Patents

Literature

128results about How to "Ensure heating uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

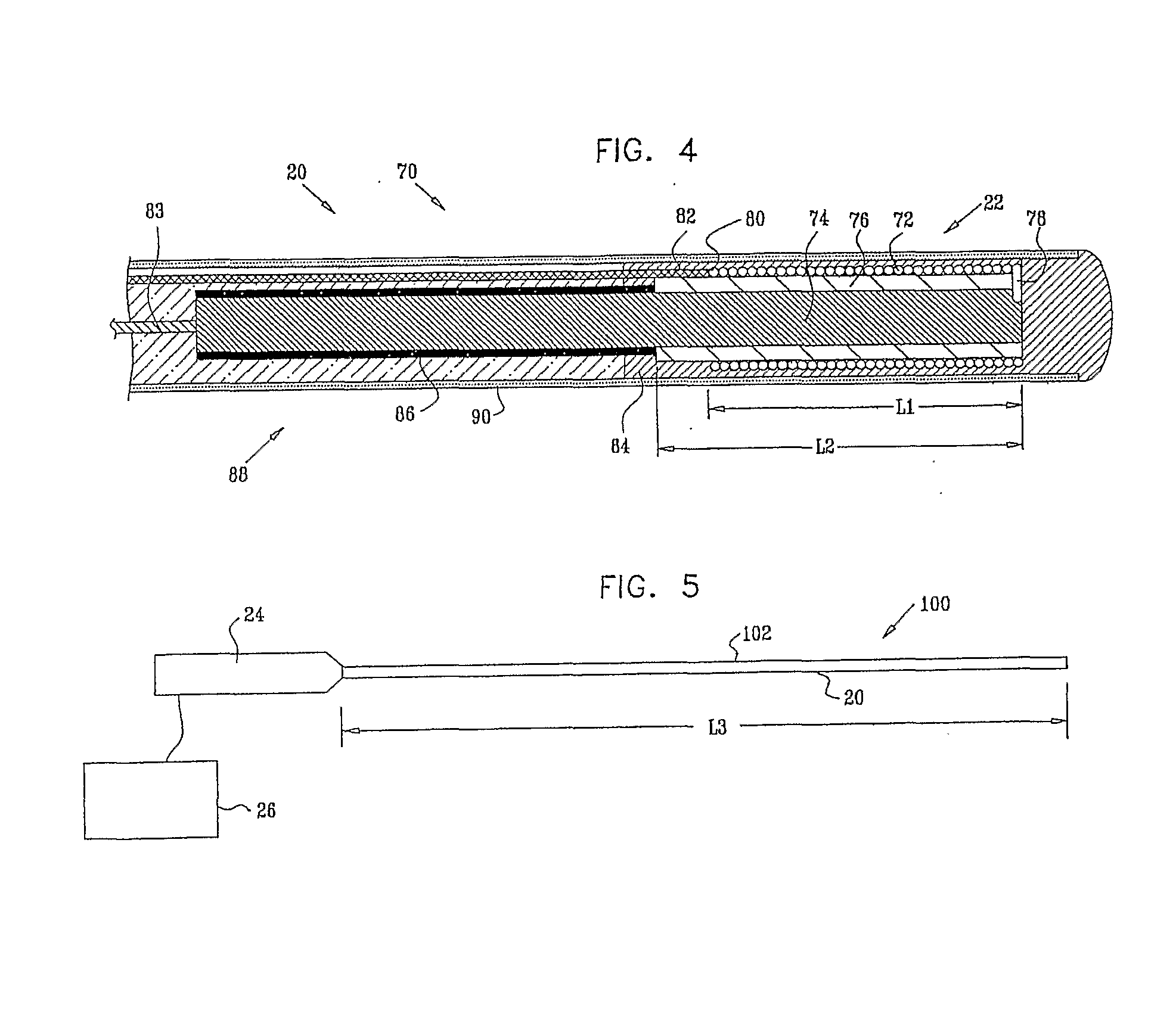

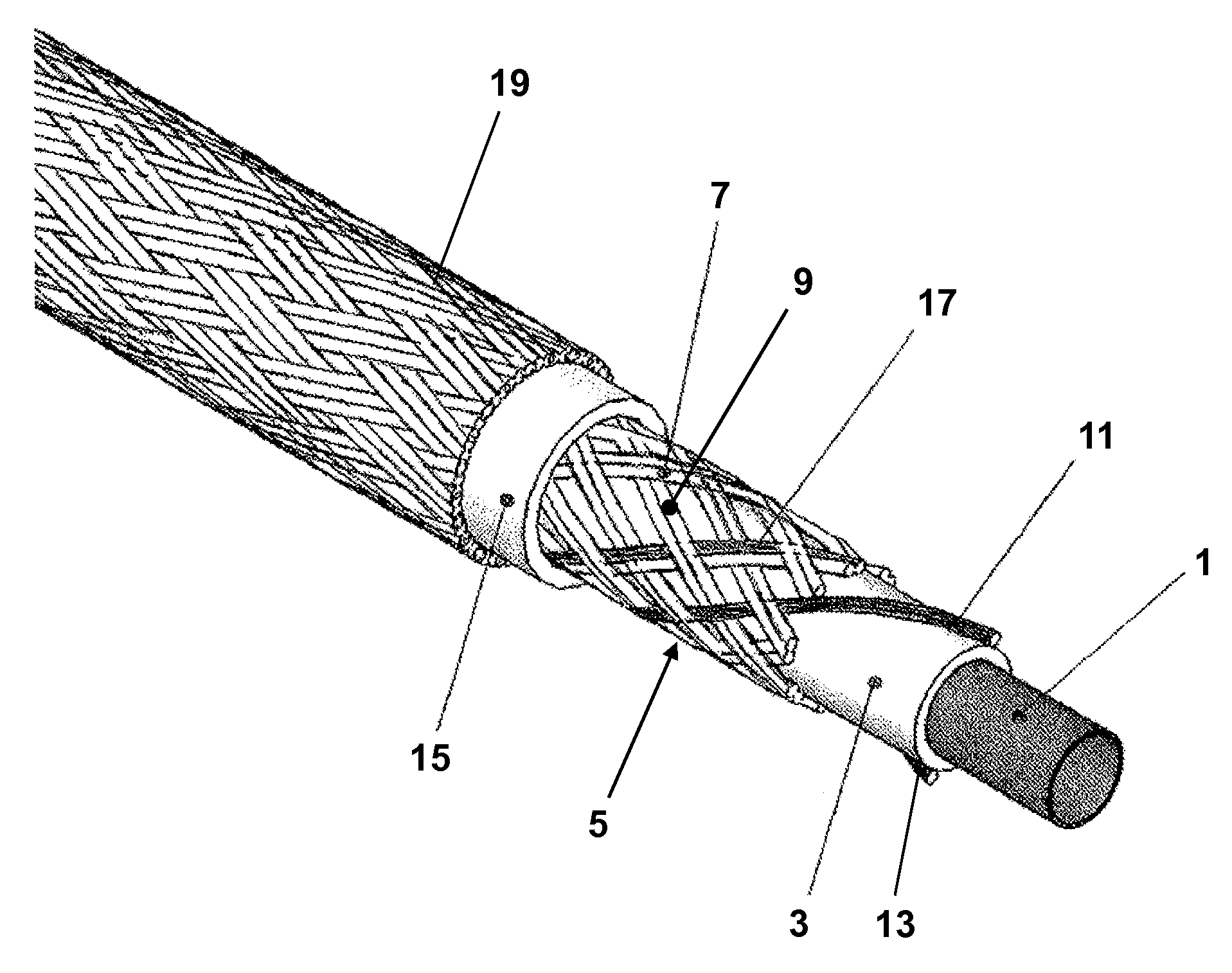

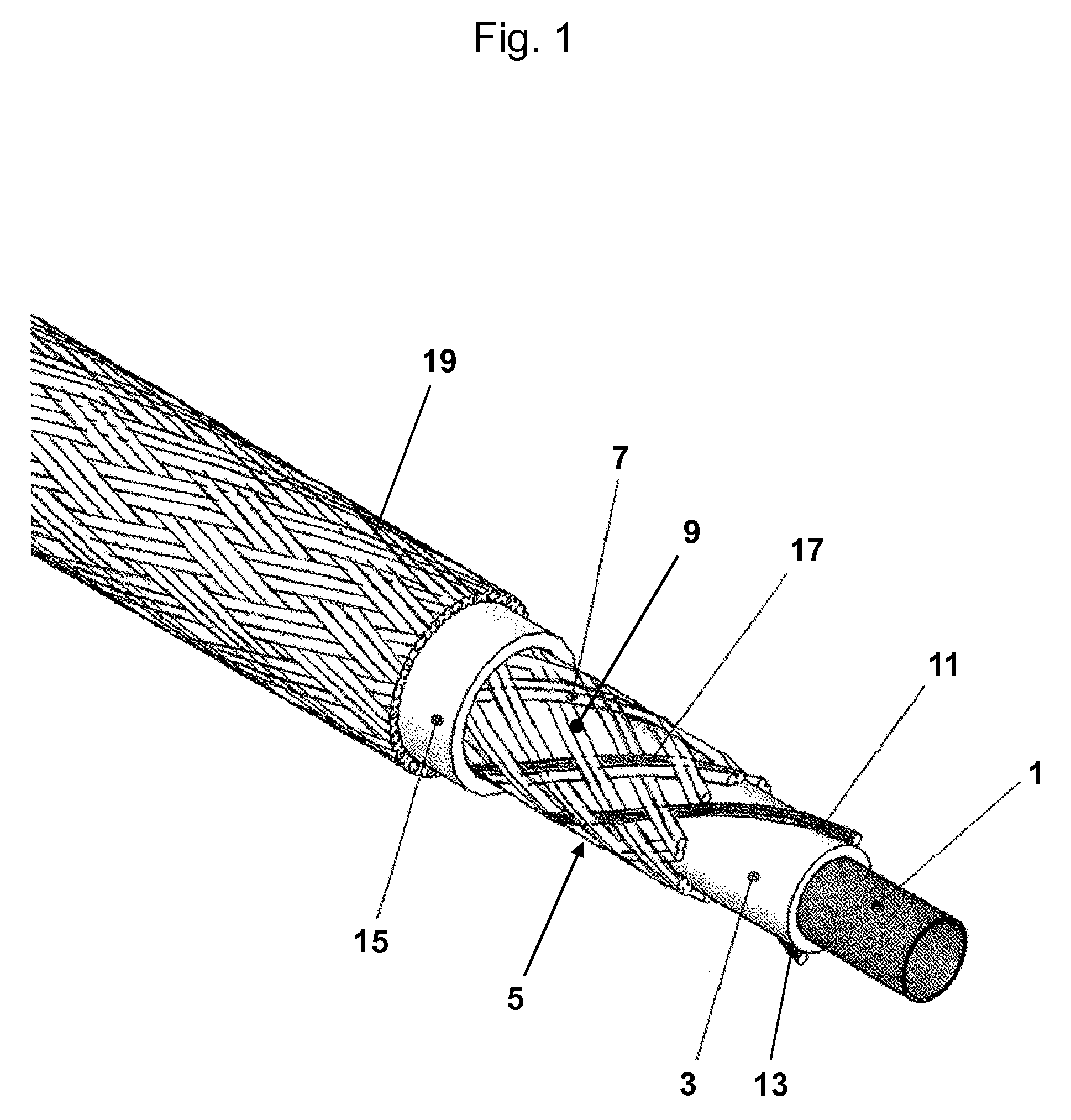

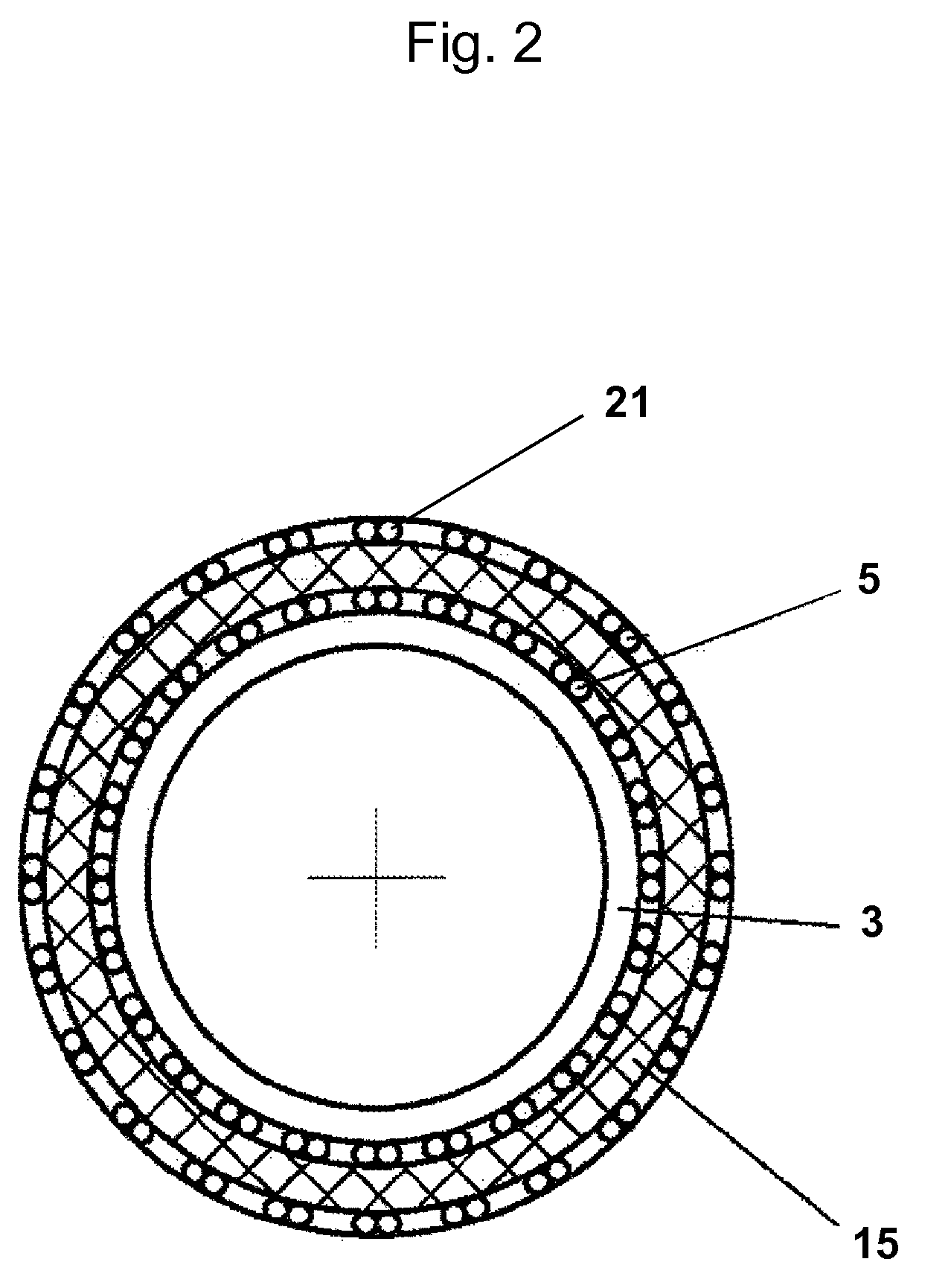

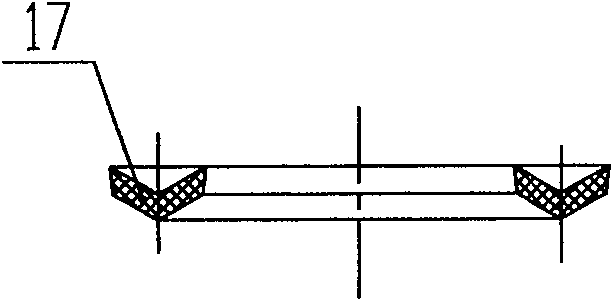

Flexible, Electrically Heatable Hose

InactiveUS20100126986A1Ensure heating uniformityPipe heating/coolingFlexible pipesElectrical conductorConductor Coil

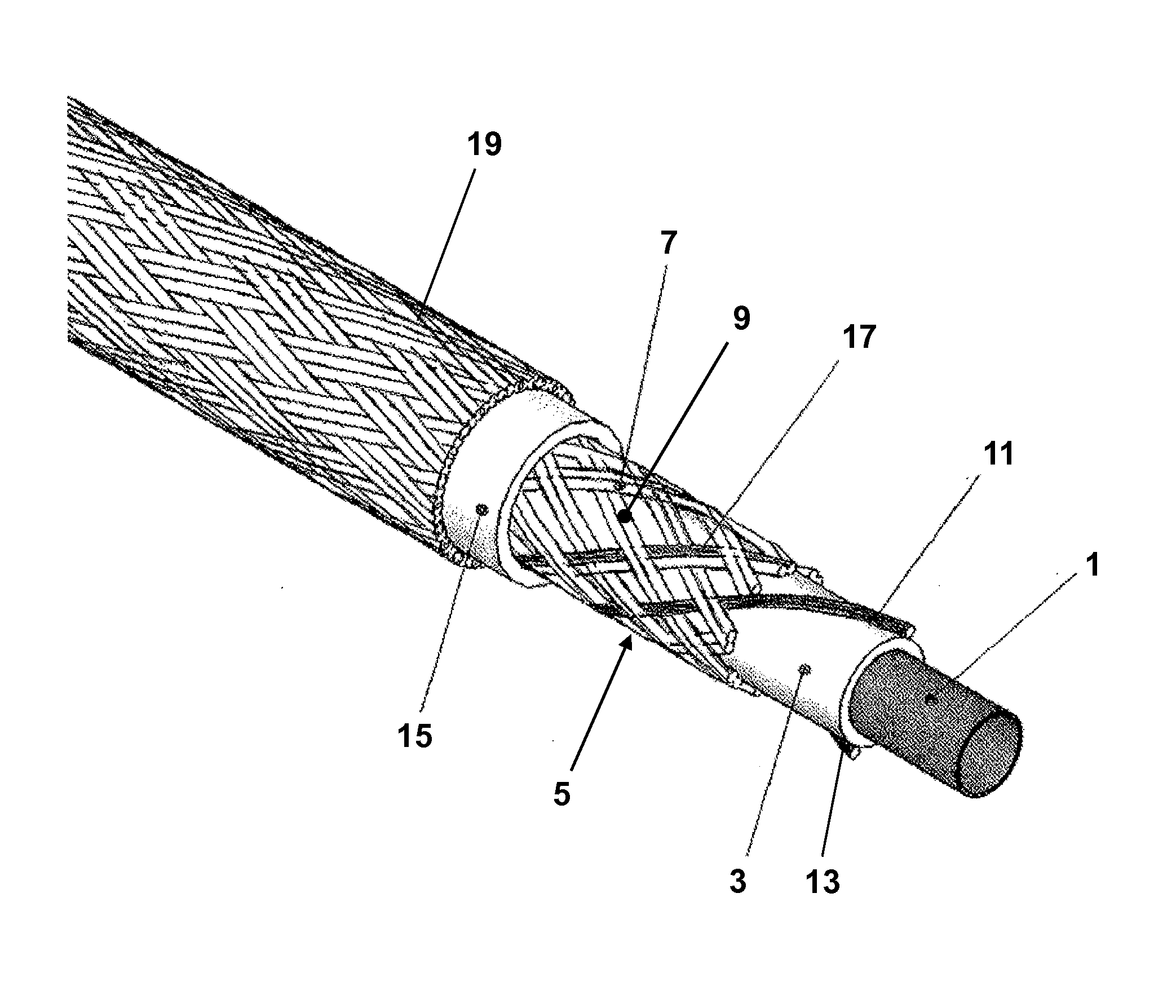

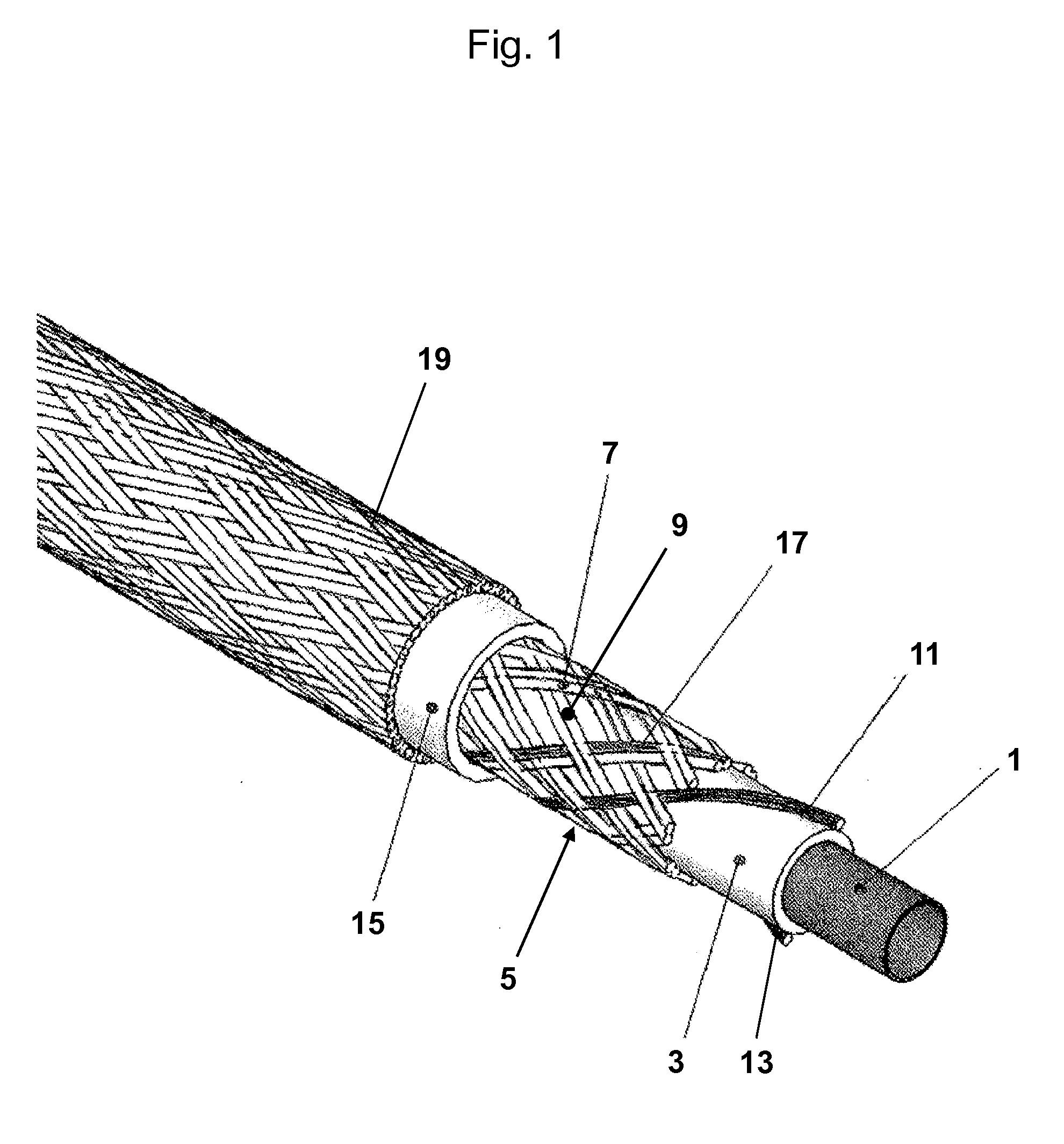

A flexible, electrically heatable hose having an elongated electrical conductor which extends in the helical shape in the hose direction is illustrated and described. The object of providing a flexible, electrically heatable hose in which uniform heating over the hose length is ensured even in the event of major deformation of the hose, is achieved by a hose which has an elongated electrical conductor which extends in a helical shape in the hose direction, wherein the electrical conductor is embedded in a braid. In this case, the braid has first and second strands, wherein the first strands extend in a helical shape in the hose direction in the same winding direction as the electrical conductor, and the second strands extend in a helical shape in the hose direction in the opposite winding direction to the electrical conductor. The pitch angle of the electrical conductor, which extends in a helical shape in the hose direction, of the first strands and of the second strands is in this case between 50° and 80°.

