Patents

Literature

45results about How to "Reduce radial temperature gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation device and application of silicon carbide single crystal

ActiveCN110904508ASlow down uneven carbonizationReduce radial temperature gradientPolycrystalline material growthFrom condensed vaporsCarbide siliconSeed crystal

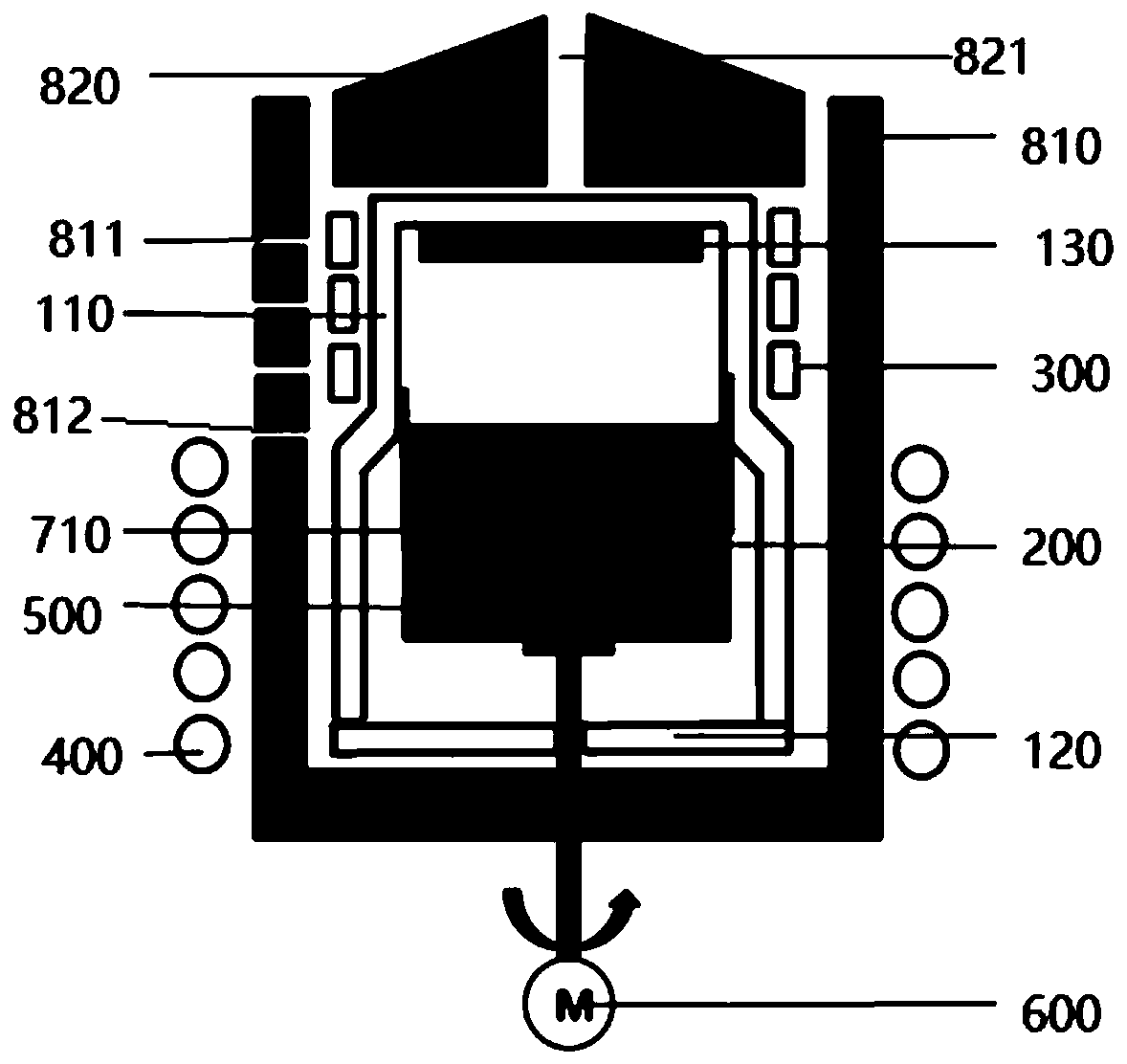

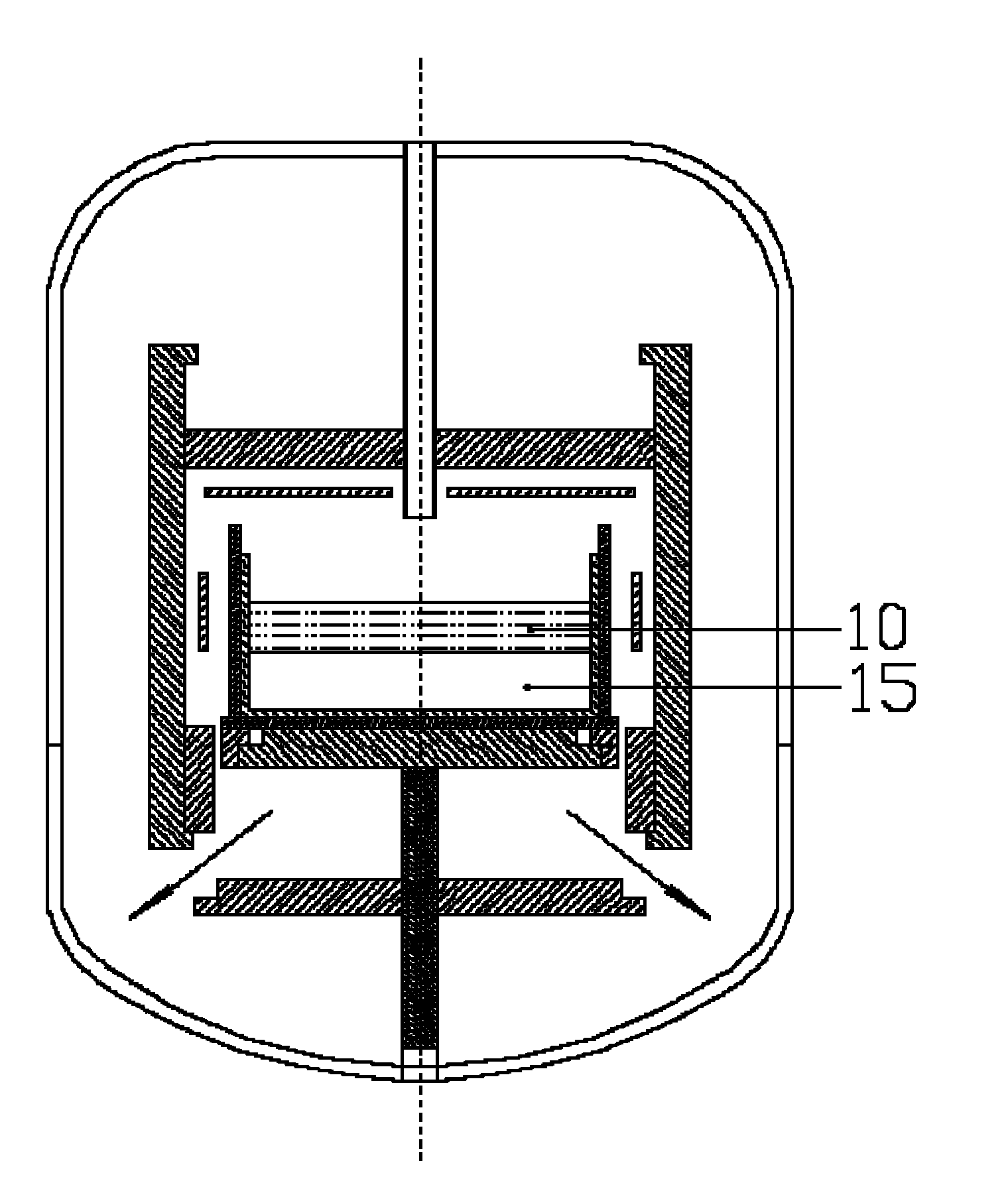

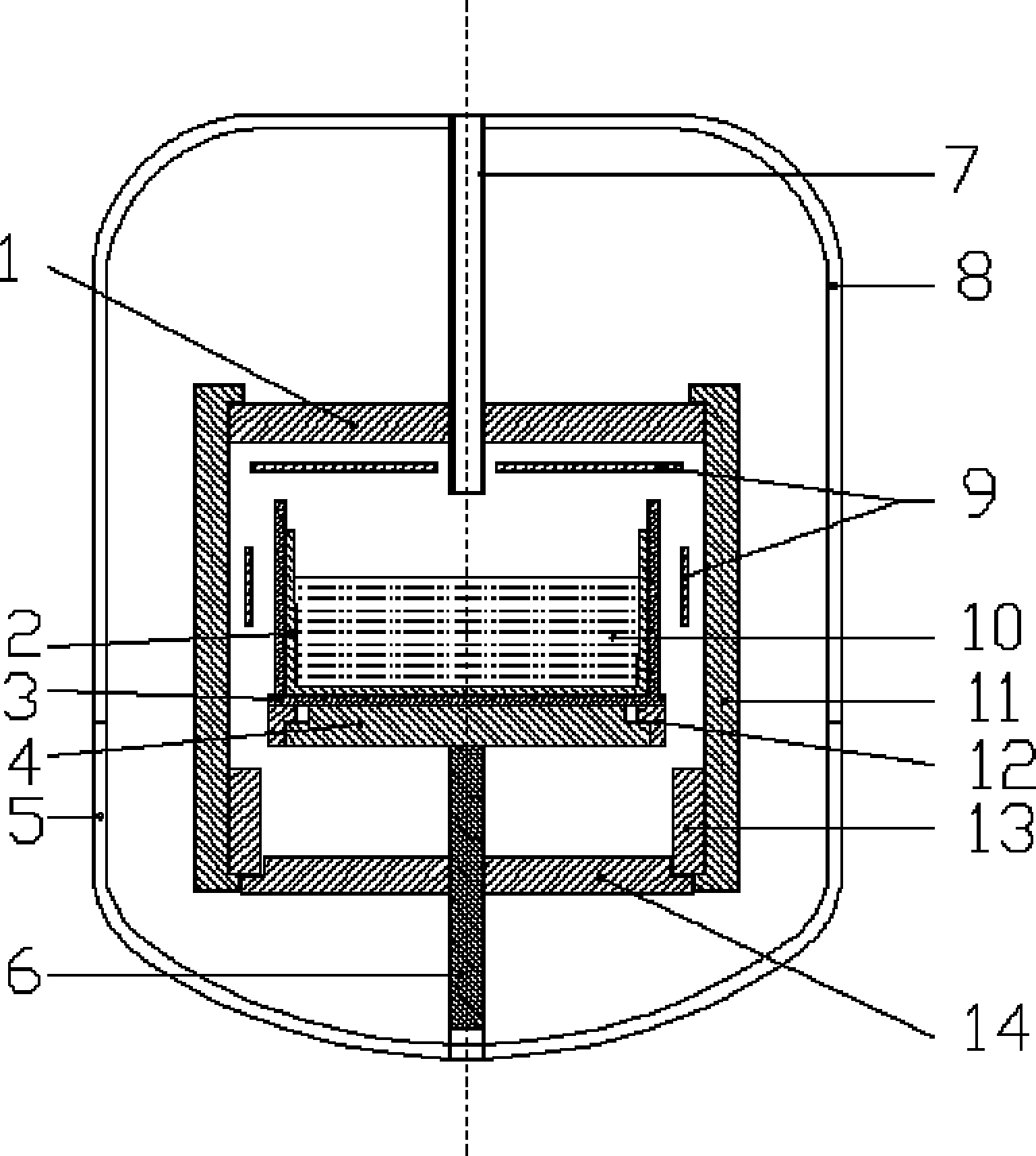

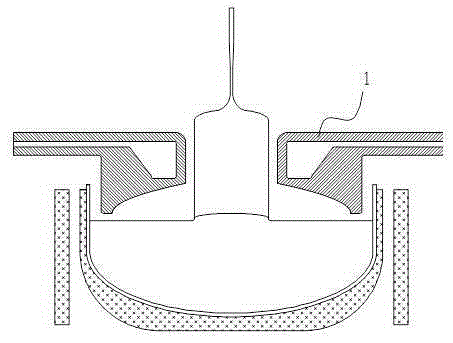

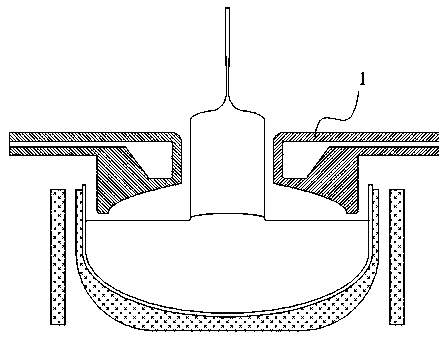

The invention discloses a preparation device and application of a silicon carbide single crystal, and belongs to the field of preparation of single crystals. The preparation device of the silicon carbide single crystal comprises a crucible, a charging basket and a rotary lifting unit, the crucible comprises an upper crucible and a lower crucible; wherein the charging bucket comprises a bucket bodyand an opening part, the bucket body is arranged in the lower crucible, the opening part is rotatably connected with the upper crucible, and the charging bucket and the upper crucible form a growth cavity for preparing the silicon carbide single crystal by a physical vapor transport method; an isolation cavity is formed between the charging bucket and the lower crucible; the rotary lifting unit drives the charging bucket to rotate and lift relative to seed crystals. According to the preparation device, the charging bucket is accurately and stably located in the center of the crucible servingas a heating body in the rotary lifting process, the interior of the charging bucket is heated evenly due to the consistent temperature of the sections of the charging bucket in all directions, then the defects that carbon inclusions are generated in the prepared silicon carbide single crystal and the like are overcome, and the quality of the prepared silicon carbide single crystal is improved.

Owner:SICC CO LTD

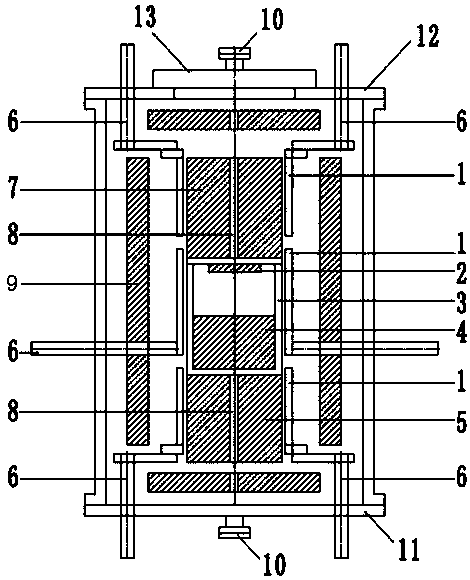

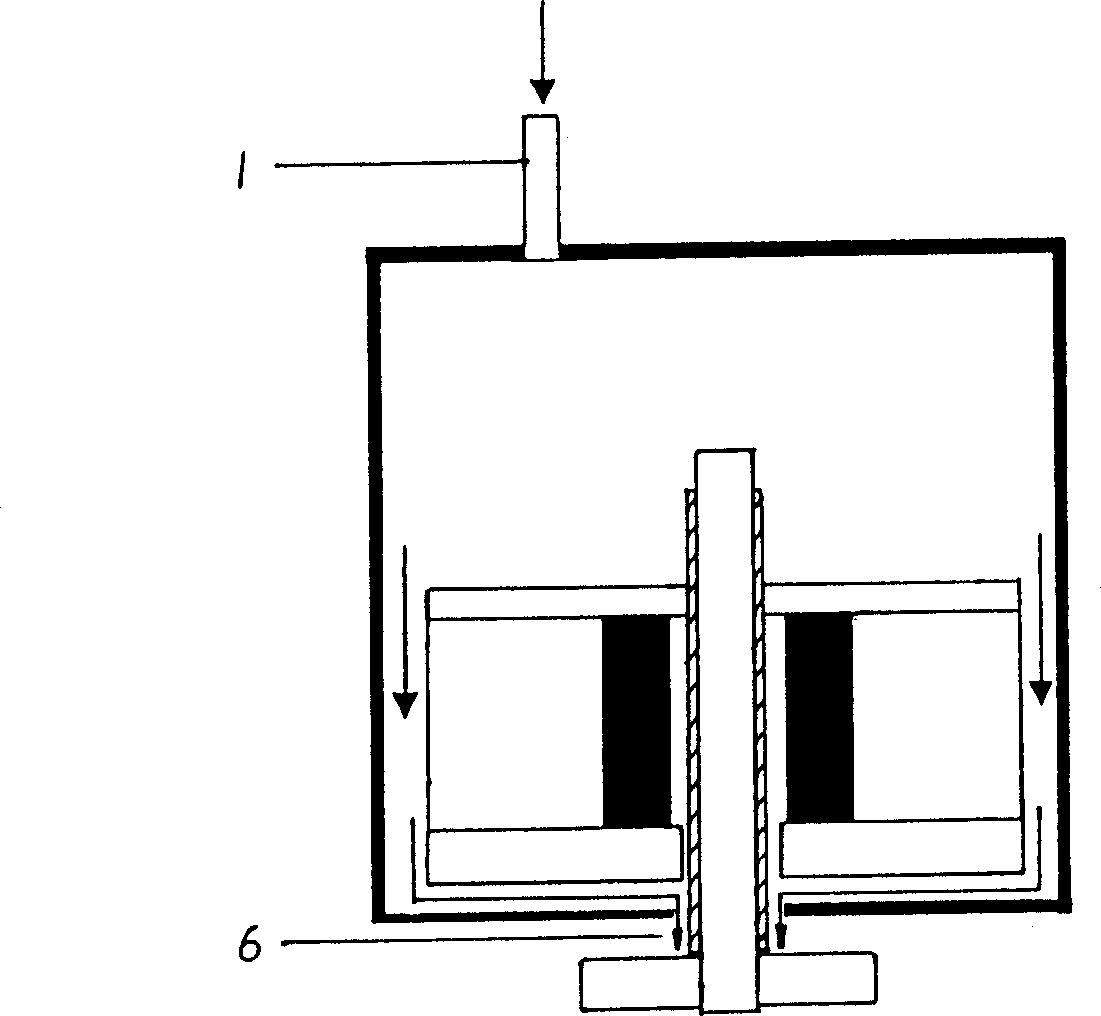

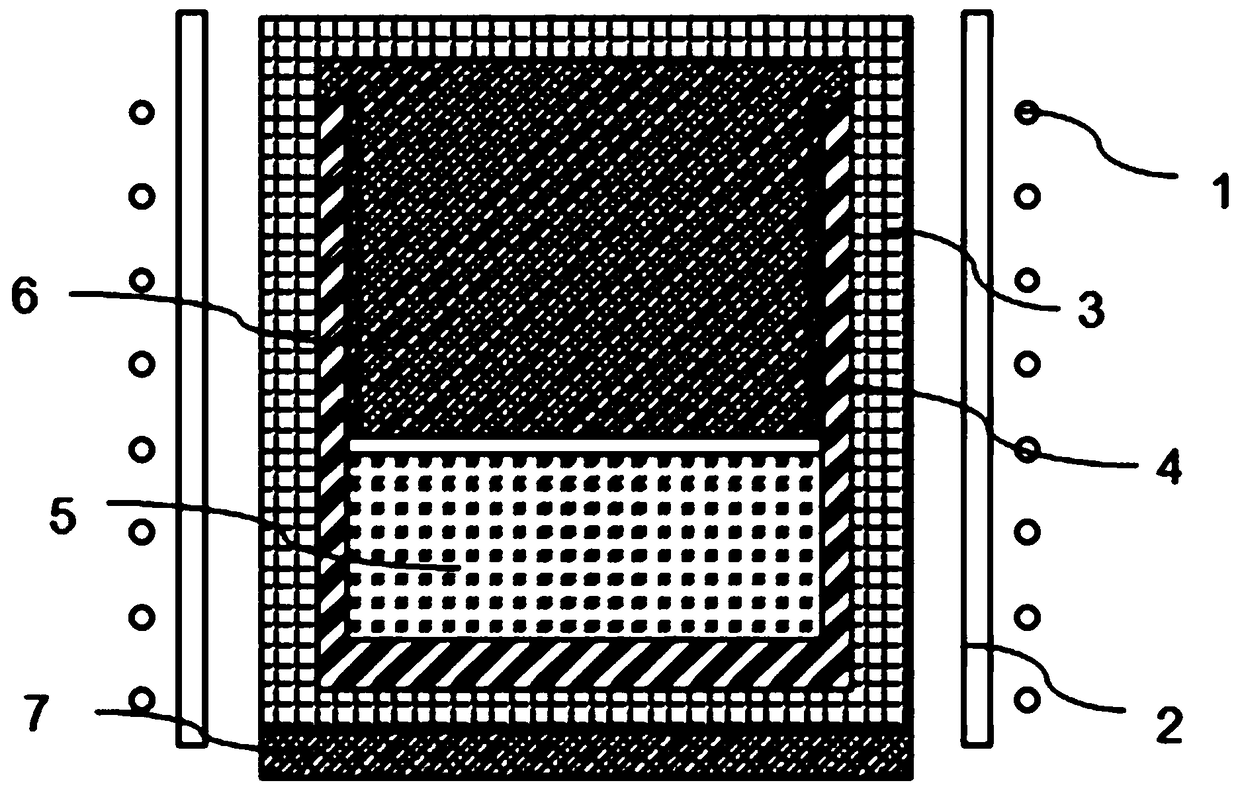

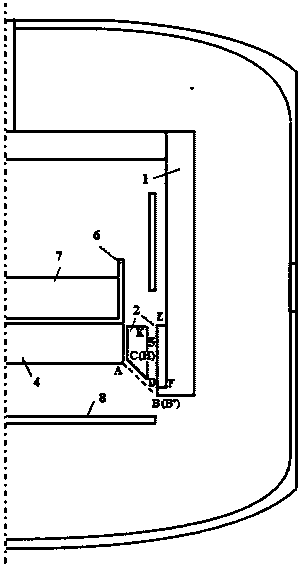

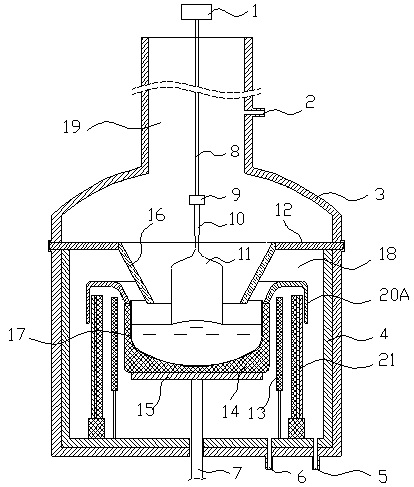

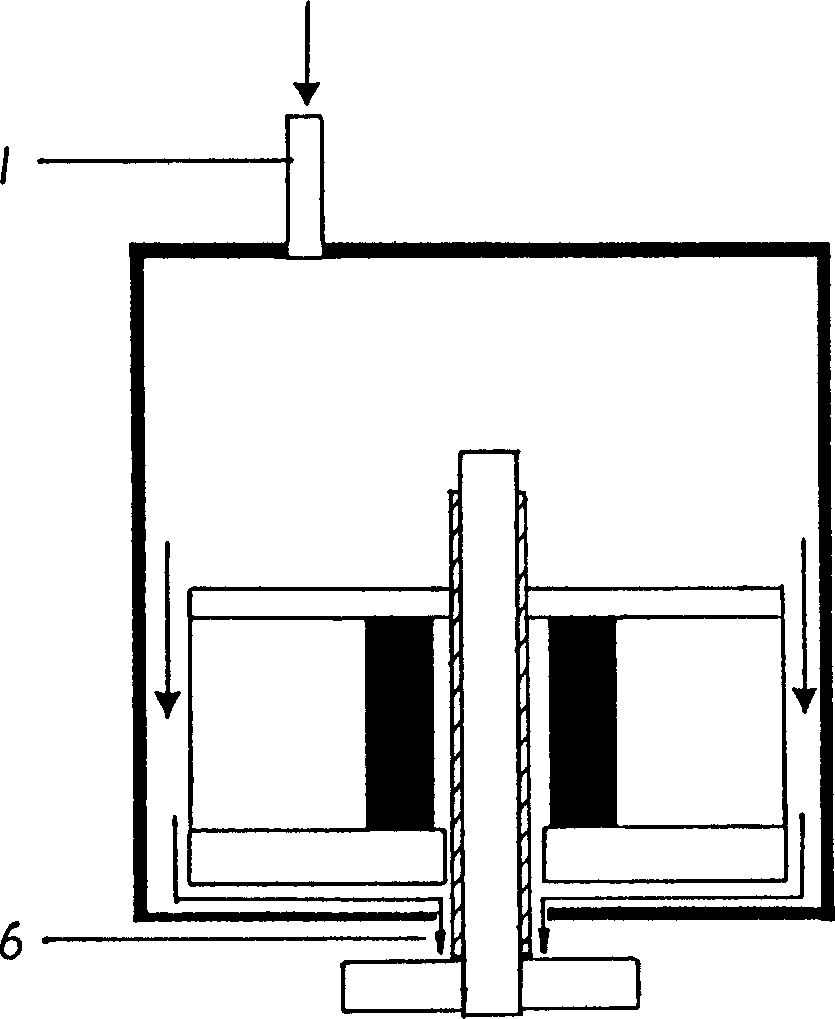

Thermal field structure used in polycrystalline silicon ingot furnace for controlling crystal growth interface

InactiveCN102108544AIncreasing the thicknessReduce radial spreadPolycrystalline material growthFrom frozen solutionsElectricityGraphite

The invention relates to a thermal field structure used in a polycrystalline silicon ingot furnace for controlling a crystal growth interface. The structure comprises an upper furnace body and a lower furnace body; a heat isolation cage and an upper heat insulation plate are arranged in the upper furnace body, and a bottom heat insulation plate is arranged in the lower furnace body; a support rod supports a graphite coagulating assistant block in the heat isolation cage; L-shaped heat insulation plates are hung upside down on the edges of two ends of the graphite coagulating assistant block; a side heat insulation plate is mounted at the bottom on the inner wall of the heat isolation cage. The heat isolation cage, the side heat insulation plate, the bottom heat insulation plate and the upper heat insulation plate form a sealed cavity during heating; and the side heat insulation plate keeps a clearance of 5-30mm with the L-shaped heat insulation plates during the crystal growth. The thermal field structure enables the crystal interface to always maintain a relatively-ideal plane state during the ingot growth of polycrystals, thereby enabling the radial resistivity of cast polycrystalline ingots to be more uniform, improving the uniformity in the electrical performance of a silicon wafer, and reducing the gradient for radial temperature of the crystals. Therefore, the thermal stress of the crystals can be reduced, the defects of the crystals can be reduced and the conversion efficiency of the battery is improved.

