Patents

Literature

32results about How to "Increased axial temperature gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

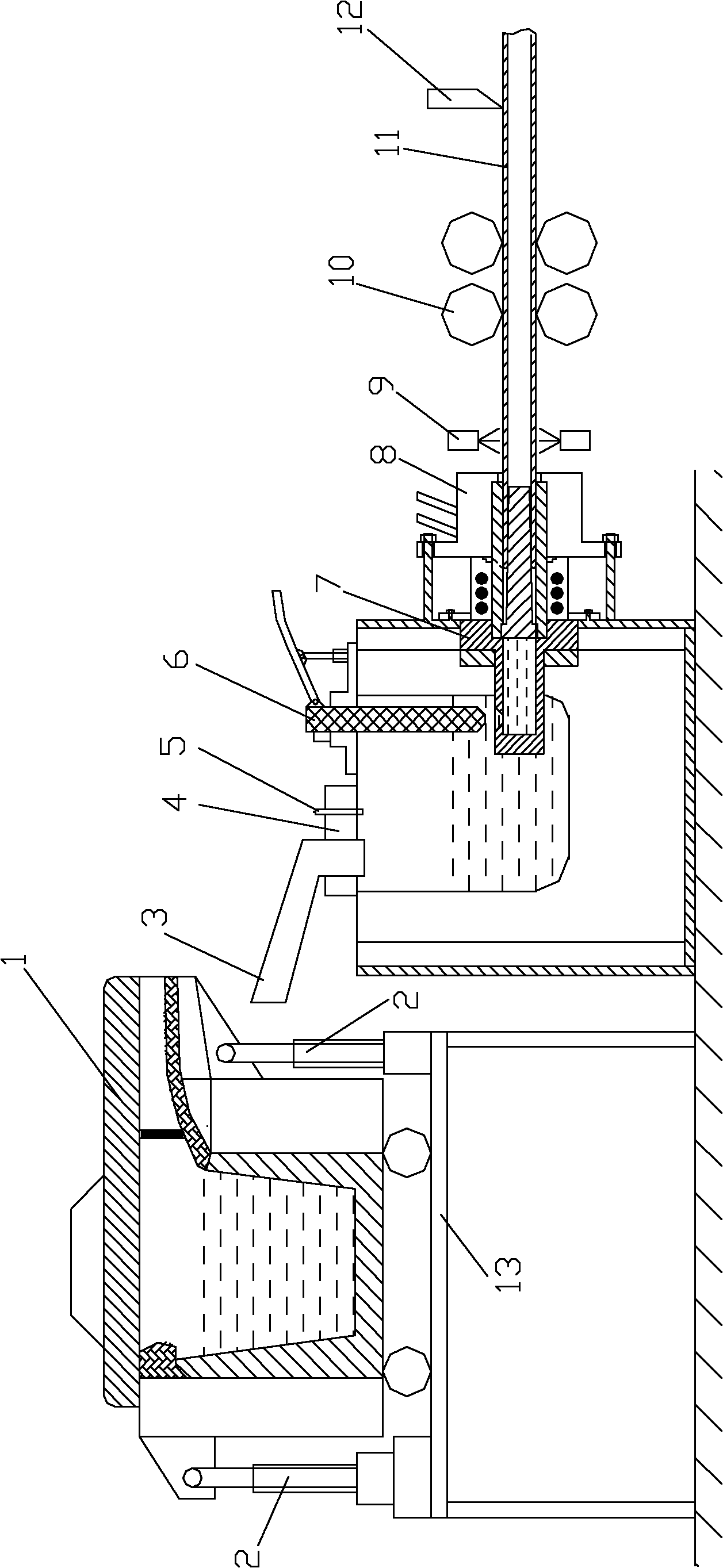

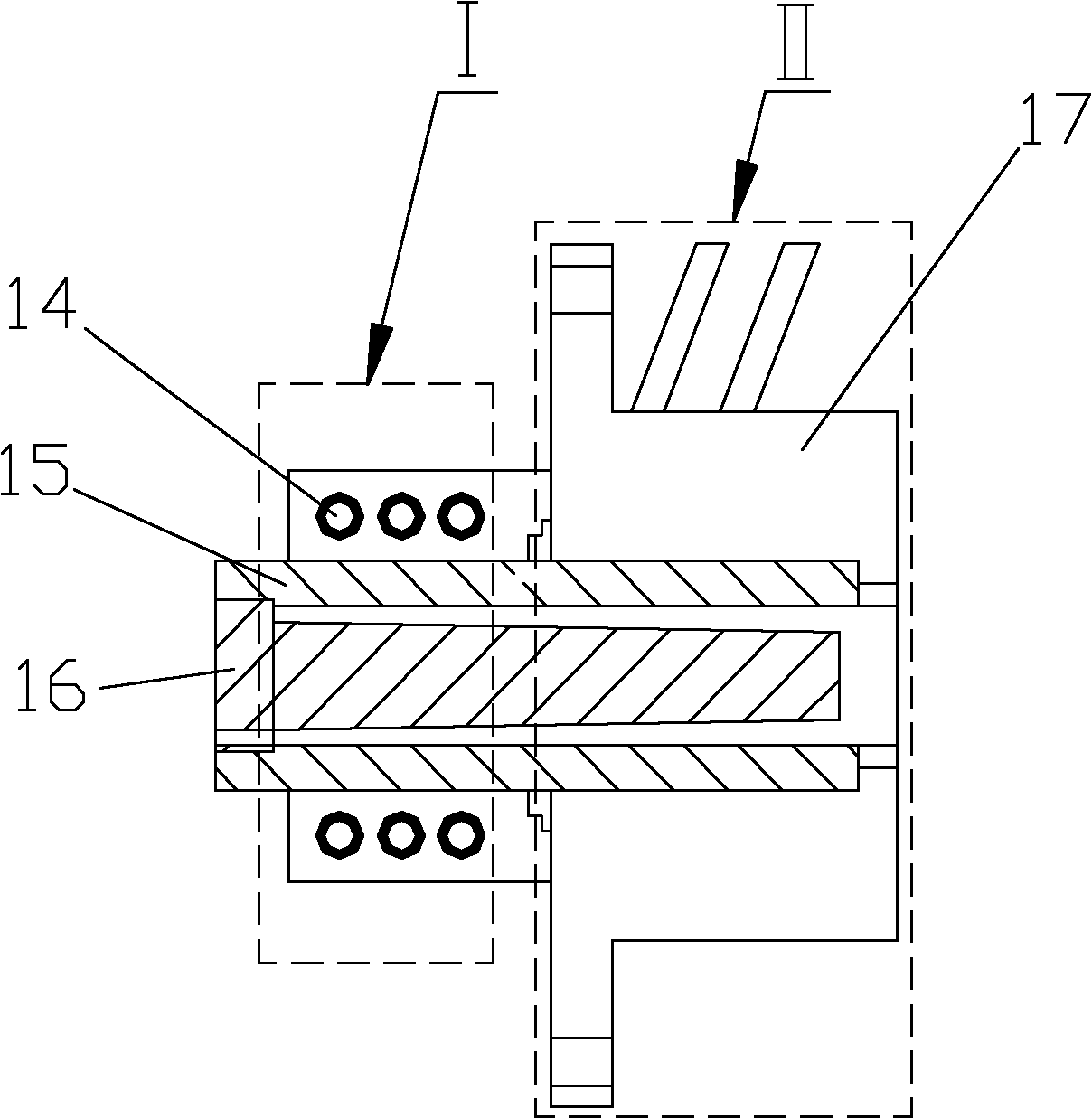

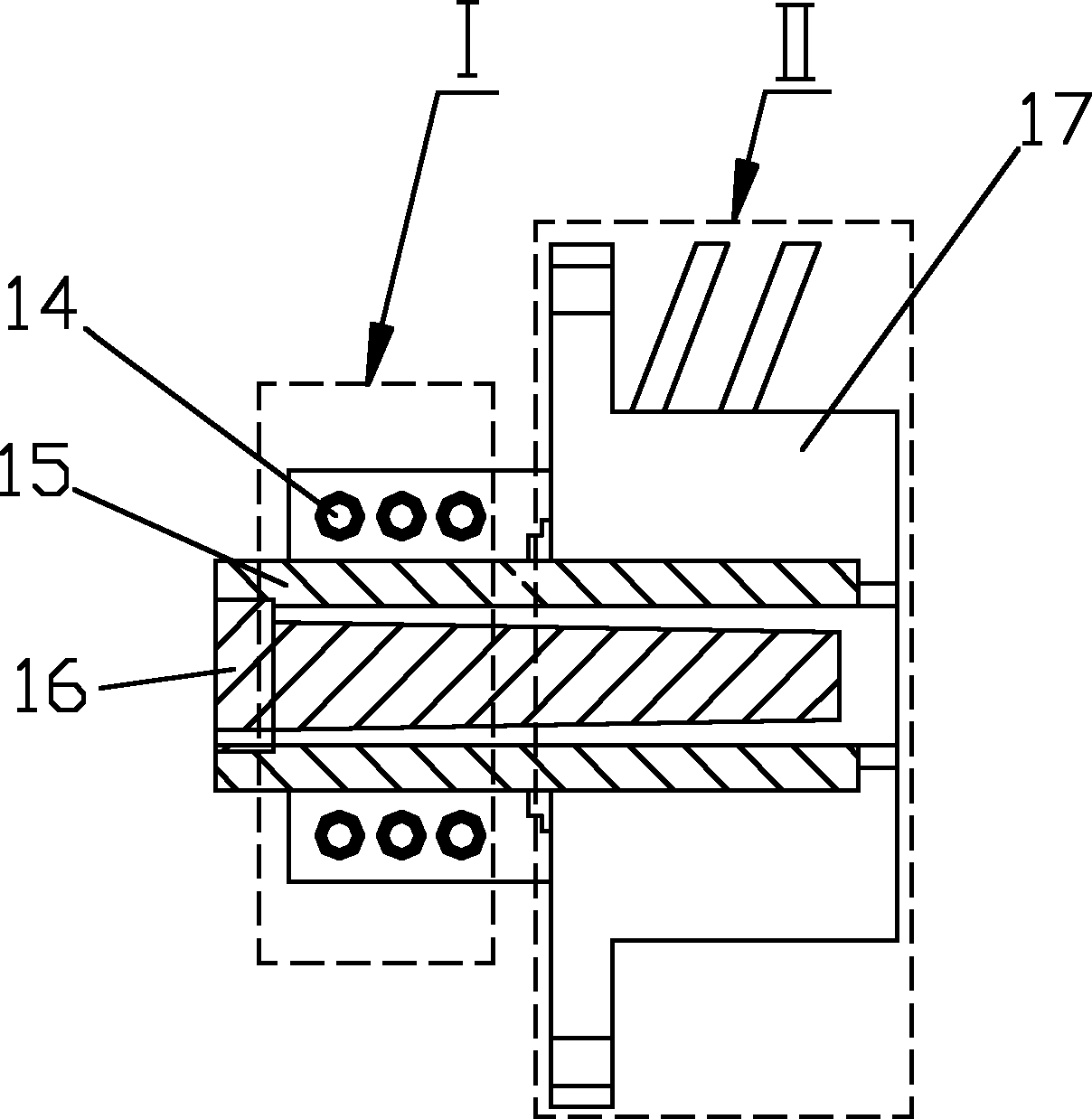

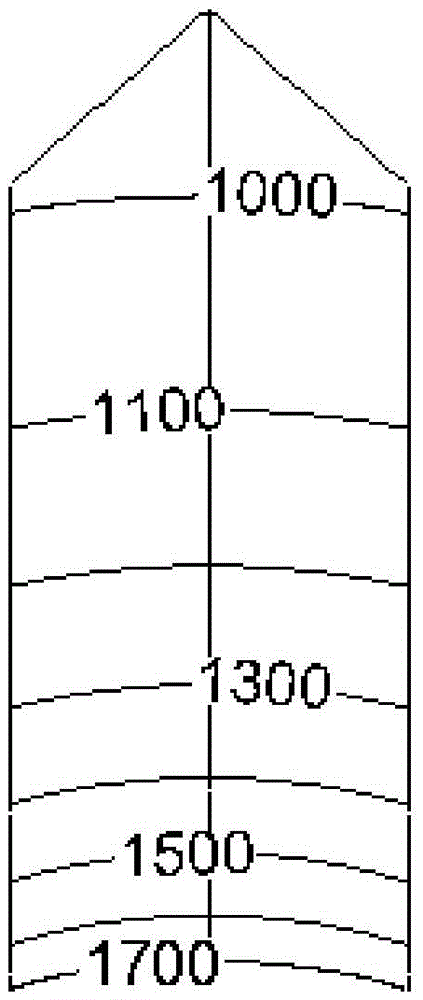

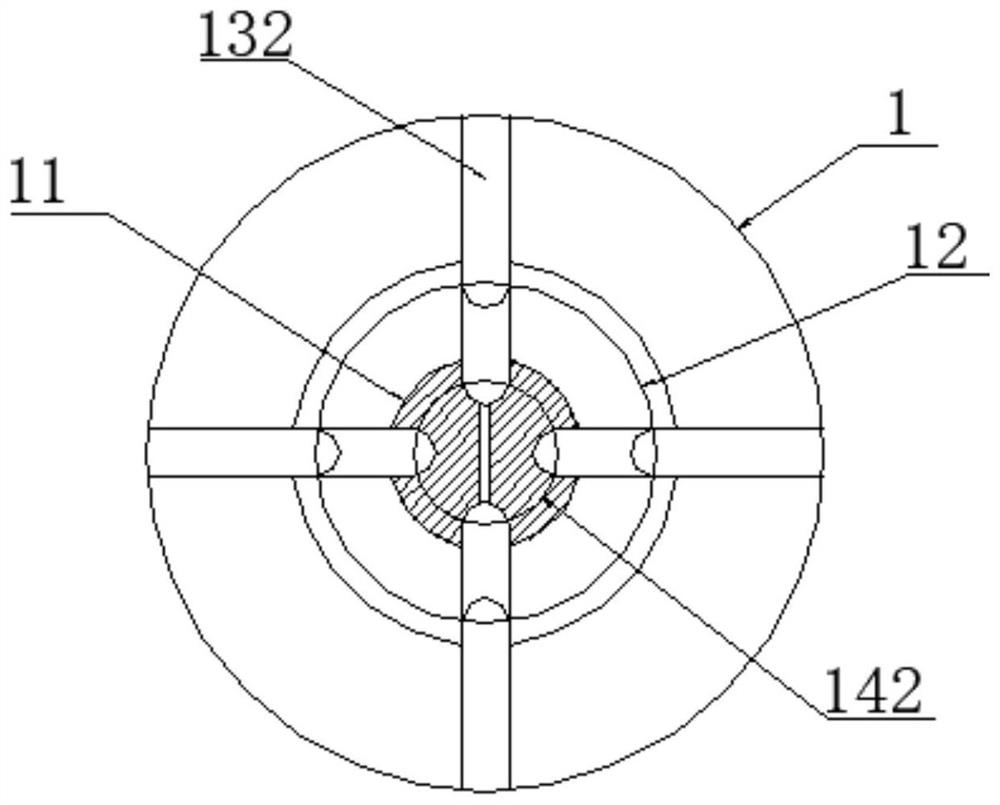

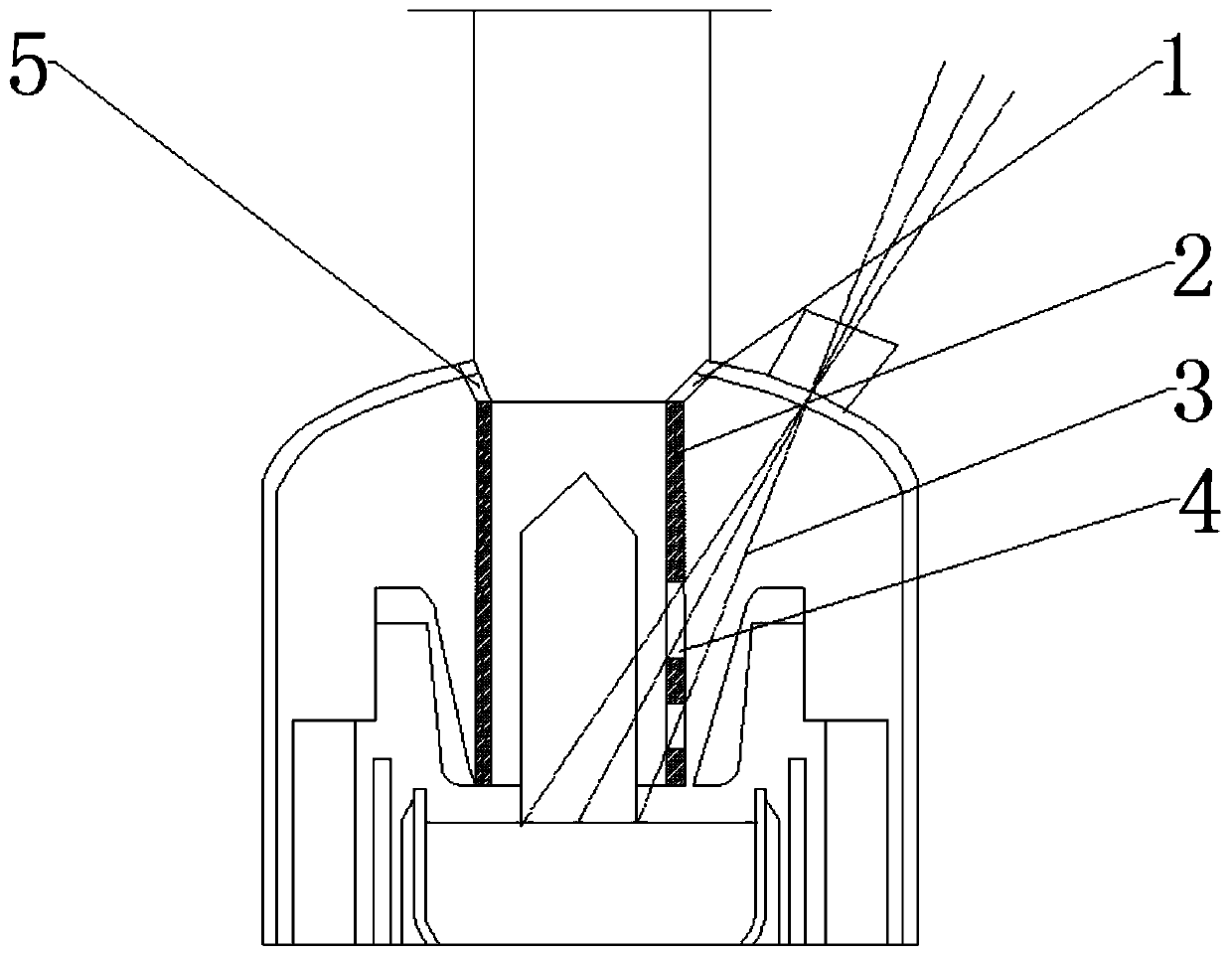

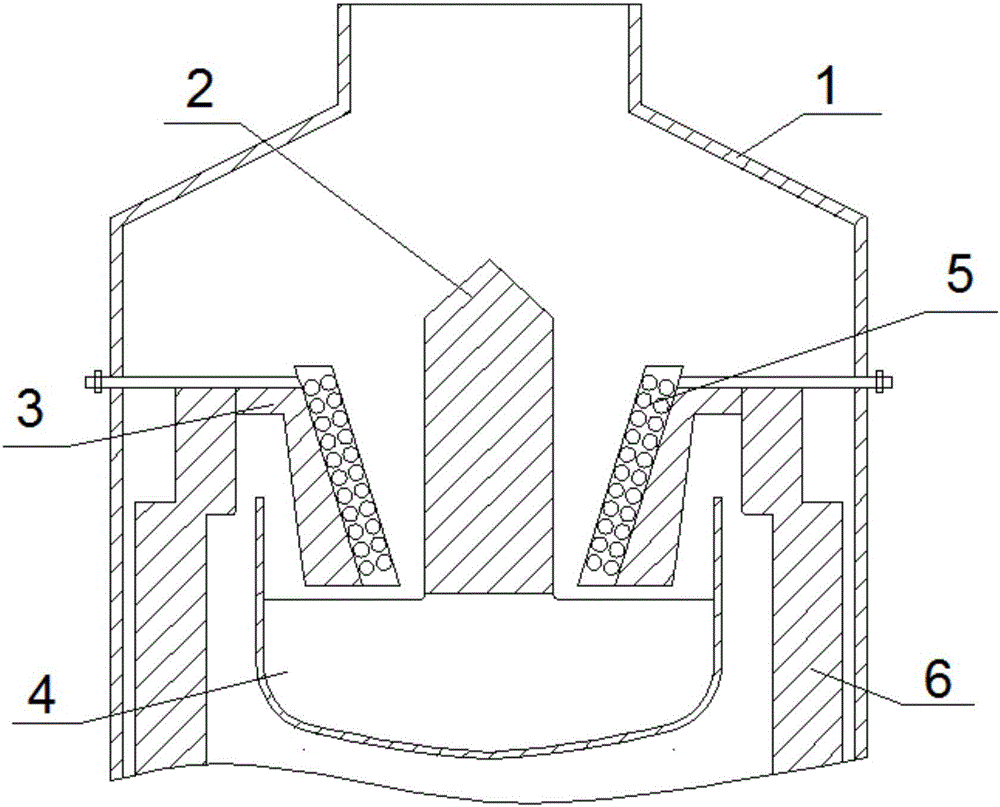

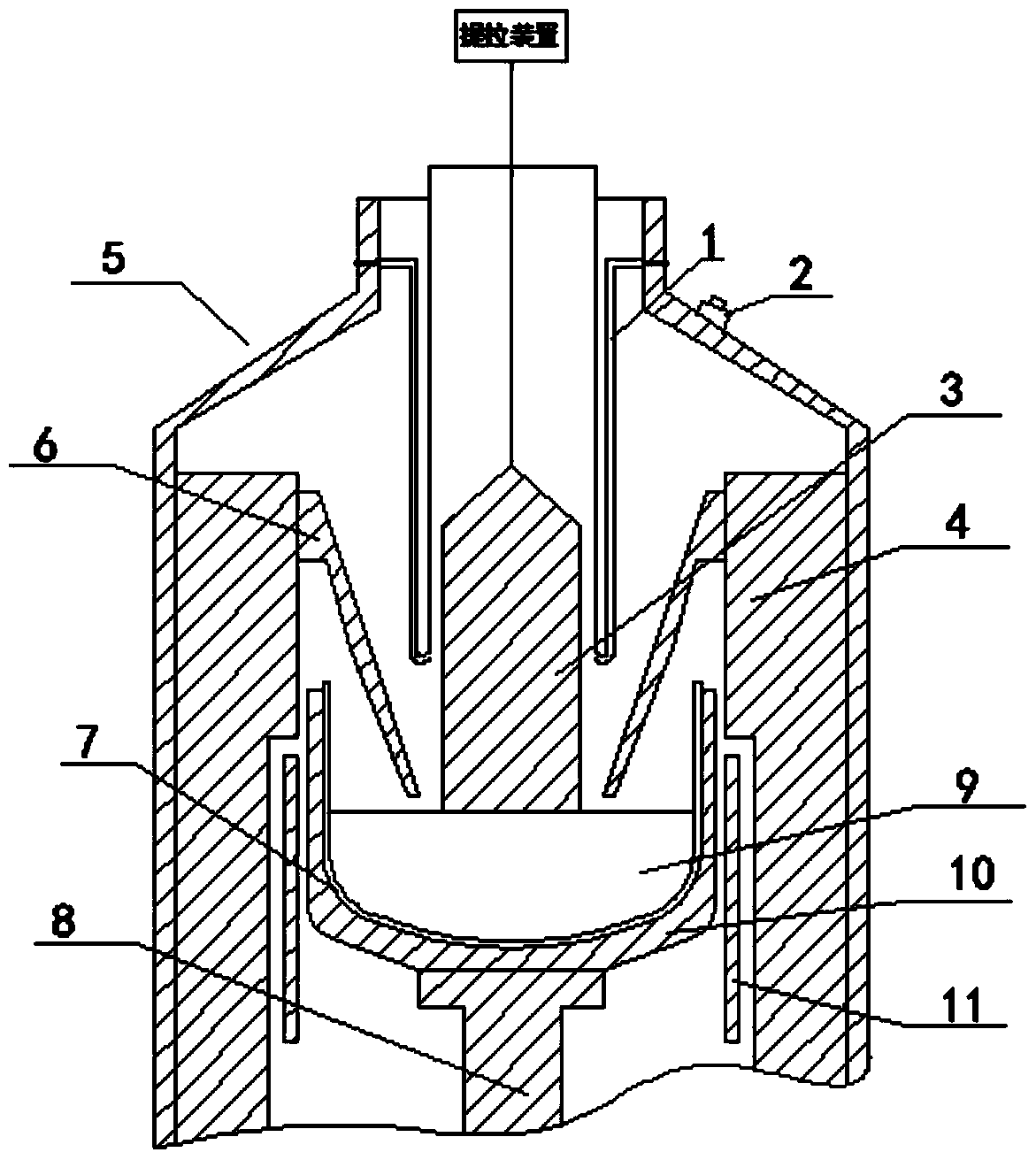

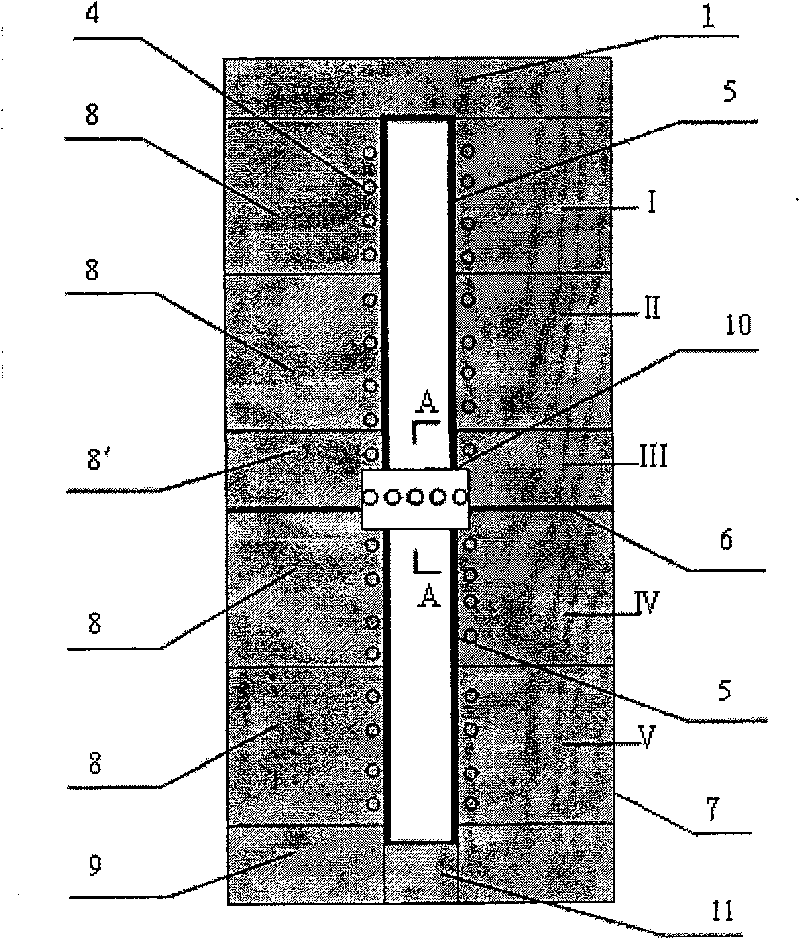

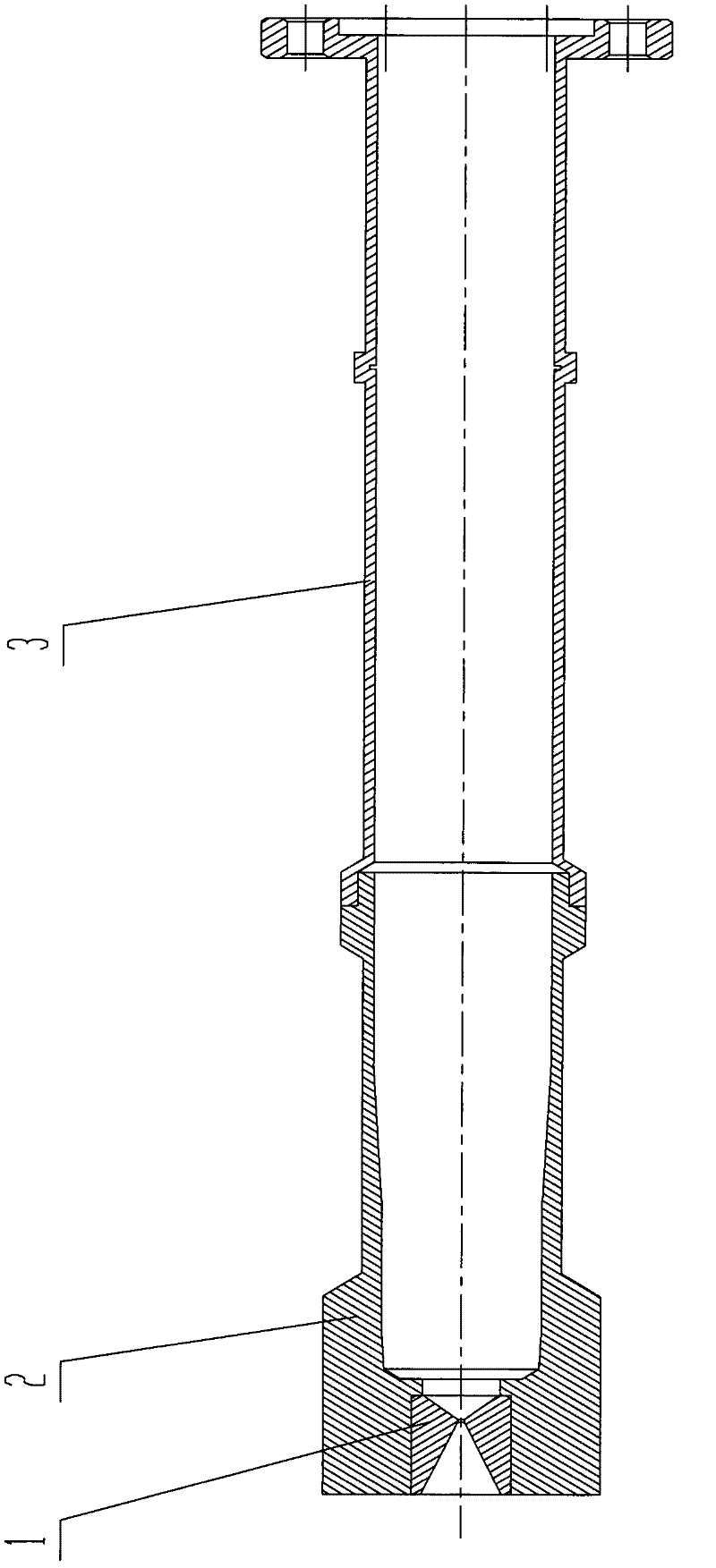

Hot-cold combined casting mould horizontal continuous casting equipment of cupronickel tubing and technology thereof