Owner:MASTERFLEX SE

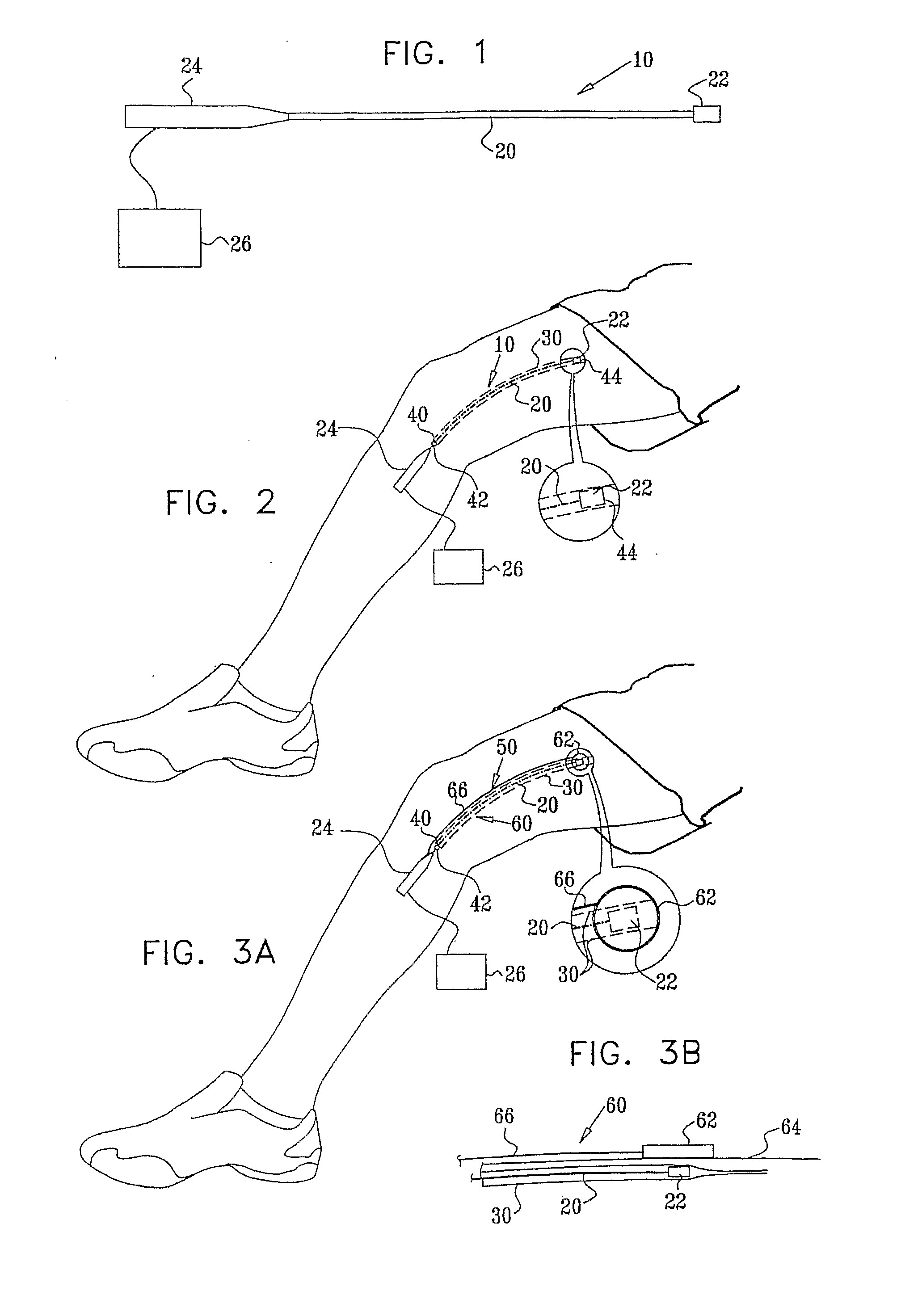

Techniques for Heating-Treating Varicose Veins

InactiveUS20080167643A1ShrinkShorten the construction periodSurgical instruments for heatingElectrical resistance and conductanceVein

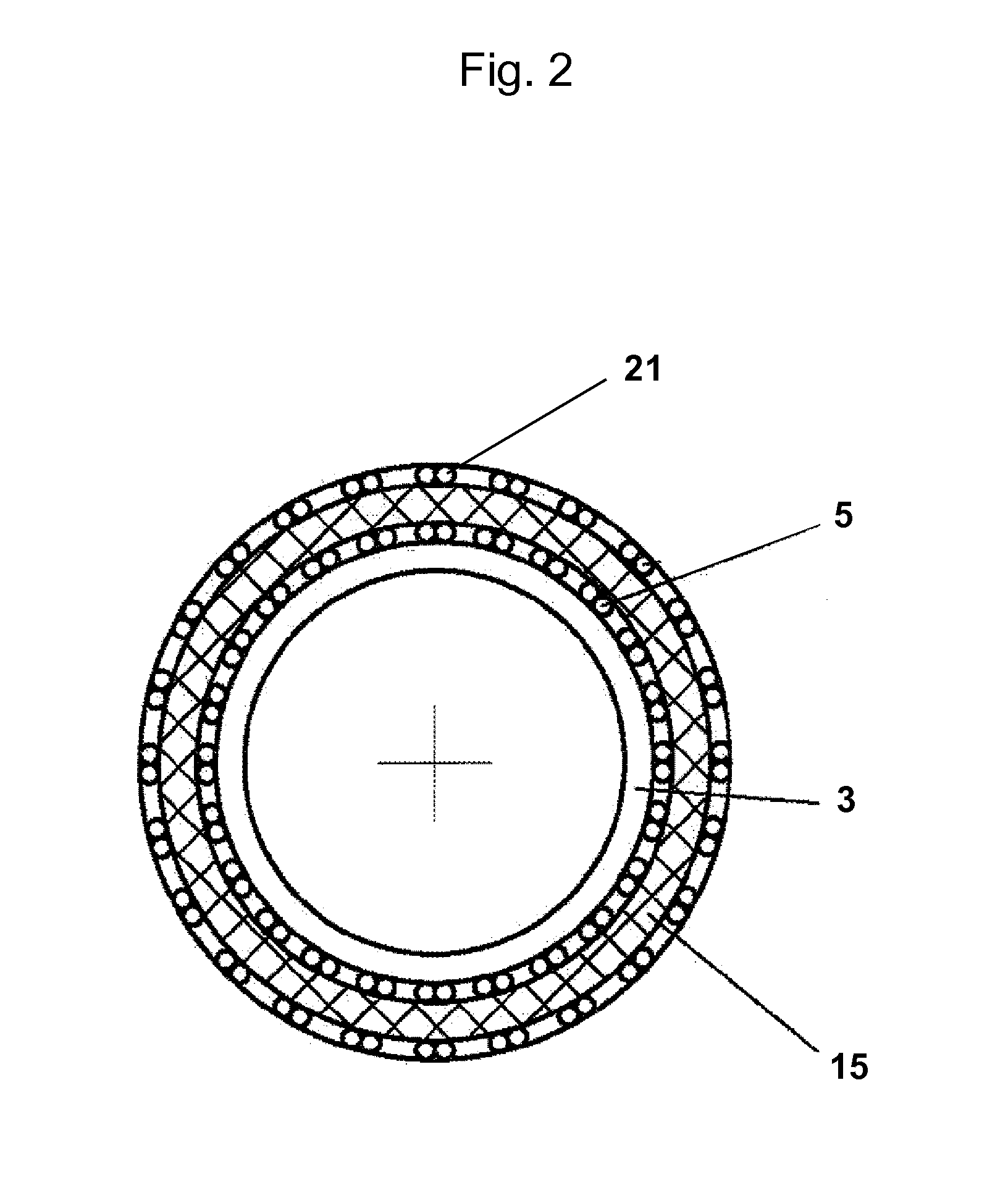

An apparatus for treating varicose veins includes a catheter (20) where the distal end is placed within a varicose vein and the proximal portion remains outside the body of the subject. A heating element (22) heats the vein. A cooling element (62) can be applied to an external surface of the skin above the vicinity of the heating element. A control unit (26) can drive the heating element to apply heat to the vein simultaneously. Alternatively, the control unit can apply a current to the heating element to resistively heat a resistive element. A method for treating a varicose vein includes inserting the elongated heating element into the vein, and driving the heating element to apply heat to the segment of vein simultaneously from the entire active heating portion.

Owner:CARDIODEX

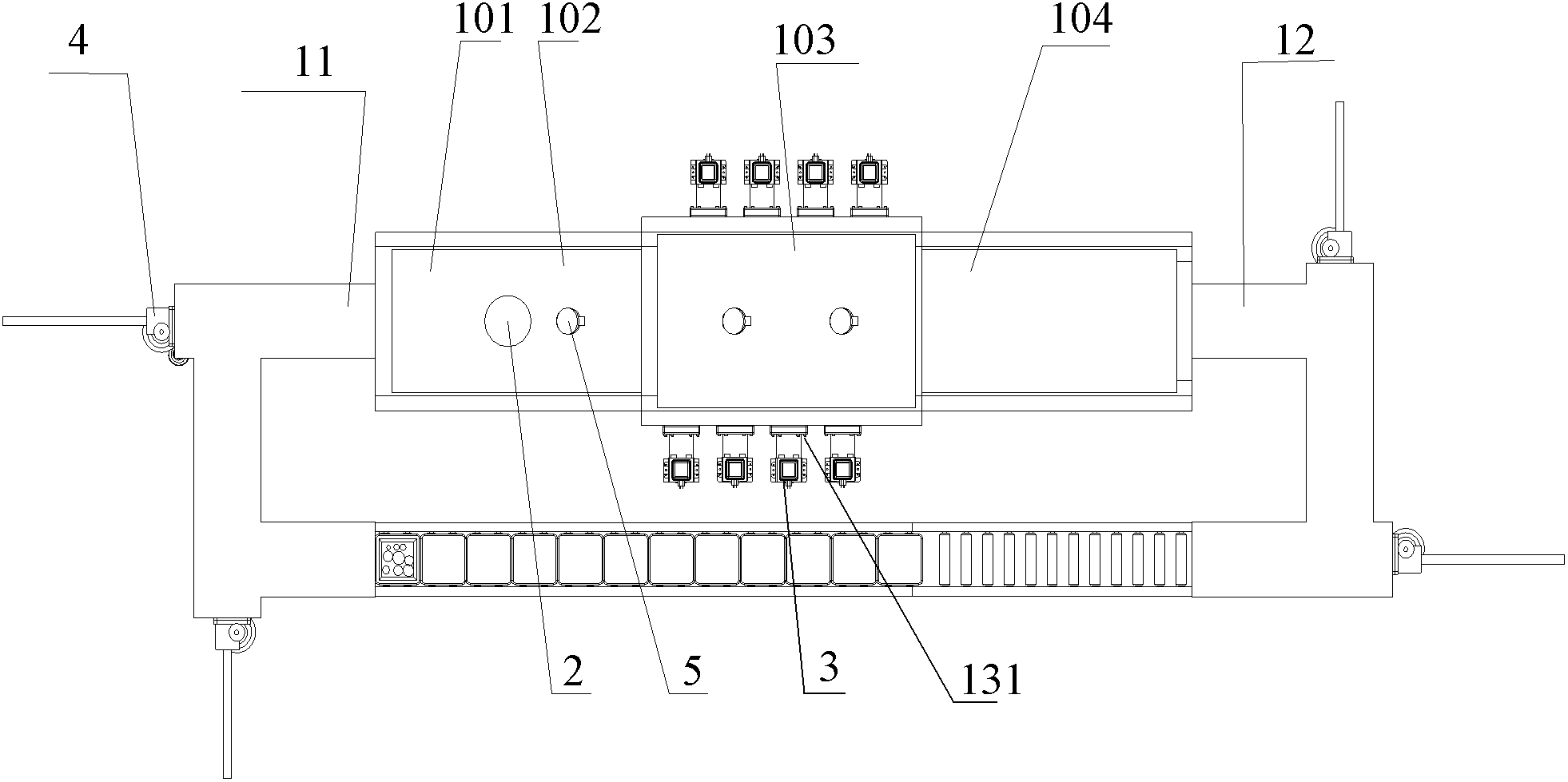

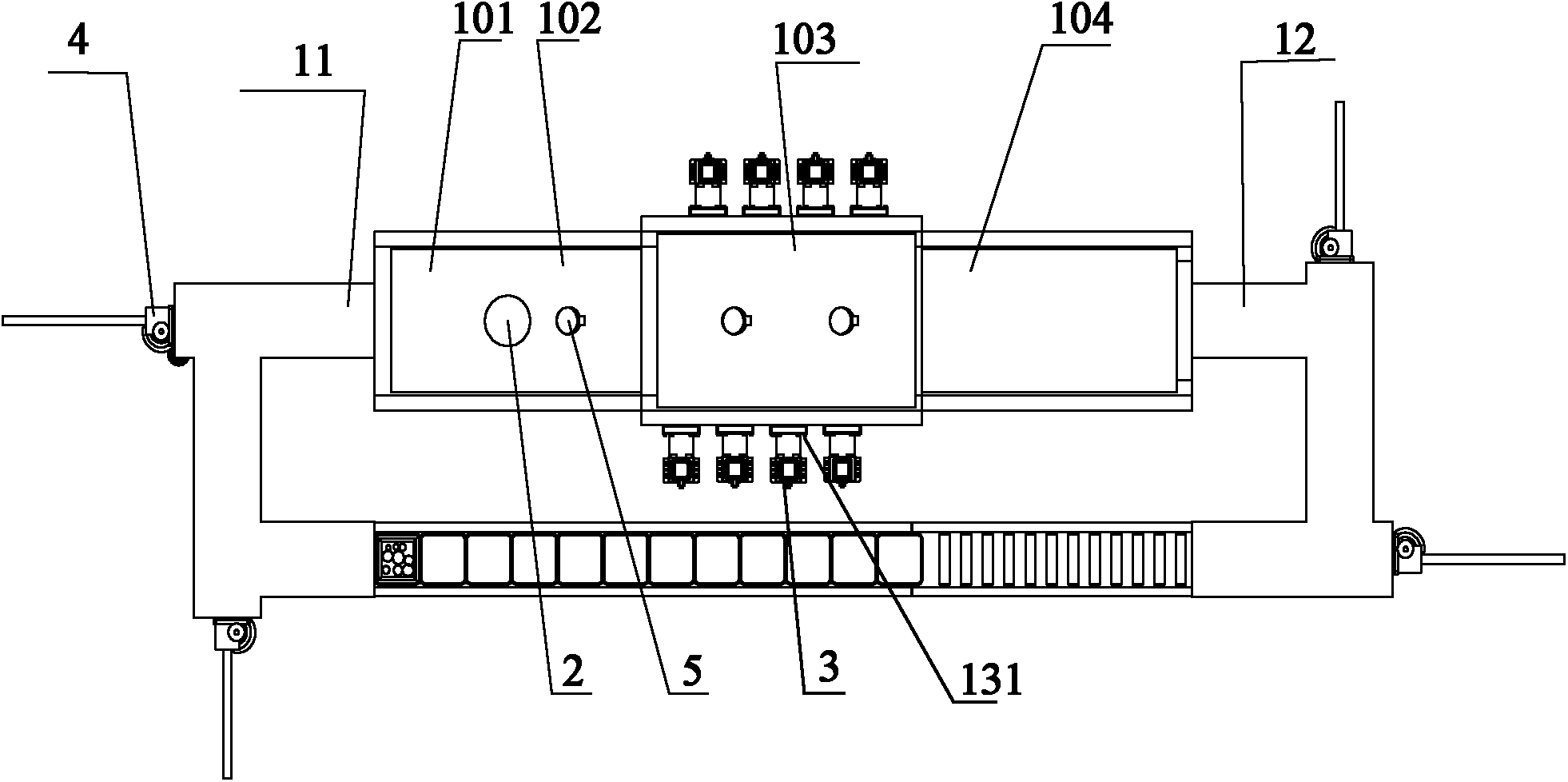

Technique for producing and reducing ilmenite in industrial microwave kiln

InactiveCN102534264AImprove yieldEnsure heating uniformityFluidised-bed furnacesMaterials scienceReducing agent

The invention provides a method for reducing ilmenite, which comprises the following steps: sending ilmenite, a reducer and a desulfurizer, which serve as raw materials, into a microwave high-temperature kiln; sequentially preheating, sintering and cooling; and sequentially pulverizing, screening, carrying out magnetic separation, and carrying out jet mil blending, wherein in the sintering process, microwaves of which the frequency is 2450MHz are emitted to the raw materials until the reduction temperature of the sintering belt in the kiln reaches 600-800 DEG C. In the sintering step, the microwaves of which the frequency is 2450MHz are emitted to the raw materials, so that the raw materials quickly absorb microwave energy from inside to outside, thereby ensuring the integral heating uniformity of the material, enhancing the heating uniformity of the raw materials, enabling the ilmenite to sufficiently participate into the reducing reaction, and being beneficial to enhancing the grade of the product; the microwave heating speed is high, so that the time for reaching the temperature required by the generation of the reducing reaction is shortened, thereby shortening the production cycle and lowering the energy consumption. Therefore, the ilmenite prepared by the method provided by the invention has the characteristics of high product yield and low energy consumption.

Owner:湖南阳东微波科技有限公司

High-quality silicon carbide single crystal, and substrate and efficient preparation method thereof

ActiveCN111118598AQuality improvementLow density defectPolycrystalline material growthFrom condensed vaporsCarbide siliconSemiconductor materials

The invention discloses a high-quality silicon carbide single crystal, and a substrate and an efficient preparation method thereof, and belongs to the field of semiconductor materials. The preparationmethod comprises the following steps: putting raw materials and seed crystals into a crucible, assembling the crucible and a heat preservation structure into a crystal growth furnace, arranging a heating coil assembly at the periphery of the side wall of the crystal growth furnace, and mounting an adjusting mechanism; removing impurities; and growing the crystal, wherein the heating coil assemblycomprises a first coil assembly arranged corresponding to a raw material area and a second coil assembly arranged corresponding to a crystal growth area, and the inner diameter of the second coil assembly is increased in the direction from raw materials to seed crystals. The preparation method of the silicon carbide single crystal is characterized in that the axial temperature gradient in a growth cavity is formed, so the high-quality silicon carbide single crystal can be prepared; the radial temperature gradient in the growth cavity for growing the single crystal is adjusted, so the crystalgrowth rate and the crystal growth quality are improved; and the radial temperature gradient is reduced, and a certain axial temperature gradient can be ensured, so the high-quality silicon carbide single crystal can be efficiently prepared.

Owner:SICC CO LTD

S460G2+M steel plate for seaborne weldable structure and production method thereof

ActiveCN108374122AAchieve economyIncrease production capacityFurnace typesHeat treatment furnacesSteelmakingSlow cooling

The invention discloses an S460G2+M steel plate for a seaborne weldable structure and a production method thereof and relates to the field of metallurgy. The production method comprises the followingsteps: carrying out steelmaking: utilizing a large-section continuous casting blank and adopting a continuous casting blank type C segregation accurate control technology to segregate the center of the continuous casting blank for C0.5 and C1.0 grades; heating: adding the casting blank into a heating furnace and heating, wherein the heating coefficient is greater than or equal to 10.0min / cm and the heating temperature is 1180 to 1220 DEG C; rolling: under a low compression ratio, adopting a two-stage controlled rolling technology, wherein the temperature of first-stage rolling is 980 to 1150 DEG C, the final two-path reduction rate of rough rolling is greater than or equal to 20 percent and the initial rolling temperature of the second stage is less than or equal to 820 DEG C; cooling: putting a rolled steel plate into an ultra-rapid cooling system and rapidly cooling, wherein the re-reddening temperature is 550 to 590 DEG C; then carrying out stacking and slow cooling, wherein the stacking time is 72h or more. The steel plate developed by the invention reach performance requirements of EN10225 standards, and economical and batch production of the steel plate can be realized; utilization requirements under seaborne various working conditions and bad natural environments are met.

Owner:NANJING IRON & STEEL CO LTD

Automatic control hydrogen absorption and desorption system and method for solid hydrogen storage material

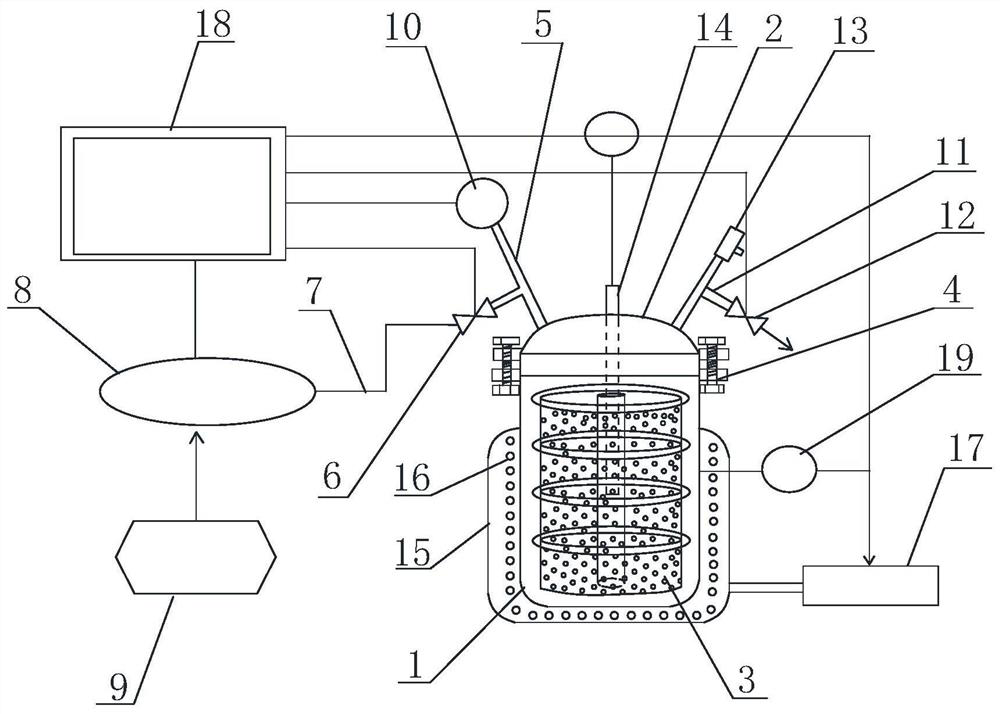

ActiveCN112082087AFast heatingEvenly heatedVessel mounting detailsVessel wallsAutomatic controlHydrogen pressure

The invention discloses an automatic control hydrogen absorption and desorption system for a solid hydrogen storage material. The automatic control hydrogen absorption and desorption system comprisesa hydrogen filling pipe section, a hydrogen desorption pipe section and a stainless steel hydrogen storage tank. The stainless steel hydrogen storage tank comprises a stainless steel tank body and a tank body cover, and a plurality of metal baskets are arranged in the stainless steel tank body. A hydrogen filling hole and a hydrogen desorption hole are formed in the left end and the right end of the tank body cover respectively, and a temperature measuring hole is formed in the middle of the tank body cover. The hydrogen filling hole is connected with a hydrogen compressor through a hydrogen filling pipeline. The hydrogen desorption hole is connected with a hydrogen desorption pipeline. A thermocouple is inserted in the temperature measuring hole, and the lower part of the thermocouple extends into a central pipe. A heat preservation layer is arranged on the outer side of the stainless steel tank body, an electromagnetic heating coil is arranged in the heat preservation layer, and theheat preservation layer and the electromagnetic heating coil form an electromagnetic heating sleeve with a heat preservation function. The hydrogen compressor and the thermocouple are respectively connected with a computer control device. The automatic control hydrogen absorption and desorption system can achieve automatic control of temperature and hydrogen pressure, can be suitable for most solid hydrogen storage materials and has a wide application range.

Owner:SHANDONG UNIV OF SCI & TECH

Technological process for producing manganese oxide mineral powder using industrial microwave furnace

The invention provides a pyrolusite reduction method, comprising the following steps of: mixing the pyrolusite and reductant and agglomerating the mixture to obtain mixtures; feeding the mixtures into a microwave high-temperature kiln to microwave sinter the mixtures at the microwave sintering frequency of 2450MHz and the sintering temperature of 800-900 DEG C; and cooling the sintered mixtures to obtain manganese oxide. The microwave sintering way provides the energy to the reduction reaction and during the sintering process, the mixtures quickly absorb the microwave energy from inwards to outwards, the whole body of the material is uniformly heated, and the heated uniformity of the raw material is improved, thus the pyrolusite completely participates into the reduction reaction and the utilization rate of the raw material is increased. In addition, the heating way makes the mixtures achieve the temperature required by the reduction reaction n short time, furthermore the production period is shortened and the energy consumption is also reduced.

Owner:湖南阳东微波科技有限公司

Active portable welding joint intelligent detector

PendingCN109765267ARealize portable rapid detectionQuick evaluationMaterial flaws investigationInformation processingLuminosity

The invention relates to an active portable welding joint intelligent detector which comprises an active heat source positioned above a welding joint position of a welding workpiece. The upper part ofthe active heat source is connected with an information detection and processing unit by a mounting bracket; a power supply module is respectively connected with the active heat source and the information detection and processing unit so as to provide a power supply to the active heat source and the information detection and processing unit; the information detection and processing unit comprisesan array-type infrared temperature detection module for detecting a temperature of a welding joint and a visible light and depth camera module for detecting luminosity of the welding joint; an information processing module is respectively connected with the array-type infrared temperature detection module and the visible light and depth camera module; and the information processing module is alsosequentially connected with a data storage module and a data transmission module. By the active portable welding joint intelligent detector disclosed by the invention, rapid evaluation on welding quality can be implemented; and compared to existing welding quality evaluation, the evaluation of the active portable welding joint intelligent detector has the advantages of light weight, convenience in carrying and low cost.