Owner:TRINA SOLAR CO LTD

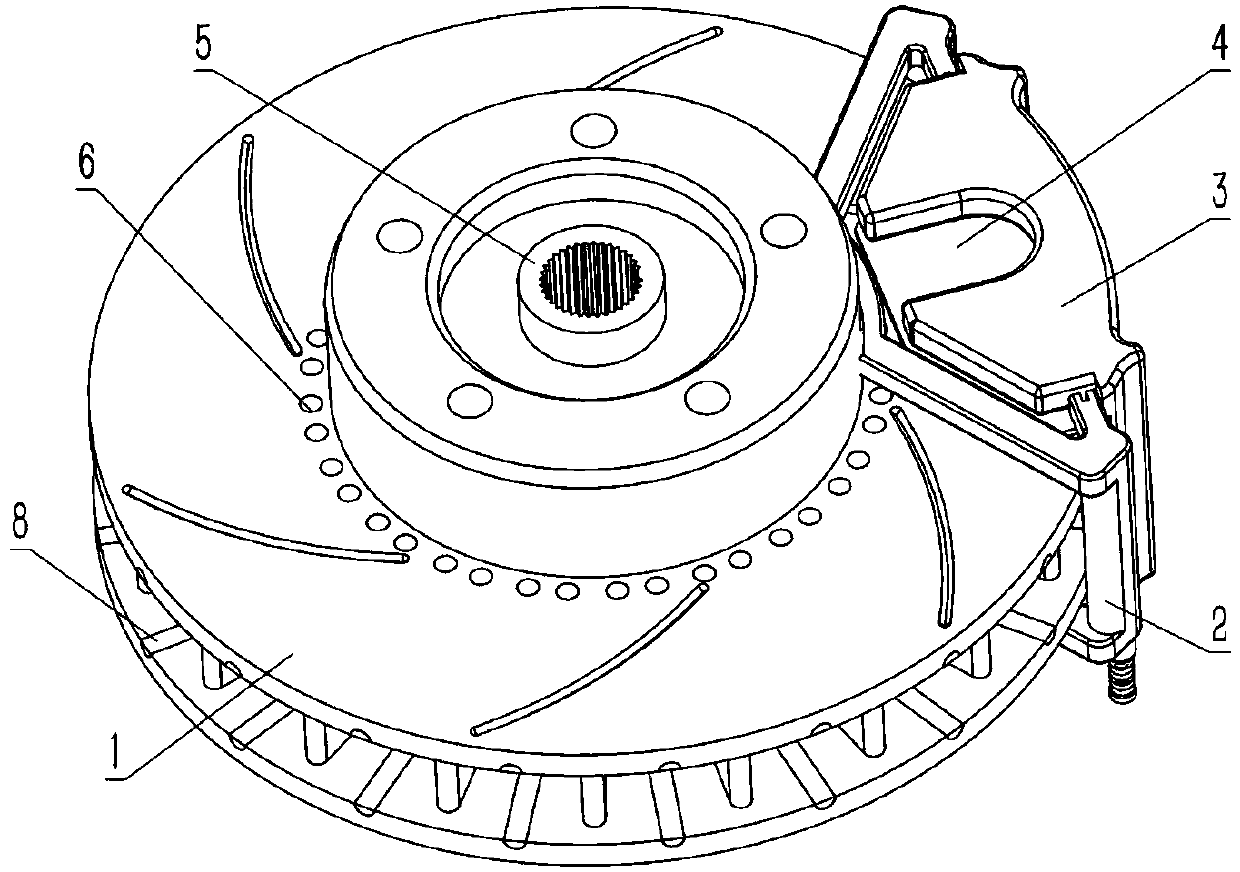

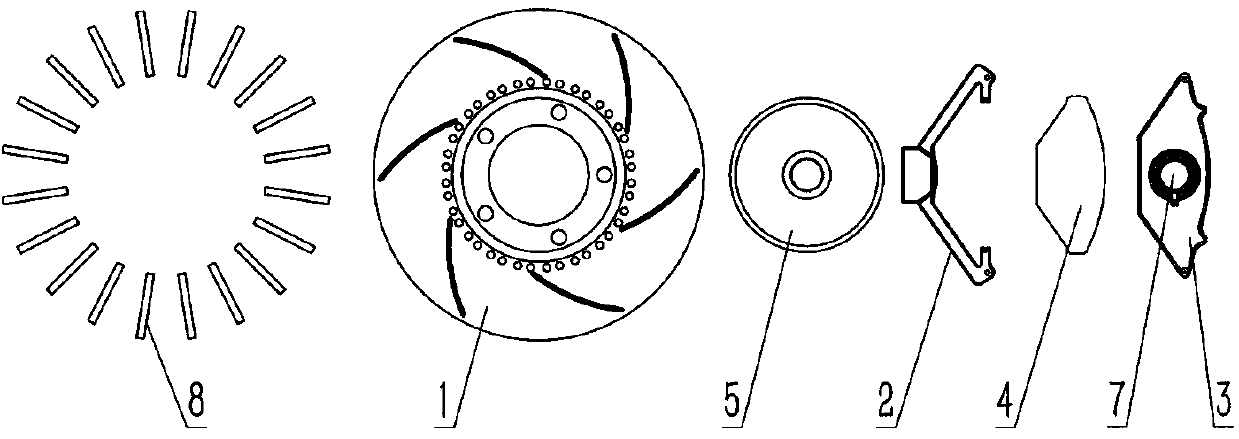

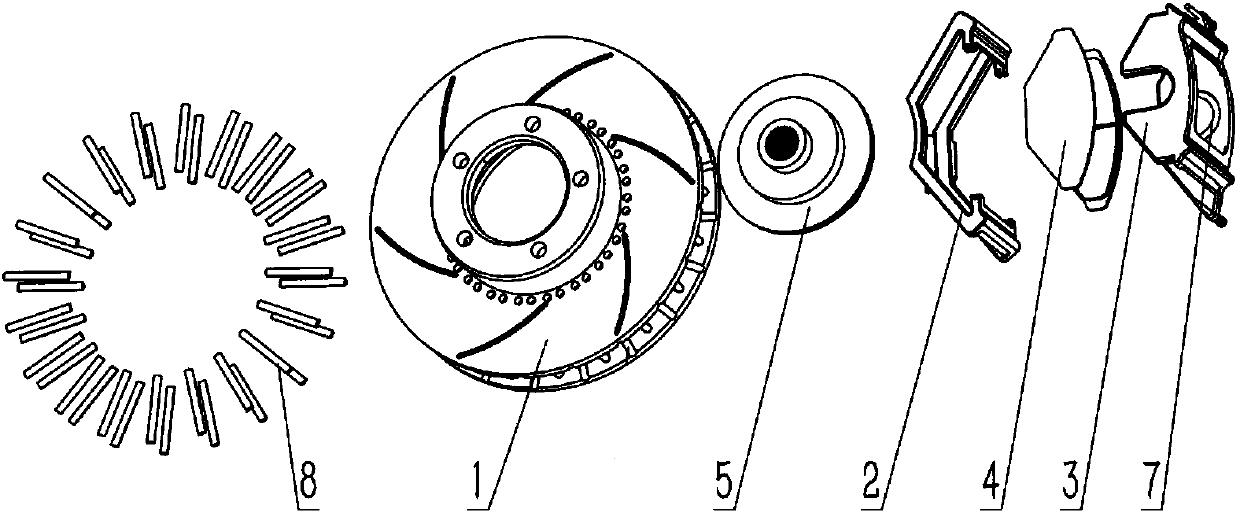

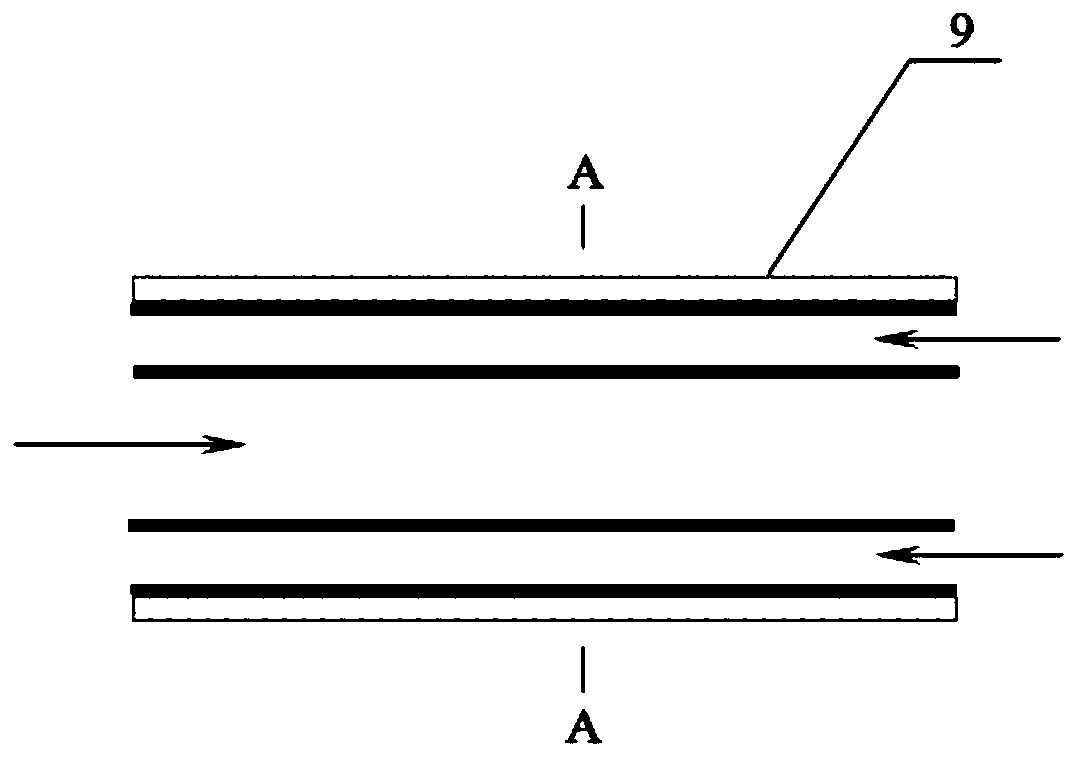

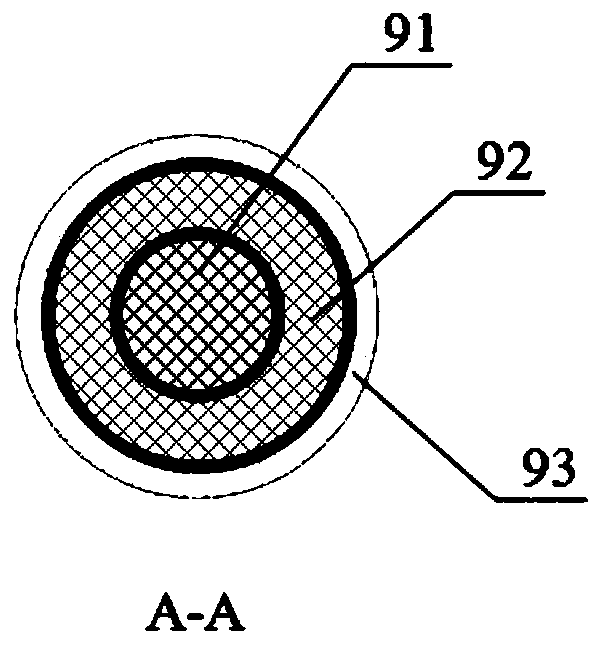

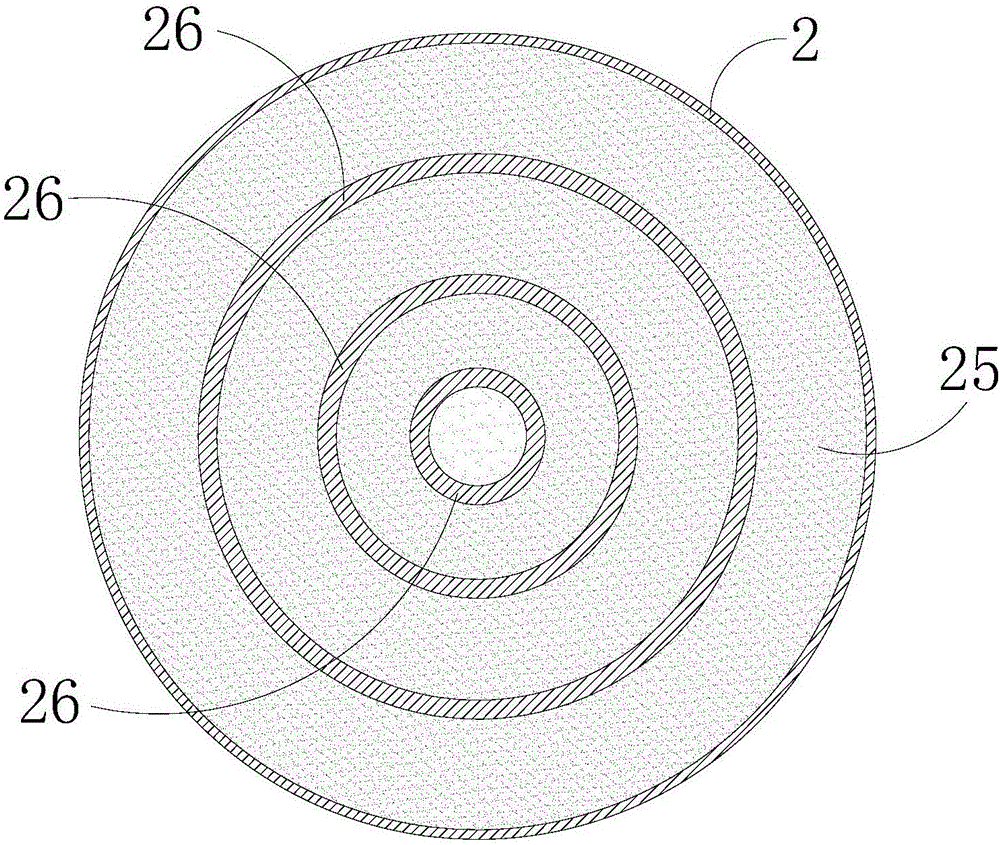

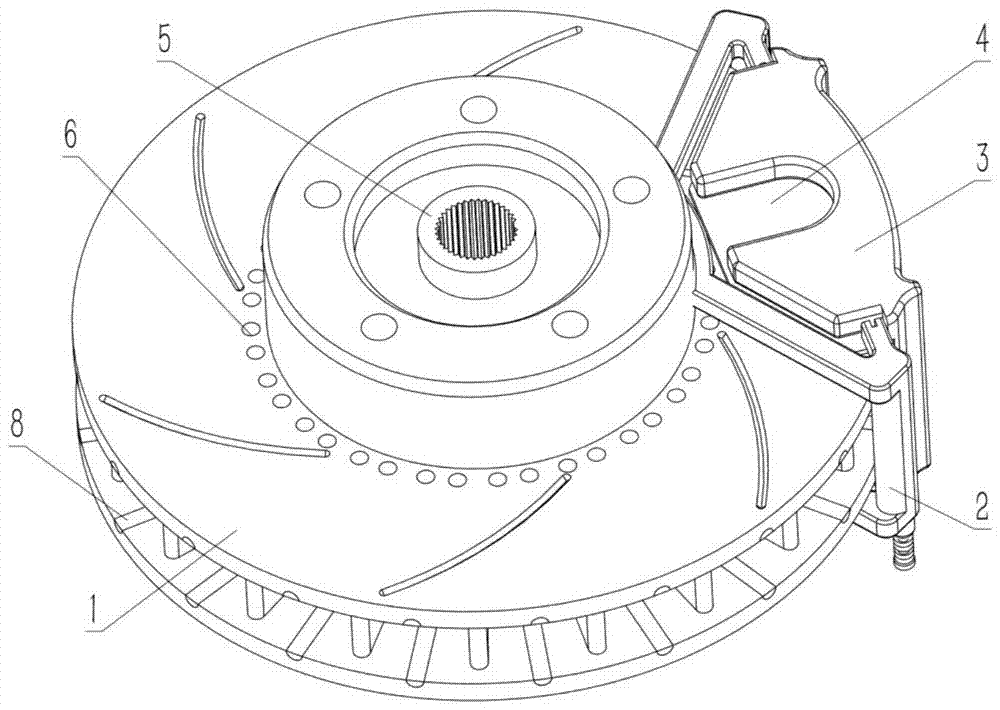

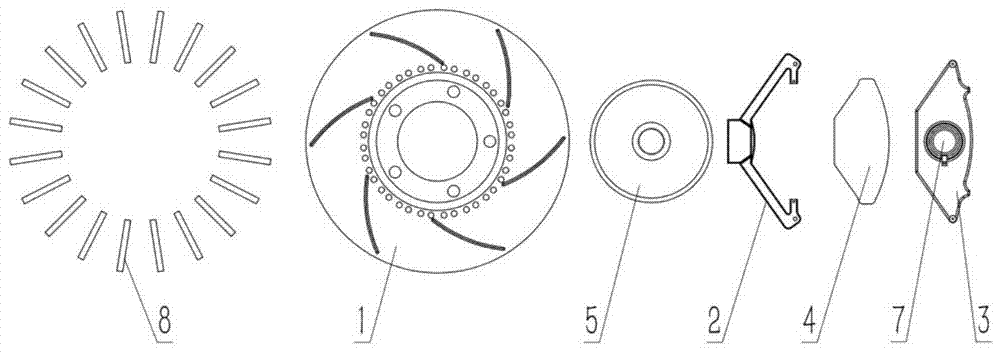

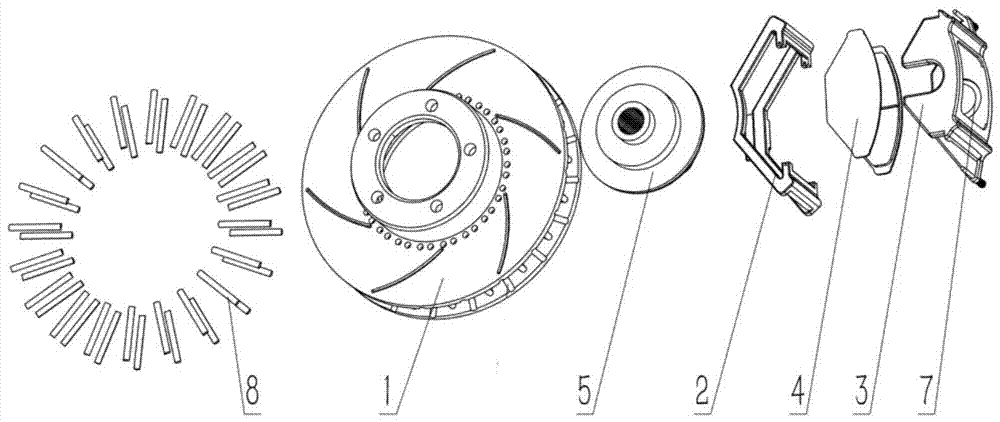

Heat pipe even-temperature heat dissipation device used for vehicle disc brake

The invention discloses a heat pipe even-temperature heat dissipation device used for a vehicle disc brake. The device comprises a brake disc composed of brake flanges arranged oppositely. Heat pipe arrays are arrayed on the opposite faces of the two brake flanges respectively in an annular shape, and the heat pipe arrays are fixed to the brake flanges in a surface contact mode through heat pipe grooves formed in the brake flanges. According to the device, it is unnecessary that an extra auxiliary power source is used for maintaining operation of heat pipes, extra motion components do not need to be arranged inside the brake disc, in this way, reliability is high, and it is avoided that the motion components fail because of abrasion, collision and others. The structure of an existing brake disc is sufficiently used, the heat pipe grooves are formed in air ducts between the opposite surfaces of the brake flanges, people do not need to change the overall structure of the brake disc, adaptability is high, the technology is simple, and the cost is low. According to the device, the technology means is simple and easy and convenient to implement, the even-temperature performance of the brake disc is good, the surface average temperature and the transient temperature are low, the structure is simple, the reliability is high, and installing is convenient.

Owner:SOUTH CHINA UNIV OF TECH

Graphite resistance heating SiC crystal growth furnace

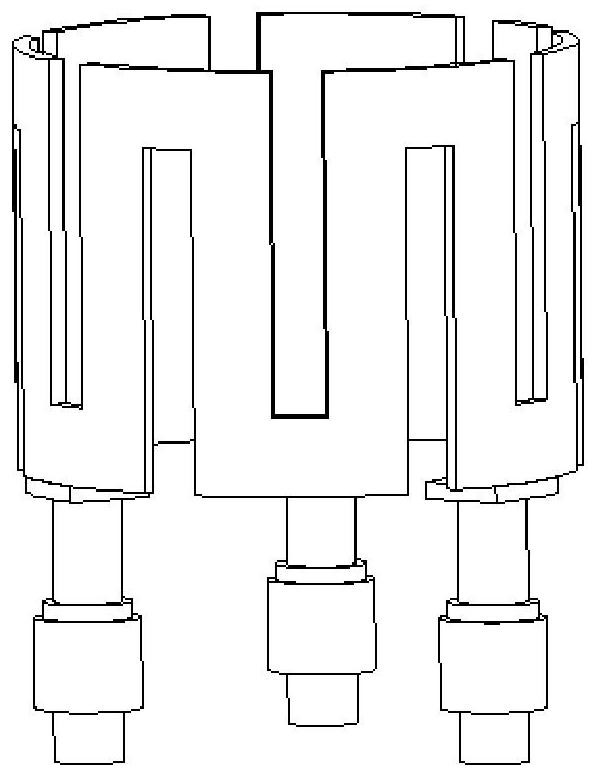

PendingCN108277534AIncrease the lengthAchieve growthPolycrystalline material growthFrom condensed vaporsCrucibleGraphite

The invention discloses a graphite resistance heating SiC crystal growth furnace. The graphite resistance heating SiC crystal growth furnace comprises a furnace chamber, a crucible and a heating unit,wherein an upper flange cover and a lower flange cover are respectively arranged at the upper end and the lower end of the furnace chamber; an upper furnace cover is arranged on the upper flange cover; the crucible is arranged in the furnace chamber; a seed crystal cover is arranged on the upper part of the crucible; both of heat-insulating felts are arranged above the crucible and below the crucible; at least one section of graphite heating units are arranged on the outer part of the crucible from bottom to top; the graphite heating units are used for heating graphite resistance; each section of the graphite heating units is separately provided with a corresponding heating power control device; a corresponding heat insulating layer is arranged at the periphery of each section of the heating units. The growth furnace adopts multi-section graphite resistance heating, so that control of a crystal growth temperature field can be conveniently carried out, including a temperature gradientof a growth interface forward position and length of a growth constant-temperature zone. The growth furnace can be used for growing large-sized SiC crystals with high quality, so that the diameter andthe thickness of a product can be greatly improved, a utilization ratio of the SiC crystal is greatly improved, and the growth cost of the SiC crystal is reduced.