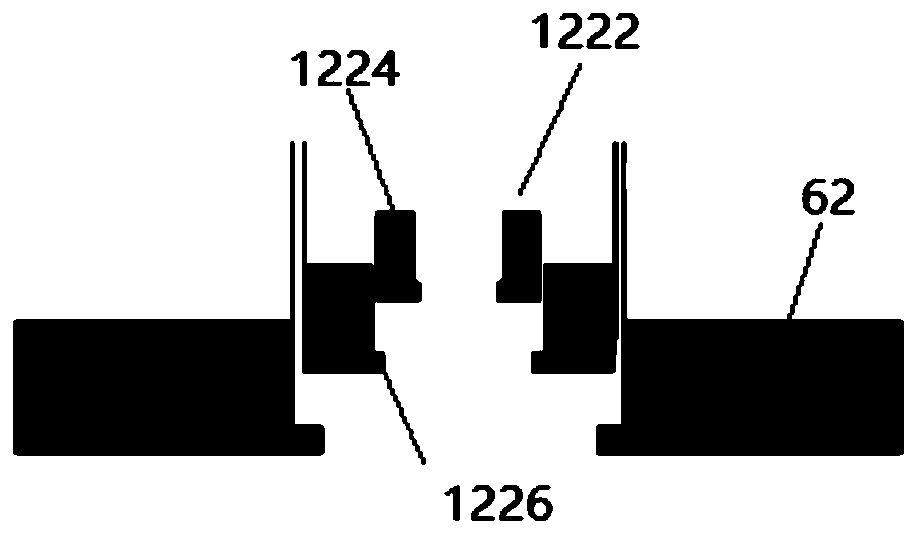

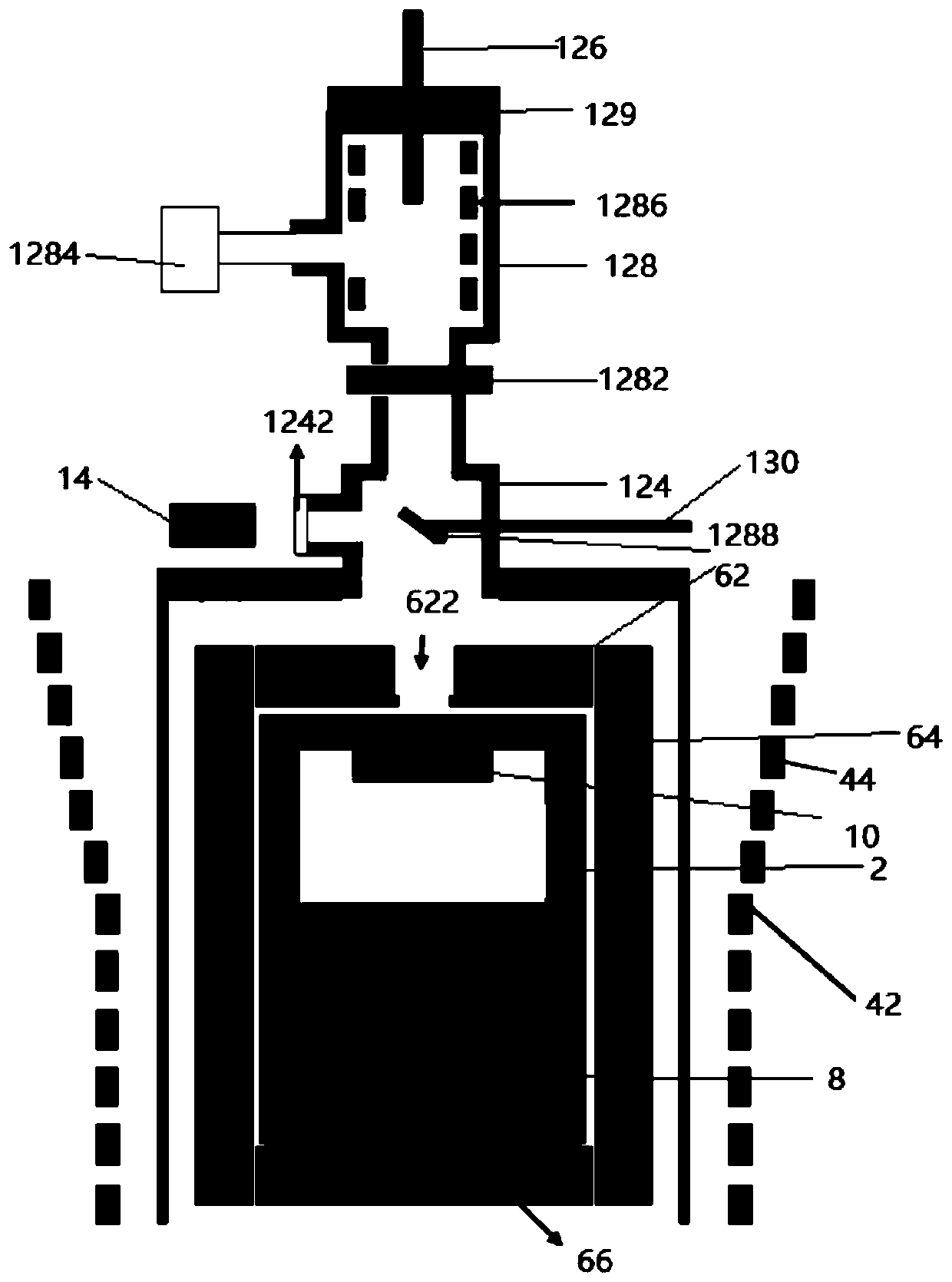

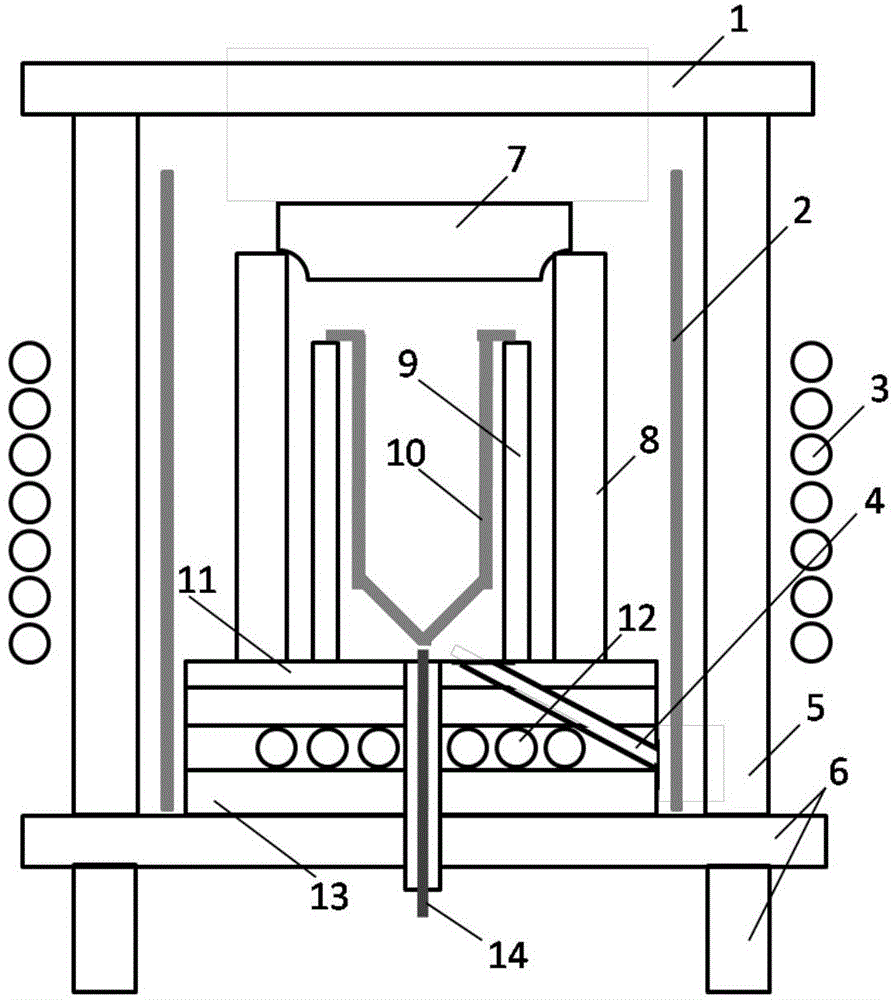

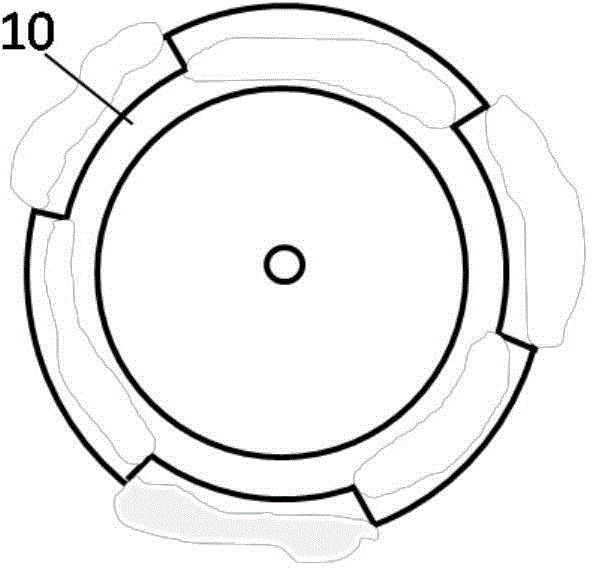

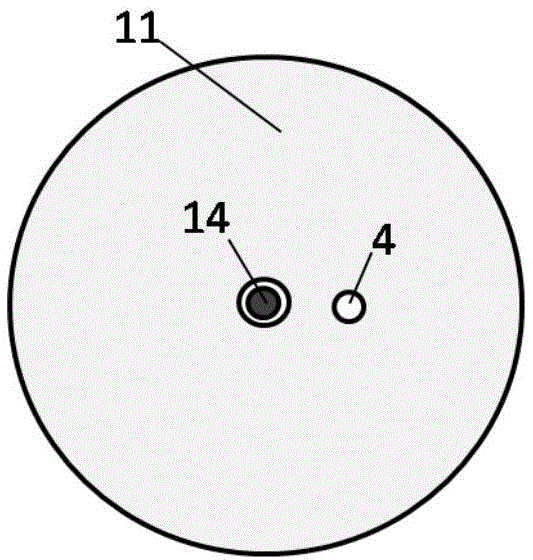

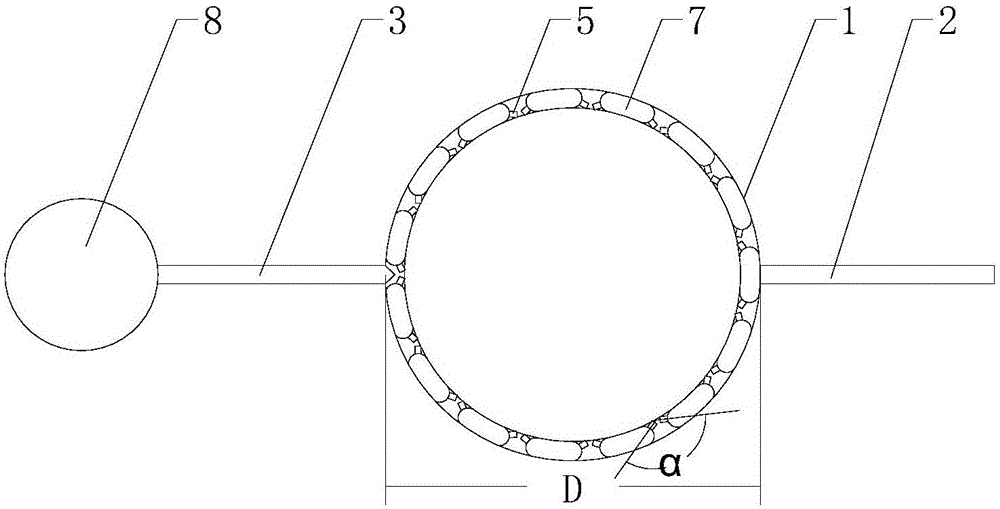

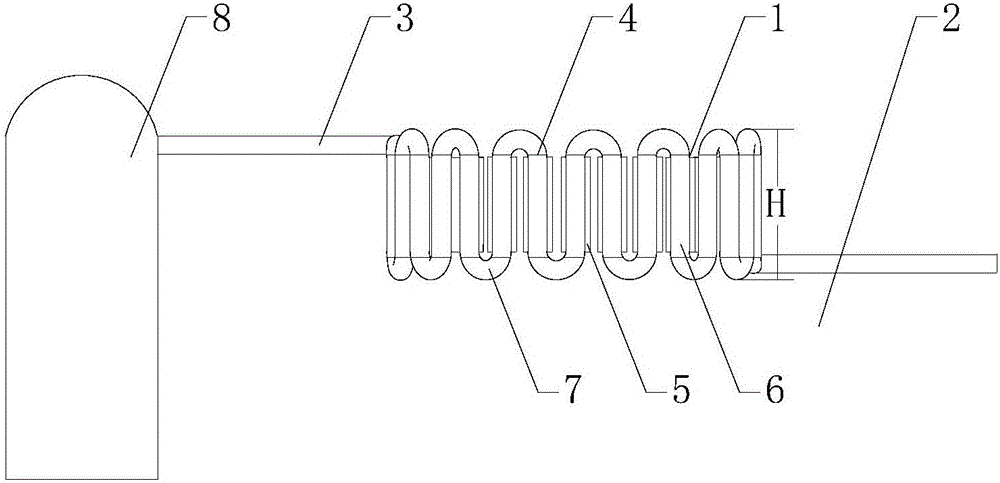

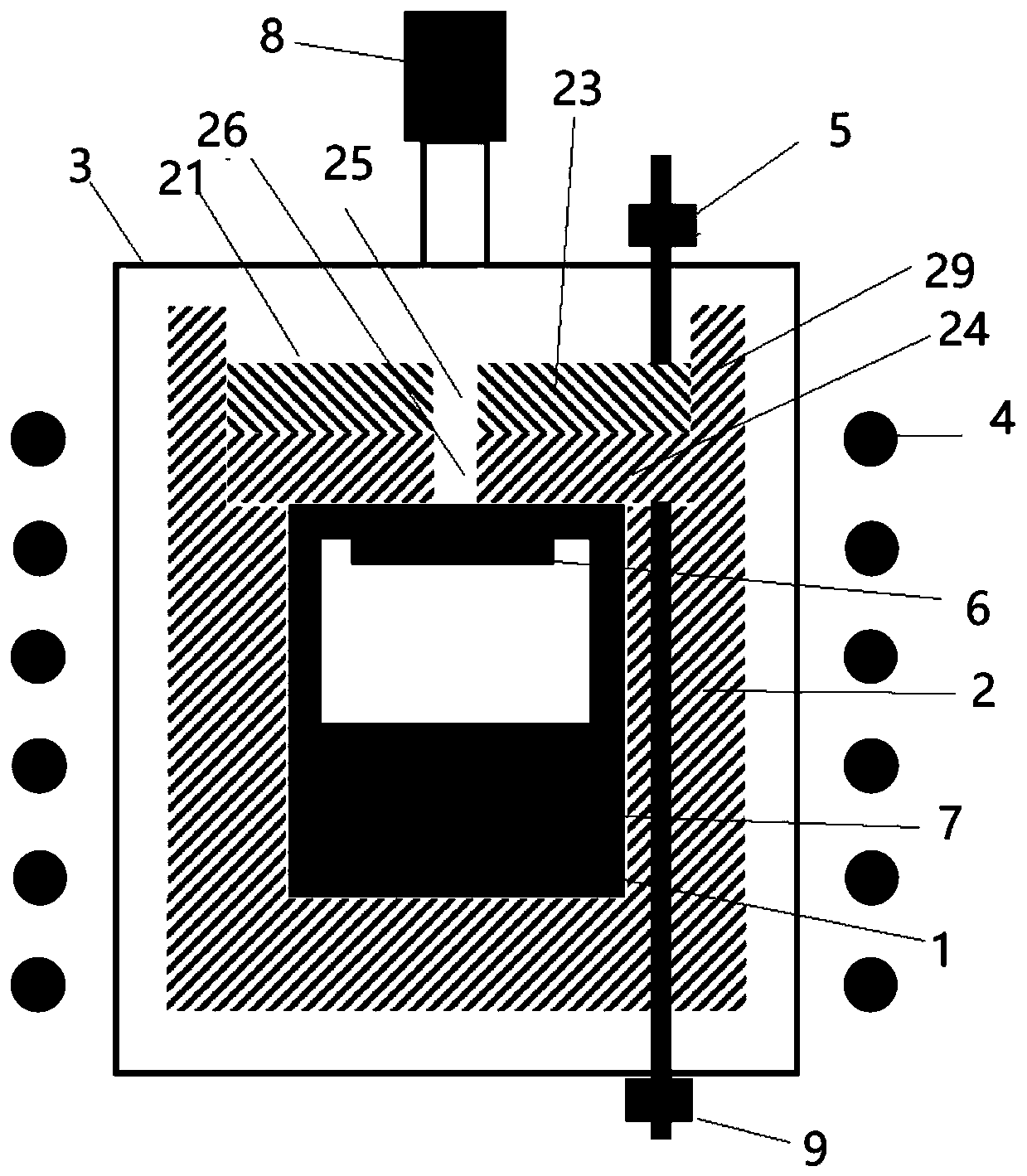

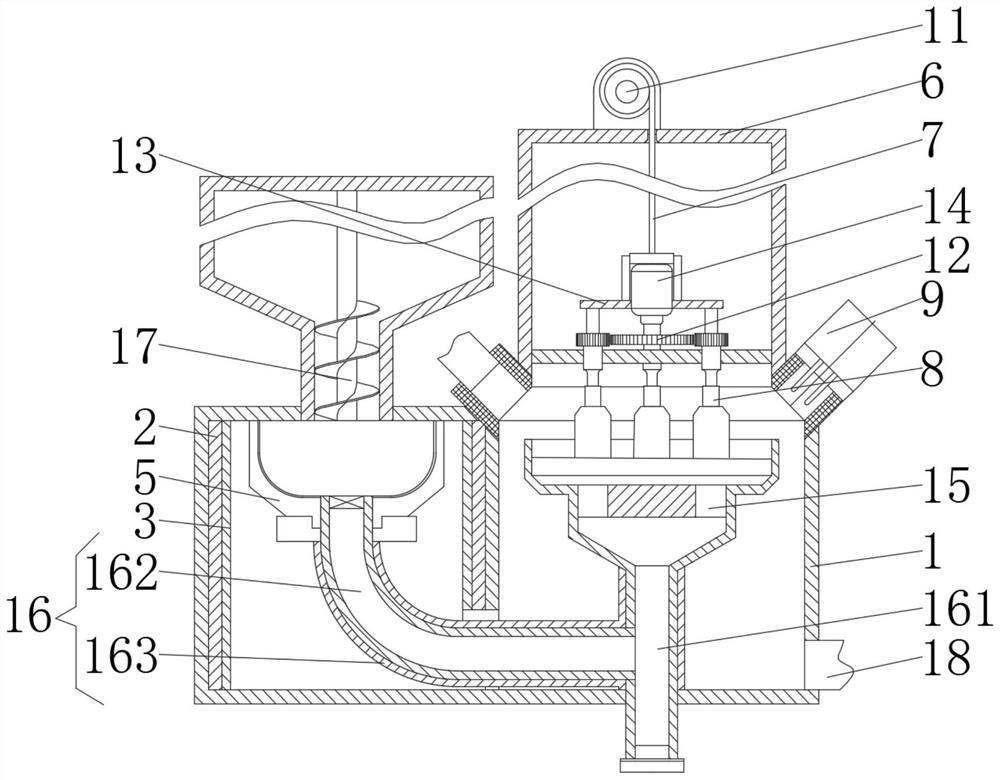

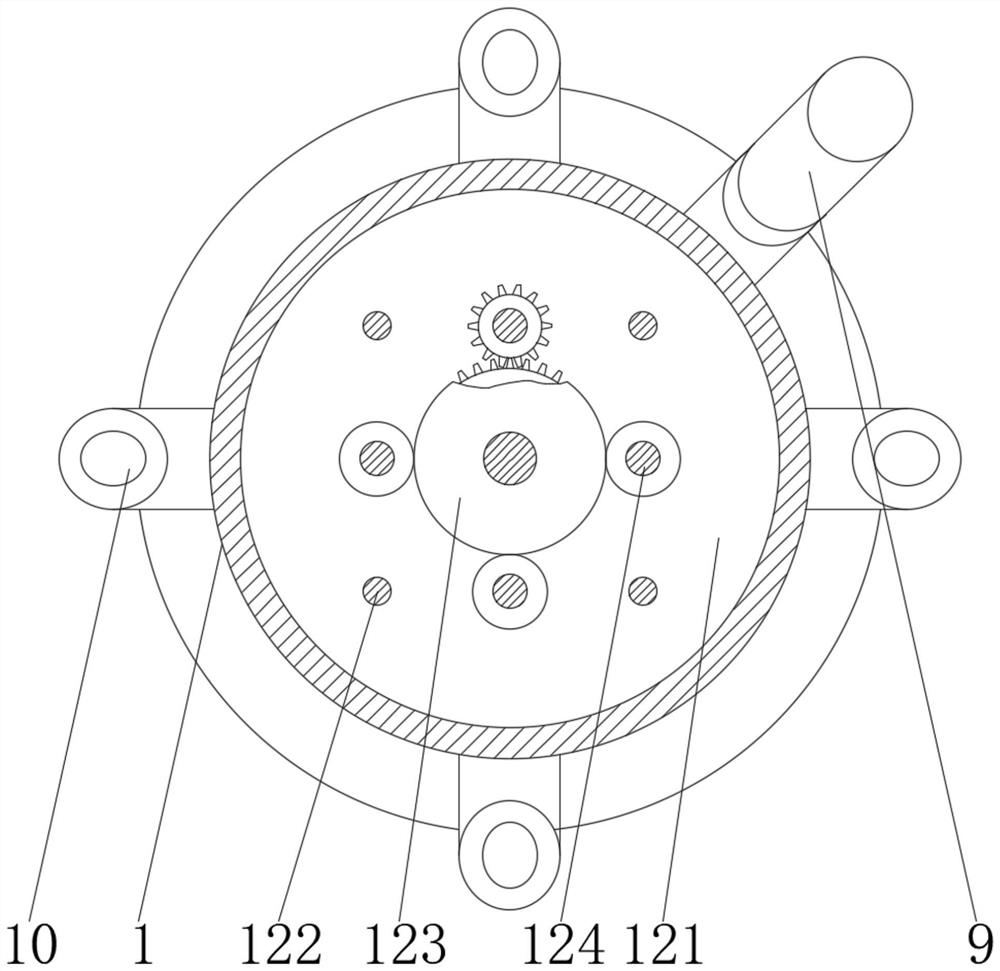

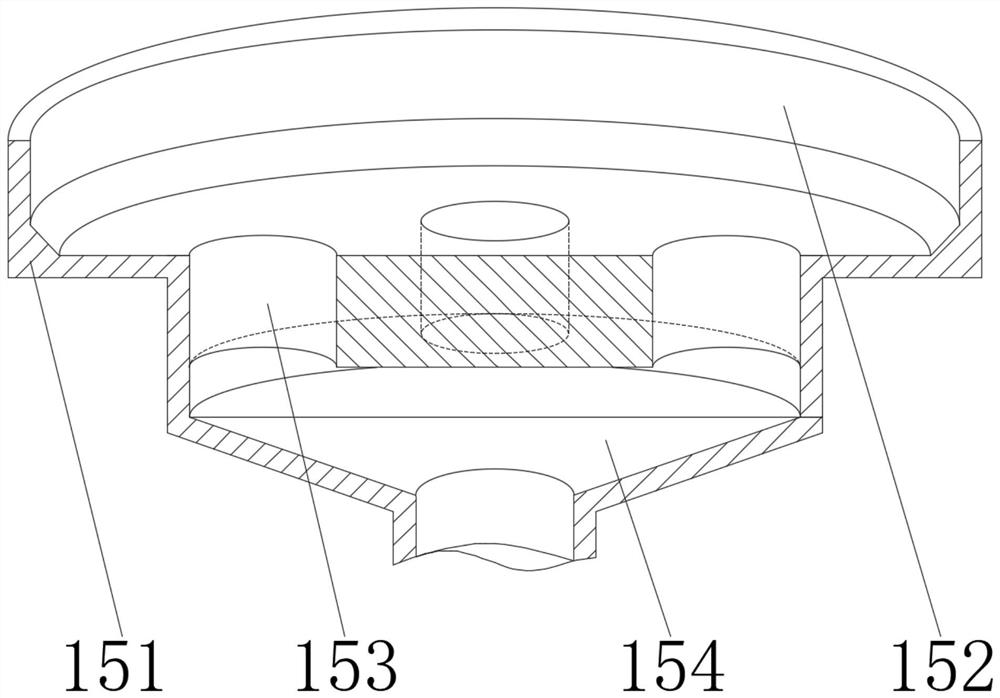

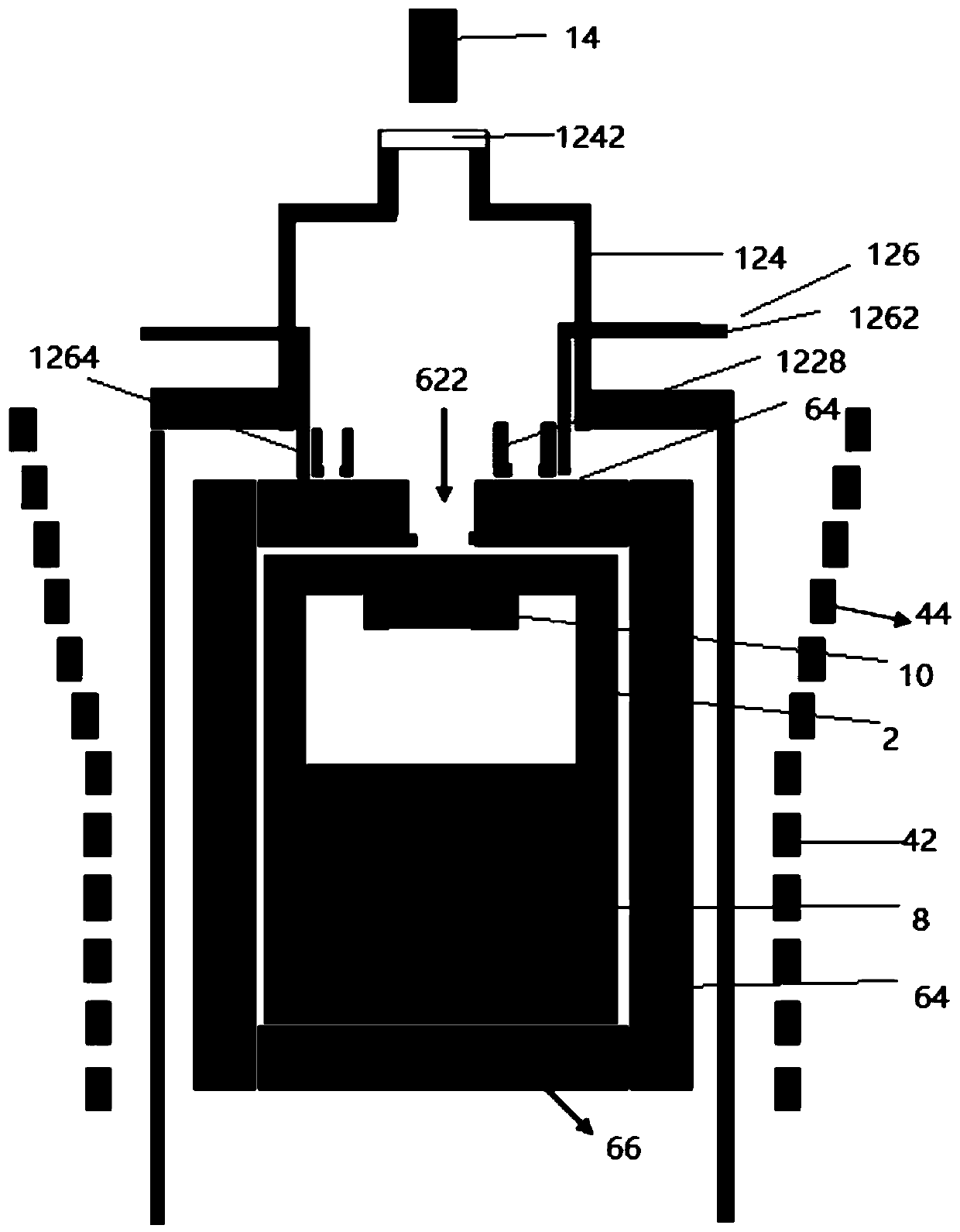

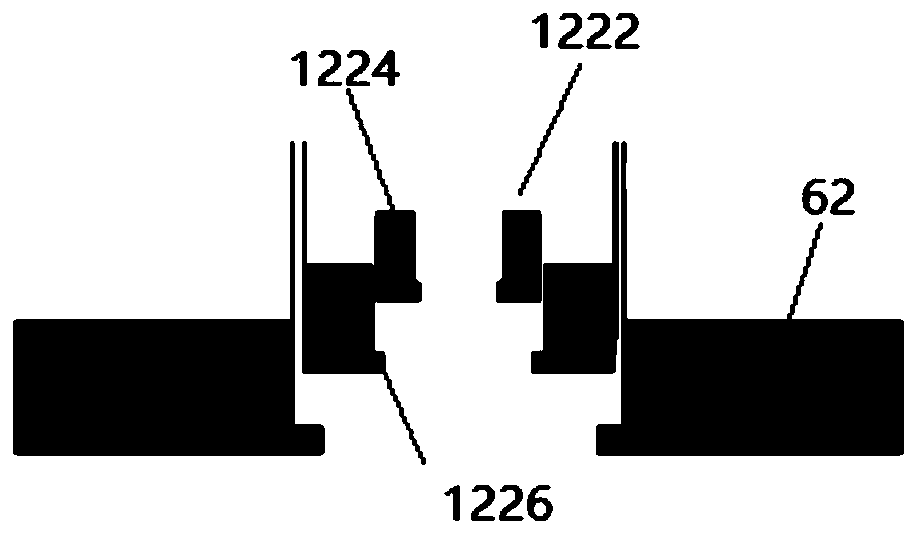

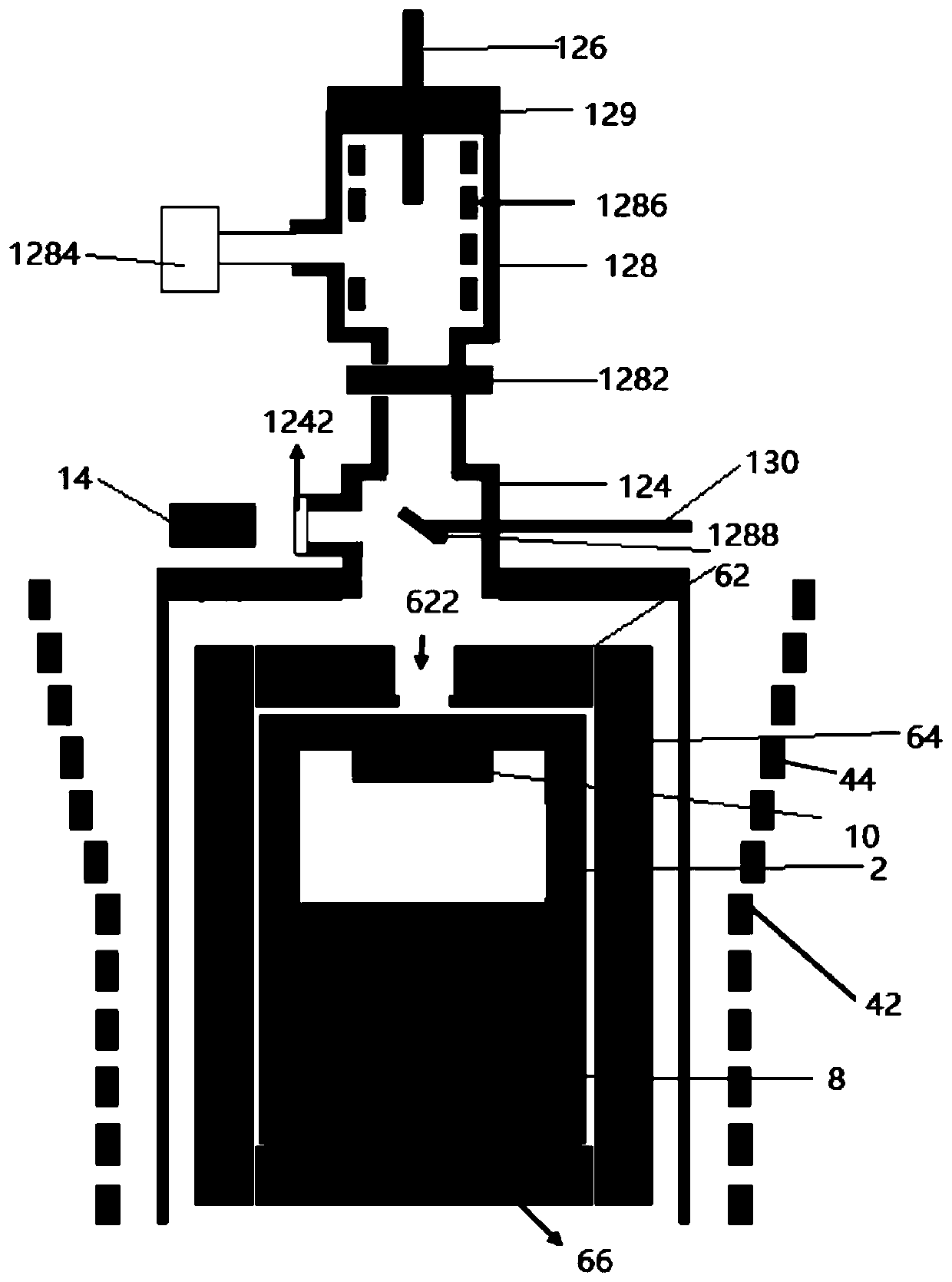

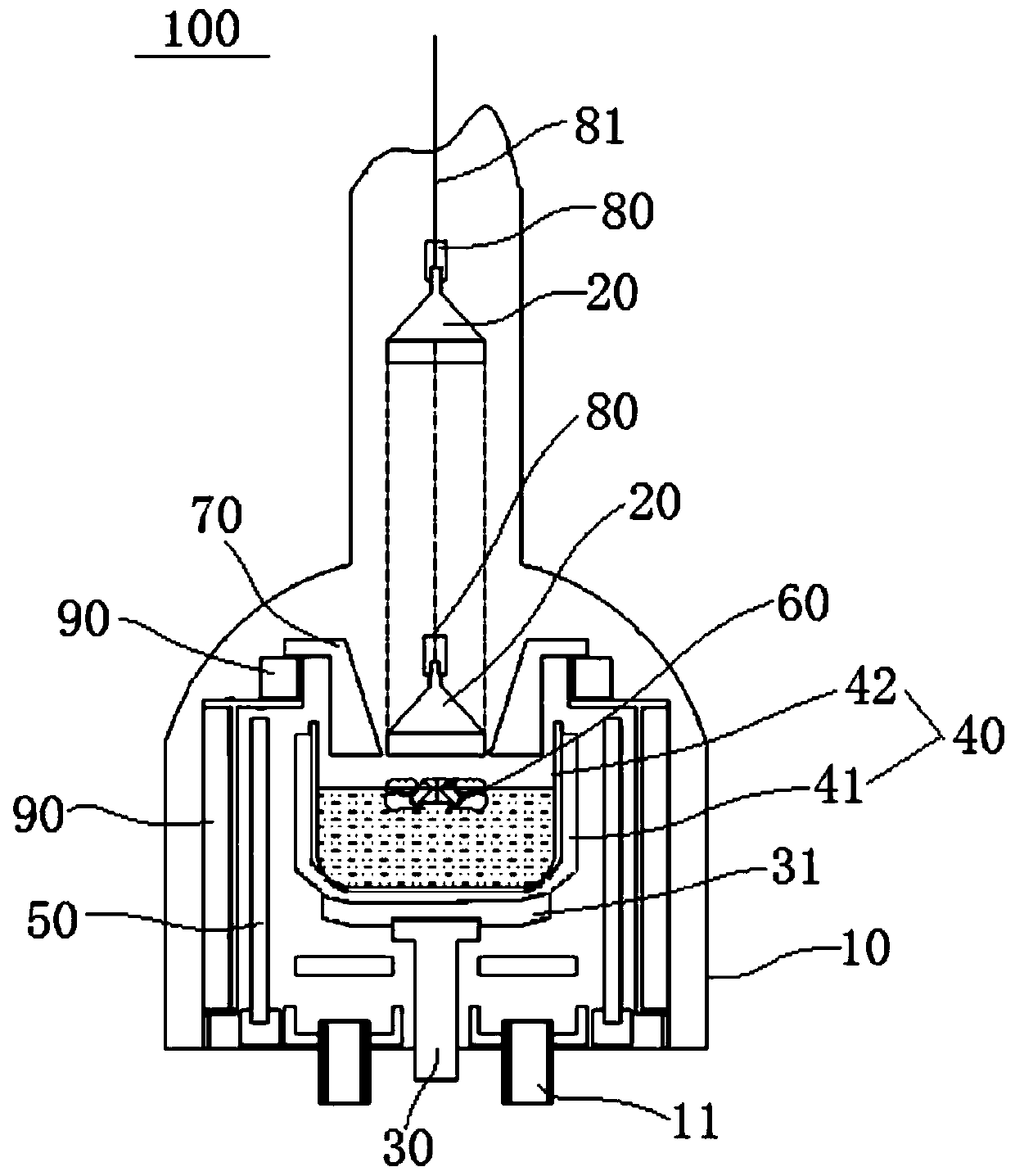

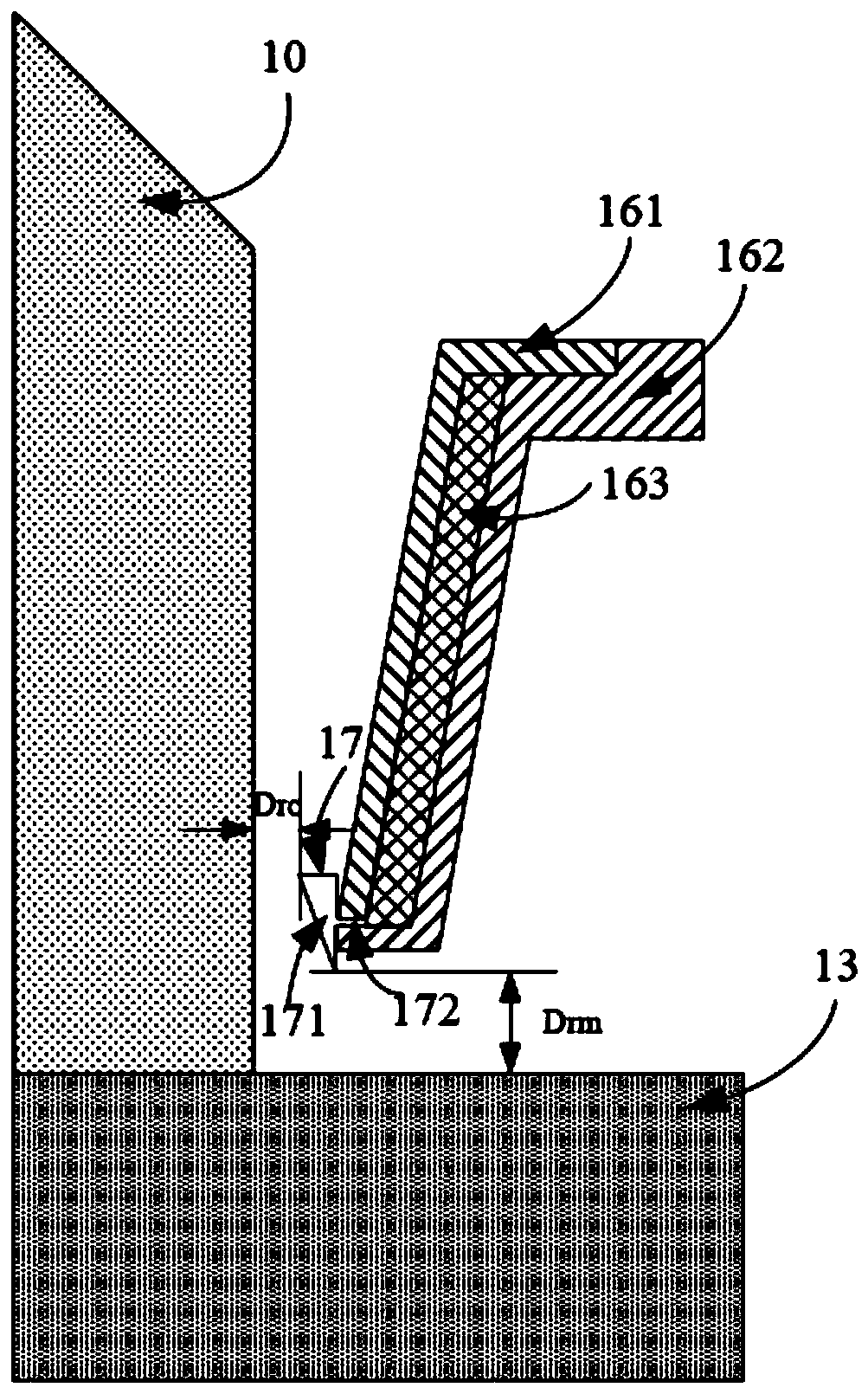

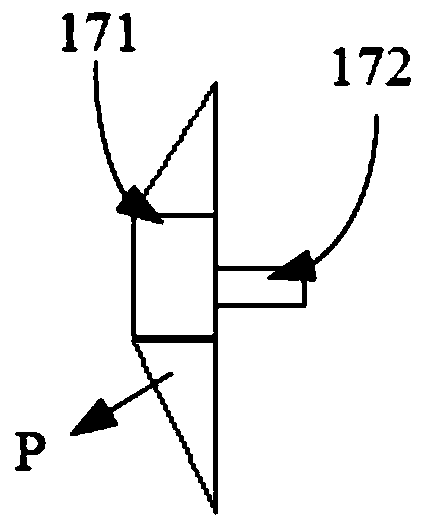

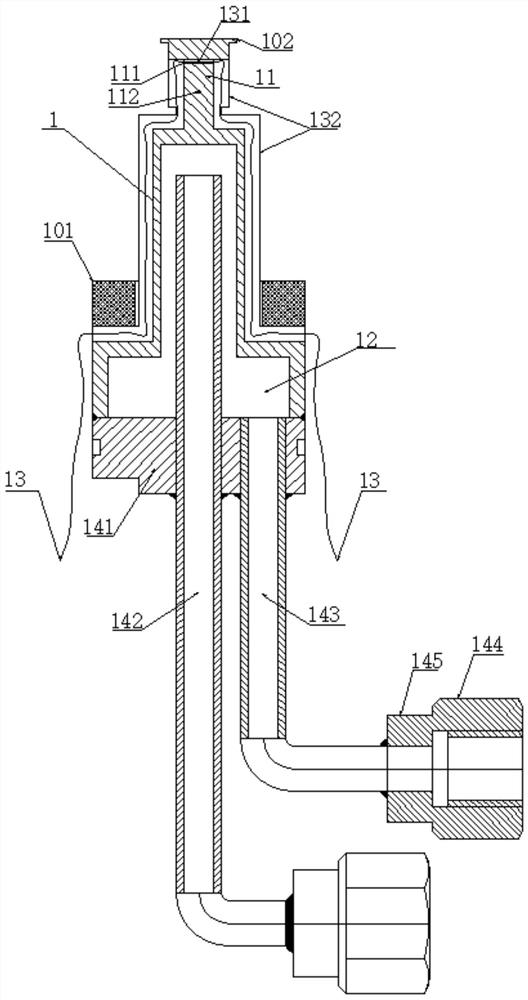

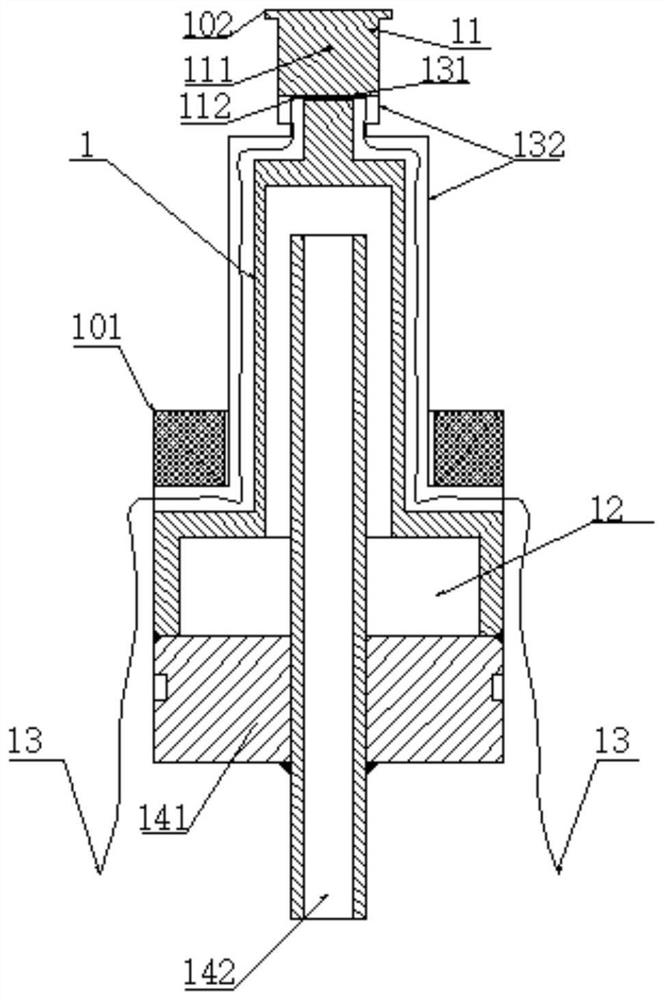

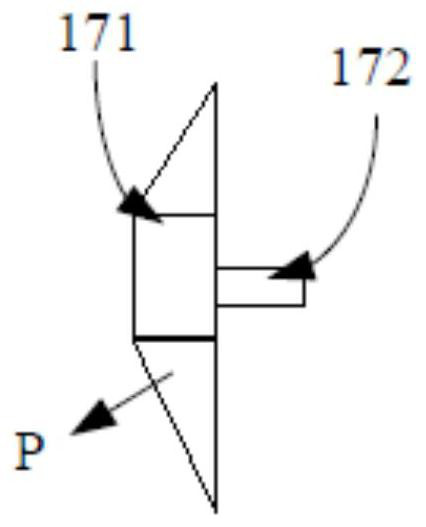

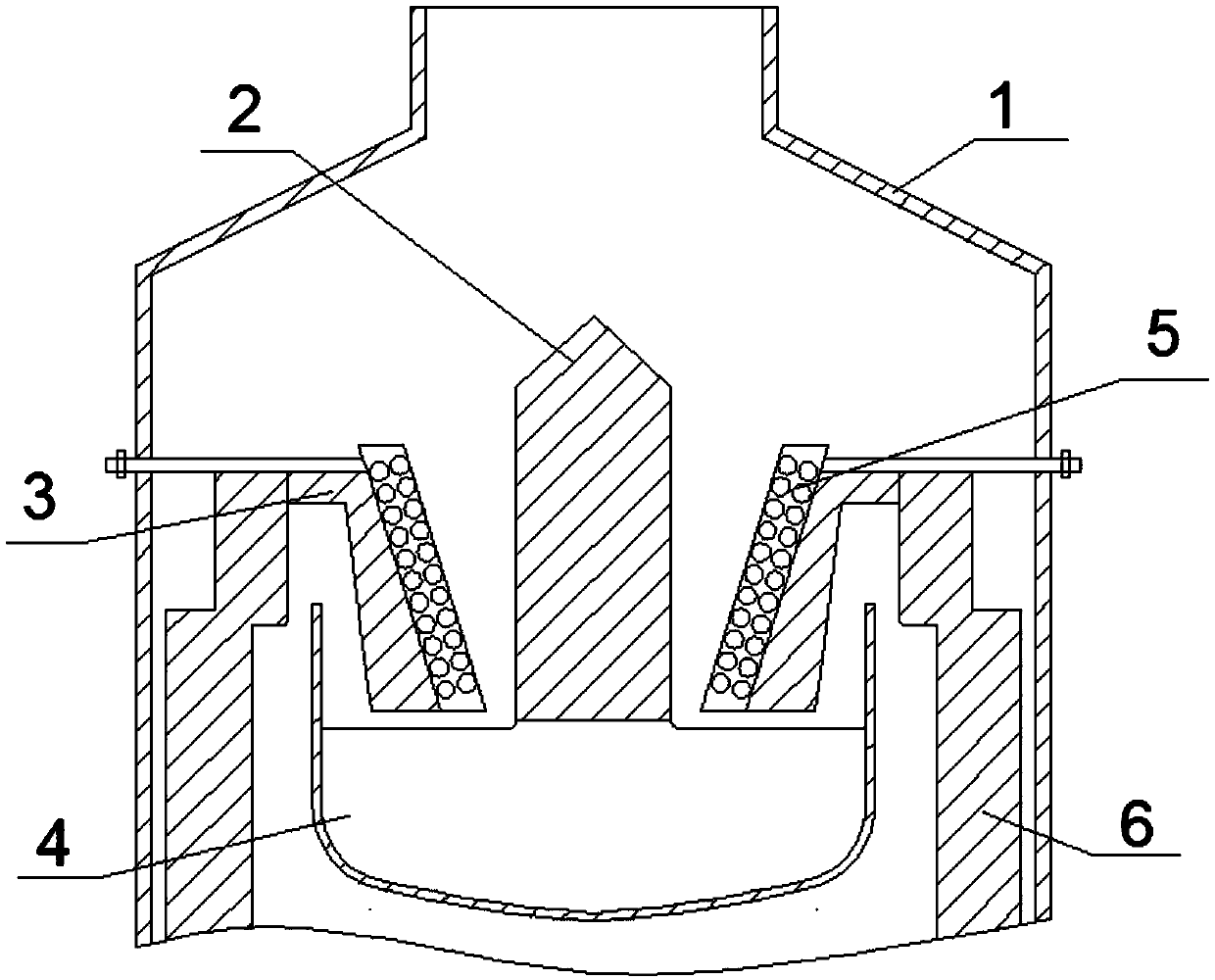

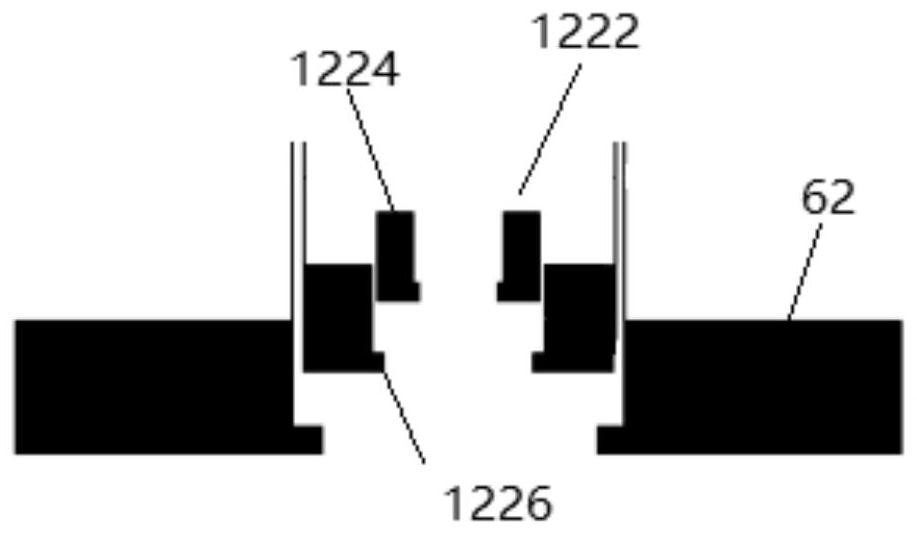

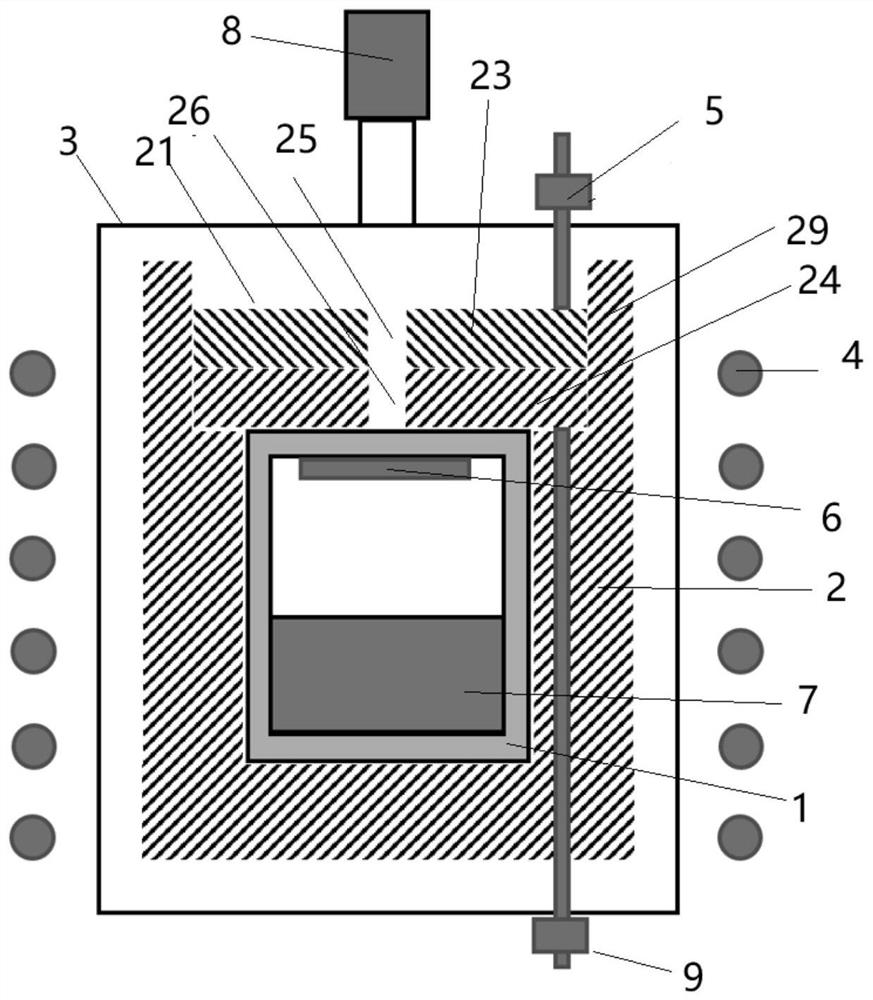

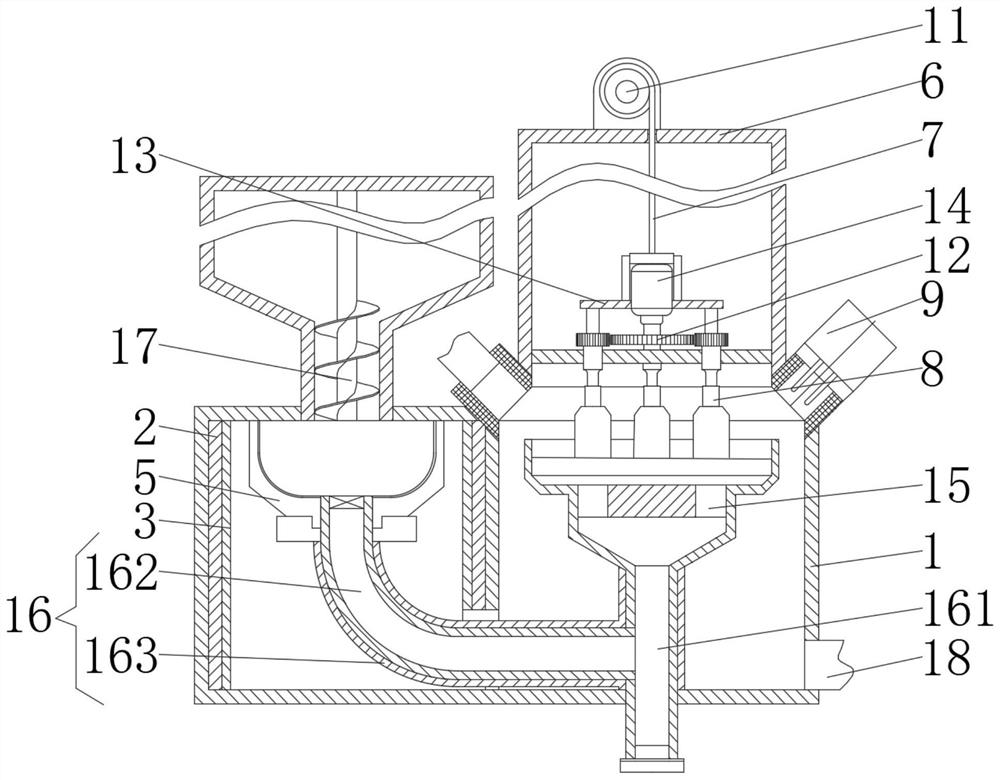

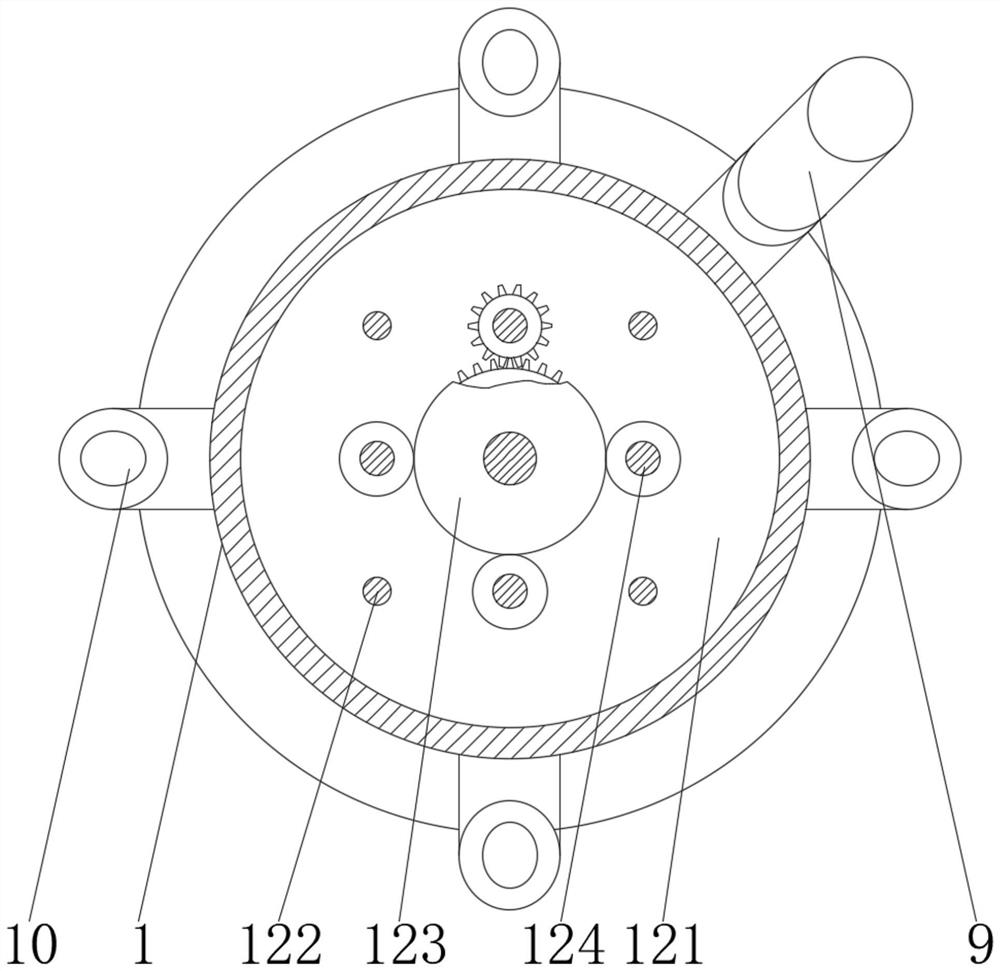

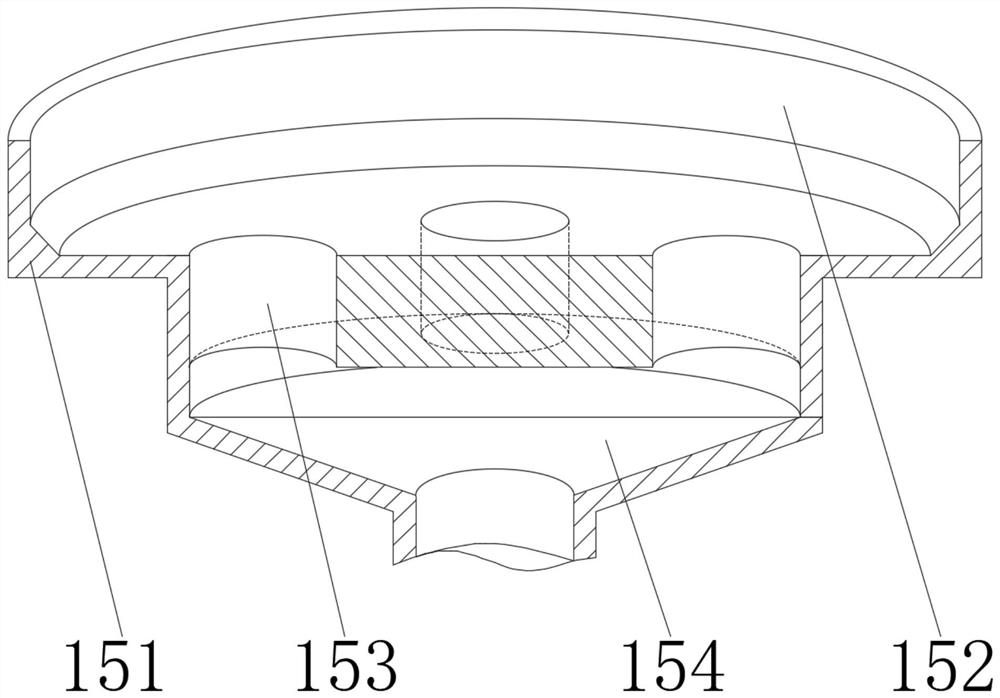

The invention provides hot-cold combined casting mould horizontal continuous casting equipment of cupronickel tubing and a technology thereof. The equipment comprises a smelting system for melting metal, a heat insulation system for storing molten metal, a horizontal continuous casting system for casting and shaping and an auxiliary system, wherein in the continuous casting system, the