Owner:朱清

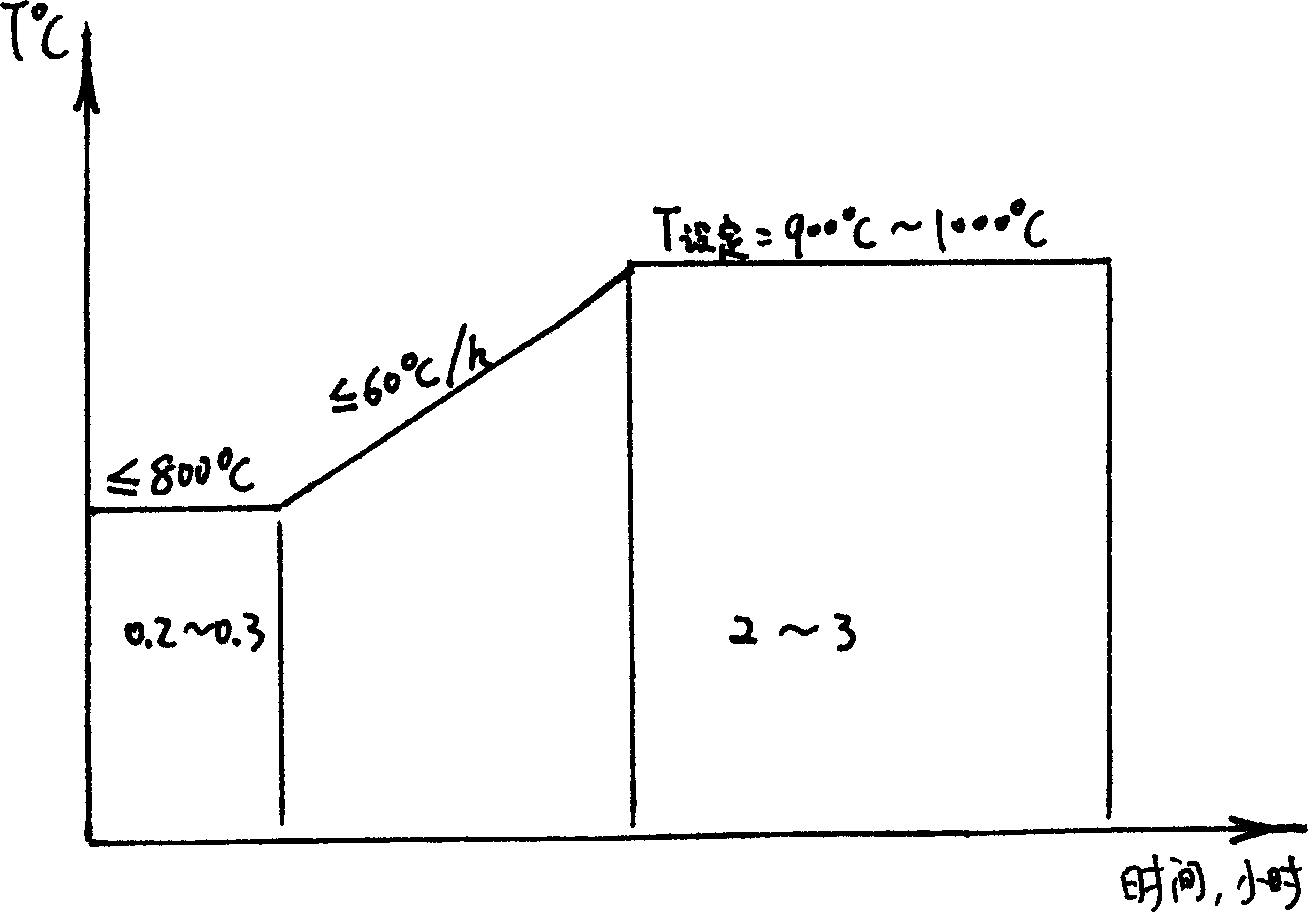

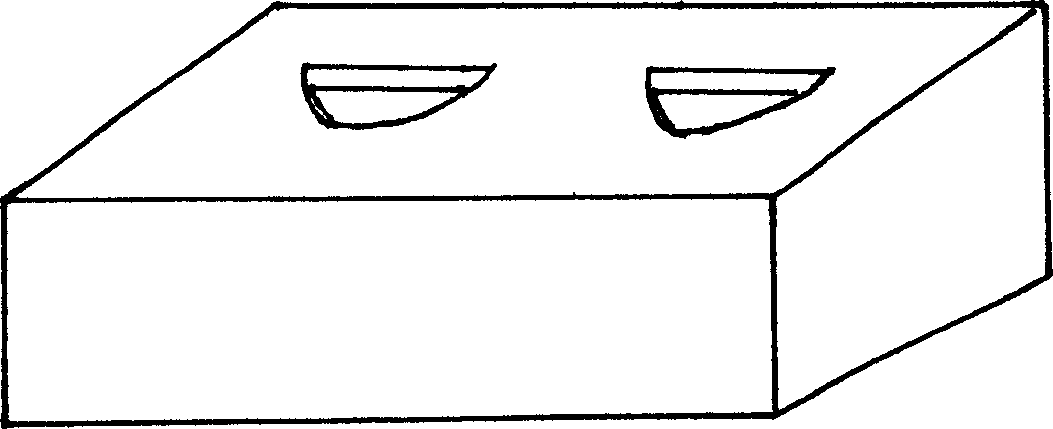

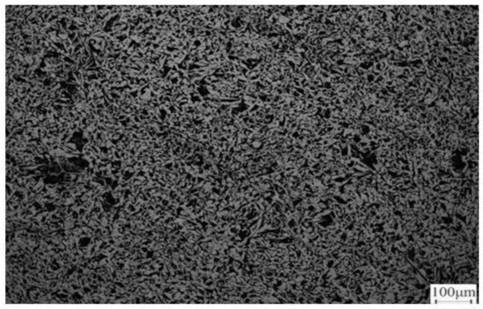

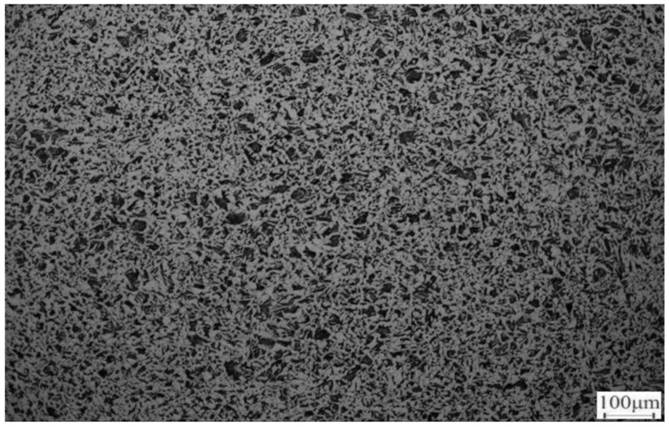

Method for heating titanium and titanium alloy ingot

ActiveCN1609240AEnsure heating uniformitySolve efficiency problemsFurnace typesHeat treatment furnacesTitaniumIngot

The titanium and titanium alloy ingot heating method for cogging of titanium and titanium alloy ingot features the heating of cast ingot in soaking furnace. The heating process includes the steps of: setting isolating block with pits in the surface horizontally on the bottom of soaking furnace; leaning the cast ingot on the furnace wall with one end in the pit while maintaining some interval between adjacent ingots; and heating the ingot through maintaining in the furnace at 800 deg.c for 15 min, heating to set temperature of 900-1000 deg.c in the temperature raising speed of not higher than 60 deg.c / hr and maintaining in the temperature for 2.5 hr before discharging. The present invention has the advantages of low cost, simple technological process, etc.

Owner:宝武特冶钛金科技有限公司

Forging and heat treatment process of C-Mn high-strength steel forge piece for welding structural part

ActiveCN113088790AGuaranteed welding effectHigh strengthMetal-working apparatusProcess efficiency improvementTemperingManufactured material

The invention discloses a forging and heat treatment process of a C-Mn high-strength steel forge piece for a welding structural part. According to the technical scheme, the forging and heat treatment process of the C-Mn high-strength steel forge piece for the welding structural part is characterized by comprising the following steps: step S1, raw materials are smelted, and a steel ingot is obtained; step S2, forging and heating are performed on the steel ingot; step S3, steel ingot forging is carried out, wherein the forging process comprises two heating numbers: (1) the first heating number: the forging temperature is 1180-1220 DEG C; and (2) the second heating number: the forging temperature is 1150-1180 DEG C; step S4, heat treatment after forging is performed, specifically, (1) forging piece tempering and normalizing are performed; and (2) mechanical rough machining is carried out on the forge piece; and step S5, performance heat treatment is carried out on the forge piece, wherein the performance heat treatment comprises the following steps: (1) quenching and tempering treatment is performed: the forge piece is heated to 900-920 DEG C; and (2) tempering treatment is performed, specifically, the forge piece is heated to the tempering temperature of 480-520 DEG C, and then heat preservation is performed. The invention has the beneficial effects that: by improving the inherent quality of the forge piece, refining grains and improving the heat treatment effect, it is guaranteed that the overall mechanical performance of the product is improved, structure non-uniformity is eliminated, and various performance indexes are greatly provided.

Owner:无锡继平新材料科技有限公司

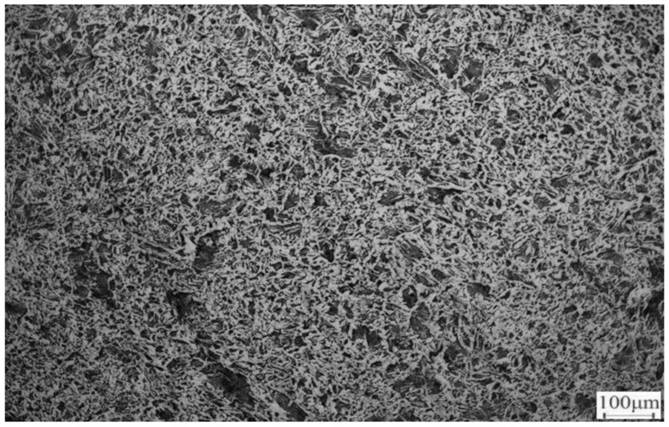

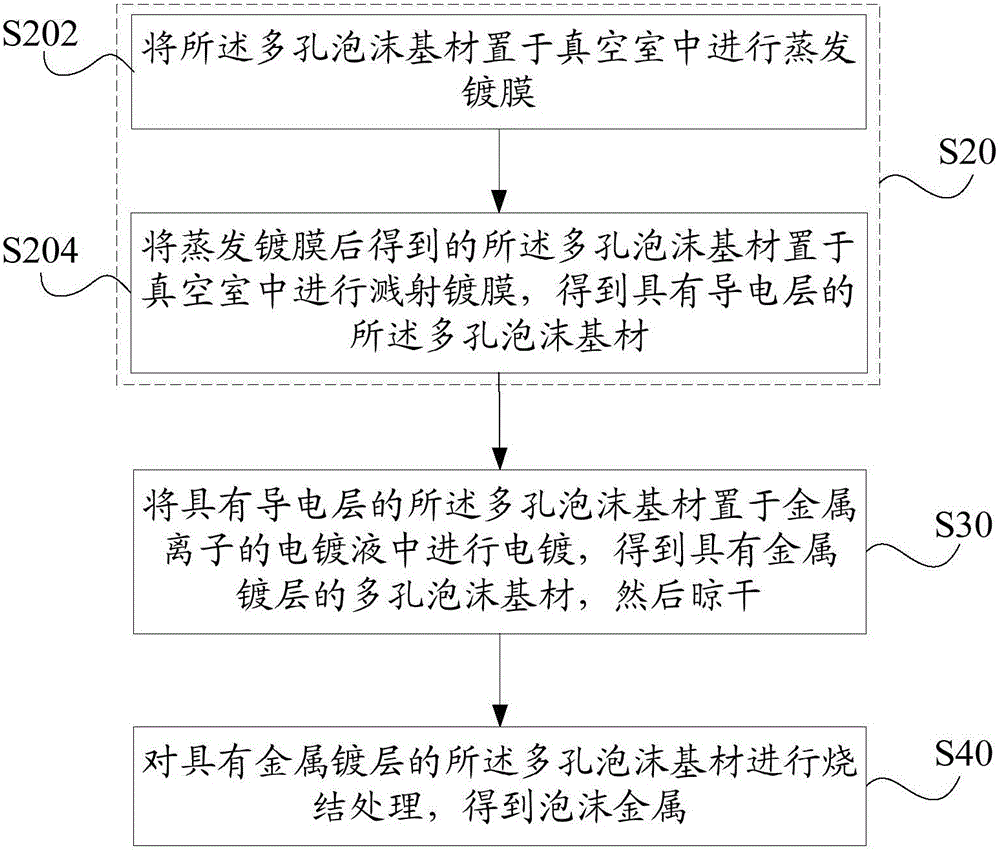

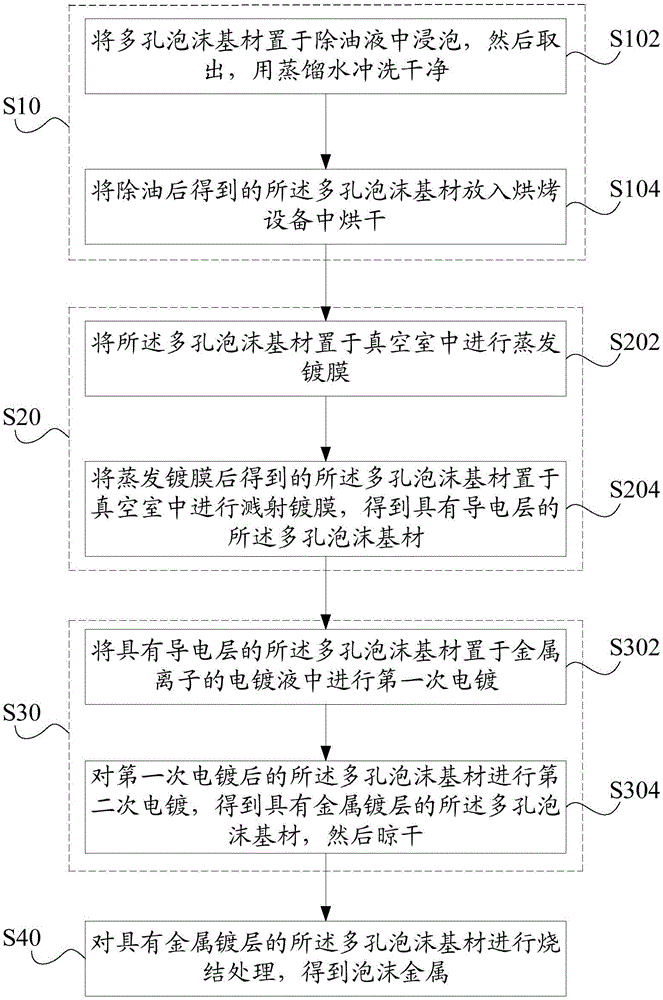

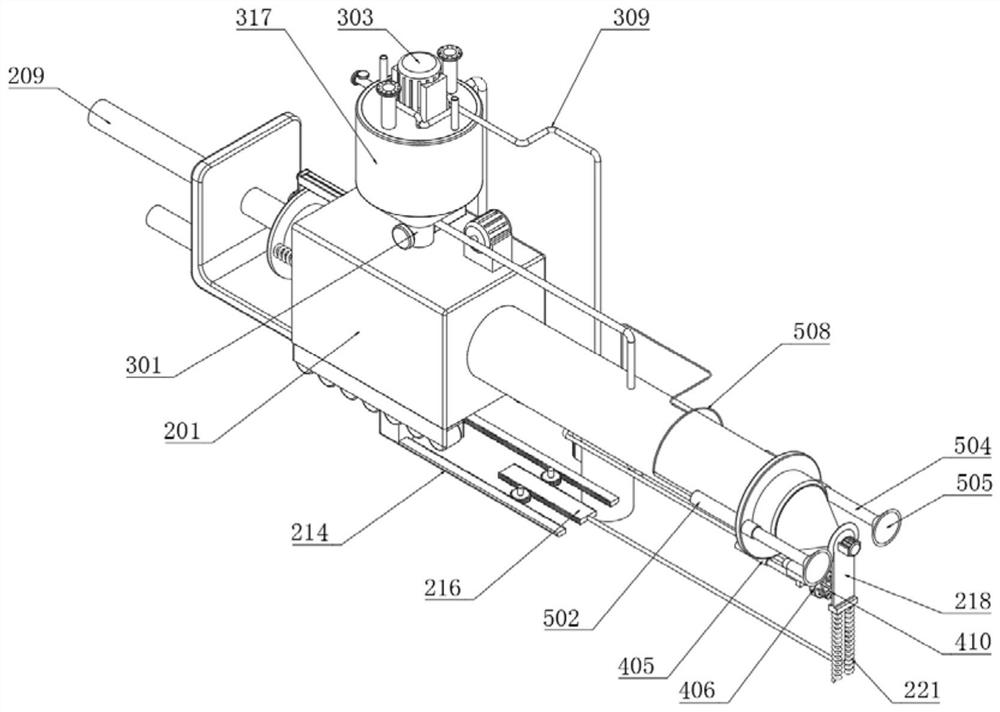

Foam metal, preparation method thereof and cookware

InactiveCN105970157ASimple manufacturing processQuality improvementVacuum evaporation coatingSputtering coatingMetal coatingSputtering

The invention provides foam metal, a preparation method thereof and cookware. The preparation method of the foam metal comprises the steps that S20, a porous foam substrate is placed in a vacuum chamber for metal coating, and the porous foam substrate with an electrical conductive layer is obtained; S30, the porous foam substrate with the electrical conductive layer is placed in an electroplating solution of metal ions for electroplating, and the porous foam substrate with a metal coating is obtained and aired; and S40, the porous foam substrate with the metal coating is subjected to sintering treatment, and foam metal is obtained. The step S20 specifically comprises the procedures that S202, the porous foam substrate is placed in the vacuum chamber for evaporation coating; and S204, the porous foam substrate obtained after evaporation coating is placed in the vacuum chamber for sputtering coating, and the porous foam substrate with the electrical conductive layer is obtained. According to the foam metal, the preparation method thereof and the cookware, the electrical conductive layer is prepared through vacuum evaporation coating and vacuum sputtering coating, so that the preparation process of the foam metal is simplified, and the quality of the foam metal is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Anti-blocking injection molding machine

The invention discloses an anti-blocking injection molding machine is characterized in that an injection molding gun barrel is welded to one end of a supporting entering box, a conveying auger is welded to the side end of a movable transmission rod, a movable supporting barrel is welded to one end of a clamping sealing block, a reset spring is welded to one end of the movable supporting barrel, and an auxiliary moving block is welded to the bottom end of the supporting entering box; and a driving rack is welded to one end of the auxiliary moving block, a cleaning plate is rotationally connected to one end of a sliding moving plate, a pushing electromagnet is installed on the inner side of a sliding cavity, a pushing spring is welded to one end of the inner side of the sliding cavity, and an anti-blocking column is welded to one end of the pushing spring. The conveying auger and a reverse flow preventing threaded column drive a raw material to move and prevent the raw material from backflow, the hollow situation is avoided, and a contact switch controls the opening and closing of the pushing electromagnet, so that the anti-blocking column can be quickly reset when needing to be reset, and the discharge port is sealed while the requirement for discharging solidified raw materials at the discharge port position is met.

Owner:姚新耿

Processing technology of silk

ActiveCN108149331AReduce adhesive forceAvoid damageAnimal materialDe-gumming silkSofteningDehydration

The invention discloses a processing technology of silk. The processing technology aims at improving the quality of the silk. The processing technology is characterized by comprising the following steps of high-temperature cocoon cooking, reeling of raw silk from cocoons, degumming, softening, dehydration and drying. The silk produced by the processing technology of the silk is smooth in surface,soft in hand feeling, pure in color and higher in quality.

Owner:桐乡瑞梦蚕桑科技有限公司

Silicon carbide single crystal, substrate and preparation method thereof

ActiveCN111074340AQuality improvementReduce defectsPolycrystalline material growthFrom condensed vaporsSemiconductor materialsInsulation layer

The invention discloses a silicon carbide single crystal, a substrate and a preparation method thereof, which belongs to the field of semiconductor materials. The preparation method of the silicon carbide single crystal comprises the following steps: forming a low-temperature region and a high-temperature region in a crucible by virtue of a temperature measuring hole formed in an upper thermal insulation layer group outside the crucible, and transmitting a raw material gas phase in the low-temperature region to the surface of a seed crystal in the high-temperature region by virtue of a physical gas phase transmission method to grow the crystal; wherein the upper heat preservation layer set comprises a second heat preservation layer and a first heat preservation layer which are sequentiallyarranged in the seed crystal direction of raw materials. The first heat preservation layer is provided with a first opening, the second heat preservation layer is provided with a second opening, anda rotary adjusting mechanism rotates the first heat preservation layer and / or the second heat preservation layer to adjust the cross sectional area of a temperature measuring hole formed by the firstopening and the second opening, so that the axial and radial temperature gradient in the crucible in the crystal growth process is adjusted. According to the preparation method of the silicon carbidesingle crystal, the radial temperature gradient in a growth cavity for growing the single crystal can be adjusted; and while the radial temperature gradient is reduced, a certain axial temperature gradient is ensured, and the high-quality silicon carbide single crystal is efficiently prepared.

