Low-rank coal vibration separation drying device and method

A technology for grading drying, low-rank coal, applied in drying gas arrangement, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems of low drying rate of low-rank coal, uneven heating of samples, etc. The effect of increasing the processing capacity of the equipment and ensuring the uniformity of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the implementation examples in the accompanying drawings:

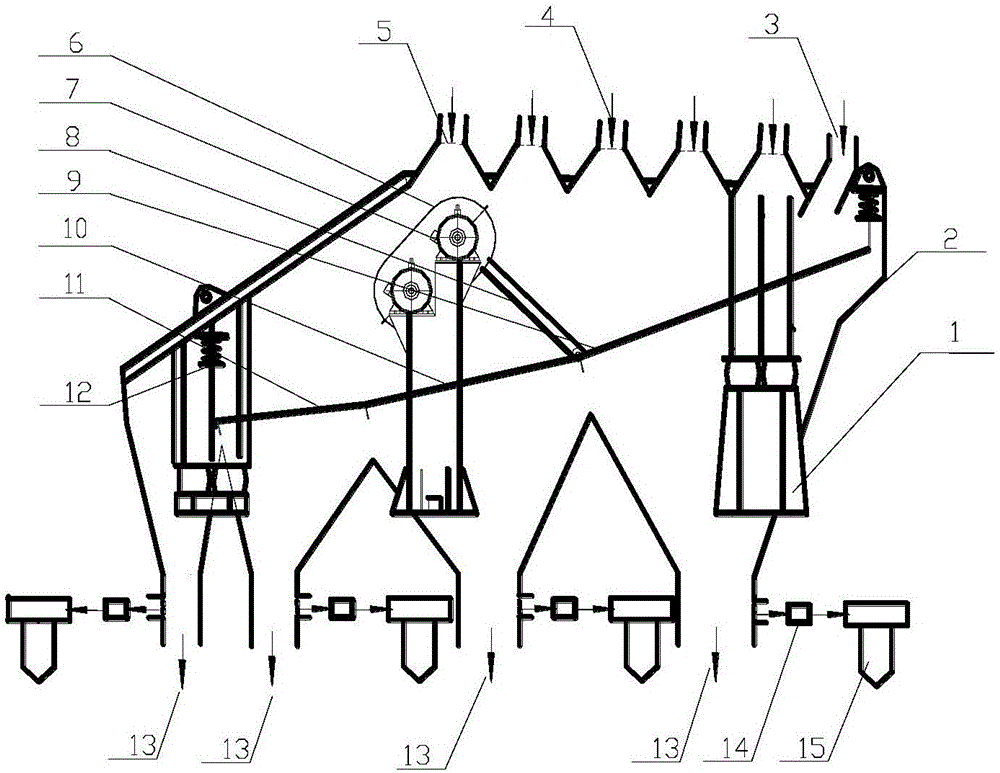

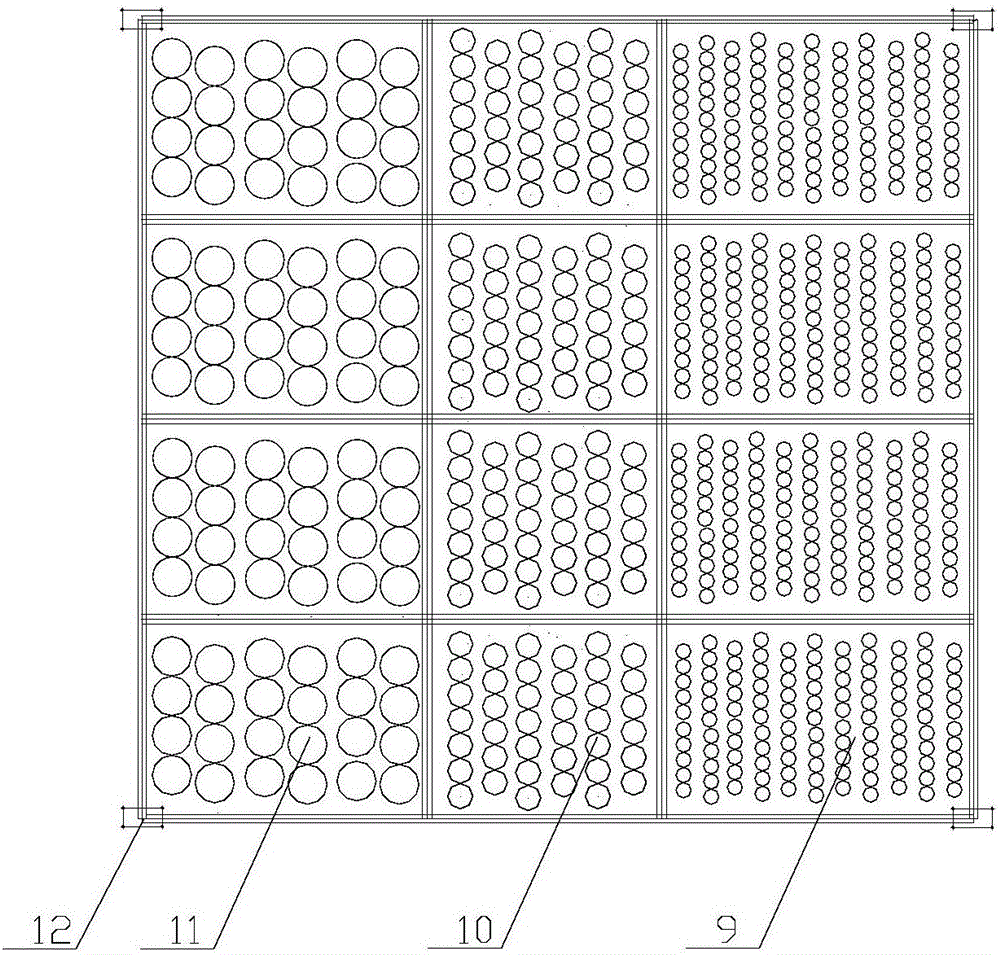

[0025] The low-rank coal vibration classification drying equipment of the present invention mainly consists of a frame 1, a box body 2, a feed port 3, a hot flue gas inlet 4, an air diffuser 5, an exciter 6, a motor 7, and a connecting shaft 8 , a sieve plate, a suspension spring 12, a discharge port 13, a degassing and dedusting negative pressure device 14, and a gas-solid separator 15; Raw coal feed port 3, hot flue gas inlet 4 and air diffuser 5; there are multiple hot flue gas inlets 4, 5 are shown in the figure, and the number can be determined according to needs. According to the condition of dry raw coal, the temperature of the hot flue gas passing through each hot flue gas inlet can be adjusted. The box body 2 is provided with a sieve plate fixed by a suspension spring 12, and an exciter 6 is arranged in the middle space of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com