Spinning cloth drying device

A drying device and cloth technology, which is applied to drying, drying machine, heating device and other directions, can solve the problems of difficult to meet drying requirements, fast heat loss, long drying time, etc. High drying efficiency and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

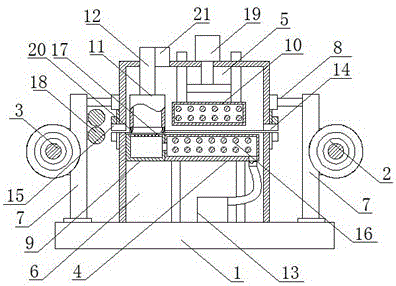

[0012] Attached below figure 1 A textile cloth drying device of the present invention will be further described.

[0013] A textile cloth drying device of the present invention comprises a base 1, an input mechanism 2, a winding mechanism 3, and a drying box 4, and a box body is fixedly installed on the base 1, and the box body consists of an upper chamber 5 and a lower chamber. cavity 6, the lower cavity 6 is fixed on the base 1, the two ends of the rear side of the upper cavity 5 are respectively connected with the columns 7 fixed on the two ends of the base 1 through the rotating shaft 8, and the upper mouth of the lower cavity 6 is provided with There is a drying box 4, one end of the drying box 4 communicates with the hot air box 9, the heat of the hot air box 9 comes from the drying box 4, and the upper chamber 5 above the drying box 4 is provided with an upper drying hanging box 10. A hot air collection cover 11 is provided in the upper cavity 5 above the hot air box 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com