front end of a cold shaping section is provided with a hot shaping section so as to effectively control the solid-liquid interface of a tube billet to be located near the juncture of a cold section and a hot section; a shorter water-cooling copper bush and electromagnetic induction heating are adopted to reasonably design coil structure and the power and the frequency of a heating power supply, reduce electromagnetic constraint force to balance the hydrostatic pressure of a metal fusant, reduce friction between a primary kish and the casting mould, improve the surface quality of the tube billet and prolong the service life of the casting mould. Thus, the inner surface and the outer surface of the tube billet manufactured by the invention have good quality and no defects of orange peel, wrinkles, cracks and the like, net shape continuous casting is realized, the production efficiency and the metal yield are improved and the production cost is obviously lowered.

Owner:UNIV OF SCI & TECH BEIJING

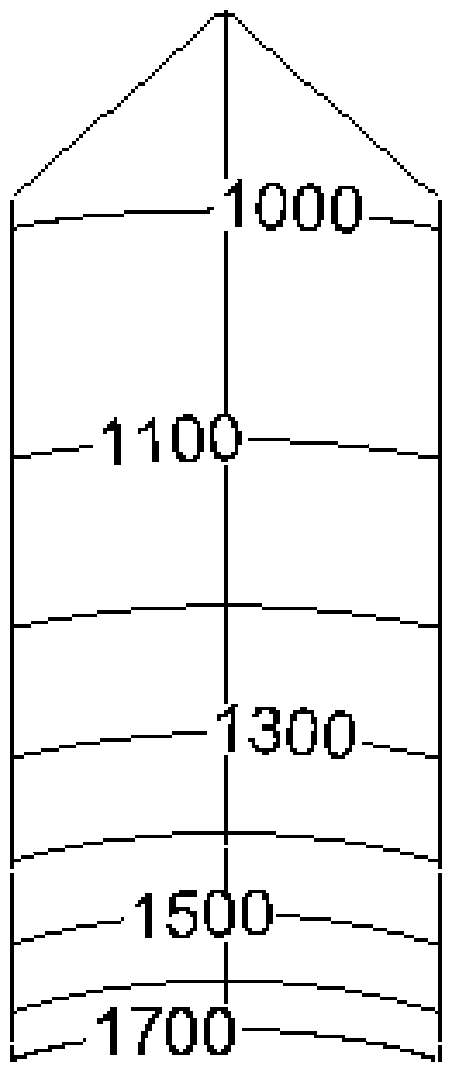

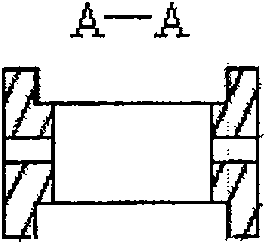

High-quality silicon carbide single crystal, and substrate and efficient preparation method thereof

ActiveCN111118598AQuality improvementLow density defectPolycrystalline material growthFrom condensed vaporsCarbide siliconSemiconductor materials

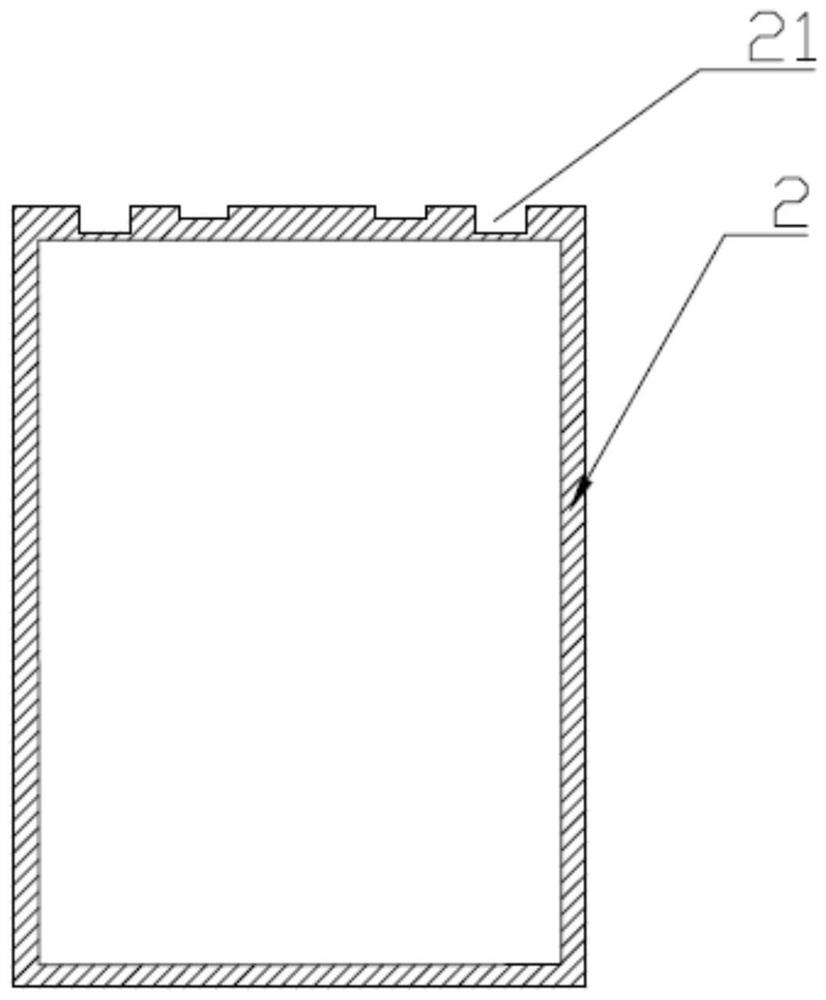

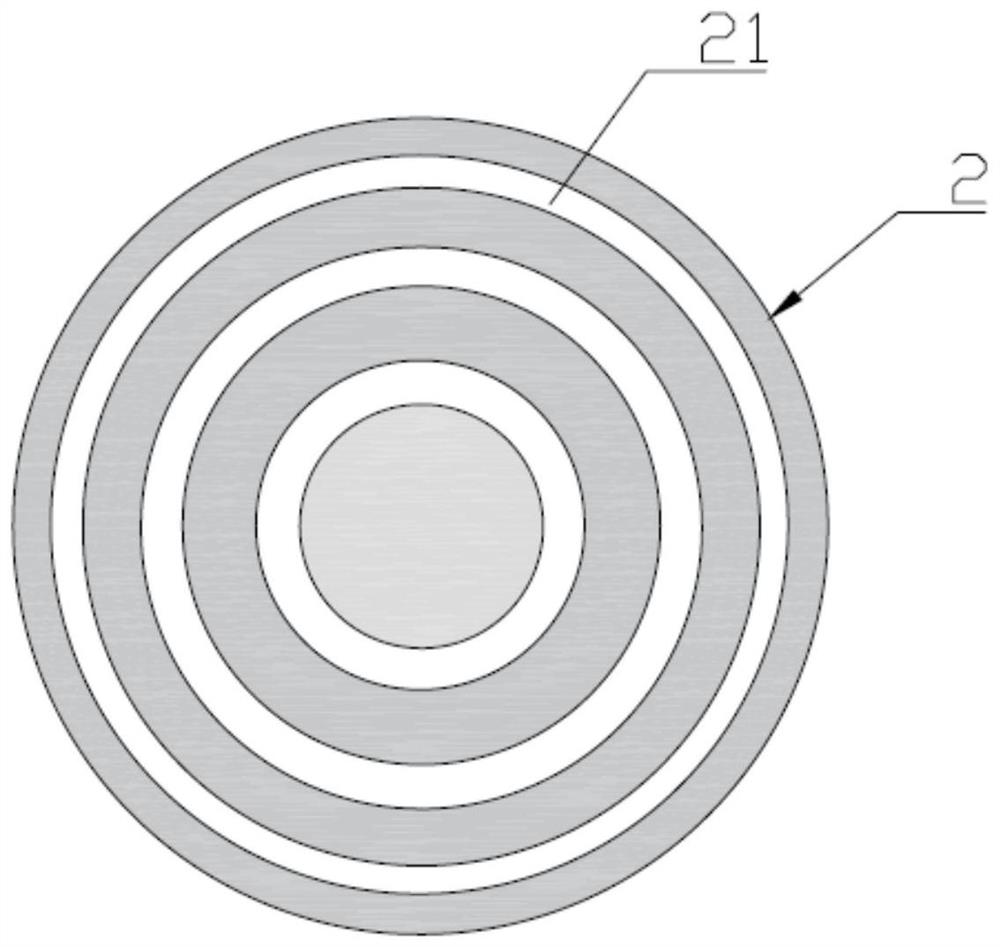

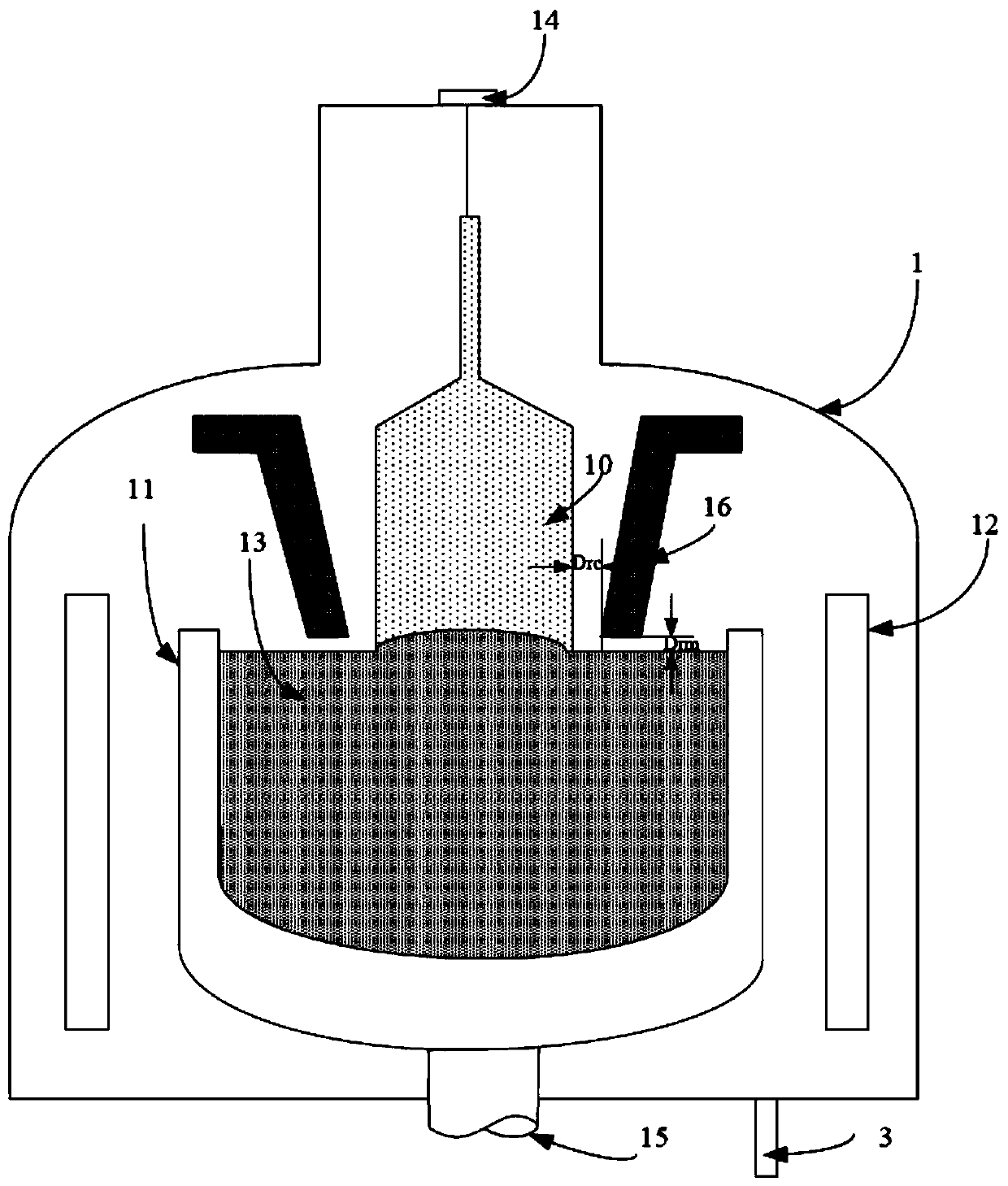

