Hot-gas welding plastic welding equipment and welding method

A technology for plastic welding and equipment, which is applied in the field of hot gas welding plastic welding equipment and welding, and can solve problems such as difficult to remove, uneven pits, and affecting welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

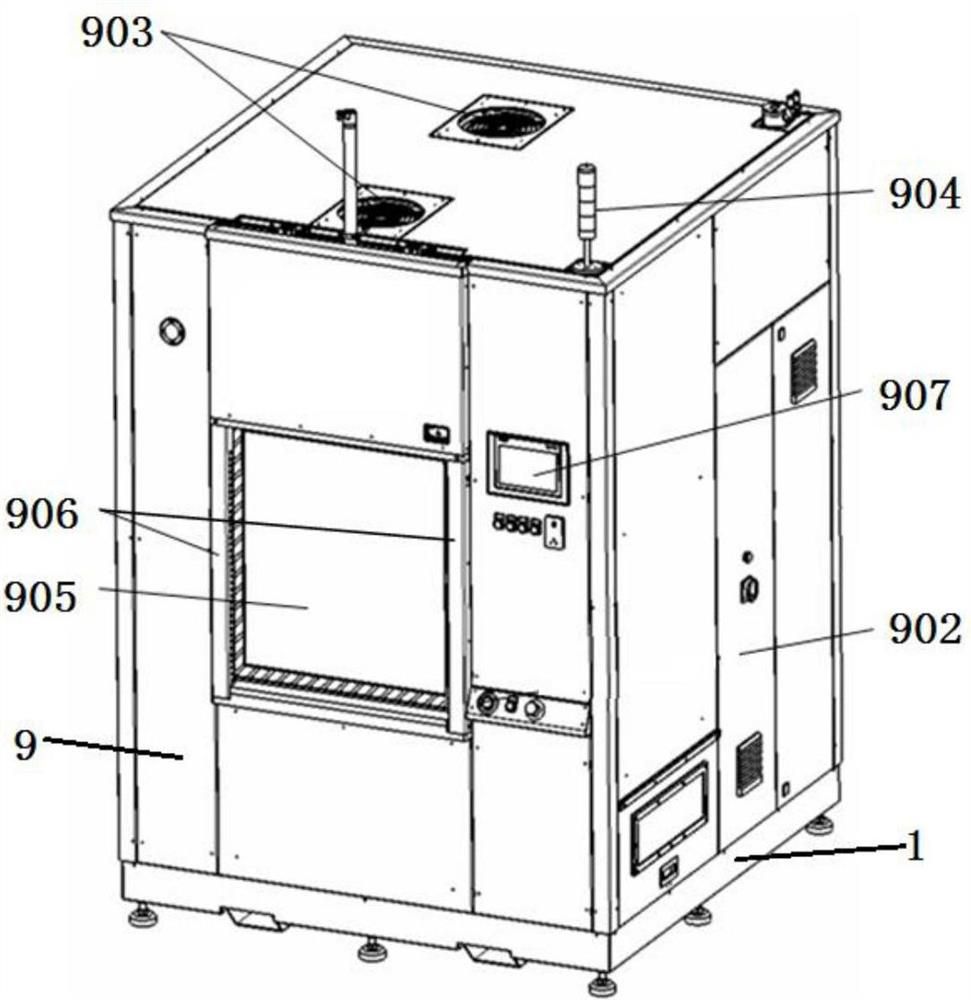

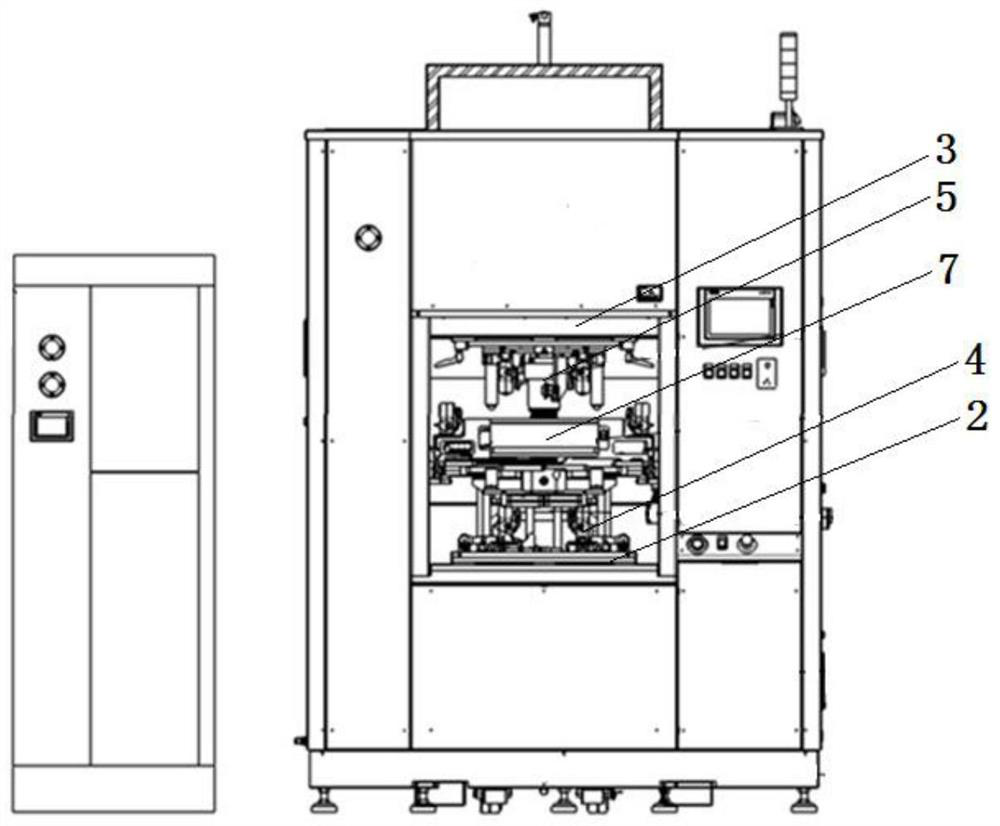

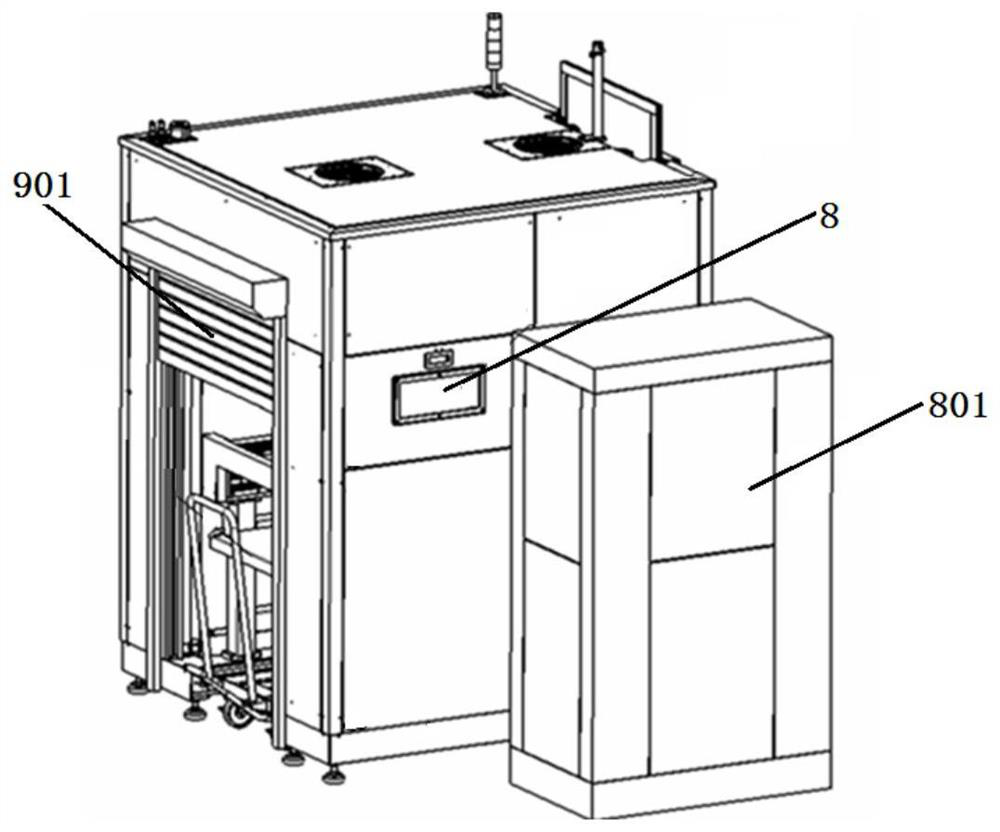

[0101] Embodiment 1: Hot gas welding plastic welding equipment

[0102] refer to Figure 2 to Figure 4 Shown: hot gas welding plastic welding equipment, including a base 1, the first frame body 101 and the second frame body 102 with the same structure and symmetrically arranged are fixedly installed on both sides of the front end of the base 1, the first frame body 101 and the second frame body Between 102, from bottom to top, a sliding platform 2 and an upper sliding platform 3 that can move up and down are arranged sequentially. The upper end of the sliding platform 2 is equipped with a lower mold fixture 4 for fixing the lower plastic parts, and the lower end of the upper sliding platform 3 is installed with a fixed upper. The upper mold fixture 5 of the plastic part; the third frame body 103 and the fourth frame body 104 with the same structure and symmetrically arranged are fixedly installed on both sides of the rear end of the base 1, and the third frame body 103 and the...

Embodiment 2

[0118] Embodiment 2: the following will be based on Figure 1 to Figure 21 The welding method of the hot gas welding plastic welding equipment provided by the present invention is described in detail.

[0119] The welding method of the hot gas welding plastic welding equipment uses the upper mold fixture 5 and the lower mold fixture 4 to clamp and fix the upper plastic part and the lower plastic part respectively; the operator takes the upper plastic part, and the welding surface of the upper plastic part faces down, With the non-welding side facing up, place the non-welding end of the upper plastic part in the upper mold positioning part 504, and use the upper mold clamping cylinder 505 on both sides and the upper mold jaw 505 to clamp and fix the upper plastic part; The worker takes down the plastic part, the welding side of the lower plastic part faces up, and the non-welding side faces down, and the non-welding end of the lower plastic part is placed in the lower mold posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com