Owner:济南金曼顿自动化技术有限公司

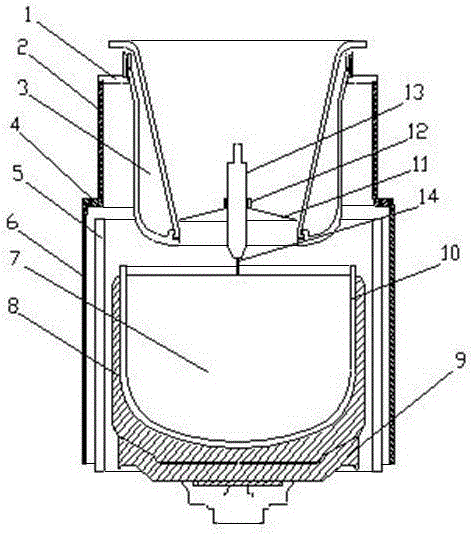

Single crystal silicon growth control method

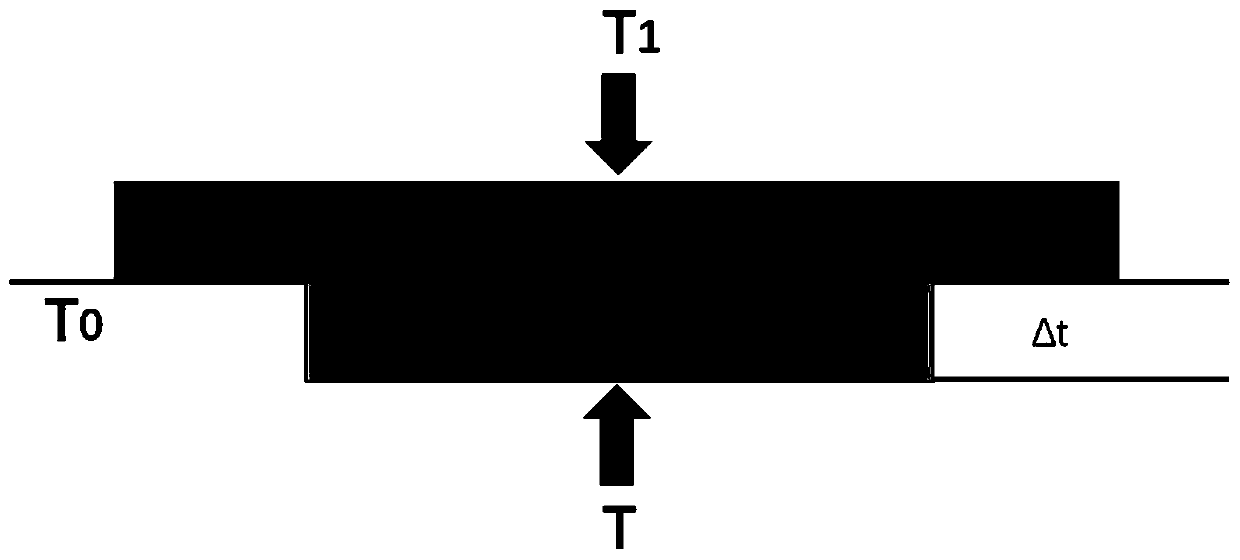

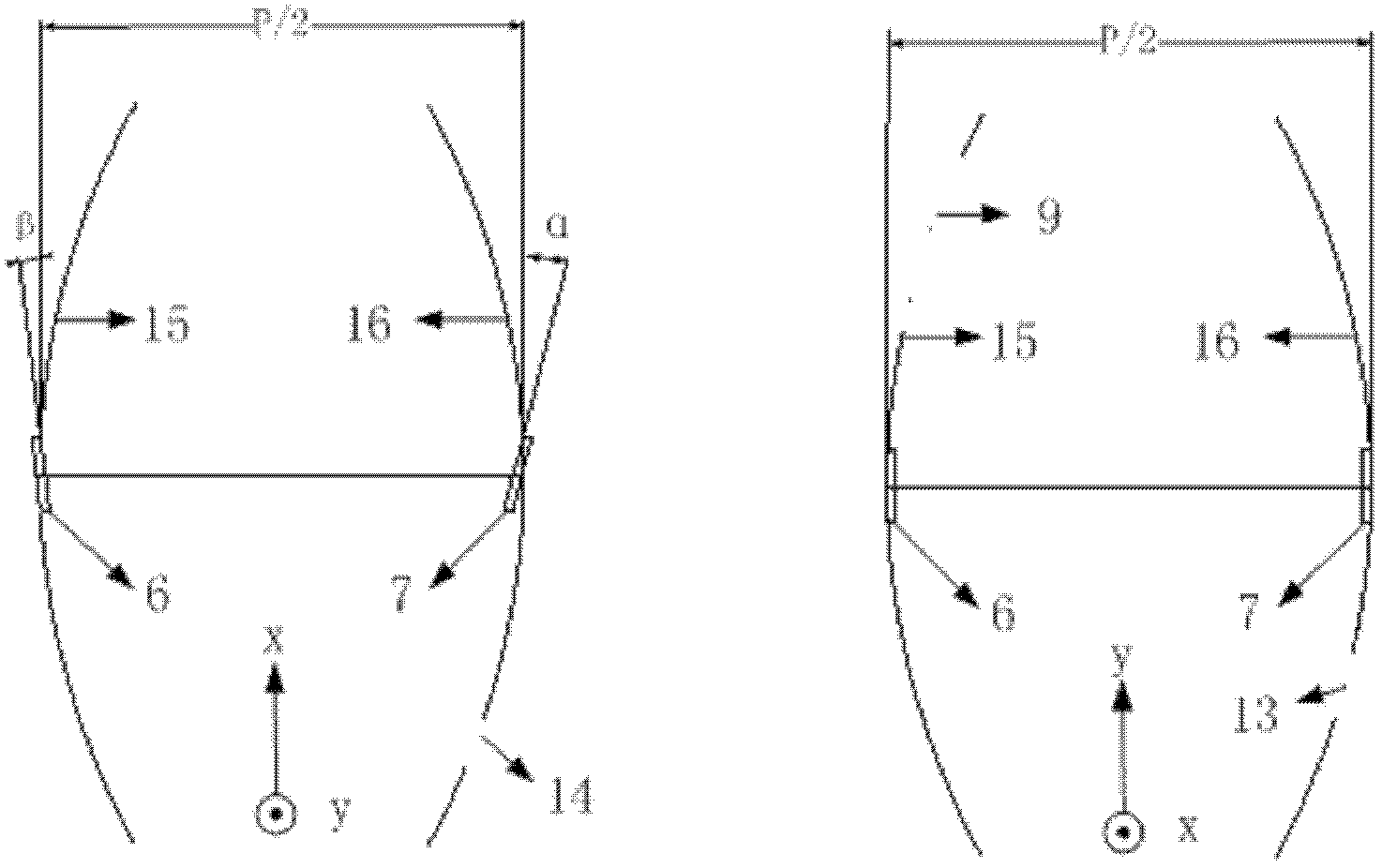

ActiveCN105401212AAvoid lostReduce radial temperature gradientPolycrystalline material growthBy pulling from meltMolten siliconGrowth control

The invention provides a single crystal silicon growth control method. The 700-920 DEG C zone of a silicon crystal rod is cooled by adopting a reflecting and cooling device, the length of the zone can be smaller than 200 mm, and the speed of lifting and pulling the silicon crystal rod is greater than 1.12 mm / min, so that the standing time of the crystal rod in the temperature interval is less than 180 minutes to avoid the formation of OSF defects. Radiating infrared rays of a molten silicon fluid are reflected by adopting a semi-parabolic arc-shaped reflection surface to irradiate the side face of the silicon crystal rod at the growth interface position and reduce the cooling speed of the lateral surface, so that the temperature gradient of the center and the surface of the growth interface position of the silicon crystal rod is reduced, and an oxygen element and doped elements on a wafer are radially and evenly distributed. The rays of a high-temperature crucible wall are reflected by adopting a smooth and clean surface to avoid the influence on the crystal rod.

Owner:SHANGHAI ADVANCED SILICON TECH CO LTD

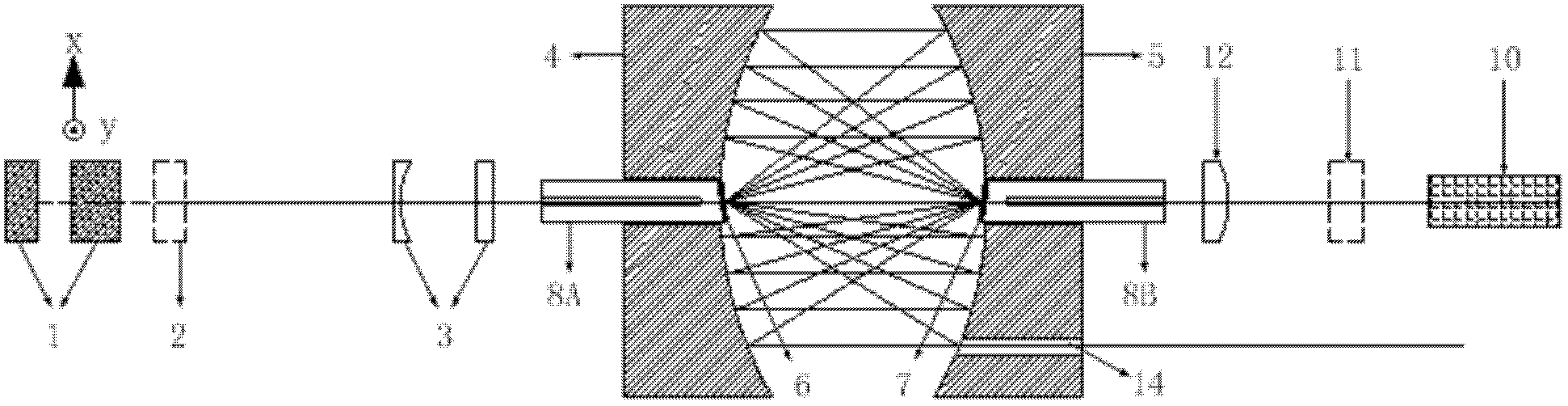

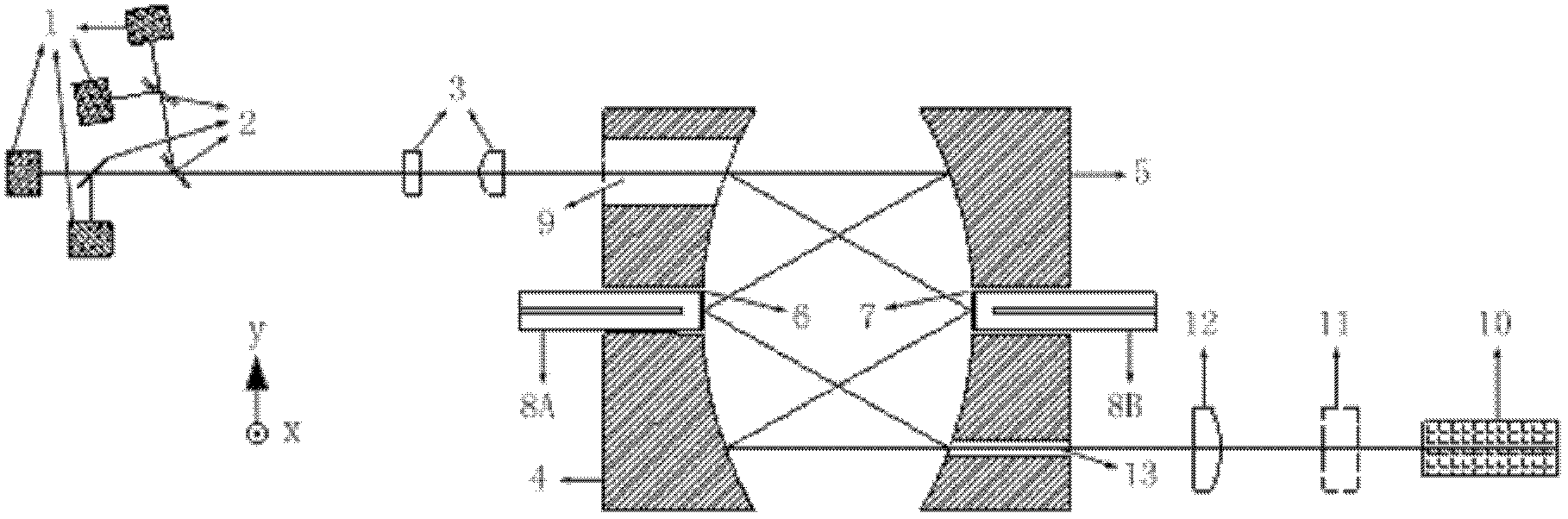

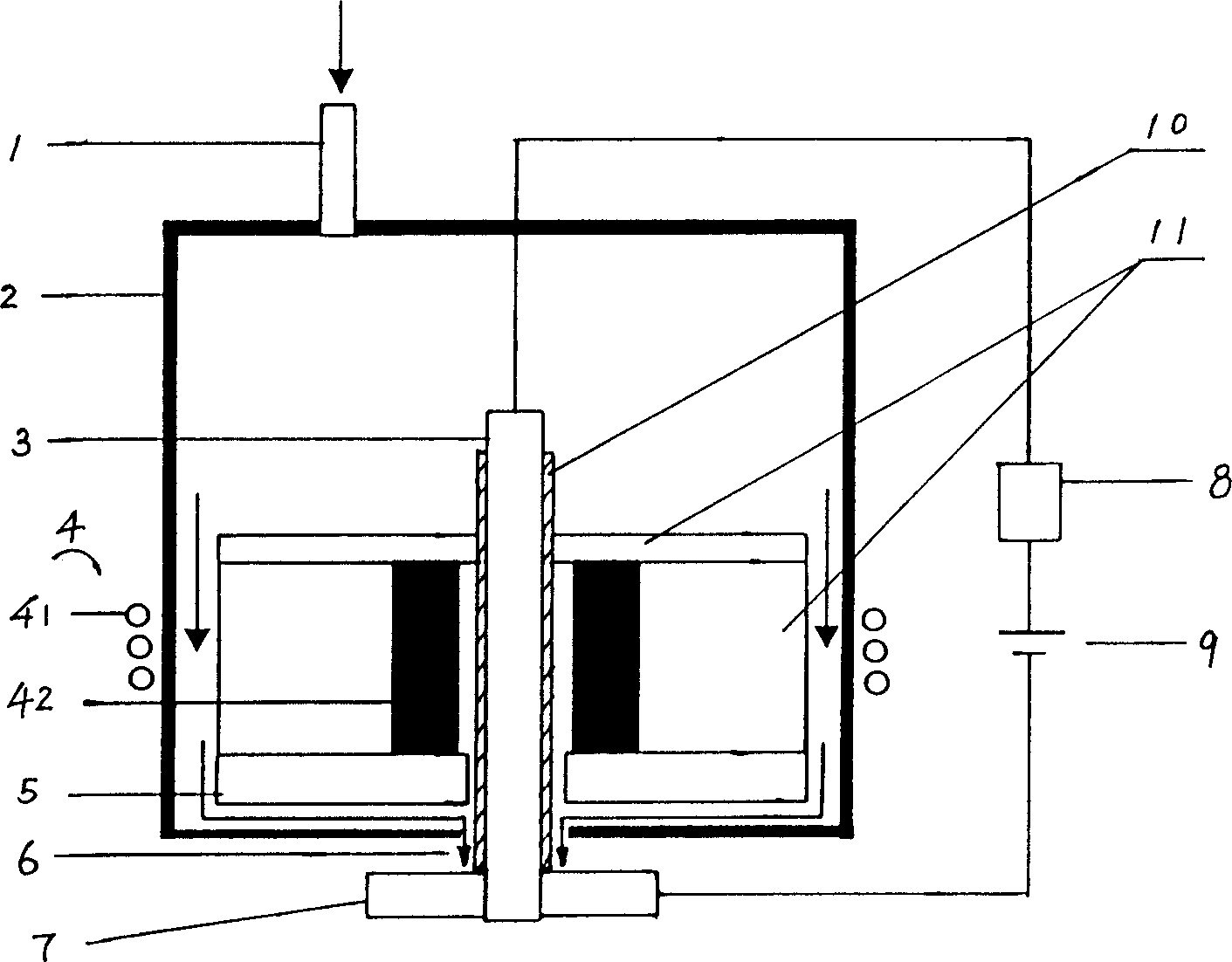

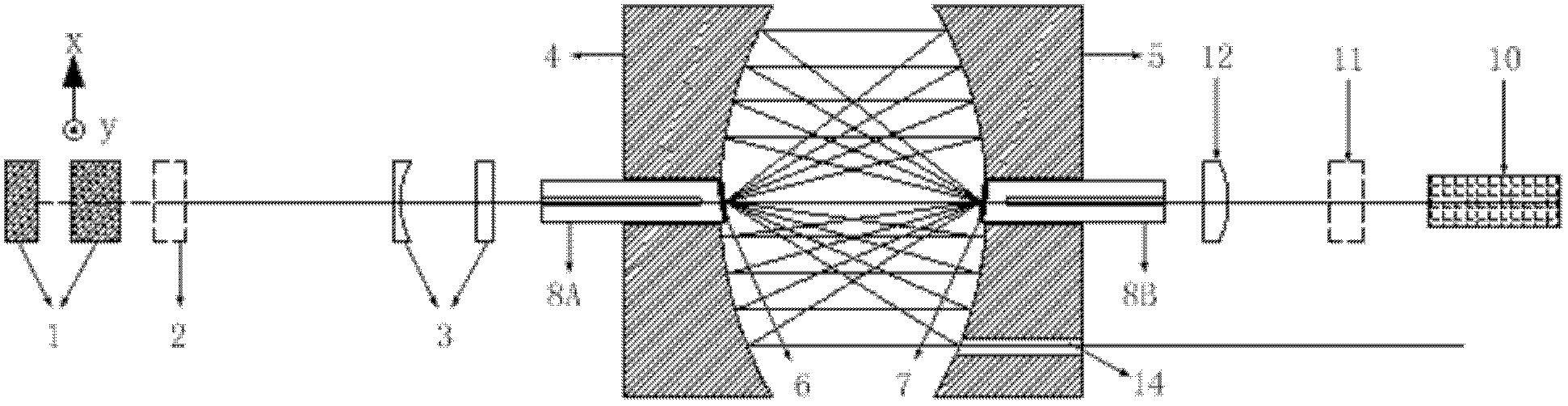

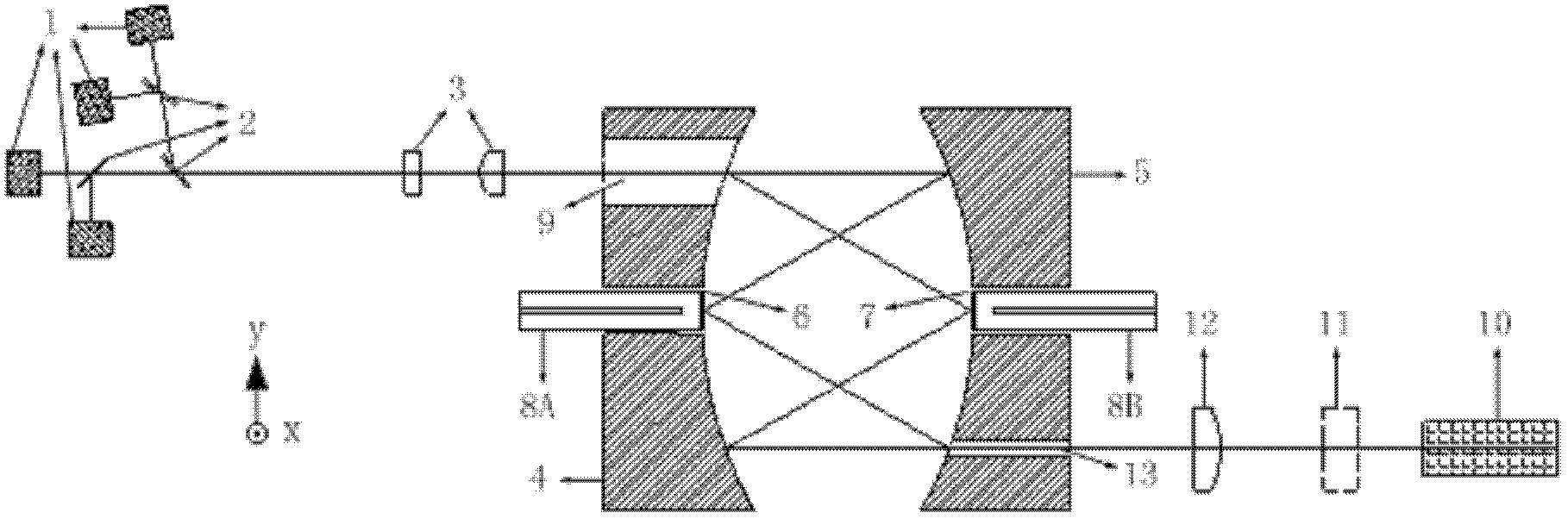

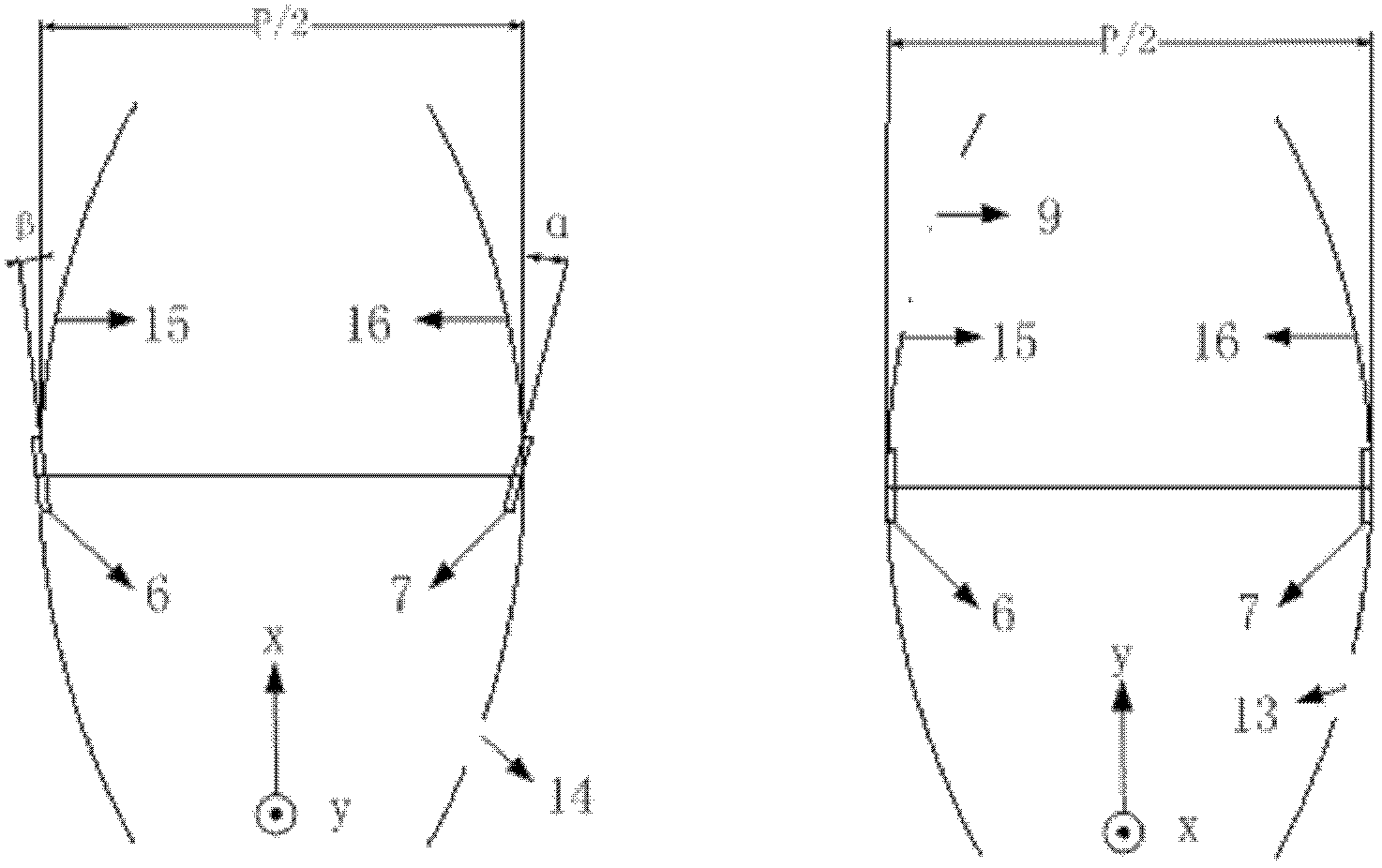

Disc laser amplifier

InactiveCN102684051AImprove efficiencySolution to short lifeOptical resonator shape and constructionActive medium shape and constructionAudio power amplifierOptical axis

The invention discloses a disc solid laser amplifier which comprises two parabolic reflectors, wherein the two parabolic reflectors are coaxially placed in a conjugate mode so as to form a parabolic reflector set; the vertex of each parabolic reflector is provided with a disc laser crystal; a certain inclined angle is respectively formed between the normal lines of end faces of two disc laser crystals and the centre shafts of the corresponding parabolic reflectors, and the two inclined angles are not equal; pump light and seed laser are parallel to an optical axis and enter in a condensing cavity formed by the two parabolic reflectors of the reflector set respectively from a pump light inlet and a laser inlet on the parabolic reflectors; and after being reflected many times in the condensing cavity, the pump light and the seed laser are alternately converged on the two disc laser crystals, thereby realizing the multiple pumping on the two disc laser crystals and the multiple amplification on the laser. By using the disc solid laser amplifier disclosed by the invention, the pump beam absorption efficiency is high, an effect of carrying out efficient amplification on the seed laser can be achieved, and better beam quality can be maintained; and meanwhile, the disc solid laser amplifier is simple in whole system structure, and easy to install and debug.