Owner:SICC CO LTD

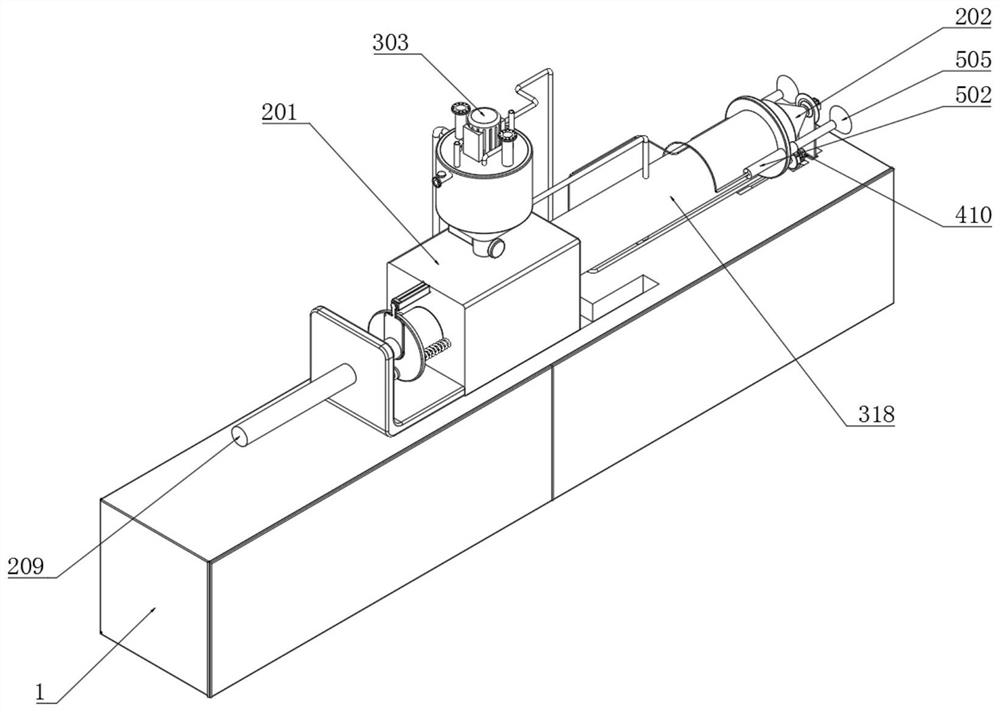

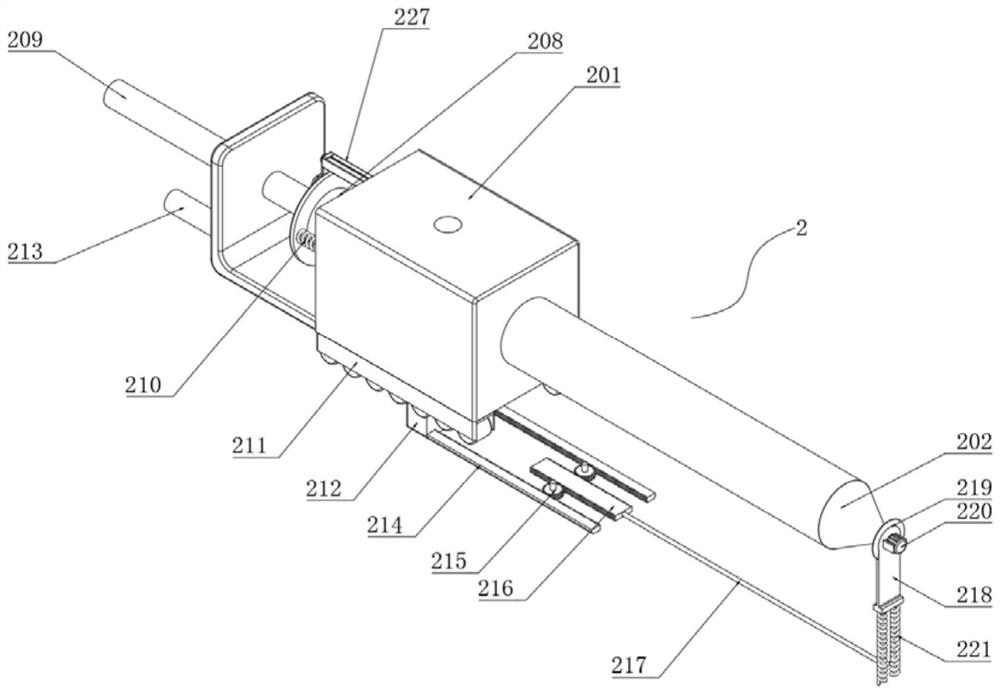

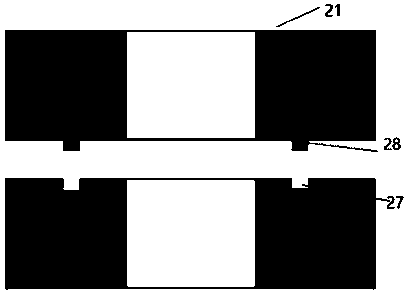

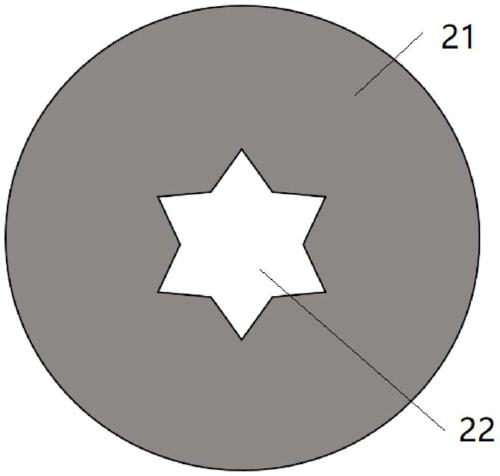

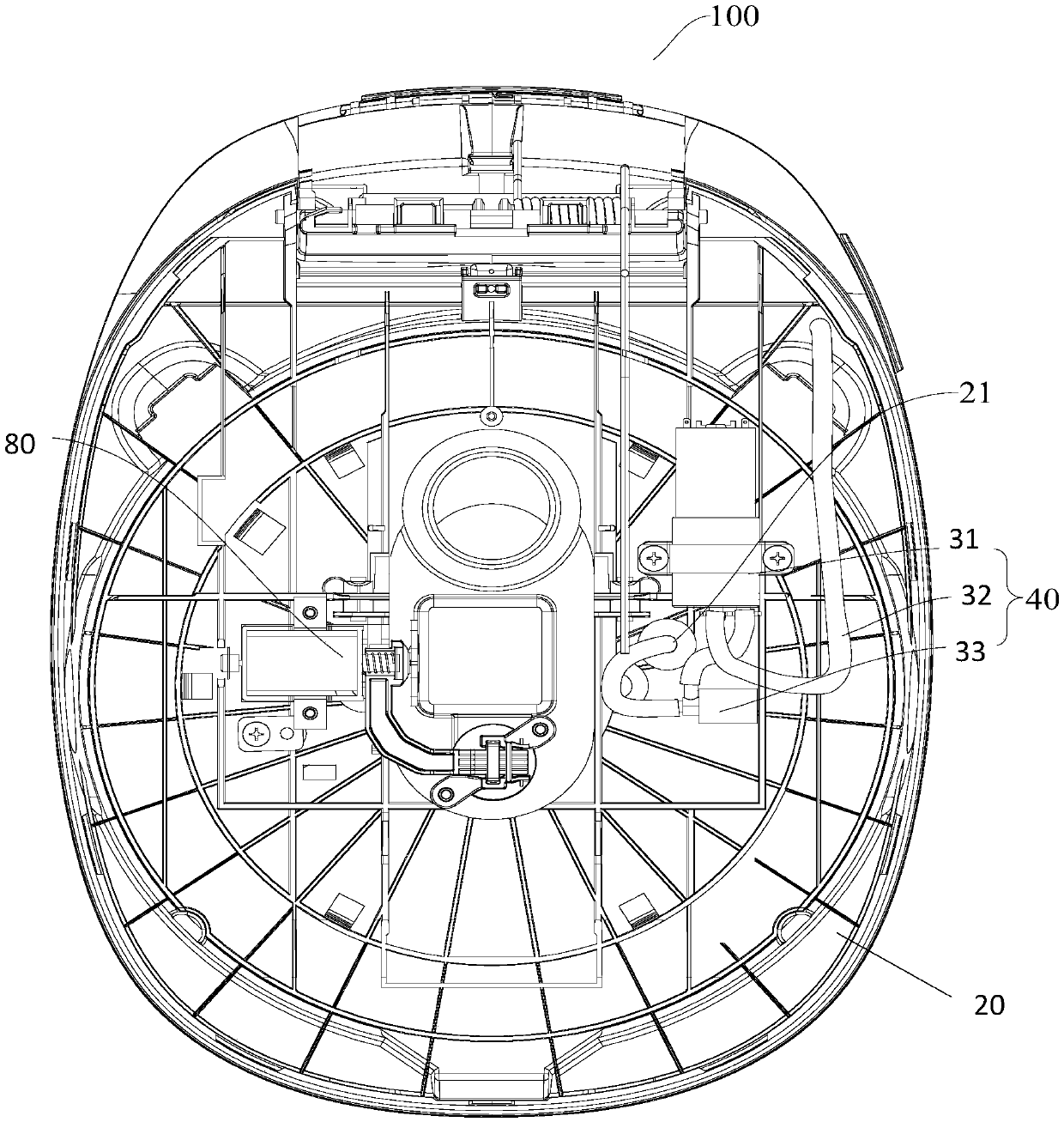

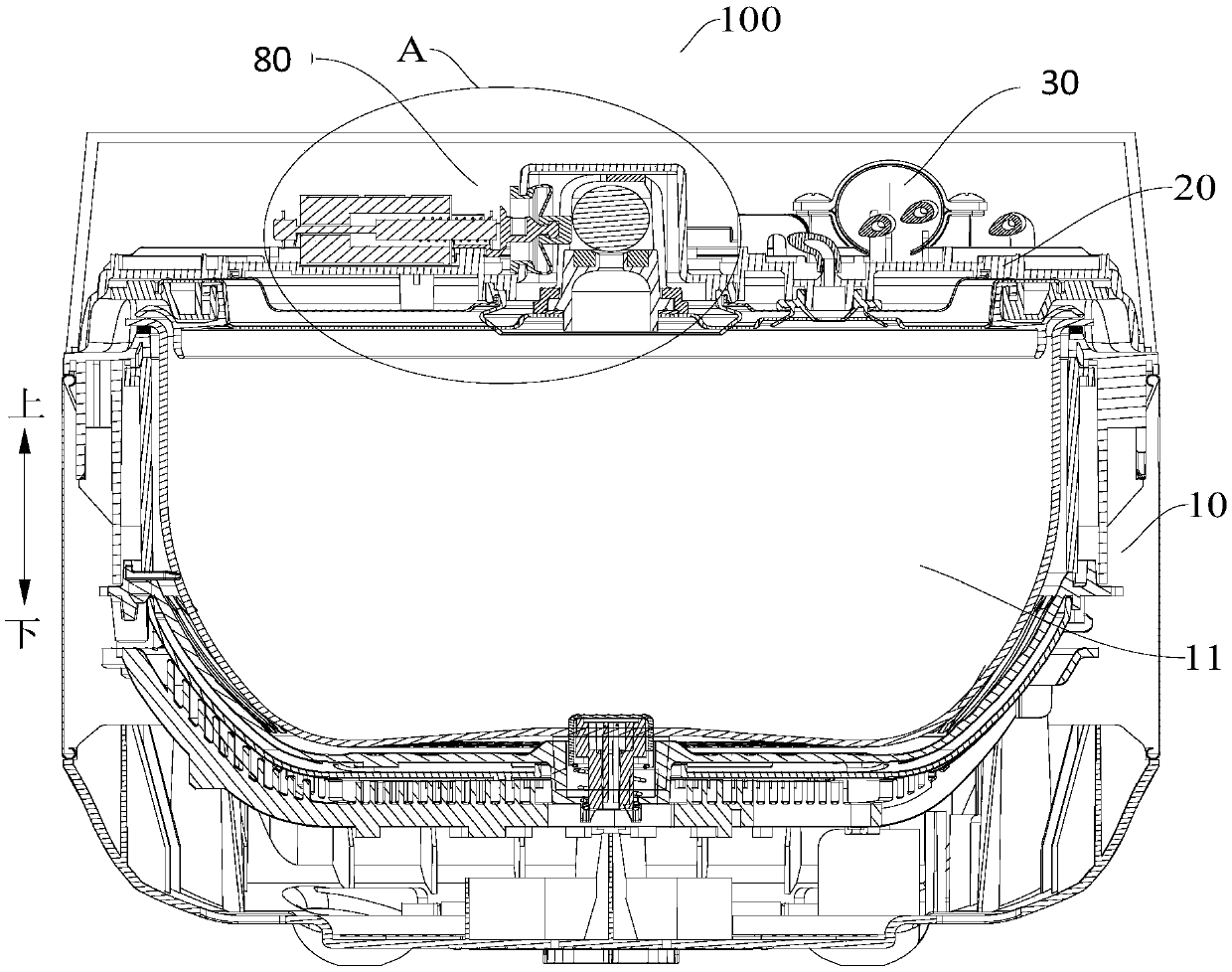

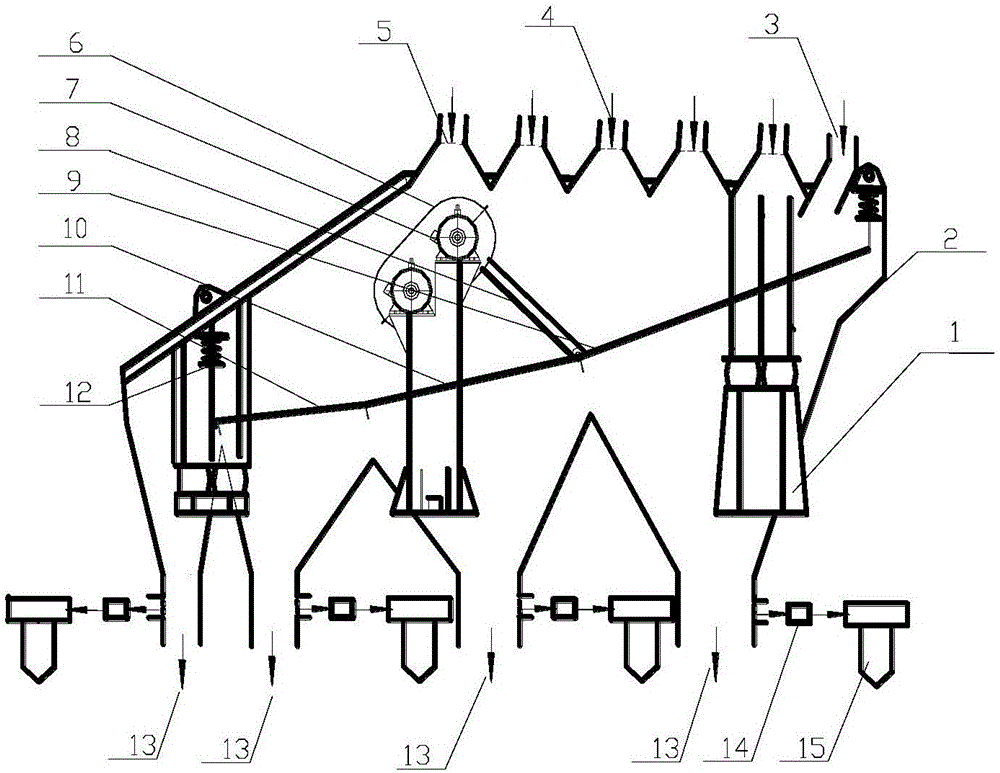

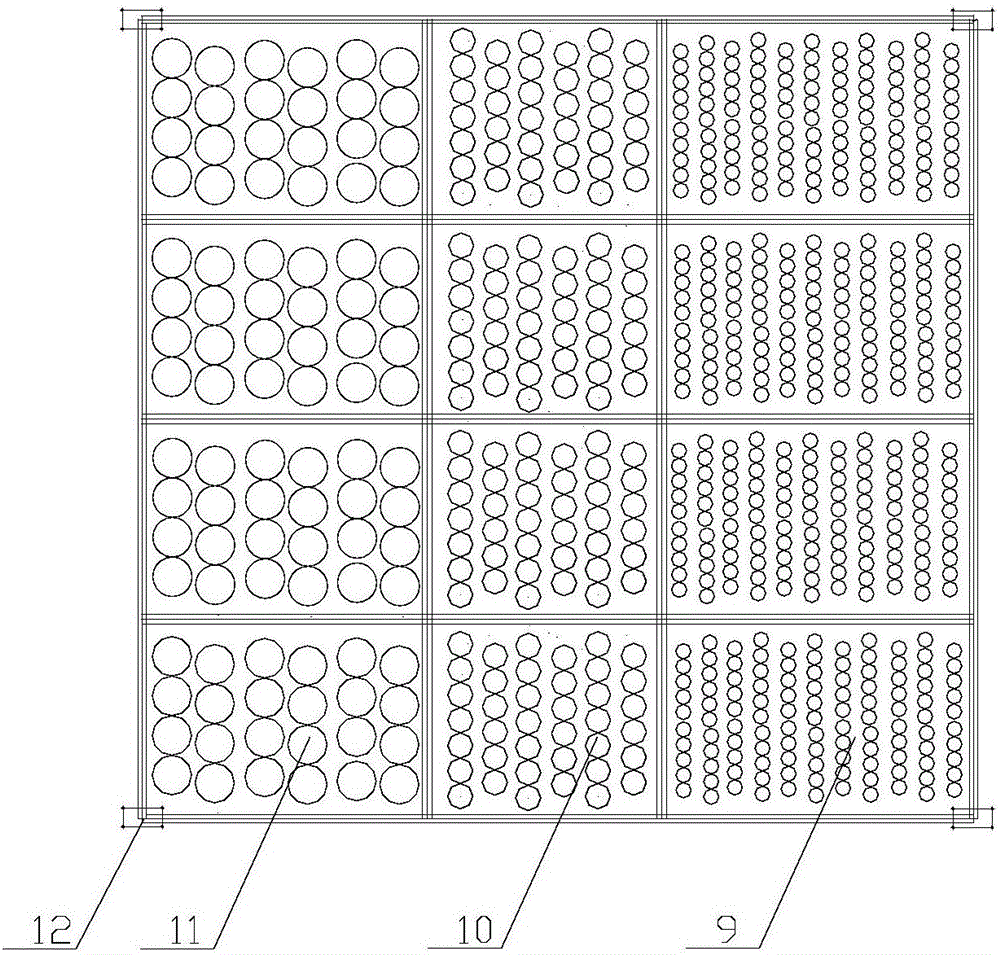

Automatic noodle cooking machine

ActiveCN109744854AGuaranteed heating efficiencyEnsure heating uniformityWater-bath cooking vesselsMechanical engineeringEngineering

The invention discloses an automatic noodle cooking machine, which comprises a frame, a noodle pot, a rotating circular disk, noodle buckets, noodle bucket brackets and a lifting mechanism, wherein the rotating circular disk and the noodle pot are mounted at the top and bottom of the frame respectively; the rotating circular disk is driven through a rotation drive mechanism to rotate around the center of the rotating circular disk; the noodle buckets are mounted on the periphery of the rotating circular disk through the noodle bucket brackets; the noodle bucket brackets comprise fixed bracketsand moving brackets; the noodle buckets are mounted on the moving brackets through rotating pins; the moving brackets are mounted on the fixed brackets through slipping pairs; the fixed brackets aremounted on the rotating circular disk; the front ends of the fixed brackets are provided with noodle bucket turnover brackets which can be in contact with the front ends of the noodle buckets; and thelifting mechanism is mounted on the frame, and is used for upwards lifting the moving brackets. According to the automatic noodle cooking machine, the noodle buckets are driven, by utilizing the rotating circular disk, to rotate for uniform heating; the automatic discharge of the noodle buckets can be achieved through the lifting mechanism; the noodle cooking efficiency is high; the speed is large; and the automatic noodle cooking machine has high market popularization and application value.

Owner:WUHAN UNIV OF TECH

Hot-gas welding plastic welding equipment and welding method

The invention provides hot-gas welding plastic welding equipment and a welding method. The equipment comprises a base, on which a first frame, a second frame, a third frame and a fourth frame are arranged, wherein a lower slide table and an upper slide table are arranged on the first frame and the second frame, the upper end of the lower slide table is provided with an upper mold clamp, the lowerend of the upper slide table is provided with a lower mold clamp, the third frame and the fourth frame are provided with a middle slide table used to occupy or avoid space positions among the lower slide table and the upper slide table and the lower slide table, and a nitrogen heating middle mold is arranged on the middle slide table. When welding with hot gas welding plastic welding equipment, there is no such problem of poor welding quality after the hot plate is contaminated by plastic parts in hot plate welding, and there is no such problem of friction debris in the process of vibration friction welding. Heated nitrogen is used to heat the welding surface of an upper plastic part and a lower plastic part to the welding temperature for welding then, which costs less than the laser welding. And as long as it is a plastic part, the plastic part can be welded by the equipment to expand the application range of the equipment.

Owner:长春超维智能设备制造有限公司

Method for soaking and germinating watermelon seeds

InactiveCN106258066AAvoid inactivationEnsure heating uniformitySeed and root treatmentMicrowaveTwo step

The invention discloses a method for soaking and germinating watermelon seeds, and relates to the technical field of seed treatment. The method comprises two steps of soaking seeds and germinating. According to the method, the soaking time can be shortened by utilizing an ultrasonic assisting method during seed soaking, and mucilage on the seed surface can be removed by ultrasonic treatment, so that extra labor cost can be reduced; two modes including hot air and microwave are adopted to germinate during seed germination so as to shorten the germinating time; and seeds are prevented from being suddenly heated due to local heating during germination by utilizing the arrangement of a screen and padding, so that the seed germination rate can be sufficiently improved.

Owner:巢湖市种子协会

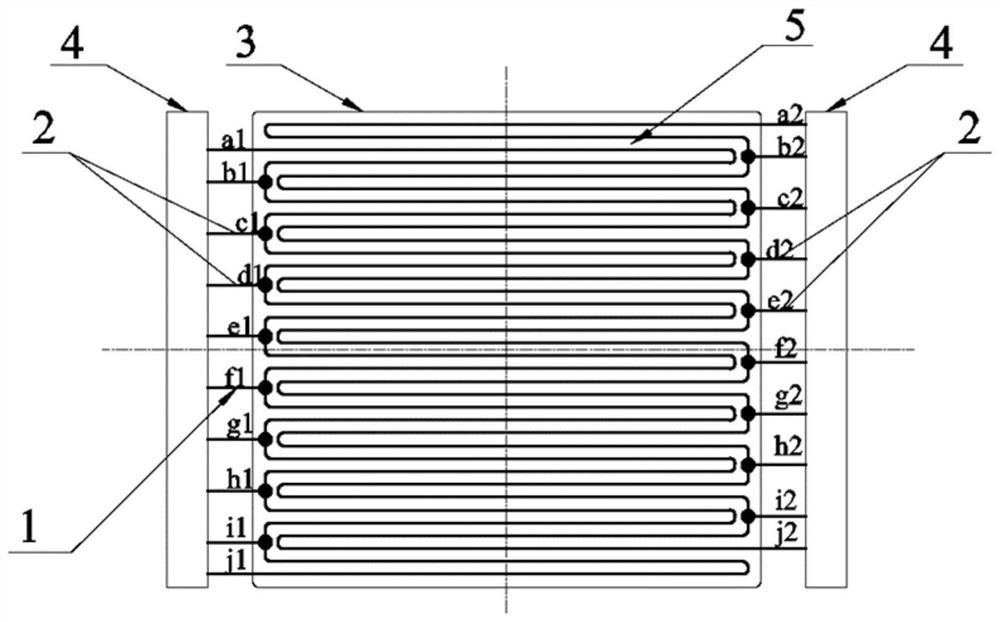

Battery heating film with variable heating power, and lithium ion battery

InactiveCN112333861AExpand the scope of workEnsure heating uniformitySecondary cellsHeating element materialsHeating filmThermal circuit

The embodiment of the invention provides a battery heating film with variable power, and a lithium ion battery. The battery heating film with variable power comprises an upper insulating coating layer, a lower insulating coating layer and a heating layer arranged between the upper insulating coating layer and the lower insulating coating layer, the heating layer comprises a plurality of heating loops, and the plurality of heating loops are composed of resistance wires and leading-out wires. The leading-out wires are arranged at the end parts and the middle parts of the resistance wires. According to the technical scheme, the battery in a low-temperature environment is heated through the battery heating film, so that the working range of the battery is expanded; the variable heating power realized by adopting the plurality of heating loops and a switching-on method can quickly reach the optimal working temperature of the battery with the most suitable heating power and heating resistance value in different low-temperature ranges; the heating loops are reasonably distributed in the heating film, so that the heating uniformity of the heating film under different heating powers is ensured; and the resistance wires forming the heating loops can be different in thickness, namely resistance wires with different resistance values, according to different battery models.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

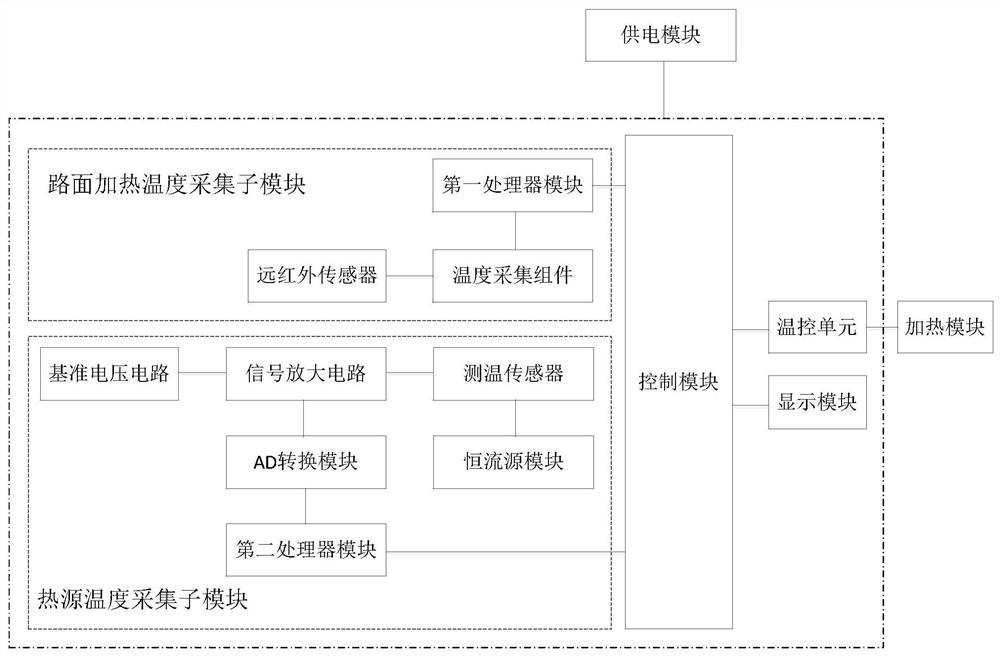

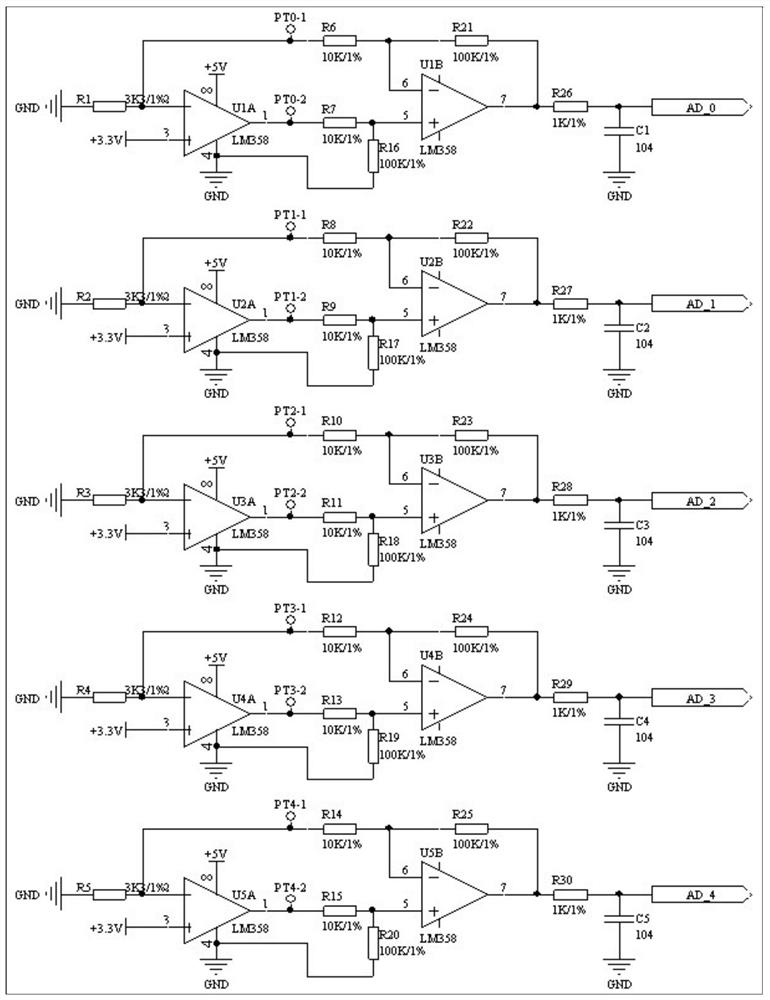

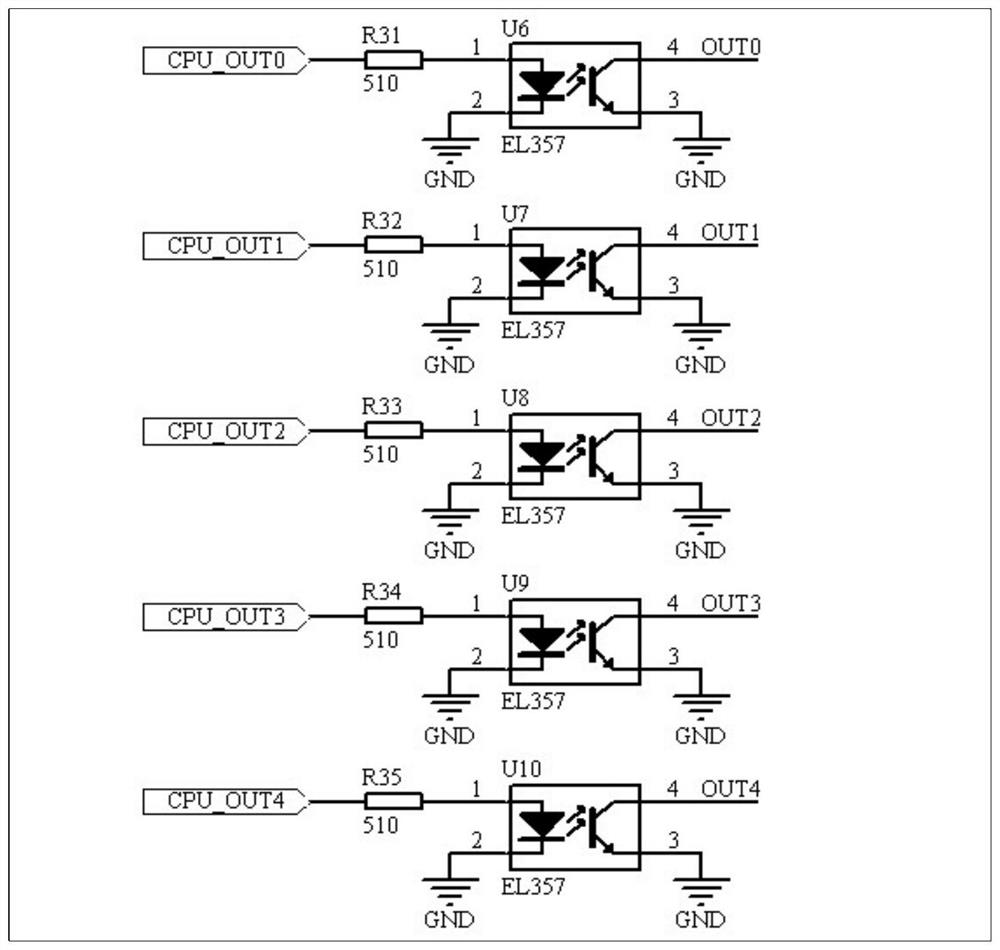

Hot in-place recycling heating temperature control system and control method

InactiveCN111794070AGuaranteed accuracyEnsure heating uniformityTemperatue controlRoads maintainenceReal time acquisitionProcess engineering

The invention relates to a hot in-place recycling heating temperature control system and a control method. The hot in-place recycling heating temperature control system comprises a control module, a first data acquisition module, a second data acquisition module and a heating device, wherein the first data acquisition module is suitable for acquiring pavement heating data in real time; the seconddata acquisition module is suitable for acquiring the heating temperature of the heating device in real time; the control module is suitable for obtaining the temperature of a heat source needing to be heated and controlling the heating device to heat the road surface; and the control module is suitable for comparing the temperature of the heat source needing to be heated with the heating temperature acquired in real time so as to control the heating device to adjust the heating temperature of the road surface in real time. According to the invention, the temperature of the heat source needingto be heated is obtained by acquiring the road surface heating data and the preset heating temperature needed by the road surface, the heating temperature is automatically adjusted by the heating device by comparing the temperature of the heat source with the heating temperature, and the quality and efficiency of road surface heating construction are improved.

