Organic solid waste pretreatment system and process and corresponding organic solid waste continuous hydrothermal treatment system and process

A technology of organic solid waste and hydrothermal treatment, which is applied in waste treatment, solid waste removal, transportation and packaging, etc., can solve the problems of lowering the temperature in the furnace, high cost of discharge up to the standard, and long residence time, so as to reduce energy consumption and Operating costs, energy-saving economic benefits are significant, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

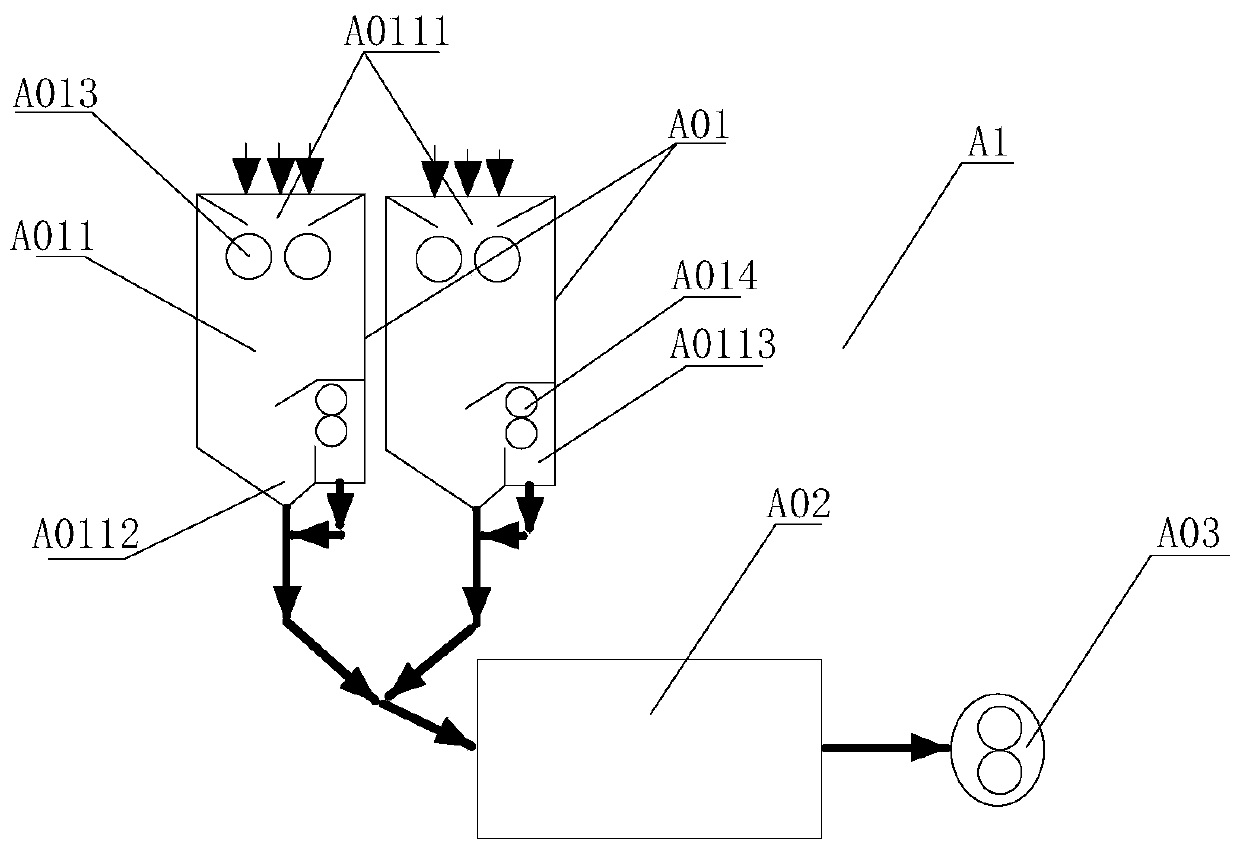

[0108] A kind of organic solid waste pretreatment system A1 of the present invention such as figure 1 As shown, it includes sequentially connected water weight sorting-crushing device A01, ball milling device A02 and first shearing device A03; wherein, the water weight sorting-crushing device A01 is used to separate light and heavy materials in organic solid waste Separating and crushing the light materials, the crushed light materials enter the ball milling device A02 for ball milling, enter the first shearing device A03 for shearing, and cut the fibrous impurities carried in the light materials to produce Obtain impurity-containing fine mud S02.