Owner:HUAZHONG UNIV OF SCI & TECH +1

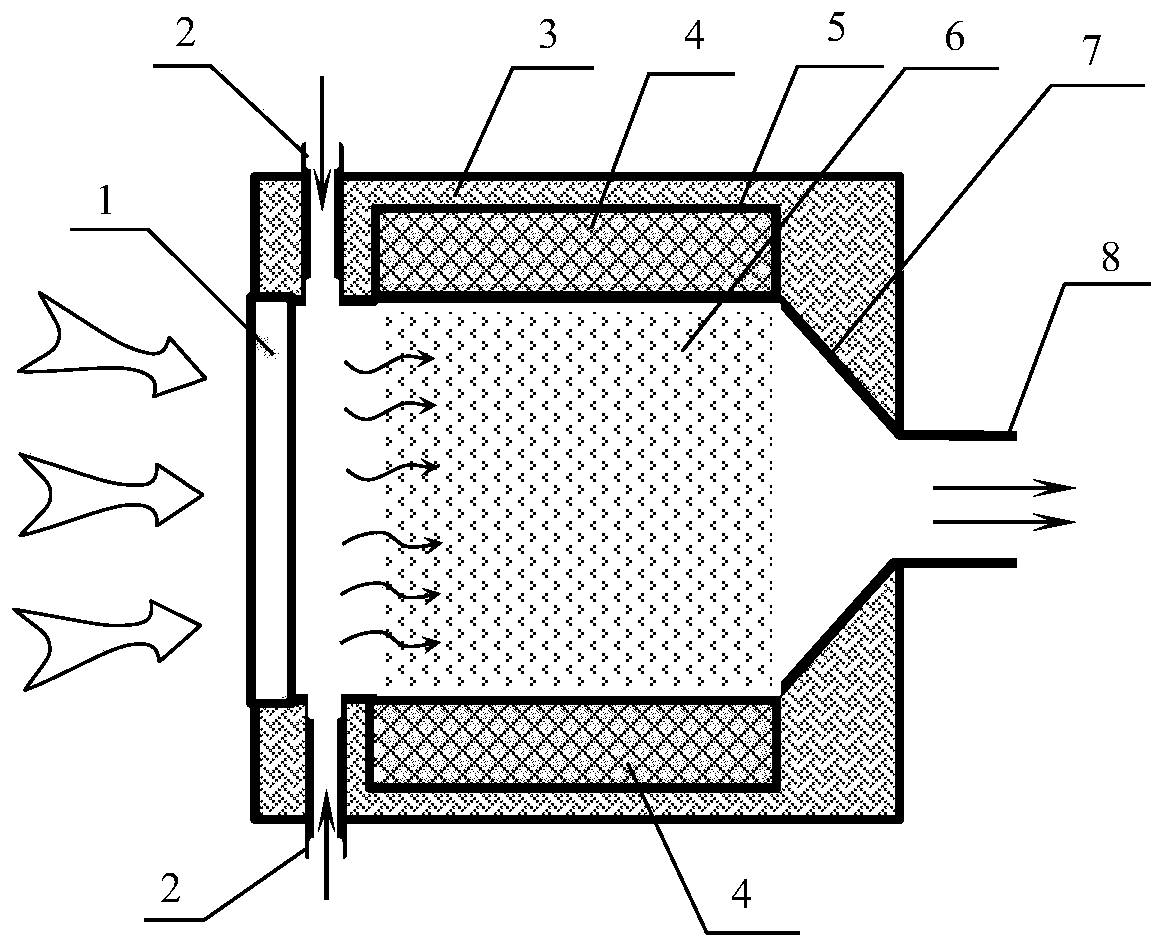

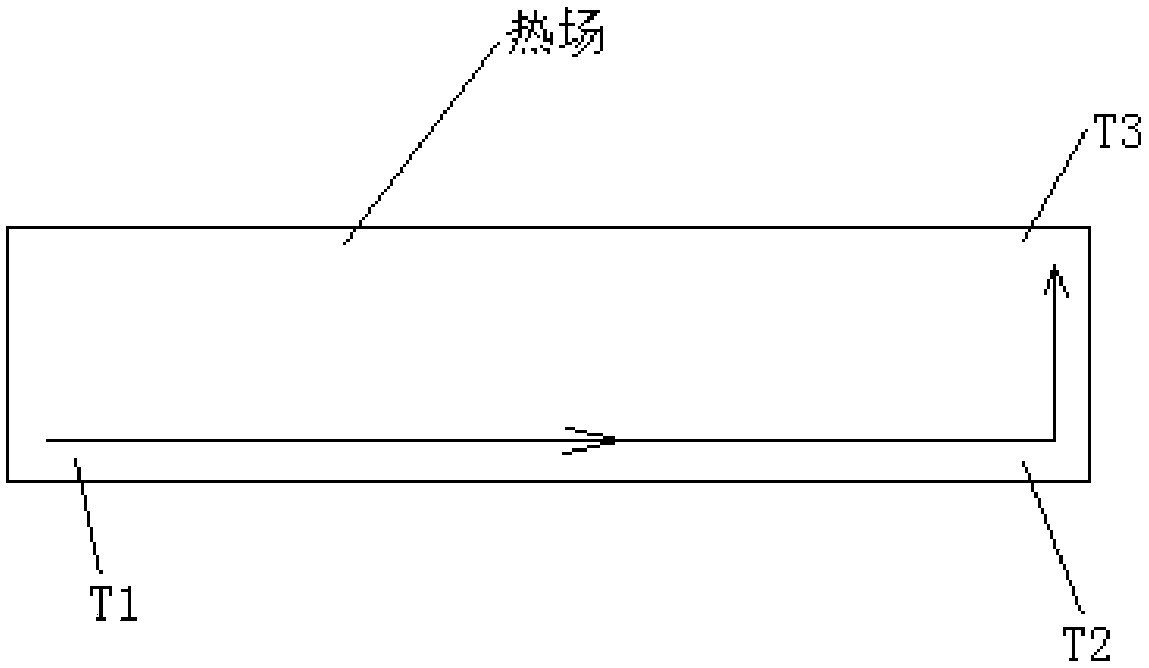

Solar high-temperature reactor integrating phase-change storage energy and chemical storage energy

InactiveCN109876753AIncrease the reaction areaReduce radial temperature gradientEnergy based chemical/physical/physico-chemical processesChemical storageThermal energy

The invention discloses a solar high-temperature reactor integrating phase-change storage energy and chemical storage energy and belongs to the field of solar high-temperature heat utilization. A quartz glass board is connected to the open end of the left side of a reactor shell, a reaction cavity is constituted by the quartz glass board and the reactor shell, a working medium inlet is formed in the left side of the reactor shell, a working medium outlet is formed in the right side of the reactor shell, an overall porous catalyst is arranged in the reactor shell, a phase-change energy storageis mounted on the outer side face of the reactor shell, a phase-change energy storage shell is arranged on the outer surface of the phase-change energy storage, and the phase-change energy storage shell is wrapped with a heat preservation layer. The solar high-temperature reactor can still provide heat energy required by a reaction when illumination is unstable and the solar high-temperature reactor is in a shadow place, and continuous conducting of the chemical reaction is kept; in addition, the temperature of the edge of a porous structure of a chemical reaction layer can be maintained, theradial temperature gradient is decreased while a reaction area is enlarged, and structural collapse caused by stress concentration is prevented; and part of heat in waste gas is recovered to preheat inlet gas.

Owner:HARBIN INST OF TECH

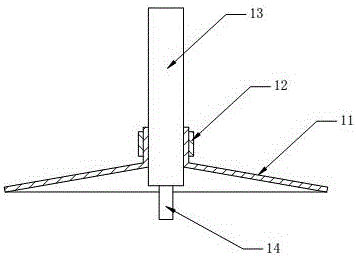

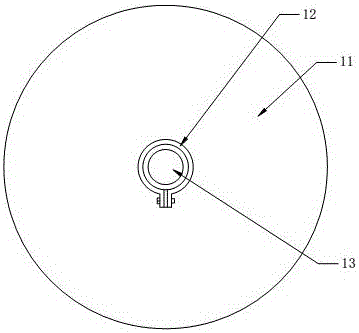

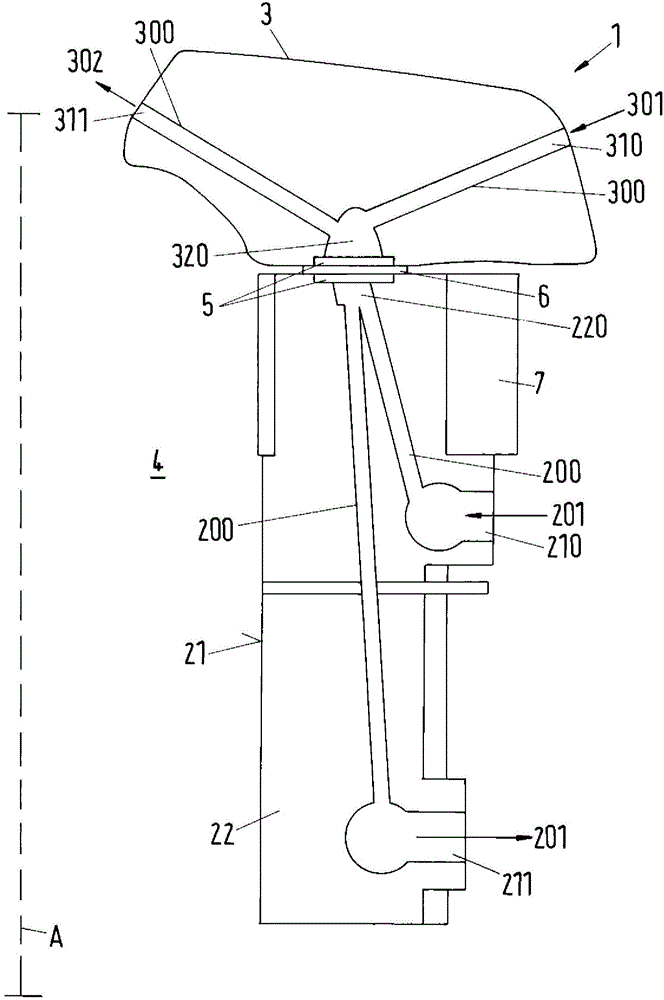

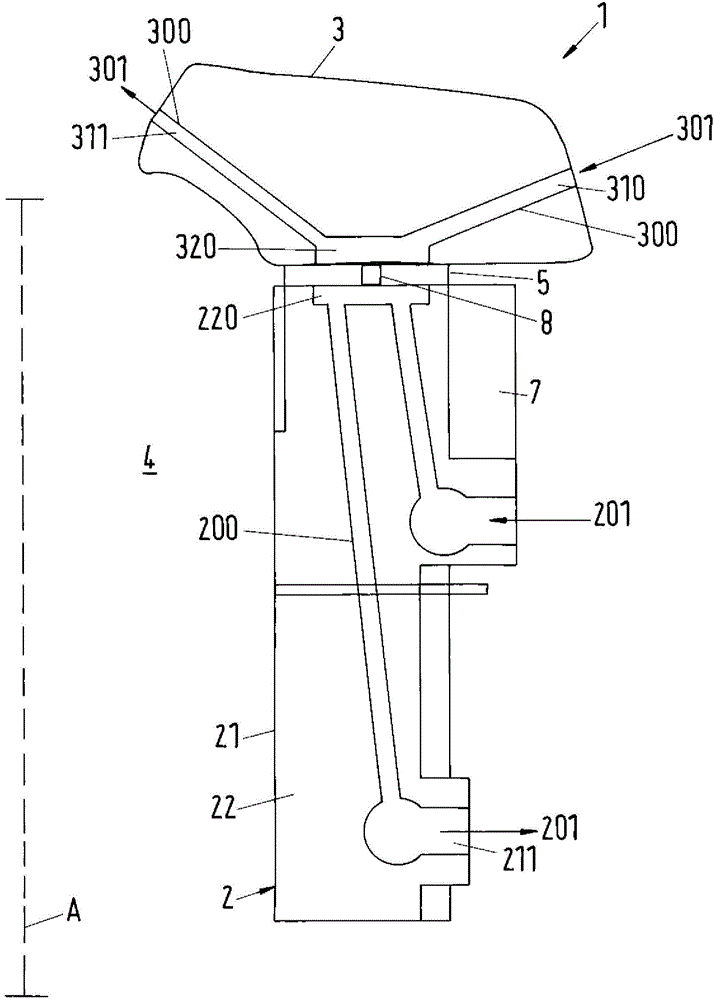

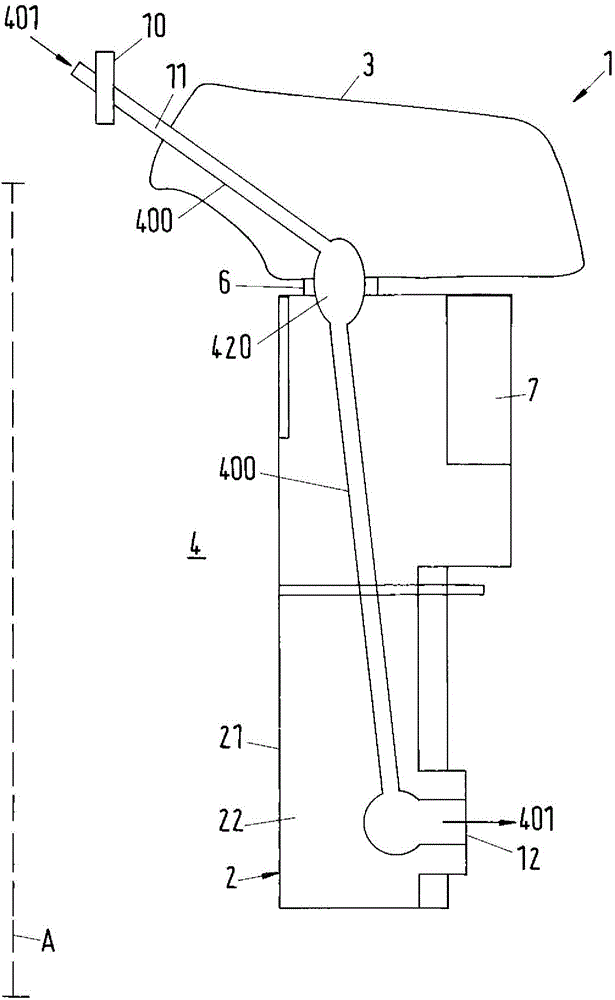

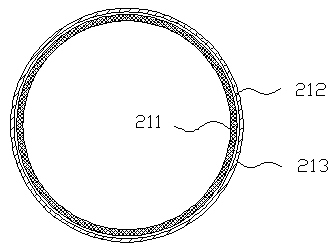

Seeding and shoulder expanding device and technique for single crystal rods and single crystal furnace

InactiveCN106435729AIncrease temperatureReduce radial temperature gradientPolycrystalline material growthBy pulling from meltMolten siliconSeed crystal

The invention discloses a seeding and shoulder expanding device and technique for single crystal rods and a single crystal furnace and belongs to the technical field of production of single crystal silicon. The seeding and shoulder expanding device for the single crystal rods comprises a hammer located above a crucible, wherein a conical reflection cover is fixed on the side wall of a connecting end, close to a seed crystal, of the hammer, the cone vertex angle is 150-180 degrees, and the conical surface faces molten silicon; the single crystal furnace comprises the seeding and shoulder expanding device for the single crystal rods; the seeding and shoulder expanding technique for the single crystal rods is performed by use of the single crystal furnace and comprises steps as follows: seeding: the rotating speed of the crucible is 8-12 rpm, the rotating speed of the seed crystal is 10-13 rpm, the seeding length is 120-200 mm, and the diameter of fine crystals is 4-8 mm; shoulder expanding: the rotating speed of the crucible is 10-12 rpm, the rotating speed of the seed crystal is 10-13 rpm, and the shoulder expanding pulling speed is 0.5-0.8 mm / min. The seeding and shoulder expanding success rate can be greatly increased, and the seeding and shoulder expanding time can be shortened.

Owner:YINGLI ENERGY CHINA

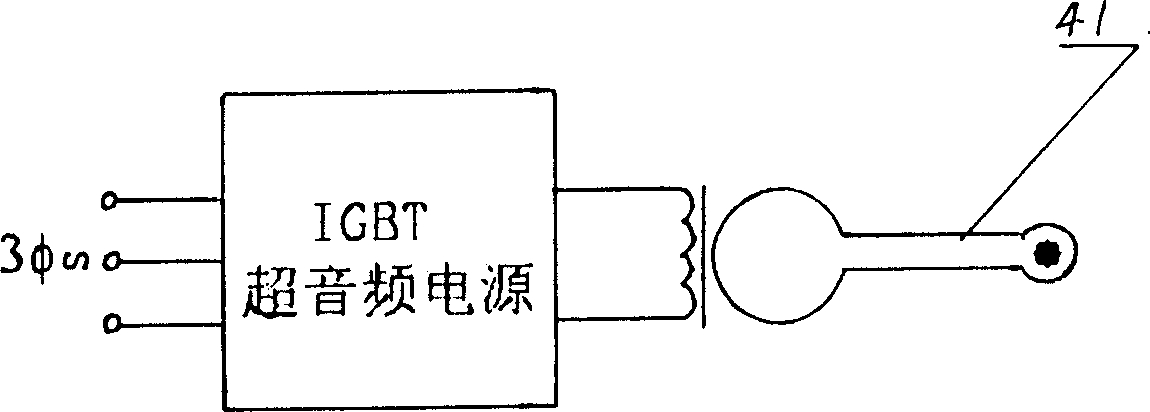

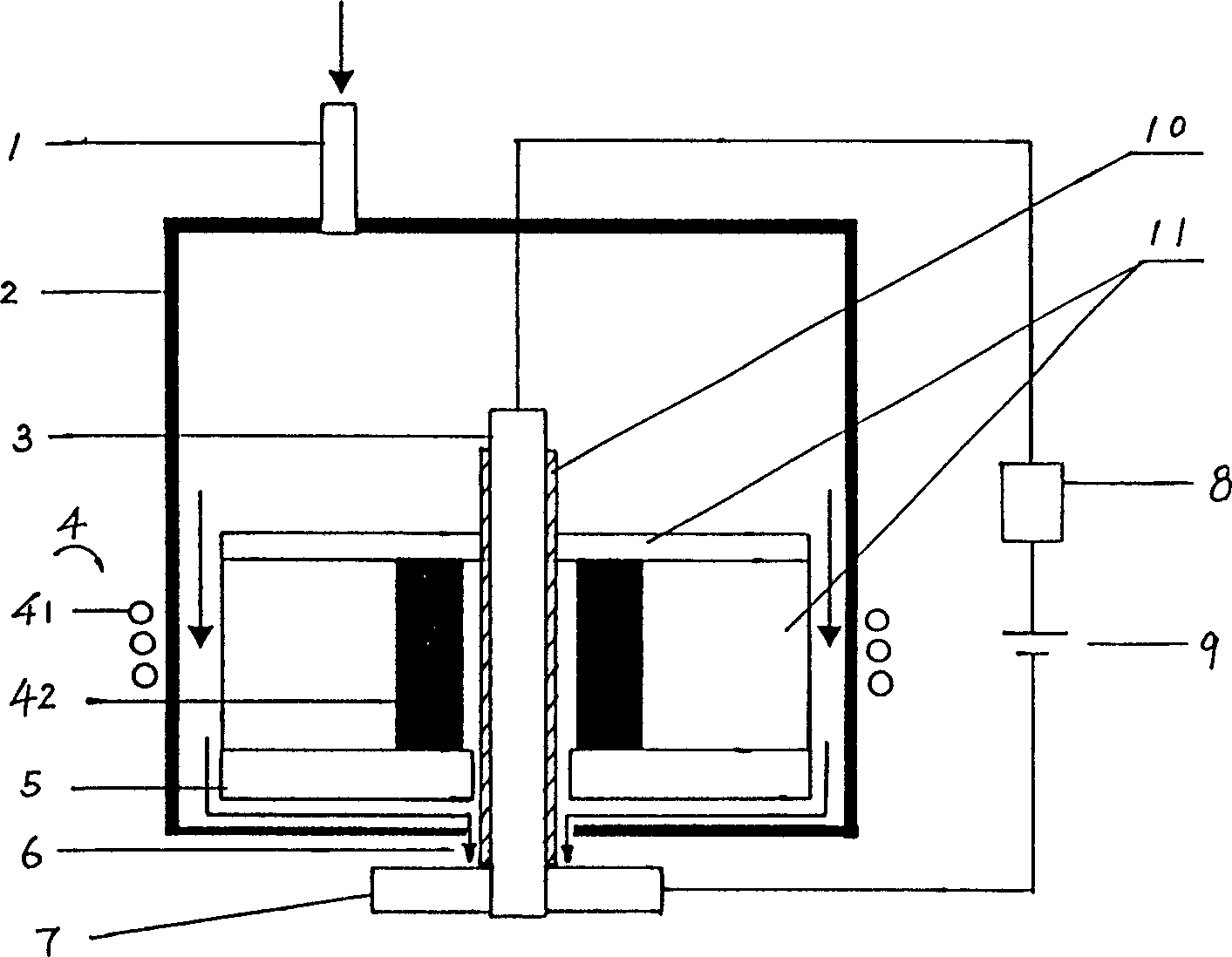

Monocrystal high temperature alloy electric field directional freeze apparatus

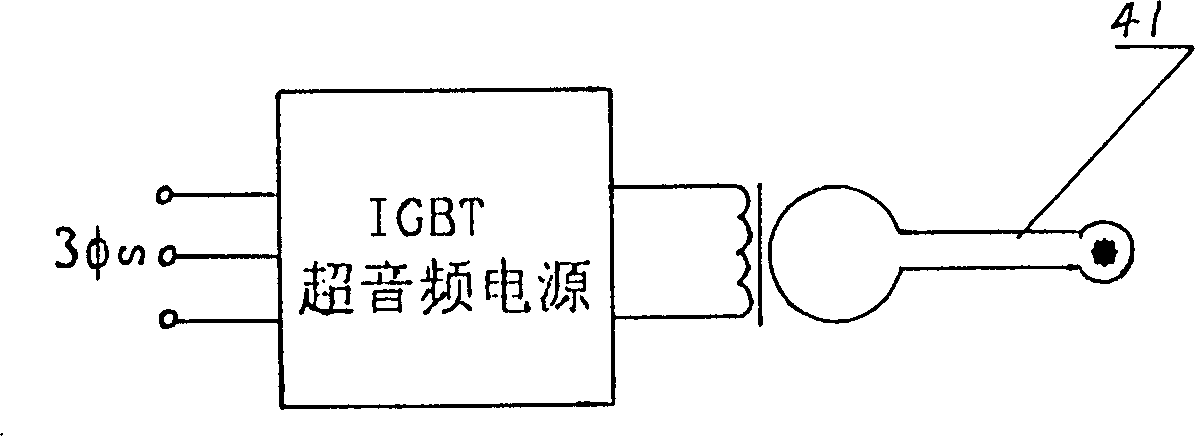

InactiveCN1508297ARefining solidified tissueEasy to useFrom frozen solutionsSingle crystal superalloySingle crystal