Owner:JSTI GRP CO LTD

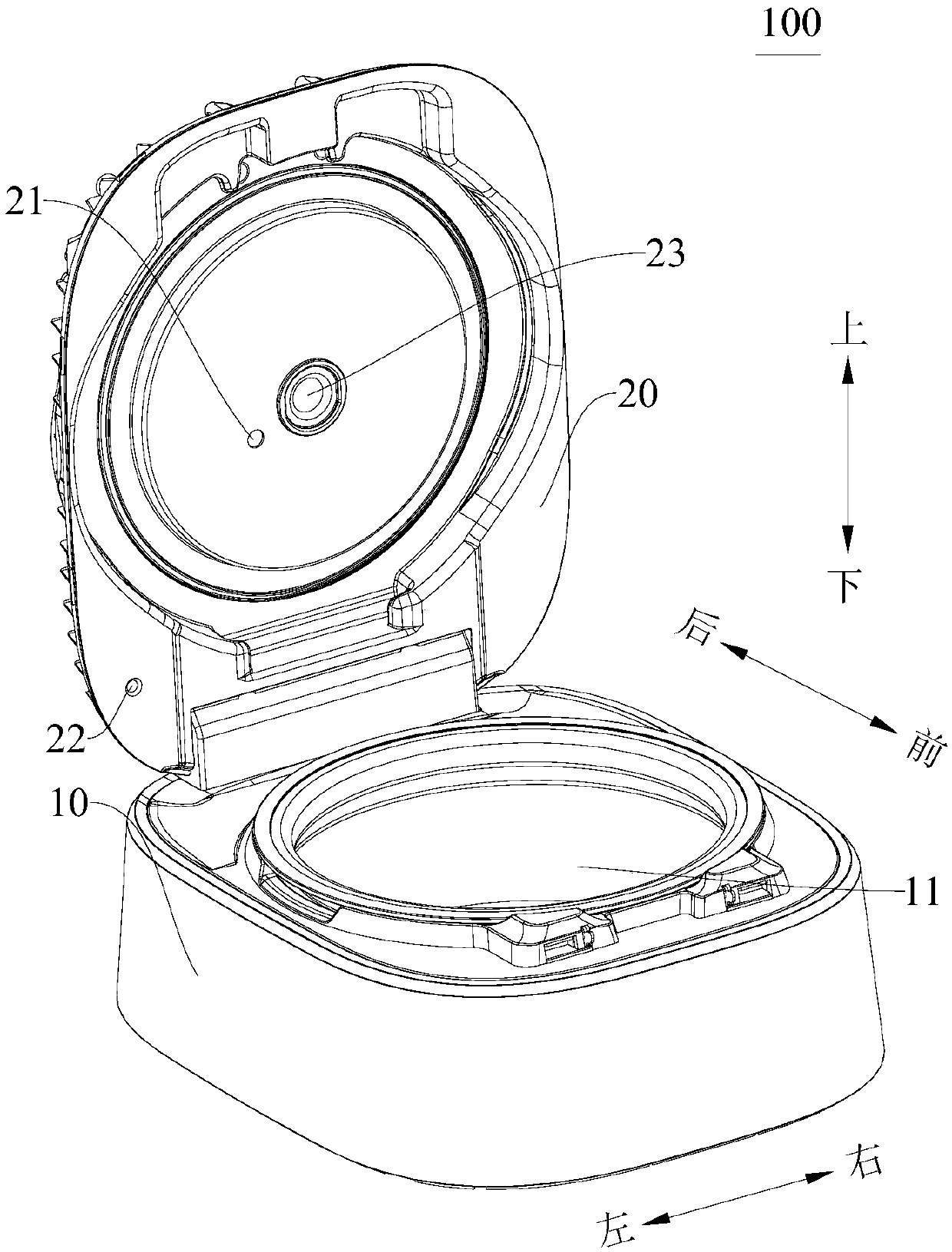

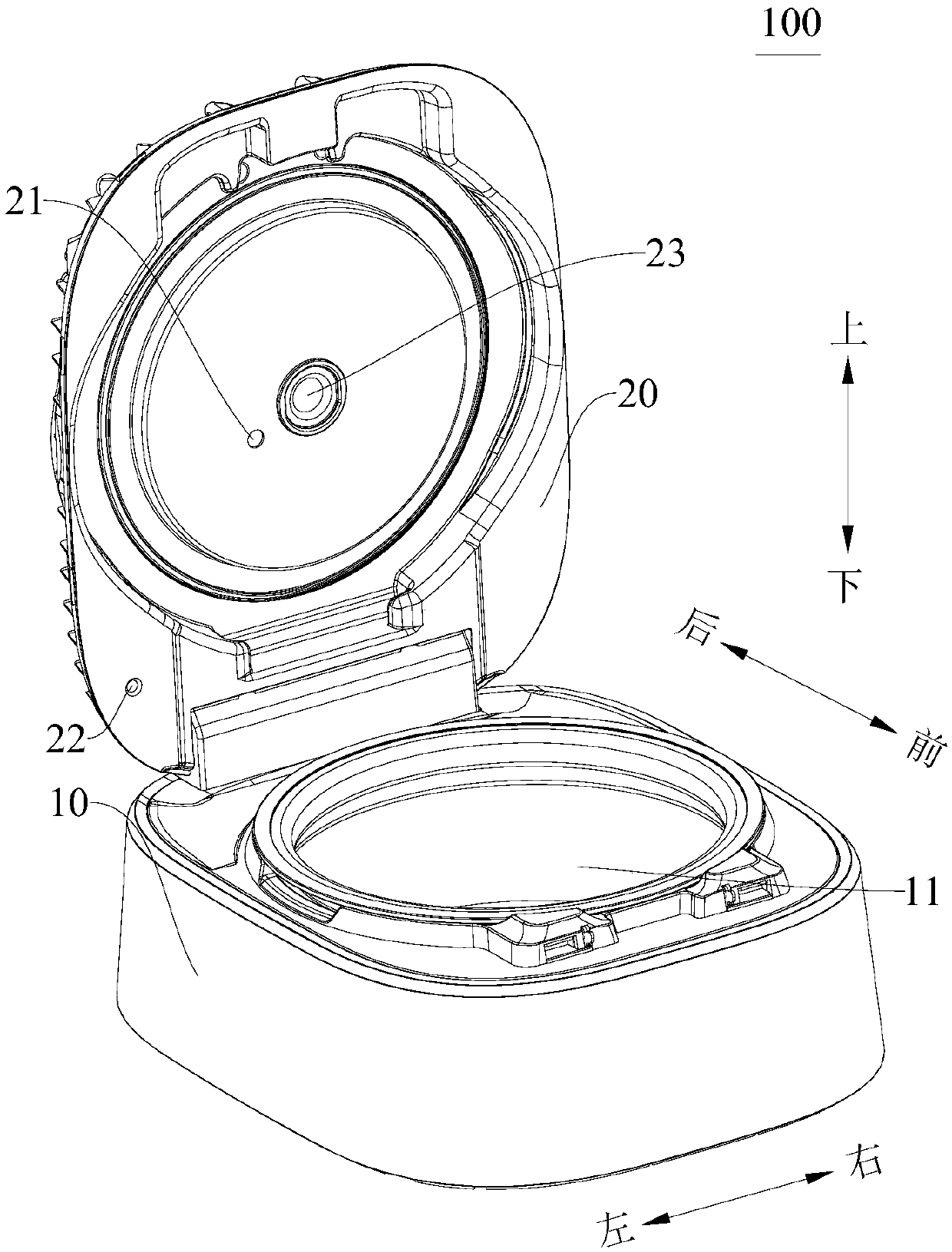

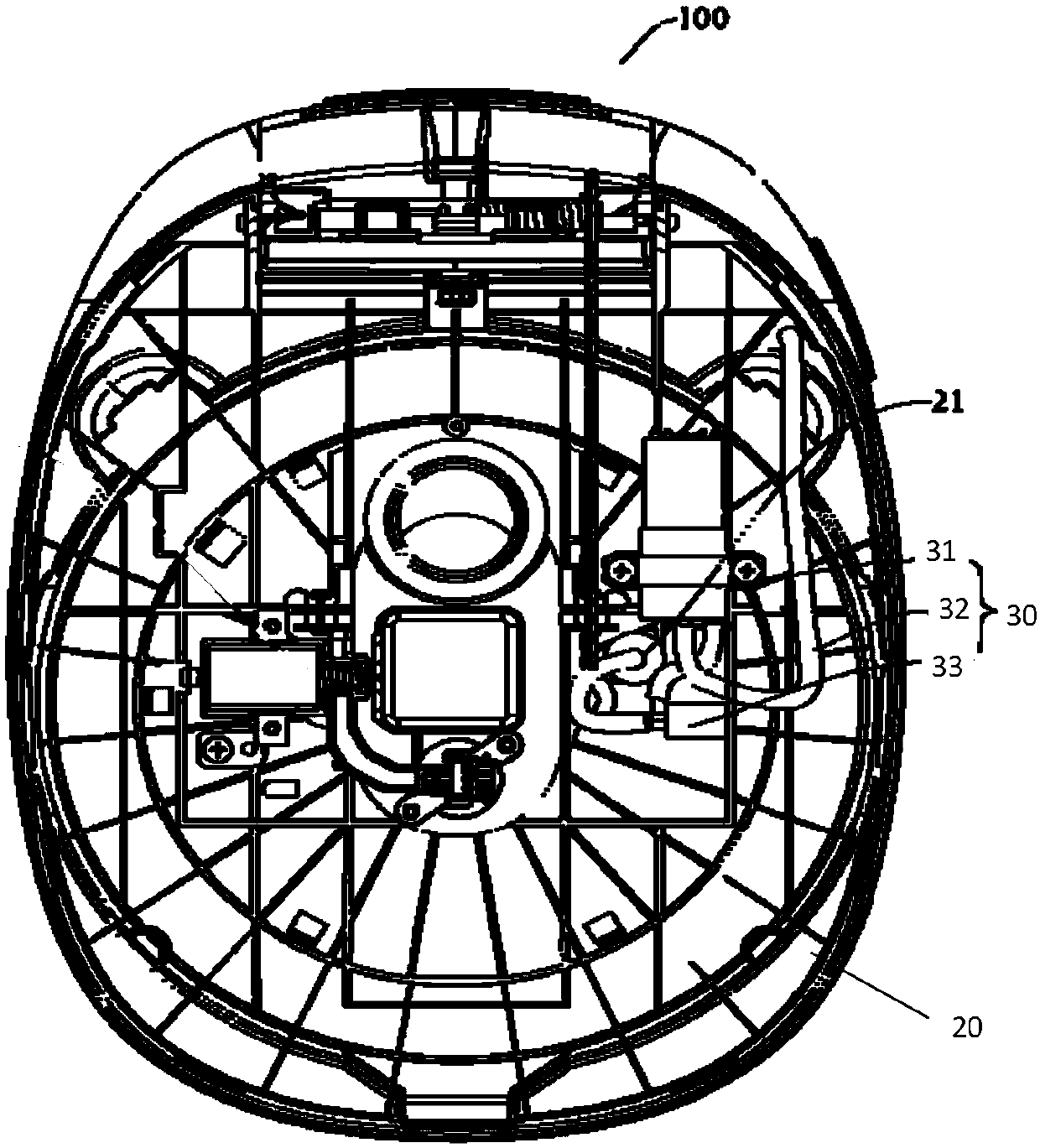

Cooking device and cooking control method of cooking device

PendingCN110856602AEnsure heating uniformityUniform tasteCooking vesselsProcess engineeringCooking process

The invention provides a cooking device and a cooking control method of the cooking device. The cooking device comprises a cooker body, a cover body, a vacuum device, a heating device and a pressure relief device, a sealed cooking chamber is formed between the cooker body and the cover body when the cover body is at a closed position, the vacuum device vacuumizes the cooking chamber, and the pressure relief device performs pressure relief on the cooking chamber. The method includes following steps: detecting cooking parameters of the cooking device in a cooking process of the cooking device, wherein the cooking process comprises a preprocessing stage, a temperature-rise boiling stage, a high-temperature boiling stage and a rice-cooking stage; and when the cooking device is in the temperature-rise boiling stage, controlling the heating device to perform heating operation, controlling the vacuum device to vacuumize the cooking chamber to enable the cooking chamber to generate boiling bubbles, and controlling the pressure relief device to perform pressure relief on the cooking chamber according to the cooking parameters of the cooking device. Therefore, pressure relief can be controlled at a proper moment, the rice-cooking uniformity can be guaranteed, and the cooking taste can be guaranteed.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

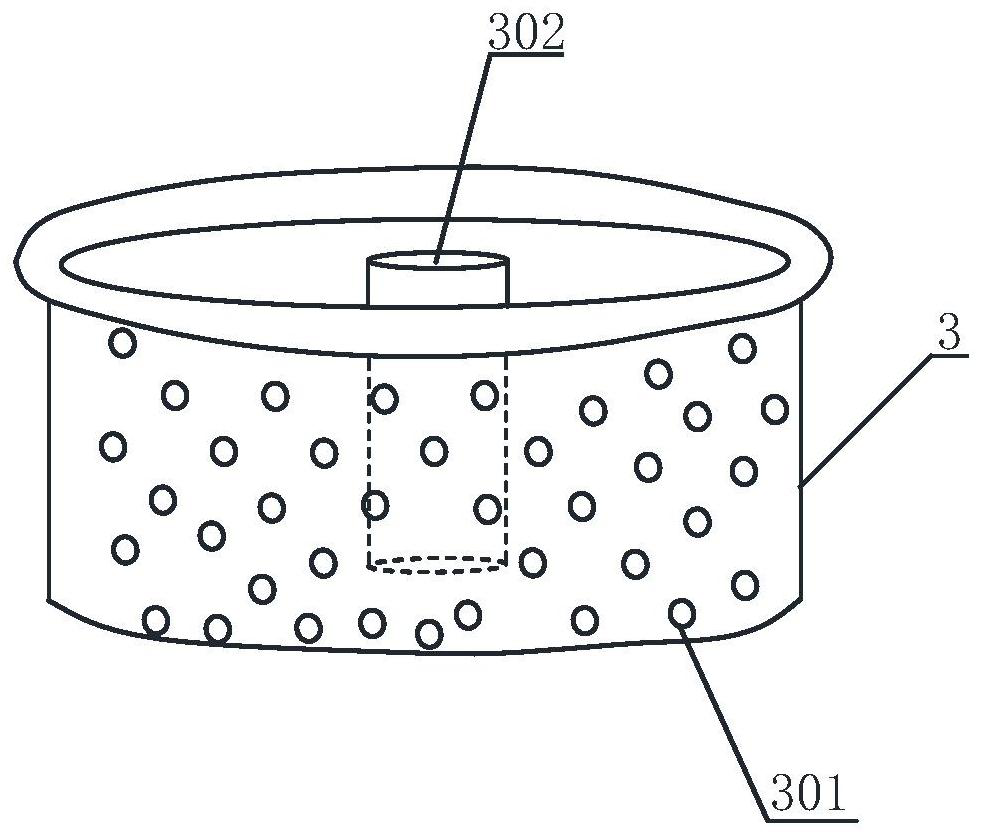

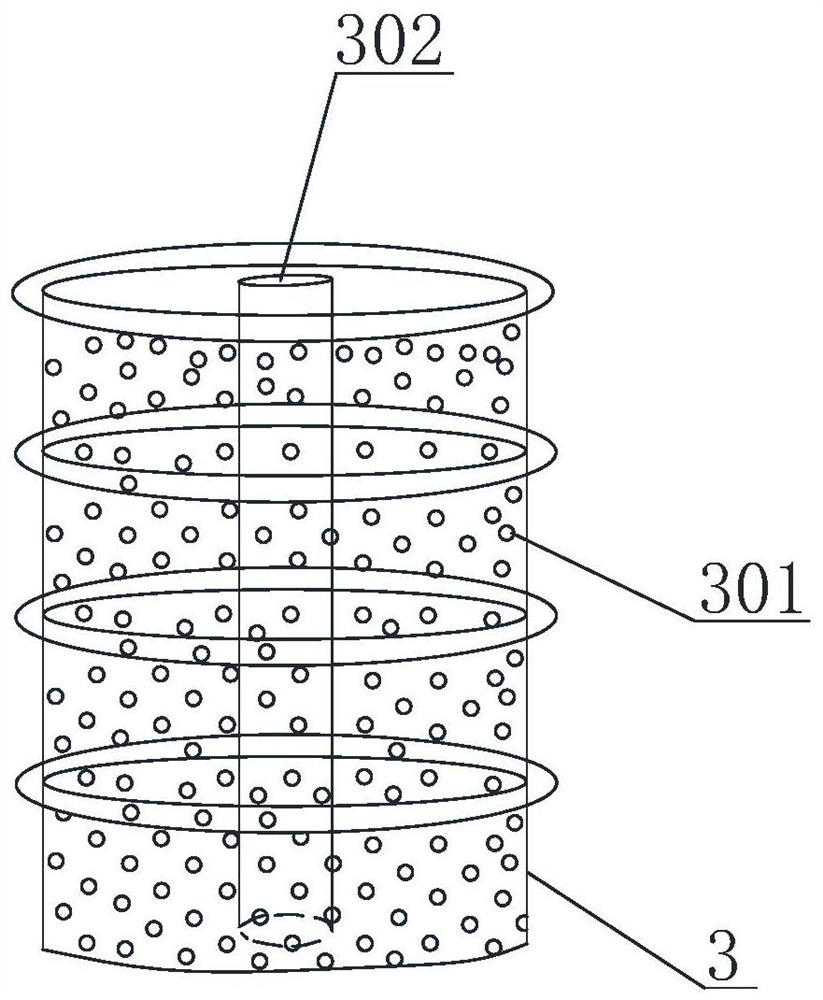

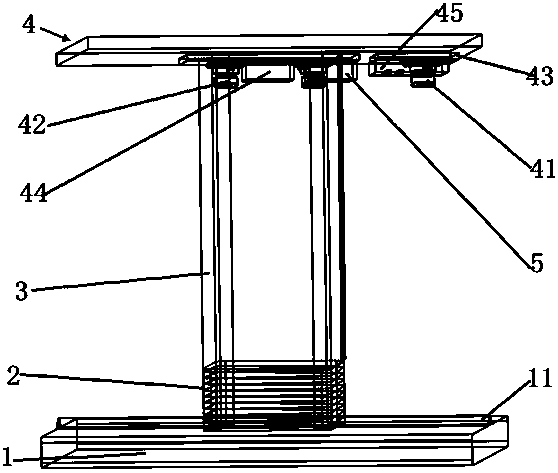

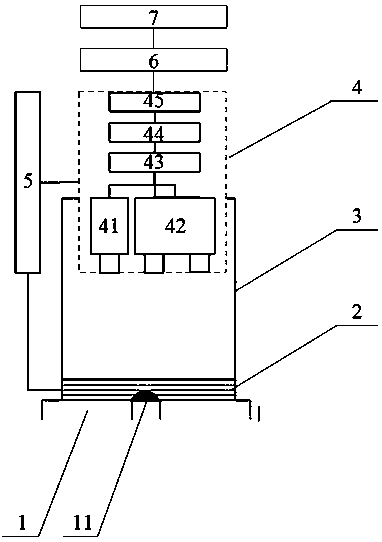

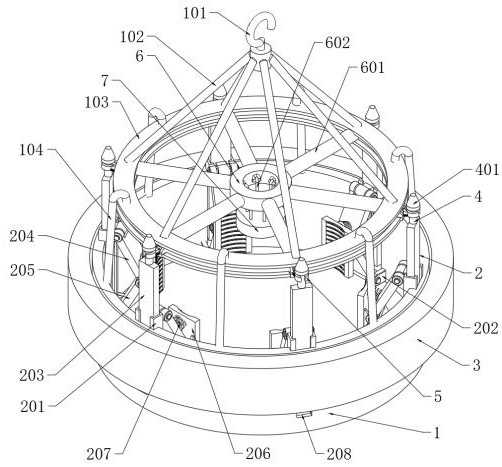

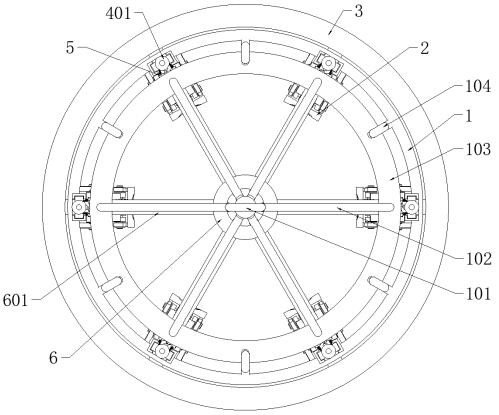

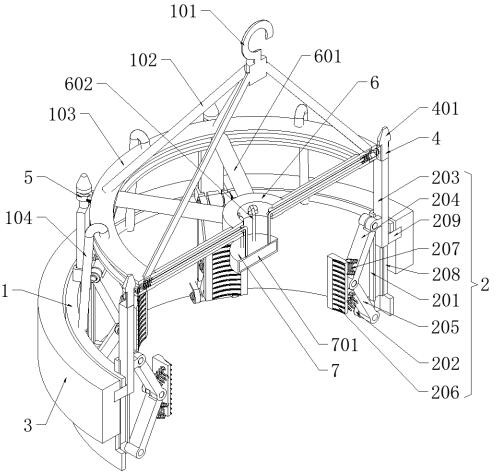

Hoisting device with self-adaptive supplement structure for metal heat treatment

The invention discloses a hoisting device with a self-adaptive supplement structure for metal heat treatment, and belongs to the field of metal heat treatment. According to the hoisting device with the self-adaptive supplement structure for metal heat treatment, a clamping part is installed on the inner wall of an annular frame to clamp the outer wall of a cylindrical iron ingot, so that the covered area during iron ingot fixing is effectively reduced; iron blocks are hoisted through the device instead of being directly stacked for heat treatment, so that the bottom of the iron ingot is effectively prevented from being covered by the contact surface when the iron ingot is placed, and the heating uniformity of the iron ingot during heat treatment is further guaranteed; through fixed connection of a clump weight and a sliding bar, power is provided for movement of the sliding bar by means of the gravity of the clump weight, so that a first clamping arm and a second clamping arm can deform in a self-adaptive manner to keep firm clamping of the iron ingot, the situation that hoisting and clamping of the iron ingot are loosened due to expansion and contraction of the iron ingot is avoided, and the using stability and safety of the device are effectively guaranteed.

