Sand core drying equipment

A technology for drying equipment and sand cores, which is applied in drying, drying machines, lighting and heating equipment, etc. It can solve the problems of affecting the quality of casting products, easy deformation of sand cores, and long drying time, etc., and achieves the goal of providing drying Efficiency, protection against radiation damage, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. The orientation words such as "up, down, left, right, front, back and side" used in the description do not limit the present invention in any way.

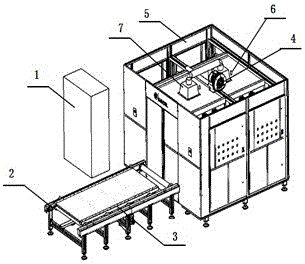

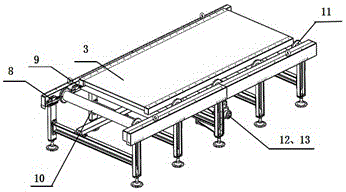

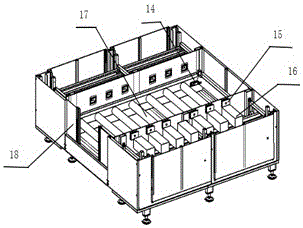

[0025] Such as figure 1 As shown, a drying equipment of the present invention includes: a control electric cabinet 1, a roller conveying device and a drying furnace main body 5; wherein, the control electric cabinet 1 is arranged on the left side of the drying furnace main body 5, and the control There is a power button inside the electric cabinet 1, which controls the start of the drying equipment, drives the rotating drum 10 to operate, transports the tray 3 to the main body of the drying furnace 5, dries the sand cores placed on the tray 3, and controls the electric cabinet 1 A program controller is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com