Patents

Literature

85results about How to "Continuous drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

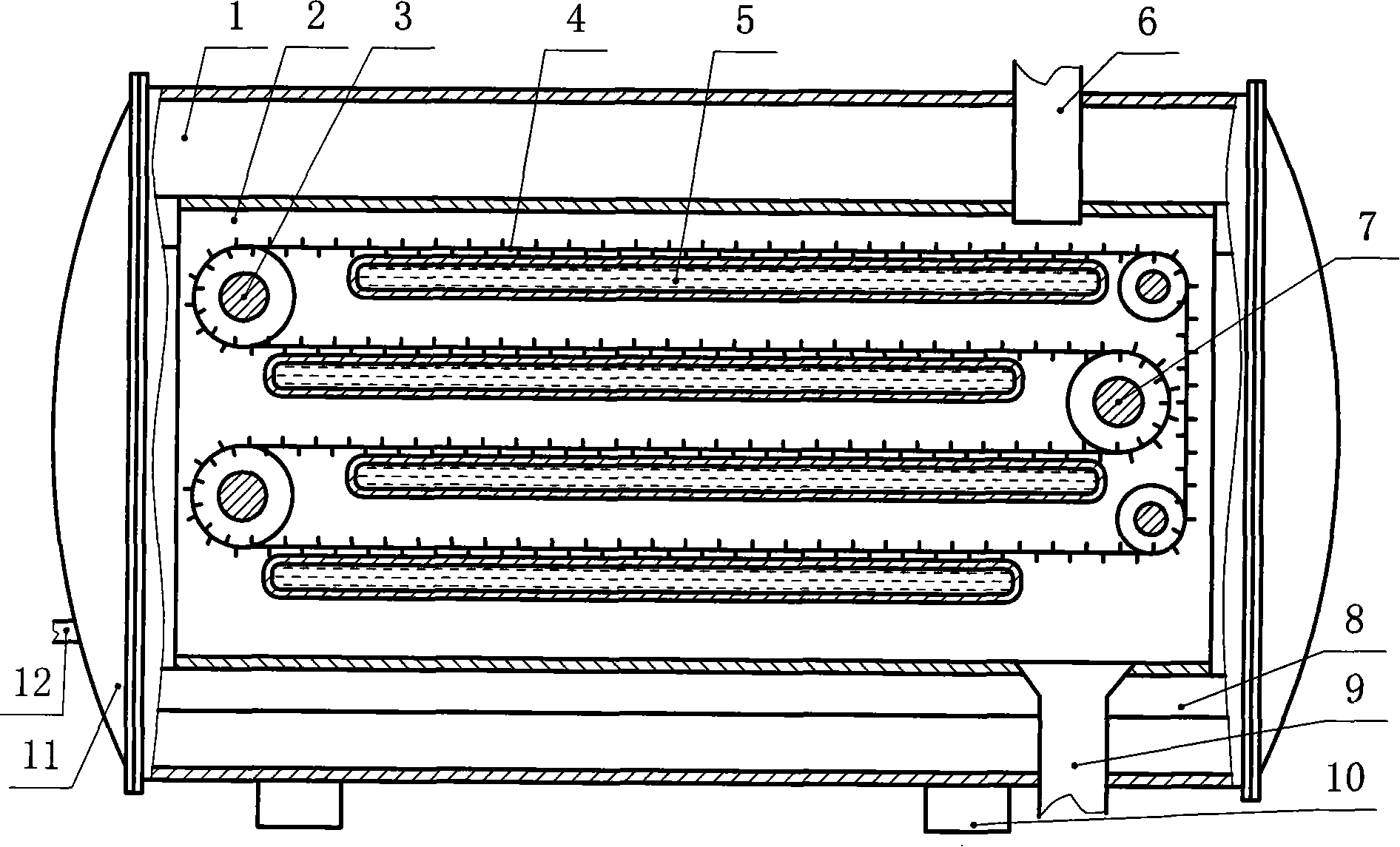

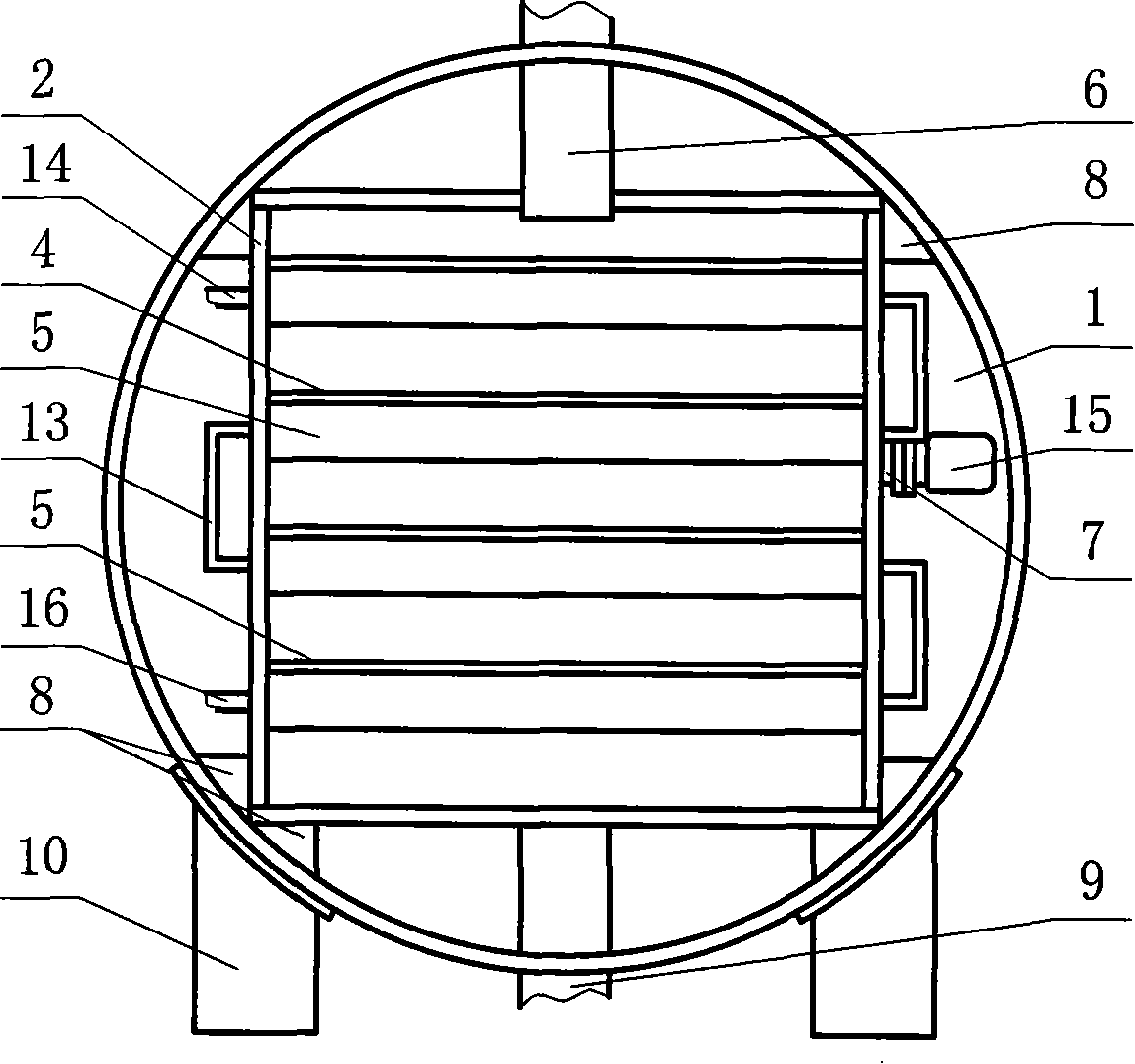

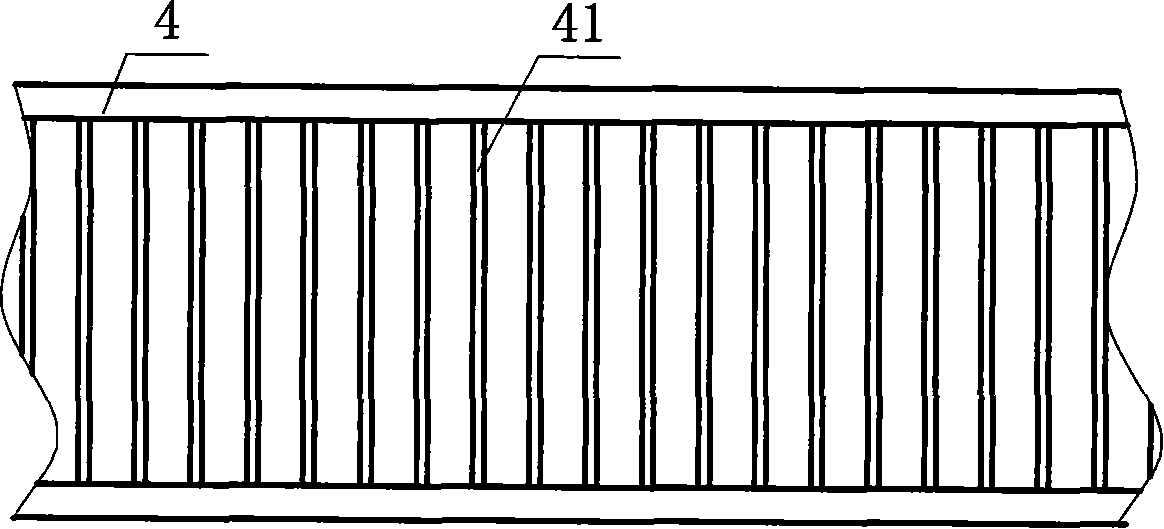

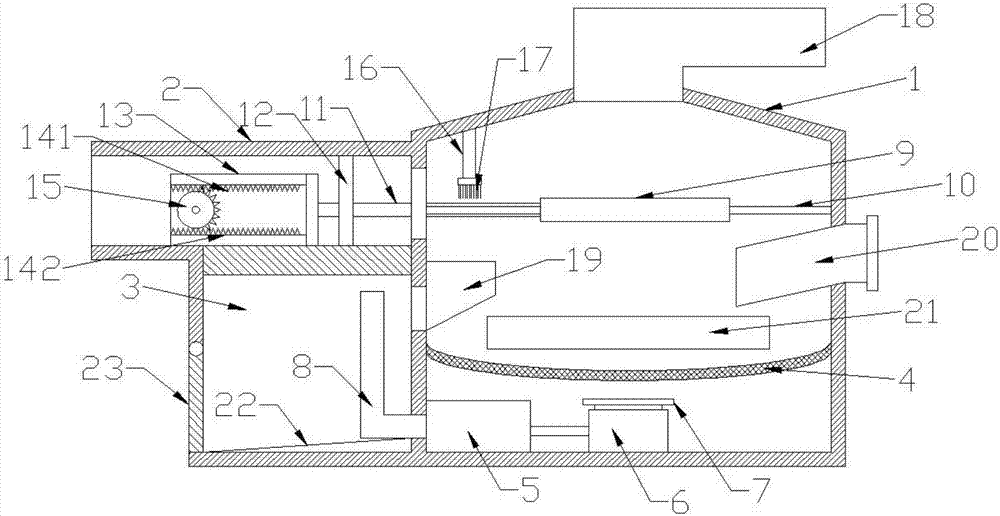

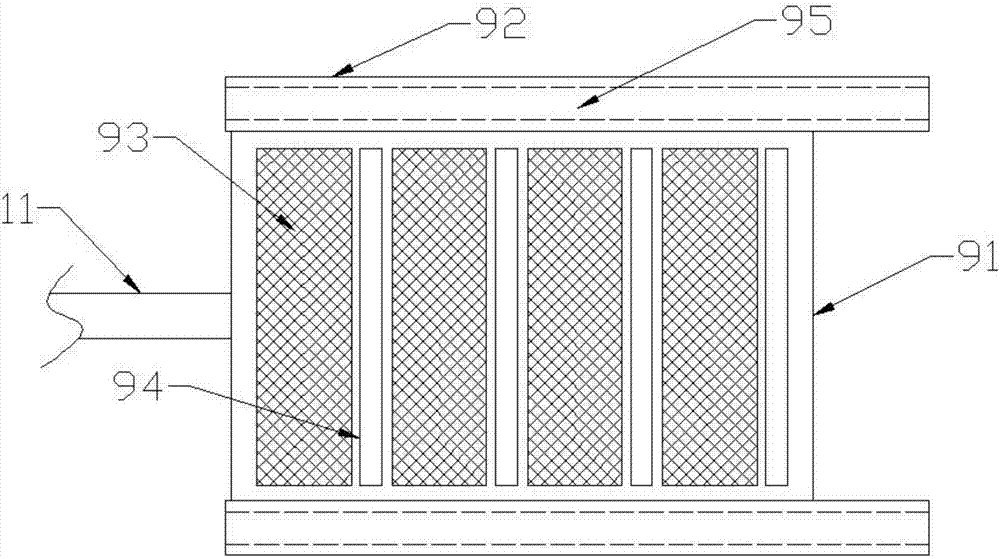

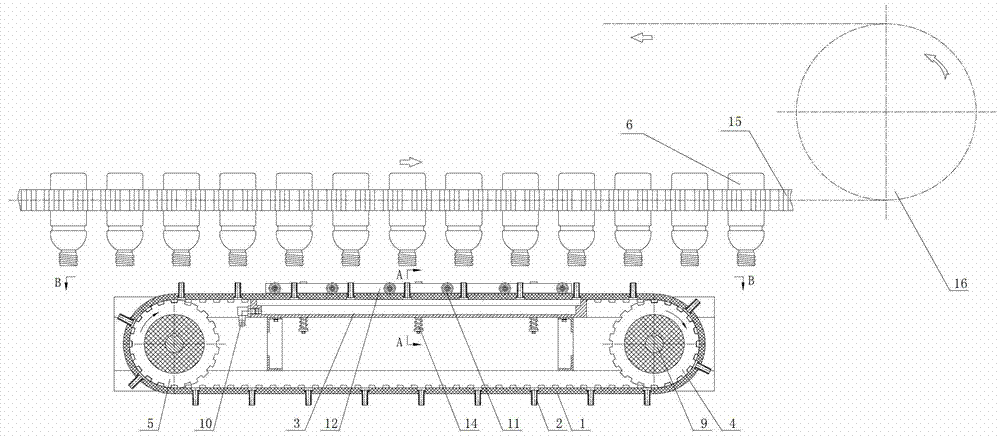

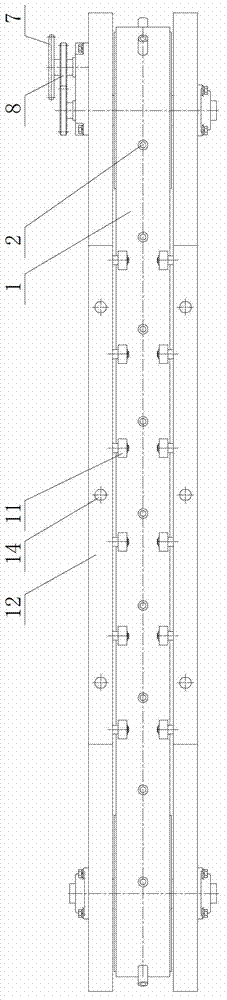

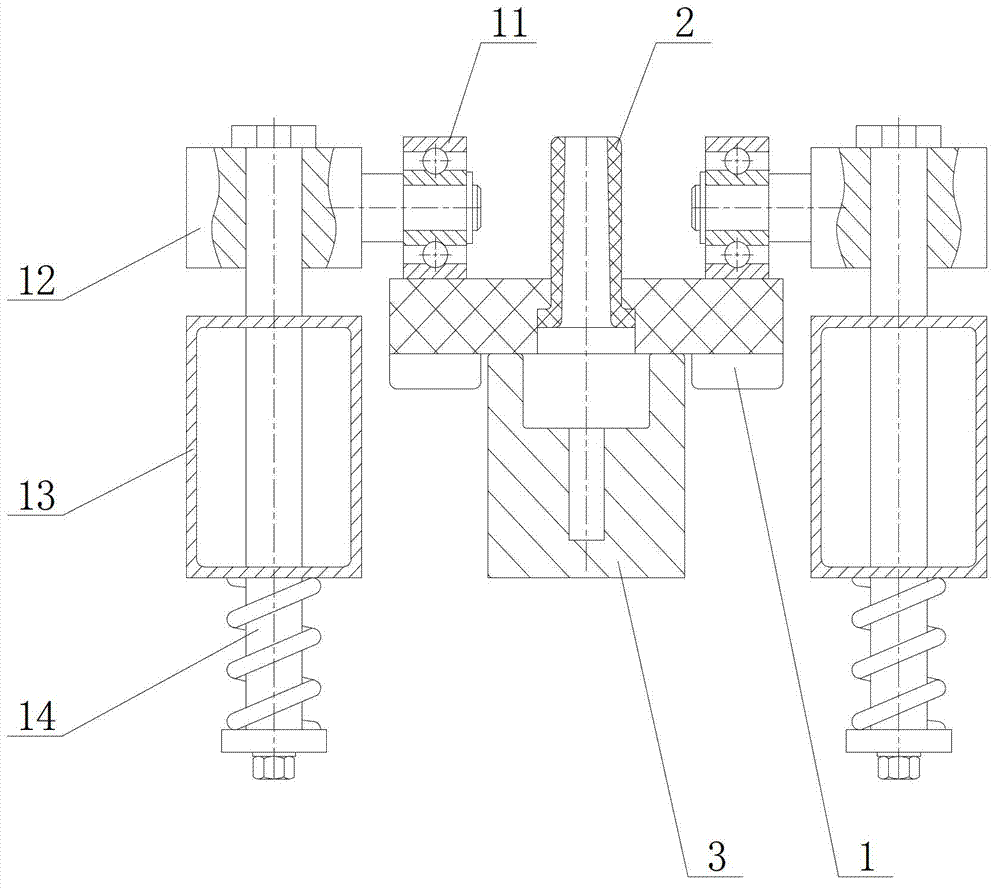

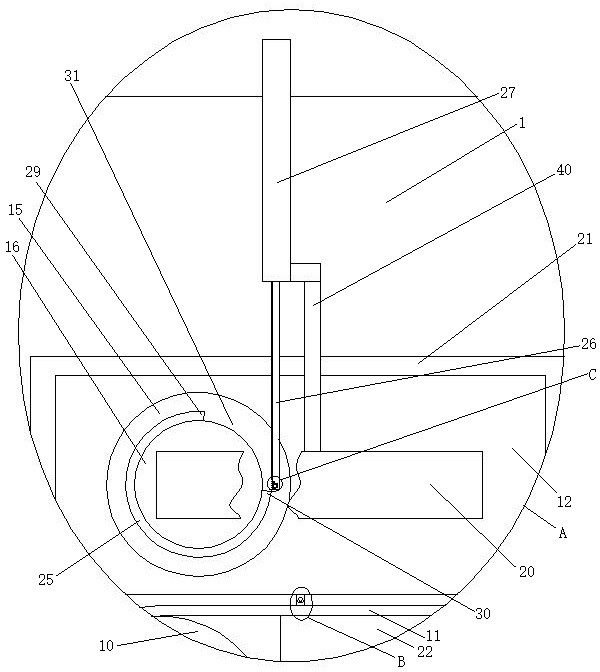

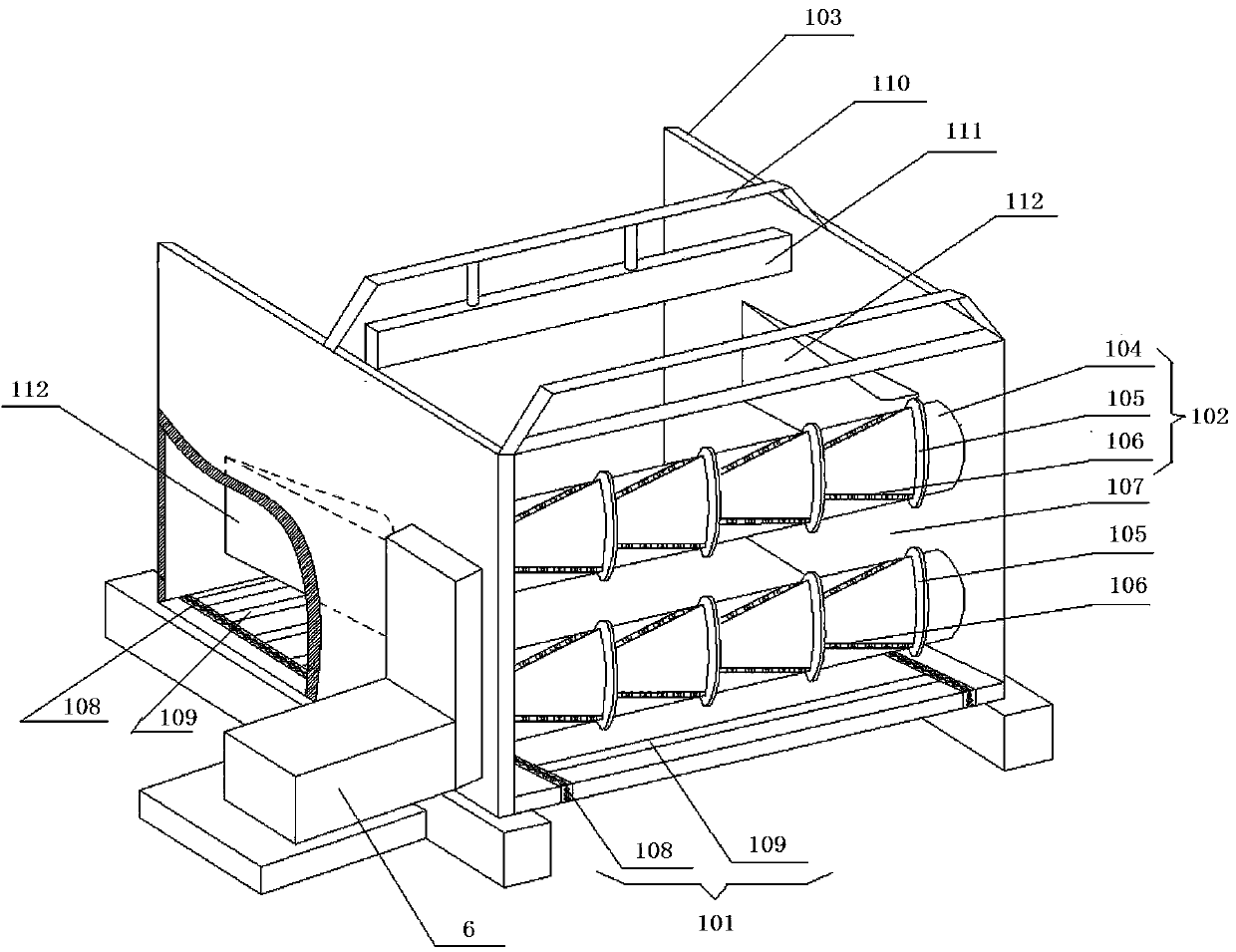

Net band transmission type vacuum continuous drying device and net band transmission type drying device

InactiveCN101187527AWon't hurtInhibit swellingDrying using combination processesDrying solid materials with heatWater flowEngineering

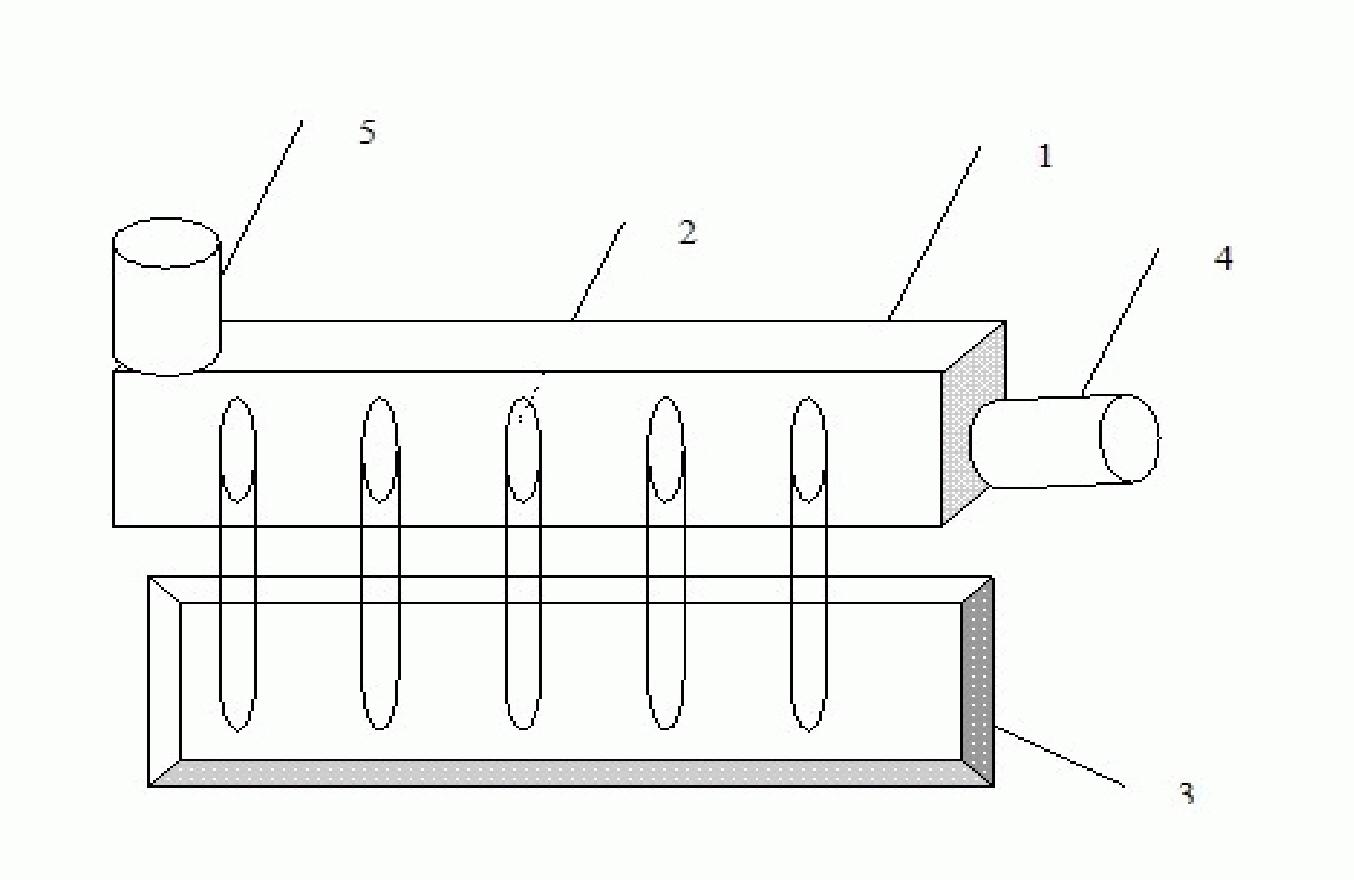

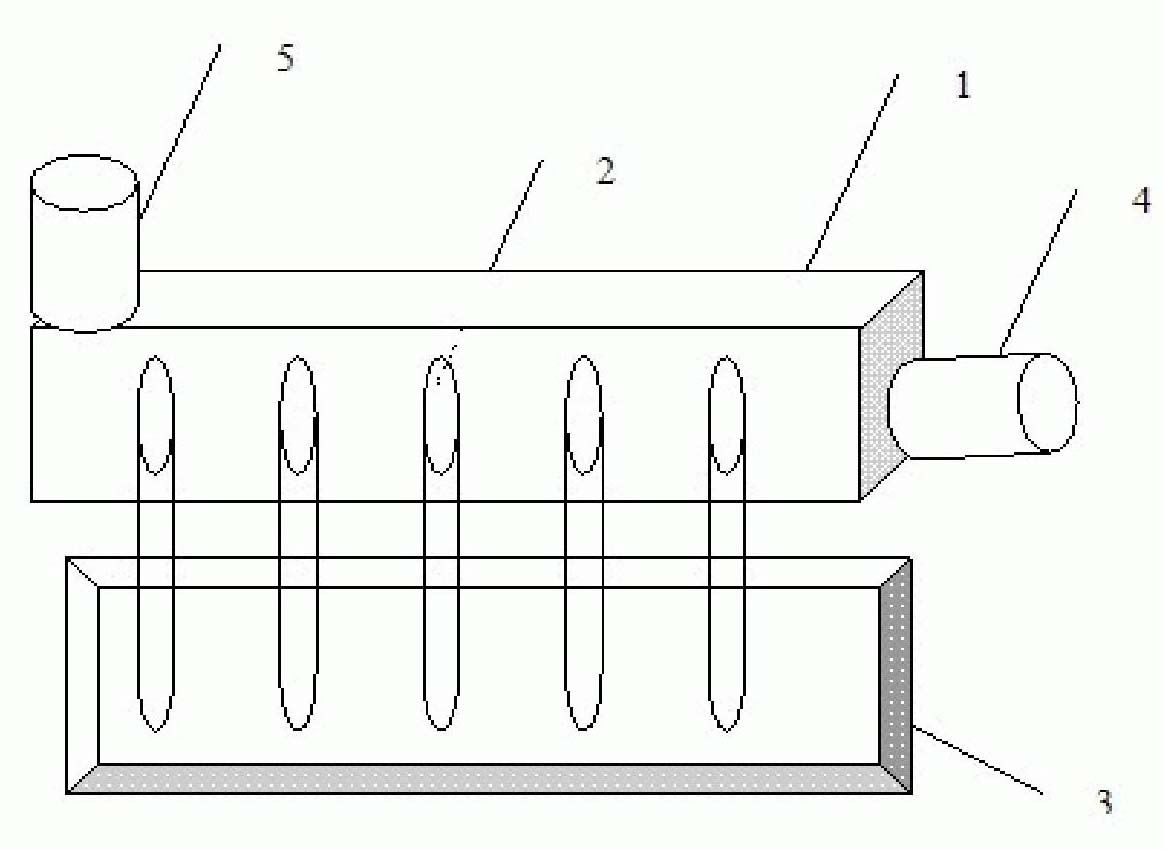

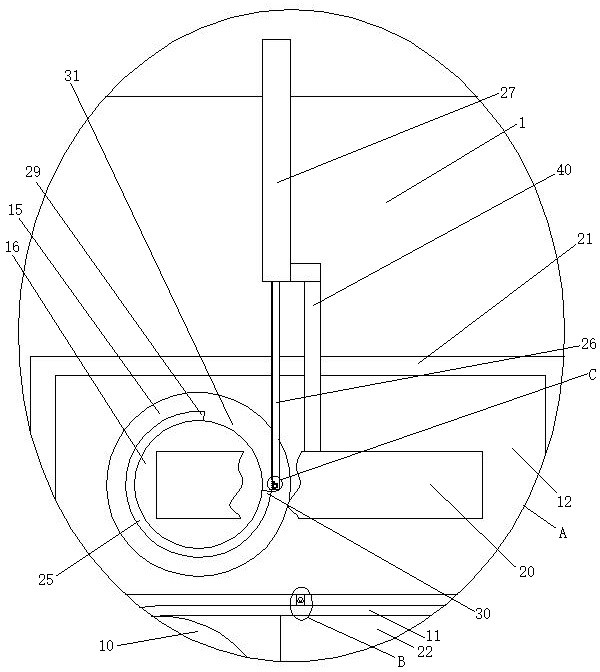

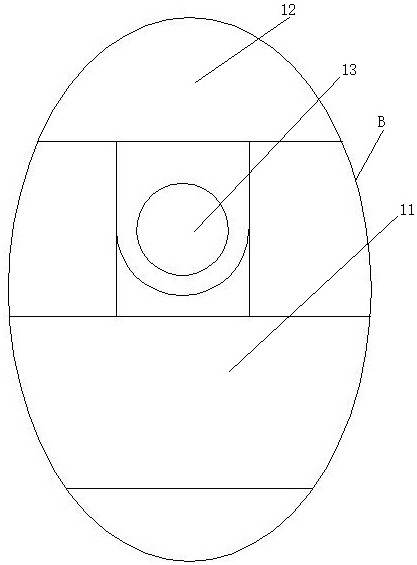

The invention discloses a mash belt transfer type vacuum continuous drying apparatus and a mash belt transfer type drying apparatus, which comprises a cylindrical barrel, a spherical cap-shape end cover, and an evacuating pipe, wherein the cylindrical barrel is horizontally arranged, a square silo is sleeved in the inner cavity of the cylindrical barrel, a certain number of floors of flat-type water pipes are mounted between two body walls of the square silo, and the flat-type water pipe which is on the highest layer is communicated with a water inlet pipe, and the flat-type water pipe which is on the lowest layer is communicated with a water outlet pipe, the intermediate flat-type water pipes are communicated end to end, and water glide path is led to take zigzag-shape arch type. A certain number of turn rollers which are regularly arrayed are mounted between the two body walls of the square silo, the turn rollers which are connected with a power mechanism are sleeved with ring-shaped mash belt, which leads materials on surface of the upper layer of the flat-type water pipe to convey to the surface of the lower layer of the flat-type water pipe, two lateral side of adjacent flat-type water pipes are alternatively arrayed respectively, and a feed inlet and a feed outlet are respectively arranged on the two sides of the adjacent flat-type water pipes which penetrates through the cylindrical barrel and the square silo.