Owner:南通江勤美金属制品有限公司

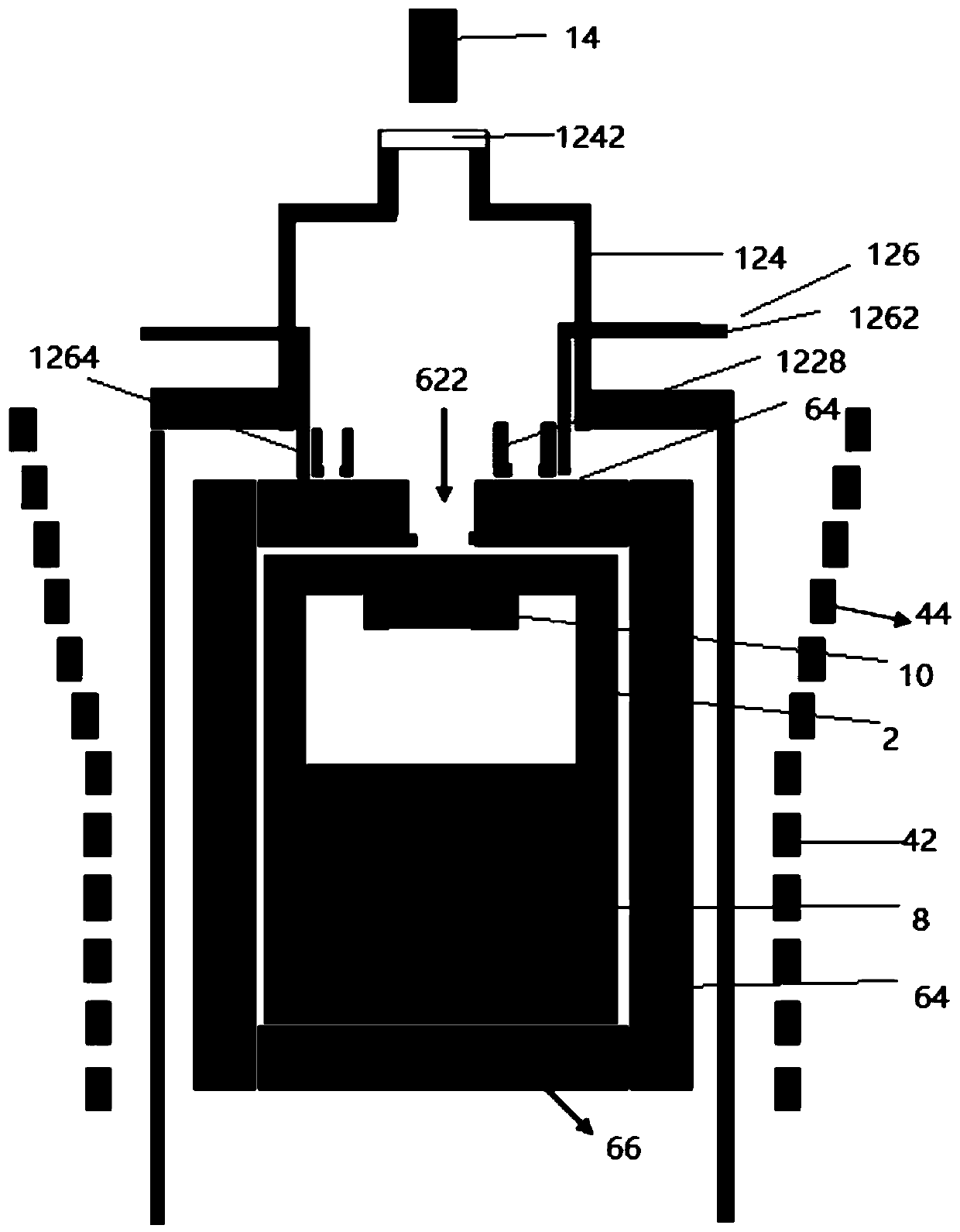

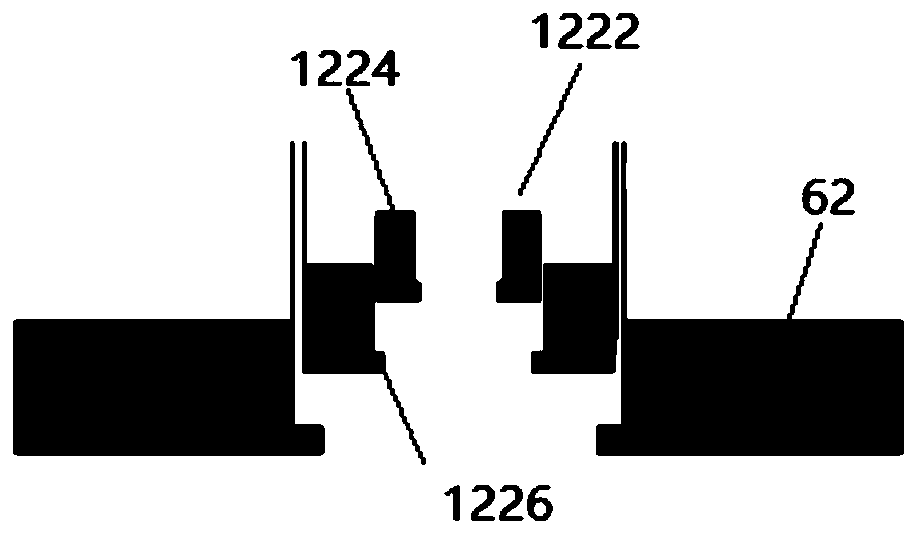

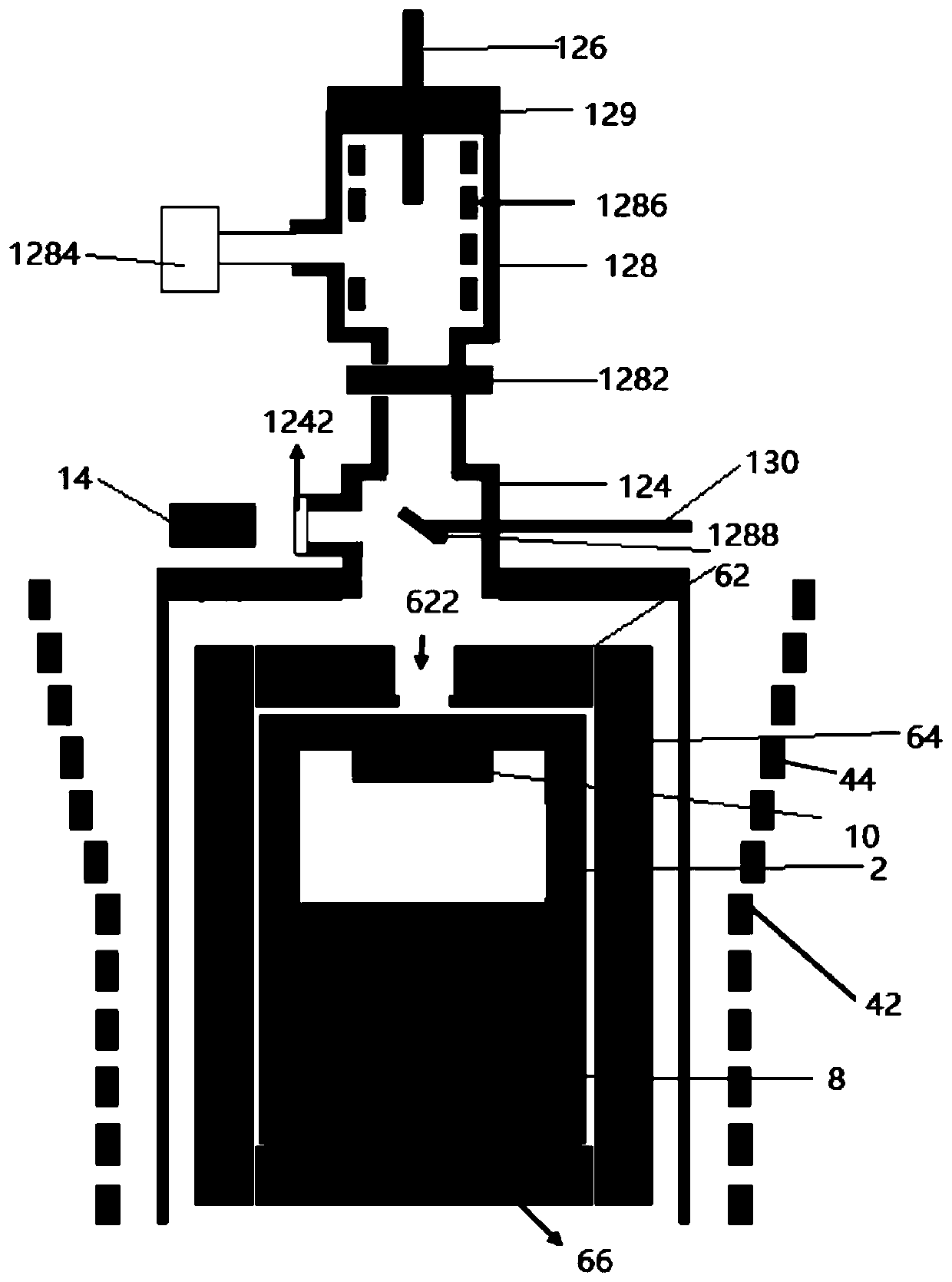

Device for preparing single crystal and method for preparing silicon carbide single crystal

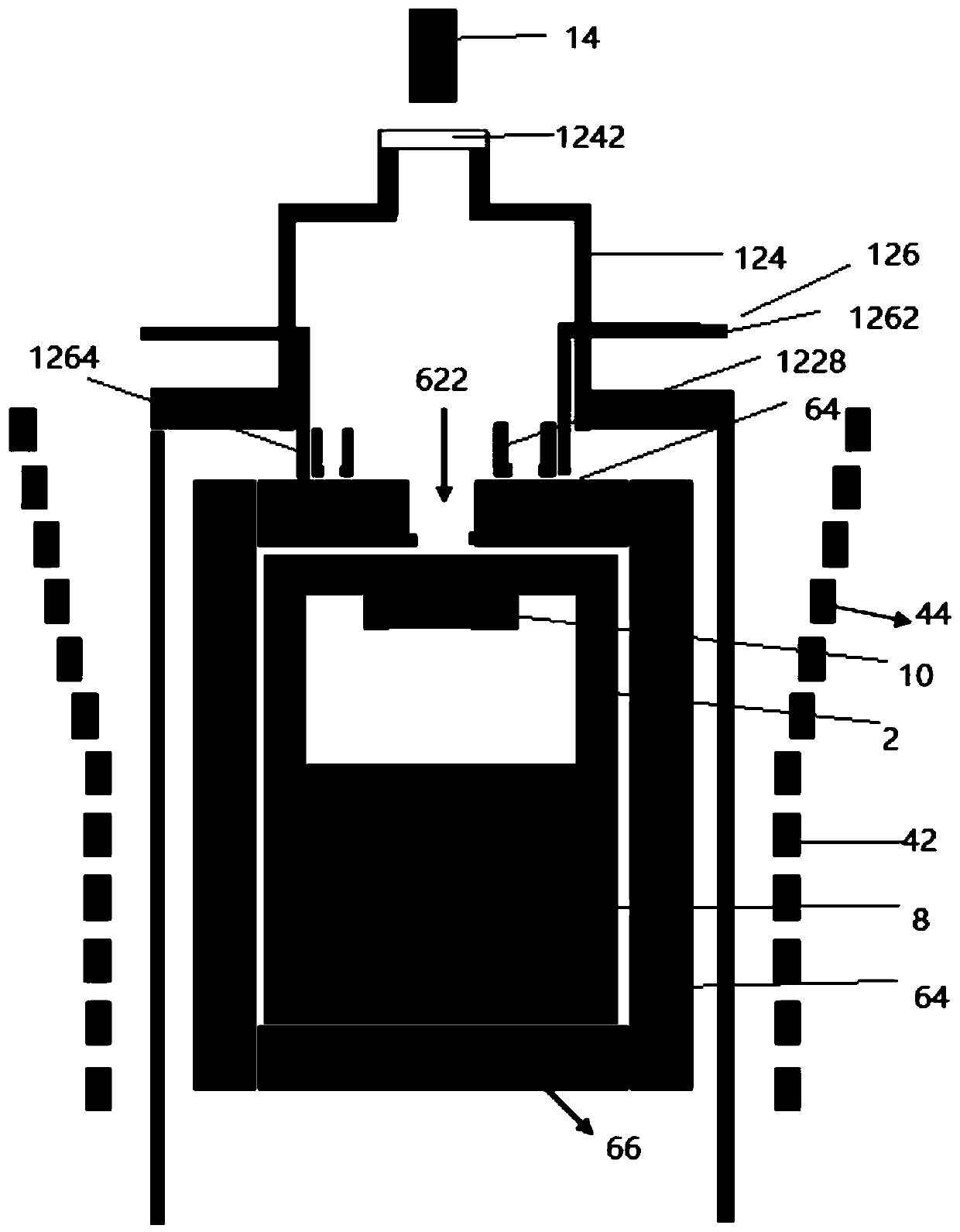

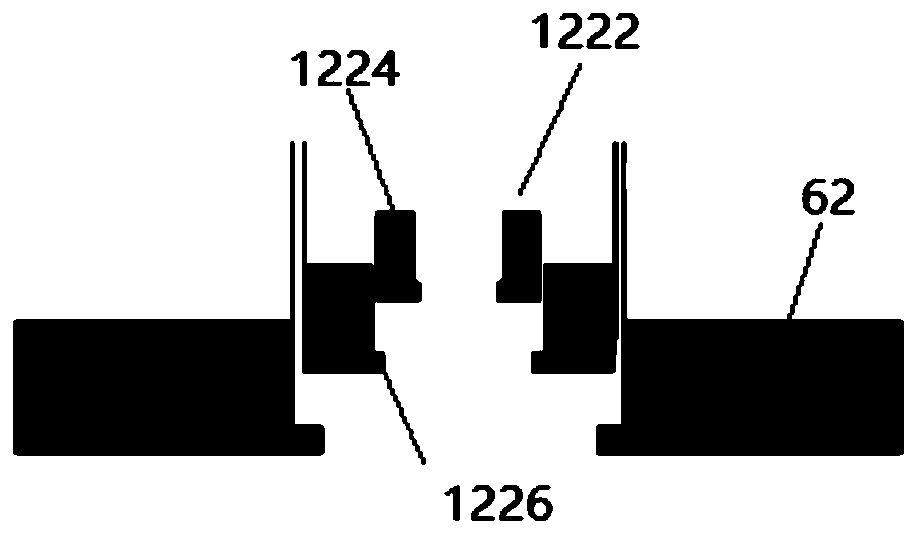

ActiveCN111088525AQuality improvementReduce defectsPolycrystalline material growthFrom condensed vaporsCarbide siliconSemiconductor materials

The invention discloses a device for preparing a single crystal and a preparation method for a silicon carbide single crystal, belonging to the field of semiconductor materials. The device for preparing the single crystal comprises a crucible, a heating coil group and a heat preservation structure, wherein the crucible forms a growth cavity which comprises a raw material area used for placing rawmaterials and a crystal growth area used for arranging seed crystals; the heating coil group is arranged around the side wall of the crucible and comprises a first coil group corresponding to the rawmaterial area and a second coil group corresponding to the crystal growth area; and the inner diameter of the second coil group is increased in a direction from raw materials to seed crystals. The single crystal growth device provided by the invention can adjust the radial temperature gradient in the growth cavity for growth of the single crystal, can reduce the radial temperature gradient, can guarantee a certain axial temperature gradient at the same time, and can realize high-efficiency preparation of high-quality single crystals.

Owner:SICC CO LTD

Soybean meal drying roller for feed

The invention discloses a soybean meal drying roller for feed. The soybean meal drying roller comprises a pretreatment unit and a drying unit, wherein the pretreatment unit comprises a vibrating screen and a supporting column, the supporting column is arranged at the bottom of the vibrating screen, and the vibrating screen is connected with a driving mechanism; and the drying unit comprises an outer cylinder, an inner cylinder and a rotating shaft, the inner cylinder is rotatably arranged in the outer cylinder, a heating element is arranged between the inner cylinder and the outer cylinder, the rotating shaft is rotatably arranged in the inner cylinder, the rotating shaft is connected with stirring blades, and the vibrating screen communicates with an inner cavity of the inner cylinder. The vibrating screen of the pretreatment unit can drive materials to vibrate to scatter caked or clustered materials in advance so as to guarantee the later drying uniformity, the materials enter the drying unit, the inner cylinder can drive the materials to rotate, the heating element heats the inner cylinder, and the inner cylinder exchanges heat with the materials so as to dry the materials; andmeanwhile, the rotating shaft is used for driving the stirring blades to stir the materials, the material heating uniformity is guaranteed, the drying effect is enhanced, convenience is provided for subsequent feed production procedures, and the finished product quality is improved.

Owner:广东省佰益科技有限公司

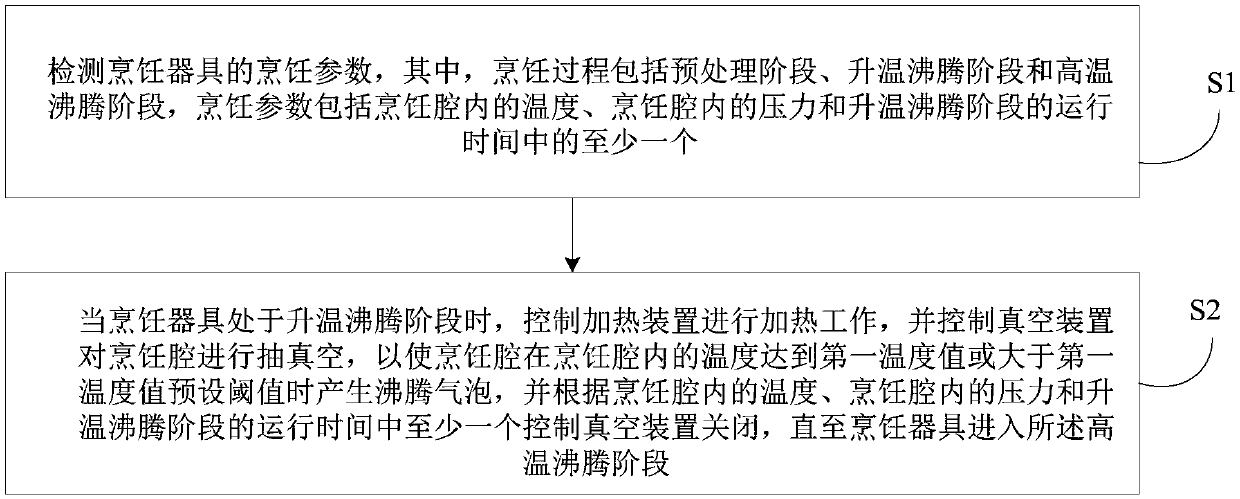

Cooking utensil and cooking control method of cooking utensil

ActiveCN110856594AEnsure heating uniformityUniform tasteTime-controlled ignitorsThermodynamicsWater vapor

The invention provides a cooking utensil and a cooking control method of the cooking utensil. The cooking utensil comprises a pot body, a cover body, a vacuum device and a heating device, wherein a sealed cooking cavity is formed between the pot body and the cover body when the cover body is in a closed position; the vacuum device is used for vacuumizing the cooking cavity; the method comprises the following steps that the cooking parameters of the cooking utensil are detected, wherein the cooking parameters comprise at least one of the temperature in the cooking cavity, the pressure in the cooking cavity and the operating time of a heating boiling stage; when the cooking utensil is in the heating boiling stage, the heating device is controlled to carry out heating work, and the vacuum device is controlled to vacuumize the cooking cavity, so that the cooking cavity generates boiling air bubbles; and the vacuum device is controlled to be closed according to at least one of the operationtime of the heating boiling stage, the temperature and the pressure until the cooking utensil enters a high-temperature boiling stage, and better boiling and tumbling are achieved; and meanwhile, water vapor generated after boiling is prevented from being lost and sucked into the vacuum device, and bacteria breeding is prevented.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

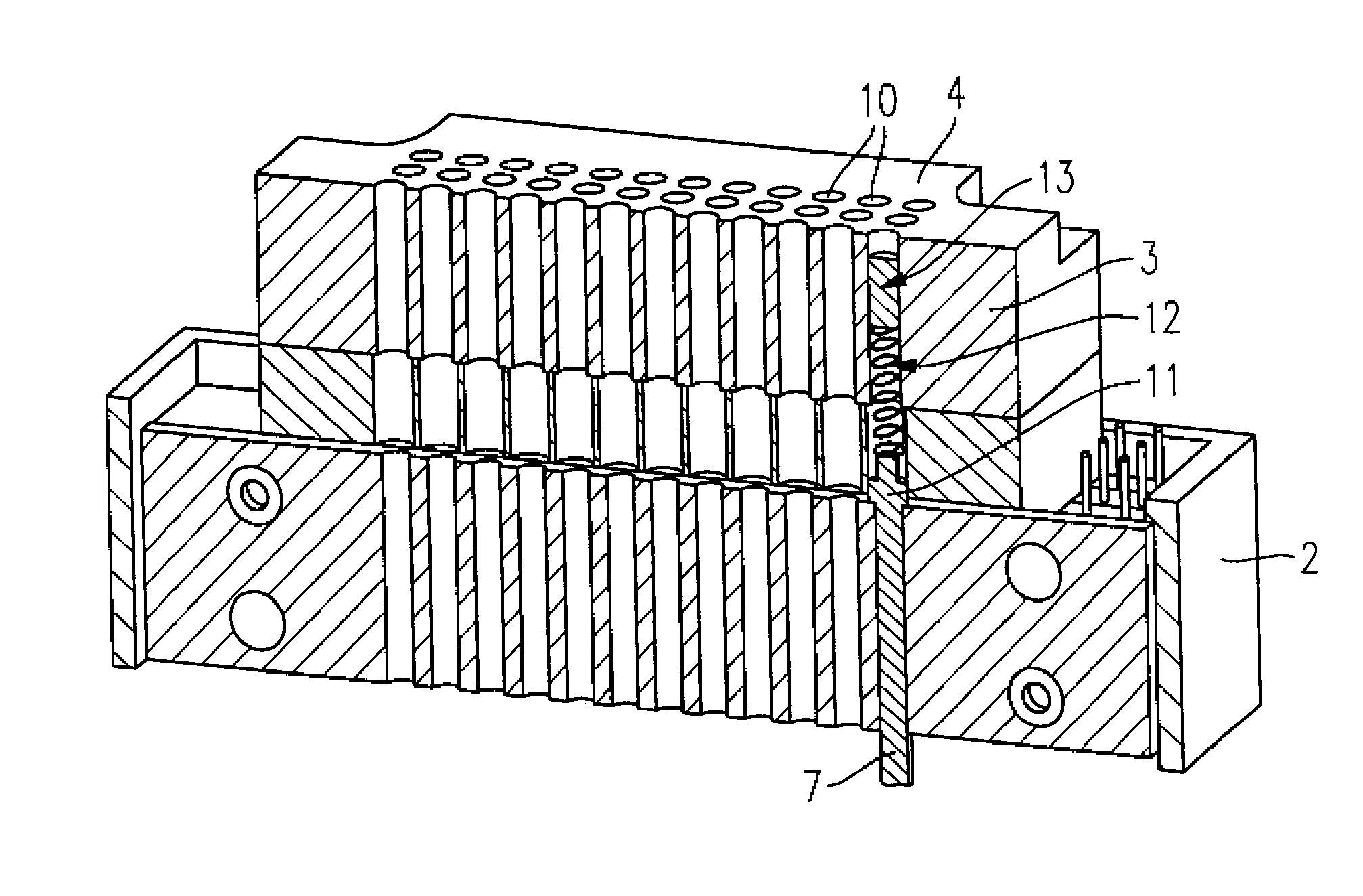

Thermode device for a multitude of semiconductor components

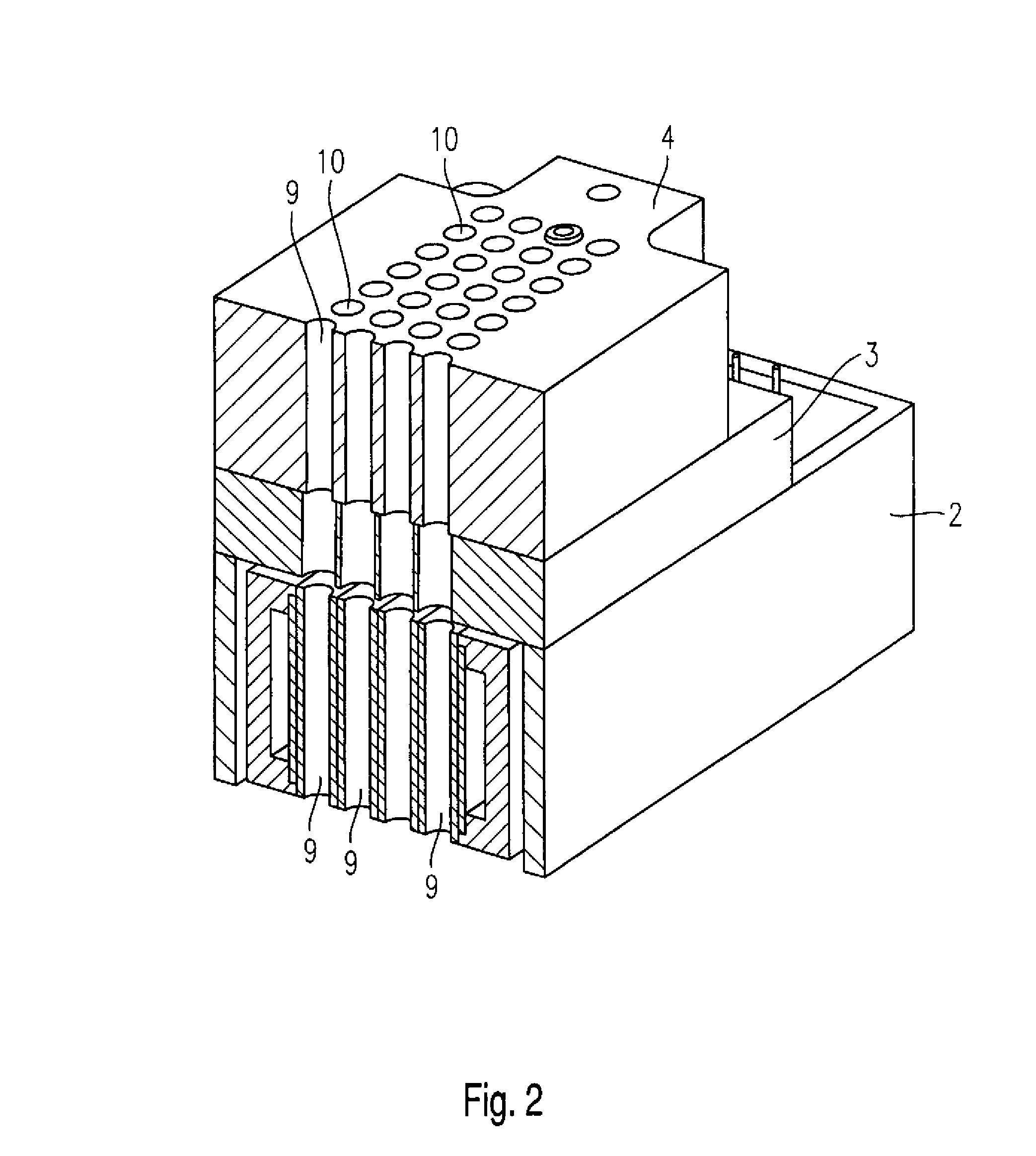

ActiveUS8735764B2Ensure heating uniformityWelding/cutting auxillary devicesHeating element shapesAdhesiveEngineering

A thermode device for connecting and / or electrically contacting a plurality of first semiconductor components to at least one support element and / or to a plurality of second semiconductor components by heating an adhesive under the application of pressure. An example thermode device includes a basic body and a heating element which can be extended out of the basic body and which, under the application of pressure, acts on at least one of the first semiconductor components, wherein the basic body has on its underside a plurality of heating plates which are oriented vertically and are arranged next to one another. Each heating plate has on its end and underside a plurality of the extendable heating elements, to the underside of each of which there is assigned a first semiconductor component.

