Patents

Literature

155results about How to "Smooth temperature change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

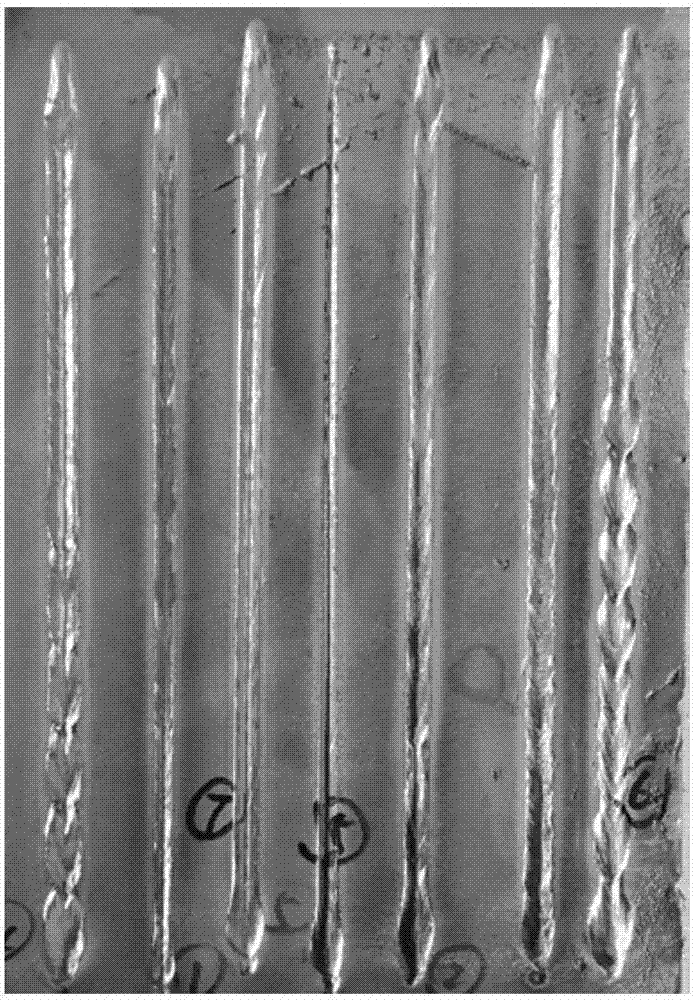

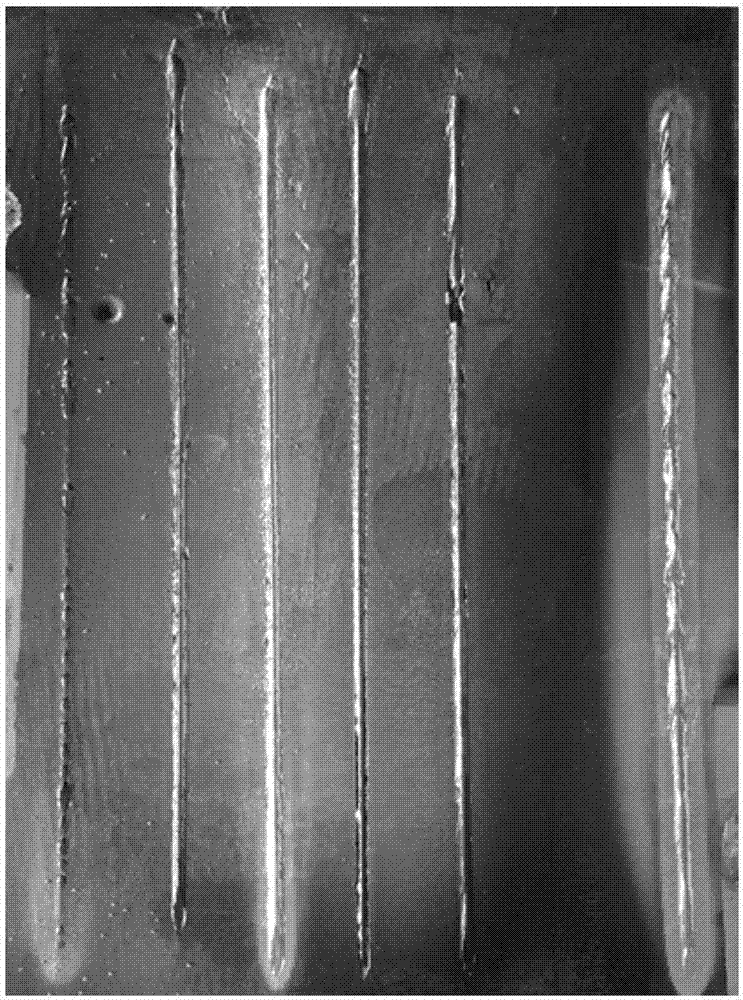

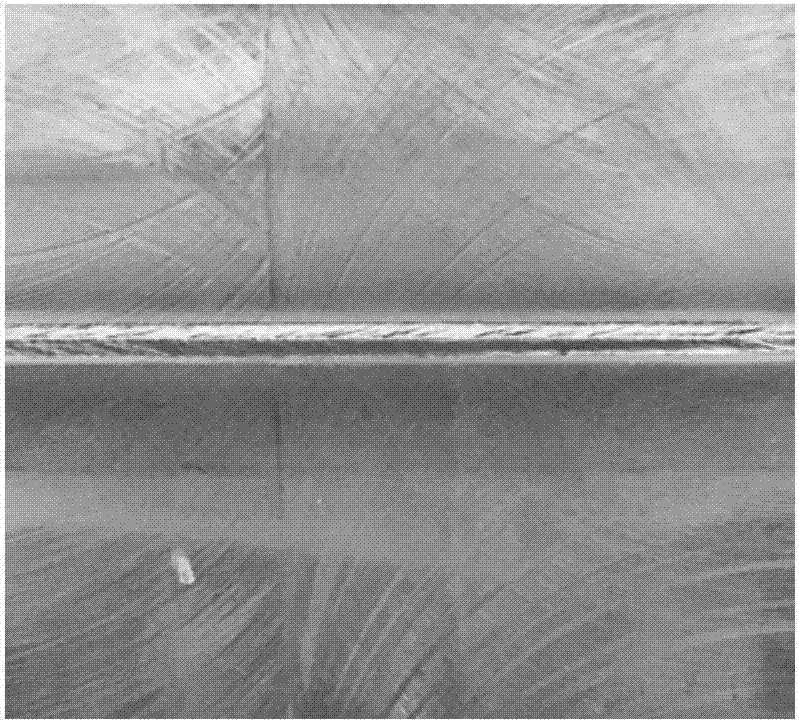

Welding method for high-temperature titanium alloy thin-wall casting electron beam

ActiveCN106862746AImprove welding qualityReduce plasticityElectron beam welding apparatusWelding/soldering/cutting articlesMelting tankHeat-affected zone

Disclosed is a welding method for a high-temperature titanium alloy thin-wall casting electron beam. High-temperature titanium alloy is preheated, subjected to heat preservation and then welded. A weld joint can obtain high energy through preheating before welding. A molten pool can be pushed forwards continuously during welding, so that the shape of the weld joint is beautiful. In addition, the area scanned by preheating before welding is larger than that obtained during welding, thus the structure of a weldment weak link, namely a heat affected zone, is heated, the temperature gradient of the weld joint and the heat affected zone is reduced, thus the structure in the heat affected zone can achieve smooth transition, and the influence caused by incoordinate deformation is weakened. For a thick weldment, the condition of incomplete melting of the weld joint can be avoided through preheating before welding. The area scanned by postweld heat treatment is the same as that of preheating before welding, the cooling rate of the weld joint and part of the heat affected zone is lowered, many acicular martensite and widmannstatten structures are prevented from being generated, and the quality of the weld joint is improved obviously.

Owner:重庆两航金属材料有限公司

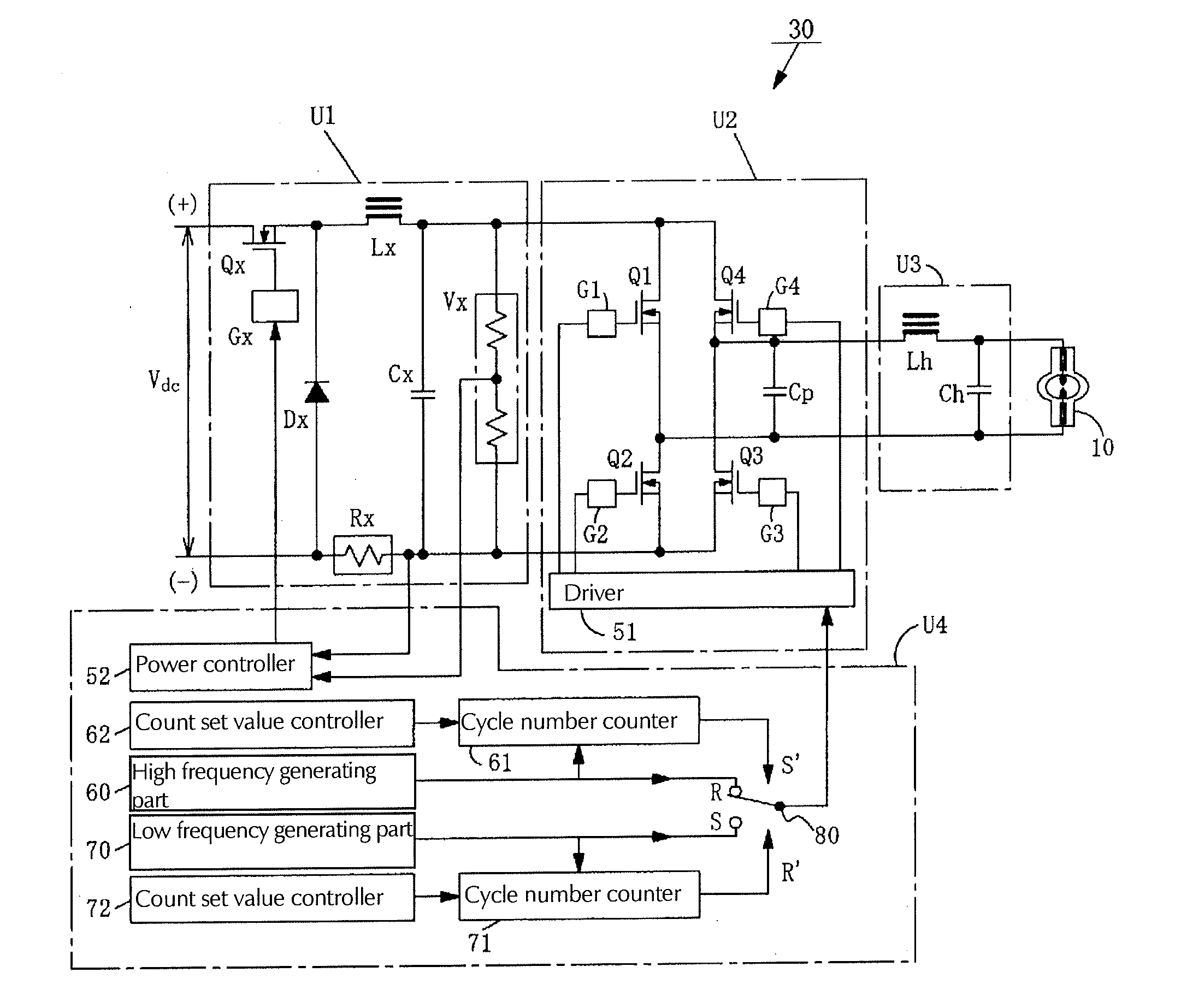

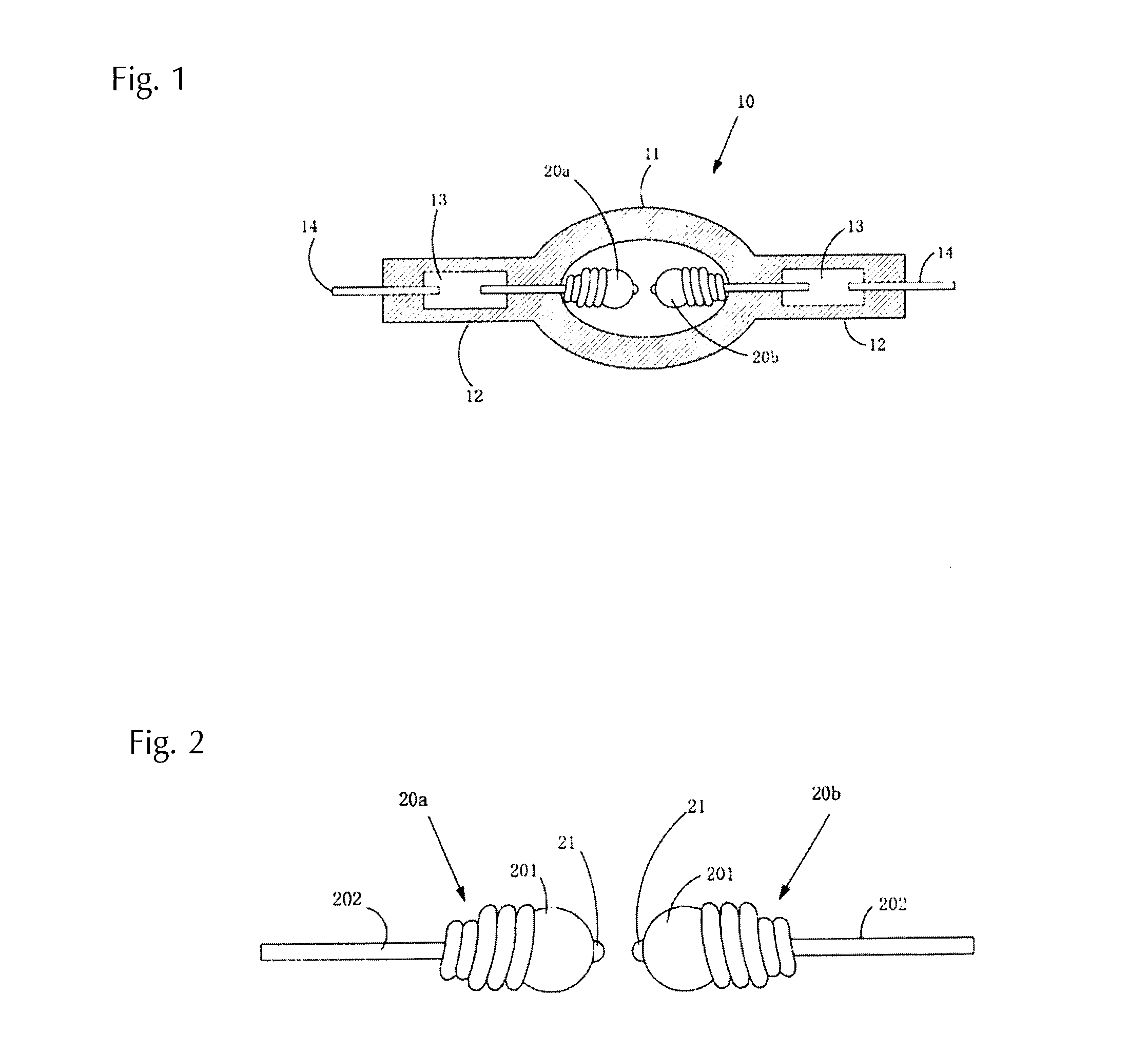

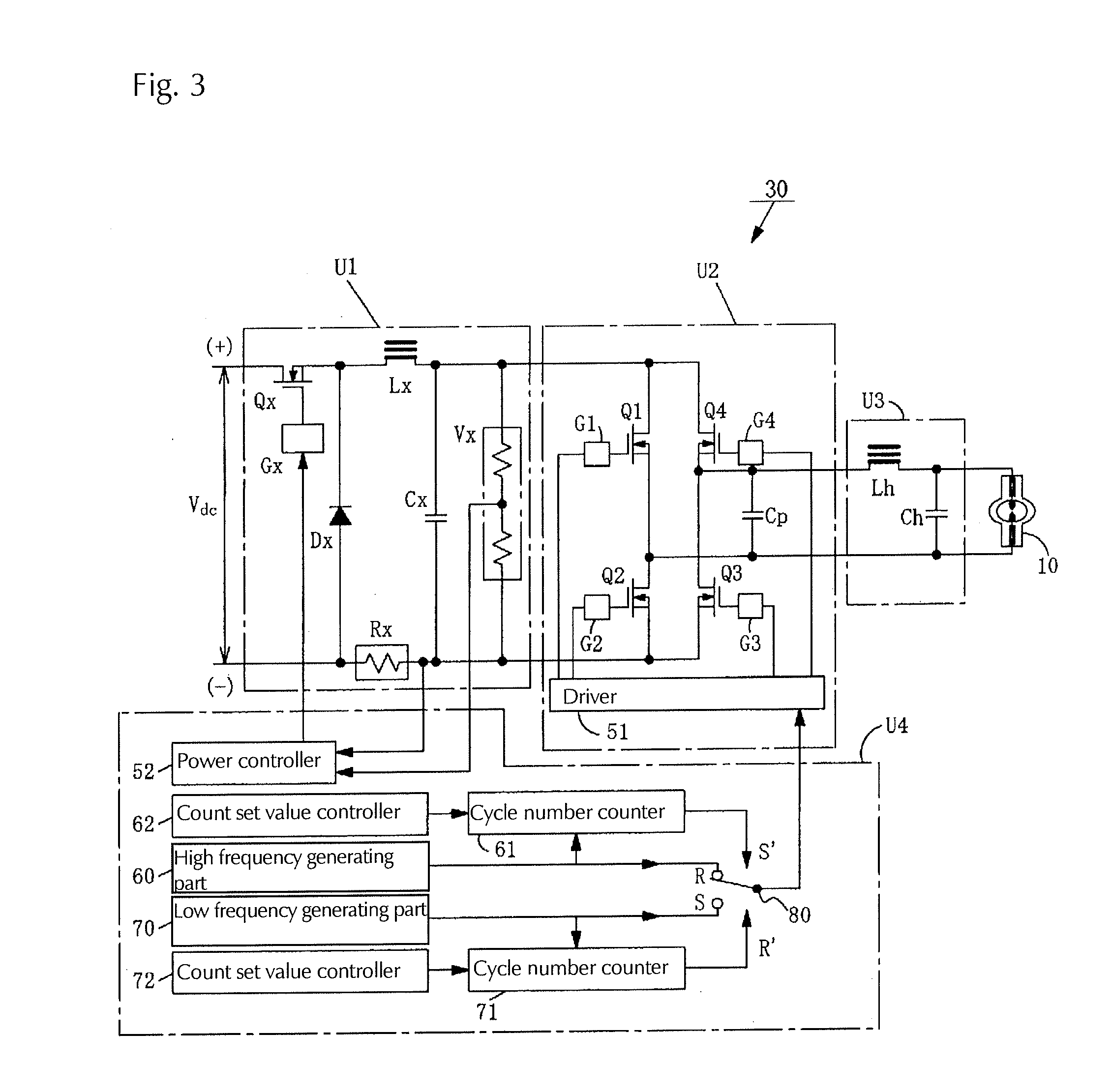

High pressure discharge lamp lighting device

ActiveUS20120313546A1Improve balanceGood body shapeElectrical apparatusElectric lighting sourcesGas-discharge lampElectrical polarity