Owner:COFCO ENG & TECH ZHENGZHOU +1

Dehydration treatment method for triethylamine

ActiveCN101085739AReduce moisture contentReduce volatile lossAmino compound purification/separationMolecular sieveInorganic compound

The invention relates to a method for dewatering triethylamine. The water- containing triethylamine is mixed with solution of base metal inorganic compound with its weight proportion being larger than 15% thoroughly, and gets triethylamine with water content being lower than 0.3% through separation. Said base matal inorganic compound comprises common salt compounds such as common salt or alkaline compounds such as caustic soda. The invention is characterized by simple process, good effect and suitability for industrial production. If the prepared triethylamine is treated with solid caustic soda and / or molecular screen, it can get higher- purity triethylamine with water content being 0.1%- 0.01%.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

Equipment for drying and feeding fruit juice powder

ActiveCN106643064AEfficient dryingContinuous dryingGranular material dryingDrying gas arrangementsFruit juiceControl system

The invention provides equipment for drying and feeding fruit juice powder, and belongs to the technical field of drying of fruit juice powder. The equipment disclosed by the invention has the beneficial effects that a single air-source heat pump is used for drying and heating the fruit juice powder in a bin, and the operation state of a mixing mechanism in the bin, the operation state of a material raising structure in the bin, as well as the humidity of the fruit juice powder in the bin are automatically detected through a control system, so that the shortcomings in the prior art that the energy consumption is high, the continuous working efficiency is low, the drying time is difficult to control, and drying is insufficient are overcome, and the purpose of efficient, continuous and sufficient drying of the fruit juice powder is achieved.