Owner:MUEHLBAUEHR AG

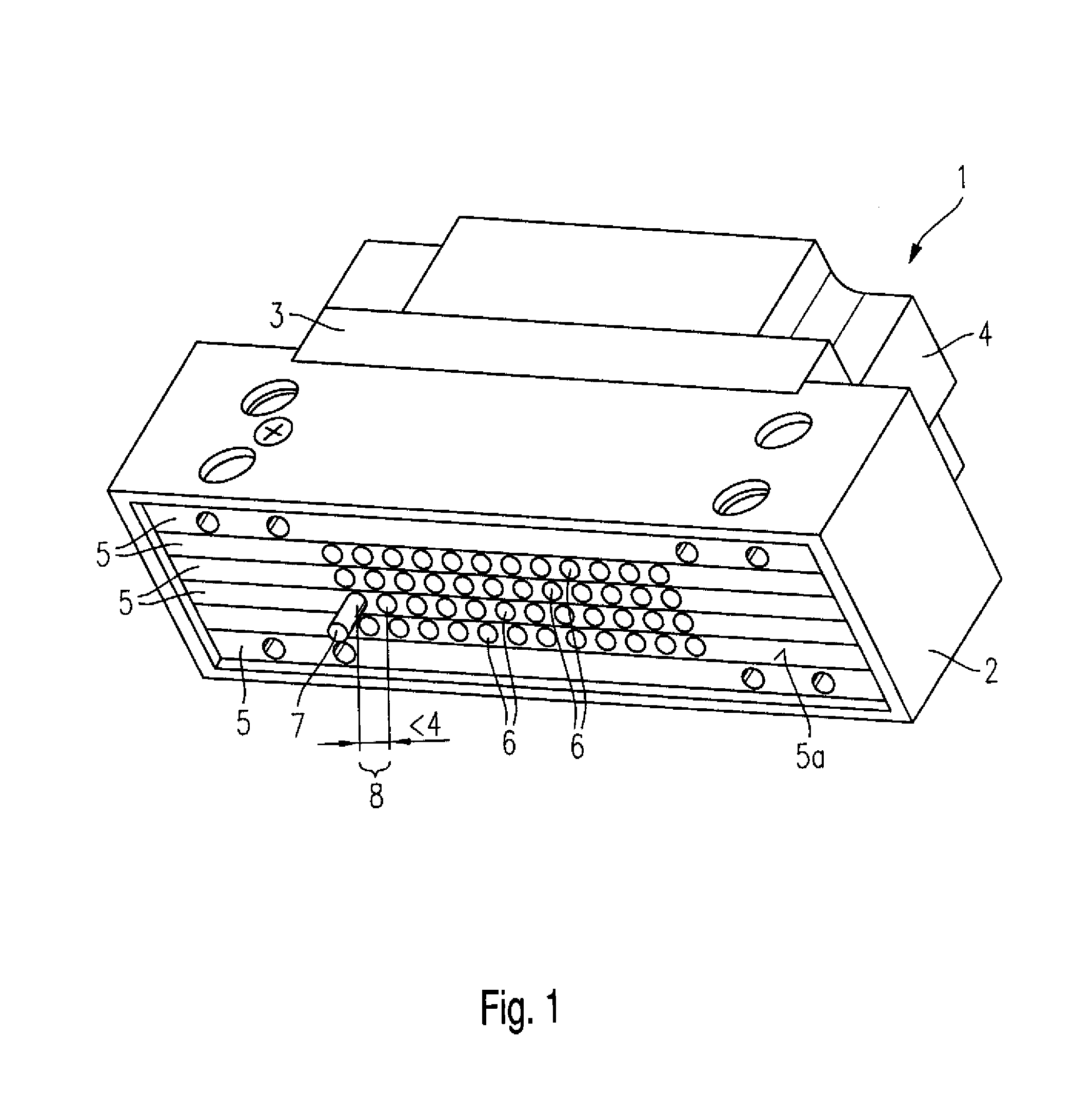

Flexible, electrically heatable hose

InactiveUS8450667B2Ensure heating uniformityPipe heating/coolingFlexible pipesElectrical conductorConductor Coil

A flexible, electrically heatable hose having an elongated electrical conductor which extends in the helical shape in the hose direction is illustrated and described. The object of providing a flexible, electrically heatable hose in which uniform heating over the hose length is ensured even in the event of major deformation of the hose, is achieved by a hose which has an elongated electrical conductor which extends in a helical shape in the hose direction, wherein the electrical conductor is embedded in a braid. In this case, the braid has first and second strands, wherein the first strands extend in a helical shape in the hose direction in the same winding direction as the electrical conductor, and the second strands extend in a helical shape in the hose direction in the opposite winding direction to the electrical conductor. The pitch angle of the electrical conductor, which extends in a helical shape in the hose direction, of the first strands and of the second strands is in this case between 50° and 80°.

Owner:MASTERFLEX SE

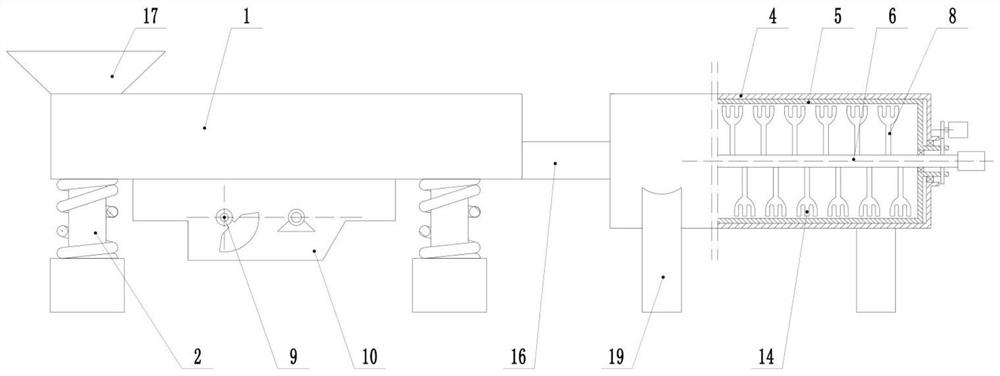

Low-rank coal vibration separation drying device and method

The invention discloses a low-rank coal vibration separation drying device and method, and belongs to the technical field of drying devices. The device comprises a rack, a box, a feeding opening, hot smoke inlets, an air flow disperser, a vibration exciter, a motor, a connecting shaft, a large-sieve-pore sieve plate, a medium-sieve-pore sieve plate, a small-sieve-pore sieve plate, a suspension spring, discharging openings, gas and dust removing negative-pressure devices and gas-solid separators. After entering the box from the feeding opening, raw coal drops on a sieve surface, wherein the sieve surface is arranged at a dip angle of 5-15 degrees, the aperture of the sieve surface is progressively increased from the feeding opening to the discharging openings, the raw coal is vibrated under the effect of the vibration exciter, and the raw coal on the sieve surface is mixed and is classified. Meanwhile, after passing through the air flow disperser, hot smoke enters the box and dries raw coal with different particle sizes, after being sieved, the completely dried raw coal enters the discharging openings, after passing through the gas and dust removing negative-pressure devices, gas and dust enter the gas-solid separators, therefore, classified drying of particles with different granularities is realized, and problems that coarse particles are dried insufficiently and fine particles are over-dried are avoided.

Owner:CHINA UNIV OF MINING & TECH

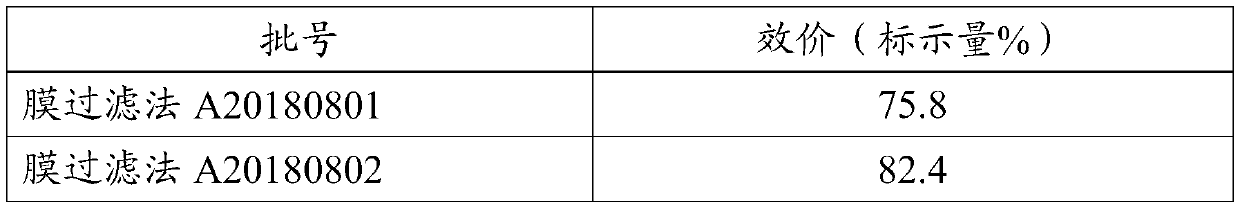

Thrombin preparation method

ActiveCN110835626AHigh potencyPotency is stable and controllablePeptidasesPhysical chemistryThrombin preparation

The invention provides a thrombin preparation method which includes the steps: freeze-drying extracting solution containing thrombin and / or increasing the temperature of a freeze-dried product containing thrombin to reach 101-107 DEG C; performing water spraying dry-heat treatment at the temperature of 100+ / 3 DEG C. The water content of the freeze-dried product containing thrombin by weight is nothigher than 3% and preferably not higher than 2.5% and more preferably not higher than 2%. According to the preparation method, the impurity content of thrombin products is further reduced, the valence of thrombin products is remarkably improved, viruses are effectively removed, and the preparation method is quite suitable for large-scale industrial production of the thrombin products.

Owner:长春雷允上药业有限公司

Rail train and side wall thereof

PendingCN109318915AWith heating functionGuaranteed temperatureRailway heating/coolingAxle-box lubricationEngineeringAir conditioning

The invention discloses a rail train side wall which comprises a wall body and a glass window mounted on the wall body. The wall body comprises an inner wall board and an outer wall board which are mutually connected, the wall body is of a double-layer interlayer structure, a separated cavity used for conveying air-conditioning airflow is formed in the middle of the wall body, the upper end of theseparated cavity is located on the upper part of the wall body and provided with an air inlet used for communicating with an air supply channel at the top of a carriage, and the lower end of the separated cavity is located on the lower part of the wall body and provided with an air outlet communicating with the interior of the carriage. Warm air generated by a warming system enters the separatedcavity from the air inlet and then is conveyed into the carriage through the air outlet in the bottom of the carriage, warming uniformity is guaranteed by utilizing a heat convection principle, and thus the side wall has a warming function, the temperature of the side wall is guaranteed in a cold environment, and the overall temperature comfort in the carriage is improved. The invention further discloses a rail train comprising the side wall.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