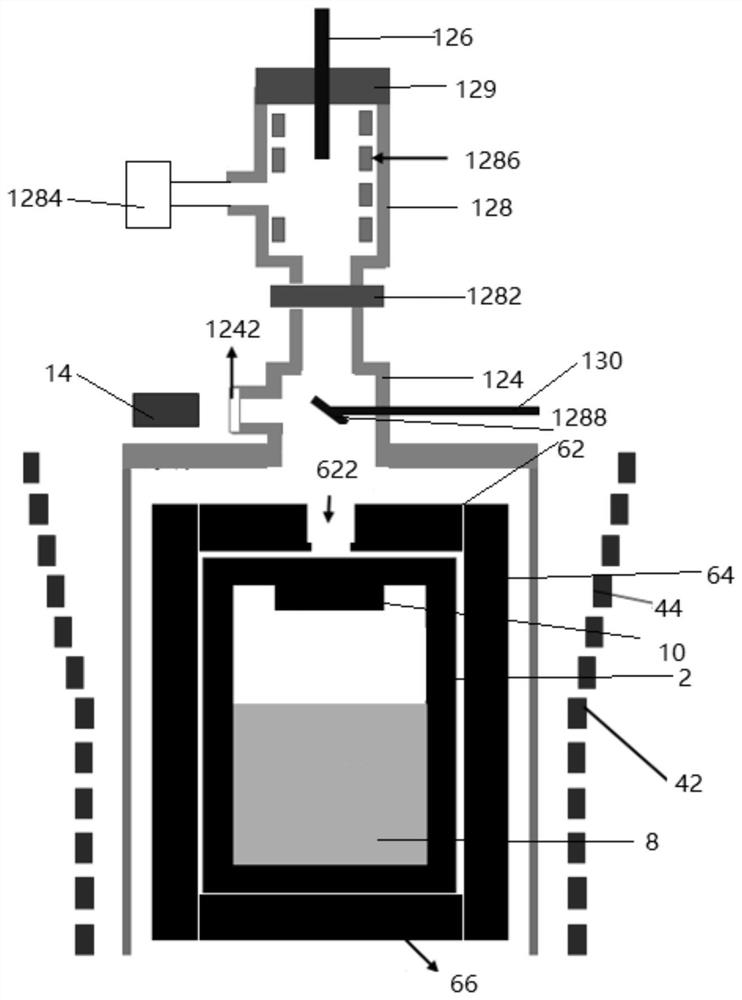

The invention discloses a high-quality silicon carbide single crystal, and a substrate and an efficient preparation method thereof, and belongs to the field of semiconductor materials. The preparationmethod comprises the following steps: putting raw materials and seed crystals into a crucible, assembling the crucible and a heat preservation structure into a crystal growth furnace, arranging a heating coil assembly at the periphery of the side wall of the crystal growth furnace, and mounting an adjusting mechanism; removing impurities; and growing the crystal, wherein the heating coil assemblycomprises a first coil assembly arranged corresponding to a raw material area and a second coil assembly arranged corresponding to a crystal growth area, and the inner diameter of the second coil assembly is increased in the direction from raw materials to seed crystals. The preparation method of the silicon carbide single crystal is characterized in that the axial temperature gradient in a growth cavity is formed, so the high-quality silicon carbide single crystal can be prepared; the radial temperature gradient in the growth cavity for growing the single crystal is adjusted, so the crystalgrowth rate and the crystal growth quality are improved; and the radial temperature gradient is reduced, and a certain axial temperature gradient can be ensured, so the high-quality silicon carbide single crystal can be efficiently prepared.