Owner:江山锐意科技服务有限公司

Sand core drying equipment

ActiveCN106123520AQuality improvementImprove the level of mechanization and automationDrying solid materials with heatDrying gas arrangementsHeating timeMicrowave

The invention relates to the field of drying devices, in particular to sand core drying equipment. The sand core drying equipment comprises a roller way conveying device, a control electric cabinet and a drying furnace main body, wherein the roller way conveying device includes an external high-load roller way, a tray, a travel switch a, a travel switch b, a power roller, an aluminum stop edge, a chain wheel and a speed reducing motor; and the drying furnace main body includes such components as a moisture discharge fan, a temperature sensor, a ventilation pipe, a rectangular wave guider, a magnetic control pipe module and a sealing door. The sand core drying equipment applies a microwave heating technology, can shorten the heating time and improve the efficiency, realizes continuous and quick drying of sand cores and paint and mechanization and automation of core making parts, adopts a metal plate labyrinth structure, adds silicon rubber bars capable of absorbing microwaves in structural gaps, reduces the microwave leakage to the greatest extent, and prevents the radiation injury of the microwave leakage to human bodies.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

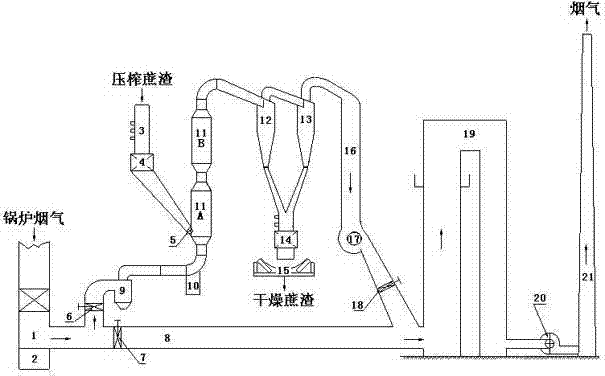

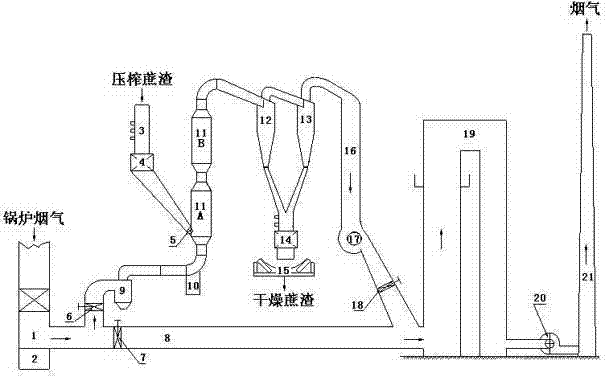

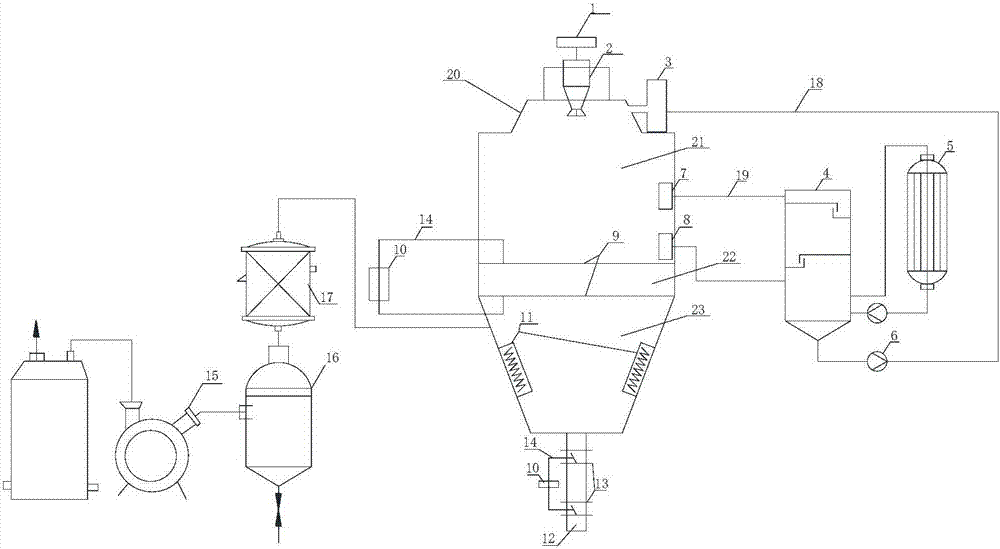

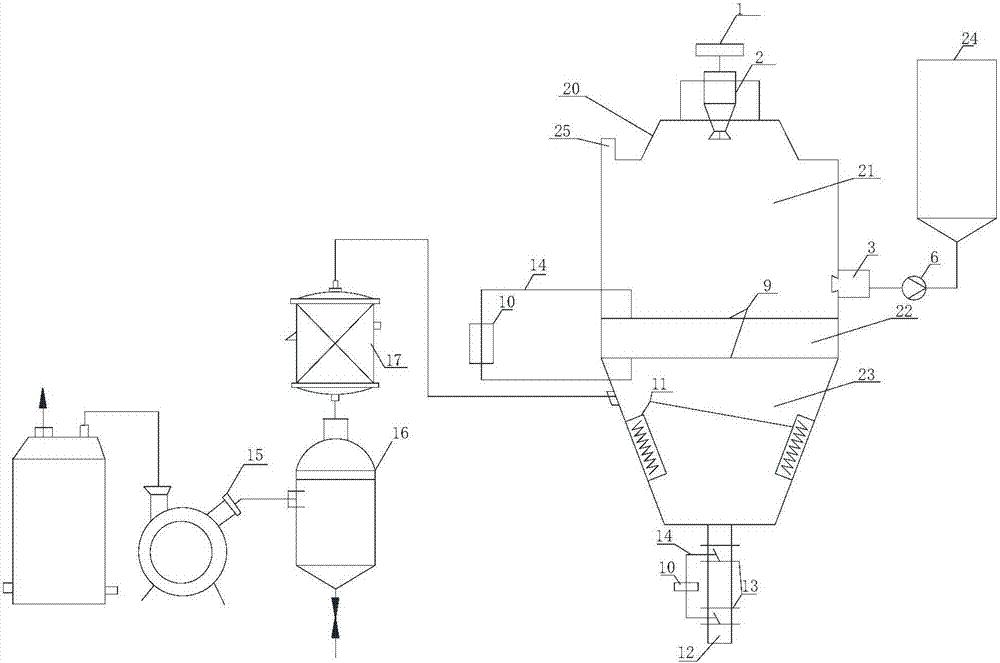

Multi-level impulse bagasse drying system

InactiveCN102345967AKeep dryLow heat transfer intensityDrying solid materials with heatDrying gas arrangementsThermodynamicsCombustion

The invention discloses a multi-level impulse bagasse drying system which is characterized in that the boiler gas serving as a drying source and an individual bypass bagasse drying system are adopted, the boiler high-temperature gas is fed into a spark separator; the boiler gas subjected to separation and purification and wet bagasse which has the water content less than or equal to 52% and is fed by a drum-type bagasse feeder are fed into a multi-level impulse dryer to be mixed, and then the dried bagasse with the water content less than or equal to 42% is obtained through a multi-level separator; the dried bagasse is discharged from a dual-roller bagasse feeder, and falls on a bagasse conveying belt and is conveyed back to a boiler room to serve as a fuel; and the flue gas is discharged from a chimney through a vertical flue, a deduster and a draught fan. The operation is controlled automatically by adopting an instrument; the material charge and discharge performances are both excellent, the negative pressure degree and smoothness of the whole drying system can be ensured; negative pressure is increased by a booster fan generally, thus the pressure loss of the drying system is counteracted, the negative pressure required by the combustion of the boiler can be ensured; the degree and depth of heat exchange are higher; the energy conservation and environmental conservation effects are better; the safety property is high; the operation stability is higher; and the system has better economic benefit.

Owner:GUANGXI JIRAN TECH CO LTD

Preparation method of cordyceps militaris nano powder

InactiveCN101926461AEnhanced overall recoveryImprove disinfection effectFood preparationBiotechnologyCordyceps

The invention provides a preparation method of cordyceps militaris nano powder, comprising the following steps: 1) separating wild cordyceps militaris paecilomyces, and purifying to prepare cordyceps militaris strain liquor; 2) selecting health and live insect pupae, sterilizing by ozone for later use; 3) infecting the insect pupae sterilized in step 2) by the strain liquor prepared by step 1); 4) performing bionic cultivation on infected insect pupae obtained in step 4) to obtain cordyceps militaris cells integrating pupalcells and sporocarps into a whole; and 5) carrying out microwave drying and nano grinding on the obtained cordyceps militaris cells cultured in step 4) to obtain the cordyceps militaris nano powder. The preparation method of the invention has low investment and low energy consumption, the prepared cordyceps militaris nano powder is not polluted by sterilization process, and the fineness of the powder can reach nano level, thus the powder can keep original functionalactivity and is easily absorbed by a human body.

Owner:李森

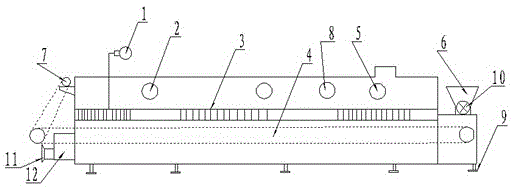

Belt type drier

InactiveCN105115271AImprove drying efficiencySmooth transmissionDrying machines with progressive movementsAgricultural engineeringMaterial distribution

The invention discloses a belt type drier. The belt type drier comprises a drier shell, a drier cavity, a transmission device and a heating drying system. The drier shell is a support of the whole belt type drier. The lower end of the drier shell is provided with a plurality of sets of drier legs. The drier shell is provided with a feeding hopper. An air inlet fan opening, a circulation fan opening, an exhaust fan opening and a humidity elimination fan opening are formed in the drier cavity. The belt type drier is stable in transmission, capable of conducting continuous drying, simple in structure, free of material blocking and even in material distribution, and the drying efficiency of materials is improved.

Owner:太仓市友联干燥粉碎设备有限公司

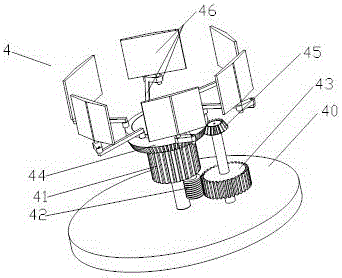

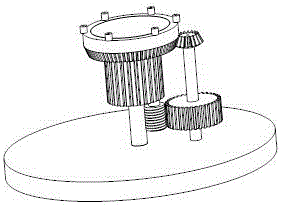

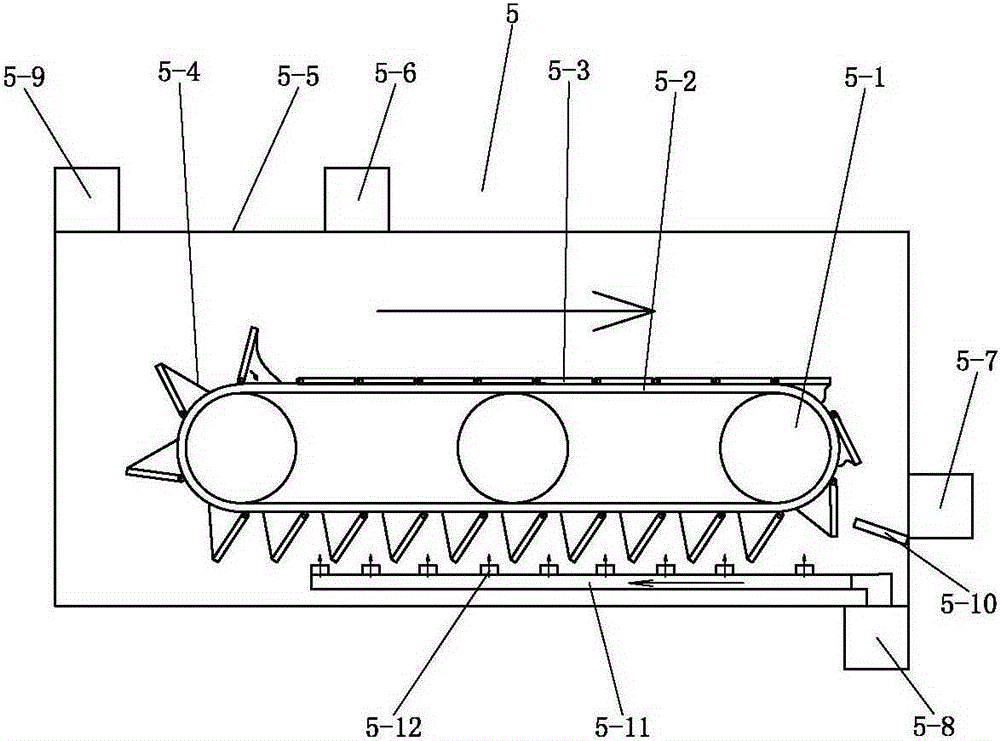

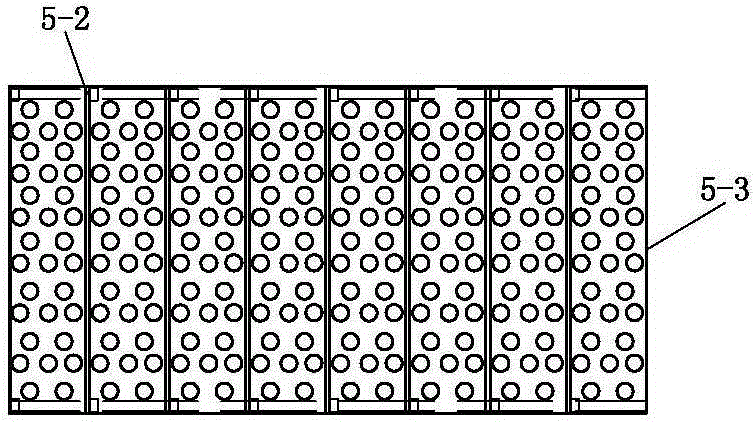

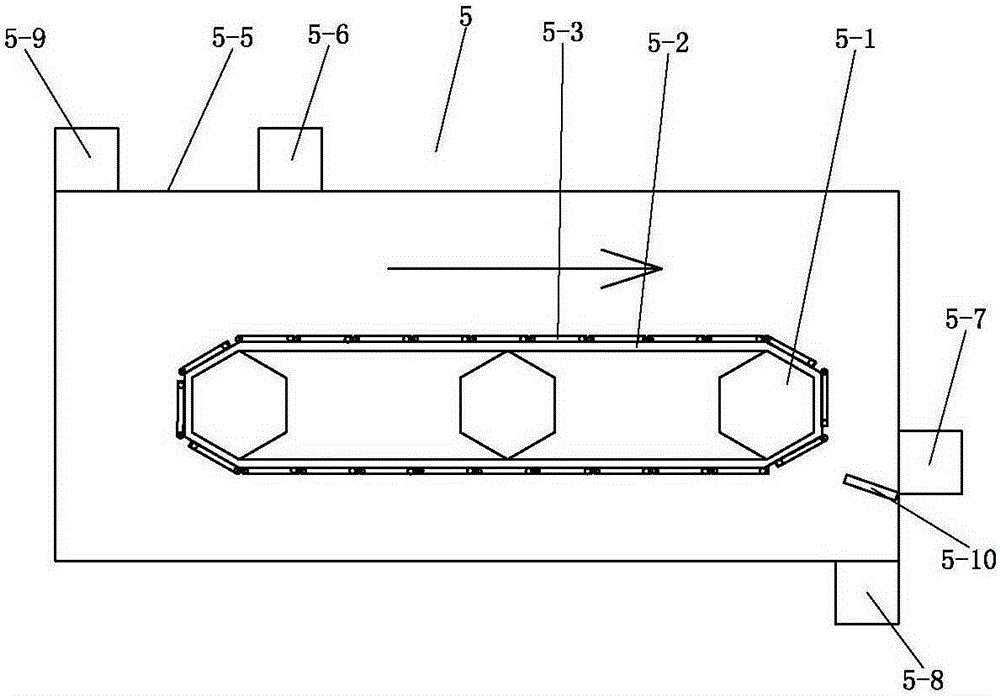

Solar heat pipe garbage drying equipment

InactiveCN101900477ADry fastContinuous dryingWaste processingSolar heat devicesThermal energyHeat pipe

The invention aims to provide solar heat pipe garbage drying equipment, which can realize the quick, uniform and continuous garbage drying at a stably-controlled temperature. In the equipment, a heat pipe is arranged in a garbage drying chamber to realize the stable, uniform, quick and continuous drying of garbage. Various solar collection techniques are used for collecting heat; the heat storage system is used for realizing heat storage; and the heat pipe arranged in the drying chamber is used for realizing the uniform, stable, possible and energy-saving heating of the garbage.

Owner:BEIJING WISWORD HI TECH

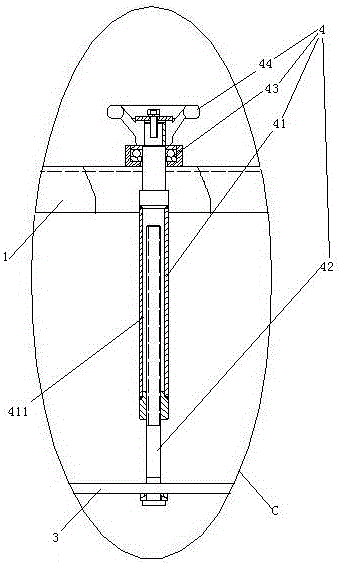

Rotary autoclaved drying kettle

A rotary autoclaved drying kettle comprises a horizontally arranged cylindrical housing, is equipped with a rotary supporting wheel group and a rotary driving mechanism, and is characterized in that an air inlet main pipe is arranged at one end of the housing; a discharging air pipe is arranged at the other end of the housing; a rotary joint A sleeves the air inlet main pipe; an air inlet run pipe and condensed water discharging pipes are mounted on the rotary joint A; a material holding tank is mounted in the housing; one end of an interlayer between the housing and the material holding tank is communicated with the air inlet main pipe; an air inlet is formed in the front end of the material holding tank; a discharging air opening is formed in the rear end of the material holding tank and is communicated with the discharging air pipe; a feed pipe mounted on the housing extends into the material holding tank; a sealing cover is arranged at the outer end opening of the feed pipe in a matched manner; a siphon pipe is mounted on the rotary joint A, and extends into the bottom area of the vapor heat-insulating interlayer. The rotary autoclaved drying kettle has the advantages that the design is unique and multi-purpose; the equipment investment is greatly reduced; the processes of the production technology are simplified; the production efficiency is high; the product quality is good; the rotary autoclaved drying kettle is mainly used for production of alpha-type semi-hydrated gypsum.

