Cleaning basket for small workpieces

A technology for cleaning baskets and small workpieces, which is applied to cleaning methods and utensils, cleaning methods using liquids, and drying solid materials. It can solve the problems of inability to clean small workpieces and low manufacturing precision, and achieve simple structure and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

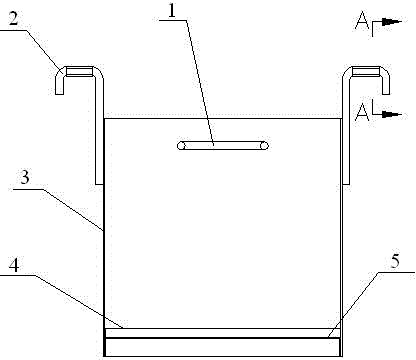

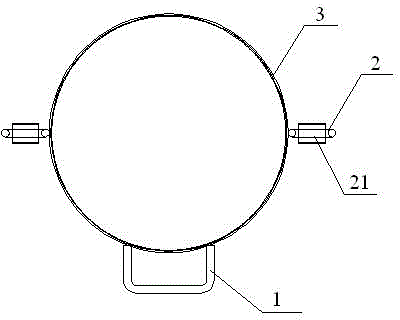

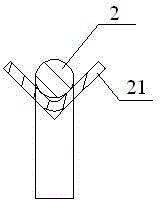

[0016] A small workpiece cleaning basket, its structure is as figure 1 with figure 2 shown. It includes a cylindrical cylinder body 3, a hand handle 1 and two symmetrical mechanical hook handles 2 are arranged on the outer wall of the cylinder body, and the center line where the two mechanical hook handles 2 are The center line where hand 1 is located is perpendicular. The hand handle 1 and the mechanical hook handle 2 are welded to the outer wall of the cylinder using a traditional welding process.

[0017] The lower part of the cylinder 3 is provided with a 30-mesh filter screen 4 horizontally, which is used to place small workpieces; the bottom edge of the cylinder 3 is provided with a reinforcement net 5, and the reinforcement net 5 is a square grid with a grid spacing of 5mm, which is used for Support the filter screen 4. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com