To maintain the shape of the projection on the electrodes of the tip end for a long time to extend the lifetime of a discharge lamp, a lighting device lighting a high pressure discharge lamp supplies alternating current such that an alternating current with a basic frequency at the time of the steady state lighting selected from a range between 60 and 1000 Hz and a low frequency of a half cycle with a frequency lower than the basic frequency are generated alternatingly. The alternating current is supplied such that the waveform with one polarity of the low frequency appears consecutively at least twice. It is also possible for the alternately generated low frequency to be lower than the basic frequency in a range from 5 to 200 Hz, and for the interval during which the basic frequency is supplied to be gradually increased and decreased at specified times.

Owner:USHIO DENKI KK

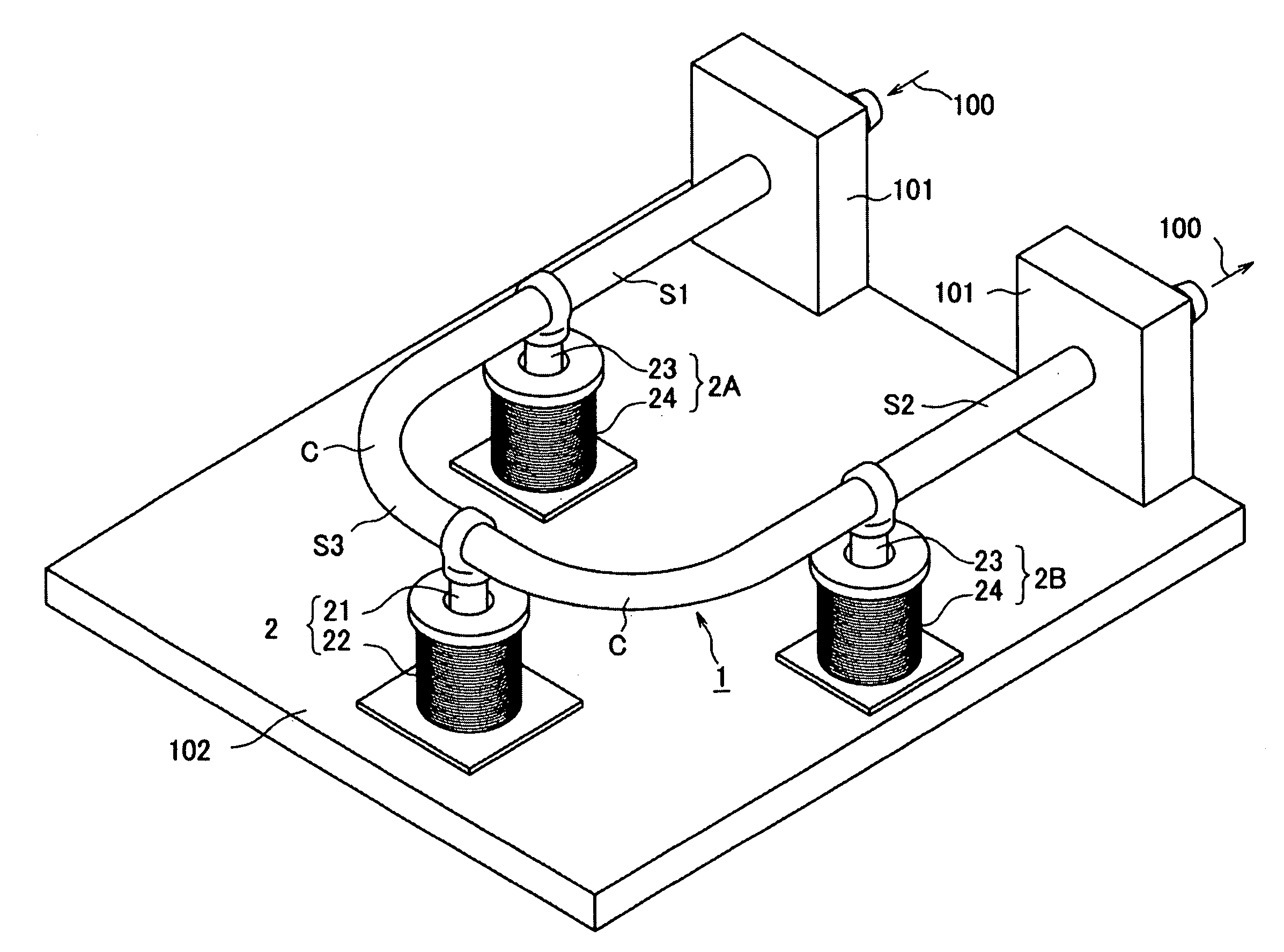

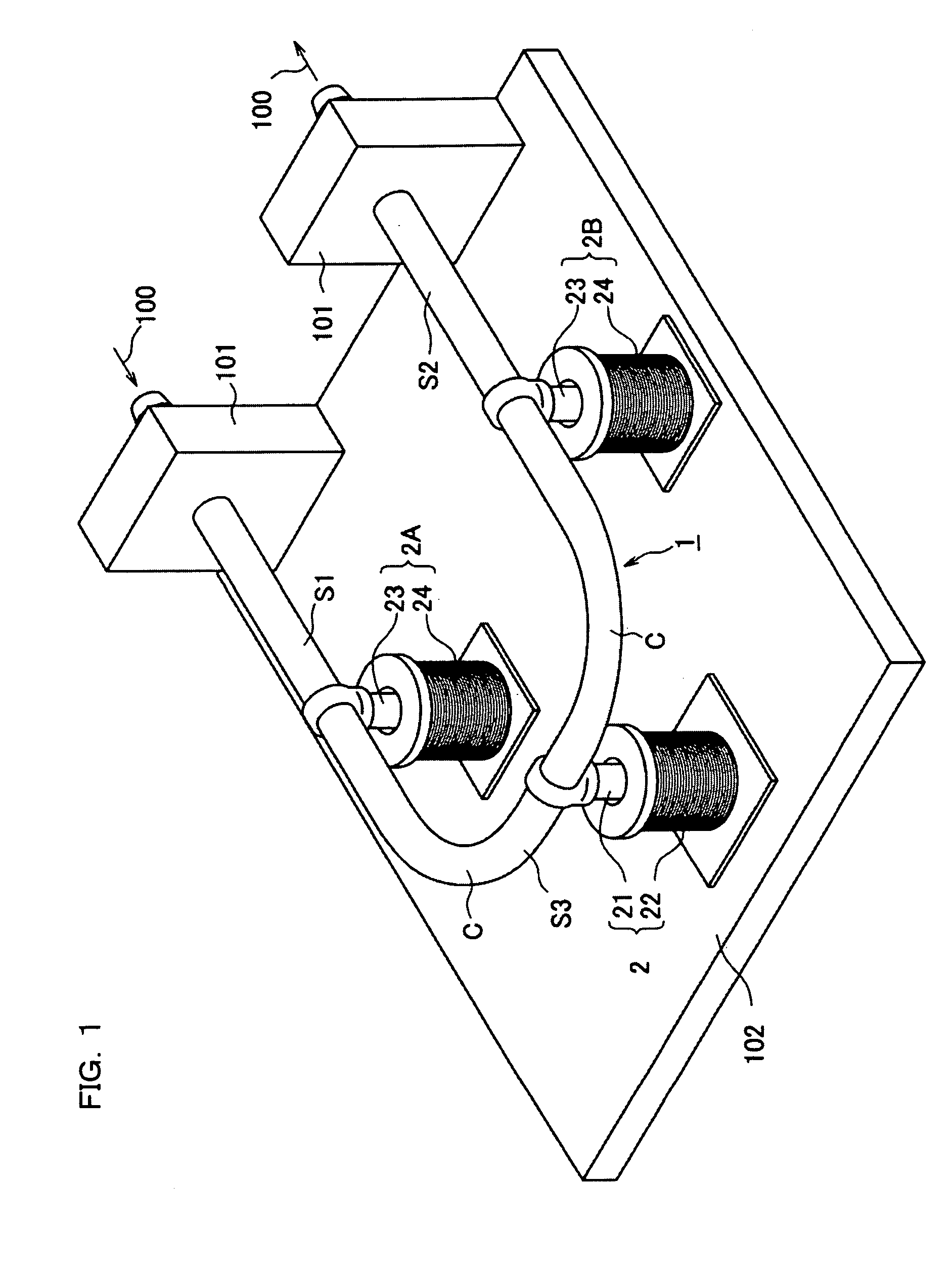

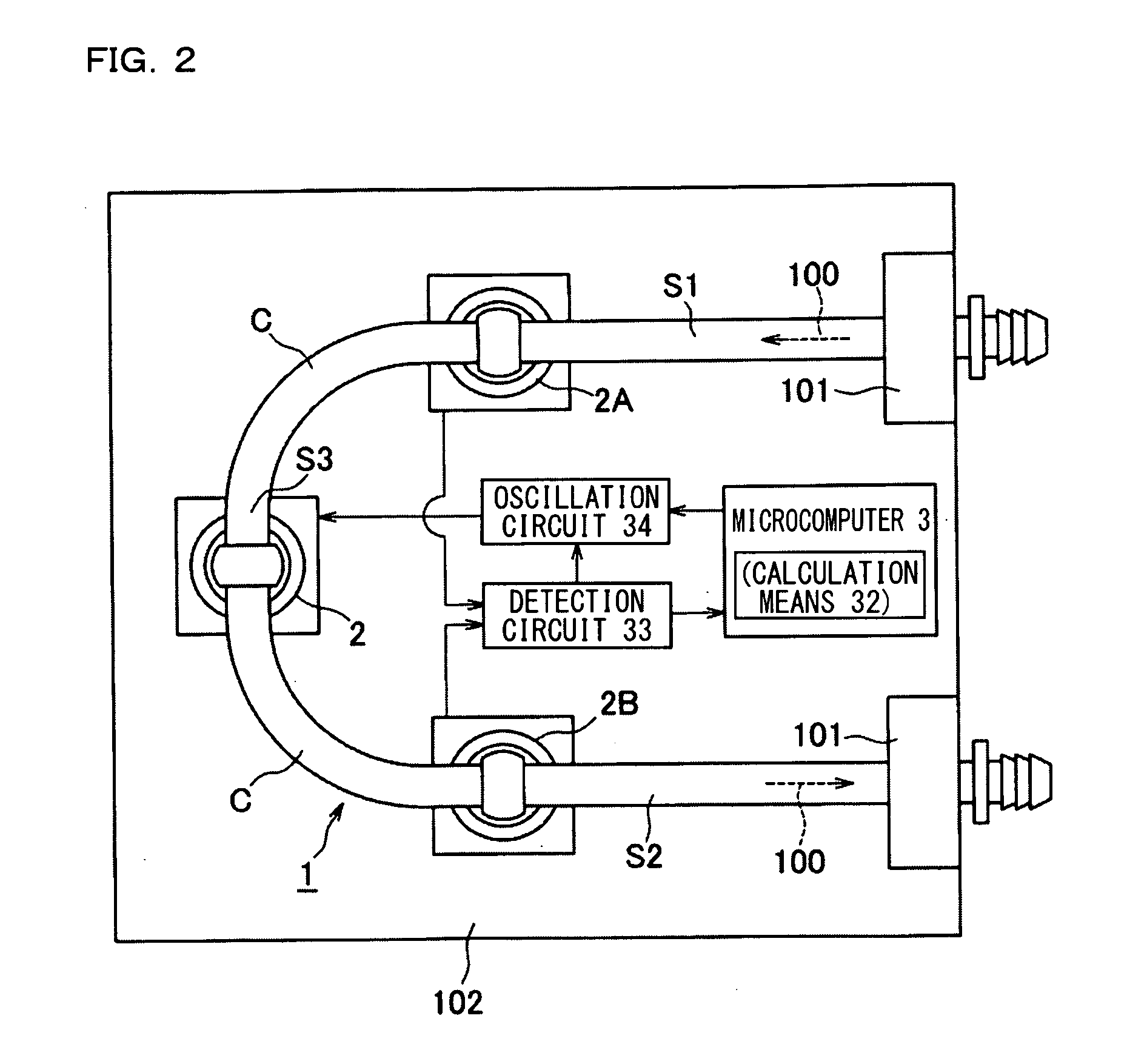

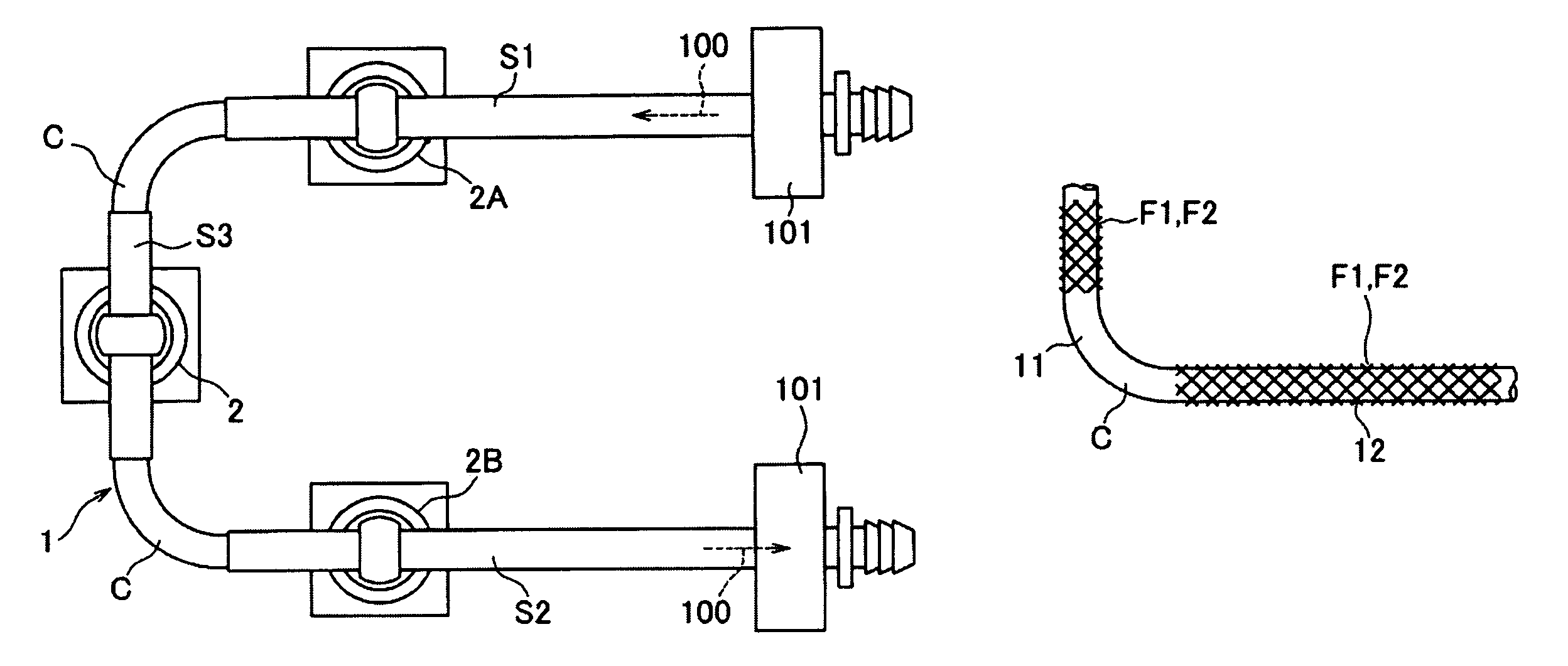

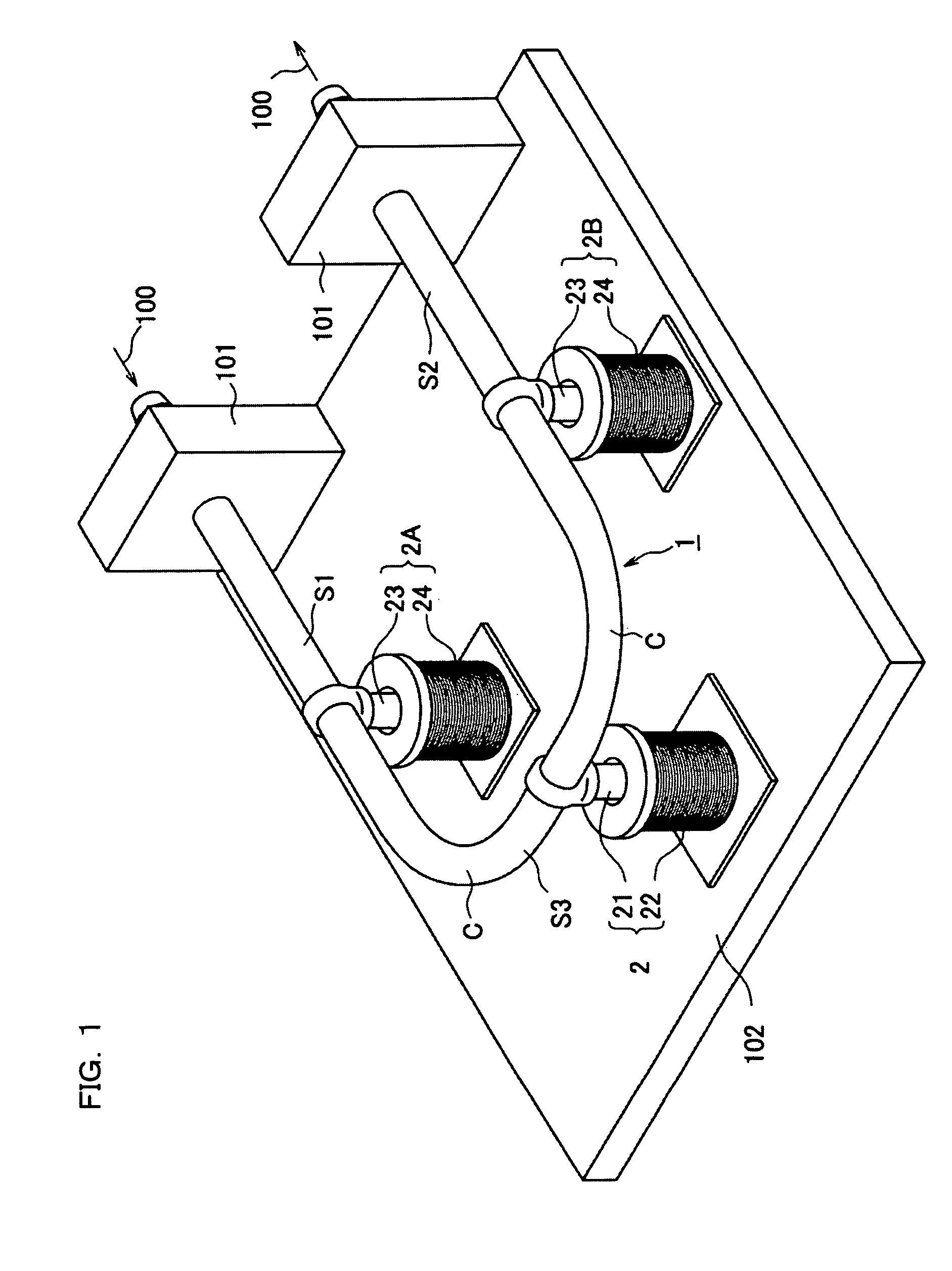

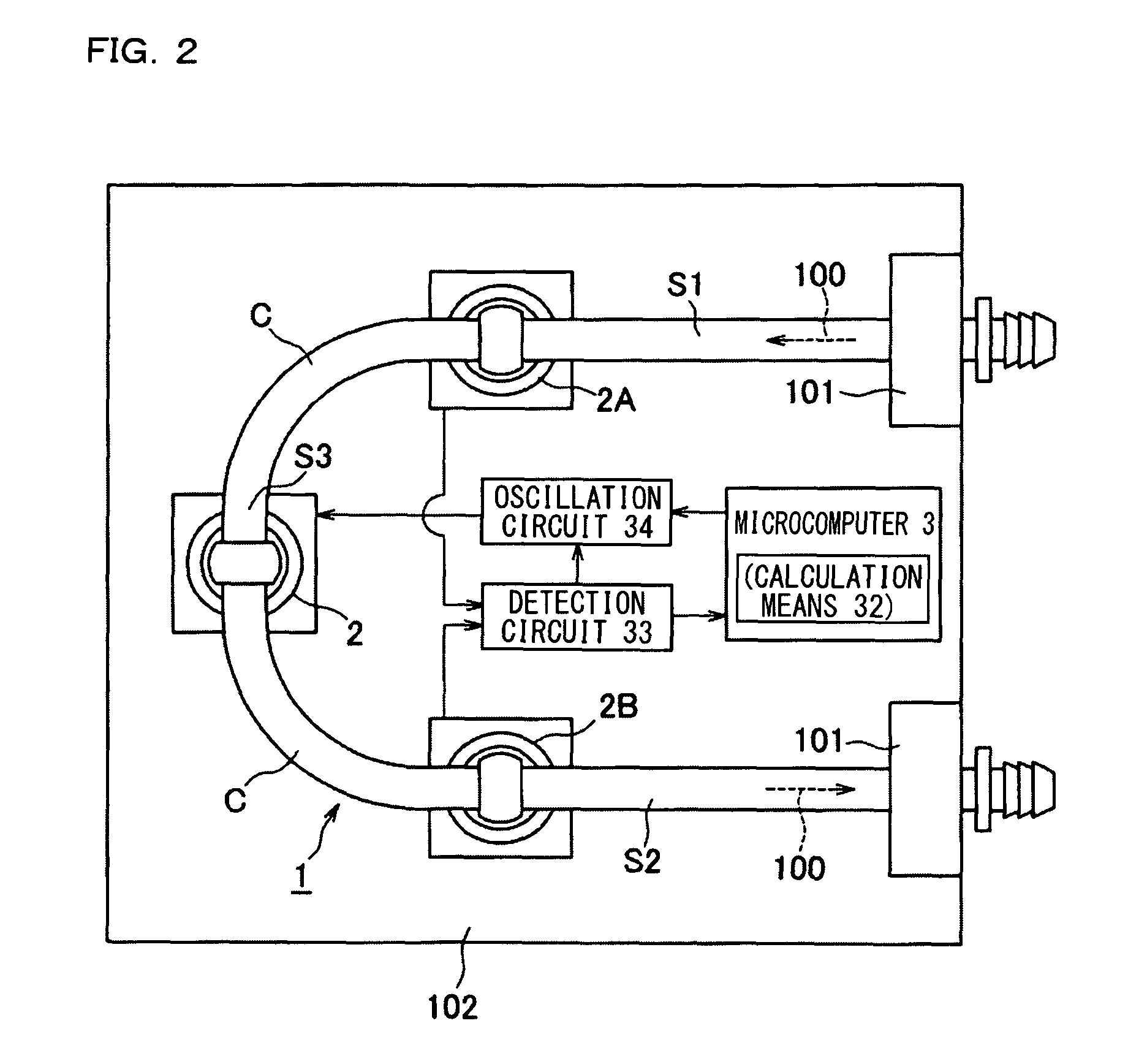

Flowmeter

InactiveUS20090173167A1Large elastic modulusImprove rigidityVolume meteringVolume/mass flow by dynamic fluid flow effectFiberStreamflow

A Coriolis flowmeter includes an oscillator for oscillating a fluid pipe that forms a flow path for allowing a measurement fluid to flow; first and second detectors that are disposed to be spaced apart from each other along the flow path of the fluid pipe so as to detect a state of oscillation of the fluid pipe; and a calculator for calculating a mass flow rate of the measurement fluid that passes through the flow path of the