Owner:HUBEI JINLU ENERGY SAVING LTD CO

Agricultural blowing and drying and screening machine

InactiveCN107166936ADry fastContinuous dryingDrying gas arrangementsDrying chambers/containersAgricultural engineeringPush pull

The invention discloses an agricultural blower drying and screening machine, which comprises a heating box, an equipment box and a collection chamber; a fan and a heating box are installed at the bottom of the heating box, and a horizontal arc-shaped Stencil; a horizontal receiving device is installed in the heating box, and the receiving device includes a plate body, a guide seat, a screen, a feeding port and a guide groove, and guide seats are fixed on both sides of the plate body; An upper rack and a lower rack are respectively installed on the top and the bottom of the push-pull cylinder, and half gears are installed in the push-pull cylinder. The invention uses the hot air blowing upwards to quickly dry the grains. The dried grains are blown upwards under the action of the wind and fall on the receiving device. The grain is put down and falls into the receiving hopper below, discharged and collected, and the fully dried grain is separated from the arc-shaped mesh plate under the wind screening, and the screening is accurate.

Owner:许晶

Continuous microwave drying method for accumulator plate

ActiveCN111834609AImprove drying rateIncrease productivityDrying solid materials with heatLead-acid accumulator electrodesMechanical engineeringKiln

The invention relates to a continuous microwave drying method for a accumulator plate, the accumulator plate continuously passes through a microwave heating kiln through a conveying mechanism, and theaccumulator plate is heated by microwaves to be dried when passing through the microwave heating kiln. The invention aims at providing the continuous microwave drying method for the accumulator plate, wherein heating is performed by microwaves, and the defects of the existing external drying mode are overcome.