The invention relates to the single crystal high-temperature alloy solidifying technique, including case, heating set, sample clamping framework and DC electric field generating set. The clamping framework is set under the case, composed of two clamping bars set on the bracket, one end of each clamping bar linked with the rotation shaft on the bracket, the other end linked through fastener, and the outer side of each clamping bar installed with tension spring, the other end of each tension spring fixed on the bracket, and the bracket opened with a through hole to make the sample pass through; the generating set is a close loop, formed by setting a programmable functional module in series between one end of the sample and one pole of the voltage-stailized source, and connecting the other end with the other pole through the clamping tool.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

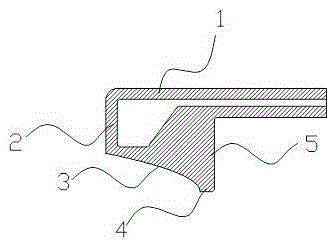

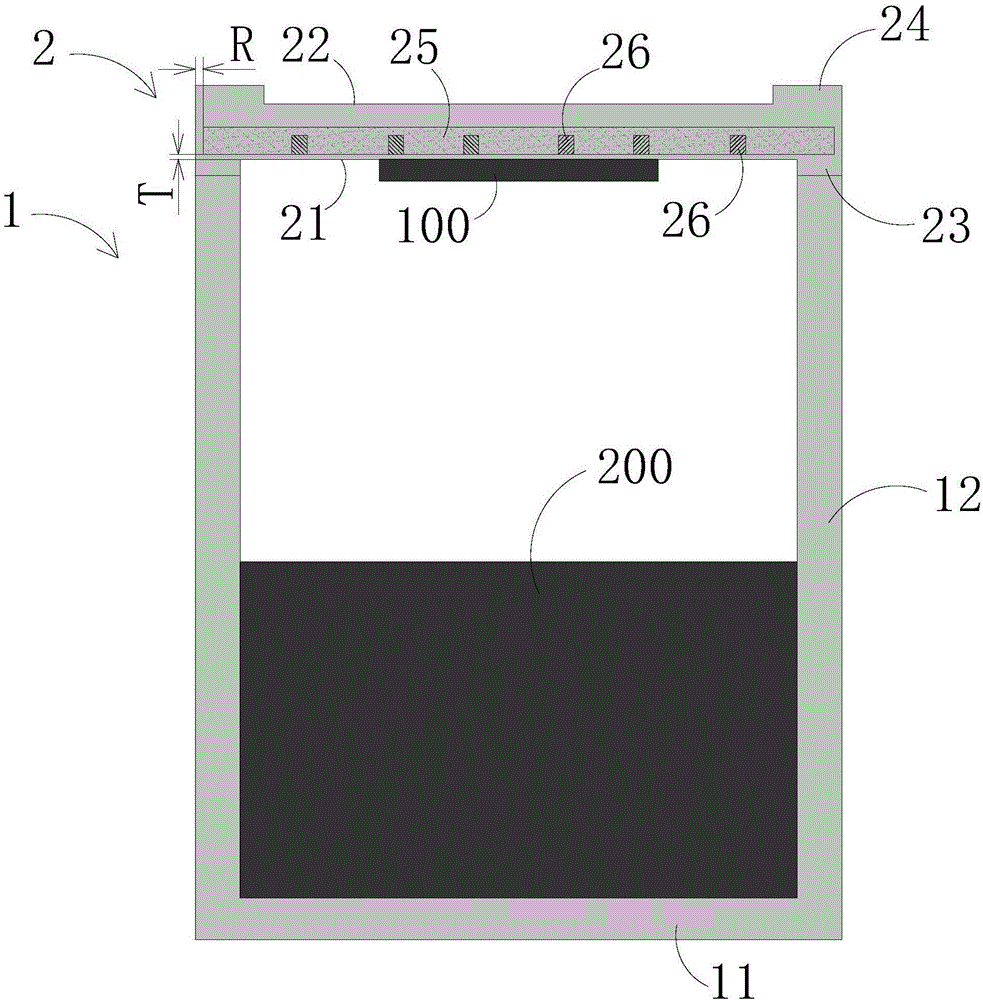

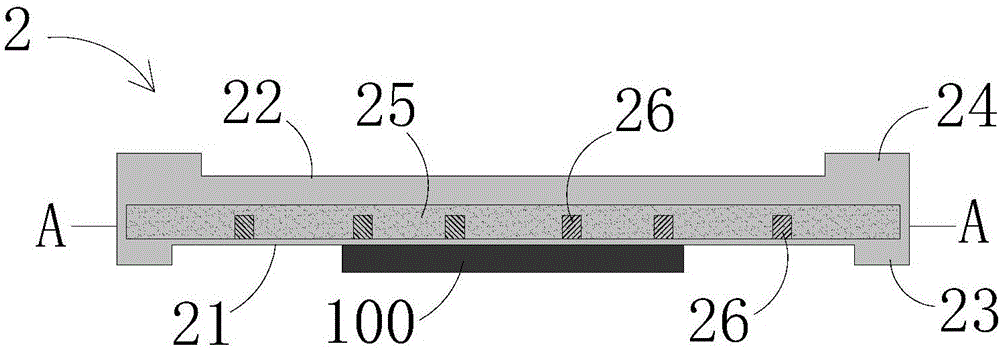

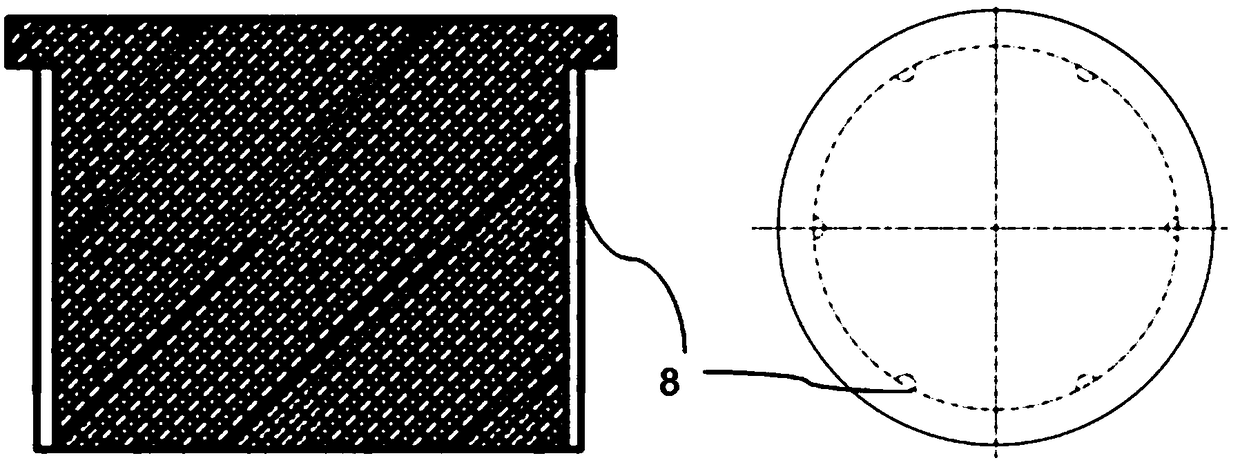

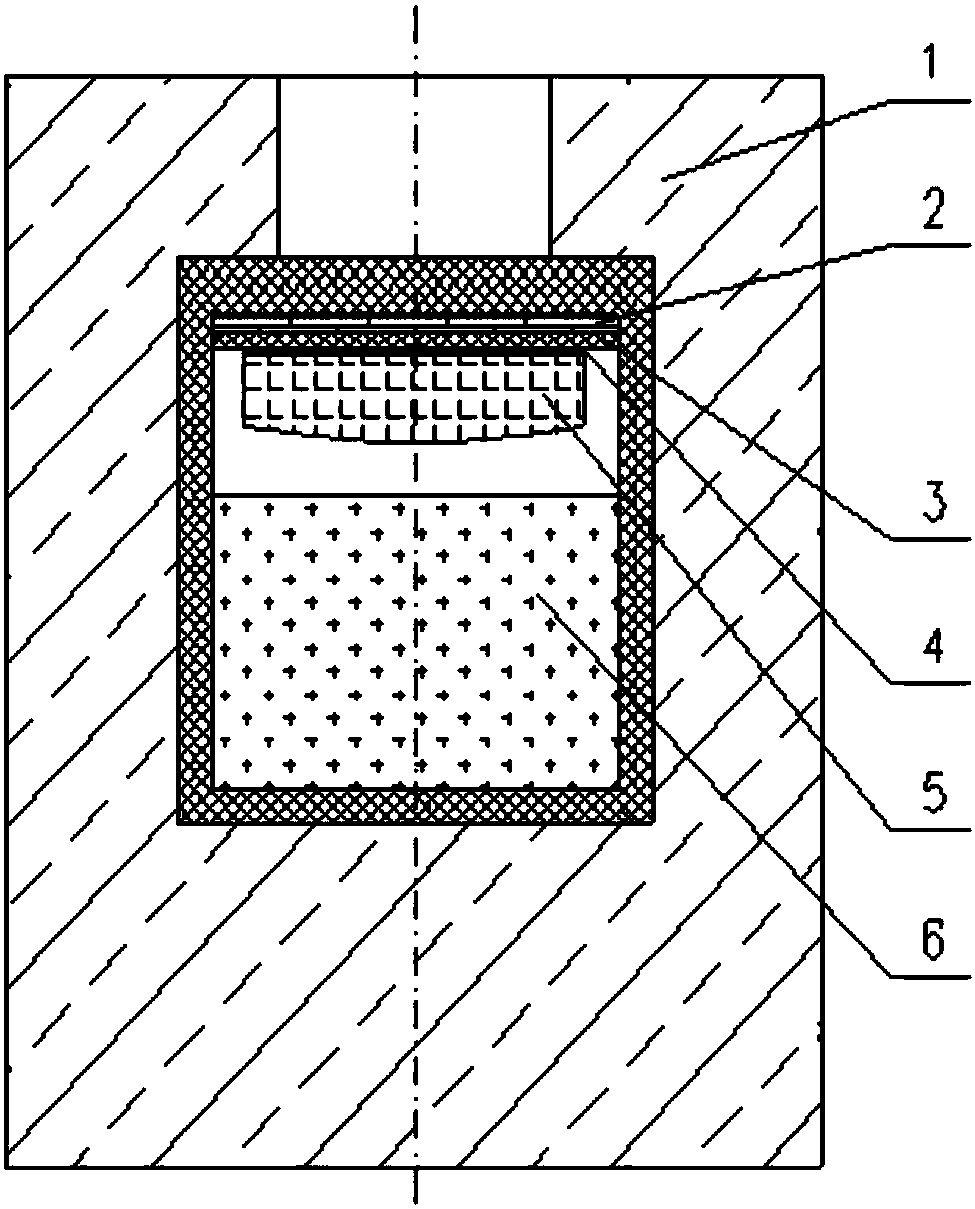

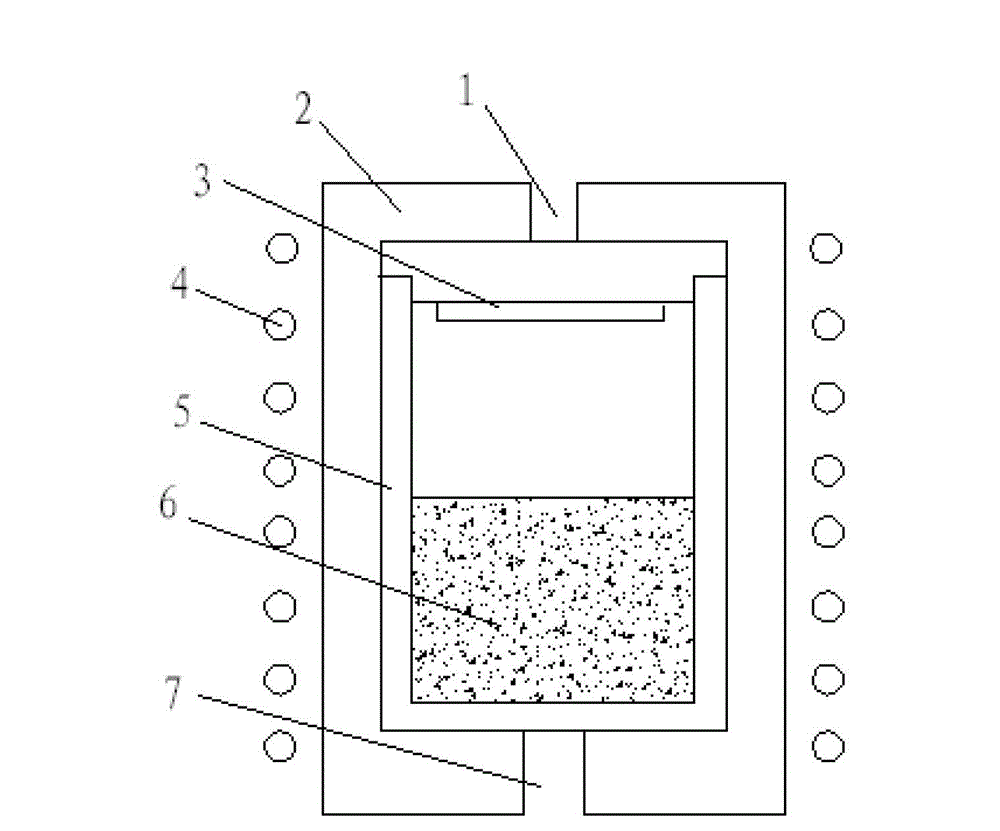

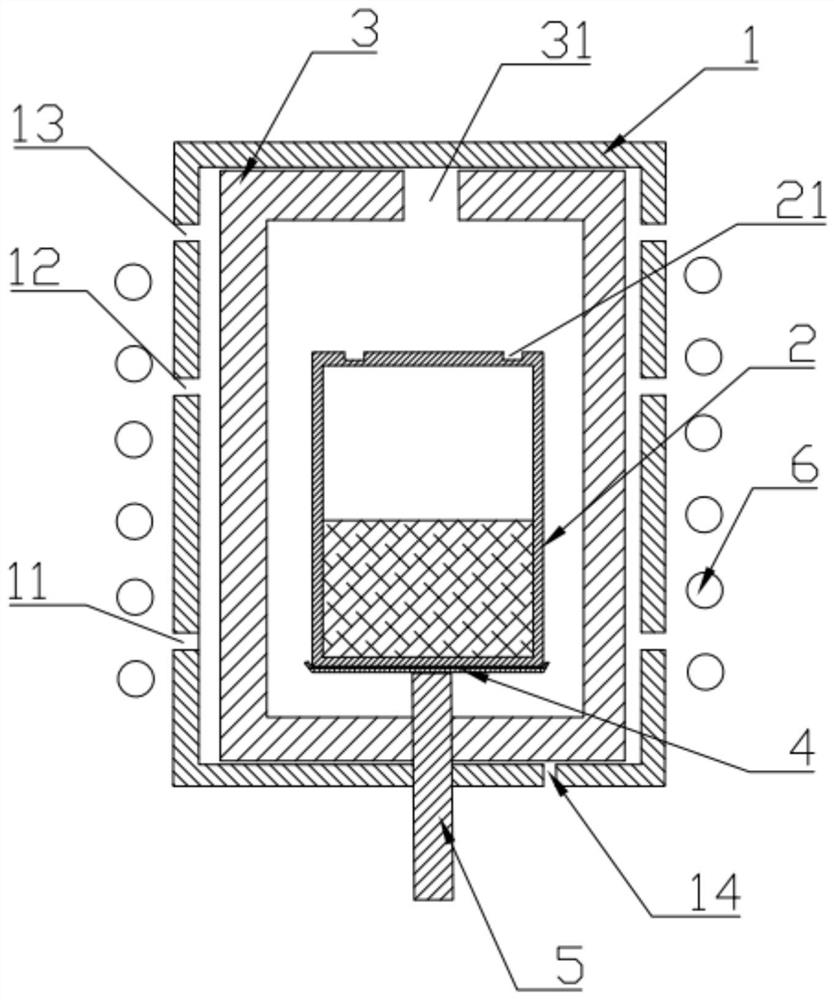

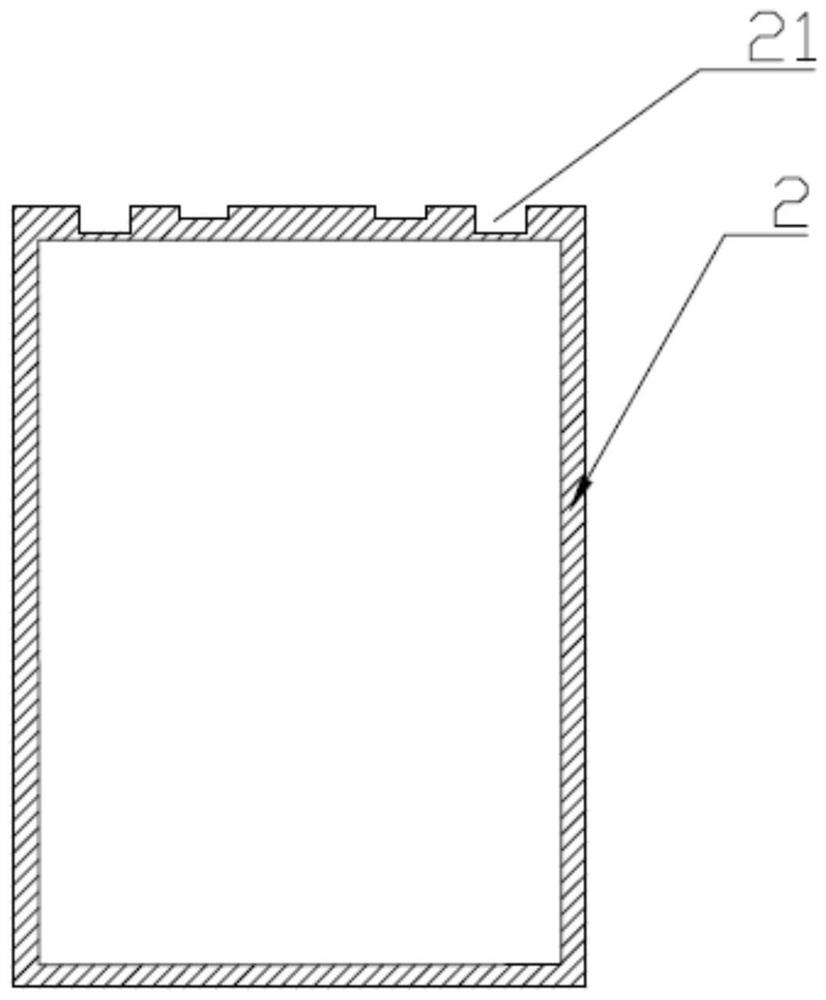

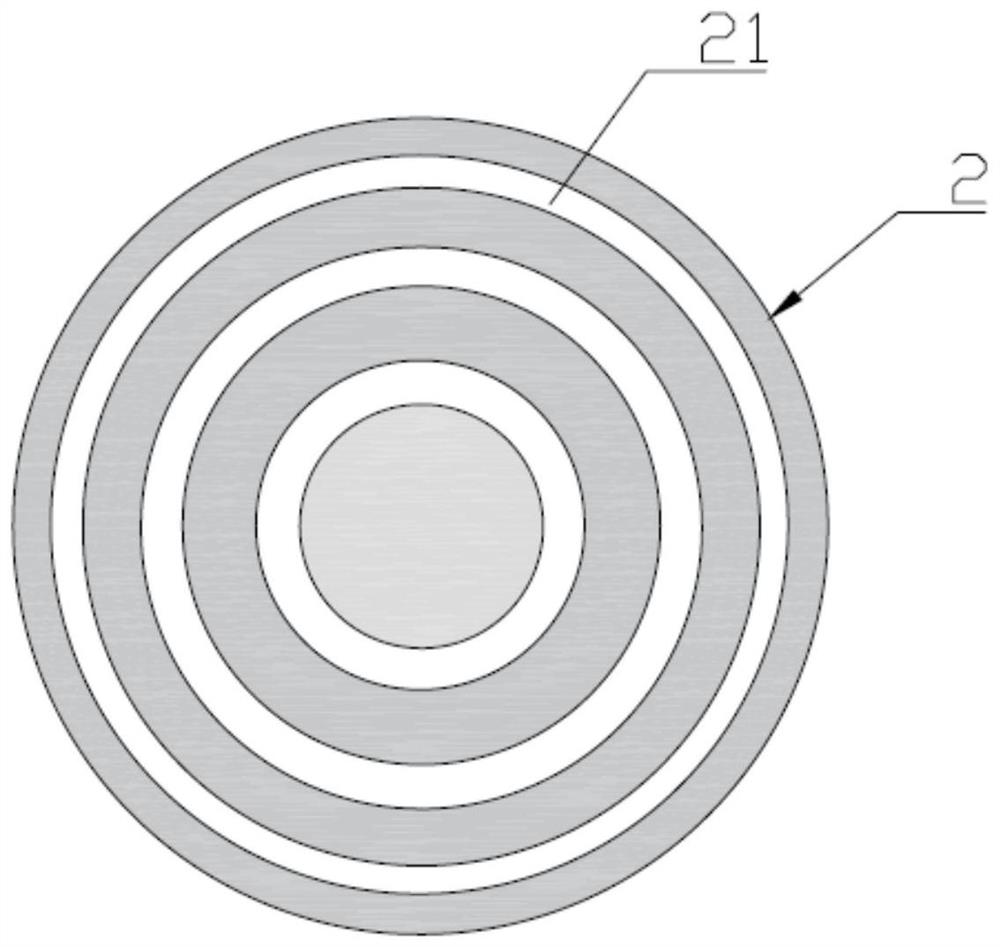

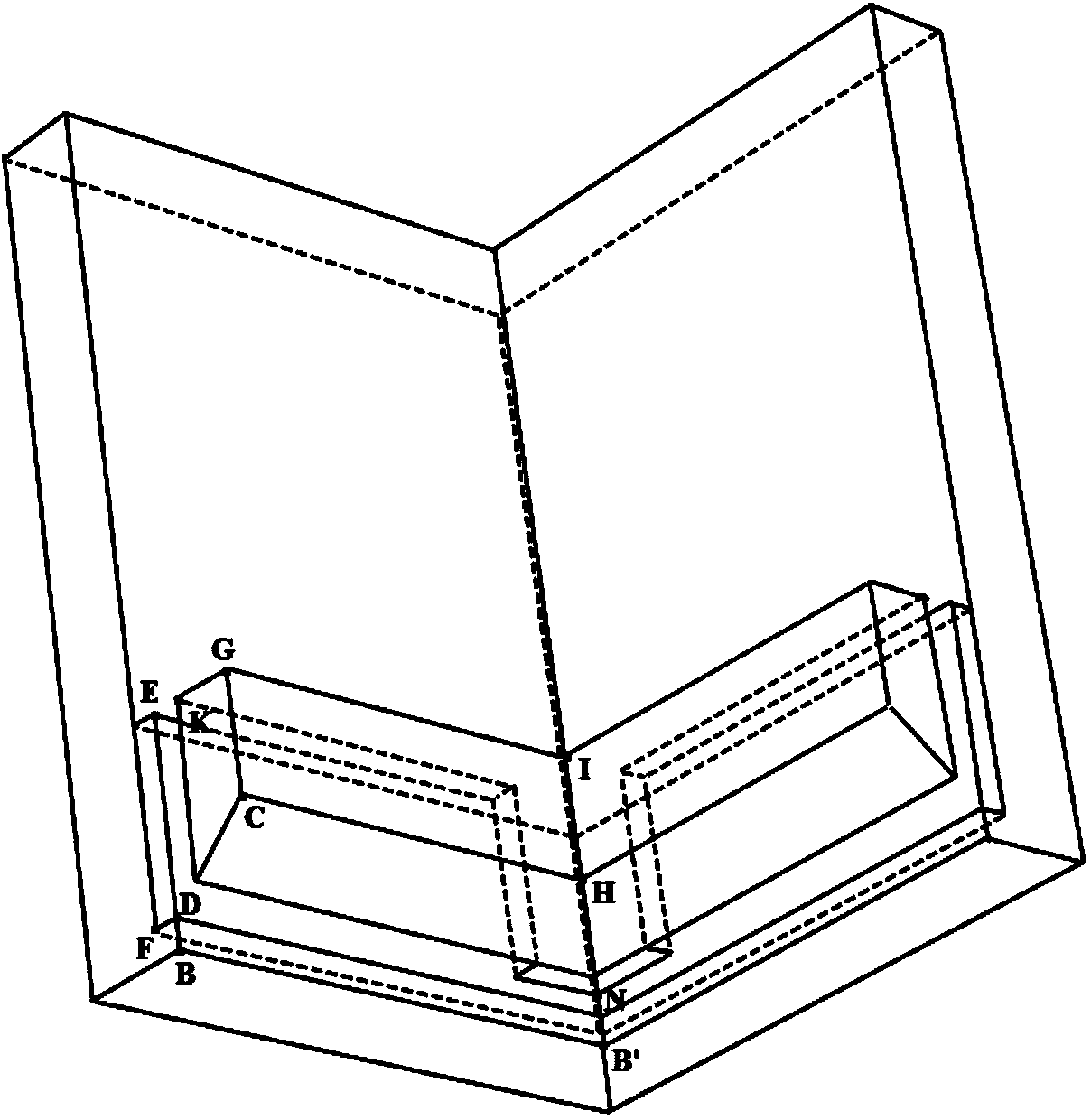

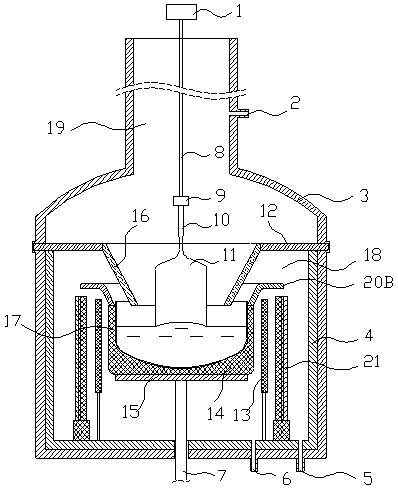

Crucible device

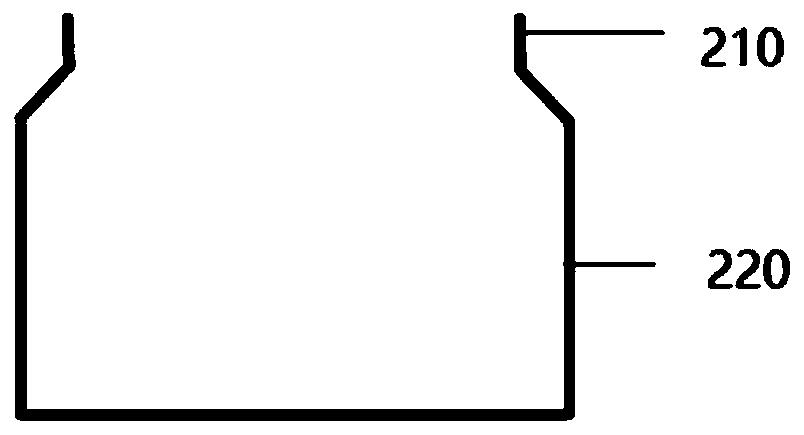

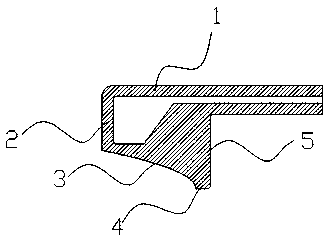

ActiveCN106637410AQuality improvementReduce radial temperature gradientPolycrystalline material growthFrom condensed vaporsCrucibleBarrel Shaped

The invention provides a crucible device capable of improving the heating uniformity of seed crystals. The crucible device comprises a crucible body and a crucible cover, wherein the crucible body is barrel-shaped and comprises a barrel bottom, barrel walls and a top opening; the barrel bottom and the barrel walls are encircled into a containing space for containing materials; the crucible cover covers the top opening of the crucible body and comprises an inner surface towards the barrel bottom and an outer space deviating from the barrel bottom; a hollow part is arranged in a central area of the crucible cover at least; the hollow part is positioned between the inner surface and the outer surface of the crucible cover; and a filler of which the heat conductivity coefficient is higher than that of the crucible cover fills the hollow part. According to the crucible device disclosed by the invention, a radial temperature gradient of the crucible cover is reduced, the overall temperature uniformity of the crucible cover is effectively improved, good conditions can be provided for enabling silicon carbide seed crystals arranged in the center of the inner surface of the crucible cover to produce into crystals, the radial temperature uniformity of the seed crystal is improved, and the thermal stress in the crystal growth process is reduced, so that crystals with higher quality can be grown.

Owner:珠海鼎泰芯源晶体有限公司

Raw material sintering process of silicon carbide crystals grown by PVT (physical vapor deposition) method

InactiveCN108624963AReduce crystallizationReduce the degree of densificationAfter-treatment apparatusPolycrystalline material growthImpurityCrystallization

The invention discloses a raw material sintering process of silicon carbide crystals grown by a PVT (physical vapor deposition) method. The silicon carbide raw material is led to the sintering processwith the PVT method, a sintering fixture is designed, the silicon carbide is sintered through the previously designed sintering fixture, and the silicon carbide crystals are grown by the PVT method.The raw material sintering process has the advantages that the silicon carbide raw material forms a certain structure through sintering of the silicon carbide raw material, crystallization of the silicon carbide raw material is weakened, densification degree of the silicon carbide raw material is lowered, impurities carried in the silicon carbide raw material can be removed during sintering, fullsublimation and stable growth speed of the silicon carbide crystals by the PVT method can be effectively controlled and maintained, and the yield of the utilization of the silicon carbide raw materialand the silicon carbide crystals is increased.