Owner:SICC CO LTD

High-speed single crystal growth device and method

ActiveCN105603520ATimely releaseIntensive Cooling Crystal SurfacePolycrystalline material growthBy pulling from meltChemical reactionShielding gas

The invention discloses a high-speed single crystal growth device and method and mainly relates to a crystal cooling manner and a reaction cylinder for conveying reactants to perform chemical reactions. The reaction cylinder is made of high-temperature-resistant materials and comprises a gas inlet cylinder and a gas discharge cylinder. The gas inlet cylinder is provided with a passage for feeding the reactants and protecting gas. The reactants are sprayed to the surfaces of growing high-temperature crystals after passing the gas inlet cylinder to perform chemical reaction so as to absorb heat and fast remove the heat on the surfaces of the crystals. The gas discharge cylinder is used for discharging the reactants not completely reacted and reaction product gas out of a furnace. The gas inlet cylinder and the gas discharge cylinder are integrally connected and fixed on a furnace wall. The high-speed single crystal growth device and method has the advantages that the chemical heat-absorption reaction is applied to the intensified cooling in crystal growth for the first time, the heat on the surfaces of the crystals can be removed fast, the axial temperature gradient inside the crystals can be increased evidently, and accordingly the crystal growth speed is increased.

Owner:徐州晶睿半导体装备科技有限公司

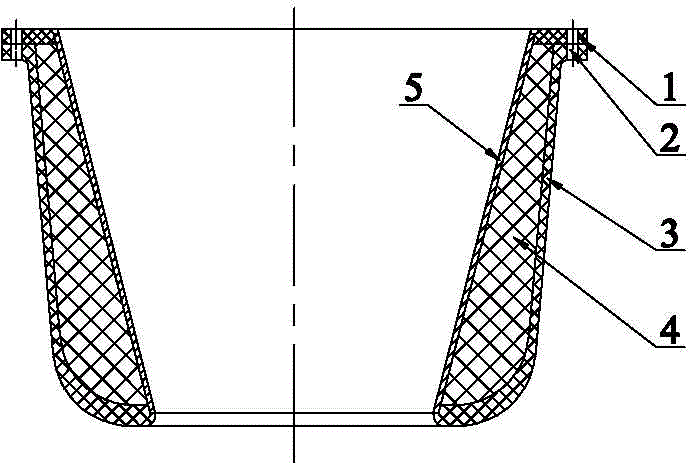

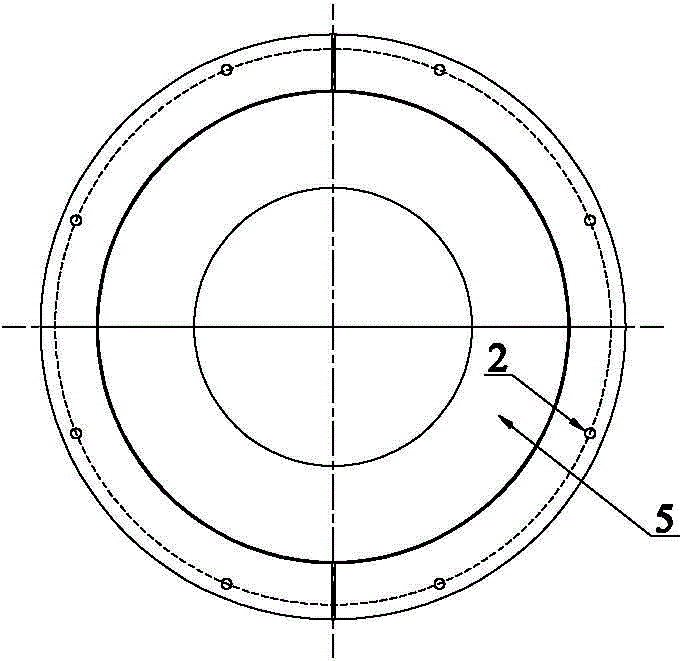

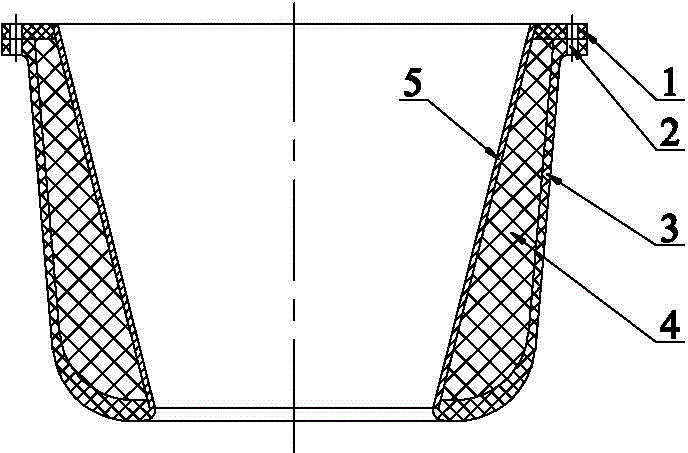

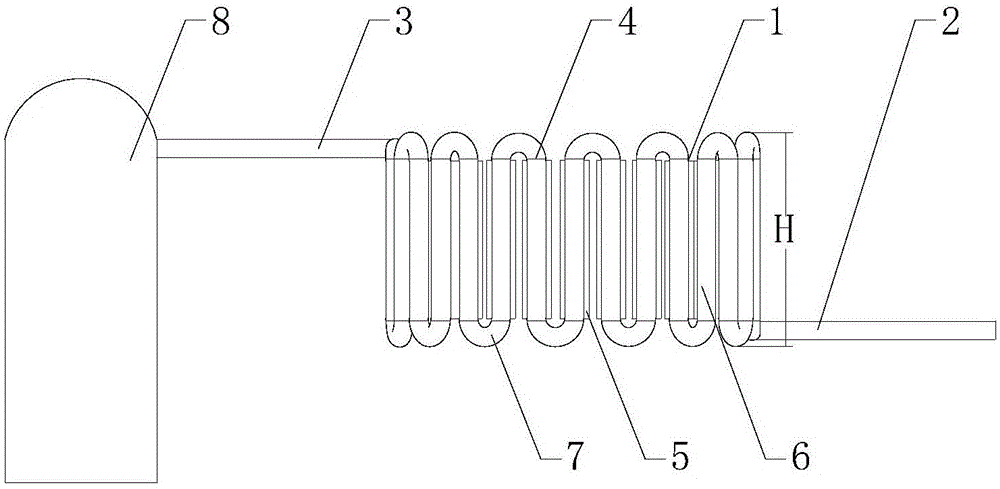

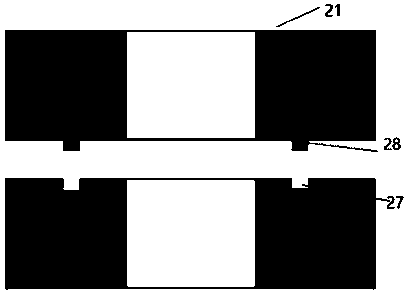

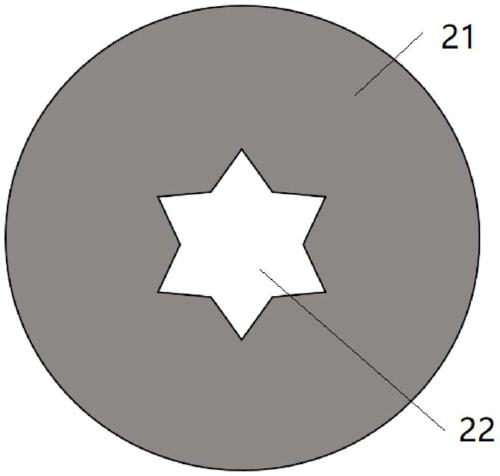

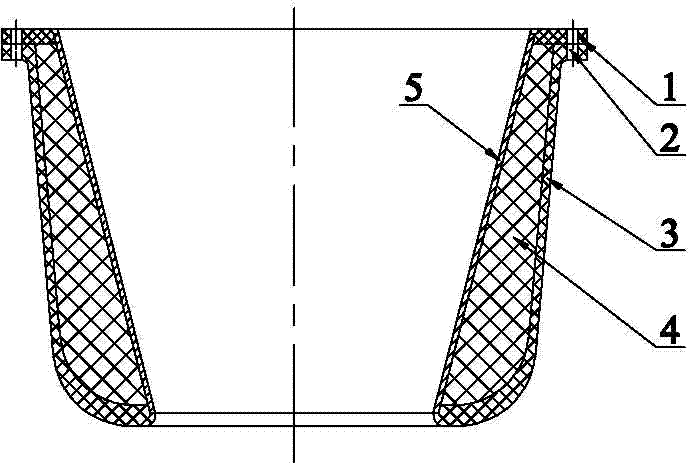

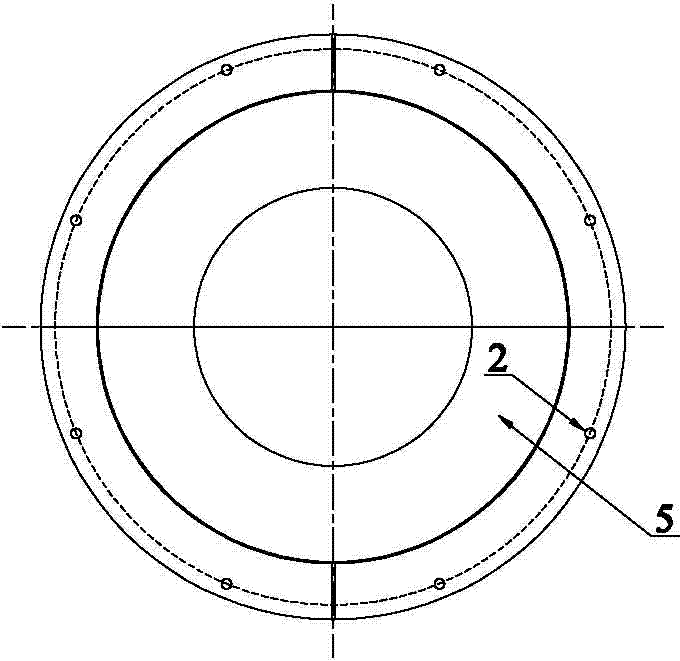

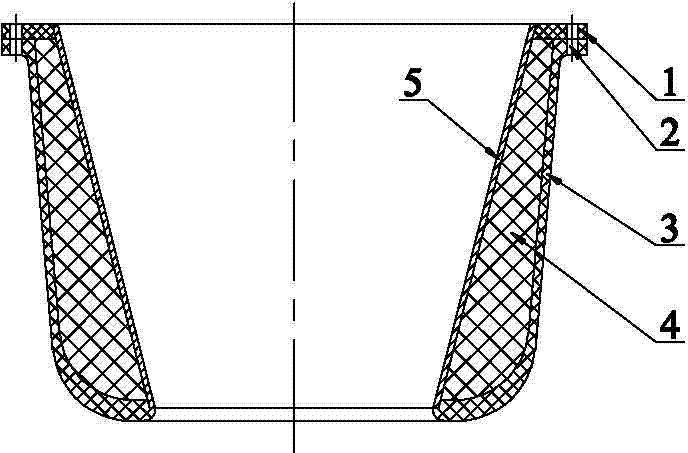

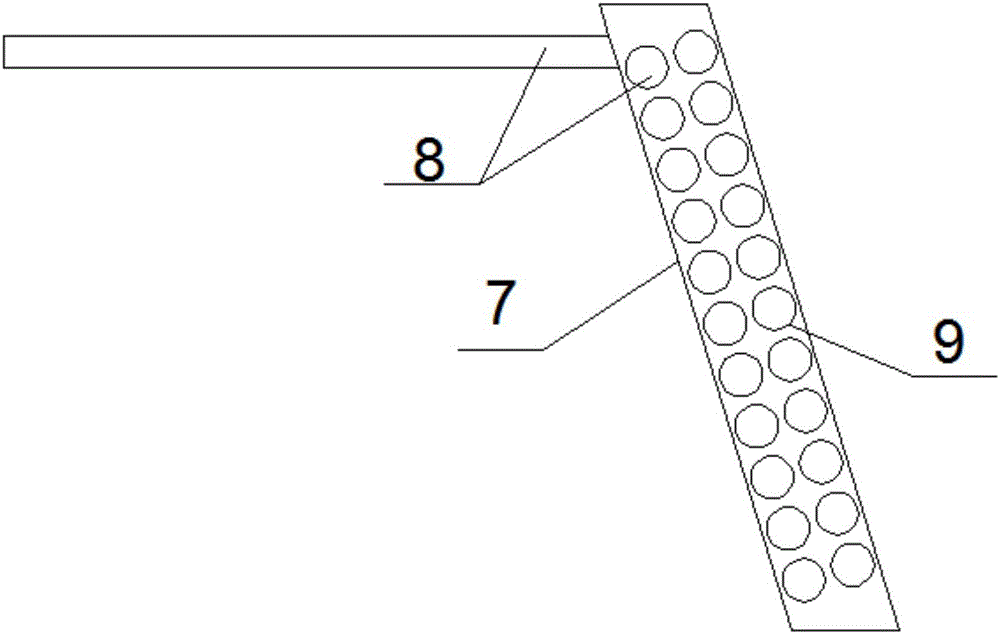

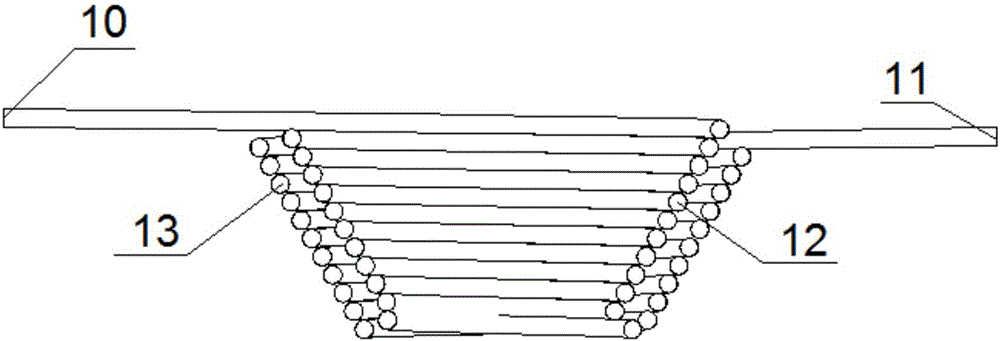

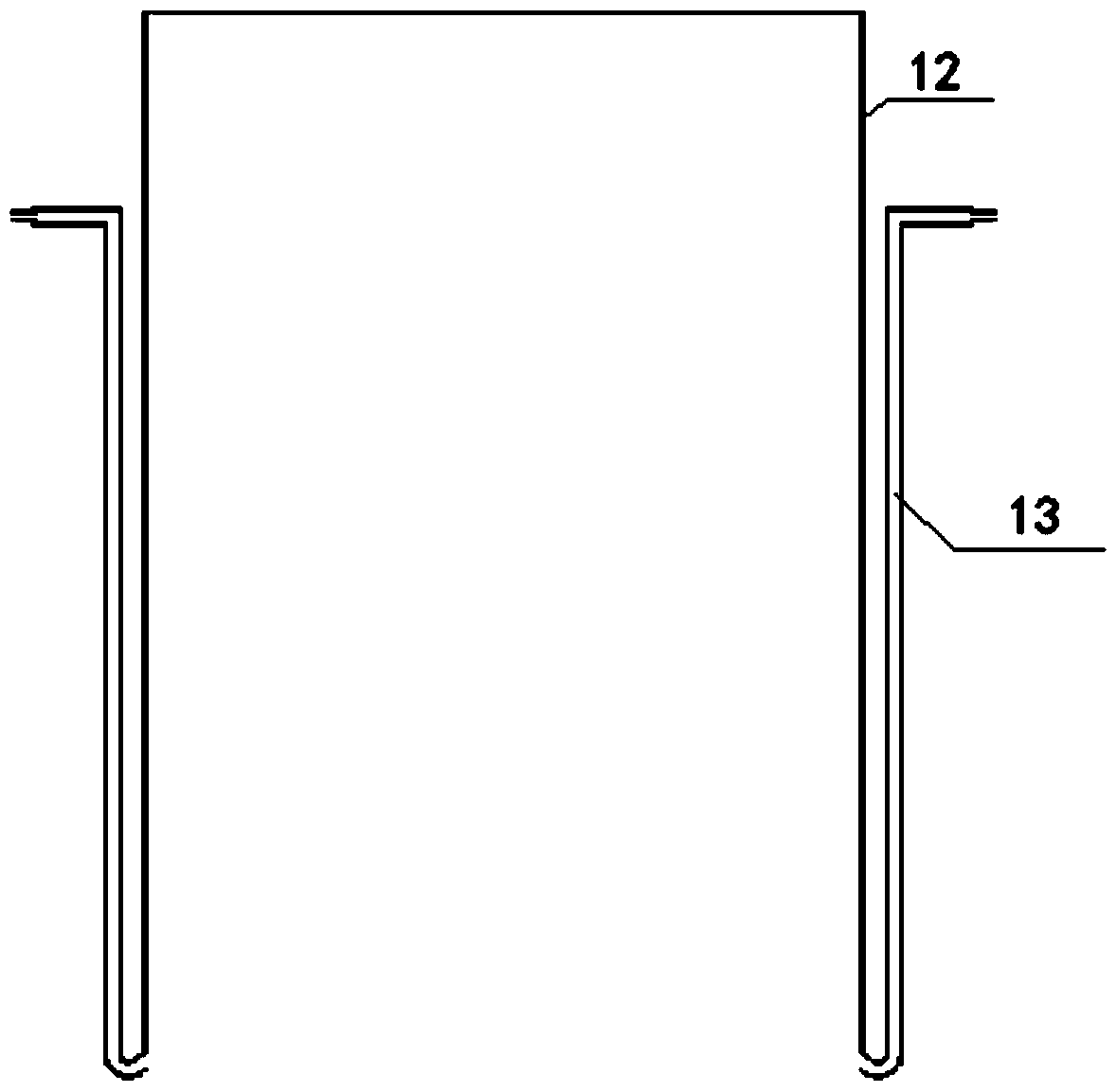

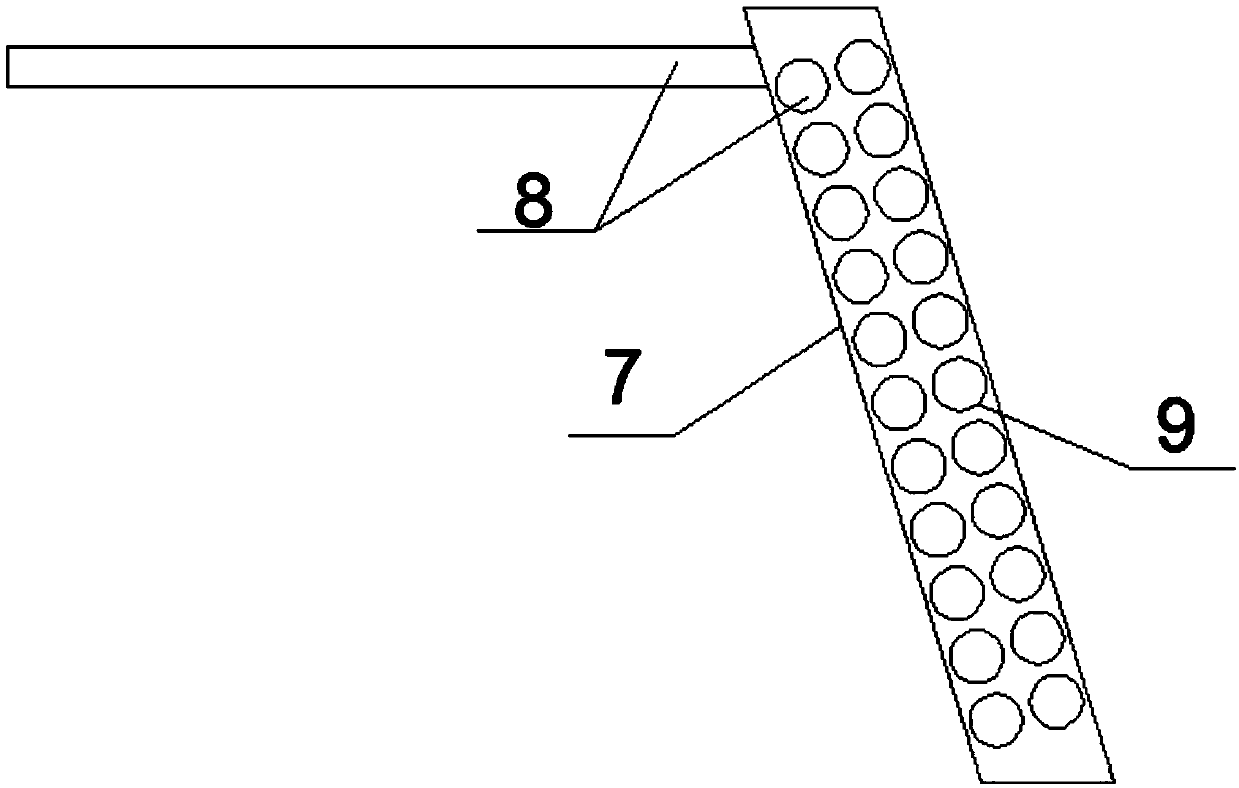

Guide cylinder and preparation method thereof

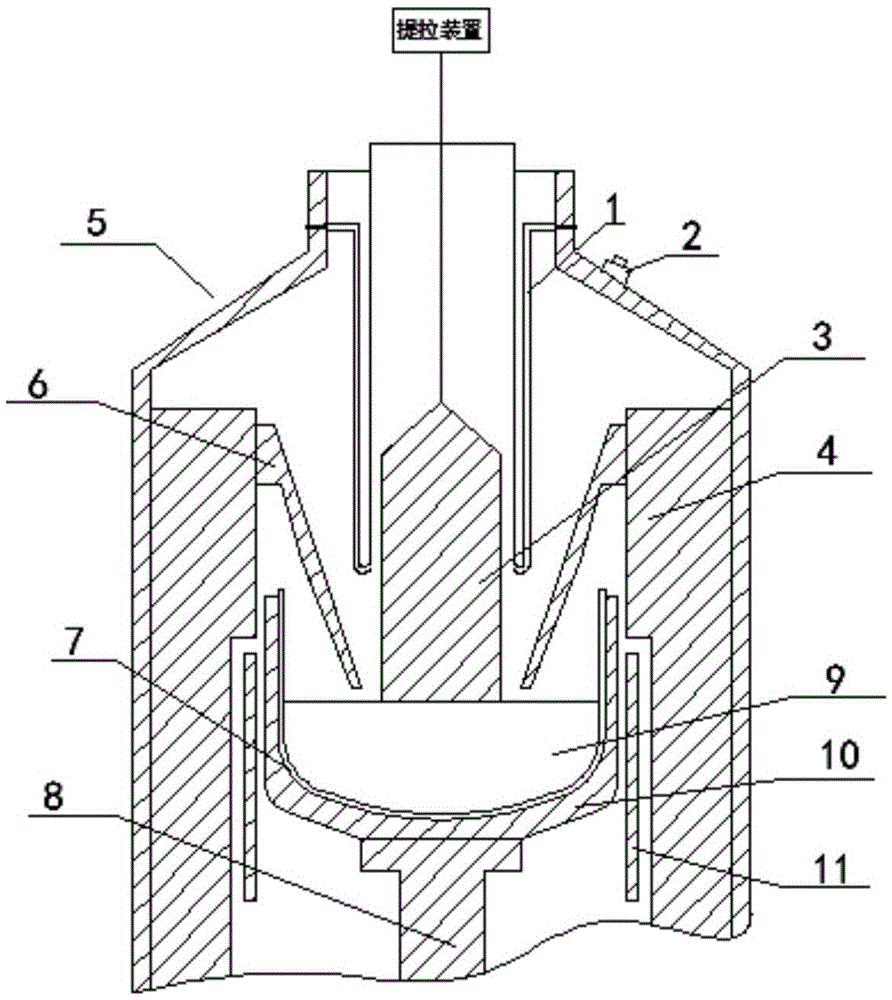

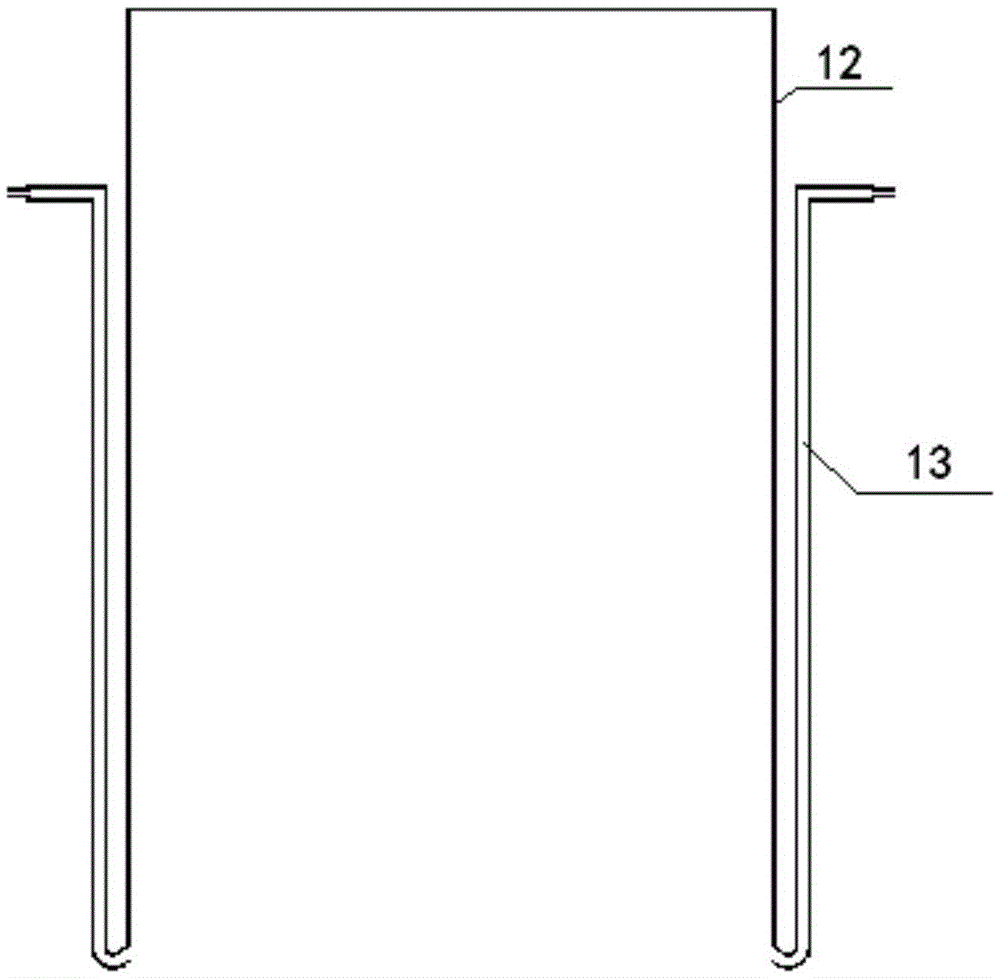

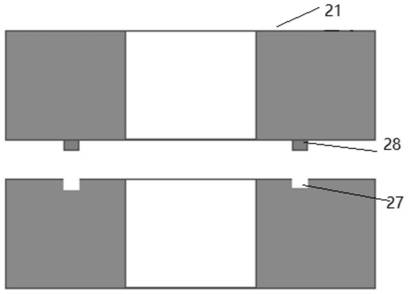

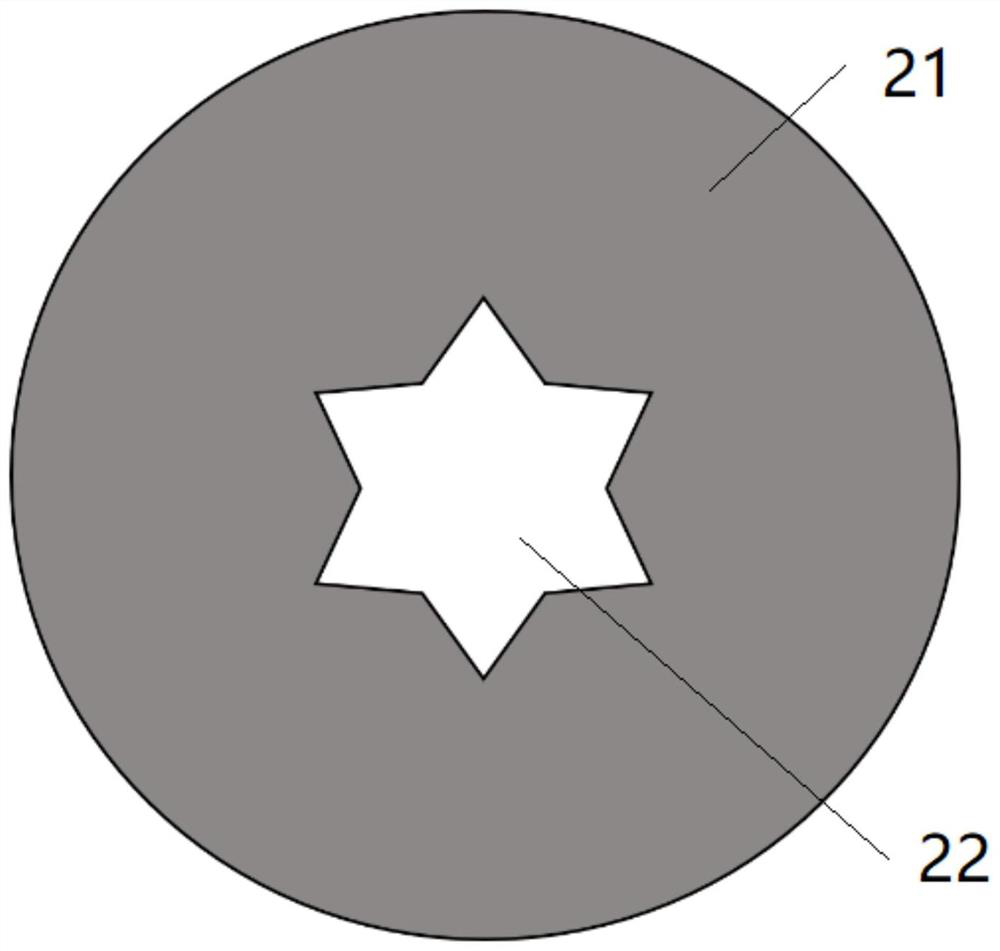

ActiveCN102912425AImprove insulation effectImprove reflective effectPolycrystalline material growthBy pulling from meltCarbon compositesThermal insulation