Owner:JIANGXI XINWEI POWER ENERGY TECH

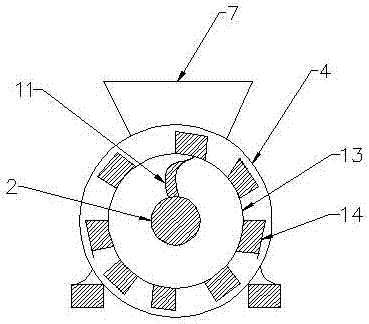

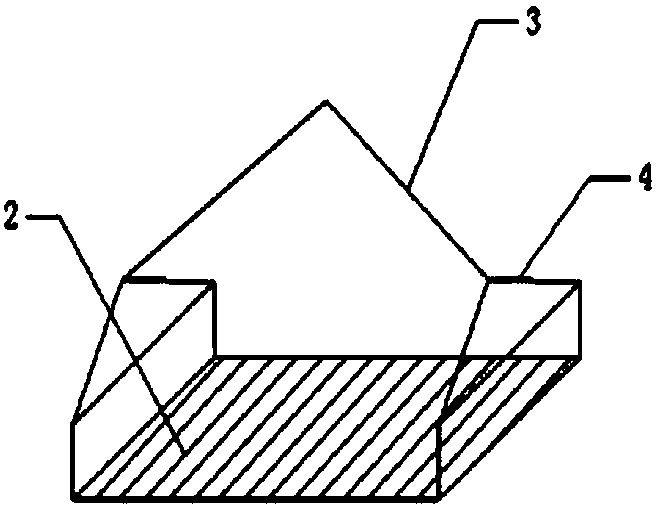

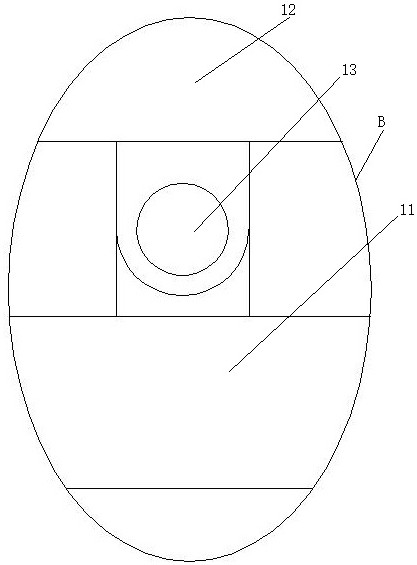

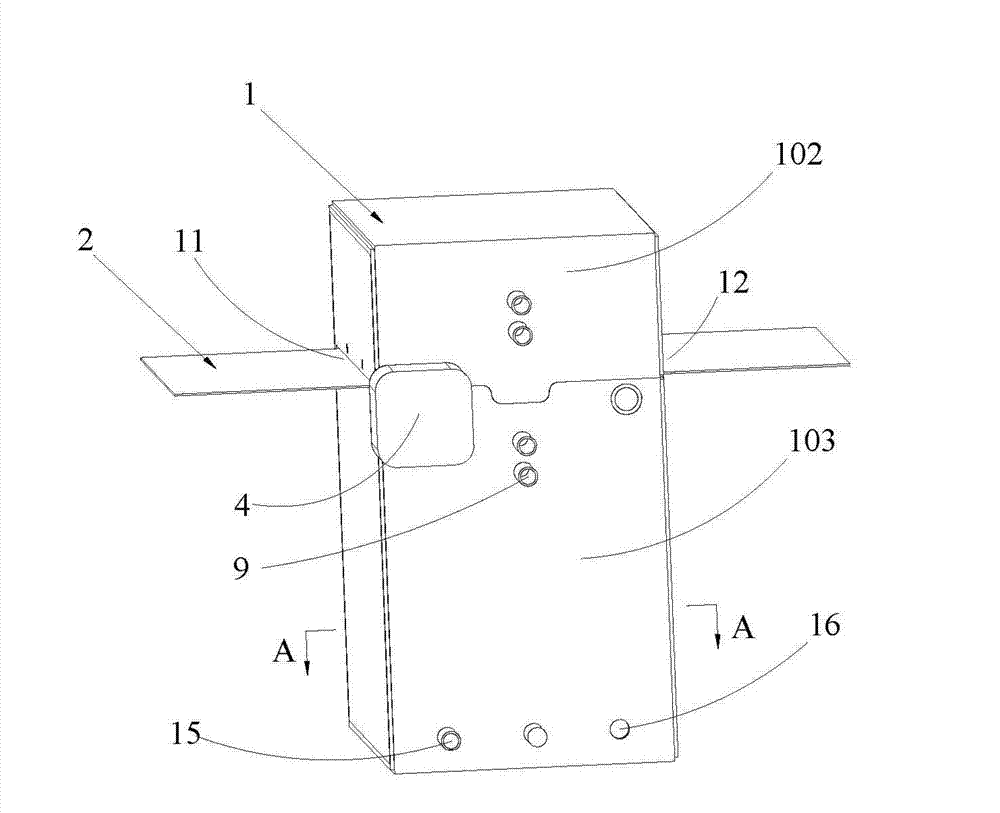

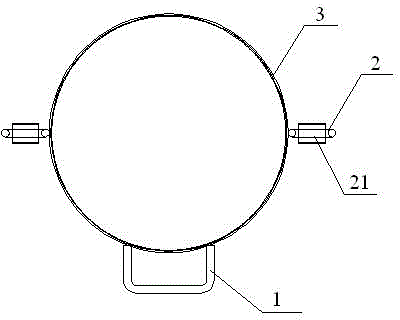

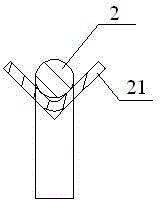

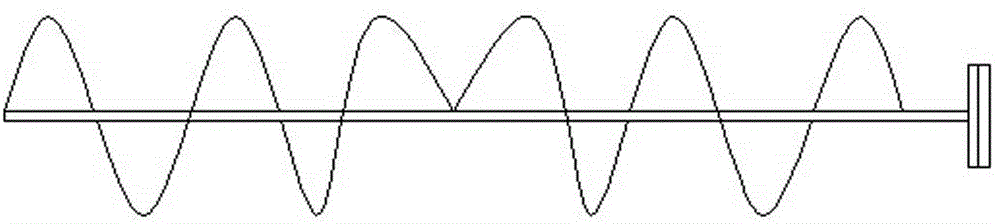

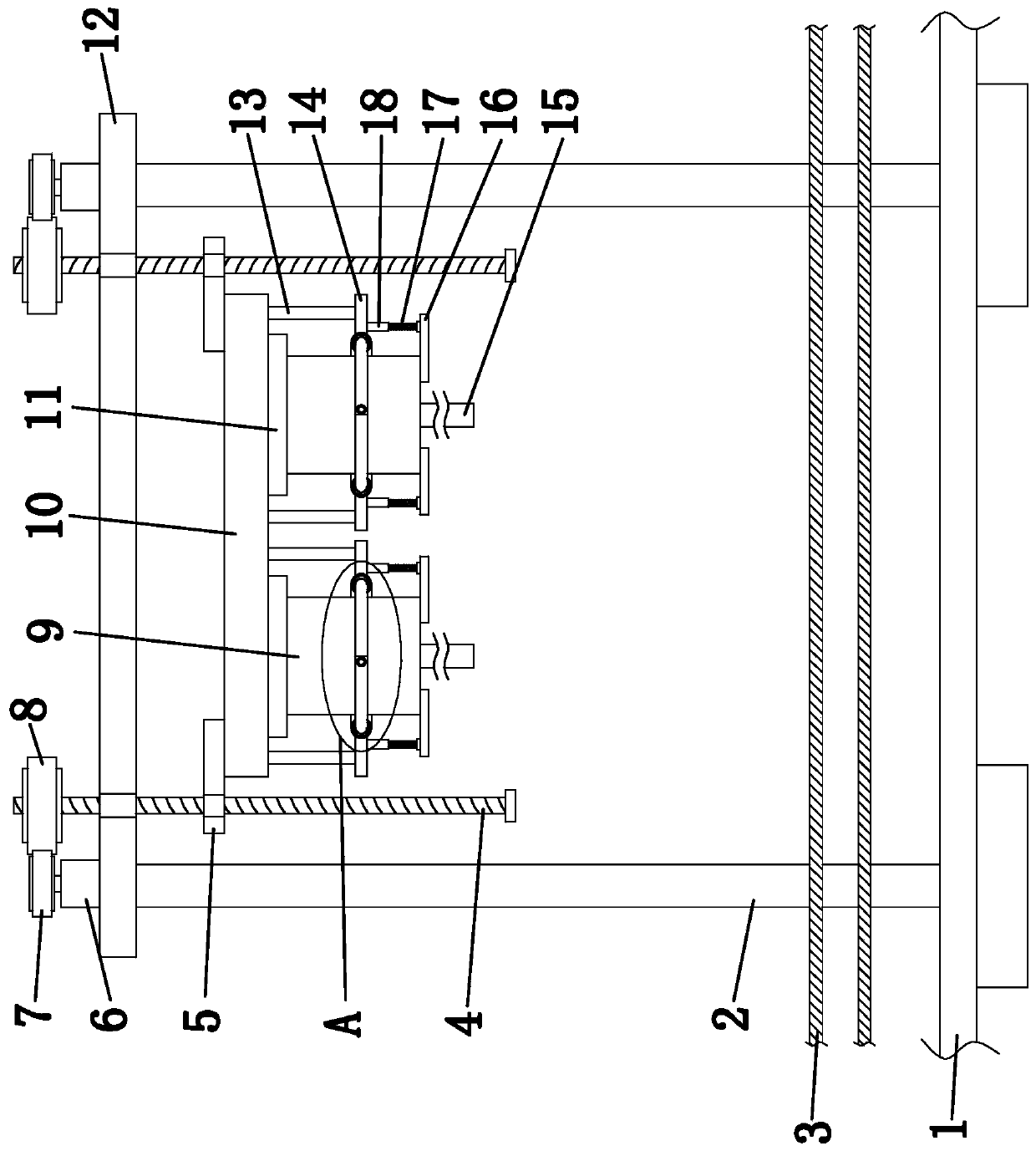

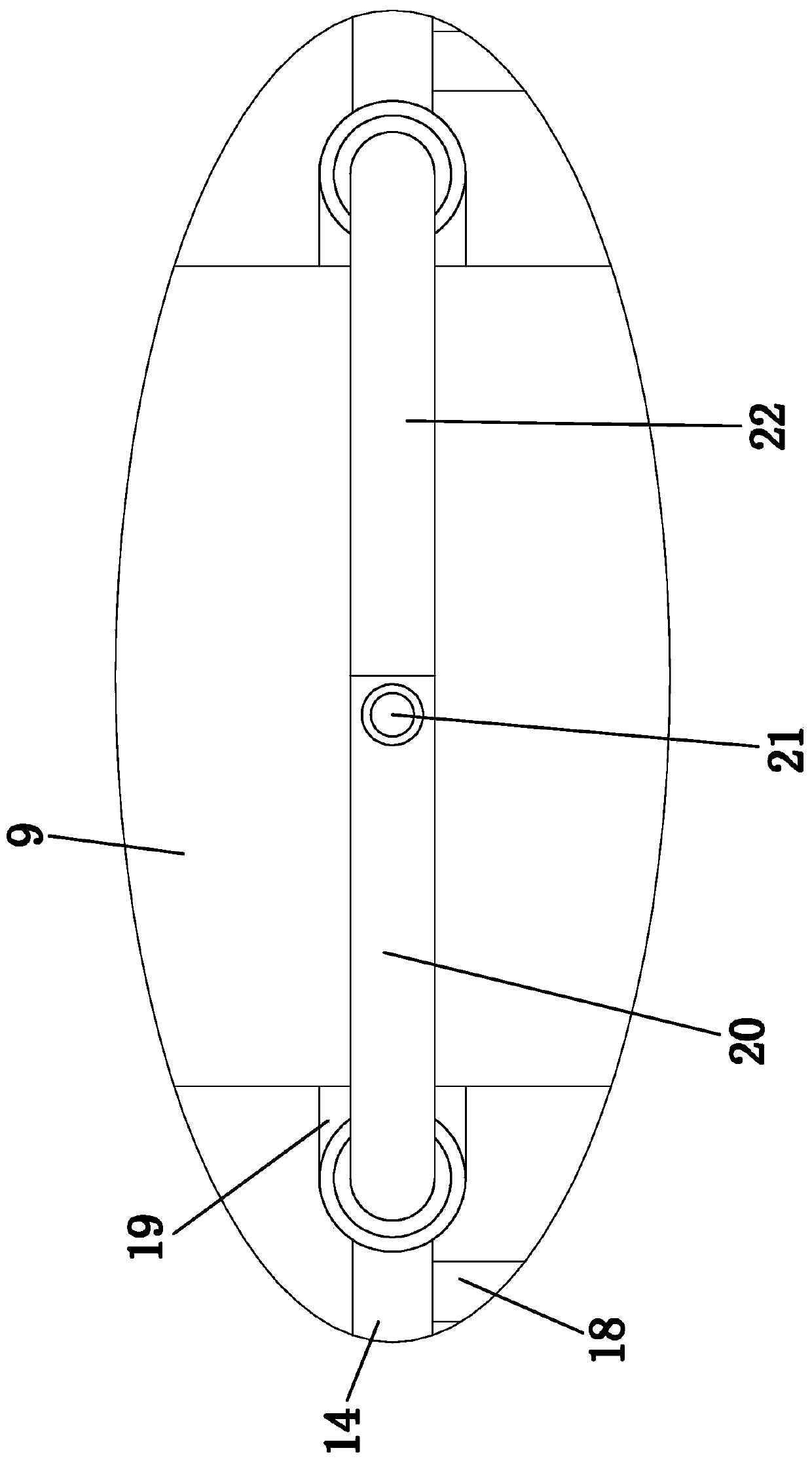

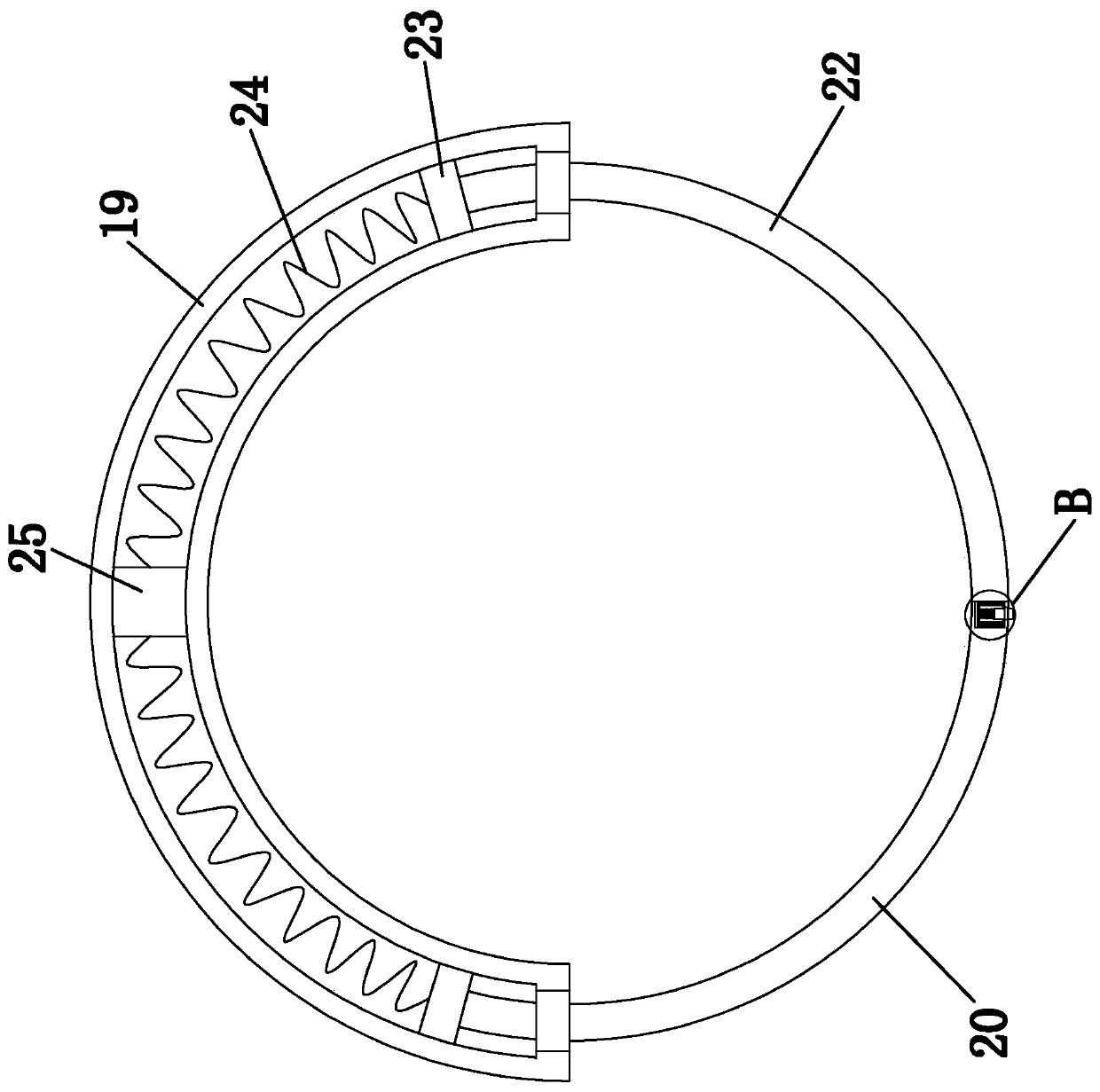

Waste plastic washing, separating and spin-drying machine

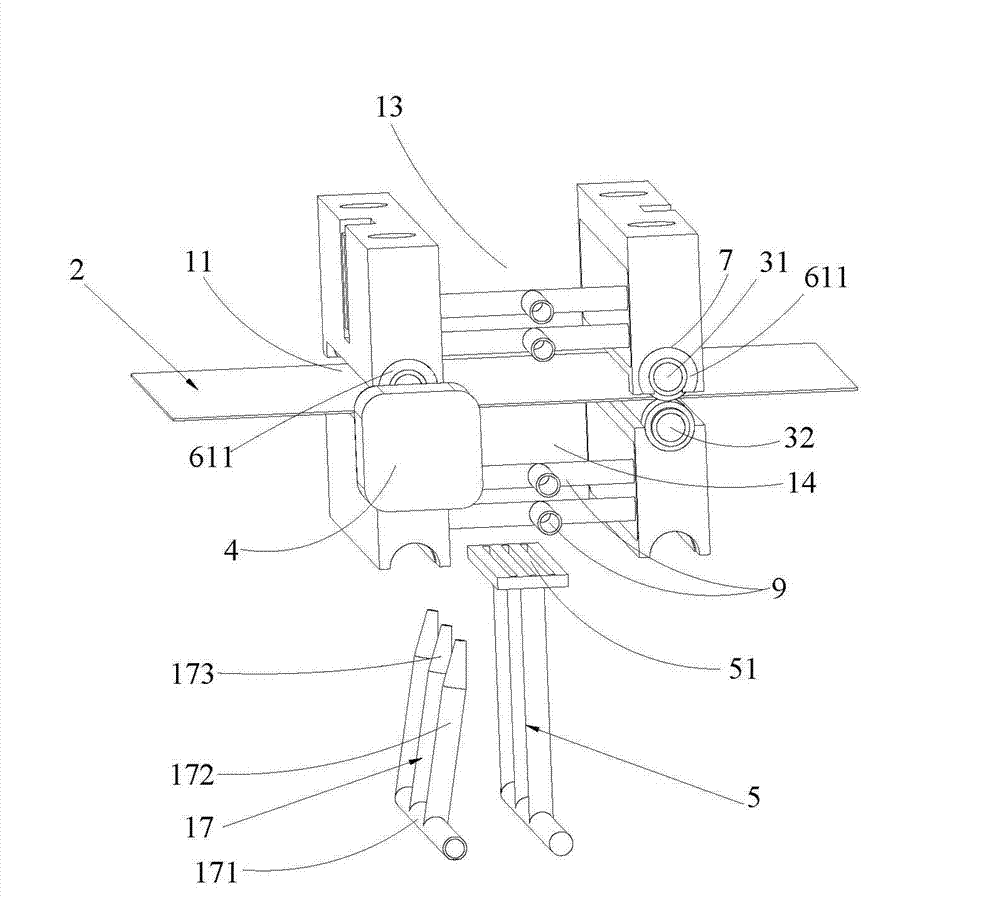

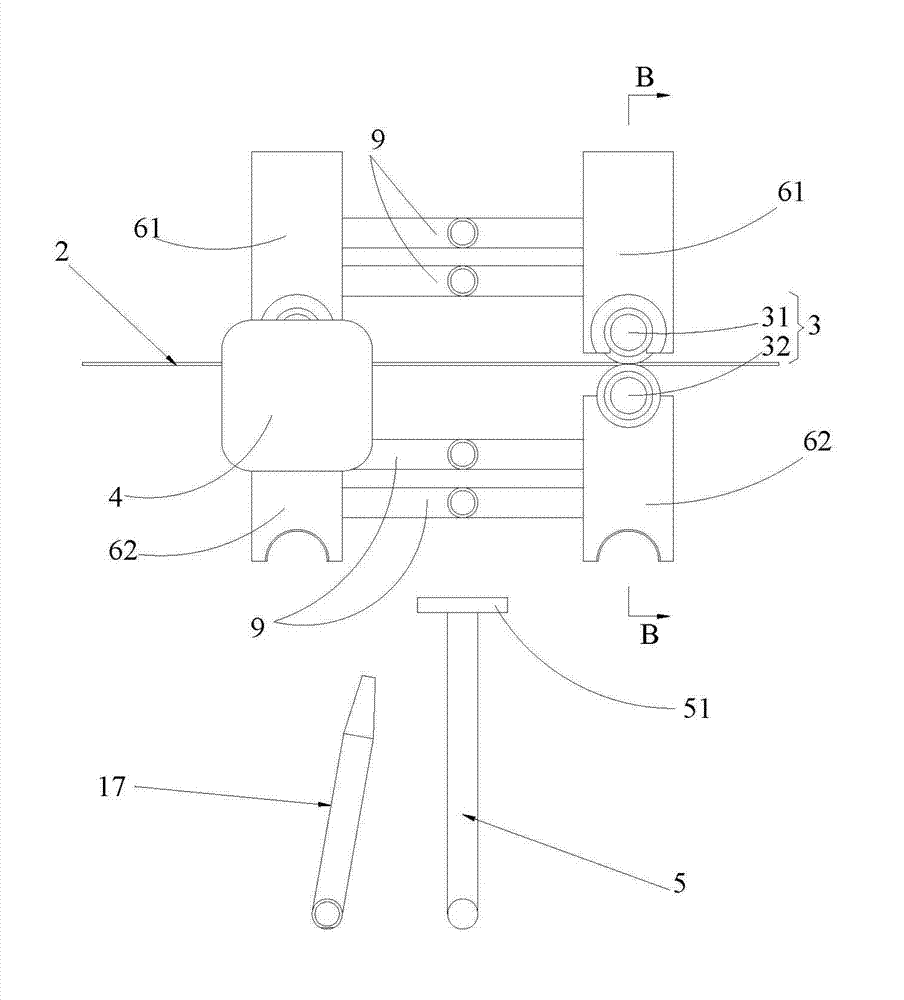

PendingCN107283678AContinuous dryingEasy to dryDrying solid materials without heatPlastic recyclingProcess engineeringConveyor belt

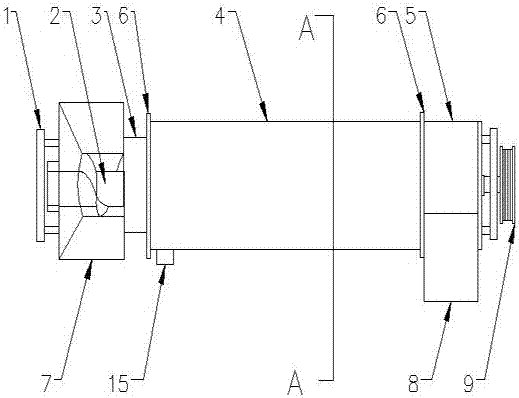

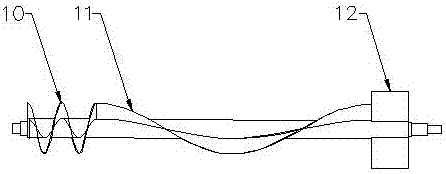

The invention relates to a waste plastic washing, separating and spin-drying machine. The waste plastic washing, separating and spin-drying machine comprises a supporting frame (1), a spindle (2), a feeding chamber (3), a spin-drying chamber (4), a discharging chamber (5) and connectors (6). The spindle (2) is fixed to the front end and the rear end of the supporting frame (1) through bearings. The front end of the spindle (2) is provided with a transmission wheel (9) connected with a motor through a transmission belt. The rear portion of the spindle (2) is provided with the feeding chamber (3), the middle portion of the spindle (2) is provided with the spin-drying chamber (4), the front portion of the spindle (2) is provided with the discharging chamber (5), and the feeding chamber (3), the spin-drying chamber (4) and the discharging chamber (5) are all cylindrical and communicate in sequence. The waste plastic washing, separating and spin-drying machine has the beneficial effects of being high in working efficiency, long in service life and convenient to maintain, having washing and spin-drying functions, is good in washing effect, and capable of continuously and quickly conducting washing, separating and spin-drying on impurities such as silt, oil stains and fine particles which cannot be washed away easily and are contained in waste plastic.

Owner:SHANDONG YUNENG MACHINERY

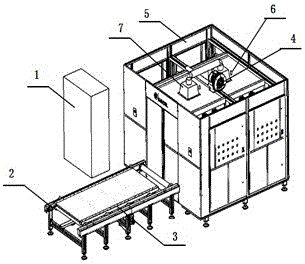

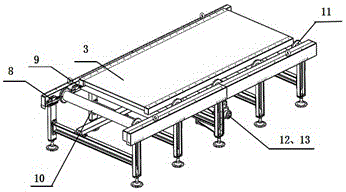

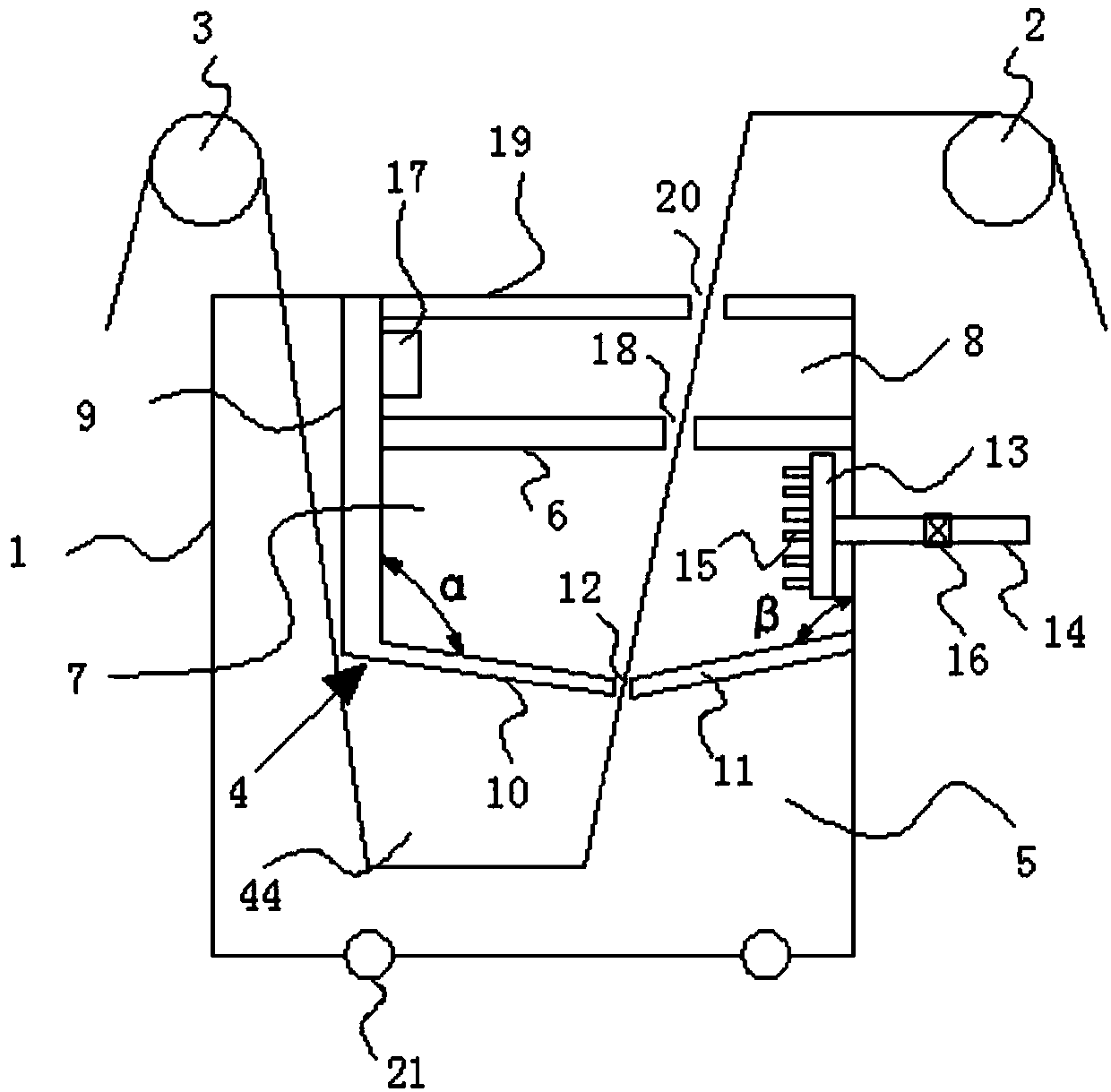

Cyclically-adjustable automatic paint spraying and drying equipment

The invention relates to cyclically-adjustable automatic paint spraying and drying equipment. By means of the equipment, continuous automated operation of paint spraying and drying for automobile plastic components is achieved; and in addition, the paint spraying and drying environment can be controlled freely and adjusted precisely. According to the cyclically-adjustable automatic paint sprayingand drying equipment, paint spraying dust is innovatively removed through circulating water; harm to employees and influence on surface quality of products are reduced; by means of a lubricating system, it can be guaranteed that the equipment is in the good lubricating state all the time; and the equipment can operate at the high load continuously and stably for a long time.

Owner:湖北三江航天江河橡塑有限公司

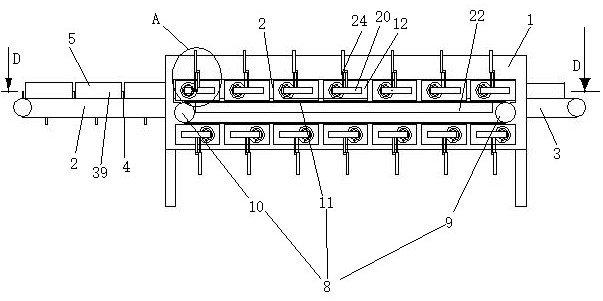

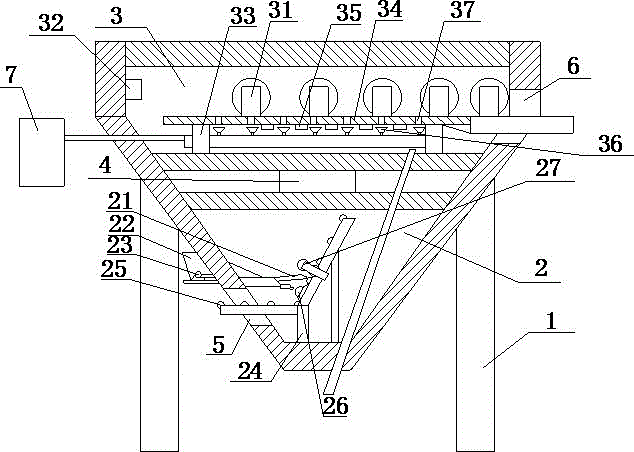

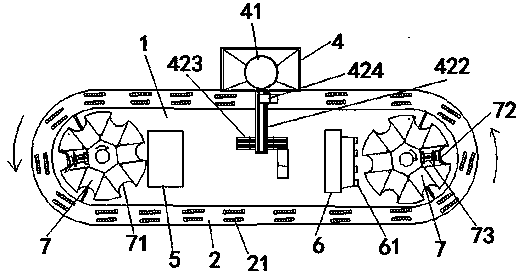

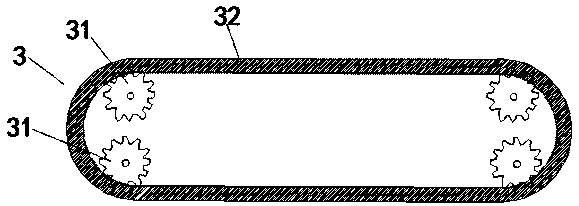

Synchronously operating jet type bottle cavity drying device and method

InactiveCN102809275AContinuous dryingDrying automaticDrying gas arrangementsDrying solid materialsSpray nozzleDrying time

The invention discloses a synchronously operating jet type bottle cavity drying device and a synchronously operating jet type bottle cavity drying method. The synchronously operating jet type bottle cavity drying device comprises a bottle clamping mechanism and a synchronous belt jet mechanism which operate synchronously. The synchronous belt jet mechanism comprises a synchronous toothed belt, synchronous pulleys, a synchronous toothed belt driving assembly, jet nozzles and an elongated slot air chamber. The two sides of the synchronous toothed belt are respectively connected with the synchronous pulleys which serve as driving wheels and are connected with the synchronous toothed belt driving assembly. A plurality of jet nozzles are distributed on the synchronous toothed belt. The elongated slot air chamber is arranged below the synchronous toothed belt between the two synchronous pulleys. The jet nozzles located above the elongated slot air chamber correspond to the openings of the bottles one by one. The method includes the steps that the bottle clamping mechanism and the synchronous belt jet mechanism operate synchronously and the jet nozzles above the elongated slot air chamber are aligned with the openings of the bottles one by one to continuously jet hot air for drying. The synchronously operating jet type bottle cavity drying device overcomes the disadvantages of short effective drying time, low efficiency and poor drying effect in the cavity of the bottle of a conventional hot air injection device, and achieves the purpose of drying the cavity of the bottle quickly and efficiently.