fluid pipe on the basis of a relative amount of the states of oscillation that are detected by the first and second detectors. The fluid pipe includes an inner pipe made of a fluororesin whose inner circumferential surface is in contact with the flow path, and an outer pipe having fibers that are arranged in order to surround an outer circumferential surface of the inner pipe and a resin that is cured in a state of close adhesion between the fibers arranged in order, and having an elastic modulus larger than that of the inner pipe.

Owner:KEYENCE

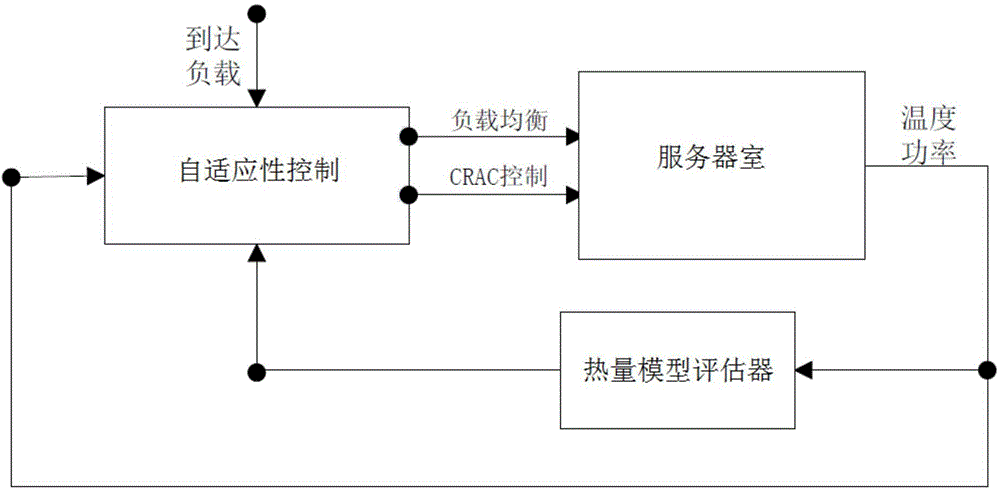

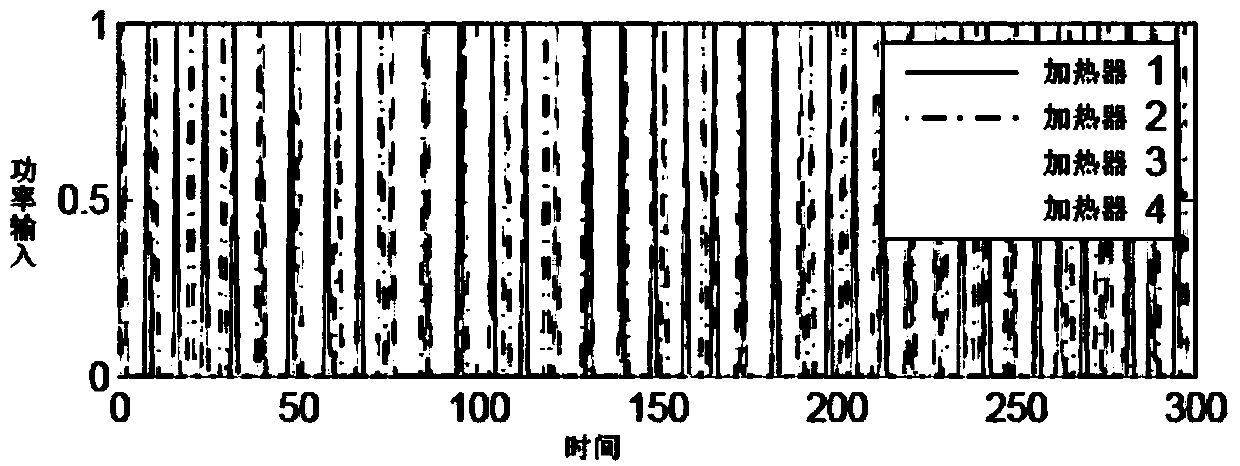

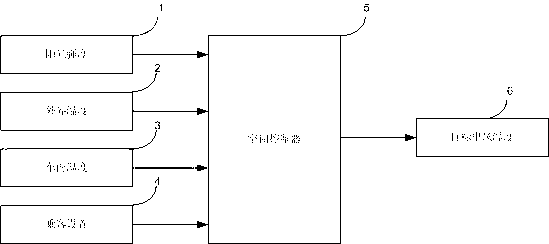

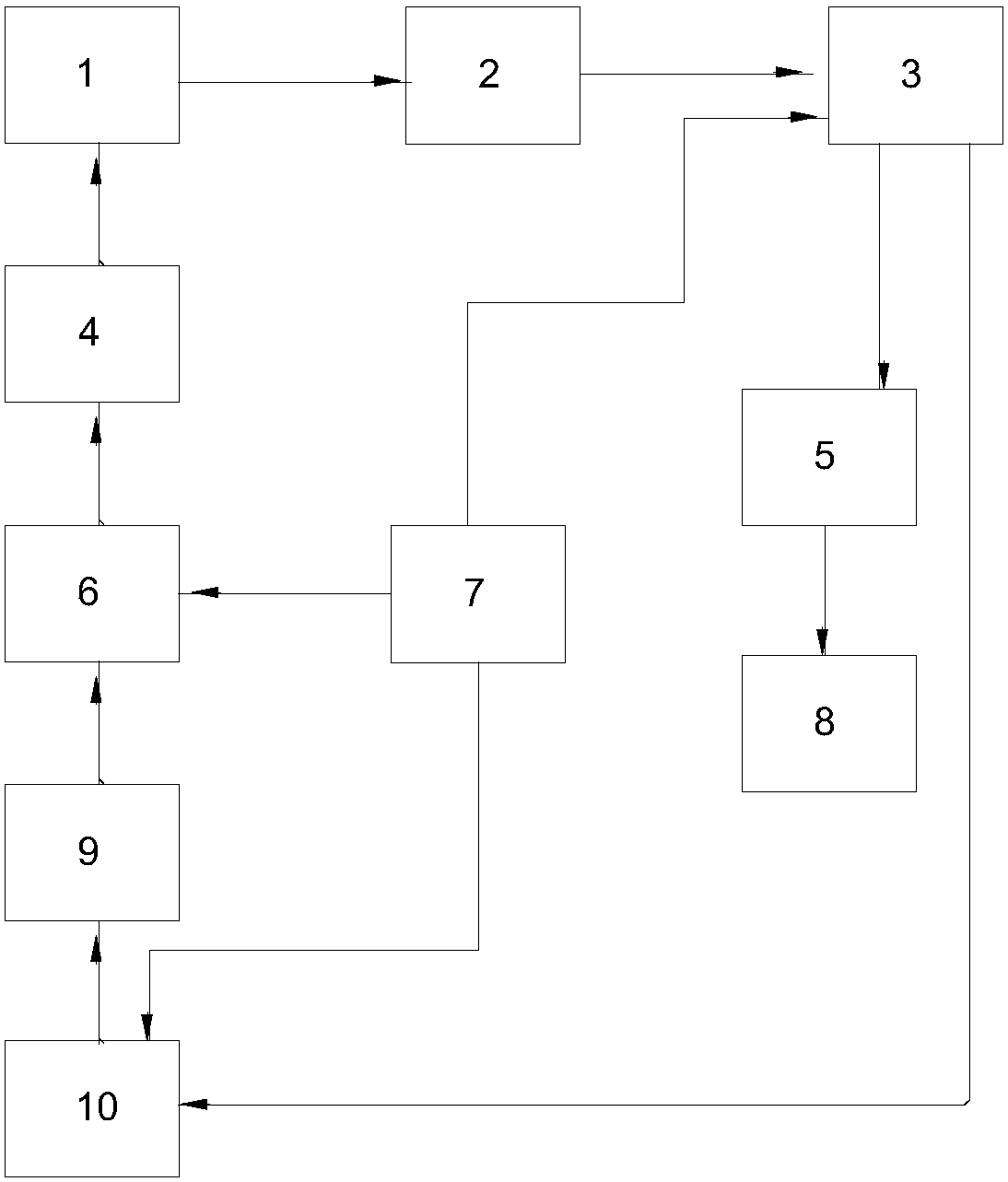

Data center self-adapting energy consumption management method based on heat load balancing

ActiveCN104158754ASmooth temperature changeReduce load peaksPower supply for data processingData switching networksData centerDistributed servers

The invention discloses a data center self-adapting energy consumption management method based on heat load balancing. In each sampling time, the following steps are adopted to perform energy consumption management: 1) using an RLS model to estimate server power consumption; 2) optimizing and solving the cost function within constraint conditions to obtain the optimal Up (k); 3) selecting the first group U (k|k) as a real manipulated variable U (k); 4) calculating the number mj of required active servers; 5) uniformly distributing the tasks to each rack. The data center self-adapting energy consumption management method can dynamically distribute server tasks to reduce the total power consumption of the server in the data center and a cooling system.