Owner:FUJIAN NORSTEL MATERIAL TECH CO LTD

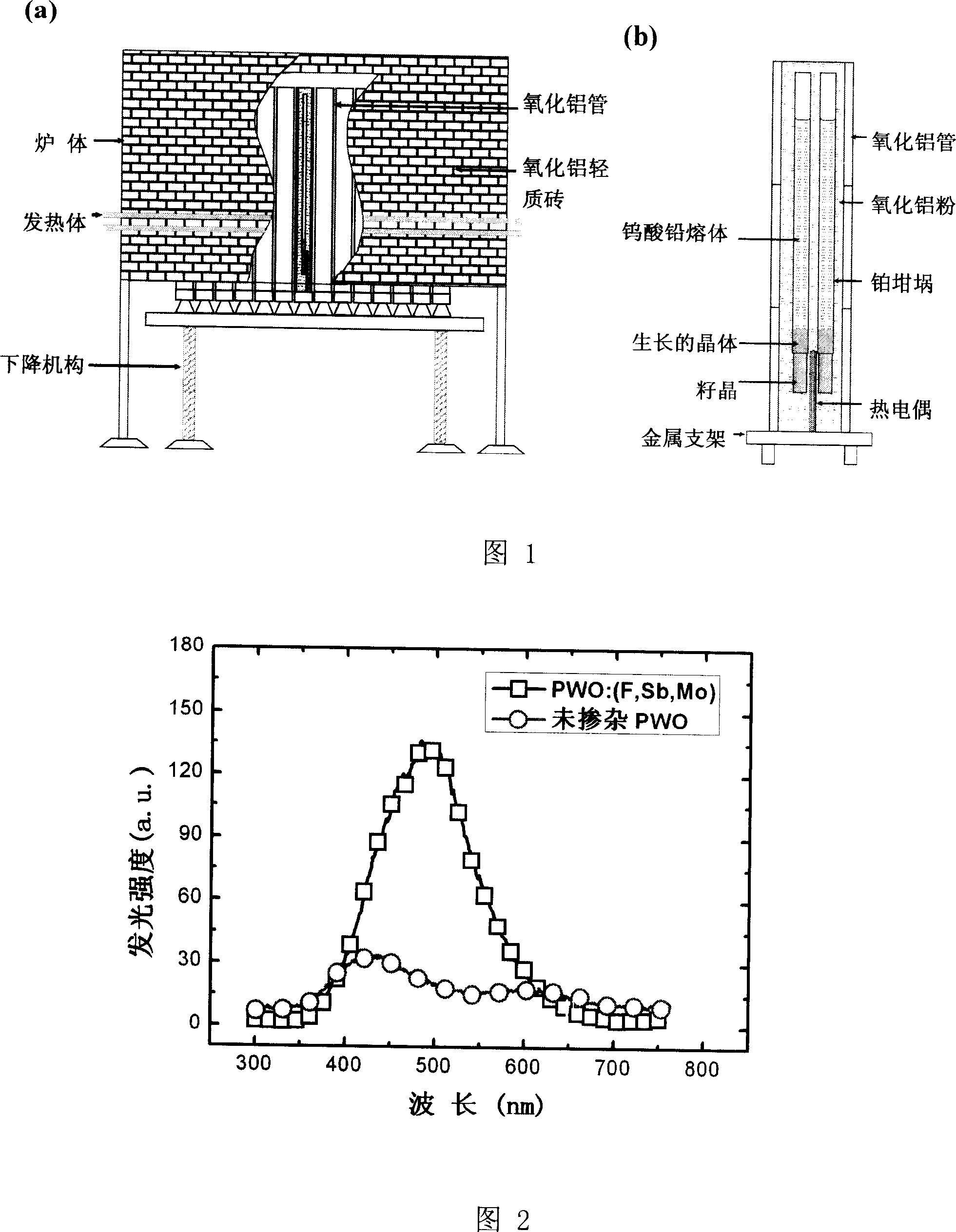

Combined different valence ions doped crystal of lead tungstate with high light yield, and prepartion method

InactiveCN101092746AReduce radial temperature gradientReduce thermal stressPolycrystalline material growthSingle crystal growth detailsUltrasound attenuationBridgman method

This invention relates to a method for preparing heterovalent ions-doped high-luminescence-yield lead tungstate crystal and its preparation method. The high-luminescence-yield lead tungstate crystal is doped with F- 100-8000 ppm, Sb3+ 100-5000 ppm, and Mo6+, V5+, Nb5+, Zr4+, and Ti4+ 0-10000 ppm, and is prepared via modified Bridgman method by using platinum crucible. The method can be used for preparing several strands of lead tungstate crystals in one process, and is suitable for mass production. The obtained heterovalent ions-doped high-luminescence-yield lead tungstate crystal has such advantages as rapid attenuation and high luminescence yield.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Crystal growth crucible and crystal growth furnace

PendingCN108018604AImprove heat transfer performanceReduce radial temperature gradientPolycrystalline material growthFrom condensed vaporsCrucibleLarge size

The invention provides a crystal growth crucible, wherein an installation position for fixing a seed crystal is arranged on the top wall of the crystal growth crucible, a heat transfer layer is arranged on the installation position, and the heat conductivity coefficient on the plane of the heat transfer layer is larger than the thermal conductivity in the thickness direction. According to the present invention, with the crystal growth crucible and the crystal growth furnace, the radial temperature gradient of the crystal thermal field can be effectively reduced, such that the problem that thecrystal easily cracks during the growth of the large-size crystal can be solved.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

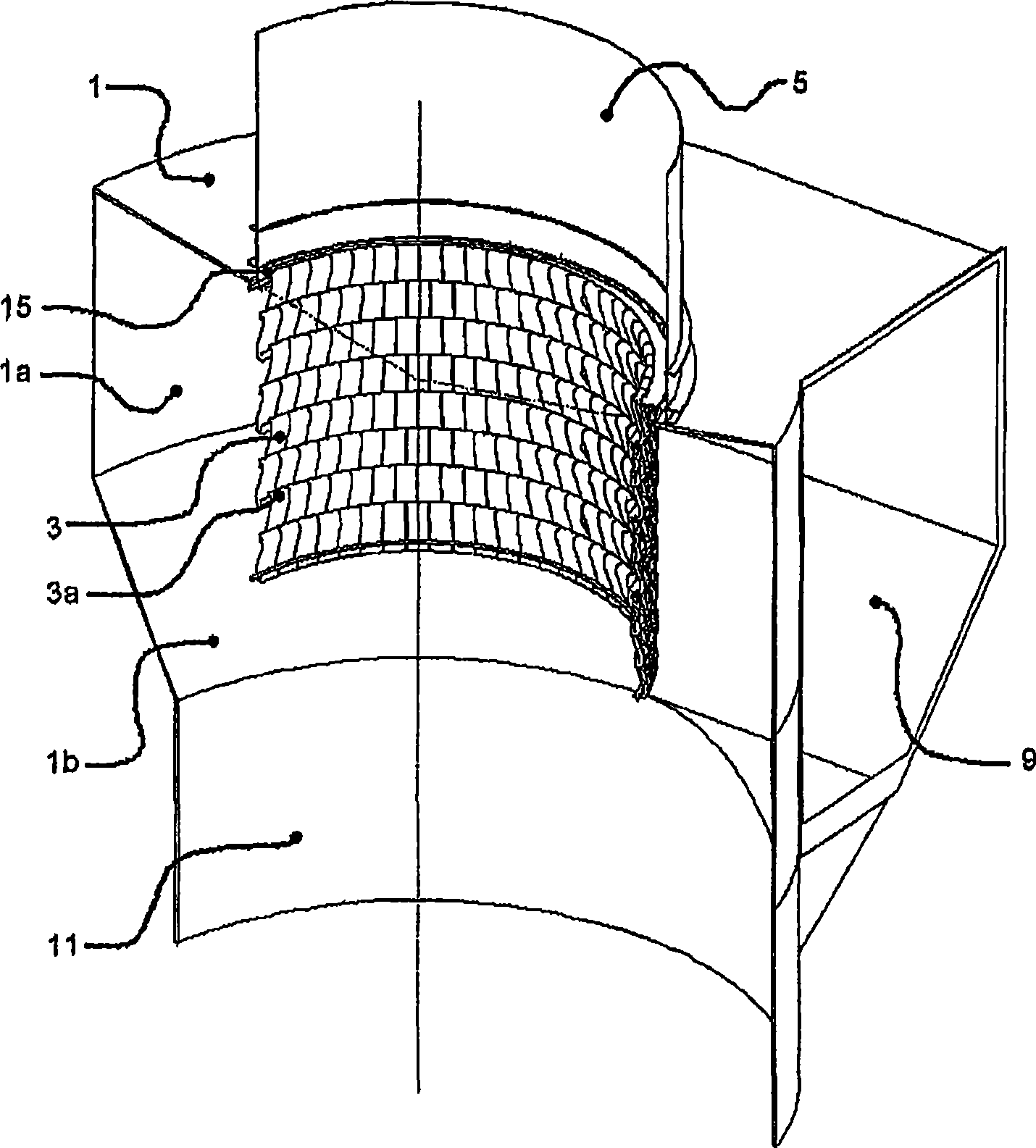

Cyclone separator

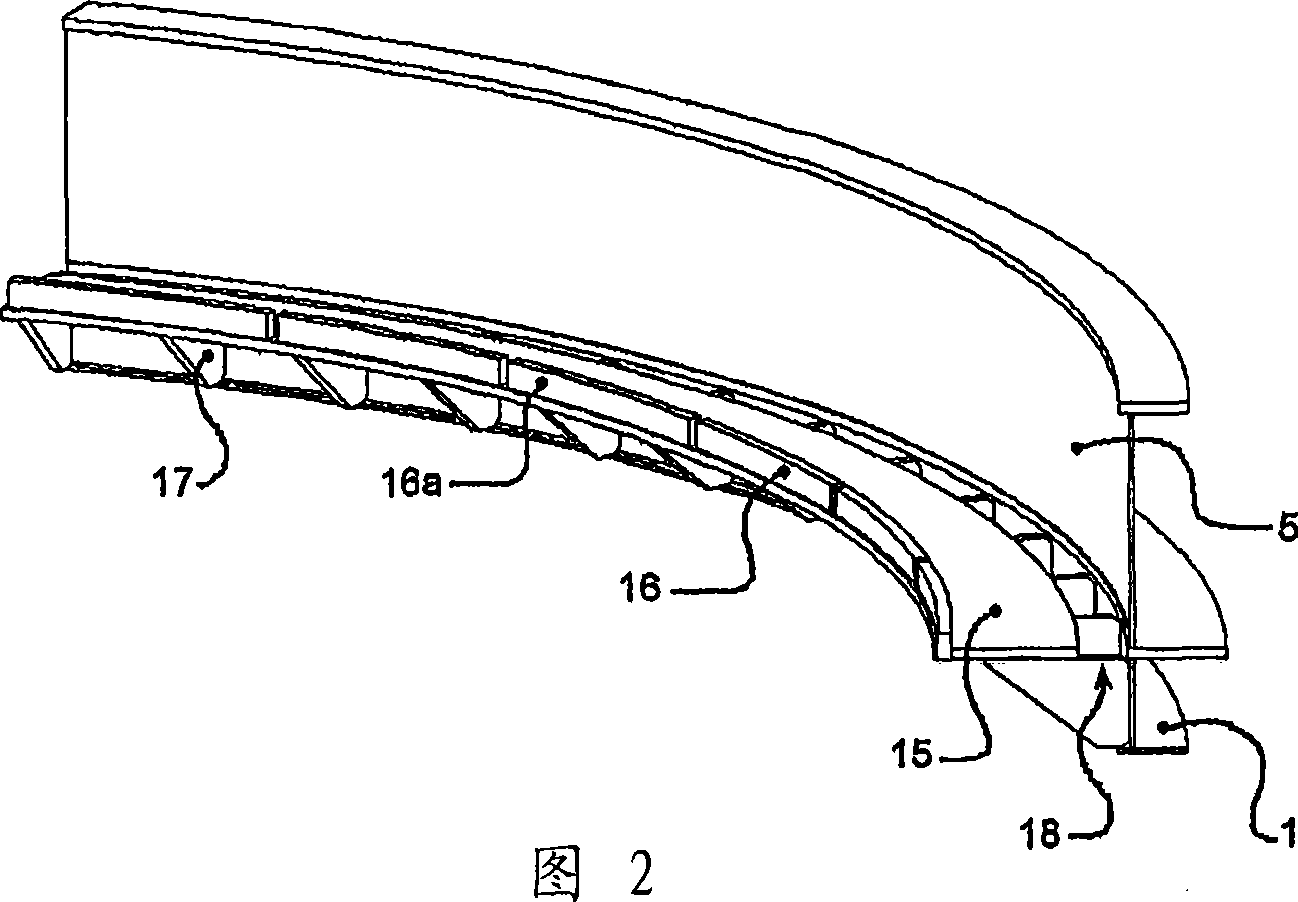

ActiveCN101400449AReduce radial temperature gradientUniform temperatureReversed direction vortexDispersed particle separationCycloneHeat transmission

Described is a cyclone separator comprising a cyclone housing (1), a discharge duct (5) and a central tube (3) for diverting gases, said central tube (3) extends axially into the cyclone housing (1) and being composed by a number of segments (3a) which are suspended on a supporting element (15) provided in the area between the cyclone housing (1) and the discharge duct (5). The cyclone separator is peculiar in that it comprises a number of carrying means (17) which are evenly distributed and fixed to the inner side of the cyclone housing (1) and / or the discharge duct (5), and in that the supporting element (15) comprises an annular disc which is loosely fitted on top of the carrying means (17) and having an outer diameter which is smaller than the inner diameter of the cyclone housing (1) and / or the discharge duct (5) so that a clearance (18) is provided between the annular disc (15) and the cyclone housing (1) and / or the discharge duct (5). Hereby is obtained a significant reduction in the heat transmission from the supporting element to the cyclone housing and / or the discharge duct so that the radial temperature gradient in the supporting element is reduced with an approximately uniform temperature over the radial cross section of the element. Hence the thermal stresses in the supporting element will be substantially reduced. This is mainly ascribable to the reduction in the contact area between the supporting element and the cyclone housing and / or the discharge duct.

