Thrombin preparation method

A technology of thrombin and porcine thrombin, applied in biochemical equipment and methods, enzymes, peptidases, etc., can solve problems such as high impurity content in products, restrictions on clinical application of thrombin products, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The preparation of embodiment 1 porcine thrombin freeze-dried product

[0071] 1) Collect pig blood and prepare anticoagulant pig plasma, inhale the anticoagulant pig plasma into the high-level storage tank, flow into the tubular centrifuge through the lower discharge valve of the tank, and turn on the tubular centrifuge for centrifugation. Specifically, add anticoagulant to fresh pig blood according to the ratio of anticoagulant to fresh pig blood volume ratio of 1:9, stir gently, let it stand at 10°C, and within 5 to 8 hours Centrifuge at 19000r / min, the centrifugation temperature is 10°C, and the centrifugation time is 15 minutes, and the upper plasma is collected. Described anticoagulant is the trisodium citrate aqueous solution of 38 grams / liter. And step by step through the 70 mesh, 100 mesh, 200 mesh filter to remove impurities;

[0072] 2) Add the pre-treated sorbent to the porcine plasma that has been filtered according to the mass ratio of 1000:2 between the...

Embodiment 2

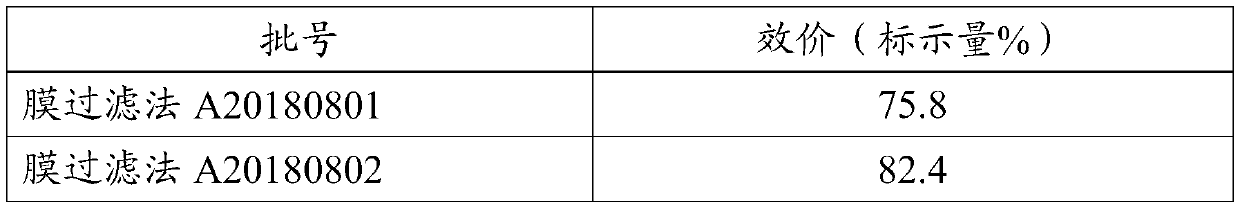

[0091] Example 2: Effects of different virus inactivation and removal methods on the potency of porcine thrombin freeze-dried products

[0092] Among the various preparation methods in this example, the virus inactivation and removal methods are respectively S / D method combined with membrane filtration method (for specific methods, see ZL201410591661.6 Chinese invention patent) and S / D method combined with dry heat method (for specific methods Referring to Example 1 of the present application, the remaining conditions used in the preparation method of the porcine thrombin freeze-dried product are the same as in Example 1. Specifically, the dry heat method controls the moisture content of the freeze-dried product within 2% by weight. The dry heat method first raises the temperature to 105°C, and then continues to control the temperature at 100±1°C for 45 minutes of dry heat treatment. The dry heat method uses water Spray type. Three batches of products were produced by various...

Embodiment 3

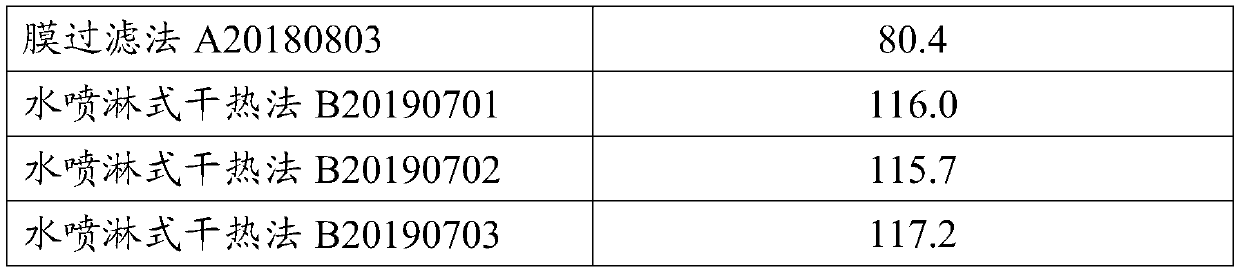

[0096] Example 3: Effects of different dry heat methods on the virus inactivation of porcine thrombin freeze-dried products

[0097] In the preparation method of this embodiment, the following dry heat methods are respectively used for virus inactivation:

[0098] (1) Water spray dry heat method: first raise the temperature to 104°C, and then continue to control the temperature at 100±1°C for 30 minutes of dry heat treatment. The dry heat method adopts the water spray dry heat method to produce three Batch, batch number is B. All the other preparation conditions of the porcine thrombin freeze-dried product are the same as in Example 1.

[0099] (2) The dry heat method is adopted in a dry heat box, and the temperature is directly controlled at 100±1°C for 30 minutes of dry heat treatment, and three batches are produced, and the batch number is C. All the other preparation conditions of the porcine thrombin freeze-dried product are the same as in Example 1.

[0100] Table 2 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com