Owner:SHANGHAI JIAO TONG UNIV

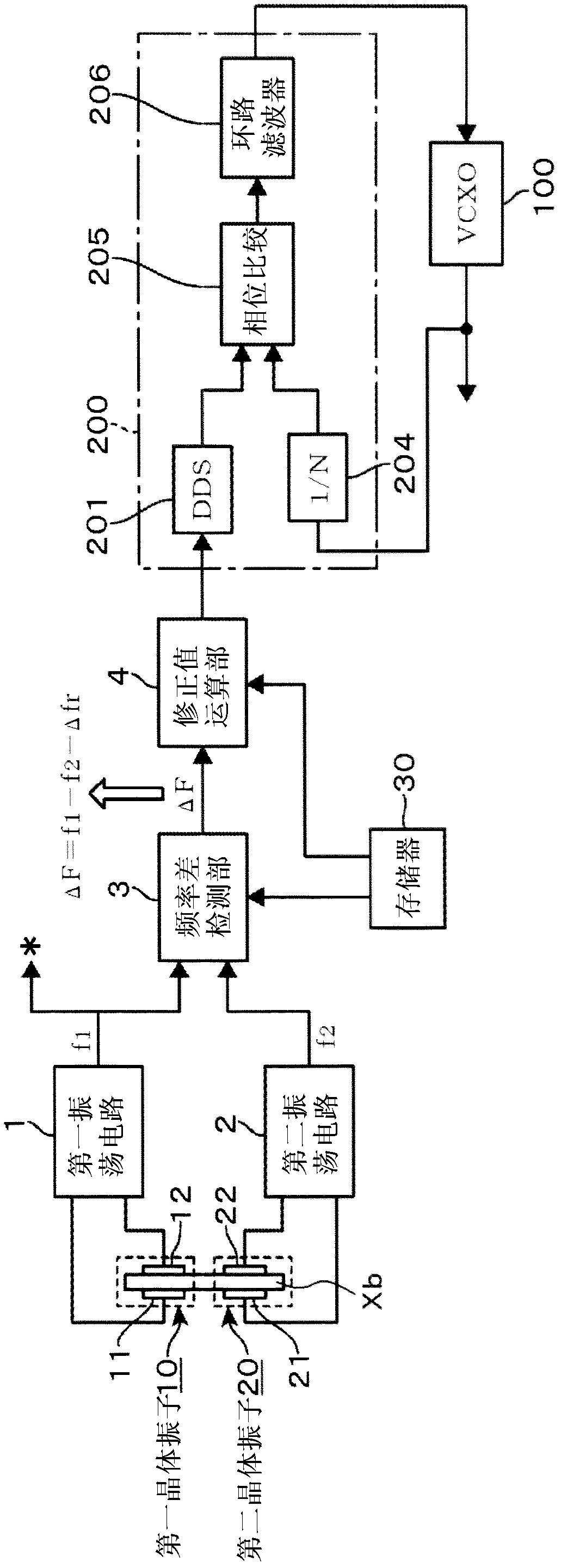

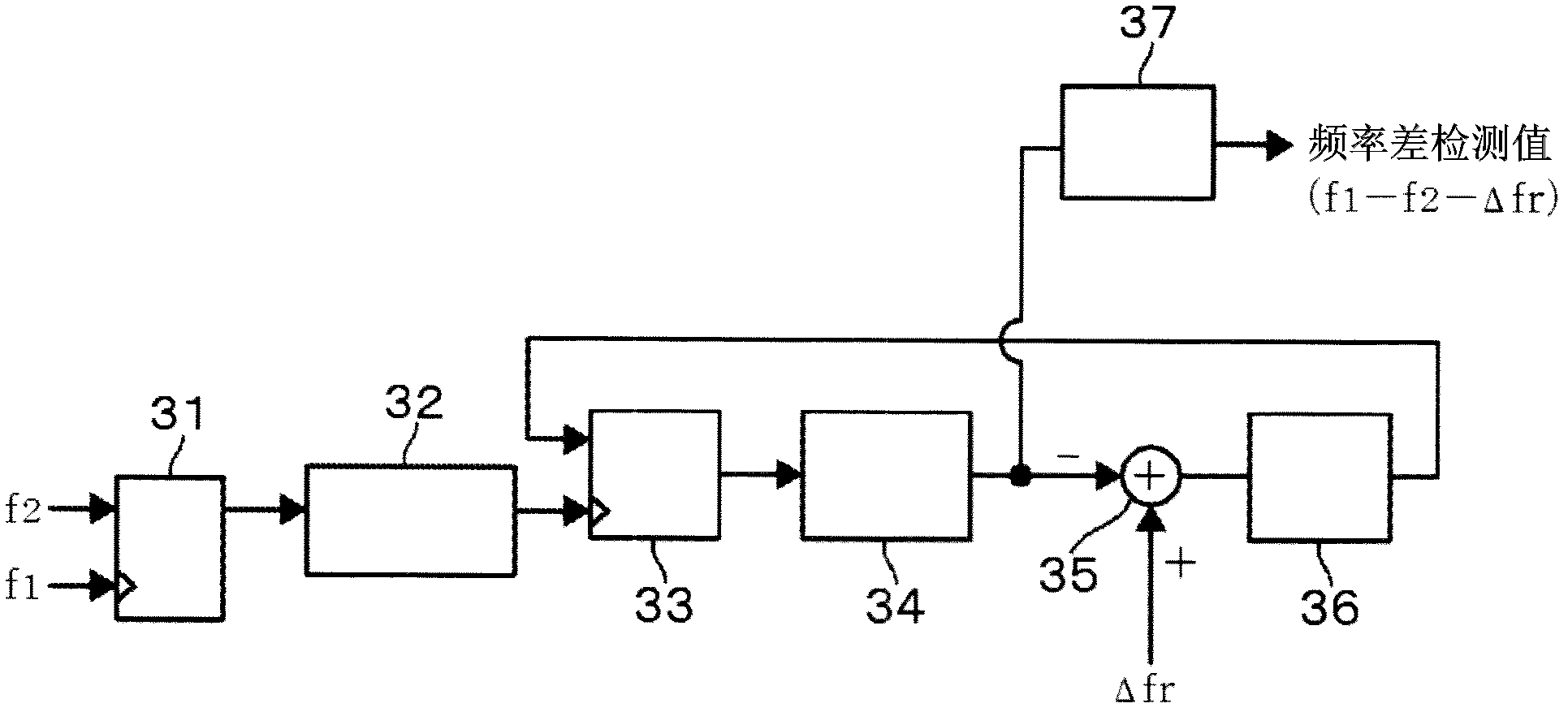

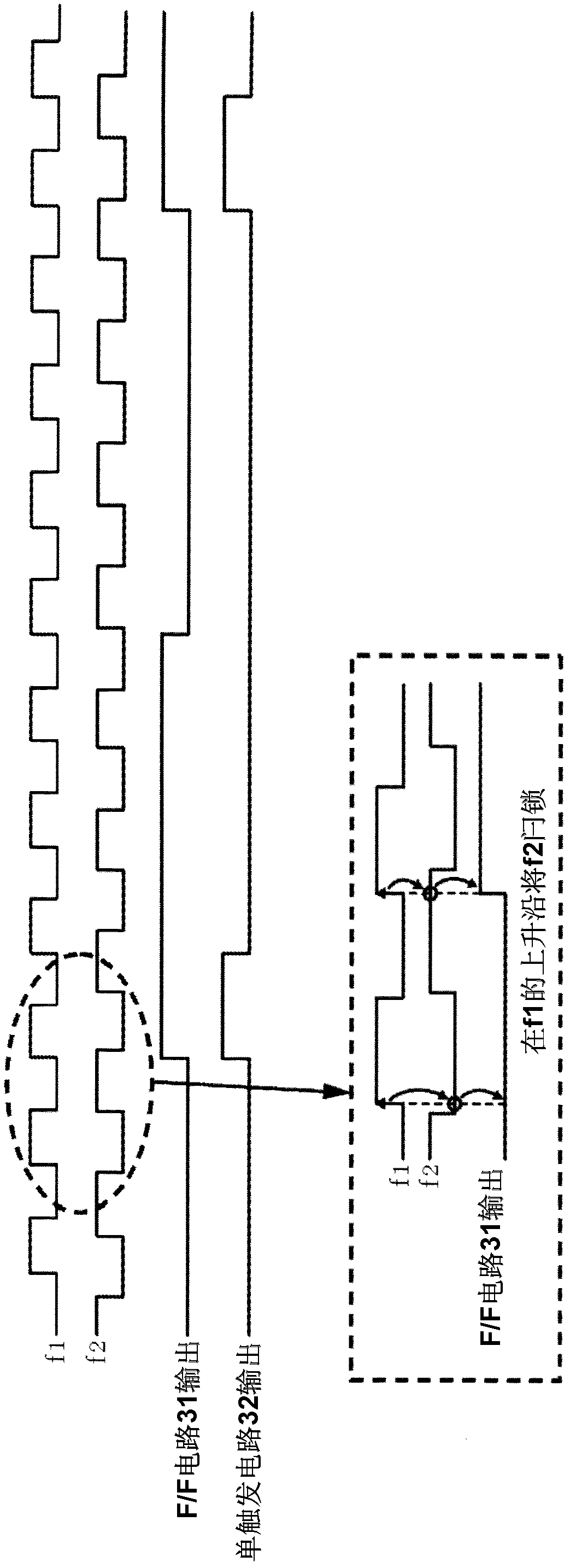

Oscillation device

ActiveCN102624330AHigh precision temperature compensationSmooth temperature changePulse automatic controlGenerator stabilizationQuartz crystal resonatorAtomic physics

An oscillation device capable of highly accurate temperature compensation of an output frequency is provided. The oscillation device includes: first and second oscillator circuits oscillating first and second quartz-crystal resonators with overtones respectively; a frequency difference detecting part finding a value corresponding to a difference value between values corresponding to differences between f1 and f1r and between f2 and f2r, where f1 and f2 are oscillation frequencies of the first and second oscillator circuits, and f1r and f2r are oscillation frequencies of the first and second oscillator circuits at a reference temperature; and a correction value obtaining part which, based on the value corresponding to the difference value and a relation between the value corresponding to the difference value and a frequency correction value of the oscillation frequency f1, obtains the frequency correction value of f1, wherein the output frequency is corrected based on the found frequency correction value.

Owner:NIHON DEMPA KOGYO CO LTD

Biodegradable material and preparation method thereof

The invention discloses a biodegradable material and a preparation method thereof. The biodegradable material comprises, by weight, 20-50% of material A, 40-60% of material B and 20-40% of PBAT thermoplastic biodegradable plastic. The material A comprises, by weight, 40-60% of PBAT thermoplastic biodegradable plastic, 30-50% of PLA and 8-15% of inorganic filler. The material B comprises, by weight, 40-60% of PBAT thermoplastic biodegradable plastic and 40-60% of starch masterbatch, wherein the starch masterbatch comprises, by weight, 60-70% of starch, 1-3% of coupling agent, 1-3% of paraffin,25-30% of glycerin, 0.1-0.3% of citric acid and 2-5% of epoxidized soybean oil.

Owner:DONGGUAN XINHAI ENVIRONMENT PROTECTION MATERIAL

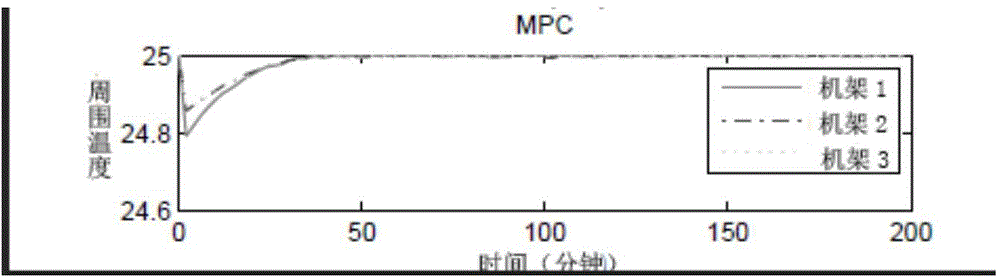

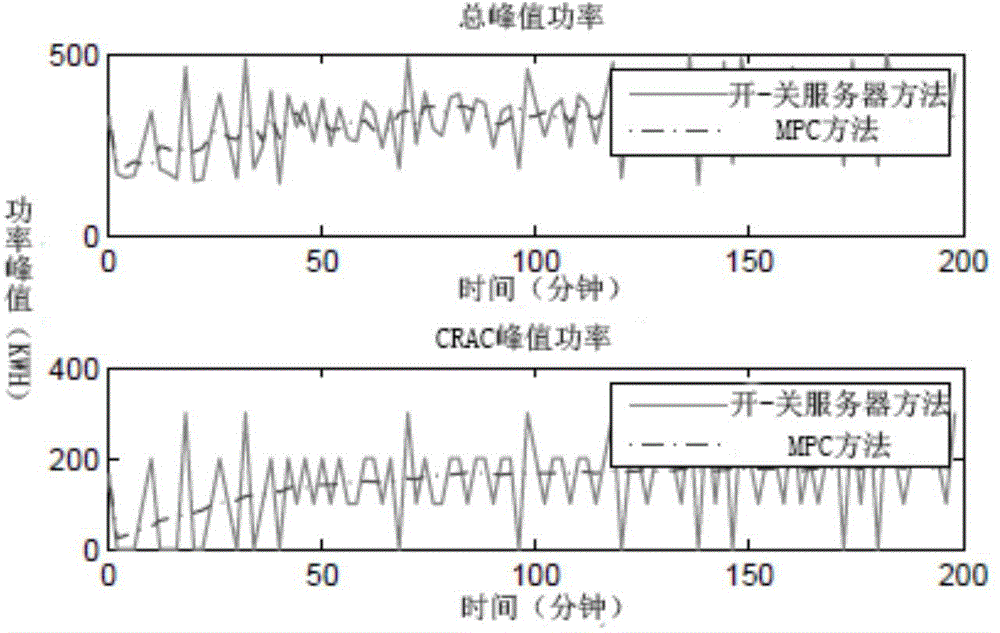

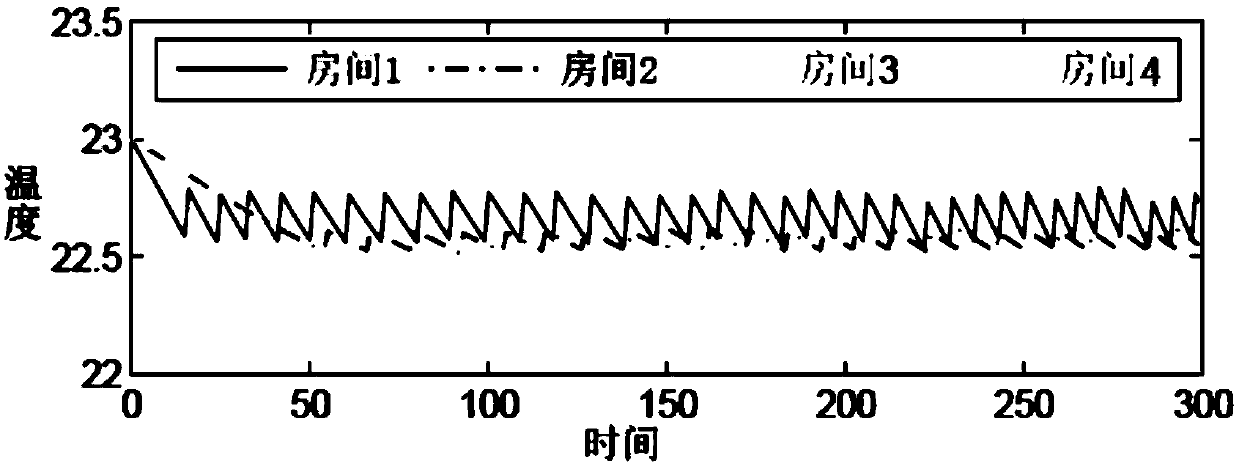

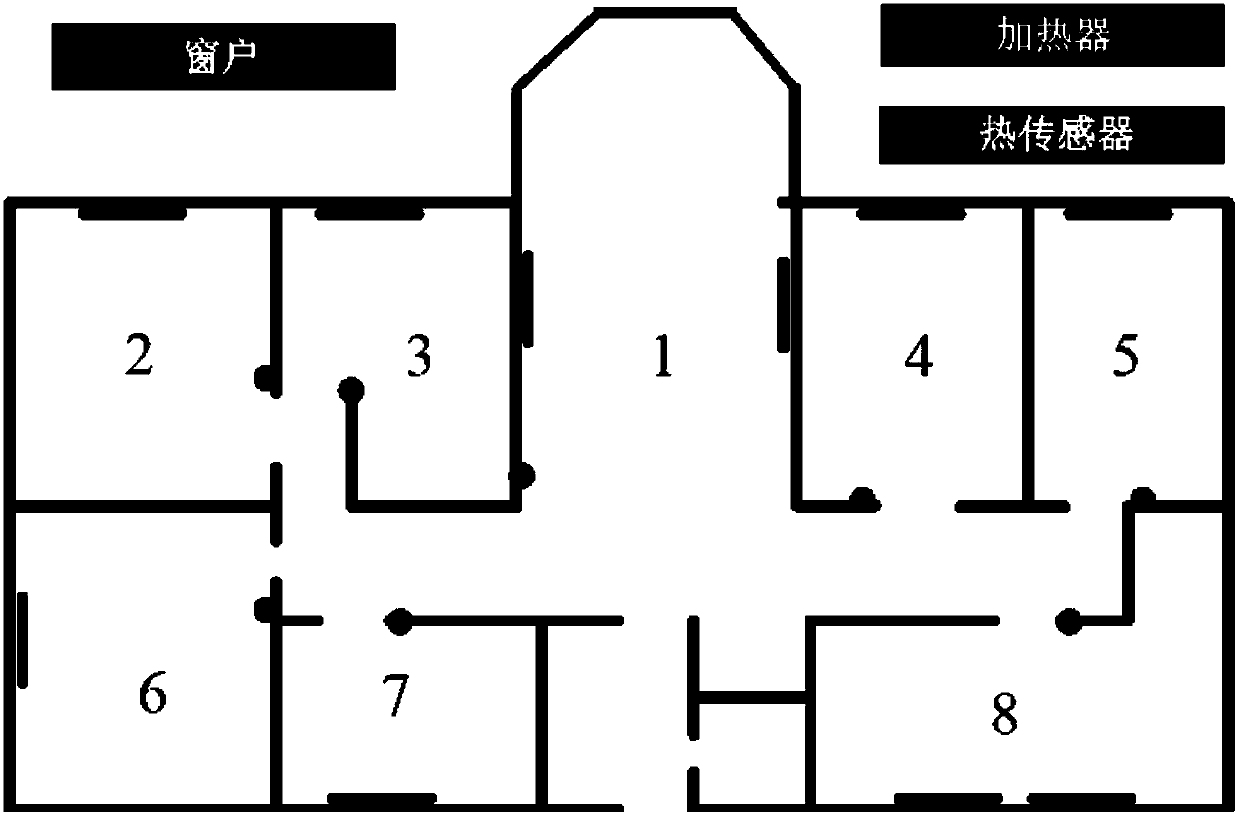

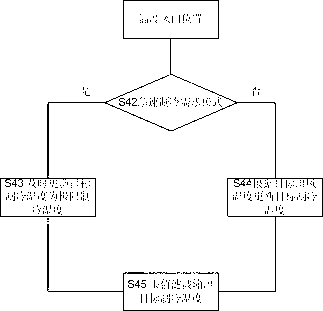

Heat prediction management based energy consumption control method in intelligent building