Owner:GUANGZHOU NANLIAN IND

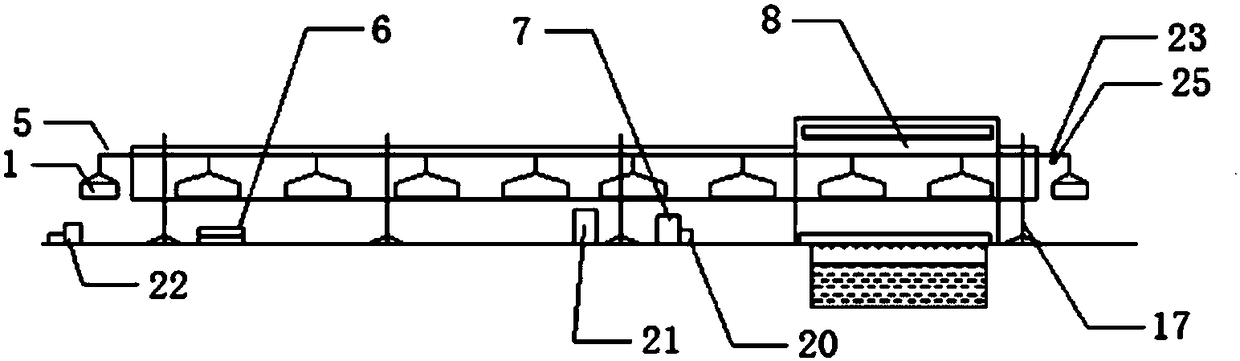

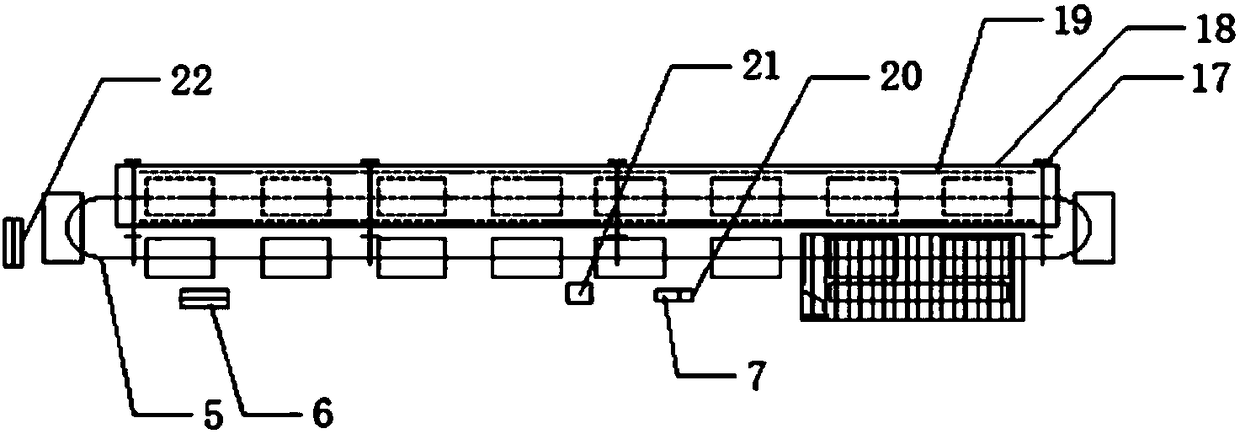

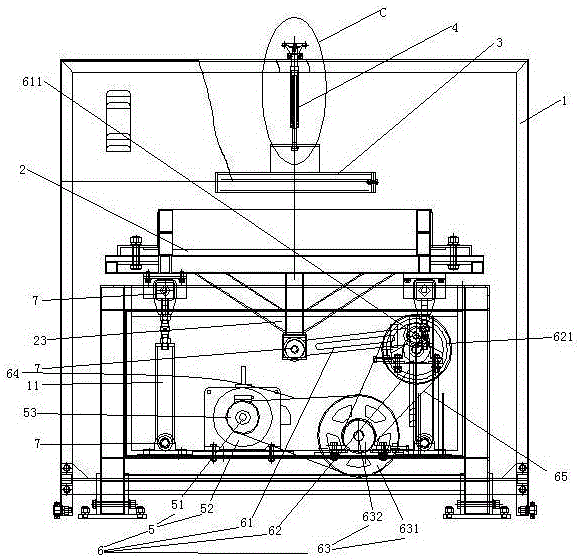

Continuous microwave dryer for accumulator plate

ActiveCN111879097AImprove drying rateIncrease productivityDrying solid materials with heatDrying chambers/containersThermodynamicsEngineering

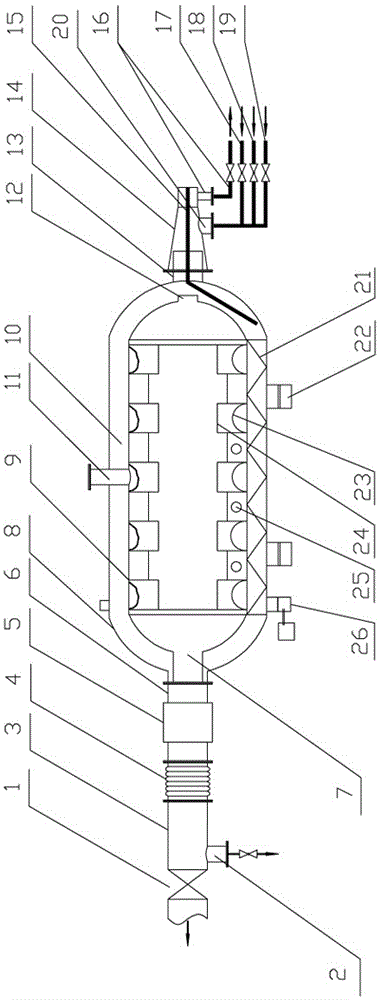

The invention relates to a continuous microwave dryer for an accumulator plate. The continuous microwave dryer comprises a microwave heating kiln, a feeding conveying belt, a discharging conveying belt and a clamping type plate transferring mechanism for clamping the two side faces of the accumulator plate in the thickness direction to transfer the accumulator plate from the feeding conveying beltto the discharging conveying belt. One end of the microwave heating kiln is provided with a feeding port, the other end of the microwave heating kiln is provided with a discharging port, the feedingconveying belt is in butt joint with the feeding port, the discharging conveying belt is in butt joint with the discharging port, and the accumulator plate is dried by the microwave heating kiln in the process of being transferred by the clamping type plate transferring mechanism. The continuous microwave dryer for the accumulator plate is used for heating by microwaves and overcomes the defects of an existing external drying mode.

Owner:JIANGXI XINWEI POWER ENERGY TECH

Tea re-drying machine

ActiveCN105115261AImprove qualityContinuous dryingPre-extraction tea treatmentDrying solid materialsEngineeringHinge point

The invention relates to tea processing equipment. A tea re-drying machine comprises a machine frame, supporting swing rods, a tank body supported on the machine frame through the supporting swing rods, a swinging mechanism for driving the tank body to swing and heating mechanisms for heating the tank body, wherein the extending direction of the tank body intersects the swinging direction of the tank body; the tank body has a low end and a high end in the extending direction; the swinging mechanism comprises a connecting rod, a rotating disc and a motor for driving the rotating disc; one end of the connecting rod is hinged to the rotating disc; the other end of the connecting rod is hinged together with the tank body; and the hinge point of the connecting rod and the rotating disc deviates from the axis of the rotating disc. The invention provides the tea re-drying machine capable of drying tea to adapt to drying of deactivated tea or tea entering a drying process so as to solve the problem that the color of tea produced by conventional equipment gets dark.

Owner:浙江上洋机械股份有限公司

Low-rank coal vibration separation drying device and method

The invention discloses a low-rank coal vibration separation drying device and method, and belongs to the technical field of drying devices. The device comprises a rack, a box, a feeding opening, hot smoke inlets, an air flow disperser, a vibration exciter, a motor, a connecting shaft, a large-sieve-pore sieve plate, a medium-sieve-pore sieve plate, a small-sieve-pore sieve plate, a suspension spring, discharging openings, gas and dust removing negative-pressure devices and gas-solid separators. After entering the box from the feeding opening, raw coal drops on a sieve surface, wherein the sieve surface is arranged at a dip angle of 5-15 degrees, the aperture of the sieve surface is progressively increased from the feeding opening to the discharging openings, the raw coal is vibrated under the effect of the vibration exciter, and the raw coal on the sieve surface is mixed and is classified. Meanwhile, after passing through the air flow disperser, hot smoke enters the box and dries raw coal with different particle sizes, after being sieved, the completely dried raw coal enters the discharging openings, after passing through the gas and dust removing negative-pressure devices, gas and dust enter the gas-solid separators, therefore, classified drying of particles with different granularities is realized, and problems that coarse particles are dried insufficiently and fine particles are over-dried are avoided.

Owner:CHINA UNIV OF MINING & TECH

A textile washing and drying integrated processing device

InactiveCN104975447BCompact structureImprove space utilizationSucessive textile treatmentsLiquid/gas/vapor removalEngineeringIntegrated processing

