Method for heating titanium and titanium alloy ingot

A heating method and titanium alloy technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of low production efficiency and high comprehensive production costs, and achieve high production efficiency, reduced metallurgical manufacturing costs, and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

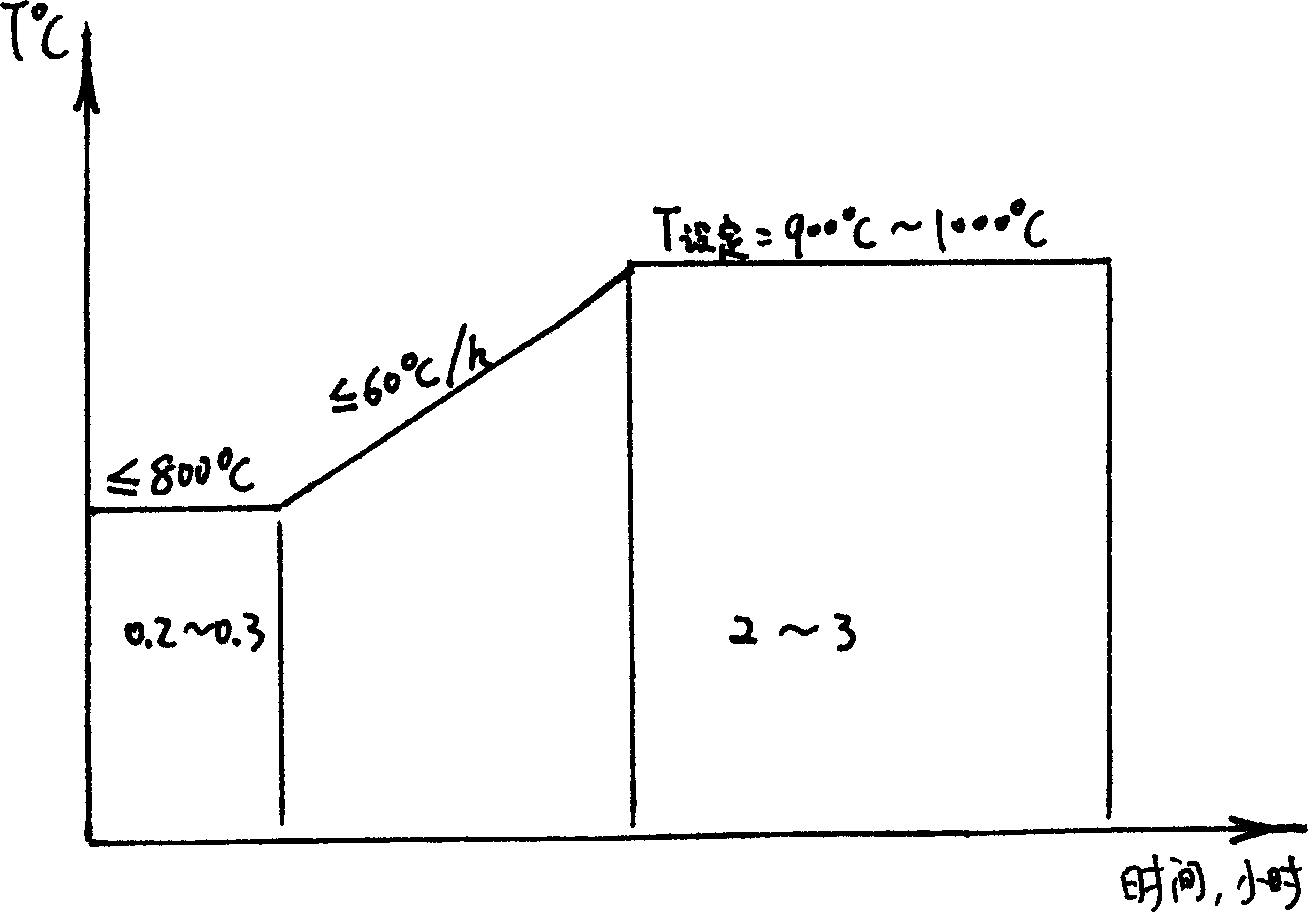

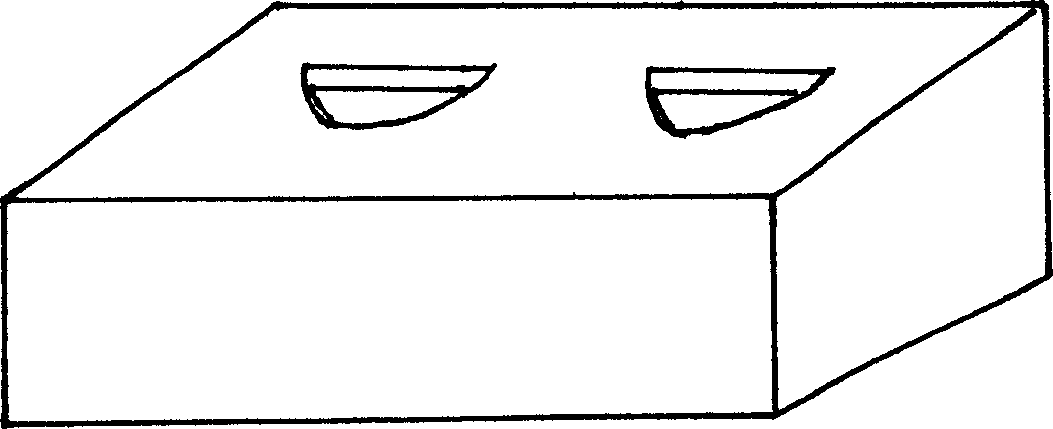

[0021] The steel rolling workshop of an iron and steel company implements the patent of the invention, and uses a soaking furnace to heat titanium and titanium alloys (TA2, TA3, TA10, GR2, GR3, GR9, etc.) , used for thermal processing and rolling blanking of φ800 blooming mill: (1) Block-shaped isolation device made of refractory material, with 2 semicircular pits on the upper surface, the pit size (φ520mm) is slightly larger than the diameter of the ingot, The pitch of pits is 500mm; (2) Clamp the block-shaped isolation device into the soaking furnace first, and place it flat on the furnace bottom near the furnace wall; then clamp the ingot into the soaking furnace, one end of the ingot along the length direction Stand vertically on the pit on the upper surface of the block-shaped isolation device, and the other end leans against the furnace wall of the soaking furnace; (3) When heating, first keep the ingot in the soaking furnace for 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com