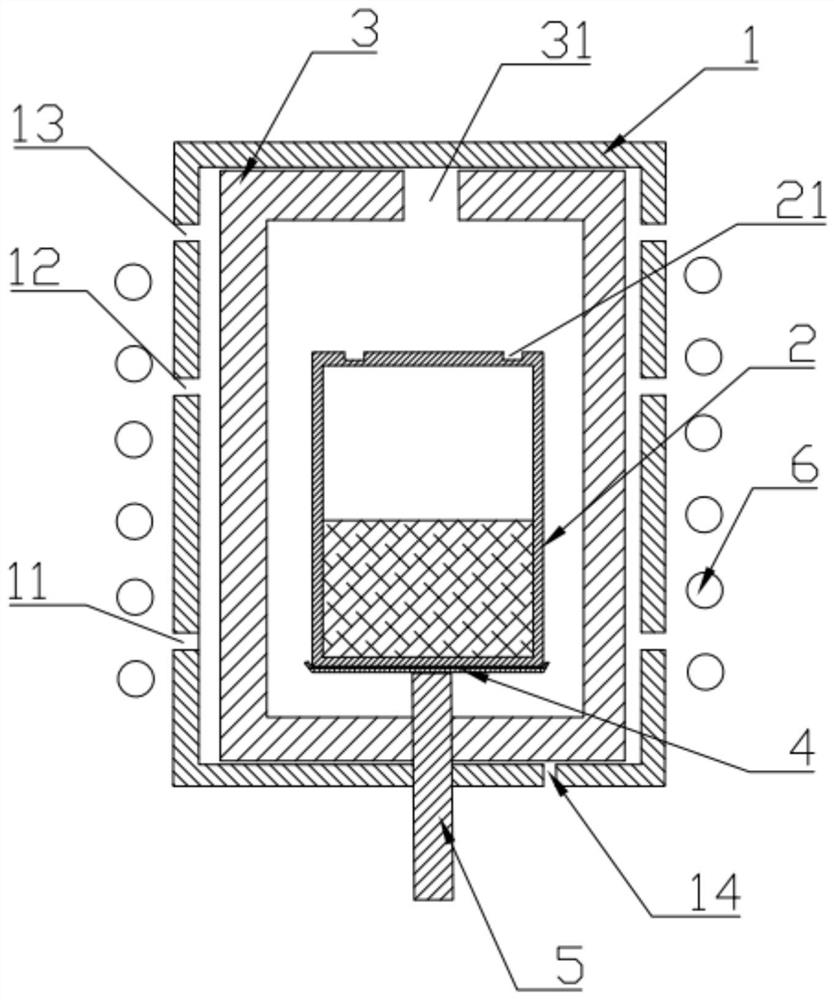

The invention discloses a guide cylinder capable of shortening the crystal pulling time and improving the crystal pulling speed and a preparation method. The guide cylinder comprises an inverted conical cylinder; the cylinder comprises an outer screen (3) and an inner screen (5); a thermal insulation layer (4) is arranged between the outer screen (3) and the inner screen (5); the guide cylinder is characterized in that the outer screen (3) is prepared from carbon / carbon composite material; the inner screen (5) is prepared from metal molybdenum or metal tungsten; the outer screen (3) is connected with a positioning disc (1) so that the outer screen (3), the inner screen (5), the thermal insulation layer (4) and the positioning disc (1) form an integral structure; and the guide cylinder is produced by the steps of blank production, purification, surface coating and cylinder assembly. The guide cylinder disclosed by the invention has good thermal insulation effect, high strength, long service life and good reflection effect, effectively increases the axial temperature gradient, accelerates the crystal pulling, shortens the crystal pulling time and effectively improves the production efficiency.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

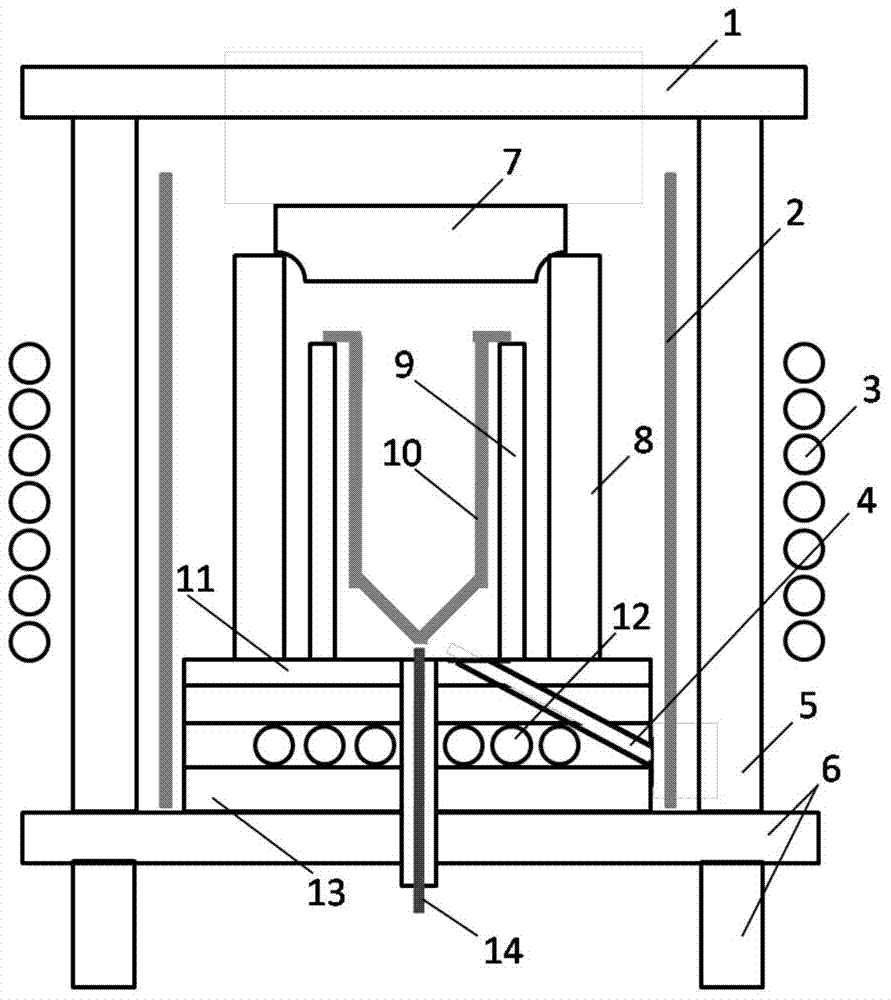

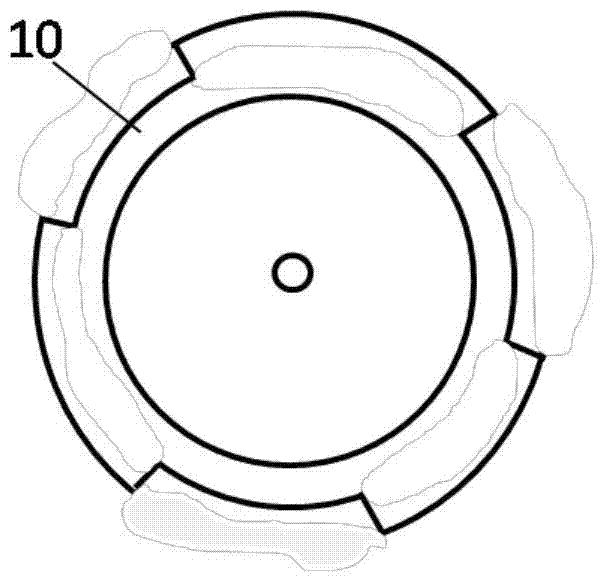

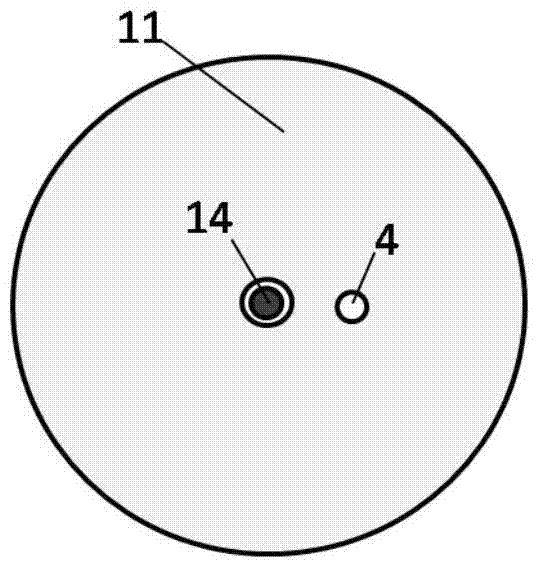

Micro-pulling-down crystal growing furnace

InactiveCN104611764AObserve the growthImprove yieldBy pulling from meltMicro-pulling-downZirconium oxide

The invention discloses a micro-pulling-down crystal growing furnace. The furnace comprises an upper heat-insulating layer and a bottom heat-insulating layer (13) which are arranged from top to bottom, wherein a tubular observation hole (4) is also formed in the bottom heat-insulating layer (13), and the included angle formed by the central axis of the observation hole (4) and the normal of the top surface of the bottom heat-insulating layer (13) is in a range of 45-60 degrees; each of an inner heat-insulating layer, a middle heat-insulating layer and the bottom heat-insulating layer (13) is formed by pressing and calcining zirconium oxide and aluminium oxide in the mass ratio of 1:9. According to the micro-pulling-down crystal growing furnace, the crystal growing condition of a crystal growing interface can be timely observed via the formed observation hole; besides, the effect caused by the observation hole on the temperature field of the crystal growing furnace is low, and the crystal growing yield can be further increased.

Owner:HUAZHONG UNIV OF SCI & TECH

Device and method for improving pulling speed of czochralski monocrystalline silicon

InactiveCN106222735AIncreased axial temperature gradientIncrease pulling speedPolycrystalline material growthBy pulling from meltLiquid argonEnergy consumption

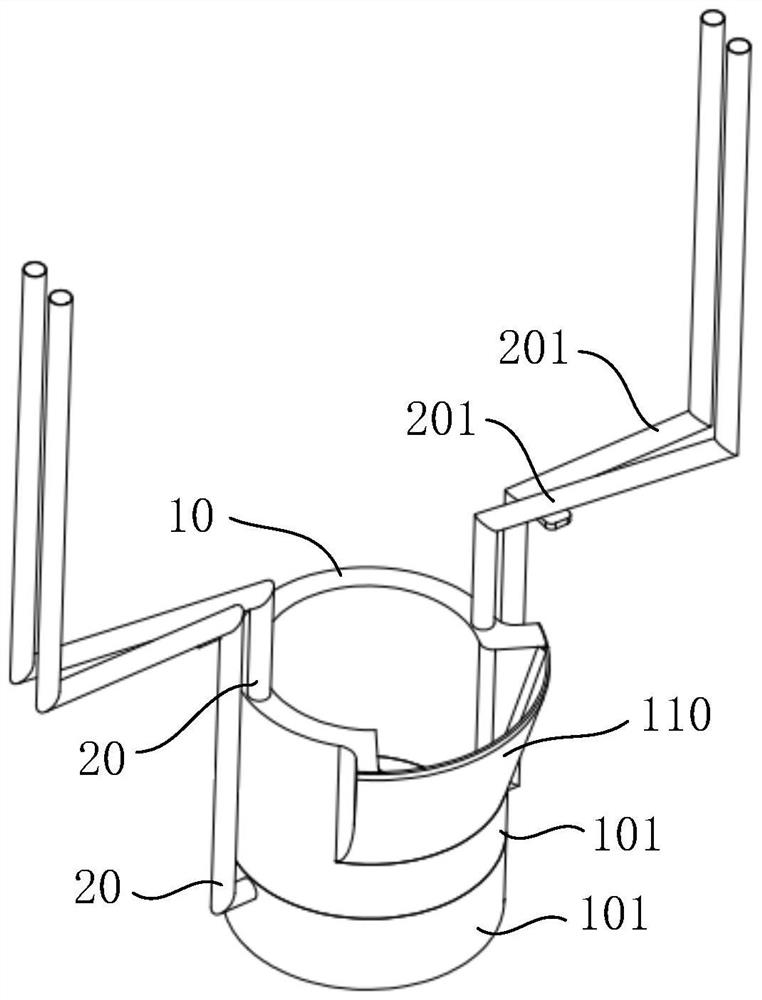

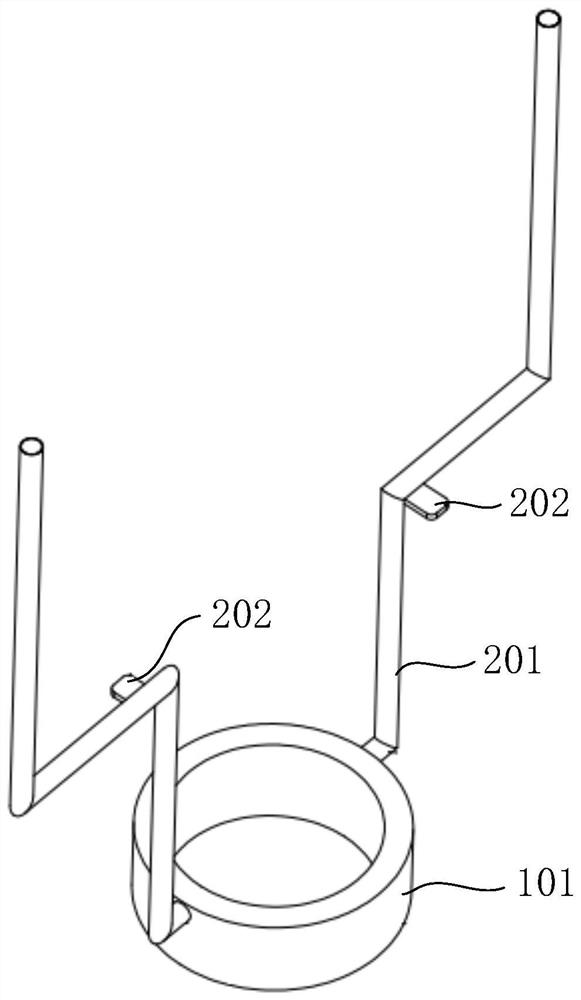

The invention discloses a device for improving the pulling speed of czochralski monocrystalline silicon. The device comprises a cylinderical cooling mechanism, a cooling medium inlet pipe and a cooling medium outlet pipe. A method for improving the pulling speed of the czochralski monocrystalline silicon comprises the following steps: firstly, preparing; secondly, heating to melt materials; thirdly, performing intermediate treatment; fourthly, performing equal diameter treatment; fifthly, ending and performing post treatment. The device and the method disclosed by the invention have the advantages that an axial temperature gradient of monocrystalline silicon rods is increased by using the principle that an inert element cooling medium gasifies to absorb heat, and the pulling speed of monocrystalline silicon is improved by 20 percent or above; an upper heat insulating mechanism and the like of a thermal field system are not changed, so that no extra energy consumption is added; the inert element cooling medium is recycled, so that the production cost of the monocrystalline silicon is reduced; the used inert element cooling medium is liquid helium or liquid argon, does not react with a silicon melt and does not affect thermal field components, so the method disclosed by the invention is safer than a conventional method, and the safety of production of the monocrystalline silicon is improved.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

Silicon carbide single crystal, substrate and preparation method thereof

ActiveCN111074340AQuality improvementReduce defectsPolycrystalline material growthFrom condensed vaporsSemiconductor materialsInsulation layer

The invention discloses a silicon carbide single crystal, a substrate and a preparation method thereof, which belongs to the field of semiconductor materials. The preparation method of the silicon carbide single crystal comprises the following steps: forming a low-temperature region and a high-temperature region in a crucible by virtue of a temperature measuring hole formed in an upper thermal insulation layer group outside the crucible, and transmitting a raw material gas phase in the low-temperature region to the surface of a seed crystal in the high-temperature region by virtue of a physical gas phase transmission method to grow the crystal; wherein the upper heat preservation layer set comprises a second heat preservation layer and a first heat preservation layer which are sequentiallyarranged in the seed crystal direction of raw materials. The first heat preservation layer is provided with a first opening, the second heat preservation layer is provided with a second opening, anda rotary adjusting mechanism rotates the first heat preservation layer and / or the second heat preservation layer to adjust the cross sectional area of a temperature measuring hole formed by the firstopening and the second opening, so that the axial and radial temperature gradient in the crucible in the crystal growth process is adjusted. According to the preparation method of the silicon carbidesingle crystal, the radial temperature gradient in a growth cavity for growing the single crystal can be adjusted; and while the radial temperature gradient is reduced, a certain axial temperature gradient is ensured, and the high-quality silicon carbide single crystal is efficiently prepared.

Owner:SICC CO LTD

Czochralski monocrystalline silicon growth furnace

ActiveCN111826709ALight in massAvoid thermal unevennessBy pulling from meltCrystallographyTemperature control

The invention relates to the technical field of czochralski monocrystalline silicon, and discloses a czochralski monocrystalline silicon growth furnace which comprises a fixed box and a pyrometer. A heat preservation cylinder I is fixedly mounted at the left part of an inner cavity of the fixed box, a heating element is fixedly mounted on the inner wall of the heat preservation cylinder I, and a seed crystal is fixedly mounted on the right side of the top of the fixed box. Through the setting of the growth box, the melting of the polycrystalline silicon is separated from the pulling place of the monocrystalline silicon body; the polycrystalline silicon is continuously melted through the quartz crucible to form a melt to provide a raw material for pulling the monocrystalline silicon body from the interior of the growth box; the quality of the monocrystalline silicon body is prevented from being reduced due to non-uniform thermal field in the quartz crucible; the growth interface temperature in the growth box can be kept within a certain range, and the temperature control difficulty is reduced; meanwhile, the quartz crucible and the growth box are arranged to ensure the sufficiency of raw materials; and through the arrangement of a rotating device, the number of single crystal silicon bodies pulled at a time is increased, and the production efficiency is improved.

Owner:杭州飞宇磁电器材有限公司

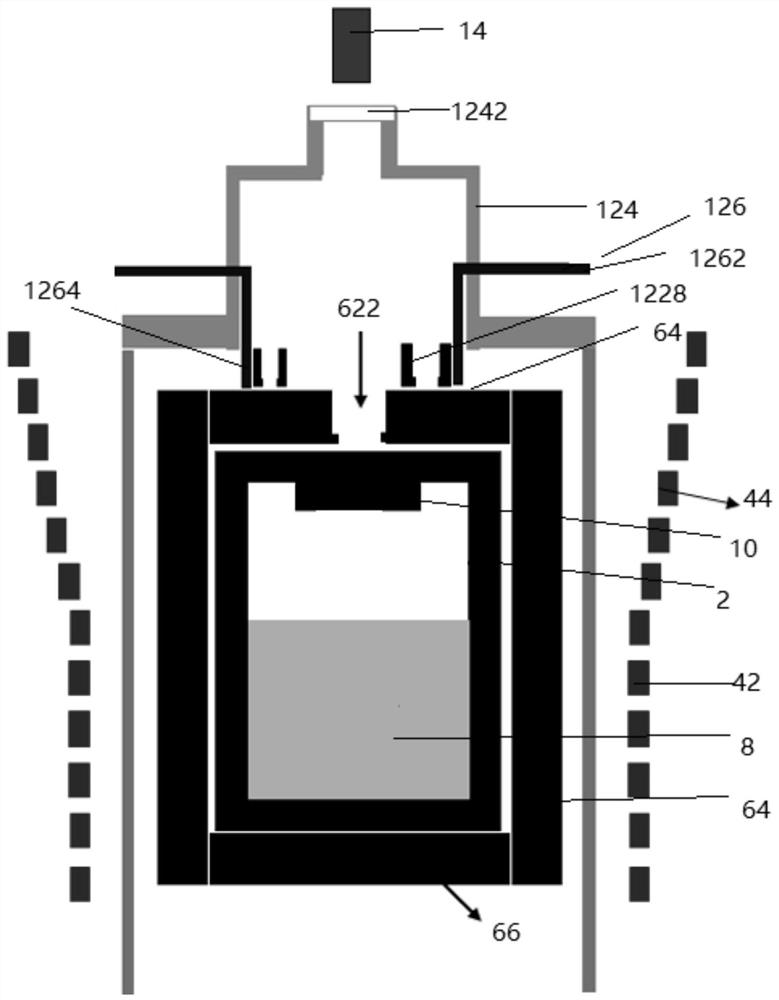

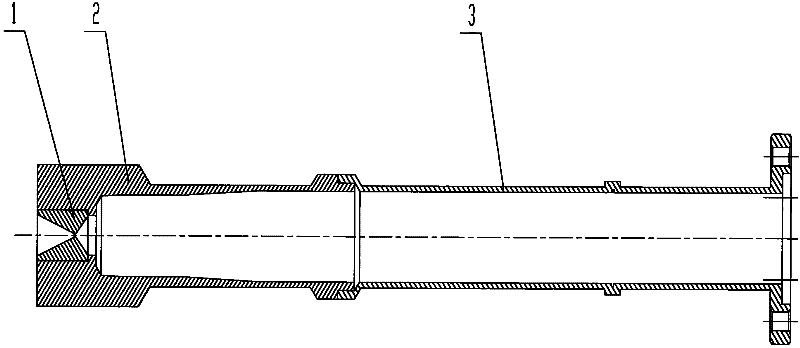

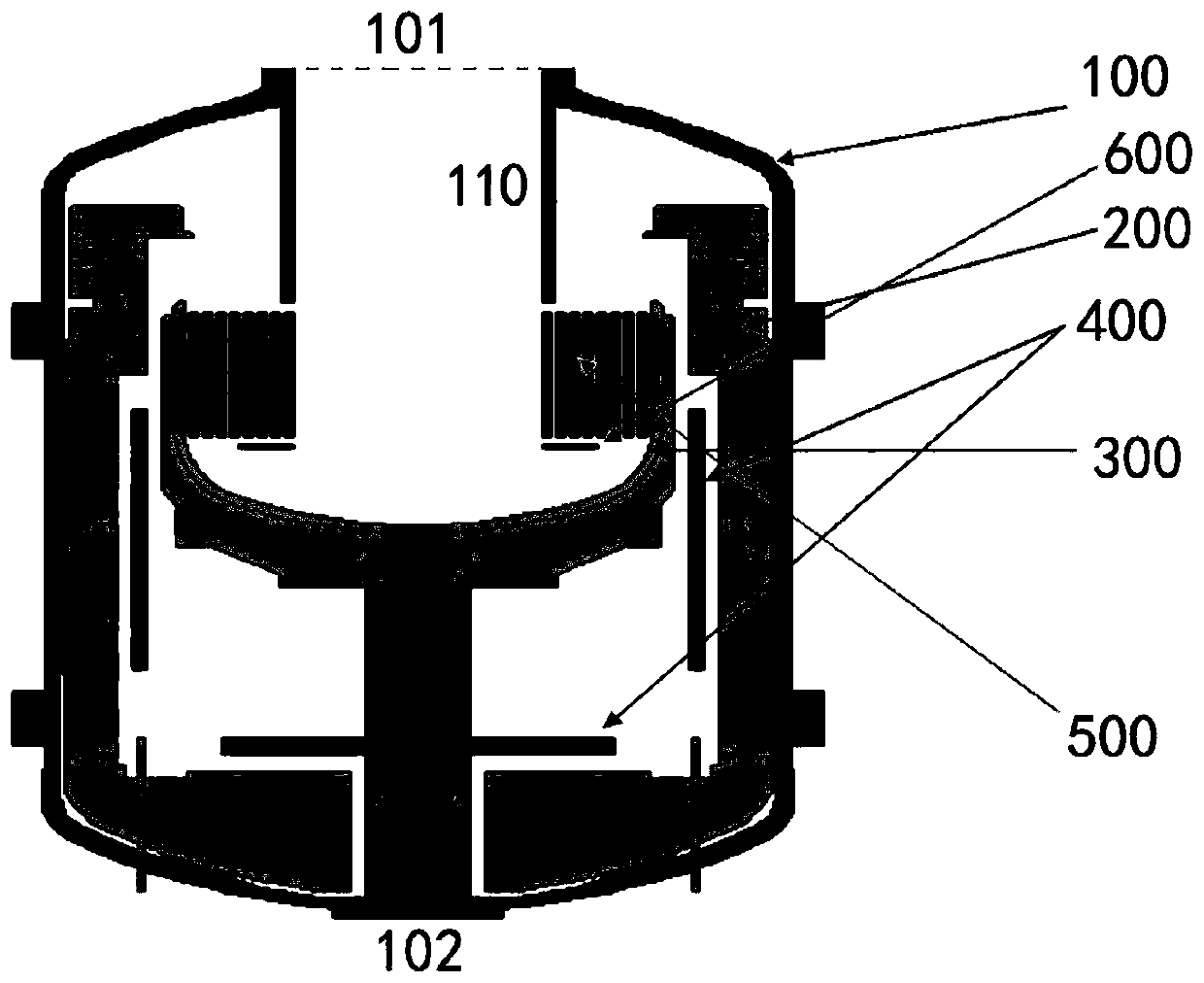

Device for preparing single crystal and method for preparing silicon carbide single crystal

ActiveCN111088525AQuality improvementReduce defectsPolycrystalline material growthFrom condensed vaporsCarbide siliconSemiconductor materials

The invention discloses a device for preparing a single crystal and a preparation method for a silicon carbide single crystal, belonging to the field of semiconductor materials. The device for preparing the single crystal comprises a crucible, a heating coil group and a heat preservation structure, wherein the crucible forms a growth cavity which comprises a raw material area used for placing rawmaterials and a crystal growth area used for arranging seed crystals; the heating coil group is arranged around the side wall of the crucible and comprises a first coil group corresponding to the rawmaterial area and a second coil group corresponding to the crystal growth area; and the inner diameter of the second coil group is increased in a direction from raw materials to seed crystals. The single crystal growth device provided by the invention can adjust the radial temperature gradient in the growth cavity for growth of the single crystal, can reduce the radial temperature gradient, can guarantee a certain axial temperature gradient at the same time, and can realize high-efficiency preparation of high-quality single crystals.