Owner:HENAN XINYE TEXTILE

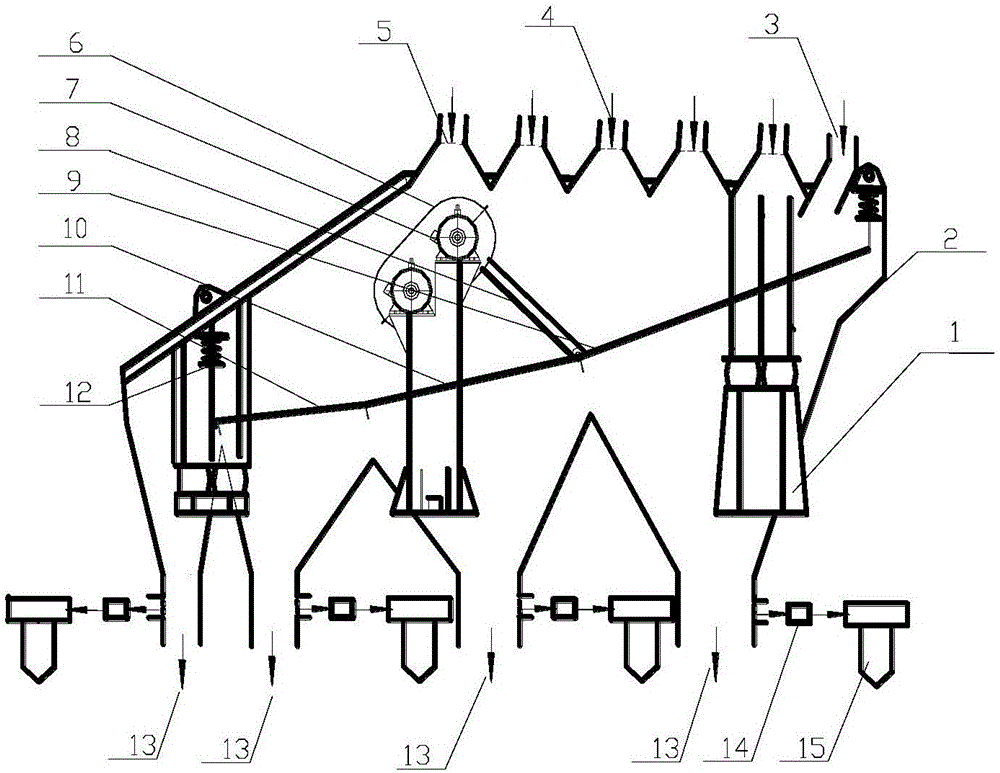

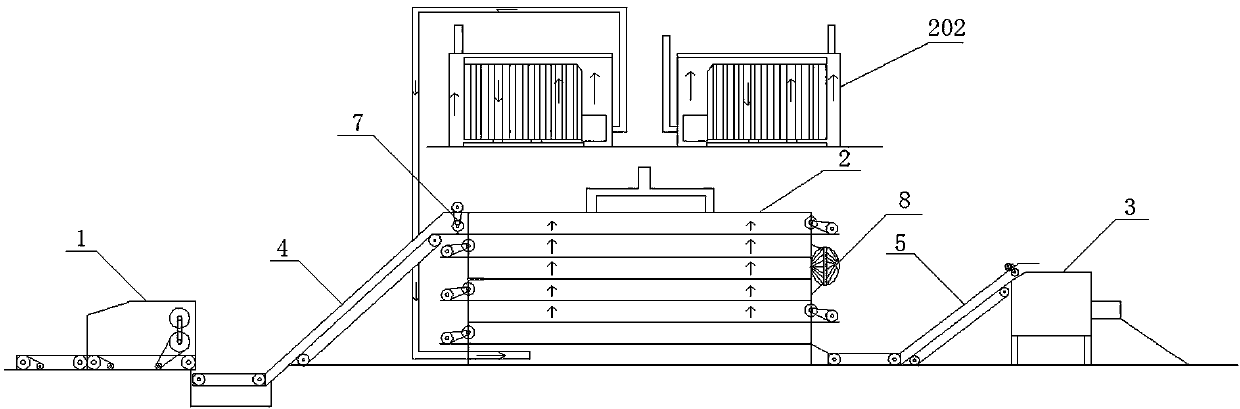

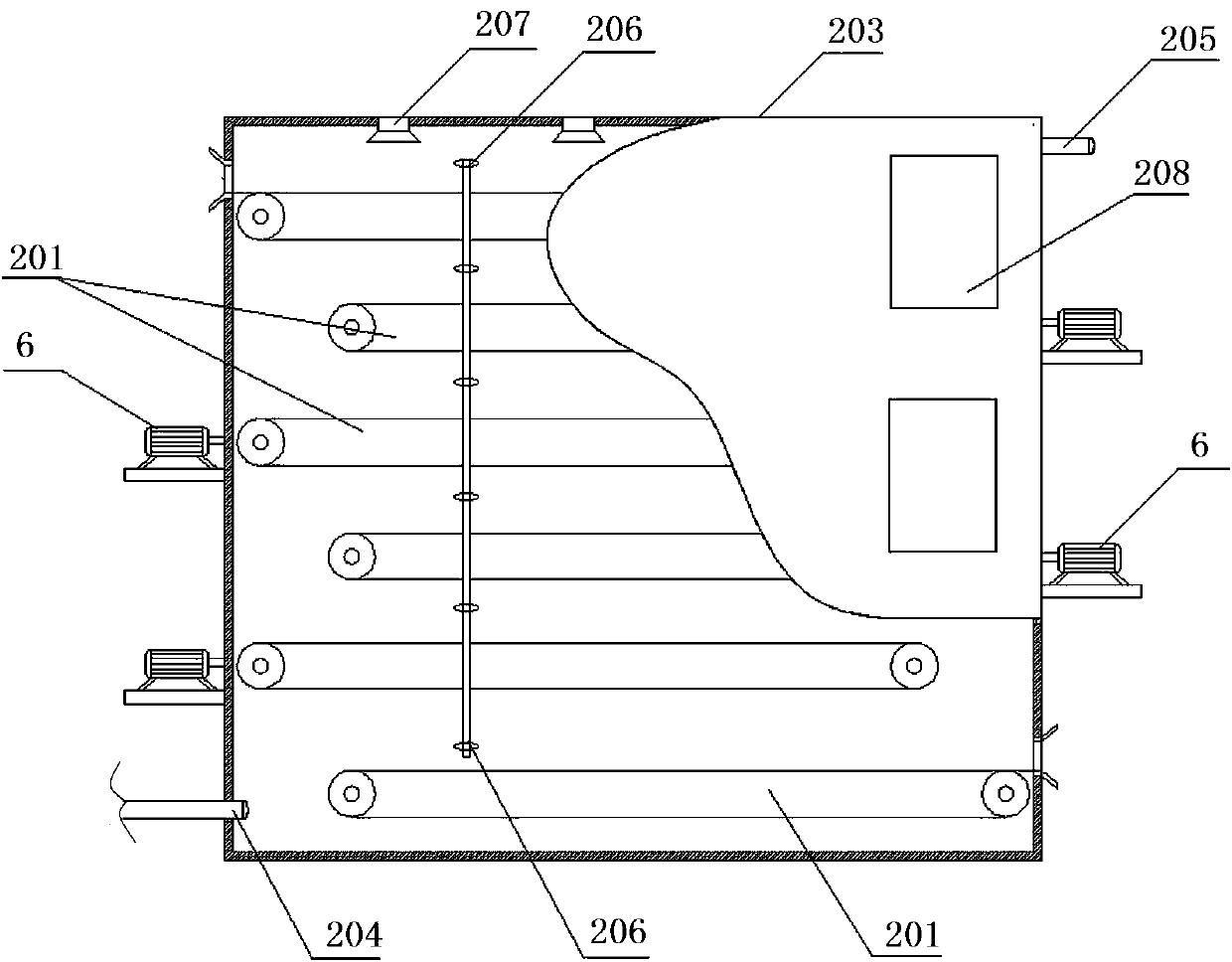

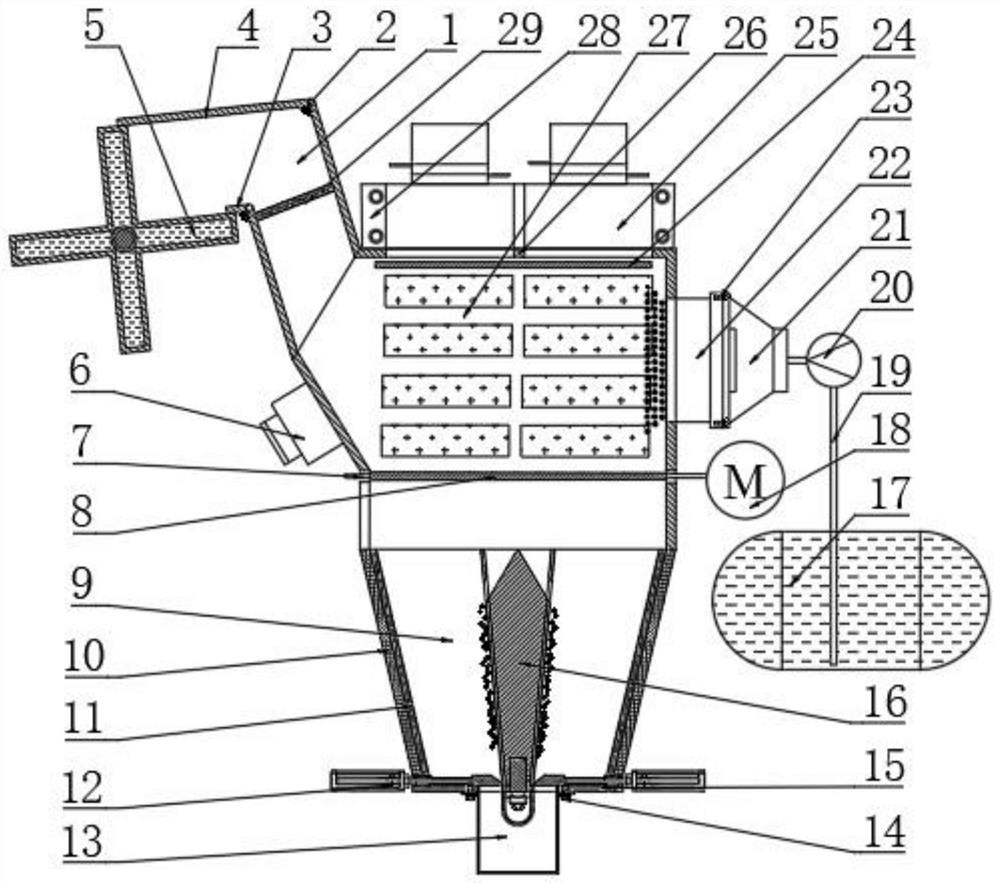

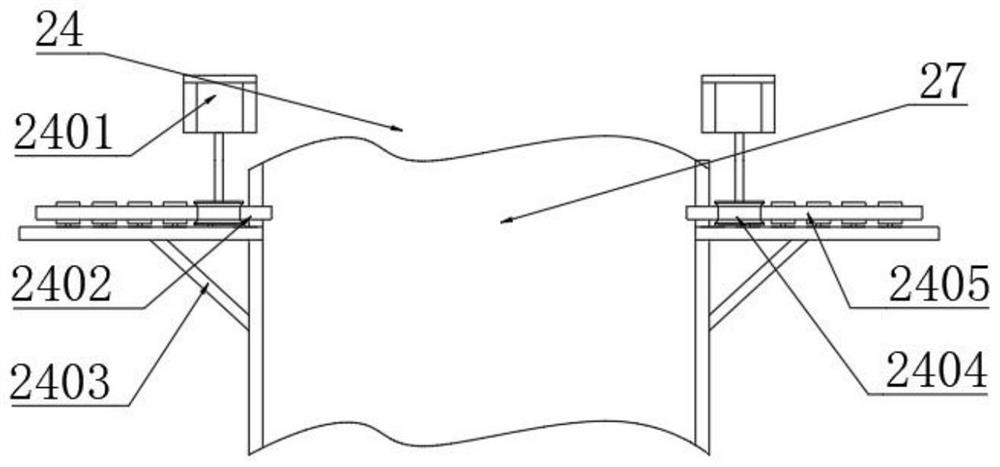

Large-scale automatic pasture processing device system

PendingCN107751579ARealize large-scaleImprove processing qualityBalingAnimal fodder preservationAgricultural scienceHot air oven

The invention discloses a large-scale automatic pasture processing device system. The large-scale automatic pasture processing device system comprises a bundle breaking and feeding device, a layered drying device and a forming and binding device, wherein a pushing mechanism is arranged at one end of the body of the bundle breaking and feeding device, a bundle breaking and feeding mechanism is arranged closely to the pushing mechanism, a discharge port of the bundle breaking and feeding device is connected with a feed port of a forage conveying belt I device, multiple layers of belt-type conveyors used for conveying pasture are arranged horizontally in a shell of the layered drying device, the conveying belts of the conveyors are of a ventilated mesh type structure, dry high-temperature airis introduced into the shell by a hot-blast stove for drying the pasture in the process that the pasture is conveyed layer by layer, a discharge port of the layered drying device is connected with afeed port of the forming and binding device through a forage conveying belt II, and the devices are powered by a variable frequency motor. The large-scale automatic pasture processing device system can realize large-scale, mechanical and automatic processing and production of pasture, obviously improve the processing quality of the pasture, shorten the processing cycle of the pasture, improve theproduction efficiency and reduce the production cost.

Owner:山丹县天泽农牧科技开发有限责任公司

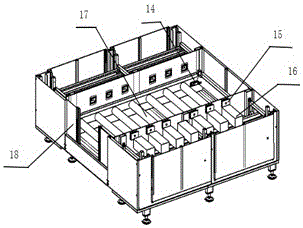

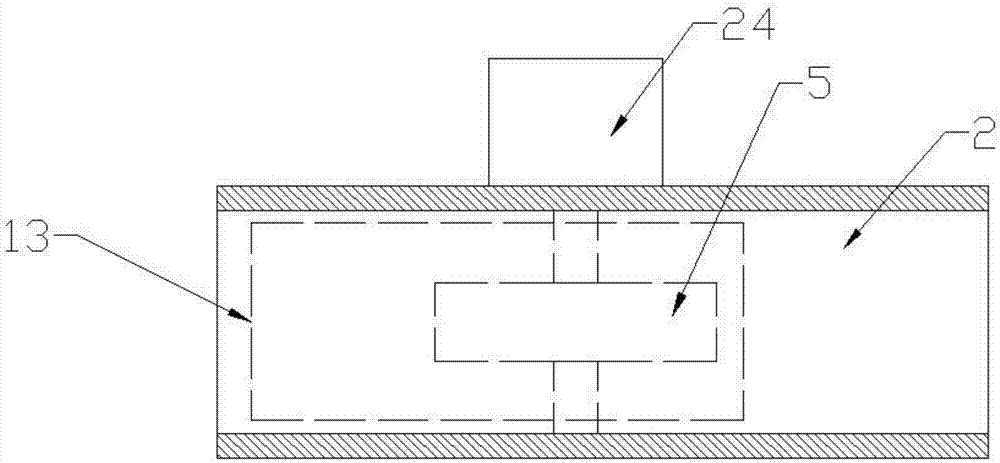

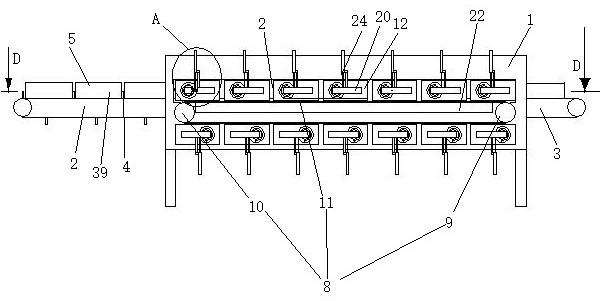

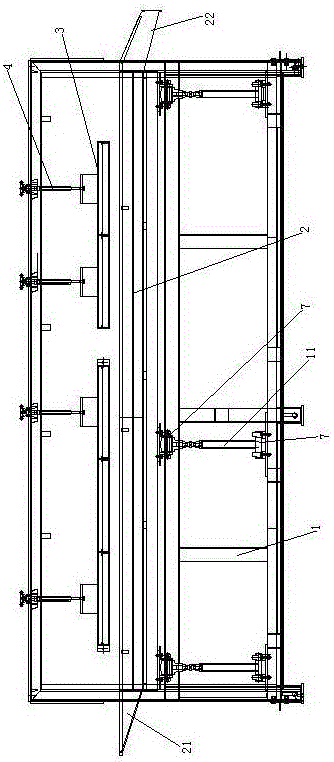

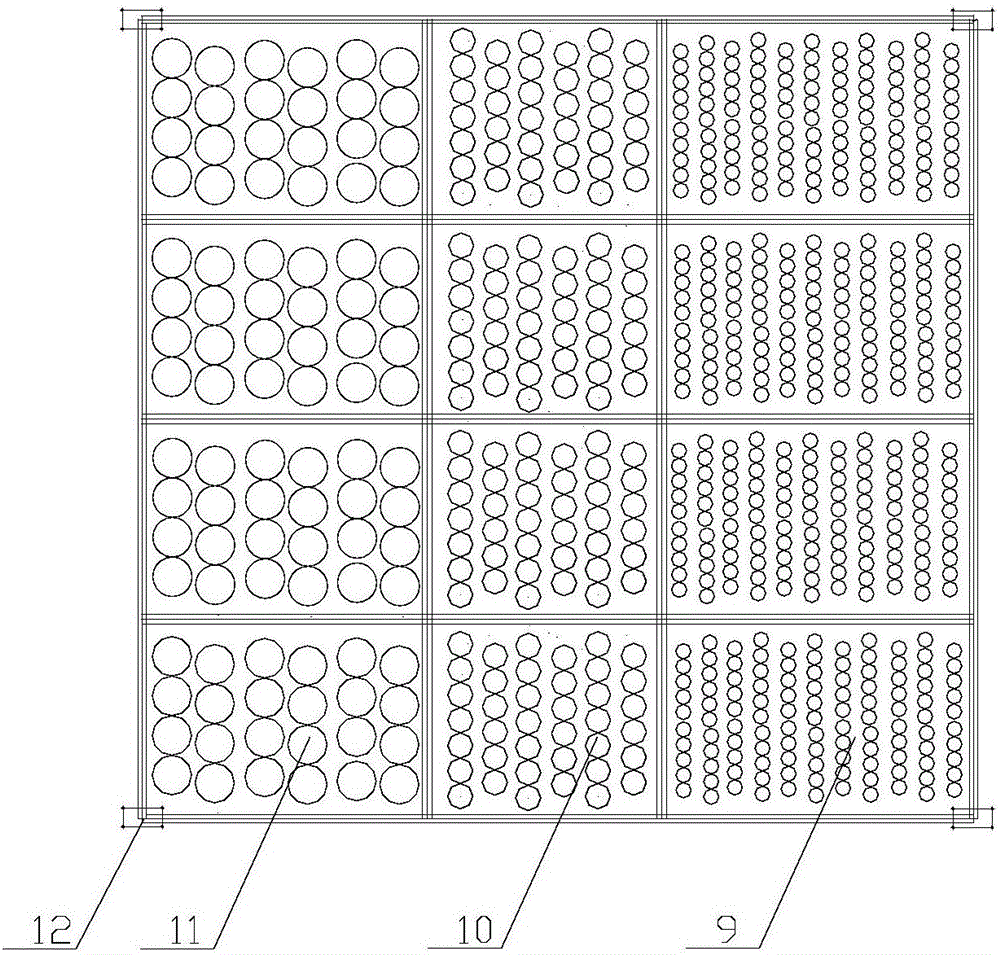

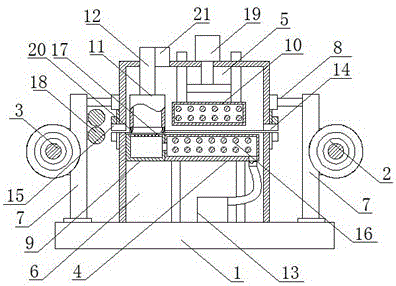

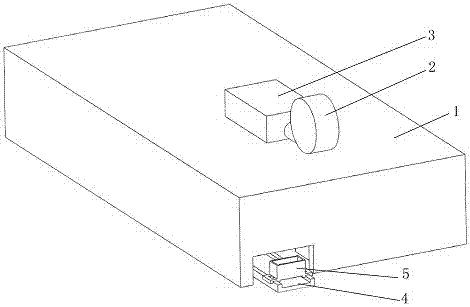

Continuous drying module for use in semiconductor integrated manufacturing production line

InactiveCN103050426AContinuous dryingAchieving a modular designSemiconductor/solid-state device manufacturingSemiconductorModular design

The invention relates to the field of semiconductor integrated manufacturing, in particular to a continuous drying module for use in a semiconductor integrated manufacturing production line. The invention provides a continuous drying module for use in a semiconductor integrated manufacturing production line. Both sides of a shell are provided with an inlet and an outlet through which a conveying belt passes, and drum groups for dynamically clamping the conveying belt are arranged at the inlet and the outlet, so that the effect of dynamically sealing the shell and the conveying belt is achieved when the conveying belt passes through the shell from the inlet and the outlet. Due to the adoption of the continuous drying module provided by the invention, a continuous drying function on a photosemiconductor substrate can be realized, and the quality of a gas in the shell can be controlled in real time in a drying process; and meanwhile, a modular design of a drying process in the semiconductor integrated manufacturing production line is realized.

Owner:王奉瑾

Spinning cloth drying device

InactiveCN107178980ASimple structureReasonable designDrying gas arrangementsDrying machines with progressive movementsMechanical engineeringEnergy consumption

The invention discloses a spinning cloth drying device, and belongs to the field of textile machinery. The spinning cloth drying device comprises a base, an input mechanism, a winding mechanism and a drying box; a box body is fixedly mounted on the base, and consists of an upper cavity and a lower cavity; the lower cavity is fixed on the base; the two ends of the back side of the upper cavity are dynamically matched and connected with stand columns fixed at the two ends of the base through rotating shafts; the drying box is arranged in an upper opening of the lower cavity; one end of the drying box communicates with a hot wind box; an upper drying hanging box is arranged in the upper cavity above the drying box; a hot wind collecting cover is arranged in the upper cavity above the hot wind box; an exhaust pipeline is arranged at the top of the hot wind collecting cover; and a fan is arranged in the lower cavity for communicating with the drying box. The spinning cloth drying device is simple in structure, reasonable in design, convenient to use and excellent in drying effect, performs multiple drying modes at the same time, can quickly and continuously dry cloth through continuous contact drying, and is high in drying efficiency and low in energy consumption.

