Seeding and shoulder expanding device and technique for single crystal rods and single crystal furnace

A single crystal rod and single crystal furnace technology, which is applied in the field of single crystal silicon manufacturing, can solve the problems of not ensuring stable temperature change, delay and oscillation, increasing seeding and shoulder placement time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

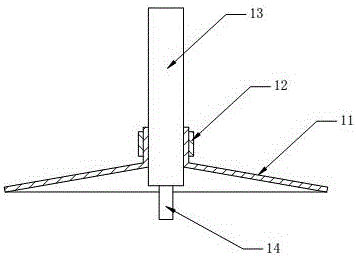

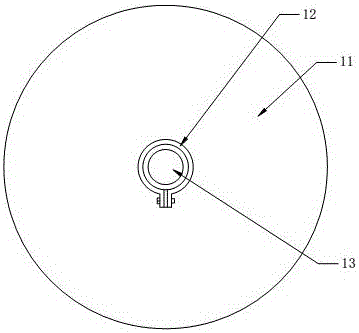

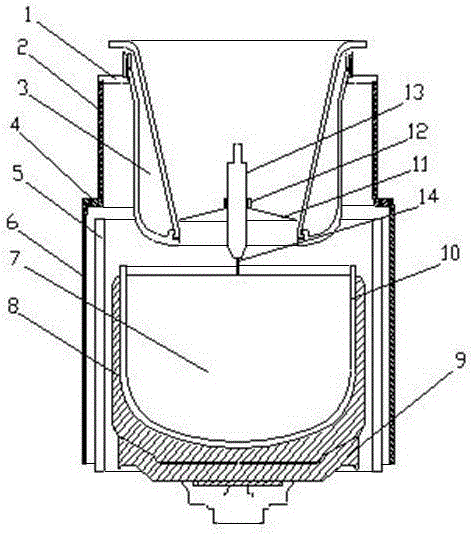

[0032] Example 1: A polished molybdenum sheet with an outer diameter of 175 mm and an included angle of 180 degrees, 300 mm away from the surface of the silicon liquid, was installed on the weight of a Shangyu 100 single crystal furnace; The seeding length is 180mm; the rotation speed of the shouldered crucible is 10rpm, the rotation speed of the seed crystal is 10rpm, and the pulling speed of the shoulder is 0.8mm / min.

Embodiment 2

[0033] Example 2: A polished molybdenum sheet with an outer diameter of 205 mm and an included angle of 180 degrees, 300 mm away from the surface of the silicon liquid, was installed on the weight of a Shangyu 100 single crystal furnace; the seeding crucible rotated at 10 rpm and the seed crystal at 12 rpm. The seeding length is 180mm; the rotation speed of the shouldered crucible is 10rpm, the rotation speed of the seed crystal is 10rpm, and the pulling speed of the shoulder is 0.8mm / min.

Embodiment 3

[0034] Example 3: A polished molybdenum sheet with an outer diameter of 215 mm and an included angle of 180 degrees, 300 mm away from the surface of the silicon liquid, was installed on the weight of a Shangyu 100 single crystal furnace; The seeding length is 180mm; the rotation speed of the shouldered crucible is 10rpm, the rotation speed of the seed crystal is 10rpm, and the pulling speed of the shoulder is 0.8mm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com