Owner:SICC CO LTD

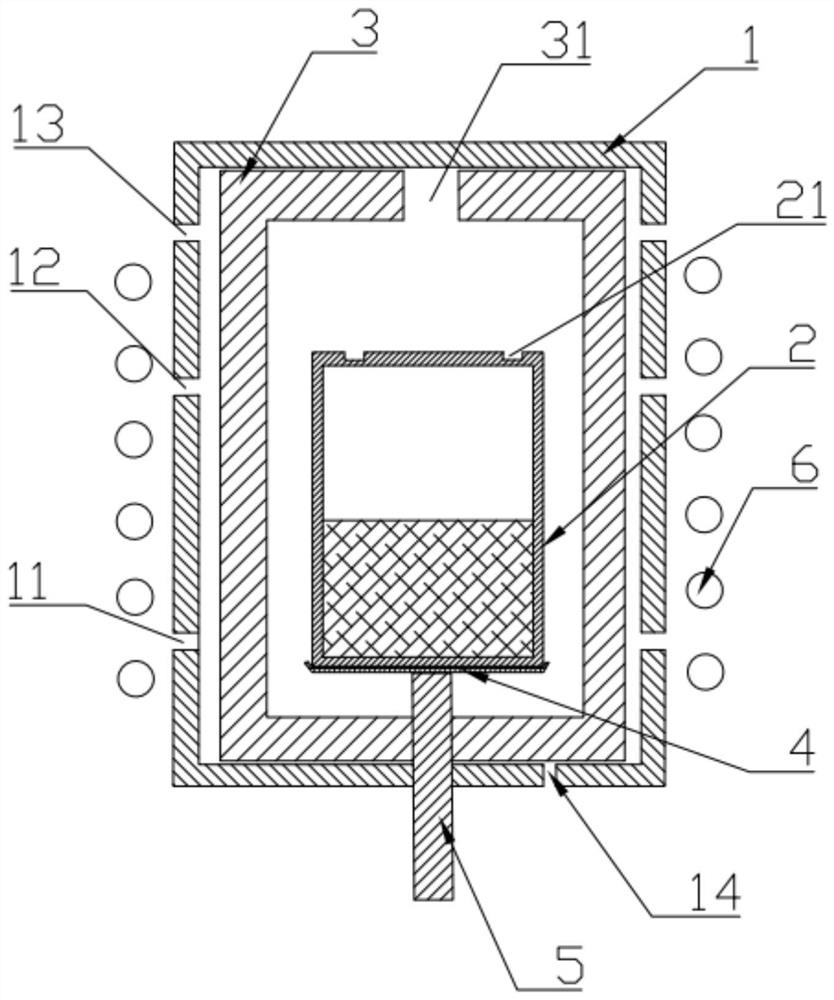

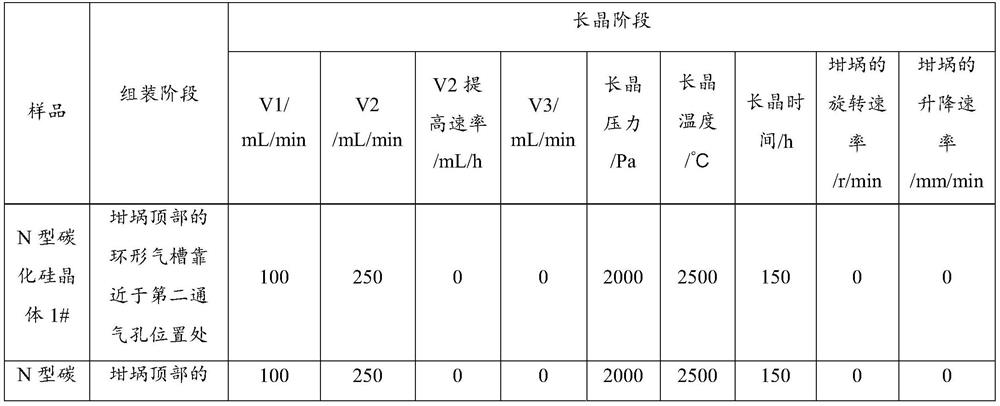

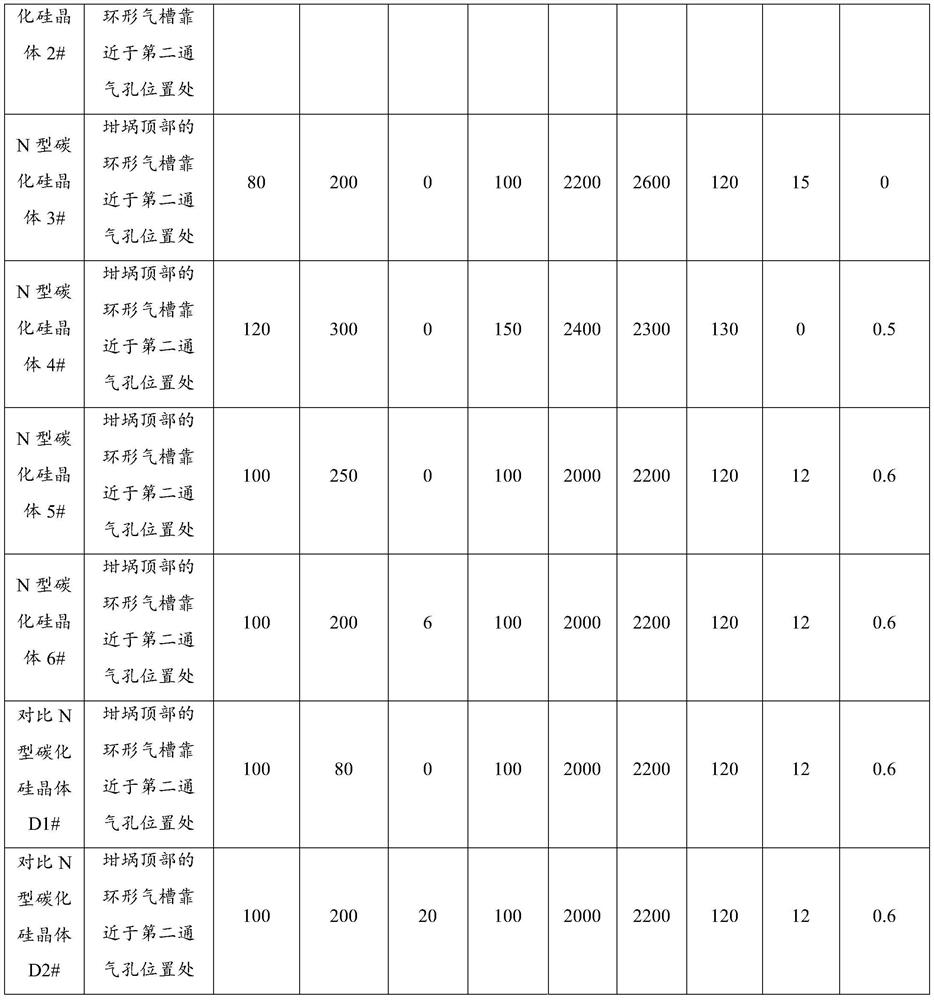

Preparation method and growth device of N-type silicon carbide crystal

ActiveCN112813499AReduce radial temperature gradientQuality improvementPolycrystalline material growthFrom condensed vaporsCarbide siliconCrucible

The invention provides a preparation method and a growth device of an N-type silicon carbide crystal. The method comprises the following steps: (1) placing a raw material in a high-temperature area of a crucible, placing a seed crystal in a low-temperature area of the crucible, recessing the outer wall of the top of the crucible inwards to form an annular gas groove, placing the assembled crucible in a furnace body of a crystal growth furnace, and enabling the annular air groove to be close to a vent hole of the furnace body; and (2) in a crystal growth stage, introducing nitrogen source gas into the furnace body through the vent hole, controlling crystal growth temperature and crystal growth pressure, and enabling the N-type silicon carbide crystal to grow on the seed crystal. The annular gas groove is close to the vent hole of the furnace body, the introduced gas can flow along the annular gas groove, a gas flow speed is high, the gas is diffused into the crucible, heat transmission away from the central axis in the crucible is accelerated, the radial temperature gradient of the crucible is reduced, and crystal growth quality is improved.

Owner:SICC CO LTD

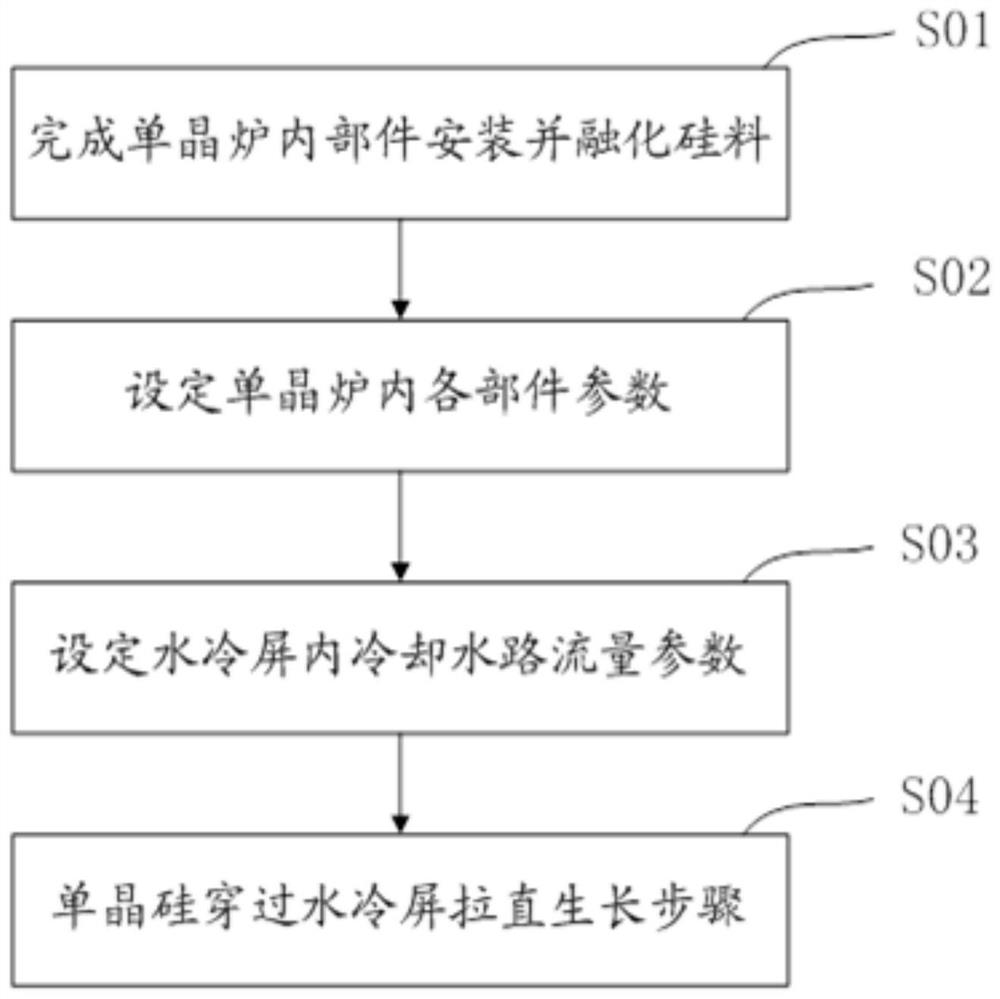

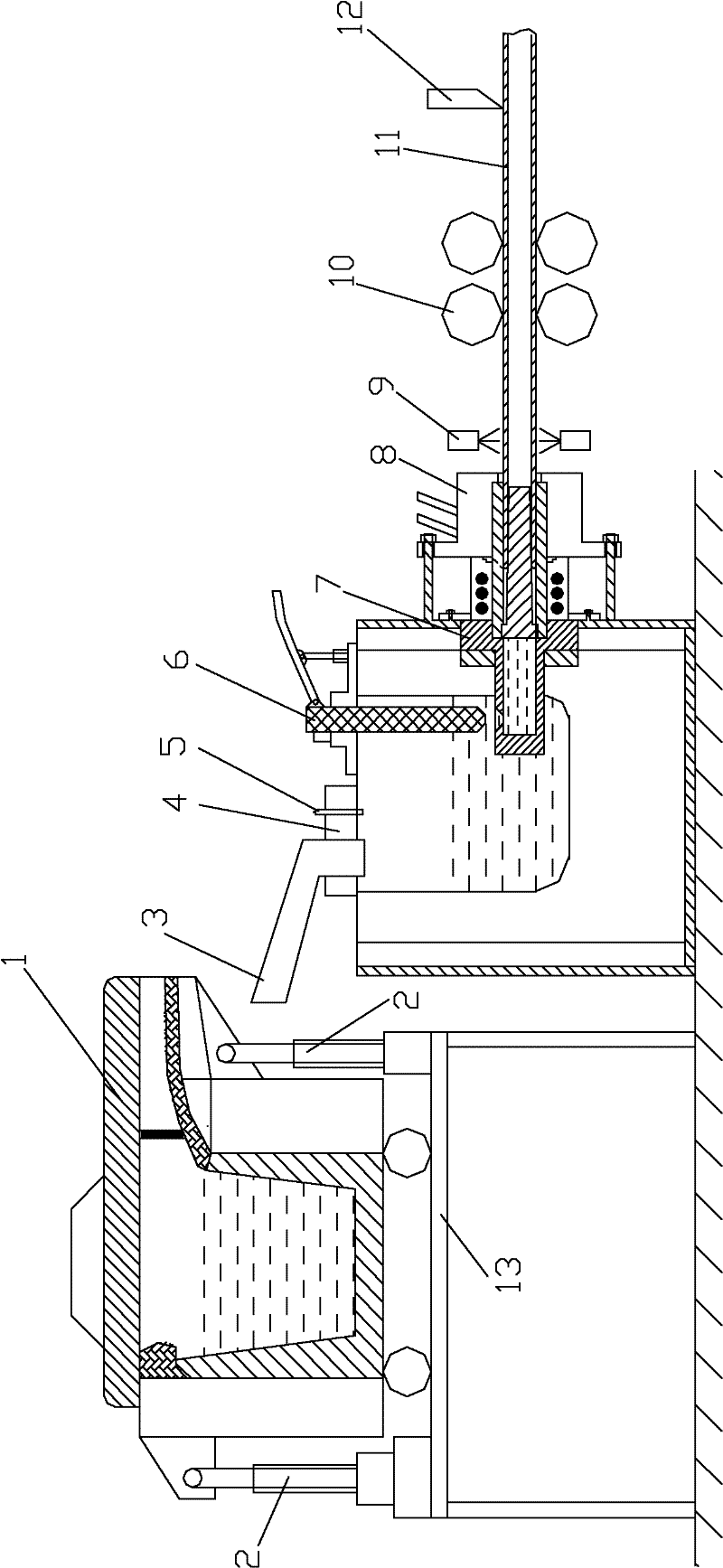

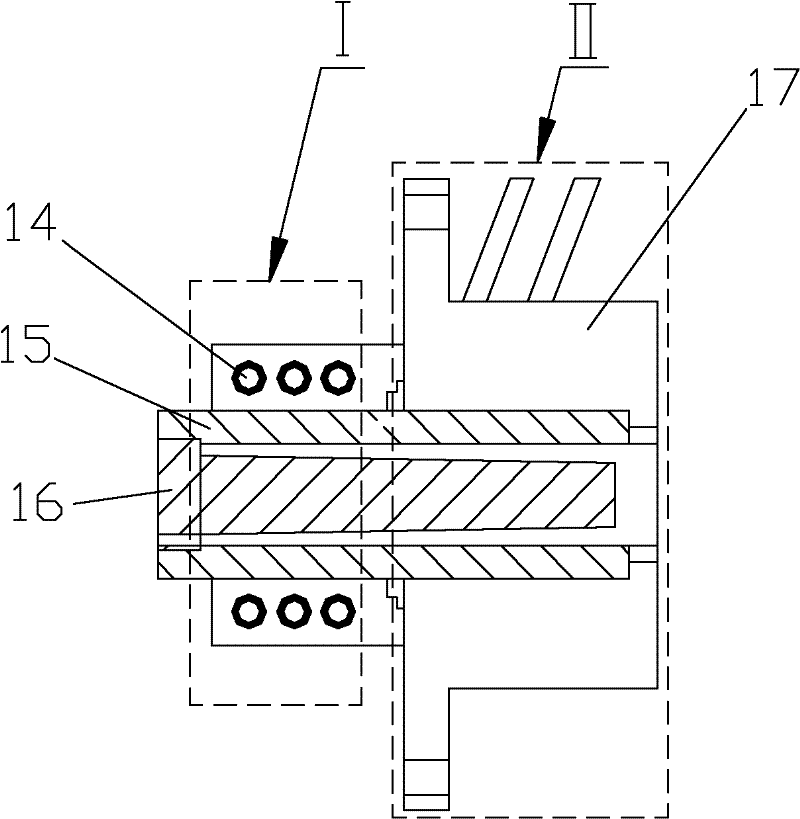

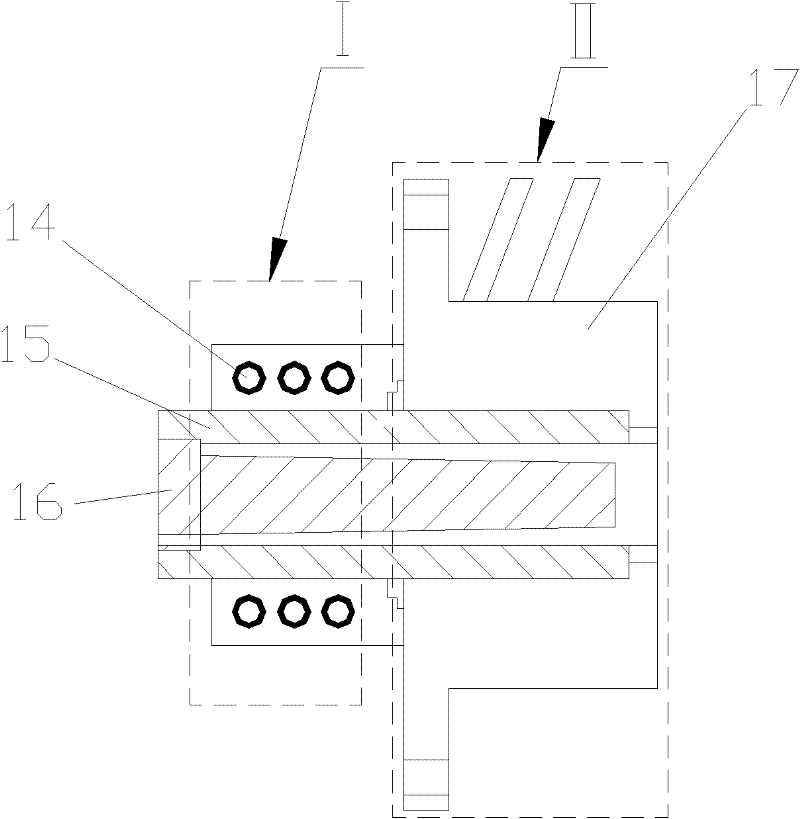

Water cooling screen, monocrystalline silicon growth device and monocrystalline silicon growth method

PendingCN113981524AIncrease heat transfer rateIncreased axial temperature gradientPolycrystalline material growthBy pulling from meltThermodynamicsEngineering

The embodiment of the invention discloses a water cooling screen, which comprises a water cooling screen body and a cooling water path arranged in the water cooling screen body, wherein the cooling water path at least comprises two cooling water path branches, the cooling water path branches are mutually independent, and the cooling water path branch at the corresponding position is in a low-temperature state when a silicon rod rises to a certain height by controlling the water supply time or the water supply flow of cooling water. According to the water cooling screen provided by the invention, the heat exchange rate of the water cooling screen can be improved through time-sharing and component water supply, so that the axial temperature gradient during growth of a silicon rod is increased, and the growth speed of monocrystalline silicon is effectively improved. The embodiment of the invention also discloses a monocrystalline silicon growth device and a monocrystalline silicon growth method.

Owner:双良硅材料(包头)有限公司

Hot-cold combined casting mould horizontal continuous casting equipment of cupronickel tubing and technology thereof

The invention provides hot-cold combined casting mould horizontal continuous casting equipment of cupronickel tubing and a technology thereof. The equipment comprises a smelting system for melting metal, a heat insulation system for storing molten metal, a horizontal continuous casting system for casting and shaping and an auxiliary system, wherein in the continuous casting system, the front end of a cold shaping section is provided with a hot shaping section so as to effectively control the solid-liquid interface of a tube billet to be located near the juncture of a cold section and a hot section; a shorter water-cooling copper bush and electromagnetic induction heating are adopted to reasonably design coil structure and the power and the frequency of a heating power supply, reduce electromagnetic constraint force to balance the hydrostatic pressure of a metal fusant, reduce friction between a primary kish and the casting mould, improve the surface quality of the tube billet and prolong the service life of the casting mould. Thus, the inner surface and the outer surface of the tube billet manufactured by the invention have good quality and no defects of orange peel, wrinkles, cracks and the like, net shape continuous casting is realized, the production efficiency and the metal yield are improved and the production cost is obviously lowered.