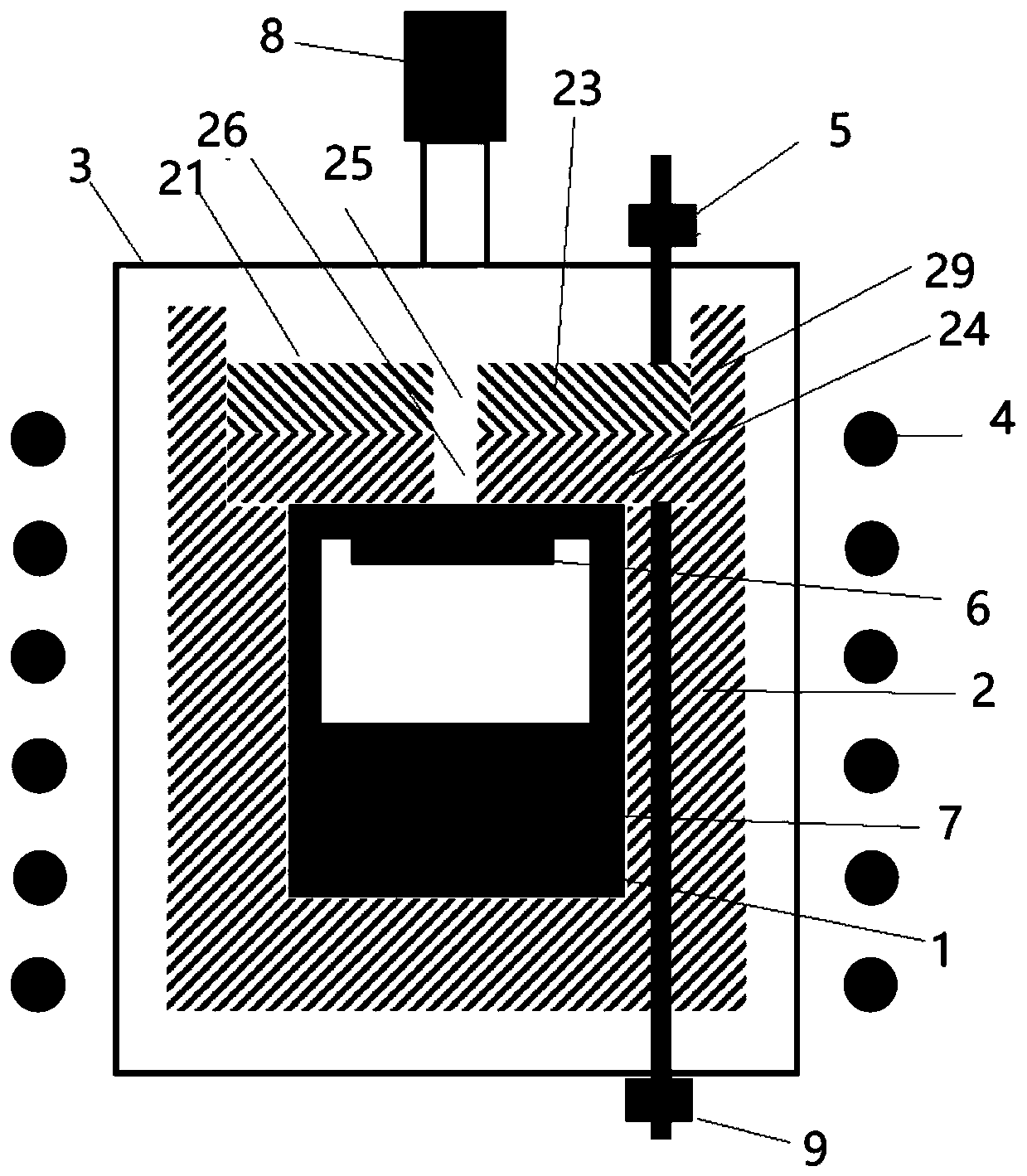

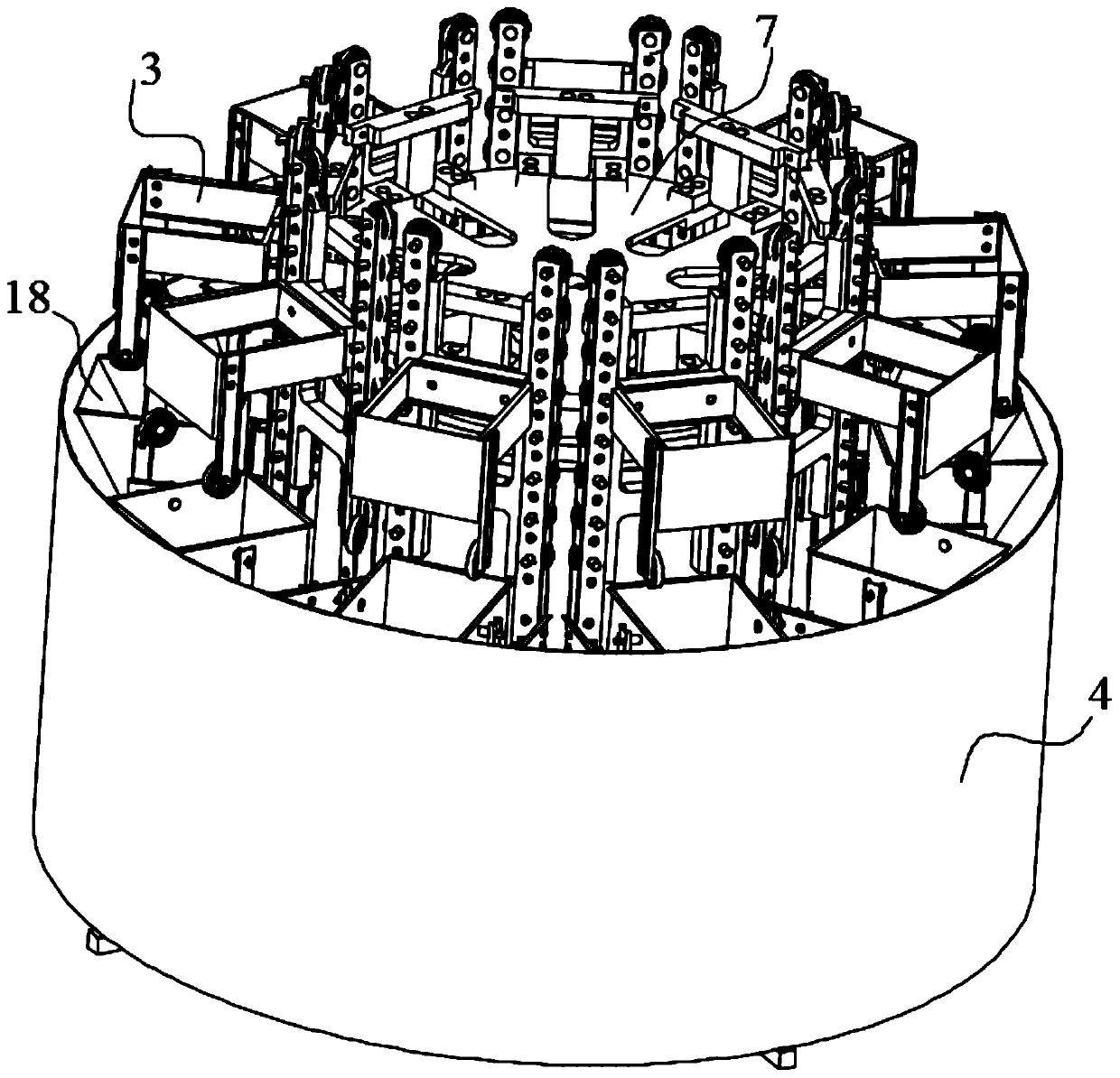

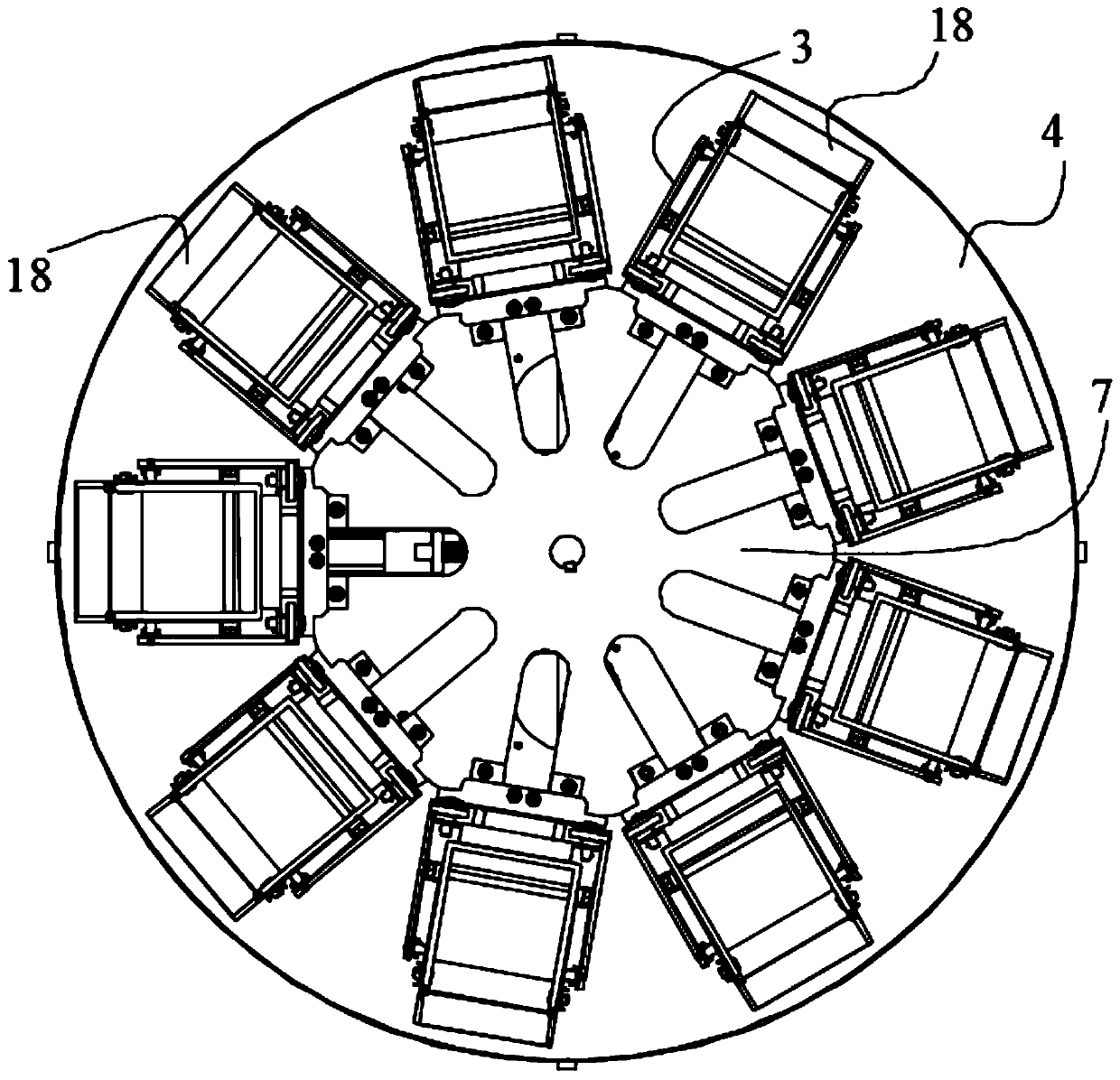

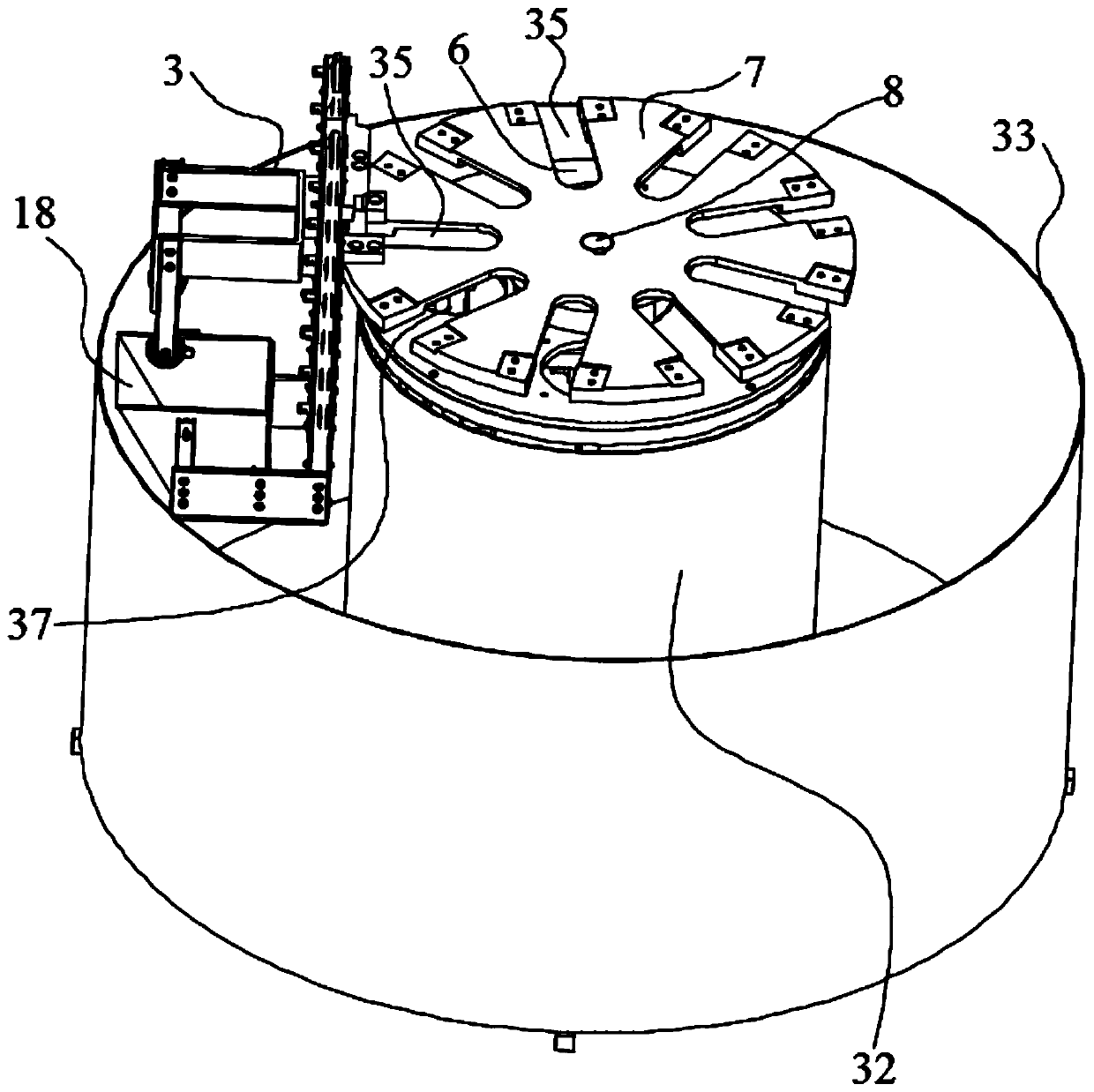

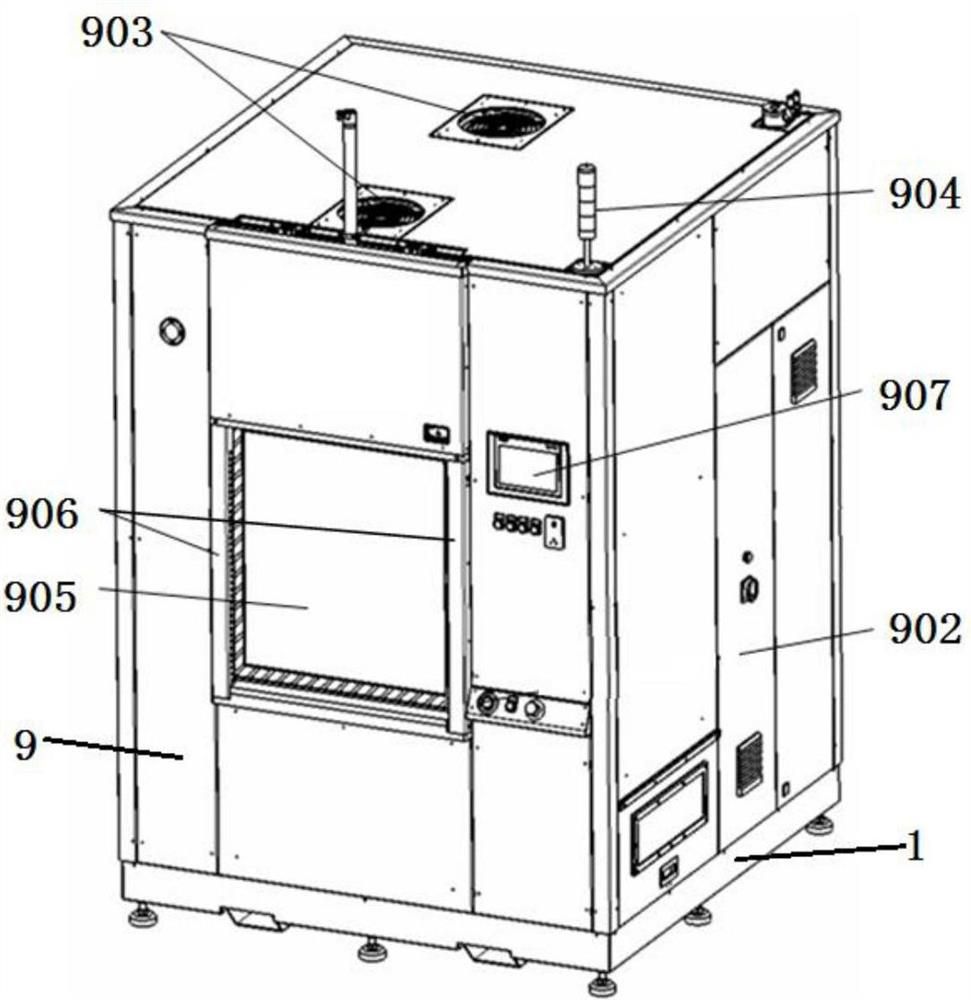

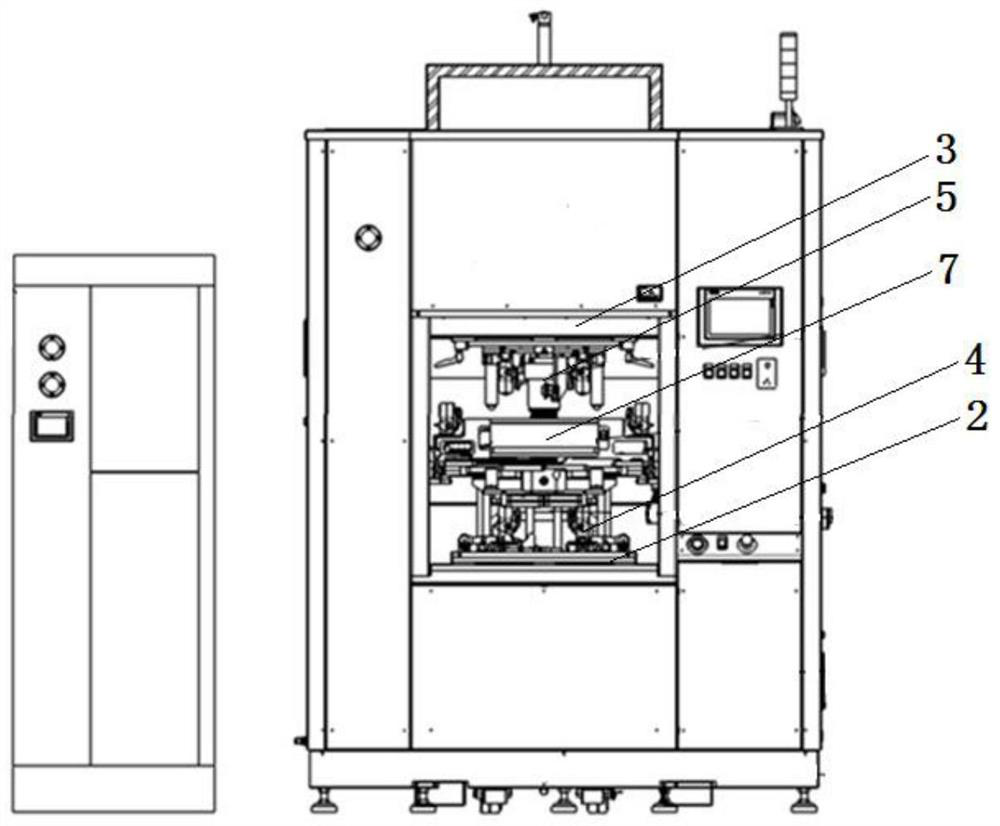

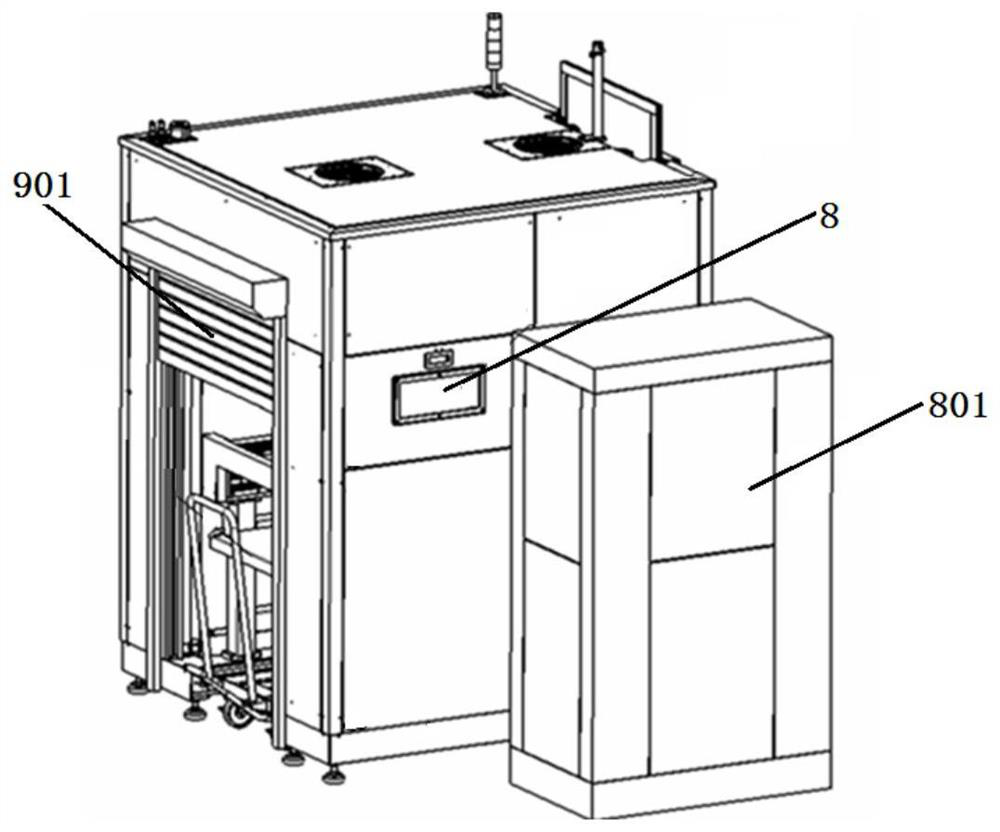

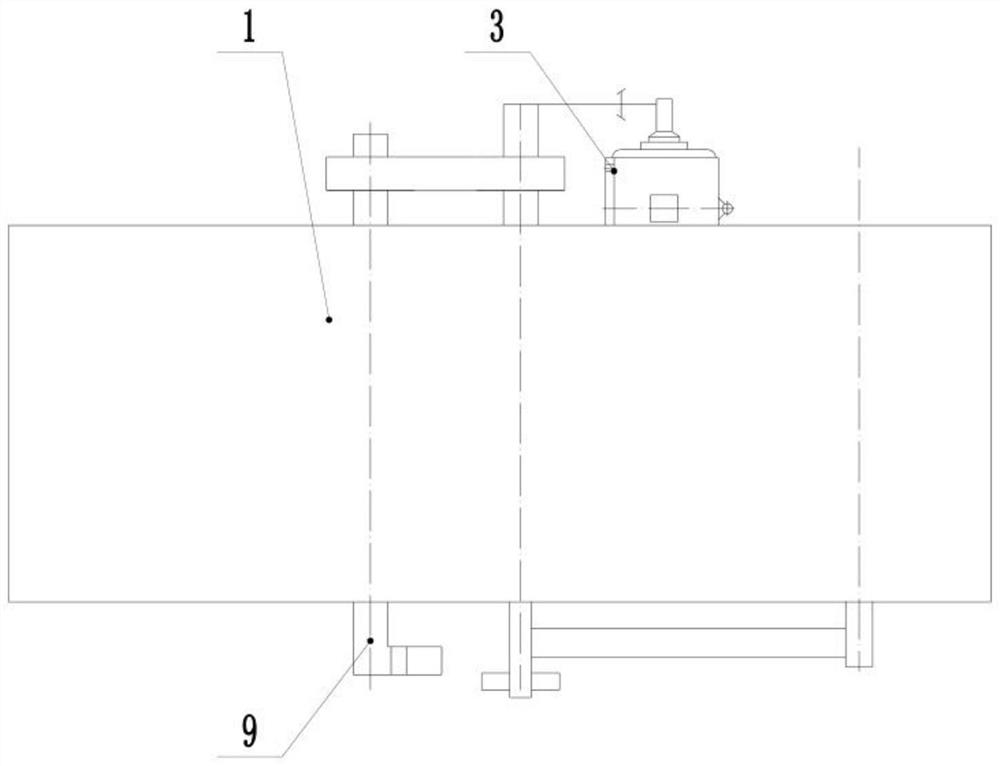

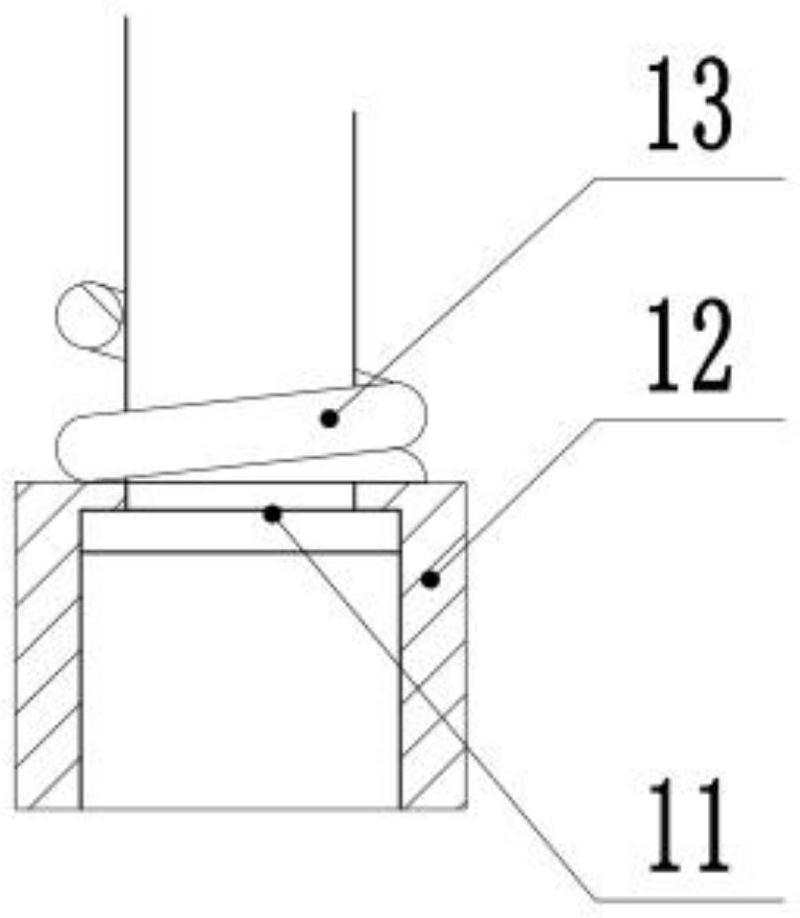

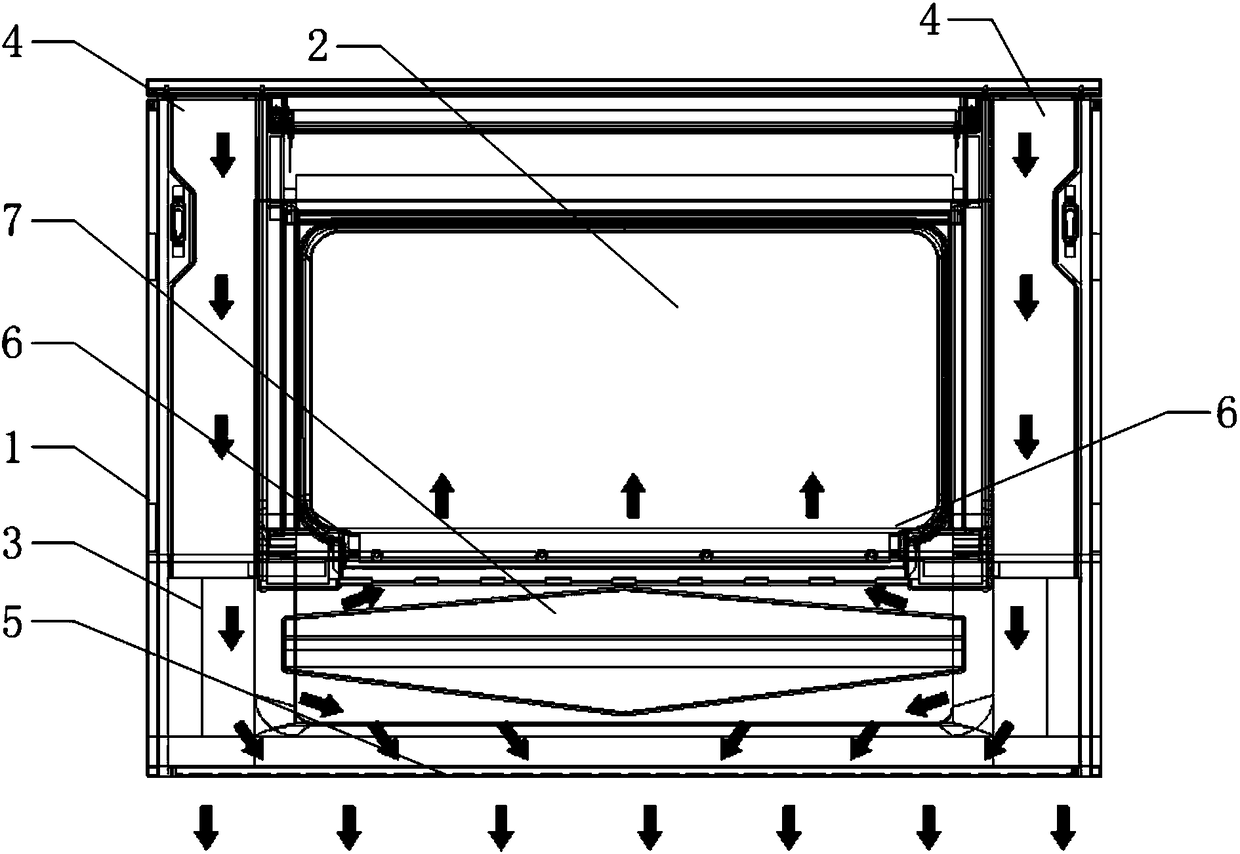

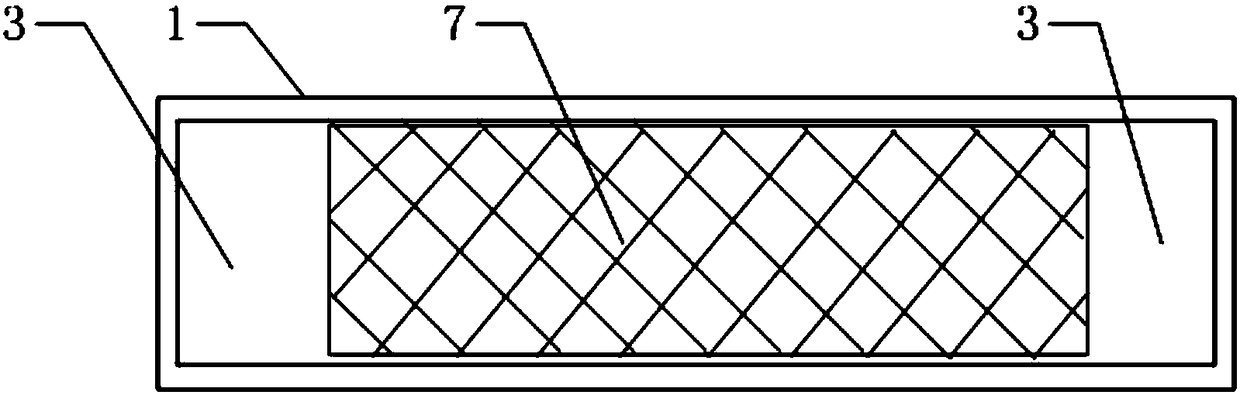

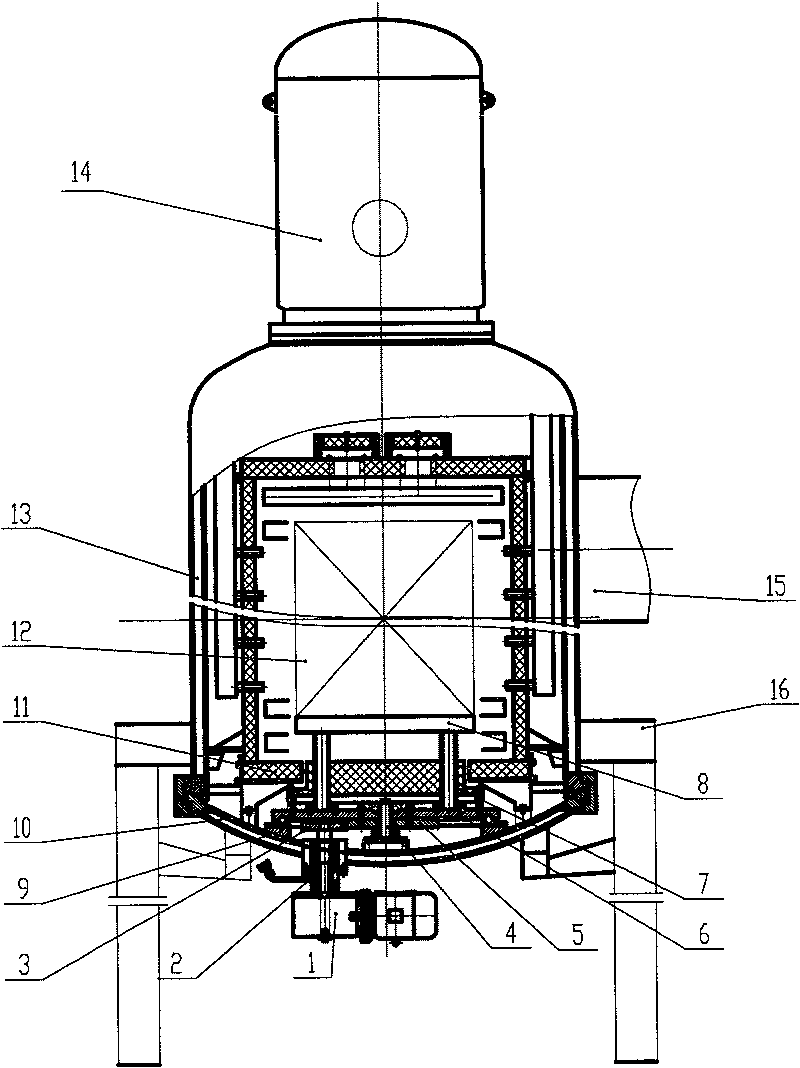

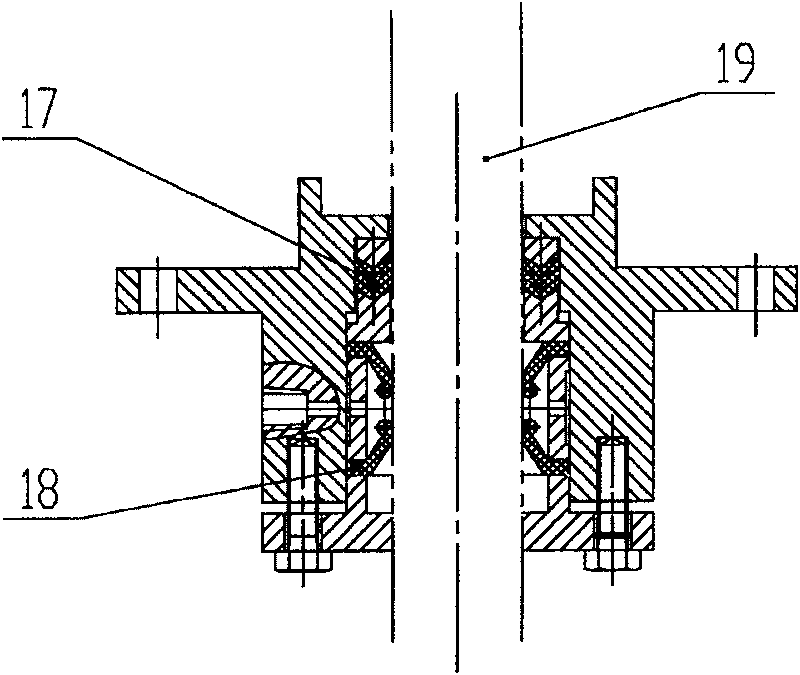

Vertical vacuum heavy pressure gas quenching furnace with rotatable material rest

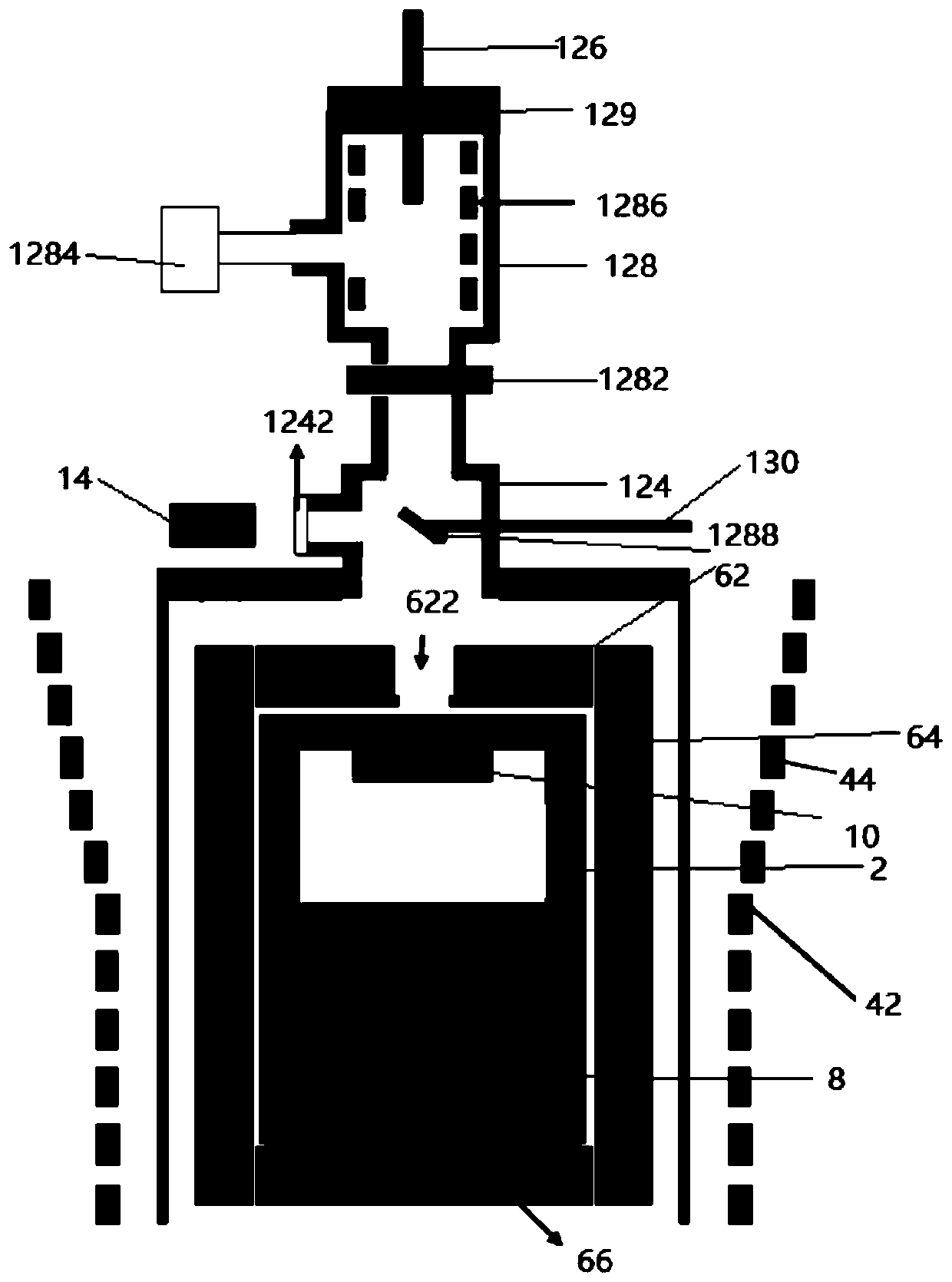

InactiveCN101319272BEnsure heating uniformityImprove product qualityQuenching agentsQuenching devicesPositive pressureControl system

The invention discloses a vertical vacuum high-pressure gas-quenching furnace with a rotatable material rest, which is a bottom charging type vacuum furnace with a vertical downward-acting door and comprises a control system taking an industrial control computer and a PLC as main parts. The vertical vacuum high-pressure gas-quenching furnace is characterized in that: an inner circle of the inner side of a lower furnace door is provided with a rotating platform support which is coaxially provided with a rotating disc and the material rest, the lower part of the rotating disc is coaxially provided with a big gear, a pinion which is eccentrically arranged on a rotating driving mechanism is engaged with the big gear circumferencially to drive the rotating disc to rotate further to ensure thatthe material rest bearing workpieces can rotate around a vertical central axis; the root of the material rest is provided with a thicker thermal insulating layer, a lower shielding thermal insulatinglayer of a heating chamber is of a ring shape, and a ring platform shaped clearance is reserved between the thicker thermal insulating layer and the lower shielding thermal insulating layer; the rotating disc, the thermal insulating layer and the material rest on the rotating disc, and the rotating driving mechanism lift along with a furnace door; the vacuum furnace is controlled by adopting a PLCtechnology, and various actions, the temperature in the furnace and the rotation of the material rest are controlled interlockingly. The equipment can ensure that workpieces at various positions areuniformly heated, and the performances such as vacuum, positive pressure, dynamic seal, heat preservation, cooling and so on, are better assured.

Owner:SHENYANG HENGJIN VACUUM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com