Covering and uncovering device of LF furnace

A cover-removing device and cover-recovering technology, applied in the field of iron and steel smelting, can solve problems such as the reduction of radiation heat dissipation, achieve the effects of reducing cooling degree, reducing heat loss, and eliminating auxiliary preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only parts related to the present invention are shown in the drawings but not all content.

[0025] In the recycling process of the ladle, whether it is the ladle capping or uncapping action is automatically completed by the present invention, neither the crane nor manual intervention is required, and it fundamentally realizes the automatic ladle adding / removing The effect of uncovering.

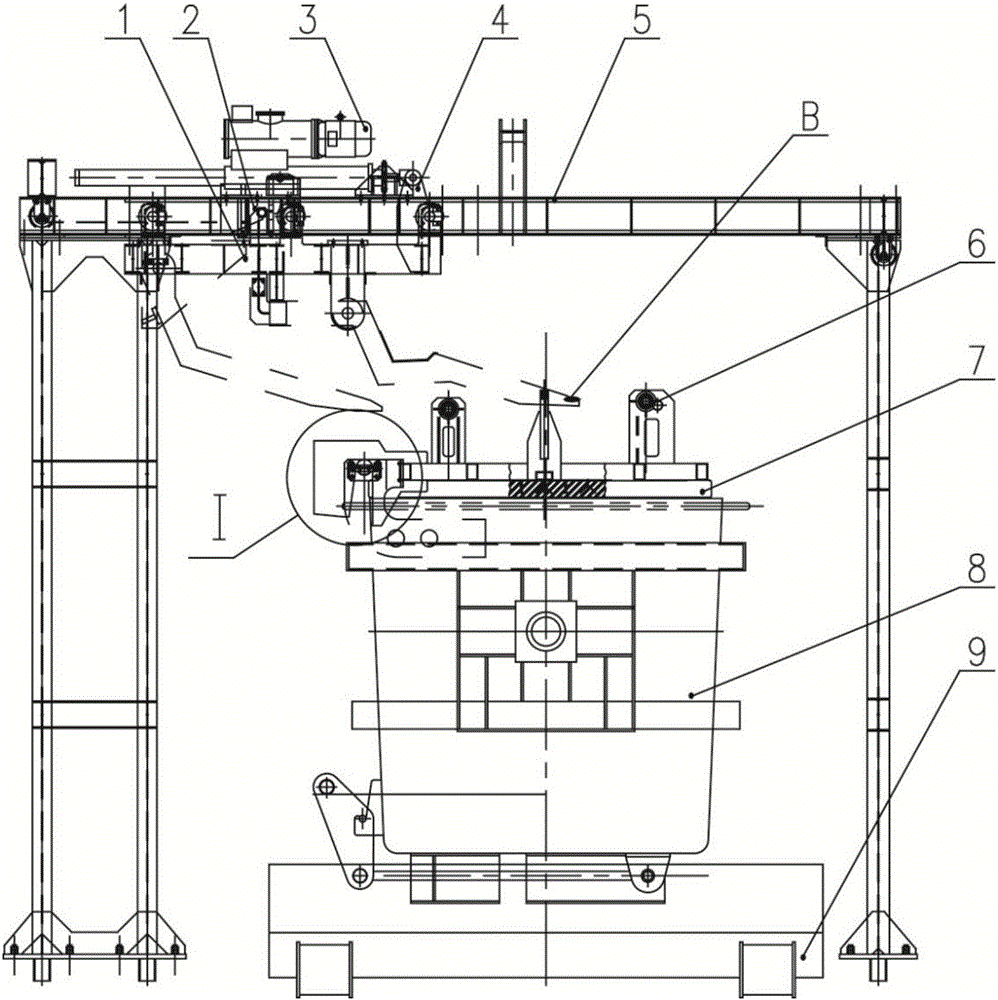

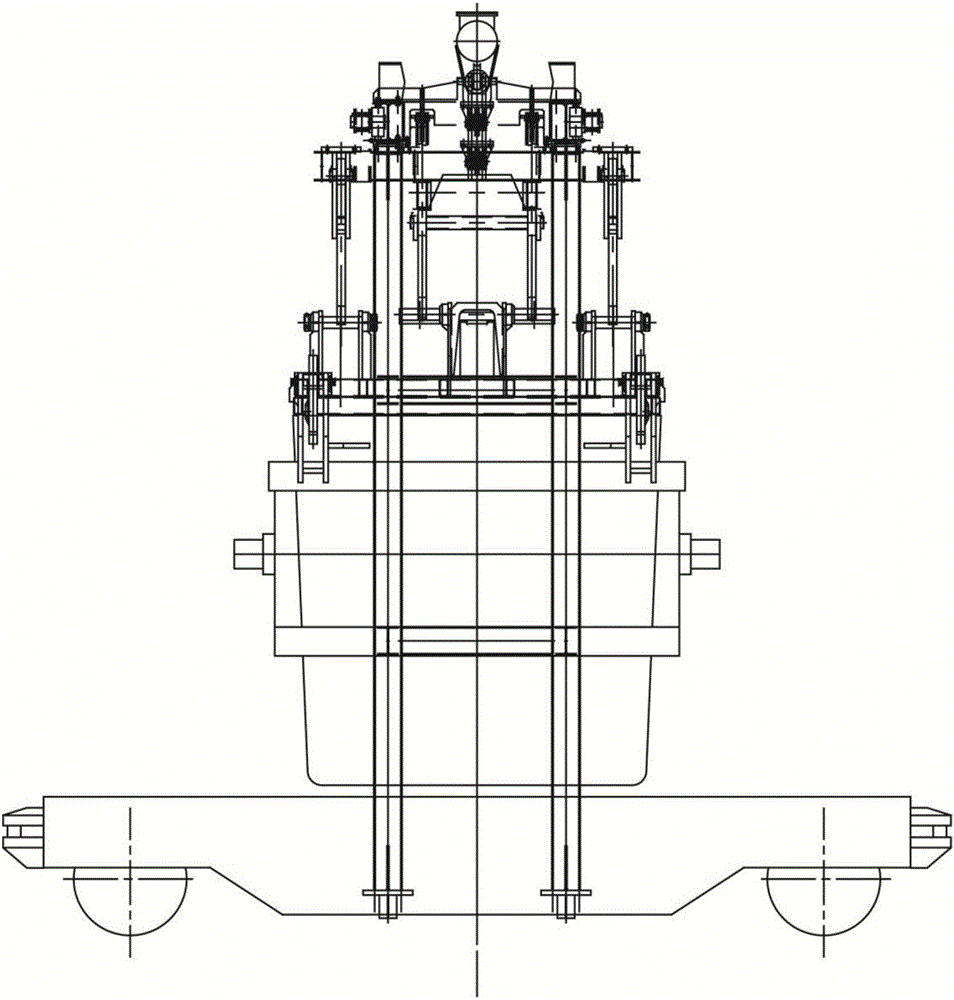

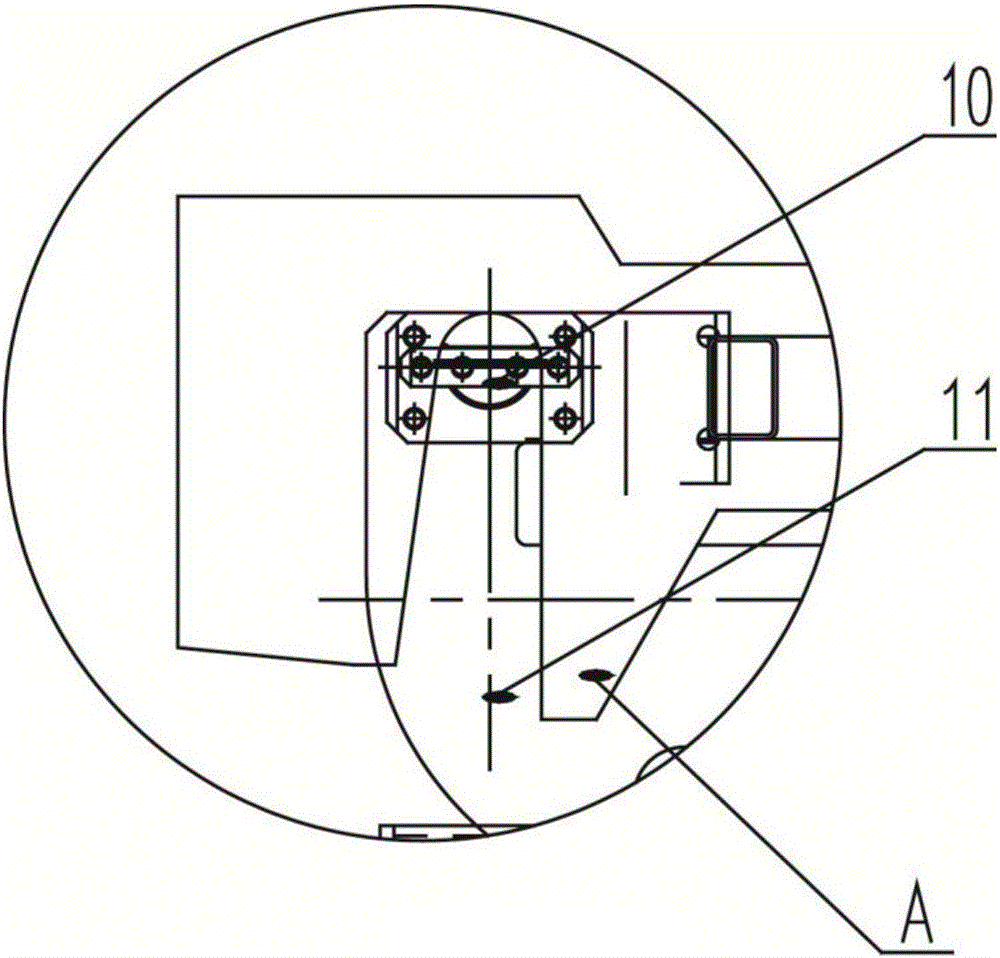

[0026] Structure of the present invention (as Figure 1 to Figure 3 Shown): 4 fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com