ActiveCN104298191AReduce peak powerGood schedulability analysisProgramme total factory controlRoom temperatureState space

The invention provides a heat prediction management based energy consumption control method in an intelligent building, which comprises the steps of 1, establishing a heat model of the building; 2, establishing a thermodynamic model in a state space; 3, carrying out a schedulability test and judging whether a heat load of the building has schedulability or not under given energy consumption load budget; and 4, operating a model predictive control (MPC) based heat control strategy to solve a corresponding control output variable. According to the invention, an HVAC (heating, ventilating and air conditioning) system in the building is adjusted, and the peak power is enabled to be reduced under various constraints such that the room temperature is small in variation, a task processing constraint is met, and the like. In addition, the system can carry out schedulability analysis very well, and carries out good judgment and correction on whether the current energy consumption budget can meet requirements or not.

Owner:SHANGHAI JIAO TONG UNIV

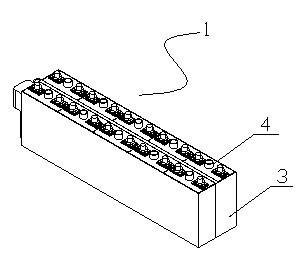

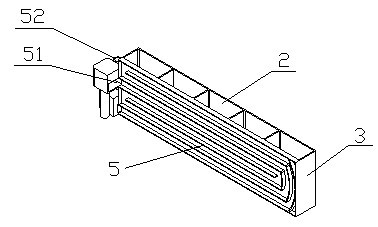

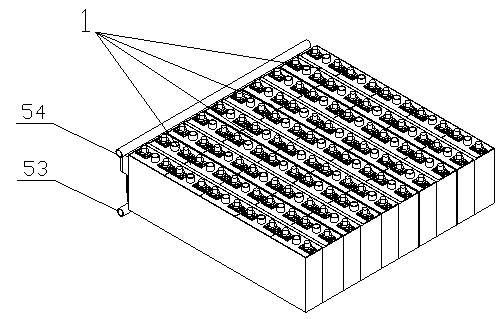

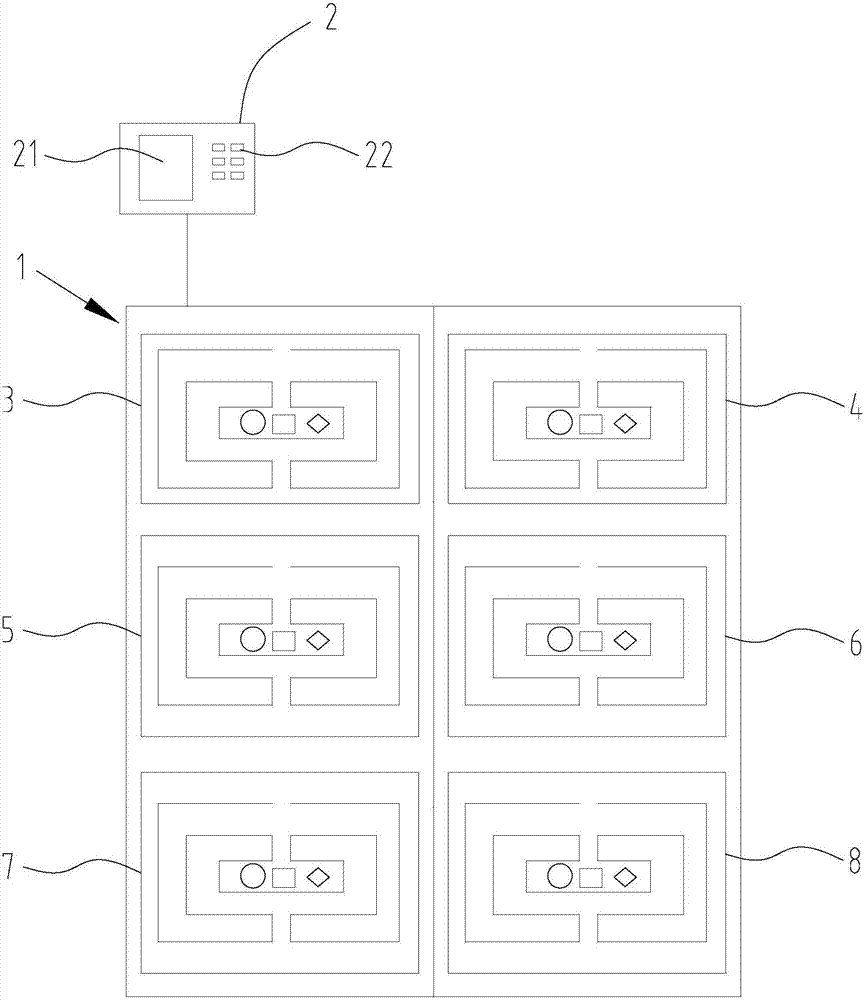

Battery pack with temperature adjusting function

The invention provides a battery pack with a temperature adjusting function, aiming to solve the problem that the temperature of the battery pack is too high or too low, so as to guarantee the performance and the service life of the battery pack. A power battery pack comprises a temperature adjusting device and a plurality of battery modules, wherein each battery module is provided with one shell with a plurality of empty cells and a battery single body is placed in each empty cell; the side wall of each empty cell is provided with a fluid pipeline, and a water inlet and a water outlet of each fluid pipeline are arranged on the side wall of the corresponding shell; the fluid pipelines of the battery modules are connected in series so as to form a fluid pipeline system; the temperature adjusting device is composed of a liquid pump, a heat radiator and a heater, which are connected through a pipeline; and the pipeline of the temperature adjusting device is connected with the fluid pipeline system to form a closed fluid loop. According to the battery pack disclosed by the invention, a fluid medium is used for cooling and heating the battery pack, cooling and radiating efficiencies are higher, the temperature change of the battery pack is slow and the temperature difference between surfaces of batteries can be kept within 3 DEG C, so that the performance and the service life of the battery pack can be effectively improved.

Owner:奇瑞新能源汽车股份有限公司

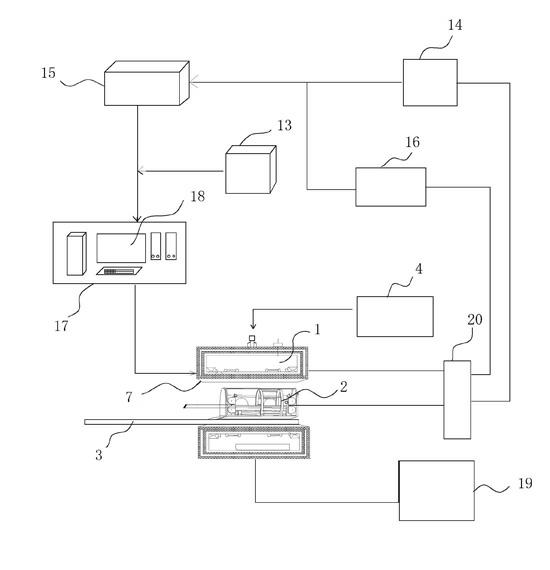

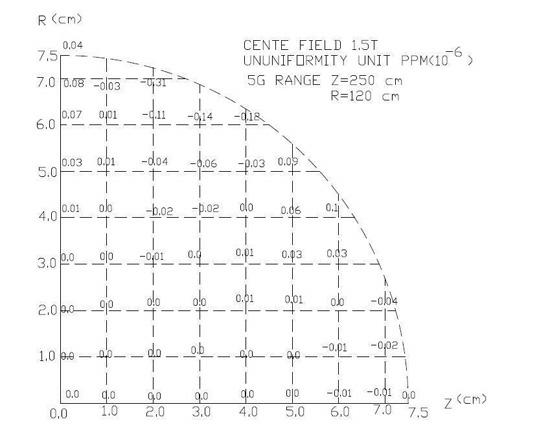

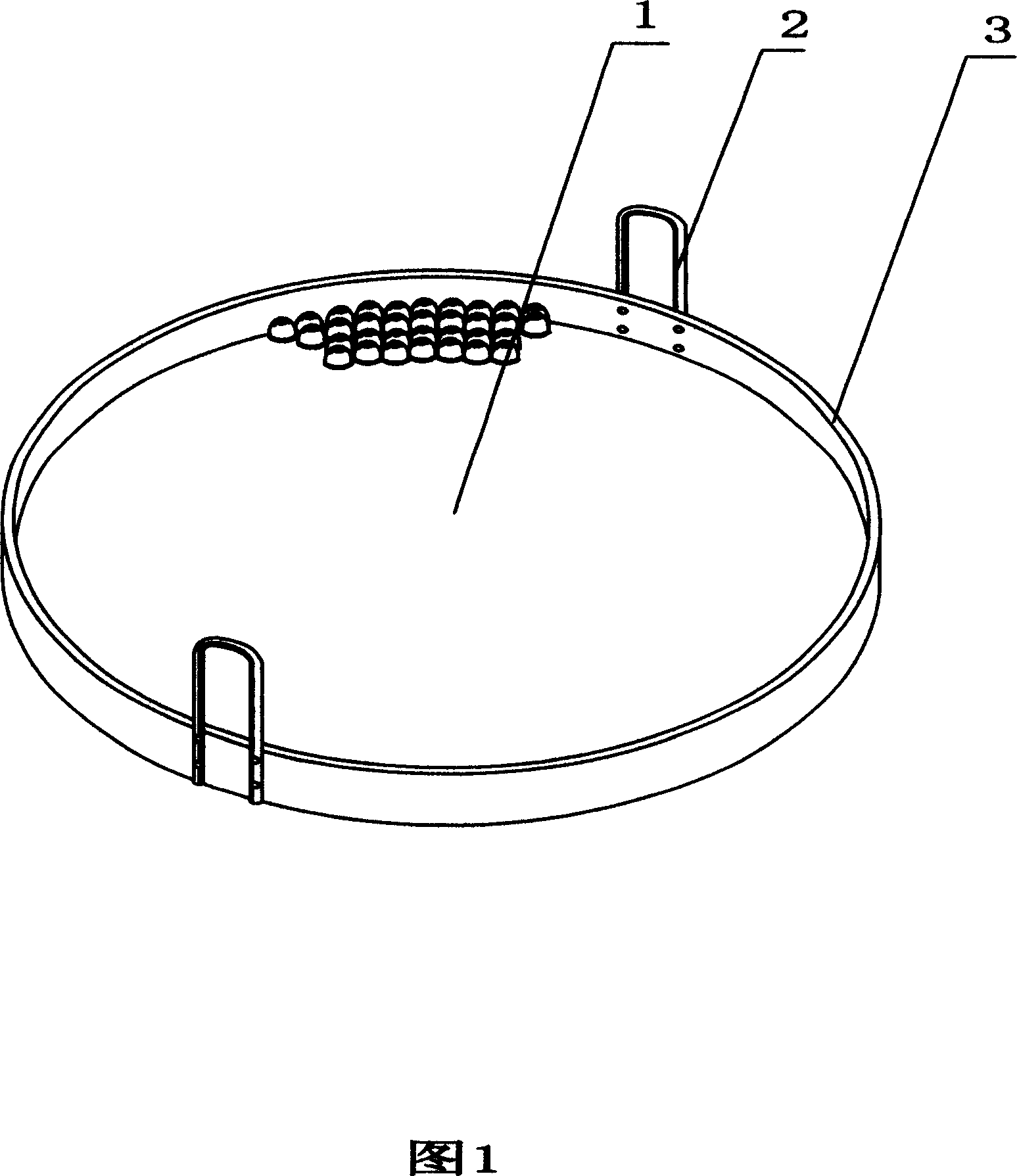

Special magnetic resonance imaging device for baby

ActiveCN102579047ASmall sizeUniform magnetic fieldDiagnostic recording/measuringSensorsSupporting systemSoftware system

The invention discloses a special magnetic resonance imaging device for a baby. The special magnetic resonance imaging device comprises a magnetic resonance imager, a filter board (20), a control device, a software system and a display system. The magnetic resonance imager consists of a superconducting magnet (1), a radio frequency system (2), a gradient system (7) and a patient supporting system (3). The superconducting magnet (1) comprises a superconducting magnetic field coil (5), a driving and driven shimming system (6) and a refrigerating system (4). The diameters of the inner walls of the superconducting magnetic field coil (5), the driving and driven shimming system (6) and the gradient system (7) are sequentially arranged in descending order. The refrigerating system is a classified refrigeration cycle system. By the adoption of the structure, the magnetic field is uniform; and the temperature variation is smooth and the environment is stable by the space positioning of a magnetic resonance imaging system signal and the two-stage refrigeration cycle system.