Owner:FLSMIDTH AS

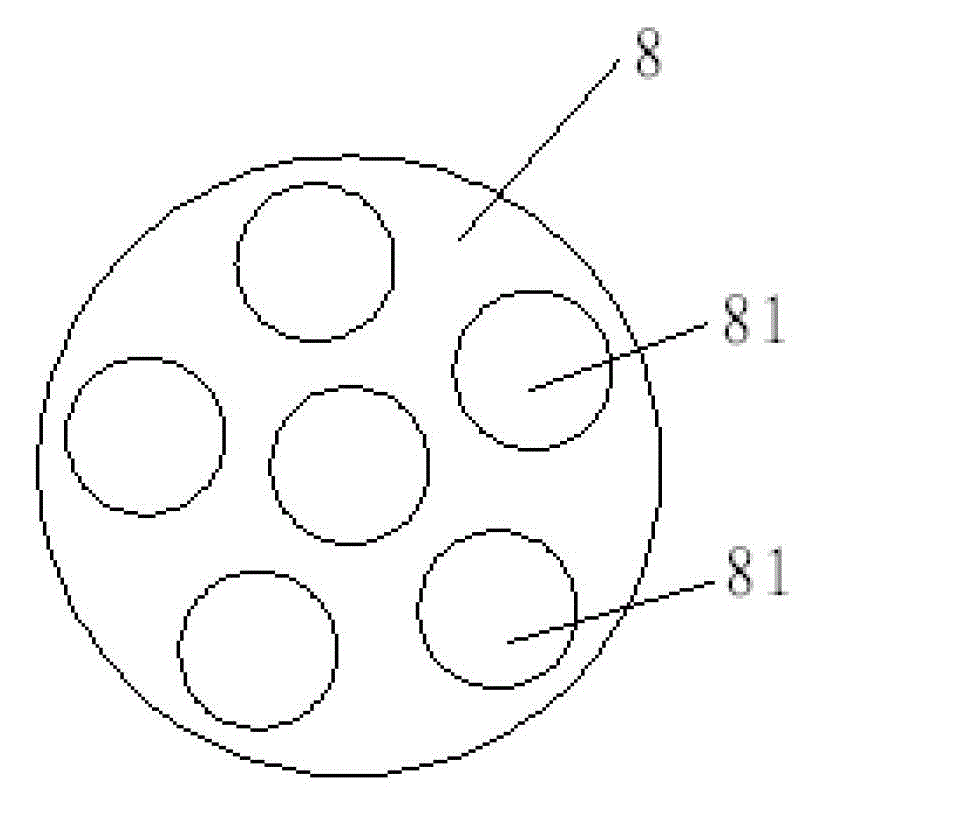

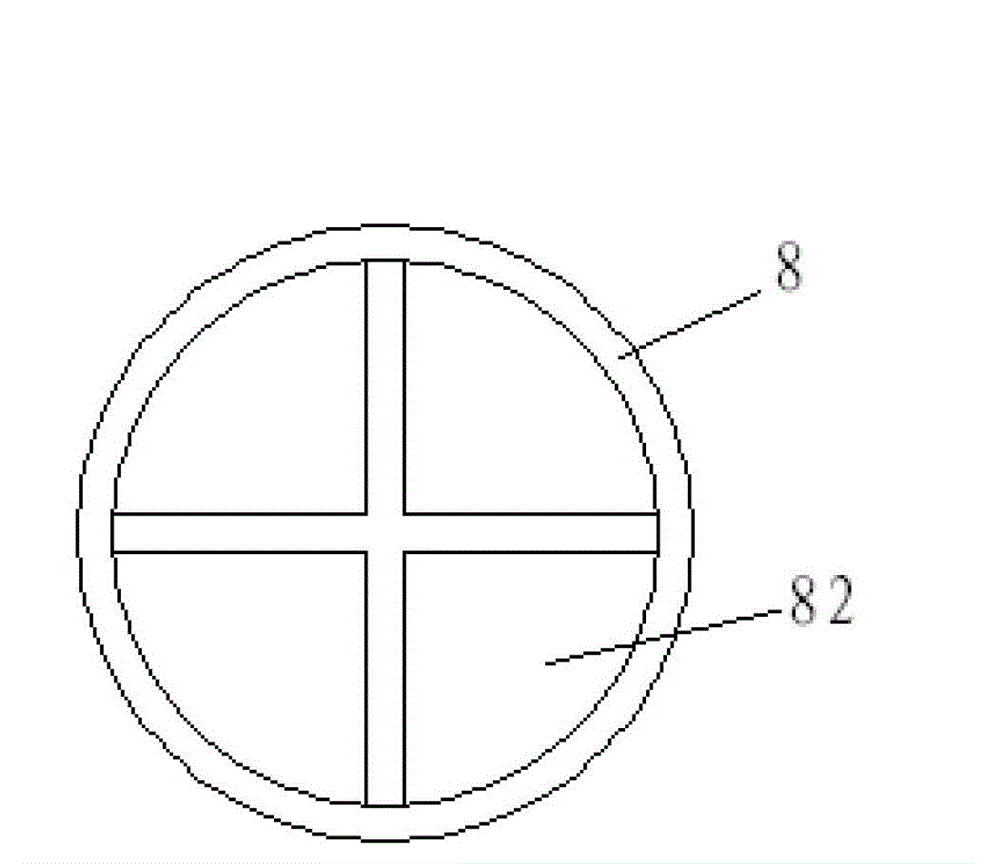

Silicon carbide crystal growth crucible for increasing utilization rate of power sources

ActiveCN102912444AReduce radial temperature gradientIncrease contact areaAfter-treatment apparatusPolycrystalline material growthCrucibleUtilization rate

The invention discloses a silicon carbide crystal growth crucible for increasing utilization rate of power sources and solves the problems that utilization rate of silicon carbide power sources is low and average growth rate of crystal is low. The silicon carbide crystal growth crucible comprises a crucible body. A cavity of the crucible body is divided into a plurality of split areas for containing silicon carbide power sources horizontally.

Owner:XIAN UNIV OF TECH

Preparation method and growth device of N-type silicon carbide crystal

ActiveCN112813499AReduce radial temperature gradientQuality improvementPolycrystalline material growthFrom condensed vaporsCarbide siliconCrucible

The invention provides a preparation method and a growth device of an N-type silicon carbide crystal. The method comprises the following steps: (1) placing a raw material in a high-temperature area of a crucible, placing a seed crystal in a low-temperature area of the crucible, recessing the outer wall of the top of the crucible inwards to form an annular gas groove, placing the assembled crucible in a furnace body of a crystal growth furnace, and enabling the annular air groove to be close to a vent hole of the furnace body; and (2) in a crystal growth stage, introducing nitrogen source gas into the furnace body through the vent hole, controlling crystal growth temperature and crystal growth pressure, and enabling the N-type silicon carbide crystal to grow on the seed crystal. The annular gas groove is close to the vent hole of the furnace body, the introduced gas can flow along the annular gas groove, a gas flow speed is high, the gas is diffused into the crucible, heat transmission away from the central axis in the crucible is accelerated, the radial temperature gradient of the crucible is reduced, and crystal growth quality is improved.

Owner:SICC CO LTD

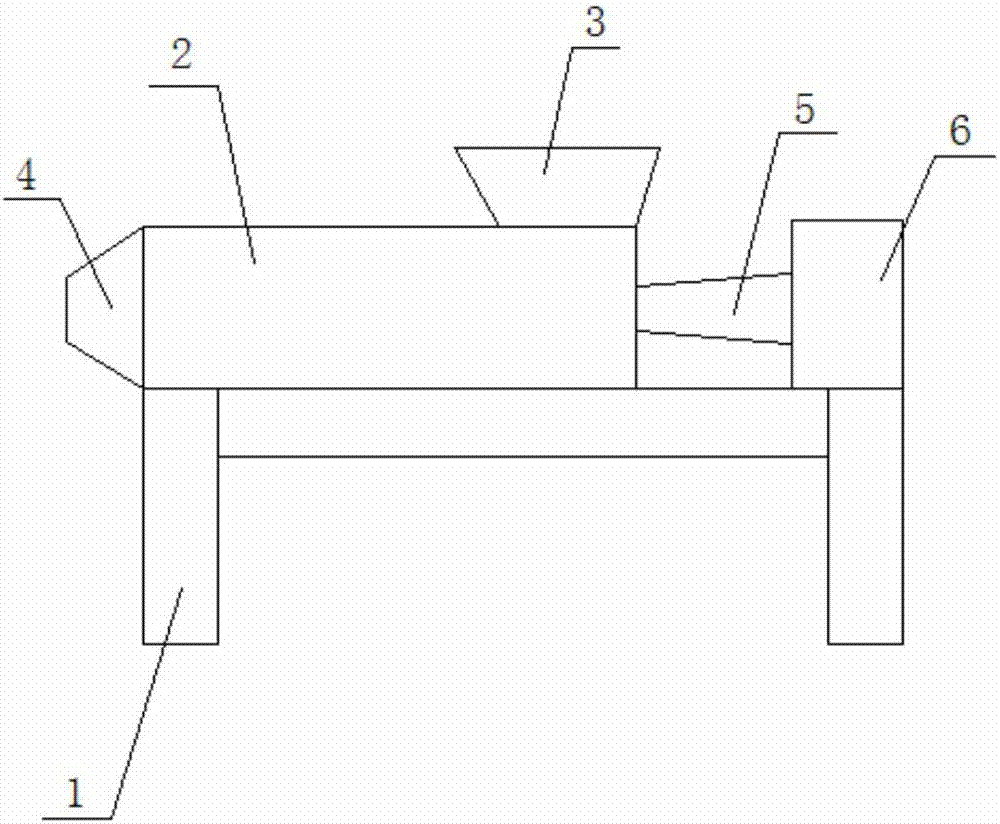

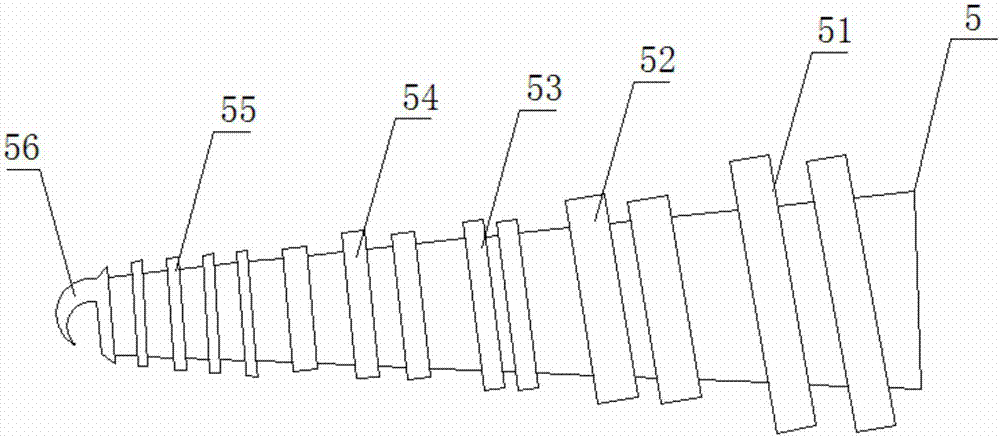

Plastic extruder

InactiveCN107322902AAccelerated corrosionImprove high temperature resistanceEngineeringTemperature gradient

The invention provides a plastic extruder, and relates to the technical field of plastic extrusion devices. The plastic extruder comprises a base, a charging barrel arranged on the base, a feeding port formed in the top of one end of the charging barrel, an extrusion port formed in the other end of the charging barrel, a screw arranged in the charging barrel, and a motor arranged on one side of the charging barrel and connected with the screw, wherein the screw is a taper angle-shaped screw, and sequentially comprises a feeding section, a plasticizing section, a compression section, an exhaust section, an extrusion section and a hook-shaped screw head from the motor to the extrusion port. The hook-shaped screw head forms a material channel from the surface of the screw to the core part of the screw, the shearing rate of molten material at the section is increased, and therefore the radial temperature gradient is reduced, the phenomenon that the material is retained and decomposed at the section is obviously relieved, and the mixing efficiency is improved.

Owner:合肥英源新材料科技有限公司

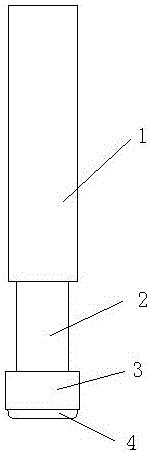

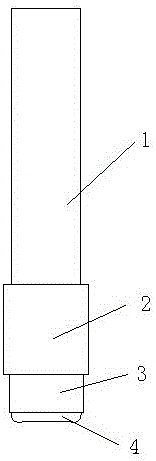

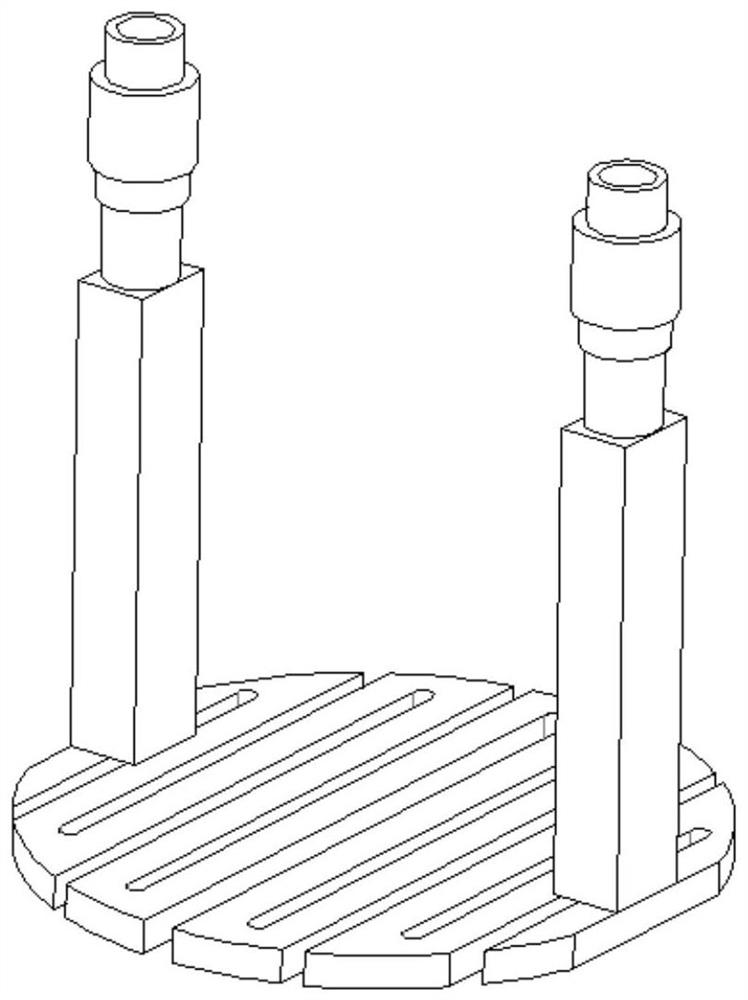

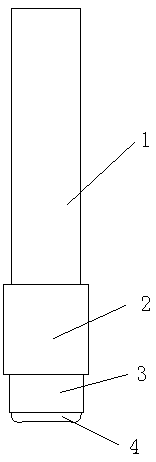

Liquid-phase growing silicon carbide seed crystal shaft device

ActiveCN105970294AGuaranteed normal growthReduce stressPolycrystalline material growthBy pulling from meltMaterials preparationGraphite

The invention discloses a liquid-phase growing silicon carbide seed crystal shaft device, and belongs to the field of novel material preparation. The device comprises a moving connection part, a heat resistant part and a graphite platform which are detachably connected in sequence, wherein a seed crystal is connected to the other end of the graphite platform; the heat resistant part is a heat resistant material of which the thermal conductivity is lower than that of graphite and does not react with silicon steam; the seed crystal can be square, round, polygonal or the like; the graphite platform is the same as that of the seed crystal in shape, and is not smaller than the seed crystal in size; the radial size of the heat resistant part is not smaller than those of the moving connection part and the graphite platform, or the radial size of the heat resistant part is not larger than those of the moving connection part and the graphite platform; each of the two ends of the heat resistant part is of an internal thread structure and each of the moving connection part and graphite platform connected with the heat resistant part is of an external thread structure, or each of the two ends of the heat resistant part is of an external thread structure and each of the moving connection part and graphite platform connected with the heat resistant part is of an internal thread structure.

Owner:SICC CO LTD

Heat insulation block for polysilicon ingot casting furnace and polysilicon ingot casting furnace comprising heat insulation block

ActiveCN104372403AAvoid cloggingAvoid hindering radiative heat transferPolycrystalline material growthSingle crystal growth detailsIngot castingCrucible

The invention discloses a heat insulation block for a polysilicon ingot casting furnace, which is arranged on the periphery of the bottom of a crucible of the polysilicon ingot casting furnace and used for heat insulation in the process of heating or cooling polysilicon with the crucible. The heat insulation block is a hollow square cylinder structure, wherein the wall of the cylinder is a hollow sandwich structure; the inner wall is used for coating the peripheral wall surface of a heat exchange block on the bottom of the crucible; a clearance is arranged between the inner wall and the peripheral wall surface of the heat exchange block; the outer wall is used for fixedly contacting a vertical heat insulation plate on the periphery of the crucible; the central line of the crucible, the central line of the heat exchange block and the central line of the heat insulation block coincide; and the top of the heat insulation block is lower than the top of the heat exchange block. The invention also discloses an ingot casting furnace provided with the heat insulation block. The heat insulation block can shorten the material melting time in the silicon ingot casting process, lowers the energy consumption, and can effectively inhibit the preferential growth of crystal grains near the crucible wall in the early nucleation period to obtain a slightly-convex and flat freezing interface, thereby enhancing the quality of the silicon ingot.

Owner:HUAZHONG UNIV OF SCI & TECH

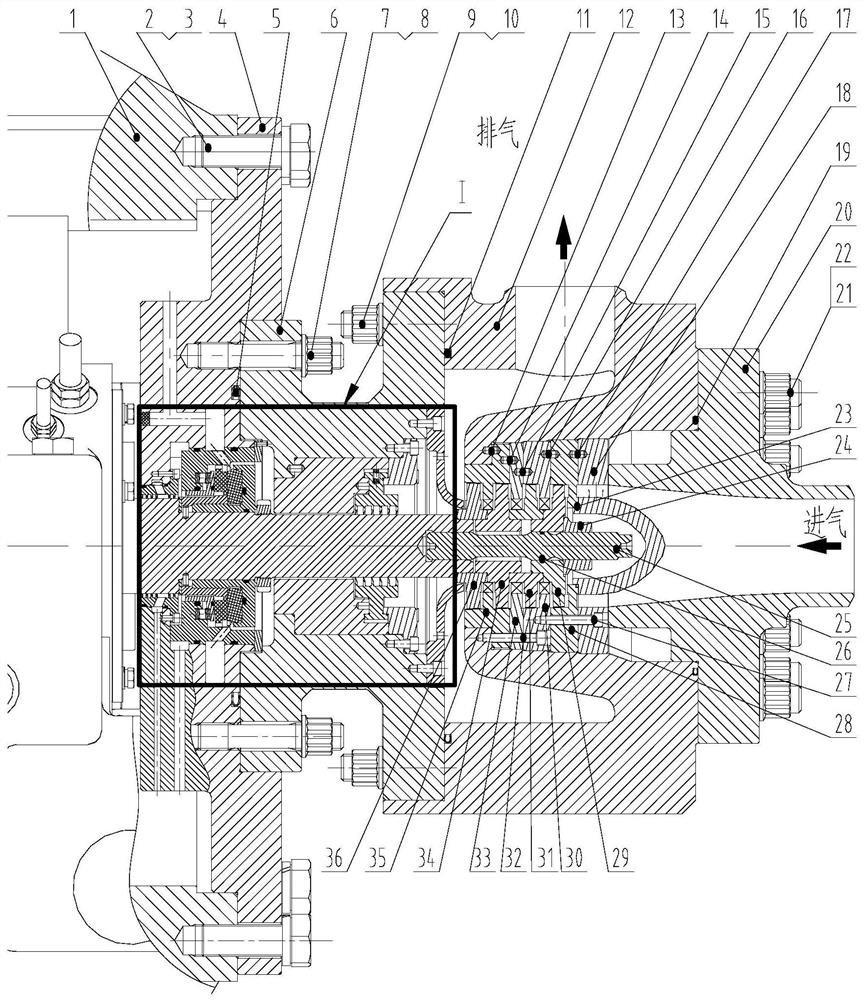

Cooling method and structure of cantilever type supercritical carbon dioxide turbine

PendingCN113969982AReduce radial temperature gradientReduce temperature stressEngine sealsBlade accessoriesPhysicsDry gas seal

The invention relates to the field of turbines, in particular to a cooling method and structure of a cantilever type supercritical carbon dioxide turbine, main sealing gas for dry gas sealing is injected from a first gas channel on a dry gas sealing shell, and the sealing gas is cooling gas which sequentially flows into the shell along a second gas channel and a first gap between a high-speed shaft and a splitting ring; and one path of cooling gas is exhausted to an exhaust flow channel in the shell through an exhaust hole of a baffle, the other path of cooling air is exhausted to the exhaust flow channel in the shell through a second gap formed by the baffle and a turbine disc, in addition, after the splitting ring and a middle shell are split into two parts, the radial temperature gradient on each part is reduced, therefore, the temperature stress on each part is reduced, the turbine can be better cooled, and the strength reliability of a unit is ensured.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Single crystal silicon growth control method

ActiveCN105401212BAvoid lostReduce radial temperature gradientPolycrystalline material growthBy pulling from meltInfraredGrowth control

The invention provides a single crystal silicon growth control method. The 700-920 DEG C zone of a silicon crystal rod is cooled by adopting a reflecting and cooling device, the length of the zone can be smaller than 200 mm, and the speed of lifting and pulling the silicon crystal rod is greater than 1.12 mm / min, so that the standing time of the crystal rod in the temperature interval is less than 180 minutes to avoid the formation of OSF defects. Radiating infrared rays of a molten silicon fluid are reflected by adopting a semi-parabolic arc-shaped reflection surface to irradiate the side face of the silicon crystal rod at the growth interface position and reduce the cooling speed of the lateral surface, so that the temperature gradient of the center and the surface of the growth interface position of the silicon crystal rod is reduced, and an oxygen element and doped elements on a wafer are radially and evenly distributed. The rays of a high-temperature crucible wall are reflected by adopting a smooth and clean surface to avoid the influence on the crystal rod.

Owner:SHANGHAI ADVANCED SILICON TECH CO LTD

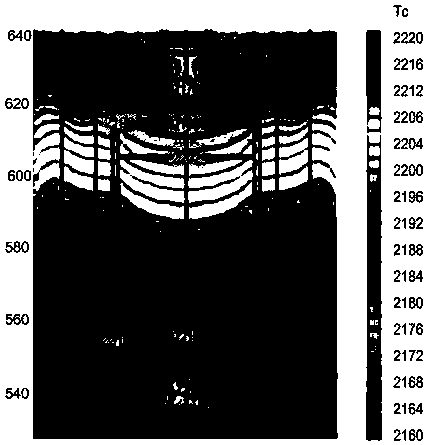

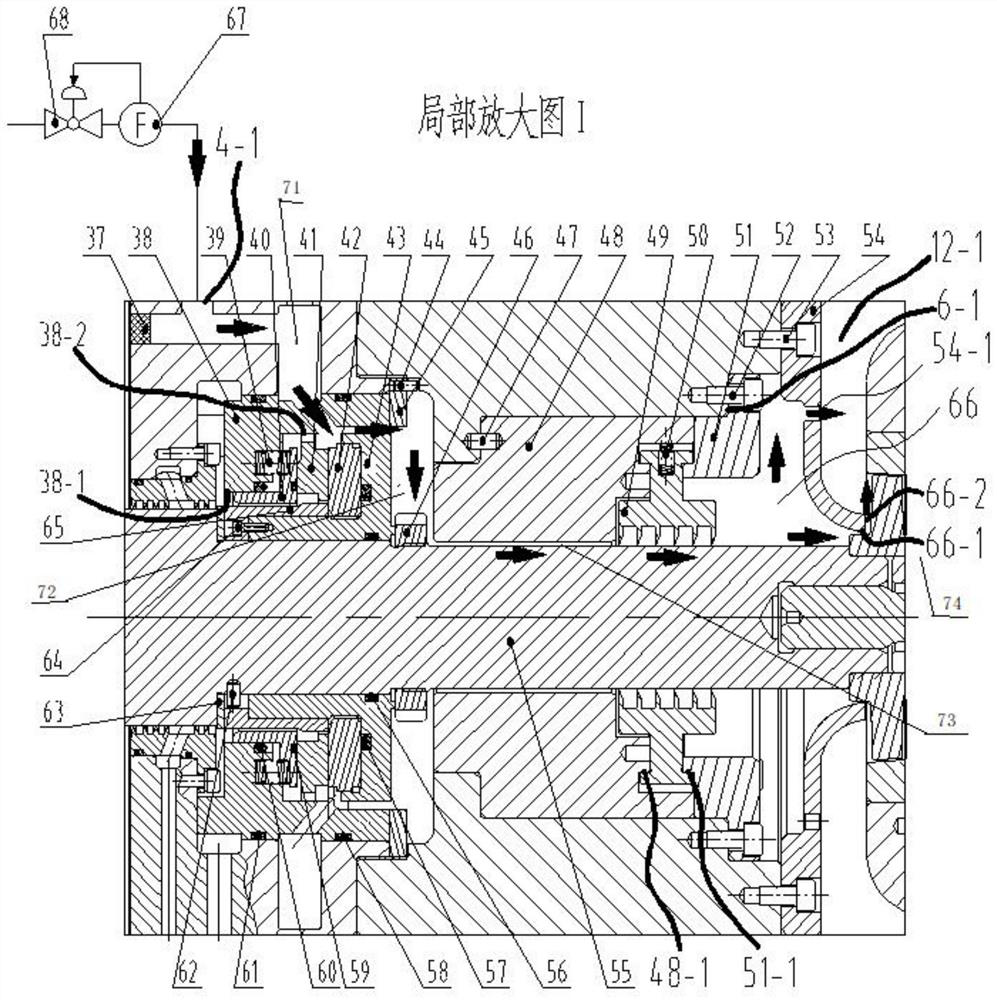

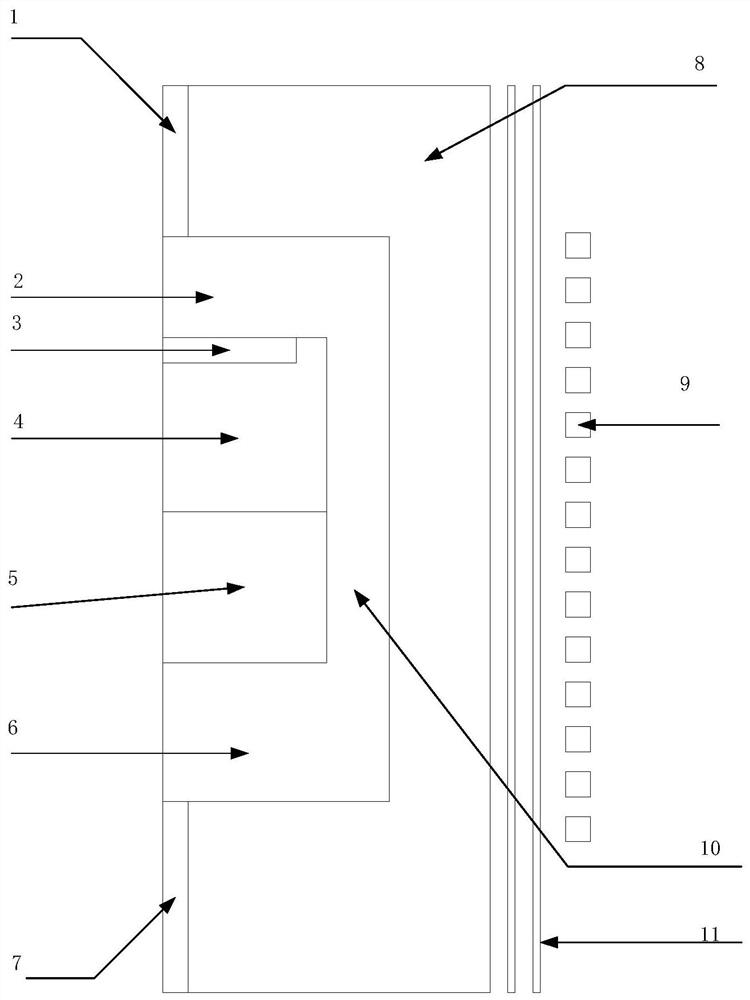

Graphite thermal-field single crystal growth device for preparing silicon carbide crystals