Owner:UNIV OF SCI & TECH BEIJING

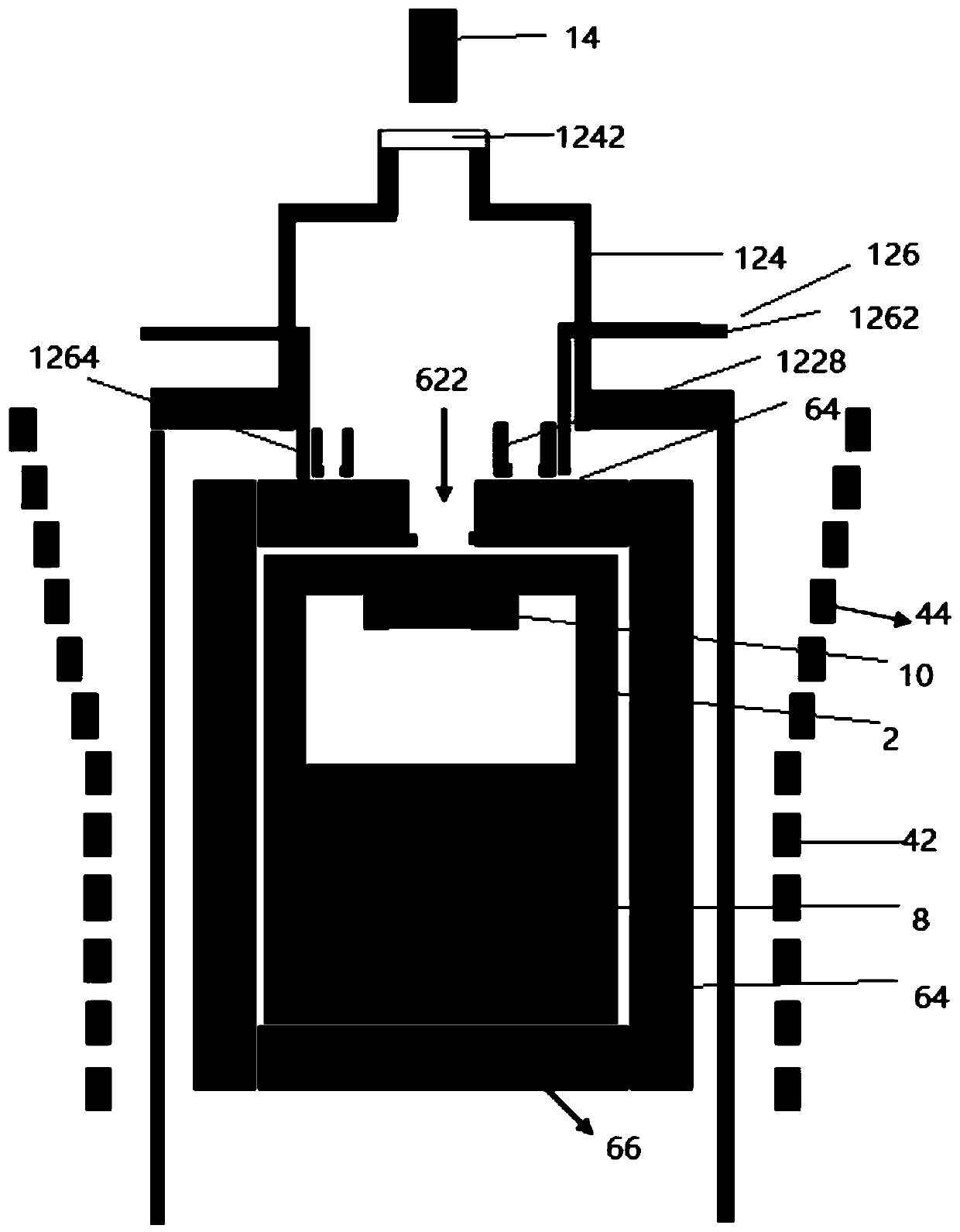

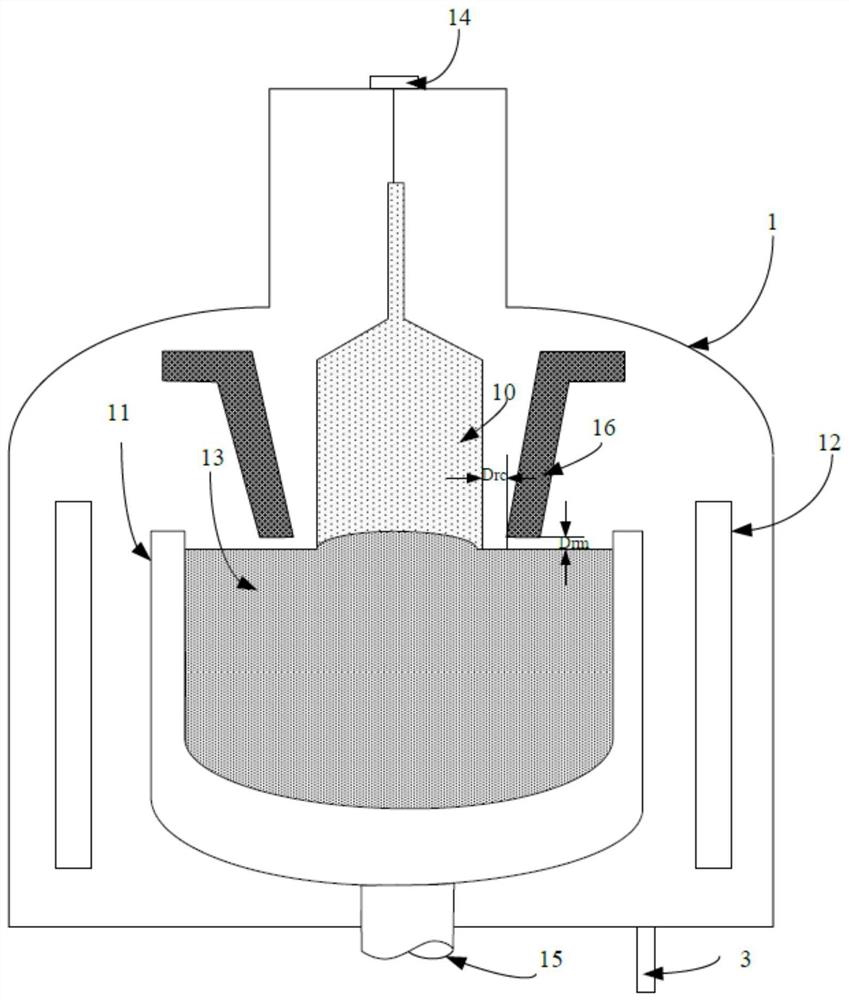

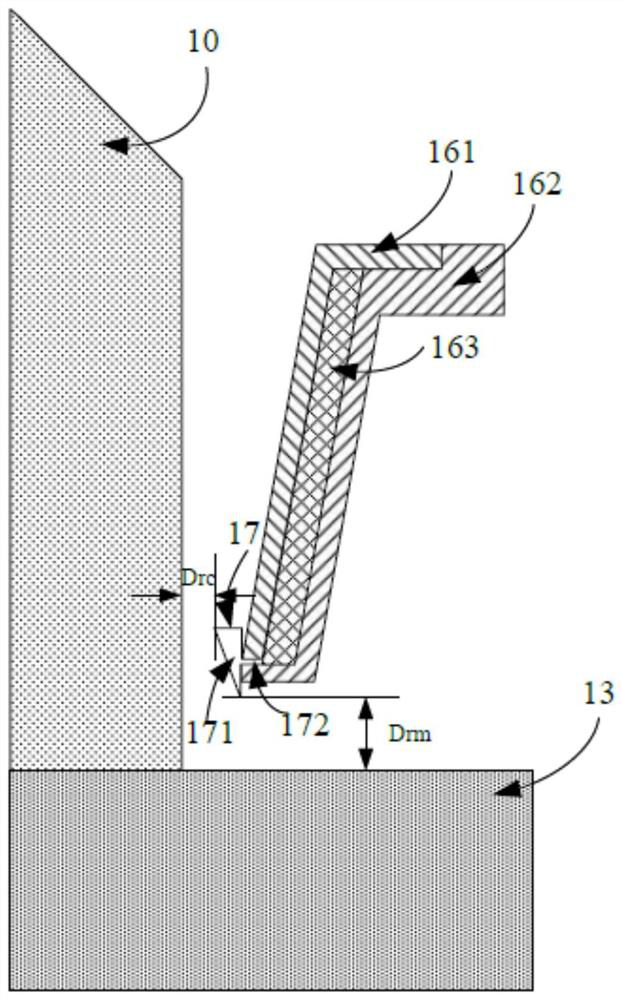

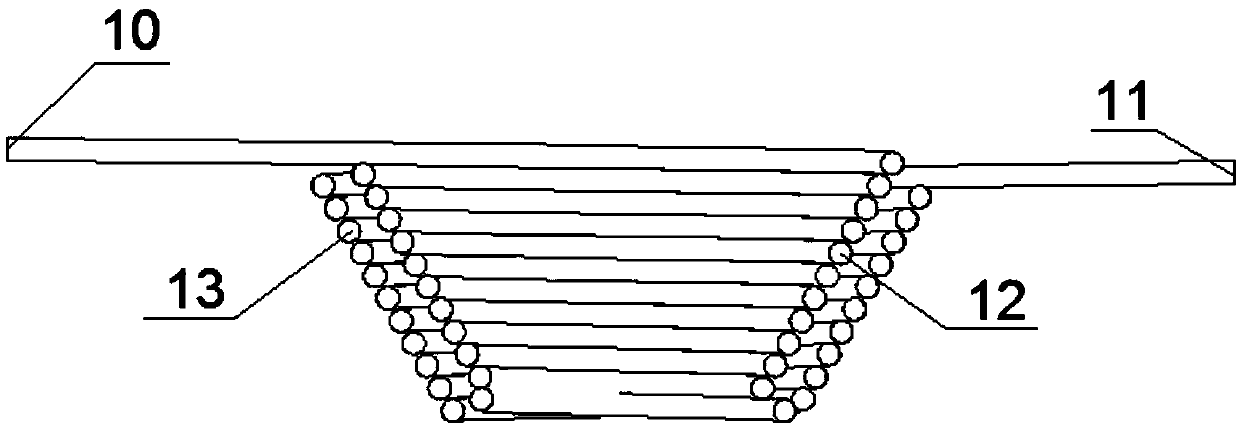

Heat shielding assembly, crystal pulling furnace system and working method of crystal pulling furnace system

ActiveCN109913939AMelting fastIncreased axial temperature gradientPolycrystalline material growthBy pulling from meltCrucibleEngineering

The invention provides a heat shielding assembly, a crystal pulling furnace system and a working method of the crystal pulling furnace system. The heat shielding assembly is arranged inside a furnacehearth of a crystal pulling furnace, the furnace hearth of the crystal pulling furnace is internally provided with a crucible for holding materials and a seed chuck, and the seed chuck is used for fixing a seed crystal or the heat shielding assembly. The heat shielding assembly comprises a heat shielding body and a reverse heat radiation material piece, wherein one end of the heat shielding body faces the crucible, the other end of the heat shielding body is detachably connected with the seed chuck, and the seed chuck can move so as to drive the heat shielding body to move in the axial direction of the furnace hearth of the crystal pulling furnace through a pulling rope; the reverse heat radiation material piece is arranged on the side, facing the crucible, of the heat shielding body. According to the heat shielding assembly provided by the invention, high-temperature heat radiation of reflection material melt liquid can be reflected effectively, the axial temperature gradient inside the crystal pulling furnace is increased, and rapid fusion of the material is promoted. The heat shielding assembly is in a cap form, and sputtering liquid during material fusion can be accommodated and returned back into the original melt liquid.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

Semiconductor crystal growth device

ActiveCN111519241AStable growthFast growthPolycrystalline material growthFinal product manufactureCrystal growthCondensed matter physics

The invention provides a semiconductor crystal growth device. The device comprises a furnace body; a crucible which is arranged in the furnace body and is used for accommodating a silicon melt; a lifting device which is arranged at the top of the furnace body and is used for lifting a silicon crystal bar out of the silicon melt; and a heat shield device which comprises a guide cylinder, wherein the guide cylinder is barrel-shaped and is arranged around the periphery of the silicon crystal bar and is used for rectifying argon inputted from the top of the furnace body and adjusting the distribution of the heat field between the silicon crystal bar and the liquid level of the silicon melt; the heat shield device further comprises an adjusting device arranged on the inner side of the lower endof the flow guide cylinder, and the adjusting device is used for adjusting the minimum distance between the heat shield device and the silicon crystal bar. According to the device, the adjusting device is arranged on the inner side of the lower end of the guide cylinder, the distance between the silicon crystal bar and the heat shield device close to the silicon crystal bar is adjusted without changing the shape and position of the guide cylinder, and the crystal growth speed and quality are improved.

Owner:ZING SEMICON CORP

Water-cooling dynamic heat flow sensor

ActiveCN113551810AReduce the difficulty of manufacturing processConducive to miniaturization designCalorimeterNuclear energy generationHeat flowMiniaturization

The invention discloses a water-cooling dynamic heat flow sensor. The sensor comprises a heat flow sensor body which comprises a heat transfer probe and a T-shaped cavity which are coaxially and integrally arranged, two butt-joint thermocouple wires which are arranged on the heat transfer probe in a penetrating manner, and a water cooling device arranged at the lower end of the T-shaped cavity. The heat flow sensor is novel in structure, stable in operation and low in preparation process difficulty, simplifies the design of a test water inlet and outlet channel, and facilitates the miniaturization design of the heat flow sensor; and under the water cooling effect of the T-shaped cavity, the axial temperature gradient of the whole heat flow sensor body is obviously increased, the axial temperature difference signal-to-noise ratio is improved, and the subsequent heat flow calculation precision can be improved. A water cooling device with high cooling efficiency is adopted at the tail part of the T-shaped cavity so that a high-heat-flow long-time test can be realized; and in combination with a hybrid dynamic heat flow test method containing calibration correction, the test accuracy of the designed water-cooling dynamic heat flow sensor is ensured, the heat flow test response speed is improved, and a foundation is laid for a dynamic high heat flow long-time test.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Guide cylinder and preparation method thereof

ActiveCN102912425BImprove insulation effectImprove reflective effectPolycrystalline material growthBy pulling from meltCarbon compositesThermal insulation

The invention discloses a guide cylinder capable of shortening the crystal pulling time and improving the crystal pulling speed and a preparation method. The guide cylinder comprises an inverted conical cylinder; the cylinder comprises an outer screen (3) and an inner screen (5); a thermal insulation layer (4) is arranged between the outer screen (3) and the inner screen (5); the guide cylinder is characterized in that the outer screen (3) is prepared from carbon / carbon composite material; the inner screen (5) is prepared from metal molybdenum or metal tungsten; the outer screen (3) is connected with a positioning disc (1) so that the outer screen (3), the inner screen (5), the thermal insulation layer (4) and the positioning disc (1) form an integral structure; and the guide cylinder is produced by the steps of blank production, purification, surface coating and cylinder assembly. The guide cylinder disclosed by the invention has good thermal insulation effect, high strength, long service life and good reflection effect, effectively increases the axial temperature gradient, accelerates the crystal pulling, shortens the crystal pulling time and effectively improves the production efficiency.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

Device suitable for large size single crystal pulling speed accelerating and head radiation

PendingCN110424050AGuaranteed lostGuaranteed cooling spacePolycrystalline material growthBy pulling from meltEngineeringSingle crystal

The invention provides a device suitable for large size single crystal pulling speed accelerating and head radiation. The device comprises a refrigeration device main body, a water inlet pipeline, anda water outlet pipeline; the water inlet pipeline and the water outlet pipeline are connected with the refrigeration device main body respectively, it is convenient for circulation flowing of coolingmedium in the refrigeration device main body; the refrigeration device main body is provided with a plurality of sight holes along the direction from a single crystal furnace cover to a crucible successively; the single crystal furnace cover is provided with an observation hole; the plurality of sight holes are arranged on the side of the refrigeration device main body opposite to the observationhole, so that it is convenient to observe single crystal growth. The beneficial effects are that: the plurality of sight holes are adopted, so that it is convenient for observation of single crystalgrowth; with a crystal crystallization region temperature ensured to be at a silicon crystallization point temperature, crystal surface heat energy loss is accelerated, crystal axial temperature gradient is increased, and single crystal pulling speed accelerating is promoted.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

Single crystal furnace for achieving rapid crystal growth through chemical heat sink enhanced cooling technology

ActiveCN106435711AAvoid chemical endothermic reactionsAvoid pollutionBy pulling from meltPhysical chemistrySingle crystal

The invention discloses a single crystal furnace for achieving rapid crystal growth through a chemical heat sink enhanced cooling technology and mainly relates to a reaction device capable of conveying reactants and carrying out a chemical endothermic reaction inside the device. The reaction device is composed of a graphite cylinder and a reaction cylinder, wherein the reaction cylinder is made of an inert material; the reactants are introduced from an inlet, the chemical endothermic reaction is carried out in the reaction cylinder at a high temperature, the temperature on the surface of the reaction device and in a nearby argon gas area thereof is reduced, heat on the crystal surface is rapidly transferred, and incompletely reacted reactants and the reaction product are discharged out of the furnace by an outlet. The single crystal furnace is reasonable in structural design, the reactants can react in the reaction device, and impurities can be prevented from being introduced into the furnace in the reaction process. According to the device disclosed by the invention, the growing crystal is subjected to enhanced cooling by virtue of the chemical endothermic reaction, the heat on the crystal surface is rapidly transferred, and the axial temperature gradient inside the crystal is obviously improved, so that the crystal growth speed is improved, and the aim of reducing the crystal preparation cost is achieved.

Owner:徐州晶睿半导体装备科技有限公司

A high-speed single crystal growth device and method

ActiveCN105603520BTimely releaseIntensive Cooling Crystal SurfacePolycrystalline material growthBy pulling from meltChemical reactionShielding gas

The invention discloses a high-speed single crystal growth device and method and mainly relates to a crystal cooling manner and a reaction cylinder for conveying reactants to perform chemical reactions. The reaction cylinder is made of high-temperature-resistant materials and comprises a gas inlet cylinder and a gas discharge cylinder. The gas inlet cylinder is provided with a passage for feeding the reactants and protecting gas. The reactants are sprayed to the surfaces of growing high-temperature crystals after passing the gas inlet cylinder to perform chemical reaction so as to absorb heat and fast remove the heat on the surfaces of the crystals. The gas discharge cylinder is used for discharging the reactants not completely reacted and reaction product gas out of a furnace. The gas inlet cylinder and the gas discharge cylinder are integrally connected and fixed on a furnace wall. The high-speed single crystal growth device and method has the advantages that the chemical heat-absorption reaction is applied to the intensified cooling in crystal growth for the first time, the heat on the surfaces of the crystals can be removed fast, the axial temperature gradient inside the crystals can be increased evidently, and accordingly the crystal growth speed is increased.

Owner:徐州晶睿半导体装备科技有限公司

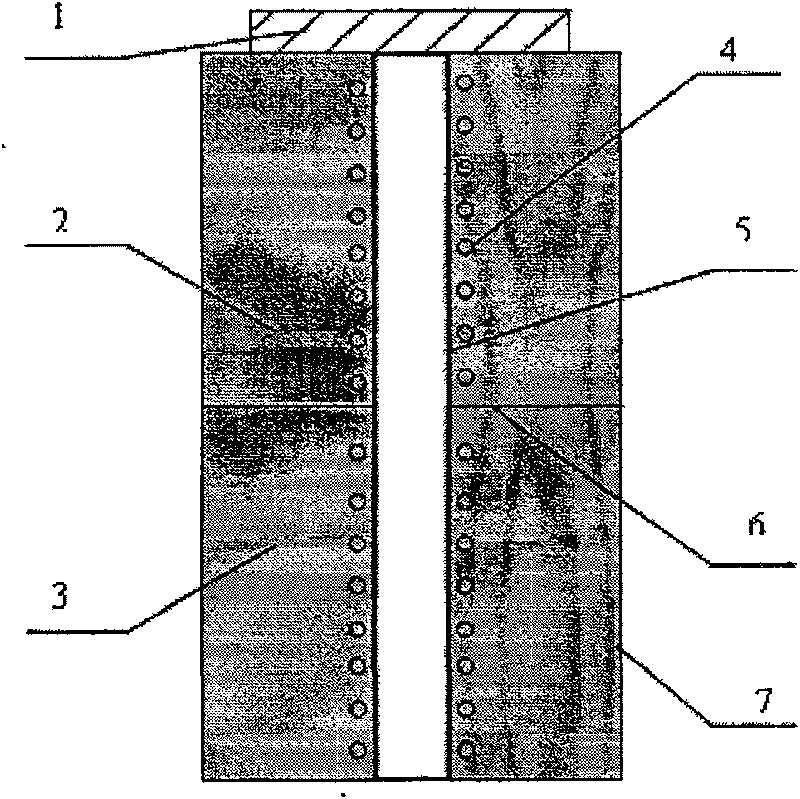

Vertical Bridgman growth furnace and method of optimizing temperature field inside furnace

ActiveCN101220502BReduce defect densityAxial temperature increasesFrom frozen solutionsSuper coolingTemperature control

The invention discloses a vertical Bridgman growth furnace. From the bottom up, the inside of an outer shell of the furnace is provided with a thermal insulating board, two groups of I type heating modules, a cooling fin, a group of II type heating modules, two groups of I-type heating modules and a furnace hearth cover. The center hole of the thermal insulating board is filled with fireproof ceramic cotton, and the center of five sections of heating modules is provided with two sections of liner tubes which are separated by the cooling fin, and the outside of the joint of the liner tubes is provided with a liner sleeve, and the surrounding of the center hole of each group of heating modules is provided with an electric heated wire of each separate temperature control system, and a Pt / PtRh10 thermocouple is arranged in the radical direction, being in the middle of the outer wall which is vertical to the outer wall of each group of modules, and the temperature measuring contact of the thermocouple is close to the outer wall of the liner tube 5. The invention also discloses the optimization method of the temperature field of the vertical Bridgman growth furnace. As the vertical Bridgman growth furnace adopts the design of five sections of modules, adjustable temperature field for growing various crystals can be obtained by changing different modules, thus solving the problem of constitutional super cooling caused by small axial temperature gradient.

Owner:IMDETEK

A semiconductor crystal growth device

ActiveCN111519241BStable growthFast growthPolycrystalline material growthFinal product manufactureCrucibleEngineering

The present invention provides a semiconductor crystal growth device, which comprises: a furnace body; a crucible arranged inside the furnace body to accommodate silicon melt; a pulling device arranged in the The top of the furnace body is used to pull out silicon crystal rods from the silicon melt; and a heat shield device, the heat shield device includes a draft tube, and the draft tube is barrel-shaped and wraps around the silicon crystal Rods are arranged around to rectify the argon gas input from the top of the furnace body and adjust the thermal field distribution between the silicon crystal rods and the silicon melt level; wherein, the heat shield device also includes The adjustment device arranged inside the lower end of the draft tube is used to adjust the minimum distance between the heat shield device and the silicon crystal rod. According to the present invention, by setting the adjustment device inside the lower end of the draft tube, the distance between the silicon crystal rod and the device close to the heat shield can be adjusted without changing the shape and position of the draft tube, thereby improving the crystal growth speed and quality.

Owner:ZING SEMICON CORP

A Micro Downward Pulling Crystal Growth Furnace

InactiveCN104611764BObserve the growthImprove yieldBy pulling from meltMicro-pulling-downCalcination

The invention discloses a micro-downward pulling crystal growth furnace, which comprises an upper heat insulation layer and a bottom heat insulation layer (13) arranged from top to bottom, and an observation hole (4) is arranged in the bottom heat insulation layer (13) for observation The hole (4) is tubular, and the included angle between its central axis and the normal to the top surface of the bottom insulation layer (13) is 45° to 60°; the inner layer insulation layer, the middle insulation layer and the bottom insulation layer (13) are all composed of mass Zirconia and alumina with a ratio of 1:9 are pressed and calcined. The observation window provided by the invention can observe the crystal growth condition at the crystal growth interface in time; moreover, the observation window has little influence on the temperature field of the crystal growth furnace, and can further improve the yield of crystal growth.

Owner:HUAZHONG UNIV OF SCI & TECH

Single crystal furnace for rapid crystal growth through chemical heat sink enhanced cooling technology

ActiveCN106435711BAvoid chemical endothermic reactionsAvoid pollutionBy pulling from meltSingle crystalGraphite

Owner:徐州晶睿半导体装备科技有限公司

A high-quality silicon carbide single crystal, substrate and efficient preparation method thereof

ActiveCN111118598BQuality improvementLow density defectPolycrystalline material growthFrom condensed vaporsCarbide siliconSemiconductor materials

The invention discloses a high-quality silicon carbide single crystal, and a substrate and an efficient preparation method thereof, and belongs to the field of semiconductor materials. The preparationmethod comprises the following steps: putting raw materials and seed crystals into a crucible, assembling the crucible and a heat preservation structure into a crystal growth furnace, arranging a heating coil assembly at the periphery of the side wall of the crystal growth furnace, and mounting an adjusting mechanism; removing impurities; and growing the crystal, wherein the heating coil assemblycomprises a first coil assembly arranged corresponding to a raw material area and a second coil assembly arranged corresponding to a crystal growth area, and the inner diameter of the second coil assembly is increased in the direction from raw materials to seed crystals. The preparation method of the silicon carbide single crystal is characterized in that the axial temperature gradient in a growth cavity is formed, so the high-quality silicon carbide single crystal can be prepared; the radial temperature gradient in the growth cavity for growing the single crystal is adjusted, so the crystalgrowth rate and the crystal growth quality are improved; and the radial temperature gradient is reduced, and a certain axial temperature gradient can be ensured, so the high-quality silicon carbide single crystal can be efficiently prepared.

Owner:SICC CO LTD

A silicon carbide single crystal, substrate and preparation method thereof

ActiveCN111074340BQuality improvementReduce defectsPolycrystalline material growthFrom condensed vaporsSemiconductor materialsInsulation layer

The application discloses a silicon carbide single crystal, a substrate and a preparation method thereof, belonging to the field of semiconductor materials. The silicon carbide single crystal preparation method comprises that the temperature measuring hole formed by the upper insulation layer group outside the crucible forms a low-temperature zone and a high-temperature zone in the crucible, and the raw material in the high-temperature zone is gas-phase transported to the surface of the seed crystal in the low-temperature zone by using a physical gas phase transport method. Carry out crystal growth; the upper insulation layer group includes the second insulation layer and the first insulation layer arranged in sequence along the direction of the raw material from the seed crystal, the first insulation layer is provided with the first opening, the second insulation layer is provided with the second opening, and the rotation adjustment mechanism Rotate the first insulation layer and / or the second insulation layer to adjust the cross-sectional area of the temperature measuring hole formed by the first opening and the second opening, thereby adjusting the axial and radial temperature gradients in the crucible during the crystal growth process. The silicon carbide single crystal preparation method can not only adjust the radial temperature gradient in the growth chamber for growing single crystals; but also ensure a certain axial temperature gradient while reducing the radial temperature gradient, and produce high-quality silicon carbide single crystals with high efficiency. crystal.

Owner:SICC CO LTD

A Czochralski method single crystal silicon growth furnace

ActiveCN111826709BLight in massAvoid thermal unevennessBy pulling from meltCrystallographyTemperature control

The invention relates to the technical field of Czochralski monocrystalline silicon, and discloses a Czochralski monocrystalline silicon growth furnace, which includes a fixed box and a pyrometer. A heating element is fixedly installed on the inner wall of cylinder one, and a seed crystal is fixedly installed on the top right side of the fixed box. Through the setting of the growth chamber, the melting of polysilicon is separated from the place where the single crystal silicon body is pulled, and the melting of polysilicon through the quartz crucible to form a melt provides raw materials for pulling the single crystal silicon body inside the growth chamber, avoiding The uneven thermal field in the quartz crucible reduces the quality of the single crystal silicon body, ensures that the temperature of the growth interface in the growth chamber can be kept within a certain range, and reduces the difficulty of temperature control. At the same time, the setting of the quartz crucible and the growth chamber ensures sufficient raw materials , and through the setting of the rotating device, the number of monocrystalline silicon bodies pulled at one time is increased, and the production efficiency is increased.

Owner:杭州飞宇磁电器材有限公司

Three-section electric arc heating thrustor

ActiveCN102518572AReduce difficultyRealize engineering designElectric discharge heatingMachines/enginesHeat resistanceWorking temperature

The invention relates to a three-section electric arc heating thrustor which adopts a sectional structure and is divided into three sections, comprising an anode section, a transitional section and high heat-resistance section. The anode section is welded and fixed inside one end of the transitional section. The other end of the transitional section is welded and fixed with the high heat-resistance section to from a shell. In the invention, high temperature performance, structural strength, conductive performance and welding performance are respectively concerned according to requirements of different parts of the thrustor on materials, thereby reducing the difficulty of selecting materials, meeting the requirements of physical properties of the materials such as using temperature, conductive coefficient, strength and the like in different temperature ranges and satisfying the welding requirements of the whole structure, so as to realize the engineering design of the structural piece of the thrustor. In the invention, the three-section structure is adopted and the three sections are made of materials with different heat resistances and heat expansion coefficients, thereby improving the axial temperature gradient of the thrustor, solving the match problem in welding of different materials and meeting the requirements of the thrustor on distribution of working temperatures with a limit size.

Owner:BEIJING INST OF CONTROL ENG

Crystal growth apparatus and crystal growth method

PendingCN111379015ALow powerIncreased axial temperature gradientBy pulling from meltCruciblePerfect crystal

The invention provides a crystal growth device and a crystal growth method. The growth device comprises a shell which defines a cavity and is provided with a first opening and a second opening which are oppositely arranged; a heat preservation layer is arranged on the inner wall of the shell; a crucible is surrounded by the heat preservation layer and is used for containing molten soup; a heater is arranged between the crucible and the heat preservation layer; a cooling sleeve is arranged below the first opening; a heat shield is arranged below the cooling sleeve and consists of a plurality ofmolybdenum sheets which are arranged in parallel; and a first micro heater is arranged below the heat shield and extends in the horizontal direction. According to the invention, heat energy loss on the crystal surface can be effectively prevented; compared with the prior art, the method has the advantages that the axial temperature gradient of the crystal is increased, the radial temperature gradient of the crystal can be reduced, the crystallization rate of the large-size crystal with the size of 12 inches or above is increased, the good time is maintained within the range of 1300-1400 DEG C, defects are fully discharged out of the crystal, and then the approximately perfect crystal is grown.

Owner:中环领先(徐州)半导体材料有限公司 +1

A kind of high-quality silicon carbide crystal and its growth method and device

ActiveCN113122923BTemperature controlControl flowPolycrystalline material growthFrom condensed vaporsCarbide siliconCrucible

Owner:上海天岳半导体材料有限公司

A kind of preparation method and growth device of n-type silicon carbide crystal

ActiveCN112813499BReduce radial temperature gradientQuality improvementPolycrystalline material growthFrom condensed vaporsCarbide siliconCrucible

The invention provides a preparation method and a growth device of an N-type silicon carbide crystal, the method comprising: (1) placing a raw material in a high temperature zone of a crucible, placing a seed crystal in a low temperature zone of the crucible, and the top outer wall of the crucible facing inward An annular gas groove is formed by the depression; the assembled crucible is placed in the furnace body of the crystal growth furnace, so that the annular air groove is close to the ventilation hole of the furnace body; (2) in the crystal growth stage, the air is passed into the furnace body through the ventilation hole Nitrogen source gas, controlling the growth temperature and pressure, and growing N-type silicon carbide crystals on the seed crystals. Through the annular air groove close to the vent hole of the furnace body, the incoming gas can flow along the annular air groove, the air flow rate is fast, and the gas diffuses into the crucible, so that the heat transfer in the crucible away from the central axis is accelerated, reducing the number of crucibles. The radial temperature gradient improves the quality of crystal growth.

Owner:SICC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com