Owner:马启元

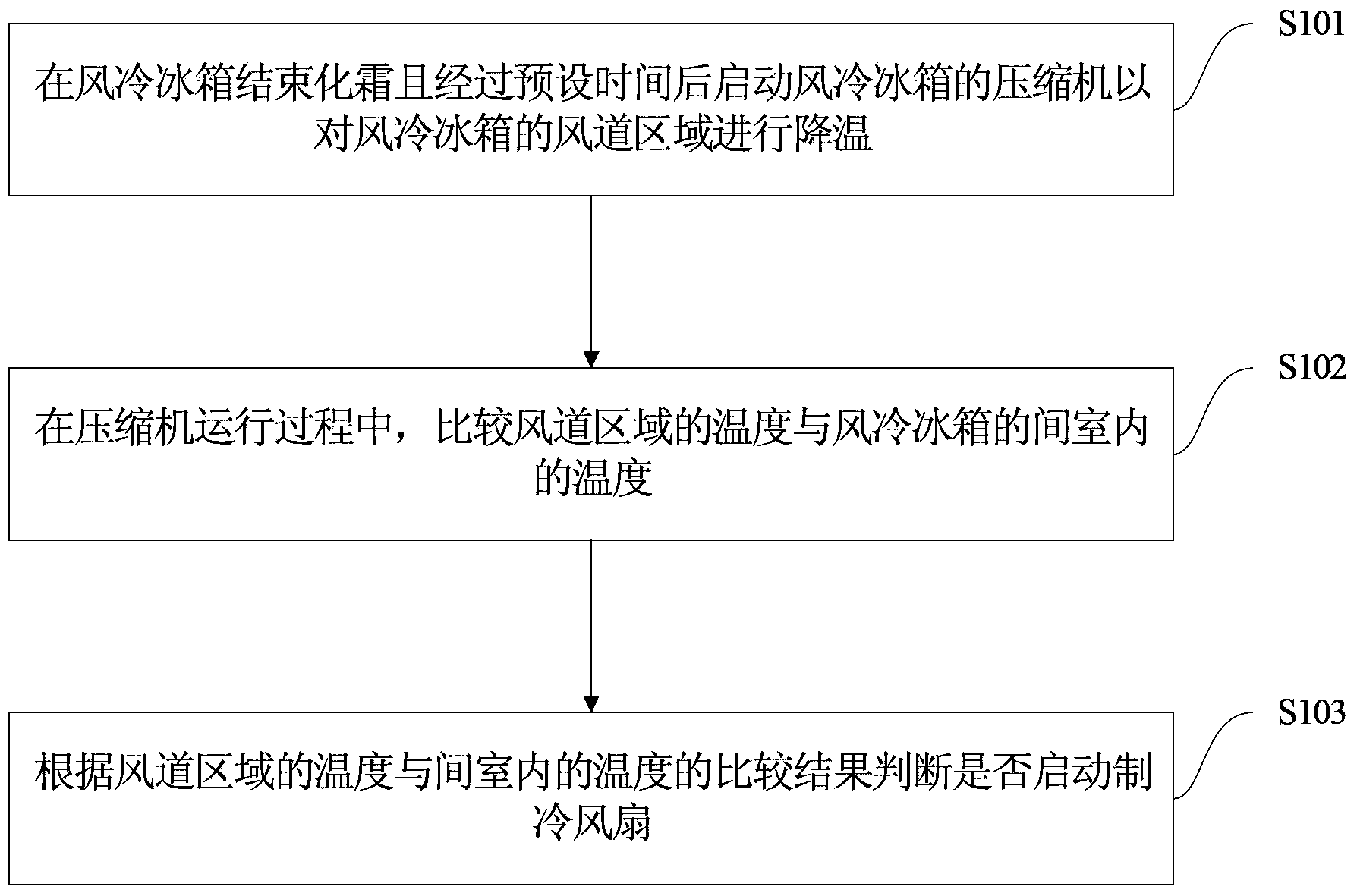

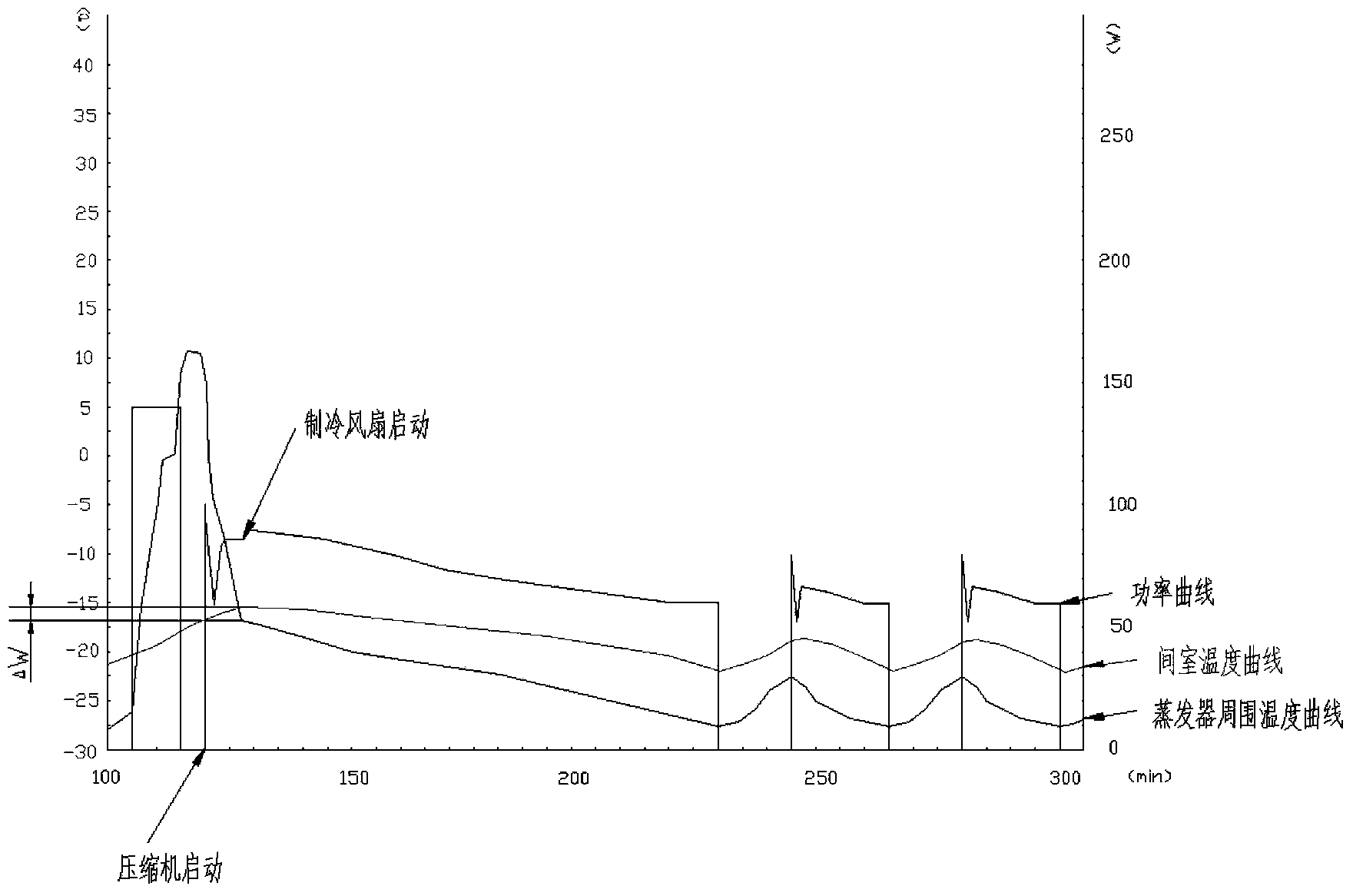

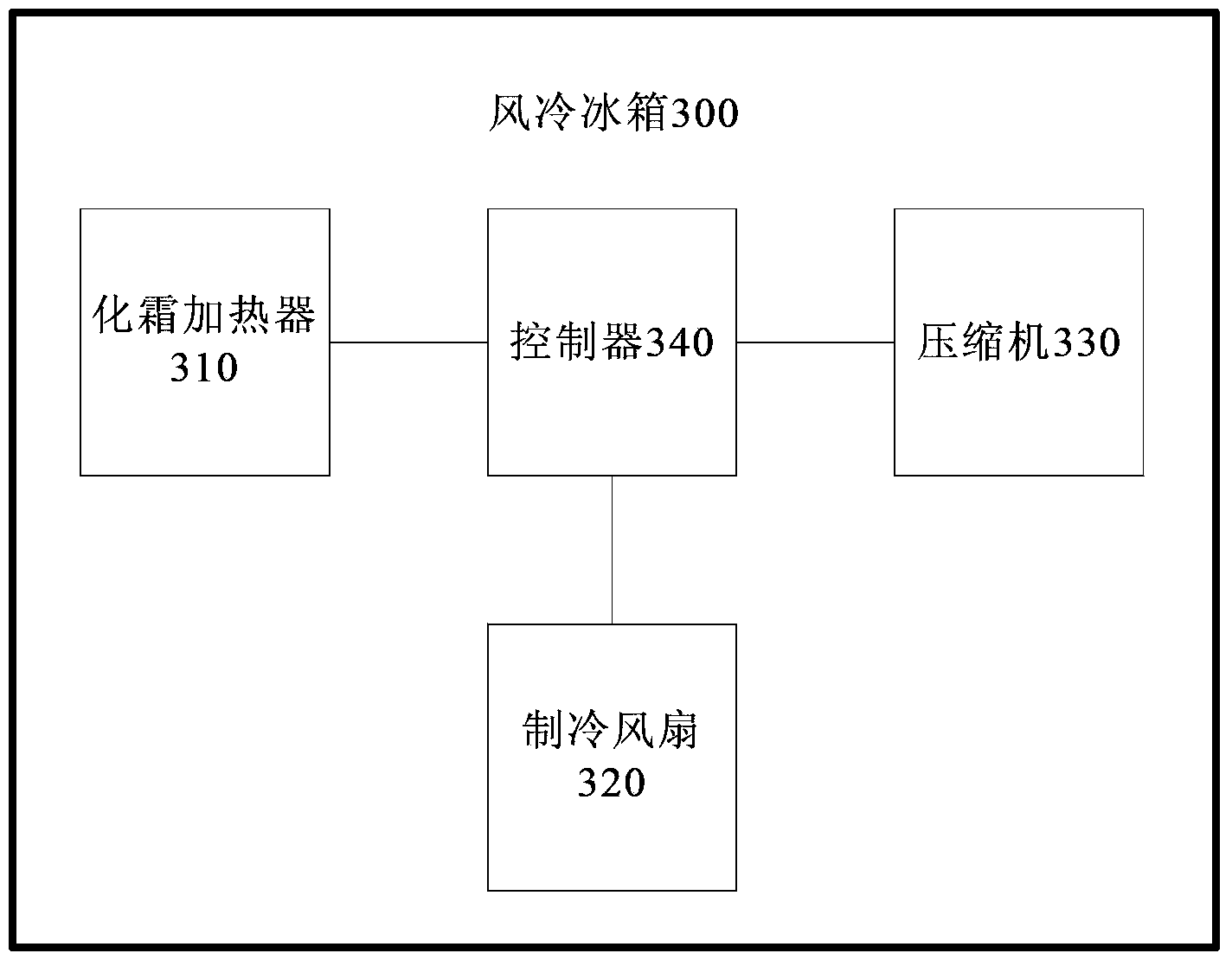

Control method of air cooling refrigerator and air cooling refrigerator

ActiveCN103471344AReduce energy consumptionGuaranteed energy consumptionDomestic cooling apparatusLighting and heating apparatusRefrigerationRefrigerated temperature

The invention provides a control method of an air cooling refrigerator. The control method comprises the following steps: after the air cooling refrigerator finishes defrosting and after a preset time, starting a compressor of the air cooling refrigerator, and cooling an air channel area of the air cooling refrigerator; during an operation process of the compressor, comparing temperature of the air channel area with temperature of a compartment of the air cooling refrigerator; and judging whether a refrigeration fan is started or not according to a comparison result of the temperature of the air channel area and the temperature of the compartment. According to the control method of the air cooling refrigerator provided by the embodiment of the invention, not only can small fluctuation of temperature in the compartment be ensured, but also the energy consumption of the refrigerator can be reduced. The invention also provides the air cooling refrigerator.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

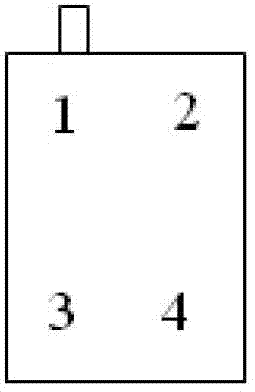

Method for pretreating raw polar plates for internal formation

ActiveCN103035884AReduce floating powderNo pollution in the processLead-acid accumulator electrodesPretreatment methodPre treatment

The invention discloses a method for pretreating raw polar plates for internal formation. The method comprises the following steps: (1), soaking the raw polar plates subjected to solidification and drying into dilute sulfuric acid with the density of 1.01 to 1.40 g / mL (at the temperature of 25 DEG C), wherein the soaking time of the positive plate is 20 to 80 minutes and the soaking time of the negative plate is 10 to 50 minutes; and (2), drying the soaked raw polar plates. By the pretreatment method, the raw polar plates are pretreated, the floating powder on the surfaces of the polar plates is obviously reduced, and dust pollution on a clamping board and a sheet wrapping board is basically avoided in the turnover process and the sheet wrapping process of the polar plates. By the pretreatment method, the temperature basically keeps at 30 to 35 DEG C after a battery is acidified, the battery temperature basically maintains to be 40 to 45 DEG C in the charging process, and advantages are brought to formation of the polar plates, so that bad hidden danger is reduced during the traditional internal formation production.

Owner:TIANNENG BATTERY GROUP

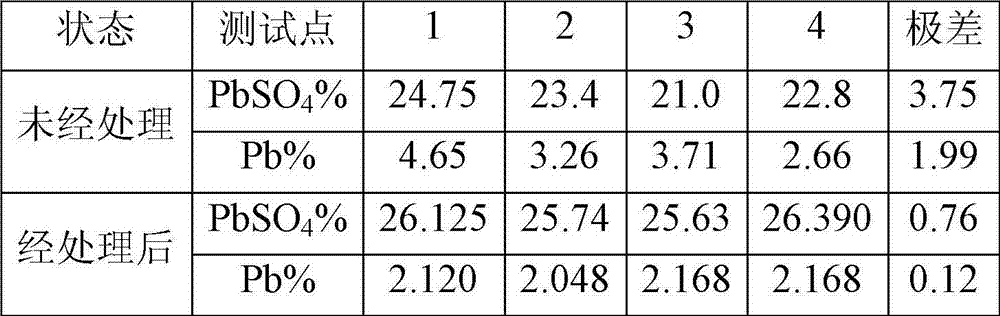

Exhaust gas heat exchanger used in ammonia water absorption refrigeration device using residual heat of exhaust gas

InactiveCN101017040AEasy maintenanceEasy to replaceBoilers/analysersClimate change adaptationPlate heat exchangerEngineering

The invention discloses a tail gas heat exchanger used in ammonia adsorption refrigerator which can utilize the left heat of tail gas. The invention can supply stable heat to the left-heat refrigerator, while the heat exchanger uses external structure to be maintained easily. Based on the ammonia adsorption refrigerator, the invention connects a tail gas heat exchanger on a gas-liquid entrance of a left-heat generator as tubular frame steam generator, and a gas-liquid separator between the tail gas heat exchanger and the left-heat generator. The invention can be used on the ammonia adsorption refrigerator on ship or engine.

Owner:ほう啓東

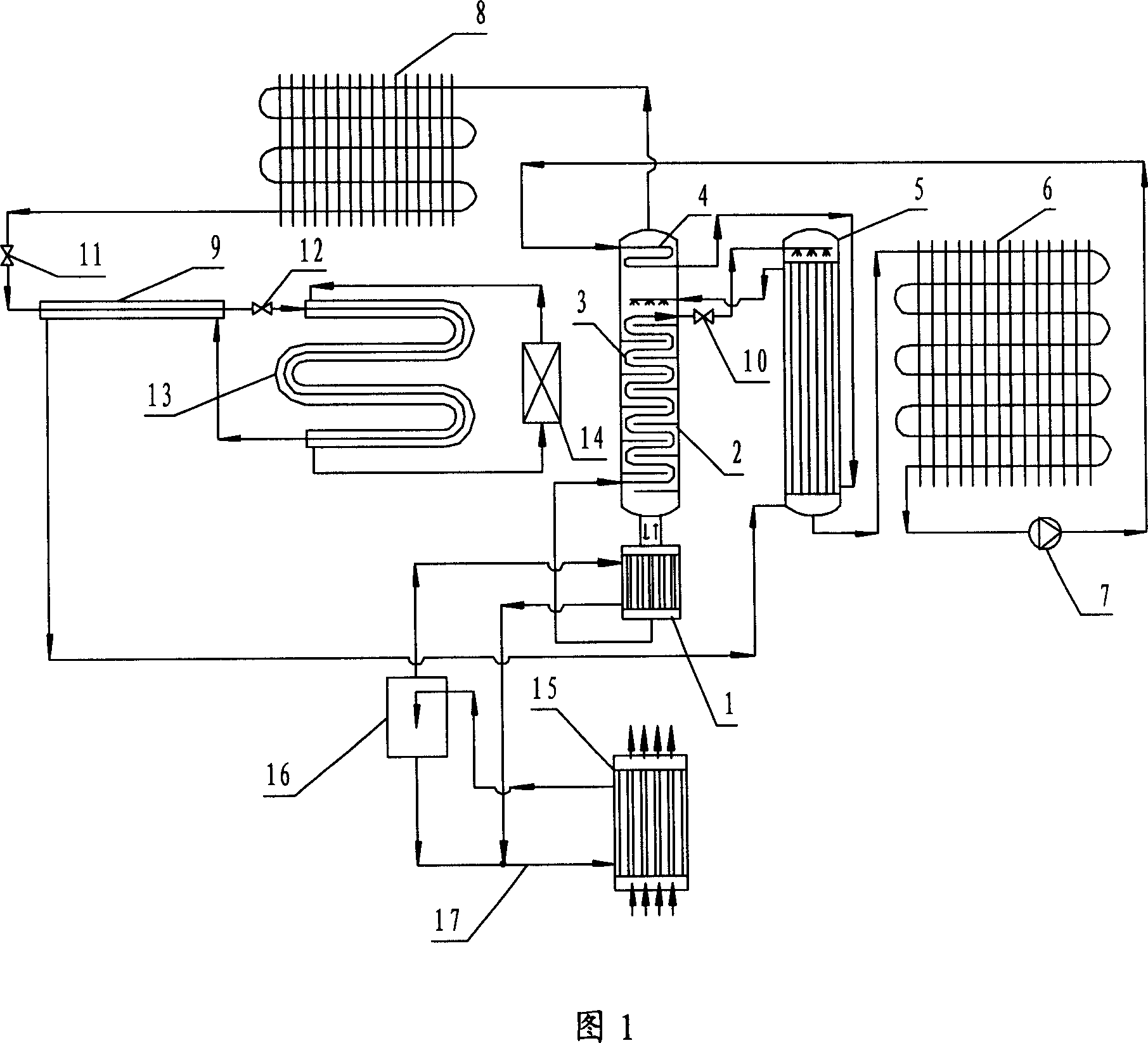

Spaceborne phased array radar load with thermal control integration with satellite platform structure

ActiveCN109413964AHighly integratedSmall footprintModifications by conduction heat transferEnvironmental geologyMicrowave signals

The present invention relates to a spaceborne phased array radar load with thermal control integration with a satellite platform structure. The spaceborne phased array radar load is integrated on a satellite deck and comprises a phased array antenna, an active module and a thermal control device. The phased array antenna covers on an outer side surface of the satellite deck; the active module ismounted on an inner side surface of the satellite deck and is arranged corresponding to the phased array antenna; the thermal control device is embedded in the satellite deck and is arranged between the active module and the phased array antenna; and the active module is connected with the phased array antenna to implement microwave signal transmission. According to the spaceborne phased array radar load provided by the present invention, the spaceborne phased array radar load and the satellite platform share one satellite deck, and the thermal control device is integrated into the inside of the satellite deck, so that thermal control integration between the spaceborne phased array radar load and the satellite platform structure can be achieved, the integration is high, the space occupation is small, and the overall weight is reduced.

