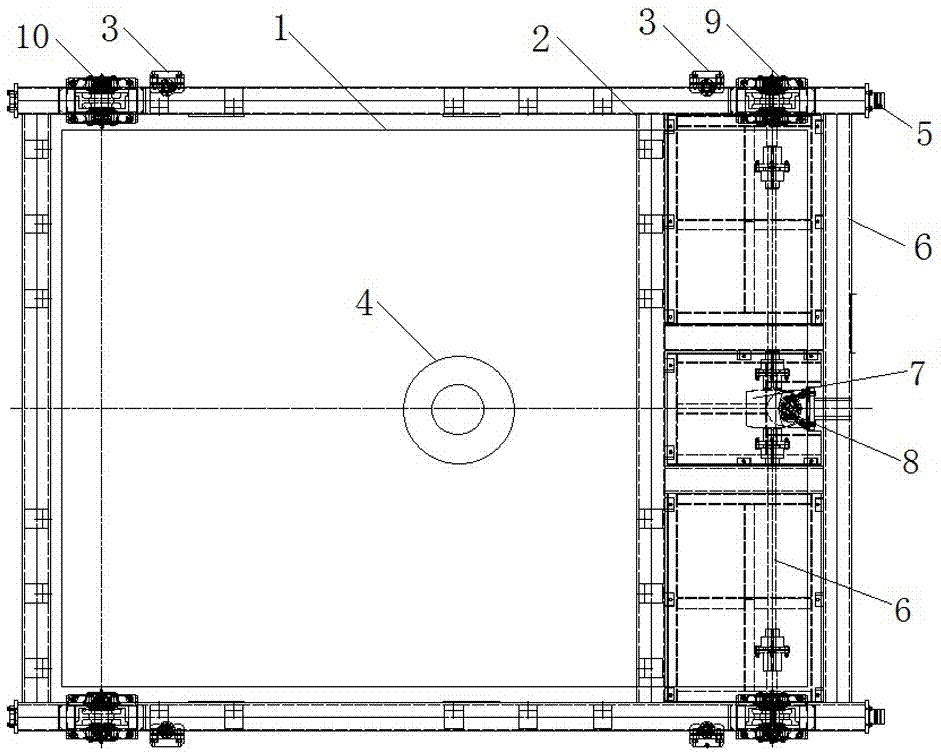

[0012] According to attached Figure 1~4 The furnace cover automatic closing device suitable for vacuum melting furnaces shown includes a furnace cover 1 body, a moving device and a control device. 4 and a power mechanism, one end of the vehicle frame 2 is provided with a drive wheel set and a power mechanism, the drive mechanism is connected to the drive wheel set, and the other end is provided with a driven wheel set, and the vehicle frame 2 between the drive wheel set and the driven wheel set A deviation correction mechanism 3 is arranged on the top, a lifting mechanism 4 is arranged at the center of the vehicle frame 2, and a furnace cover 1 is arranged below the lifting mechanism 4, and the lifting mechanism 4 is in motion with the furnace cover 1, and the lifting mechanism 4 and the power mechanism are electrically connected. Connect the control unit.

[0013] The frame 2 is provided with a guide device 5 and a buffer device 5 at one end of the driving wheel set, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com