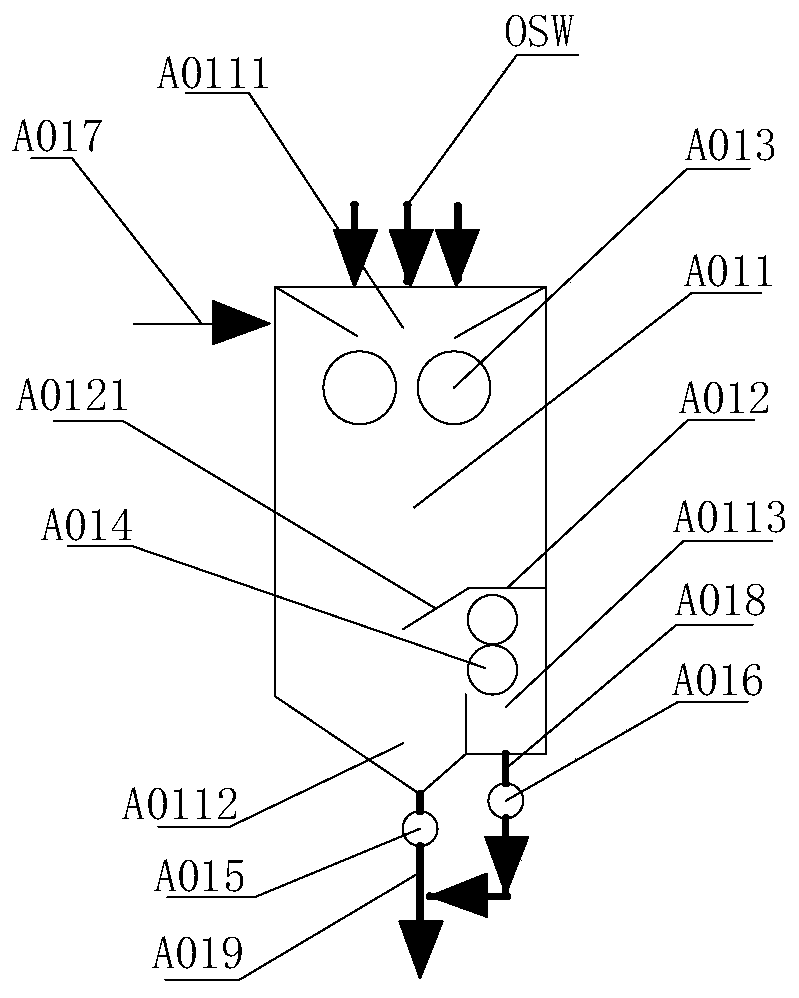

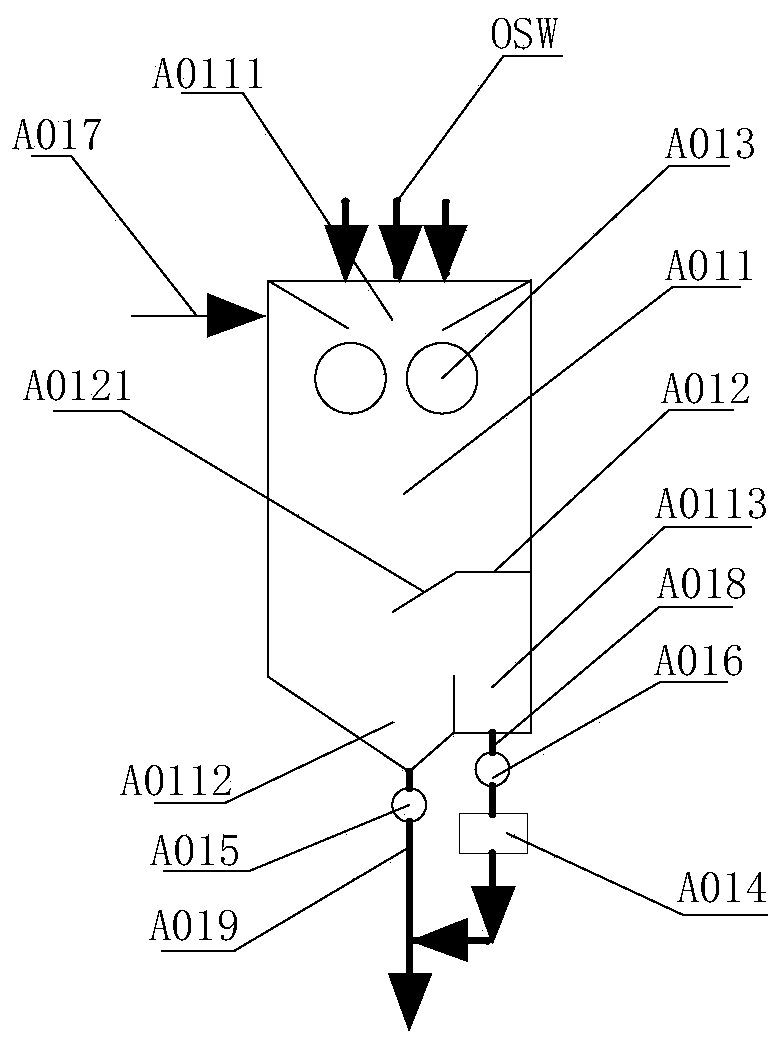

[0109] Specifically, such as Figure 1-Figure 4 As shown, the water re-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com