Owner:BEIJING INST OF RADIO MEASUREMENT

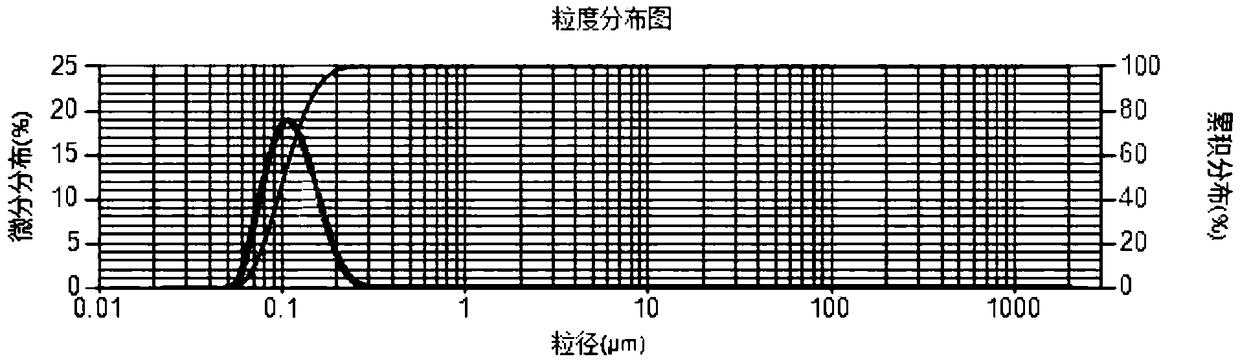

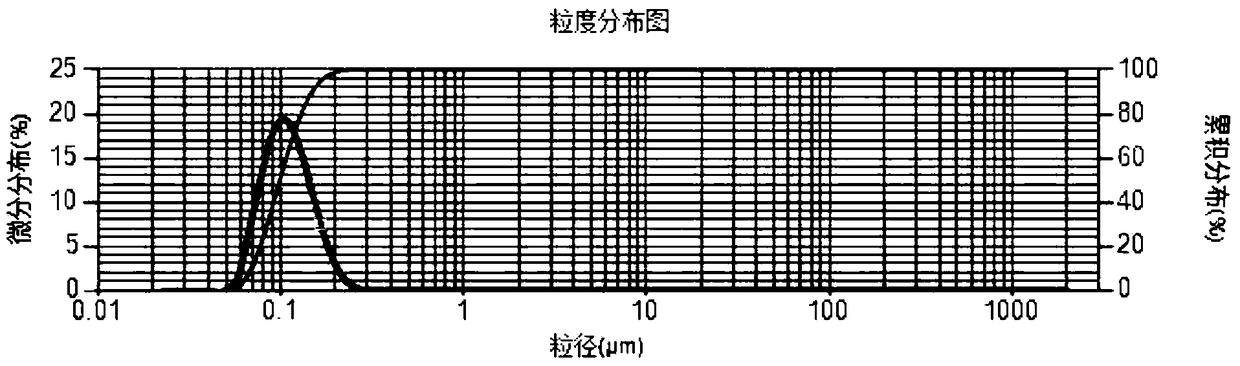

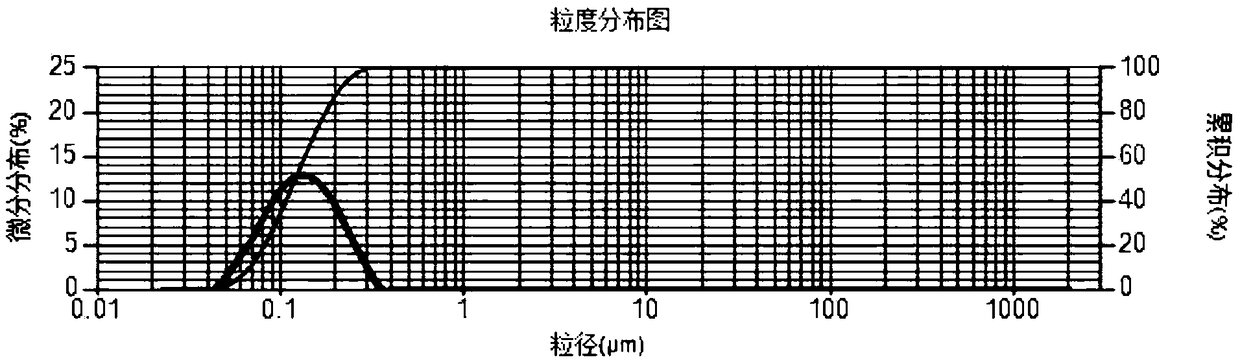

Nano-emulsion with good stability

ActiveCN109453043AImprove stabilityAuxiliary emulsification is goodCosmetic preparationsToilet preparationsTocopheryl acetateChemistry

The invention discloses a nano-emulsion with good stability. A formula of the nano-emulsion is prepared from the following components in percentage by weight: 30.0-82.13 percent of purified water, 0.01-0.1 percent of EDTA disodium, 0.5-5.0 percent of hydrogenated lecithin, 0.3-5.0 percent of a nonionic surfactant, 0.5-5.0 percent of caprylic acid / caprinic acid triglyceride, 5.0-30 percent of squalane, 1.0-5.0 percent of isononyl isononanoate, 0.01-0.5 percent of tocopheryl acetate, 0.5-3.0 percent of 1,2-hexanediol, 10.0-40.0 percent of glycerin and 0.05-8.0 percent of an oil-soluble skin conditioner. Through reasonable selection and ratio blending of components of the nano-emulsion, the strength and the elasticity of an interfacial film are improved, the interface energy is lowered, the mobility of the interfacial film is reduced, and the nano-emulsion with the stability to temperature change is prepared. The nano-emulsion wraps various efficient skin-care components and promotes transdermal absorption of functional components; and in addition, the hydrogenated lecithin as an emulsifier has better physiological activity, promotes substance metabolism of epidermic cells and enablesskin to be more pliable, tougher and more elastic; and modified soyasterol has the effect of relieving skin inflammation.

Owner:NOX BELLCOW COSMETICS CO LTD

Energy-saving control method for variable-displacement compressor of air conditioner

ActiveCN103017293AGuaranteed energy savingReduced operating power consumptionSpace heating and ventilation safety systemsLighting and heating apparatusIn vehicleRefrigeration temperature

The invention provides an energy-saving control method for a variable-displacement compressor of an air conditioner. The energy-saving control method comprises the following steps: at least determining a target air-outlet temperature according to user settings and in-vehicle and out-vehicle temperatures; calculating the corresponding target refrigeration temperature according to the target air-outlet temperature in the non rapid-cooling demand mode, wherein the target refrigeration temperature is the difference value between the target air-outlet temperature and a refrigeration compensation temperature; updating the target refrigeration temperature to an ultimate refrigeration temperature in the rapid cooling mode and under the condition that the time in the rapid cooling mode exceeds the preset refrigeration demand magnetic hysteresis time; and achieving proportional integral calculation according to the acquired target refrigeration temperature and the actual refrigeration temperature to control the displacement of the compressor. The energy-saving control method enables the variation of in-vehicle temperature to be stable so as to obtain better users' experience; and the displacement of the compressor is controlled based on reasonable calculation used in regulation so as to reduce the power consumption of the running compressor and guaranteeing the energy-saving performance of the air conditioner to the maximum extent.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