Owner:湖州南浔善琏友乐毛纺厂

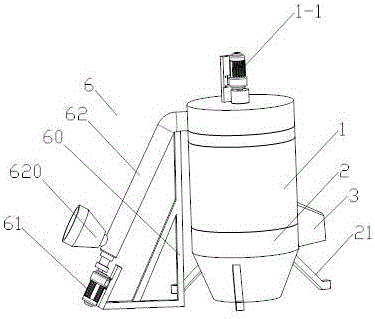

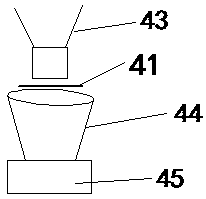

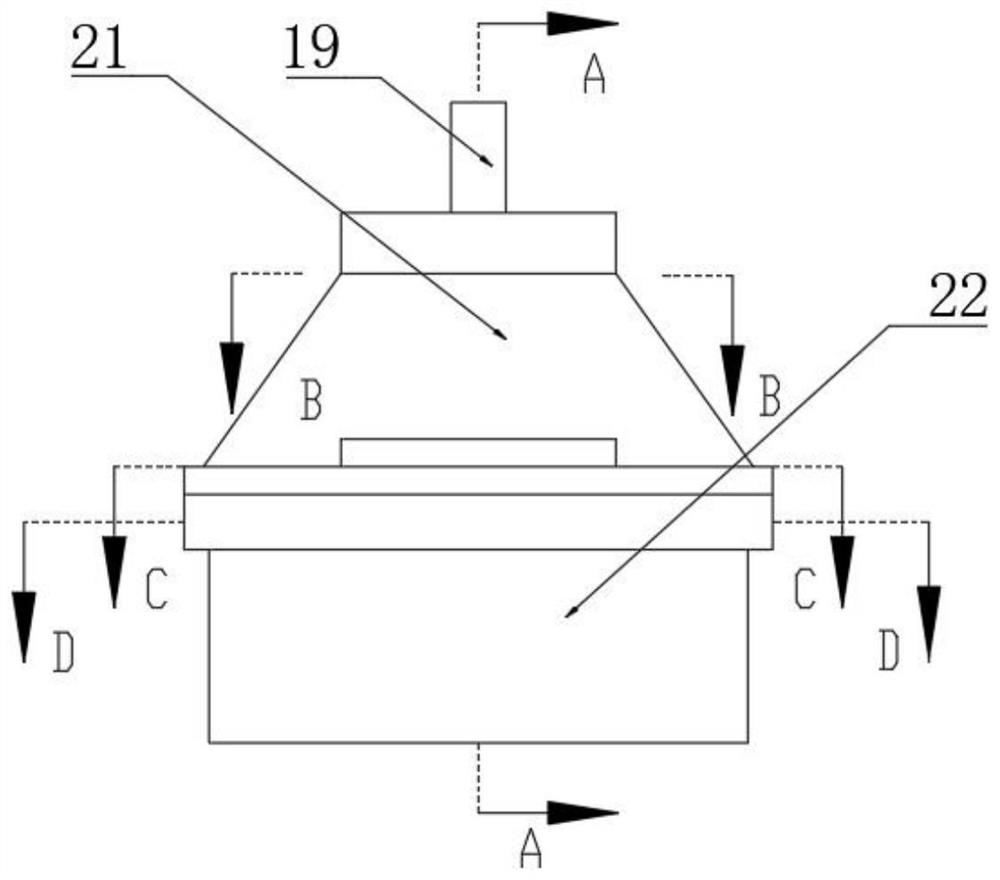

A spray freeze sublimation dryer

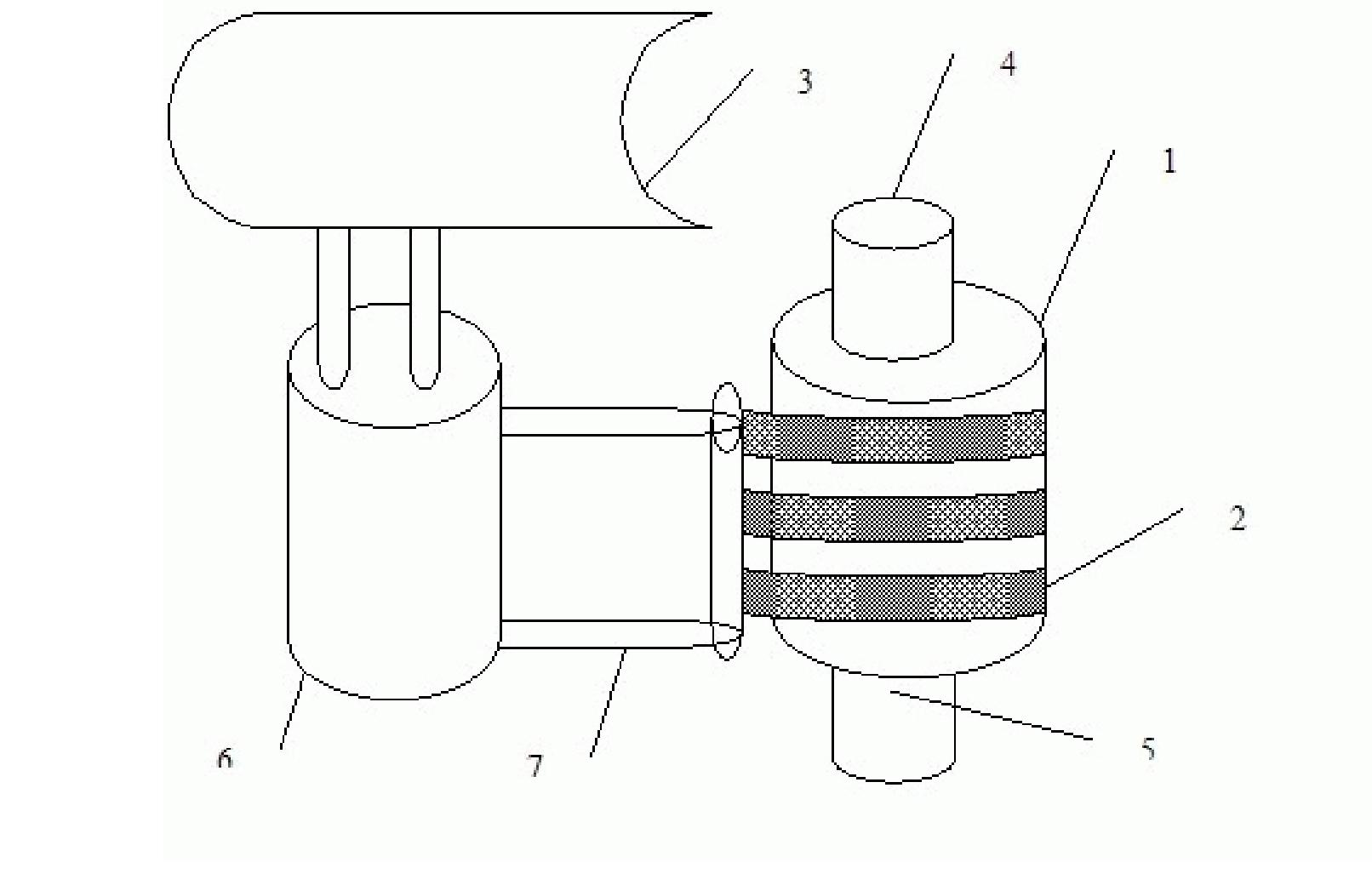

ActiveCN105664513BGuaranteed thermal sensitivityKeep aliveSublimationEvaporation by sprayingSolubilityFreeze-drying

The invention provides a spray freezing sublimation drying machine and belongs to the technical field of drying equipment for food, medicine, biological products and the like. The spray freezing sublimation drying machine is applicable to drying liquid materials and specifically comprises a drying tower for spray freezing sublimation, a feeding device is arranged on the upper portion of the drying tower, a spray device is connected to the bottom of the feeding device, two layers of grid type partition plates are arranged in the middle of the drying tower to divide the drying tower into three independent sealed spaces comprising a spray freezing bin, a buffer bin and a vacuum drying bin. The bottom of the drying tower is provided with a discharge outlet. The centrifugal spray freezing bin is connected with a liquid inert heat transfer medium injector, the wall of the spray freezing bin is provided with a gas inert heat transfer medium outlet, the vacuum drying bin is connected with a vacuum pumping device, and the side wall of the vacuum drying bin is provided with a heating device. The spray freezing sublimation drying machine is simple in structure, capable of continuously carrying out spray freezing sublimation drying operation, high in drying efficiency, good in solubility, particularly applicable to spray drying of various heat sensitive liquid materials and good in market prospect.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Textile product cleaning and drying device

InactiveCN107558068AIncrease profitContinuous dryingSucessive textile treatmentsLiquid/gas/vapor removalPulp and paper industryMaterial resources

The invention discloses a textile cleaning and drying device, which comprises a tank body, a receiving roller arranged on one side of the tank body, and a discharging roller arranged on the other side. The partition divides the tank body into a cleaning area and a non-cleaning area. The second partition in the non-cleaning area divides the non-cleaning area into a blowing area and a drying area; the first partition includes vertical side panels and flow guides. Plate, deflector comprises left deflector and right deflector, and left deflector and right deflector are all downward and inclined to the middle position of blowing area; Blowing units are provided on the opposite side walls, and heating devices are provided in the drying area; the surfaces of the left deflector and the right deflector are provided with anti-corrosion layers. The invention integrates cleaning and drying of textiles, has a simple structure and saves manpower, material resources and energy; and can return the cleaning agent remaining on the textiles to the cleaning area after cleaning, improving the utilization rate of the cleaning agent and further saving costs.

Owner:SUZHOU SISHAN NANO TECH CO LTD

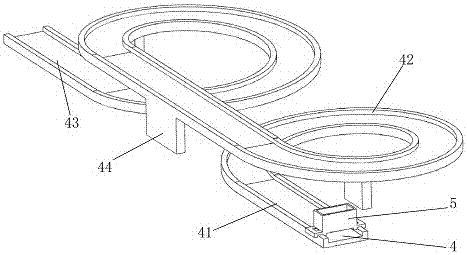

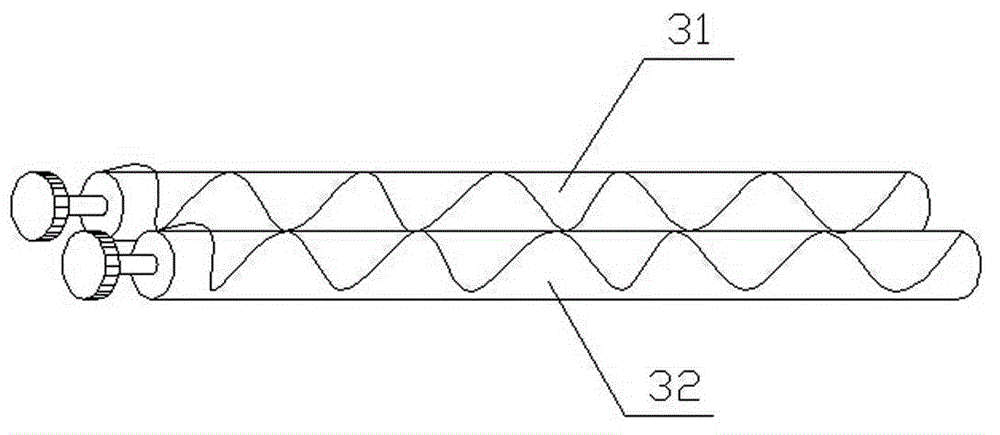

Spiral type dryer

PendingCN107131744AExtended staySmall footprintDrying gas arrangementsDrying chambers/containersSmall footprintDrying time

The invention discloses a spiral type dryer. The spiral type dryer comprises a fan which is connected with an electric heating box and is mounted on the top of a drying room; a trolley is mounted on a material rail; the material rail consists of an inlet rail, a spiral rail, an outlet rail and a supporting part; the inlet rail is exposed from an inlet of the drying room; the outlet rail is exposed from an outlet of the drying room; the spiral rail is connected with the inlet rail and the outlet rail; and the supporting part is fixedly mounted below the spiral rail. The spiral type dryer solves the problems that a conventional dryer greatly wastes space and is short in material drying time; the spiral device has the characteristics of small floor space and a long rail, so that materials are kept for a long time in the drying room, materials which enter the drying room once are many; and the trolley can automatically move, so that continuous drying operation can be guaranteed, and therefore, the spiral type dryer has the advantages of high efficiency, high structural stability and strong maneuverability.

Owner:XIANGZHOU COUNTY INST OF SCI & TECHN INFORMATION

Method for drying water-contained garbage by using afterheat of cement kiln system

ActiveCN105222601ASave energyIncrease the calorific value on a moisture basisDrying gas arrangementsIncreasing energy efficiencyDecompositionDrying time

The invention discloses a method for drying water-contained garbage by using afterheat of a cement kiln system. The method is to use tail gas having the afterheat in the cement kiln system for heating the water-contained garbage; and the water-contained garbage is heated for drying to form dried garbage. The cement kiln system comprises a cement kiln, a grate cooler and a generator; the cement kiln is provided with a decomposition furnace; the decomposition furnace is provided with a first-grade preheater; the heating of the water-contained garbage by using the tail gas having the afterheat in the cement kiln system is to lead out the tail gas having the afterheat in the first-grade preheater for heating the water-contained garbage, to lead out the tail gas having the afterheat in a low-temperature section of the grate cooler for heating the water-contained garbage and to lead out the tail gas having the afterheat in the generator for heating the water-contained garbage. The method can fully use abundant afterheat resource of the cement kiln for drying the water-contained garbage, can save a lot of energy for drying the water-contained garbage, shortens the drying time, decreases the drying floor area, and quickly improves the garbage wet base heat value.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Cleaning basket for small workpieces

InactiveCN104438188ASimple structureEasy to useDrying gas arrangementsDrying solid materialsEngineeringHooking

The invention discloses a cleaning basket for small workpieces. The cleaning basket comprises a cylindrical body, wherein a holding handle and two symmetric mechanical hooking handles are arranged on the outer side wall of the cylindrical body; the central line of the two mechanical hooking handles is perpendicular to that of the holding handle; a 30-mesh filter screen is horizontally arranged at the lower part of the cylindrical body; a reinforced screen used for supporting the filter screen is arranged on the edge of the bottom end of the cylindrical body. The cleaning basket is simple in structure, convenient to use, capable of smoothly completing cleaning and drying operation of small workpieces, and particularly suitable for workpieces with the sizes of about Phi 1 mm.

Owner:科威信(无锡)洗净科技有限公司

Apparatus and method for automatic filtering tobacco liquid

ActiveCN109499151ASave work space and timeReduced risk of production contaminationMoving filtering element filtersAutomatic filteringEngineering

The invention discloses an apparatus and a method for automatic filtering tobacco liquid. The apparatus for automatic filtering tobacco liquid comprises a worktable, a conveying rail for conveying a filter net and a rotating mechanism, wherein the conveying rail is arranged above the worktable; the rotating mechanism is arranged inside the worktable; the worktable is an annular structure; a filtering mechanism, a cleaning mechanism and a drying mechanism are respectively arranged on an annular path of the worktable; the conveying rail is connected with the rotating mechanism; and the rotatingmechanism drives the conveying rail to rotate along the annular path of the worktable. The apparatus and method can effectively integrate the conveying rail, the rotating mechanism, the filtering mechanism, the cleaning mechanism and the drying mechanism, so as to realize automatic operations of filtering, cleaning and drying, and improve the filtration efficiency without causing cross-contamination, thereby satisfying the operation demand of full-automatically filtering the tobacco liquid in large batches; and the apparatus and method have a strong promotion value.

Owner:CHINA TOBACCO GUANGDONG IND

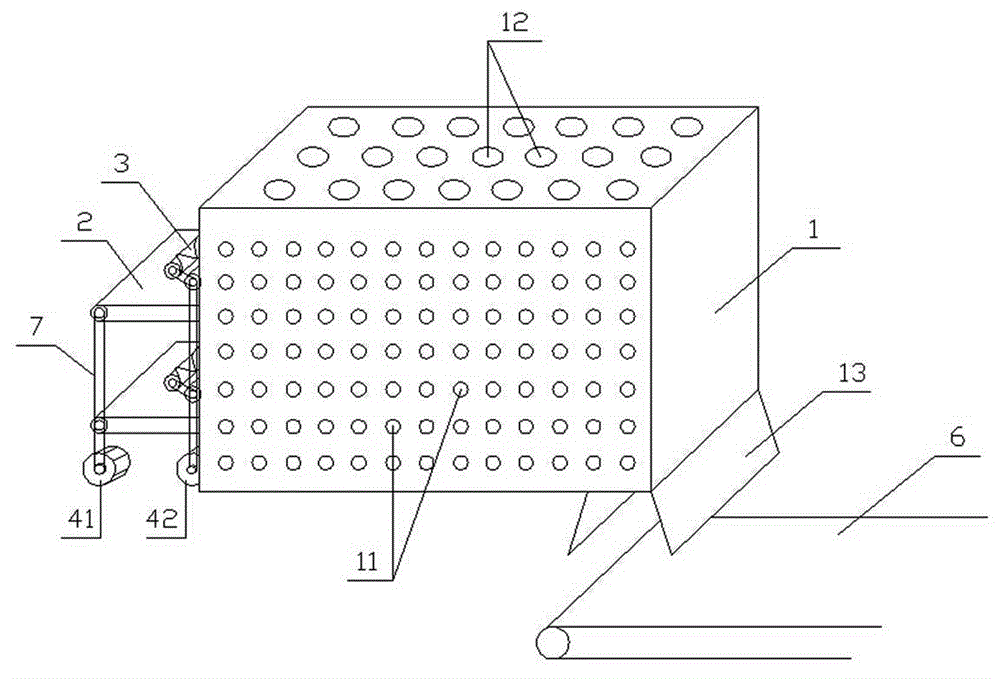

Domestic garbage drying equipment

InactiveCN105318694AMeet the needs of dryingContinuous dryingDrying machines with progressive movementsDrying solid materialsMetal meshProcess engineering

The invention discloses domestic garbage drying equipment which comprises a drying box, a metal mesh belt, a power mechanism, a limiting device and a hot air generating device. The metal mesh belt is arranged in the drying box, one end of the metal mesh belt stretches out of the drying box, the power mechanism provides work power for the metal mesh belt, the limiting device limits the length of the fed part of the metal mesh belt every time, and the hot air generating device provides dry hot air into the drying box. According to the technical scheme, the domestic garbage drying equipment has the advantages that the need for drying a large amount of domestic garbage is met, continuous production can be achieved, and drying efficiency is high; design is scientific and reasonable, the structure is simple, drying is even, high controllability is achieved, and the drying effect is good; the continuous production process can be achieved by connecting the equipment into a production line, manpower participation is not needed, production cost is reduced, and labor force is saved.

Owner:FUJIAN ZHENGREN ENVIRONMENTAL PROTECTION

A fabric surface treatment system

ActiveCN108560227BProcess continuouslyContinuous dryingMechanical cleaningPressure cleaningDust controlProcess engineering

The invention provides a surface processing system for a fabric. The technical problems that existing processing devices are too simple in structure, manual dust removal is needed, and the processingspeed is low are solved. The surface processing system for the fabric comprises a baseplate, and the baseplate is provided with a dust removing device, a spraying device and a drying device in sequence. The surface processing system for the fabric has the advantage of high processing efficiency.

Owner:湖北鱼鹤制衣有限公司

Rapid drying and collecting device for micro nano powder

ActiveCN113945070AFast dryingNot easy to reuniteDrying solid materials with heatSteam/vapor condensersMicro nanoMetallurgy

The invention provides a rapid drying and collecting device for micro nano powder, and belongs to the field of powder drying. The device comprises a micro-droplet spraying device for forming nano powder slurry into a droplet state, a rapid drying device for drying nano powder droplets to form nano powder, a dehumidification device for removing water vapor generated in the drying process of the nano powder, and a powder collecting device for collecting the nano powder. According to the device, the microwave technology, the ultrasonic technology and the electrostatic technology are organically combined, nano powder is rapidly collected under the action of an electrostatic field after being suspended and dried in a drying chamber, the device has the advantages of being high in drying speed, not prone to agglomeration, controllable in drying time and suitable for drying the nano powder with different particle sizes, and meanwhile the device is compact in structure, suitable for small-batch preparation of nano powder in scientific research laboratories, and meets the requirement of taking and using at any time.

Owner:WUXI HOPE LIGHT IND EQUIP TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com