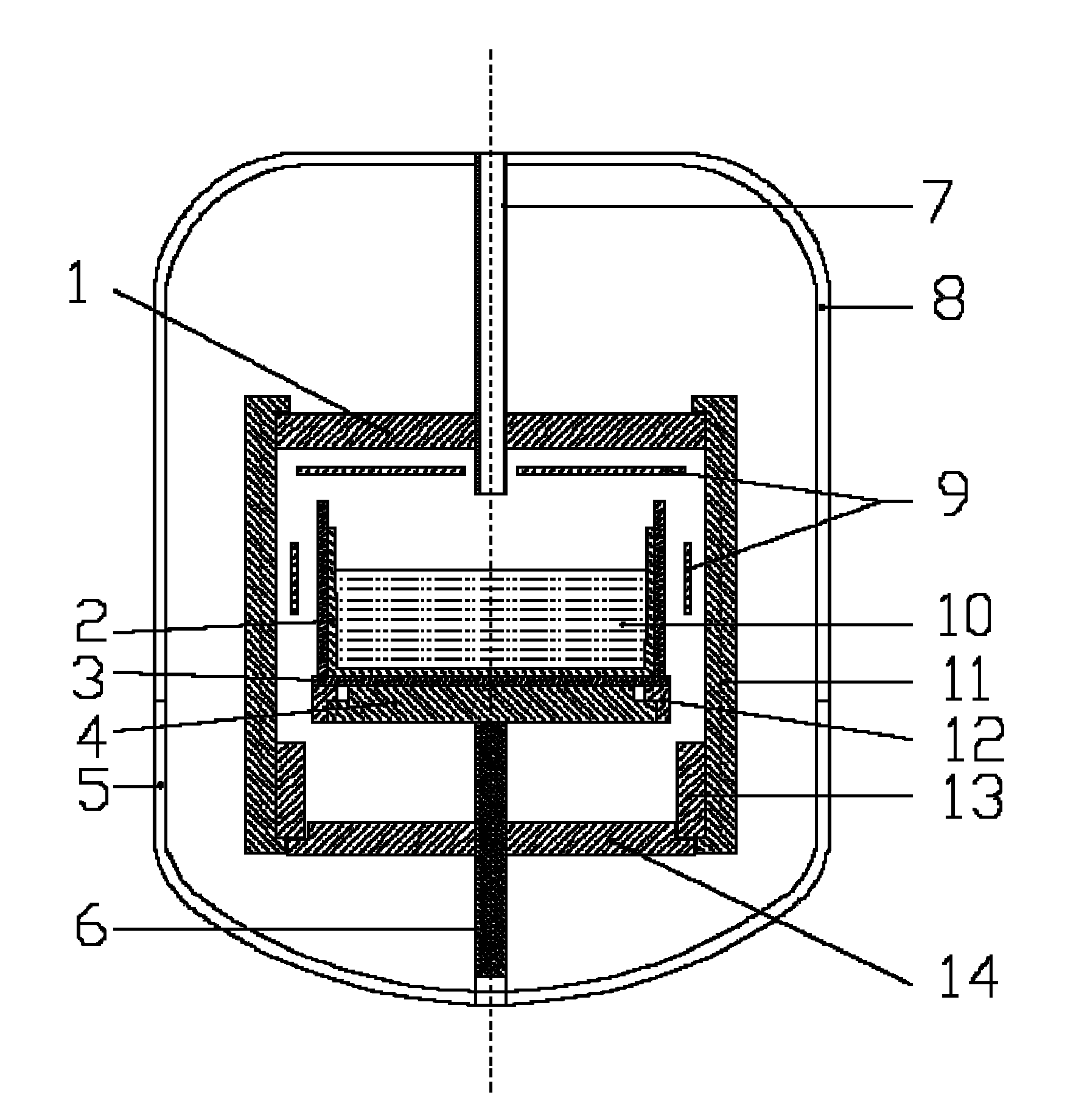

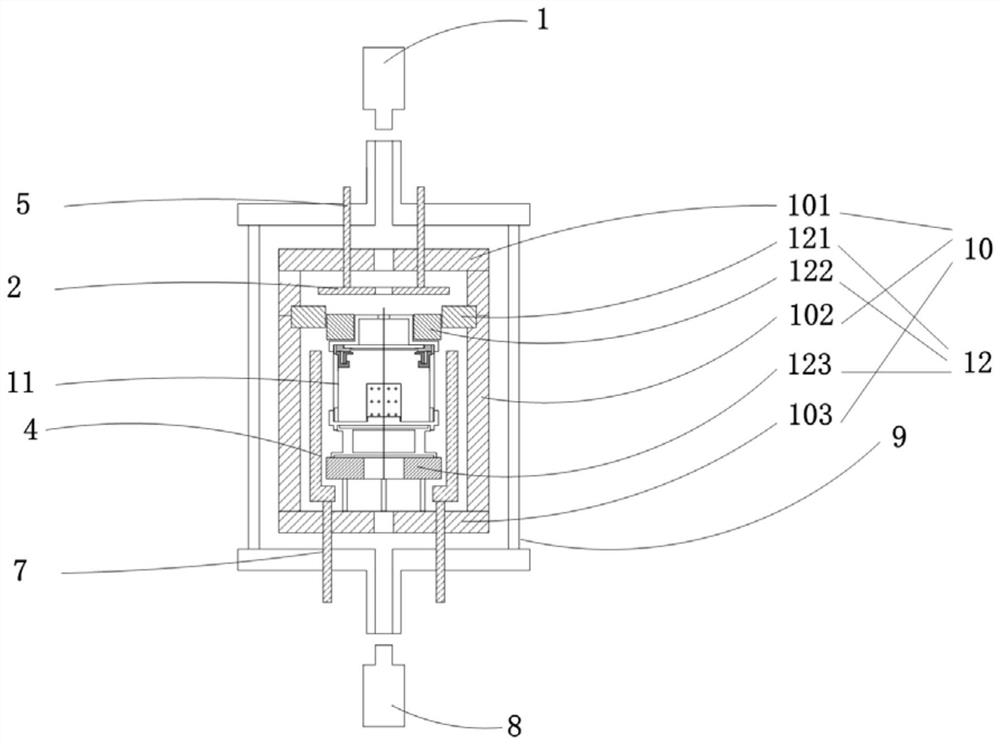

PendingCN113122917AReduce radial temperature gradientReduce radial temperature and stress gradientsPolycrystalline material growthFrom condensed vaporsSeed crystalSingle crystal growth

The invention discloses a graphite thermal-field single crystal growth device for preparing silicon carbide crystals, belonging to the technical field of silicon carbide single crystal preparation and crystal growth. The graphite thermal-field single crystal growth device comprises a sealing cavity, a heating structure, a heat preservation structure, a temperature adjusting structure, a crucible and a temperature measuring mechanism, wherein the heat preservation structure is arranged in the sealing cavity; the heating structure is arranged in the heat preservation structure; the temperature measuring mechanism is arranged on the sealing cavity; the temperature adjusting structure is arranged in the heat preservation structure, and a crucible and a seed crystal support are arranged in the heat preservation structure; the heating structure is used for heating the bottom and the top of the crucible and carrying out axial and radial temperature control on the crucible; the temperature measuring mechanism is used for respectively measuring the temperatures of the top and the bottom of the crucible; the heat preservation structure is used for carrying out heat preservation on a thermal field of the whole cavity, so heat loss of the crucible can be reduced, and accurate temperature control on each part of the crucible is realized; the temperature adjusting structure can reduce the radial temperature gradient of the crucible; and therefore, the radial temperature gradient and the stress gradient of the crystal in the growth process of the silicon carbide single crystal are reduced, the defects of crystal growth can be reduced, and the quality of the crystal is ensured.

Owner:NINGBO HIPER VACUUM TECH CO LTD

Cylinder assembly for a reciprocating piston combustion machine and cooling method

InactiveCN104421034ALiquidity Exchange Can Be ExcludedLiquidity Exchange ExclusionLiquid coolingCylinder headsTop dead centerCombustion chamber

The invention relates to a cylinder liner arrangement for a reciprocating internal combustion engine and a cooling method. The cylinder liner arrangement comprises a cylinder liner, in which a piston is installed, the factory and installed state between a top dead center and a bottom dead center so along a cylinder axis of the cylinder liner reciprocally disposed forth that a top of the piston delimits, together with a running surface of the cylinder liner and on the cylinder liner arranged in the cylinder cover a combustion chamber. The cylinder liner comprises a liner cooling system for cooling the cylinder liner by means of liner cooling fluid and the cylinder cover comprises a cover cooling system for cooling the cylinder cover by means of a cover cooling fluid, According to the invention, the liner cooling system in such a manner decoupled from the cover cooling system that a flow communication between the liner cooling fluid and the cover cooling fluid is controlled or regulated, or that the flow communication between the liner cooling fluid and the cover cooling fluid is prevented.

Owner:WAERTSILAE SCHWEIZ AG

Monocrystalline silicon growth furnace

ActiveCN106894082BReduce lossReduce radial temperature gradientPolycrystalline material growthBy pulling from meltIngotEngineering

The invention discloses a monocrystalline silicon growth furnace, which is characterized by arranging a flow dividing and guiding cylinder on a graphite crucible mouth and arranging a vertical flow dividing cylinder around a main heater, so that argon gas flow is separated into two flows by the vertical flow dividing cylinder, one flow enters the vertical flow dividing cylinder and is discharged out from a chamber through the main heater, and the other flow is directly discharged out from the chamber through the vertical flow dividing cylinder. In addition, the flow quantity of the two gas flows can be adjusted by vent valves, thus regulating heat field distribution and reducing heat loss. The monocrystalline silicon growth furnace can significantly reduce power consumption, reduces growth period of crystal ingots, and reduces production cost.

Owner:SHANGHAI ADVANCED SILICON TECH CO LTD

A liquid phase growth silicon carbide seed crystal shaft device

ActiveCN105970294BGuaranteed normal growthReduce stressPolycrystalline material growthBy pulling from meltMaterials preparationGraphite

The invention discloses a liquid-phase growing silicon carbide seed crystal shaft device, and belongs to the field of novel material preparation. The device comprises a moving connection part, a heat resistant part and a graphite platform which are detachably connected in sequence, wherein a seed crystal is connected to the other end of the graphite platform; the heat resistant part is a heat resistant material of which the thermal conductivity is lower than that of graphite and does not react with silicon steam; the seed crystal can be square, round, polygonal or the like; the graphite platform is the same as that of the seed crystal in shape, and is not smaller than the seed crystal in size; the radial size of the heat resistant part is not smaller than those of the moving connection part and the graphite platform, or the radial size of the heat resistant part is not larger than those of the moving connection part and the graphite platform; each of the two ends of the heat resistant part is of an internal thread structure and each of the moving connection part and graphite platform connected with the heat resistant part is of an external thread structure, or each of the two ends of the heat resistant part is of an external thread structure and each of the moving connection part and graphite platform connected with the heat resistant part is of an internal thread structure.

Owner:SICC CO LTD

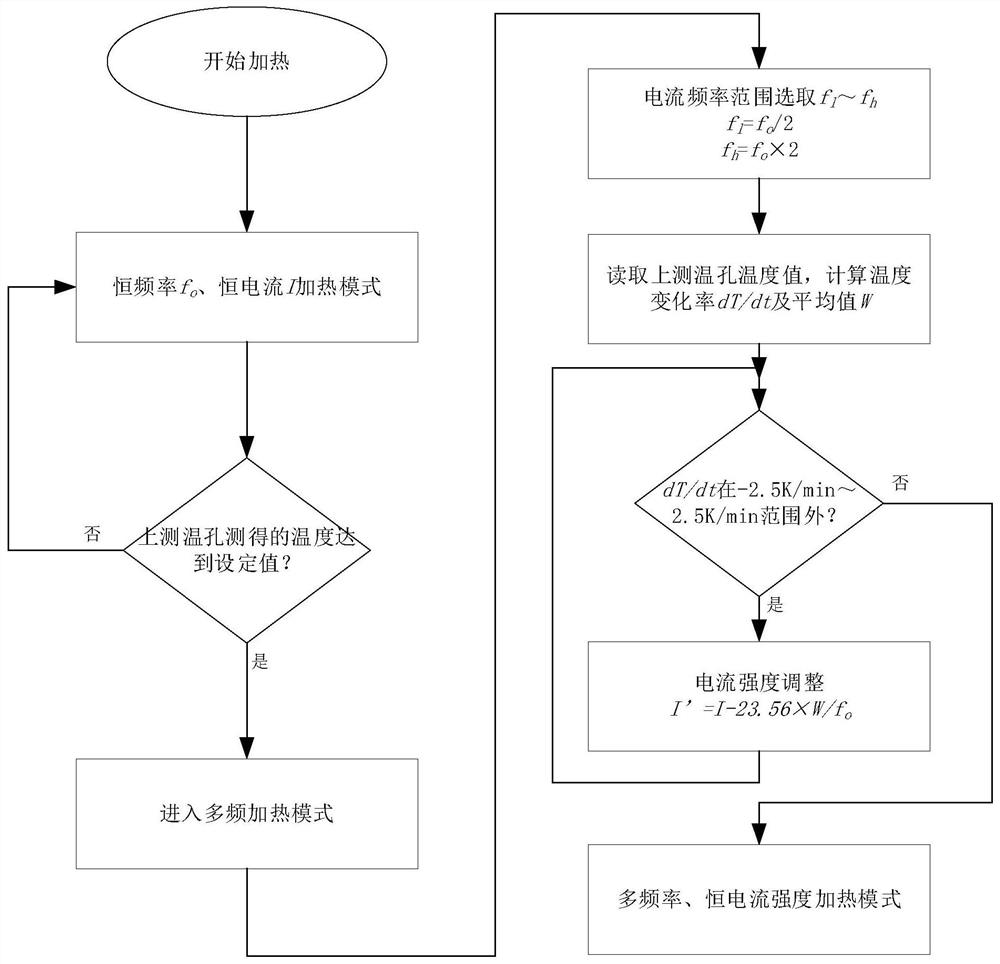

A large-size sic single crystal growth device and its working method

ActiveCN108286074BMeet heating requirementsReduce radial temperature gradientPolycrystalline material growthFrom condensed vaporsSingle crystalSingle crystal growth

Owner:SHANDONG UNIV

Monocrystal high temperature alloy electric field directional freeze apparatus

InactiveCN1226470CRefining solidified tissueEasy to useFrom frozen solutionsSingle crystal superalloySingle crystal

The invention relates to the single crystal high-temperature alloy solidifying technique, including case, heating set, sample clamping framework and DC electric field generating set. The clamping framework is set under the case, composed of two clamping bars set on the bracket, one end of each clamping bar linked with the rotation shaft on the bracket, the other end linked through fastener, and the outer side of each clamping bar installed with tension spring, the other end of each tension spring fixed on the bracket, and the bracket opened with a through hole to make the sample pass through; the generating set is a close loop, formed by setting a programmable functional module in series between one end of the sample and one pole of the voltage-stailized source, and connecting the other end with the other pole through the clamping tool.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Heat pipe uniform temperature heat dissipation device for disc vehicle brake

ActiveCN104192101BReduce the maximum temperatureReduce the temperatureBrake coolingContact modeHeat sink

The invention discloses a heat pipe even-temperature heat dissipation device used for a vehicle disc brake. The device comprises a brake disc composed of brake flanges arranged oppositely. Heat pipe arrays are arrayed on the opposite faces of the two brake flanges respectively in an annular shape, and the heat pipe arrays are fixed to the brake flanges in a surface contact mode through heat pipe grooves formed in the brake flanges. According to the device, it is unnecessary that an extra auxiliary power source is used for maintaining operation of heat pipes, extra motion components do not need to be arranged inside the brake disc, in this way, reliability is high, and it is avoided that the motion components fail because of abrasion, collision and others. The structure of an existing brake disc is sufficiently used, the heat pipe grooves are formed in air ducts between the opposite surfaces of the brake flanges, people do not need to change the overall structure of the brake disc, adaptability is high, the technology is simple, and the cost is low. According to the device, the technology means is simple and easy and convenient to implement, the even-temperature performance of the brake disc is good, the surface average temperature and the transient temperature are low, the structure is simple, the reliability is high, and installing is convenient.

Owner:SOUTH CHINA UNIV OF TECH

Disc laser amplifier

InactiveCN102684051BImprove efficiencySolution to short lifeOptical resonator shape and constructionActive medium shape and constructionAudio power amplifierOptical axis

The invention discloses a disc solid laser amplifier which comprises two parabolic reflectors, wherein the two parabolic reflectors are coaxially placed in a conjugate mode so as to form a parabolic reflector set; the vertex of each parabolic reflector is provided with a disc laser crystal; a certain inclined angle is respectively formed between the normal lines of end faces of two disc laser crystals and the centre shafts of the corresponding parabolic reflectors, and the two inclined angles are not equal; pump light and seed laser are parallel to an optical axis and enter in a condensing cavity formed by the two parabolic reflectors of the reflector set respectively from a pump light inlet and a laser inlet on the parabolic reflectors; and after being reflected many times in the condensing cavity, the pump light and the seed laser are alternately converged on the two disc laser crystals, thereby realizing the multiple pumping on the two disc laser crystals and the multiple amplification on the laser. By using the disc solid laser amplifier disclosed by the invention, the pump beam absorption efficiency is high, an effect of carrying out efficient amplification on the seed laser can be achieved, and better beam quality can be maintained; and meanwhile, the disc solid laser amplifier is simple in whole system structure, and easy to install and debug.

Owner:HUAZHONG UNIV OF SCI & TECH +1

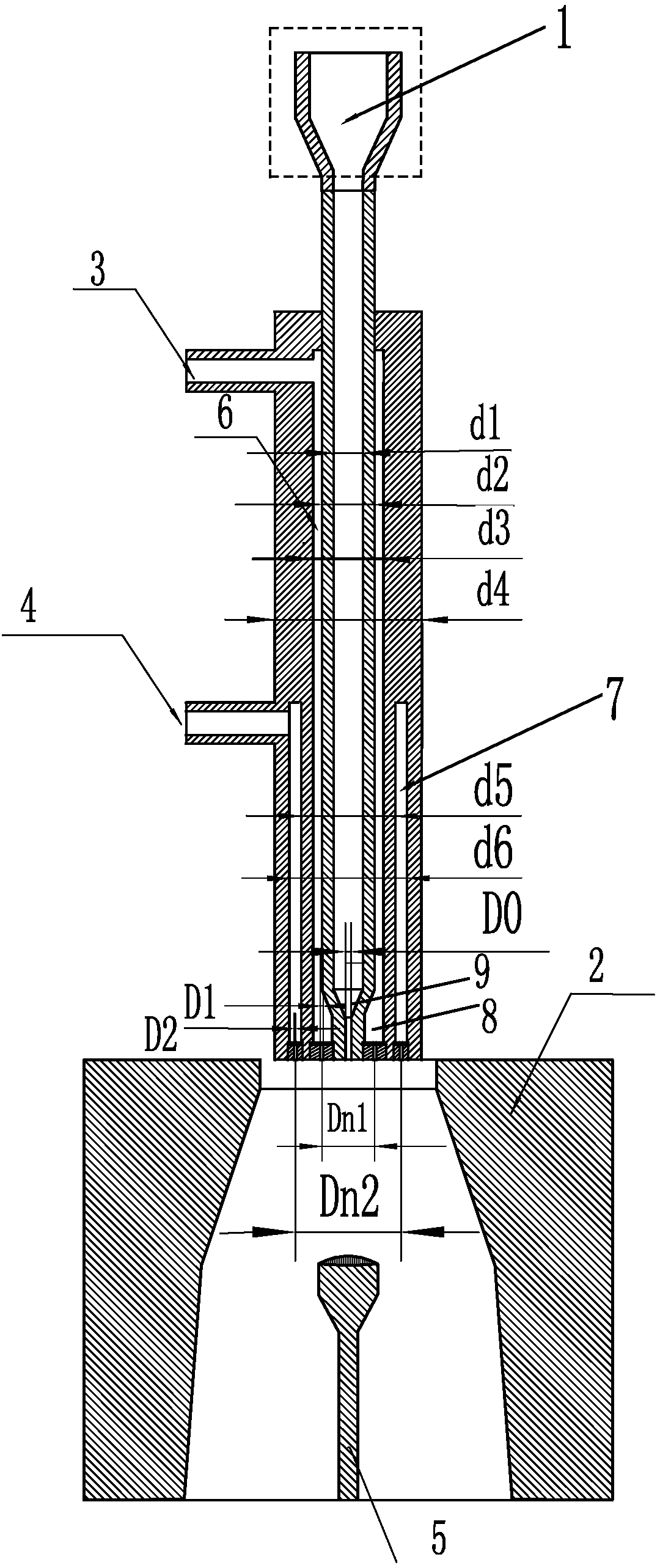

Burner for growing crystals by flame fusion method

PendingCN108277523AUniform radial distributionReduced oxygen vacanciesPolycrystalline material growthFrom frozen solutionsHydrogenCombustor

The invention discloses a burner for growing crystals by a flame fusion method. The burner comprises a conical feeding port, a central pipe, a hydrogen inlet, an external oxygen inlet, a hydrogen ring-shaped pipeline, an external oxygen ring-shaped pipeline, a crystal growing chamber and a crystal growing base, wherein the conical feeding port is connected with the central pipe; powder and oxygenare fed into the central pipe from the conical feeding port; the central pipe is externally provided with the hydrogen ring-shaped pipeline; hydrogen is filled into the hydrogen ring-shaped pipeline by the hydrogen inlet connected with the hydrogen ring-shaped pipeline; the hydrogen ring-shaped pipeline is externally provided with the external oxygen ring-shaped pipeline; oxygen is filled into theexternal oxygen ring-shaped pipeline by the external oxygen inlet connected with the external oxygen ring-shaped pipeline; the tail ends of the central pipe, the hydrogen ring-shaped pipeline and theexternal oxygen ring-shaped pipeline are respectively communicated with the crystal growing chamber; the crystal growing base is arranged in the growing chamber. The burner disclosed by the inventionhas the advantages that the radial and axial pressure distribution of the burner can be greatly reduced, so that the radial distribution of the oxygen is more uniform, oxygen vacancy of the crystal is reduced, the size and the uniformity of crystal growth are improved and the crystal quality is improved.

Owner:SHENYANG INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com