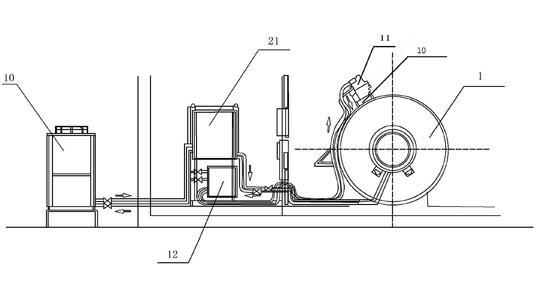

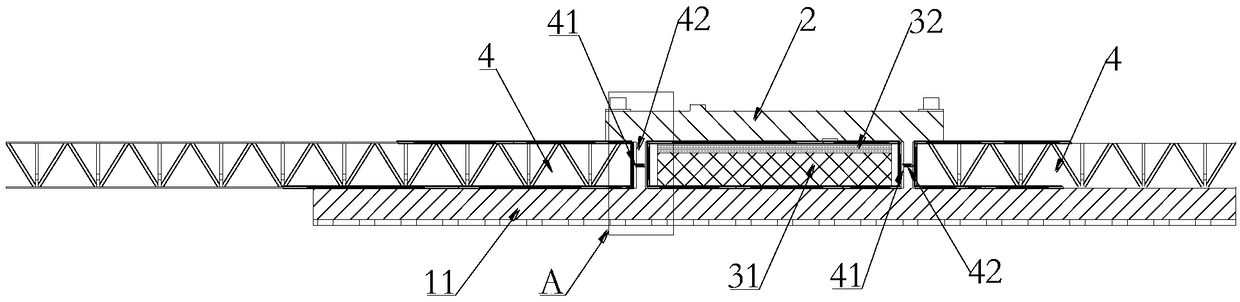

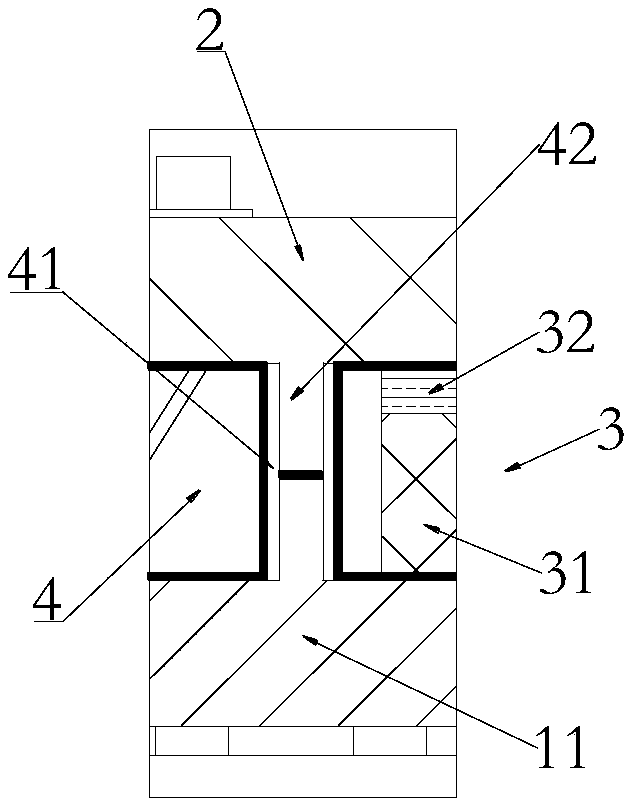

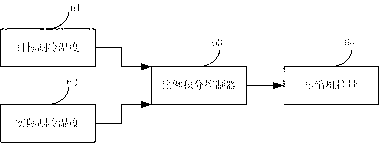

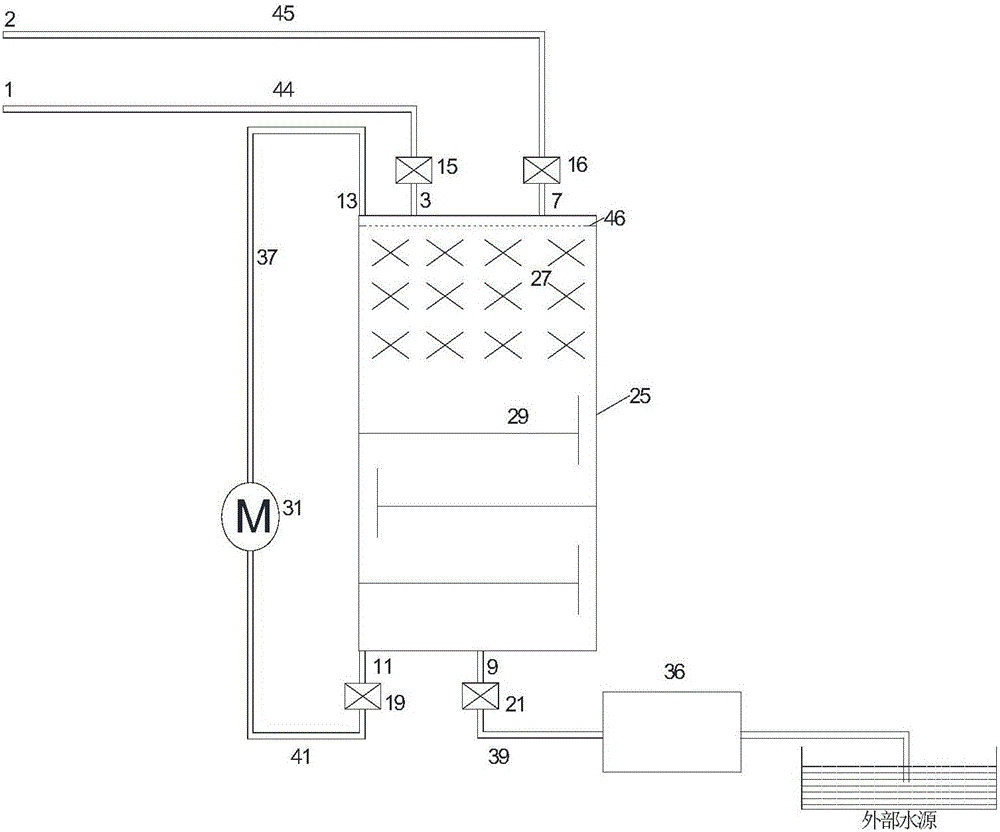

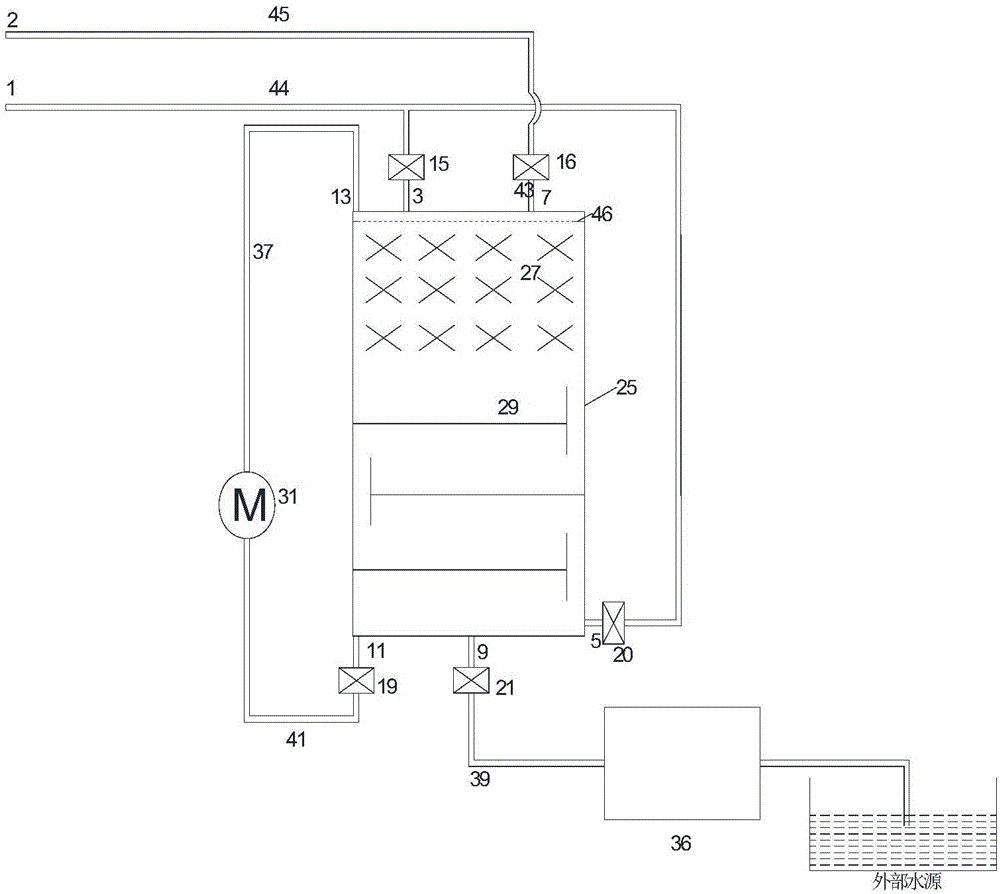

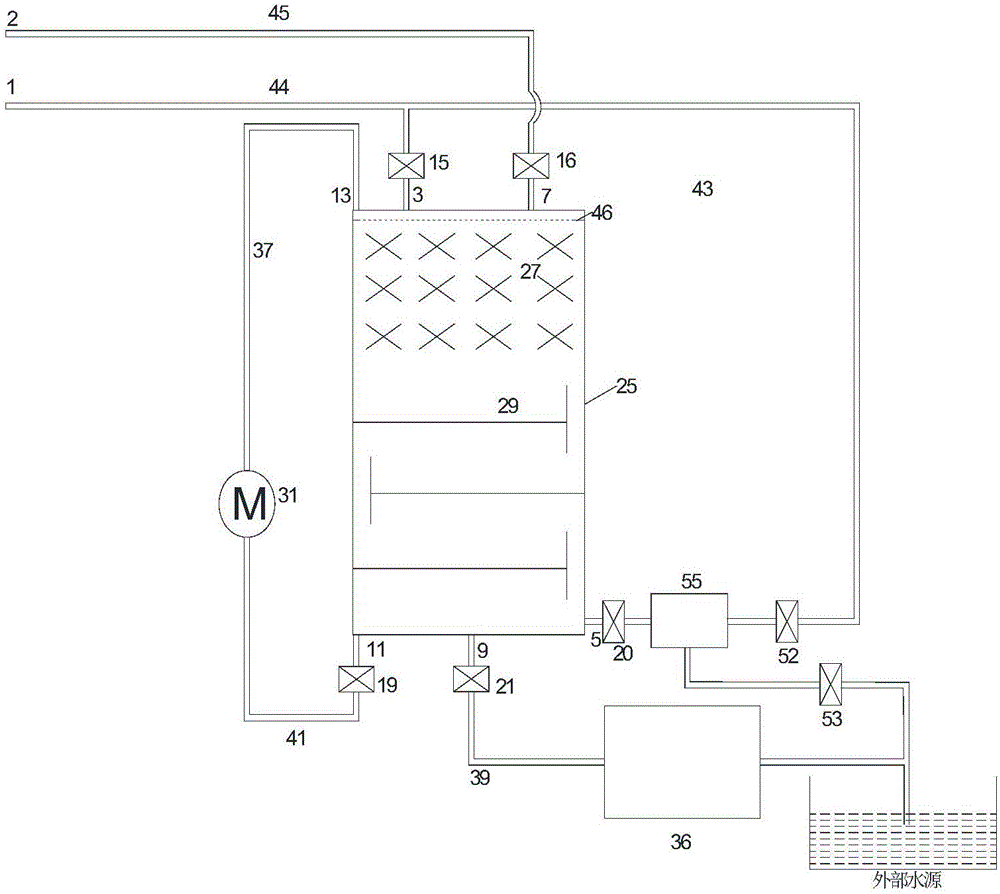

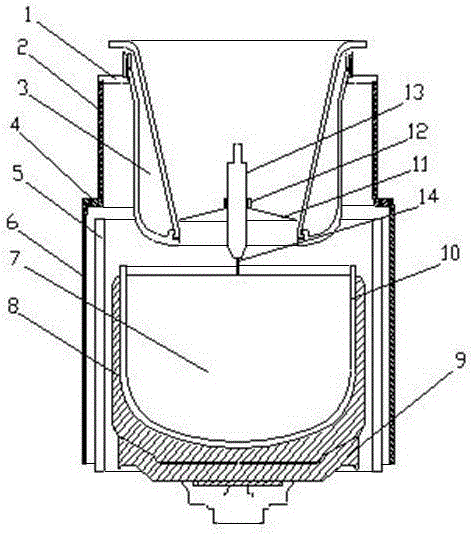

Internal temperature control liquid piston device for isothermal compressed air energy storage

ActiveCN106246230ASmooth temperature changeImprove utilization efficiencyMachines/enginesEngine componentsContact timeGrid energy storage

The invention belongs to the technical field of liquid pistons and the technical field of compressed air energy storage, and in particular, relates to an internal temperature control liquid piston device for isothermal compressed air energy storage. The device comprises a pressure container (25) connected with a low-pressure gas pipe (2) and a high-pressure gas pipe (1); a hydraulic potential conversion device (36) is connected to the bottom of the pressure container; a filler (27) or a tower plate (29) for accelerating gas-liquid heat exchange is arranged in a cavity of the pressure container; a liquid distributor (46) is arranged on the upper side in the cavity of the pressure container; and two ends of a temperature control liquid injecting device (31) are respectively connected with the upper part and the lower part of the pressure container. The device has two working modes of gas energy storage and energy release; the temperature control liquid injecting device and the liquid distributor enable temperature control liquid to uniformly flow down from the upper part of the pressure container; the gas and the liquid make direct contact for quick heat exchange; and the filler and a flat plate are provided for increasing the gas-liquid heat exchange contact area and prolonging the contact time to improve the gas-liquid heat exchange efficiency in the container. The device controls the gas temperature by using the characteristic of high specific heat of the liquid to realize similar gas isothermal zooming effect.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

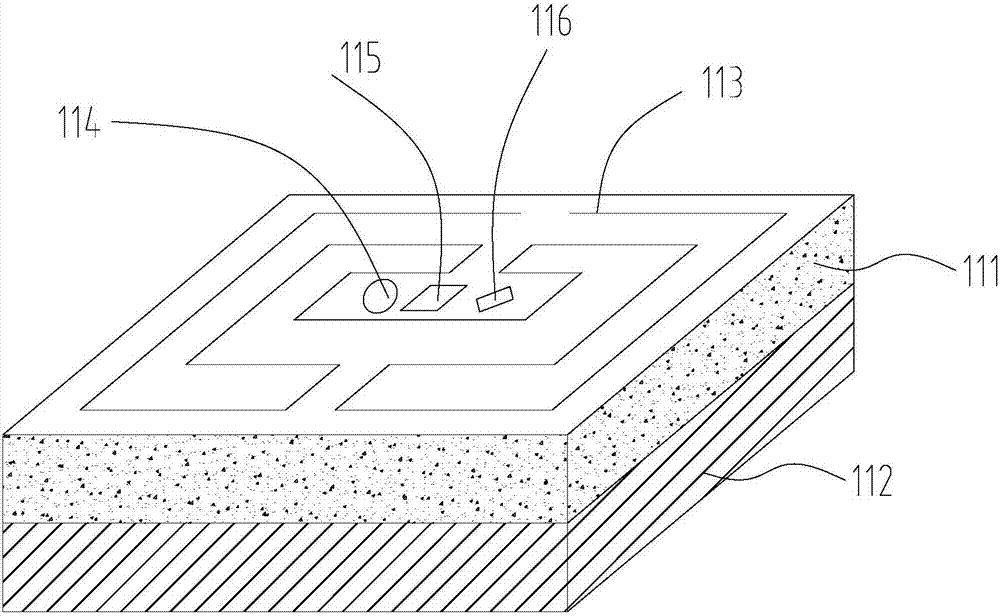

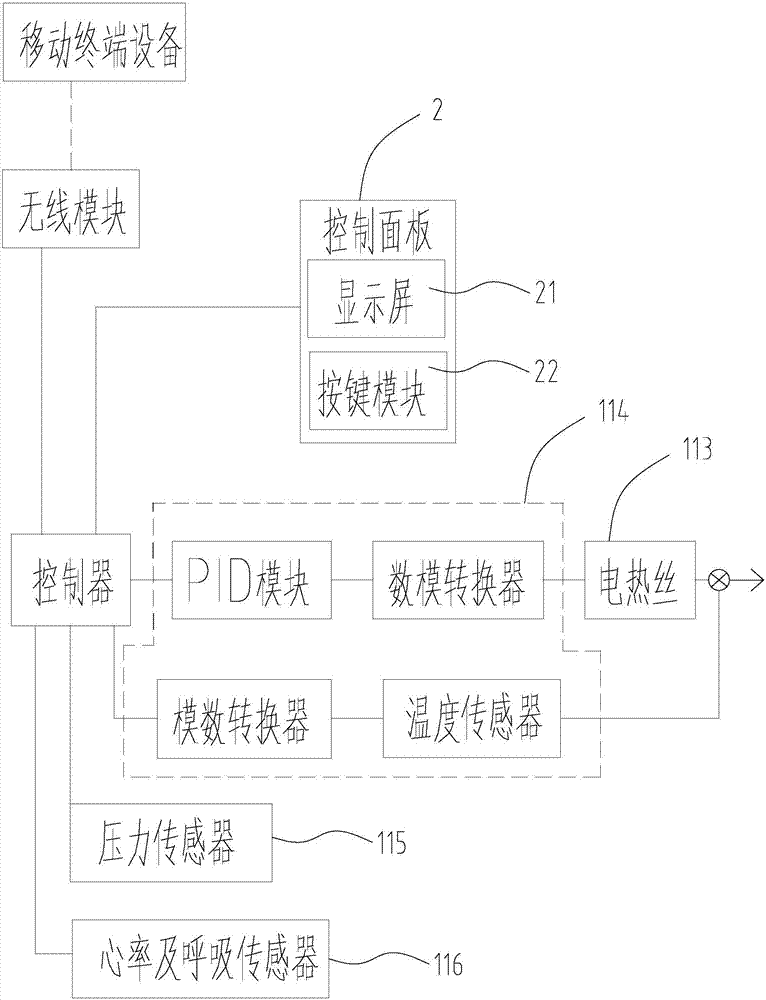

Intelligent graphene electric blanket and controlling system thereof

InactiveCN106937412AImprove thermal conductivityUniform heat conductionOhmic-resistance heating detailsHeating element materialsElectricityTemperature control

The invention relates to an intelligent graphene electric blanket comprising an insulated heat-conduction outer sleeve, a controller, a power supply, a control panel, and a plurality of electric blanket core bodies coated inside the insulated heat-conduction outer sleeve. The electric blanket core bodies consist of cloth bottom layers, graphene coating layers coating the cloth bottom layers, and heating wires seamed at the graphene coating layers; and temperature control modules, pressure sensors and heart rate and respiratory sensors are arranged at the graphene coating layers of the electric blanket core bodies. The controller and the power supply are arranged inside the control panel; and the power supply provides power for the controller and the power supply is connected with commercial power. The temperature control modules, the pressure sensors, the heart rate and respiratory sensors, and the heating wires that are arranged at the graphene coating layers are connected with the controller respectively. Therefore, problems that heat conduction of the existing electric blanket is not realized uniformly, the specific part of the electric blanket can not heated, and electric blanket controlling can not be carried out intelligently can be solved.

Owner:泉州信和石墨烯研究院有限公司

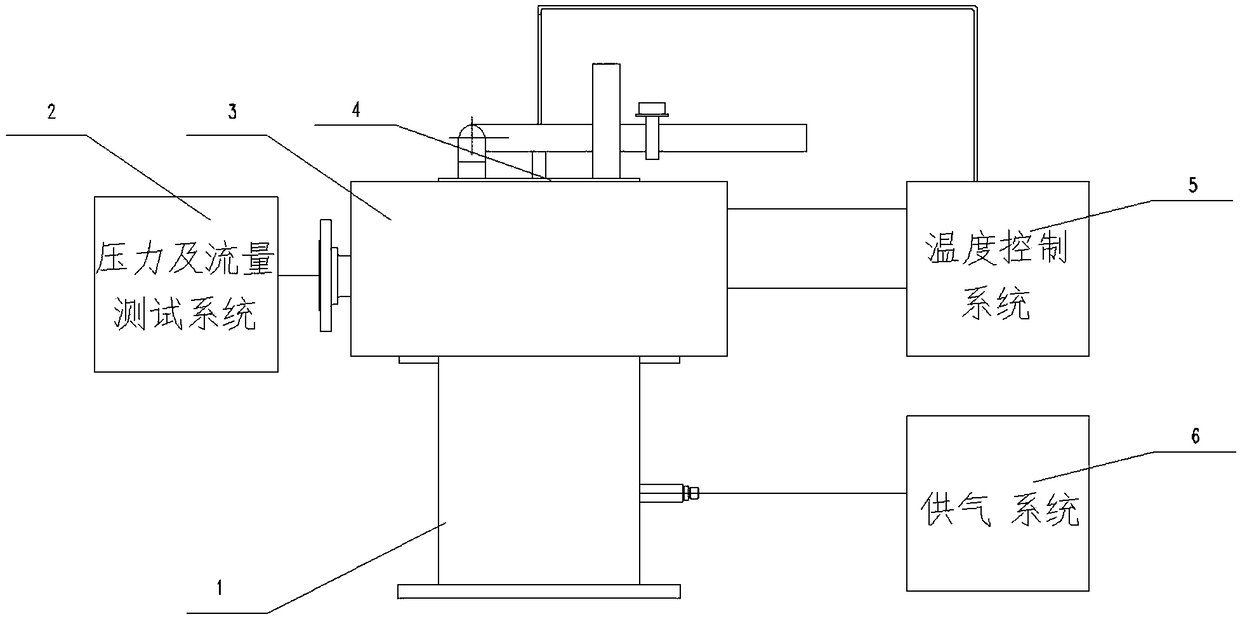

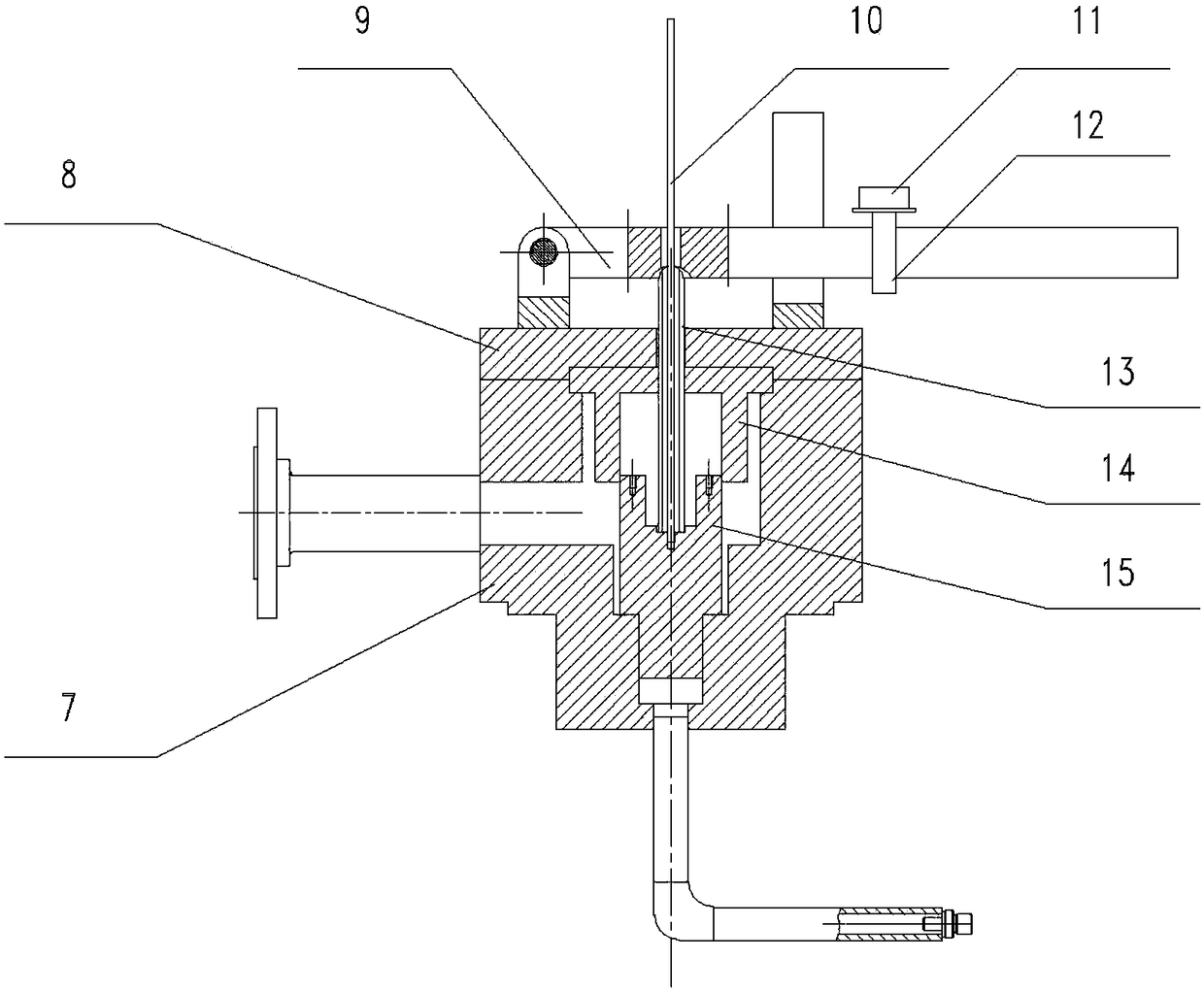

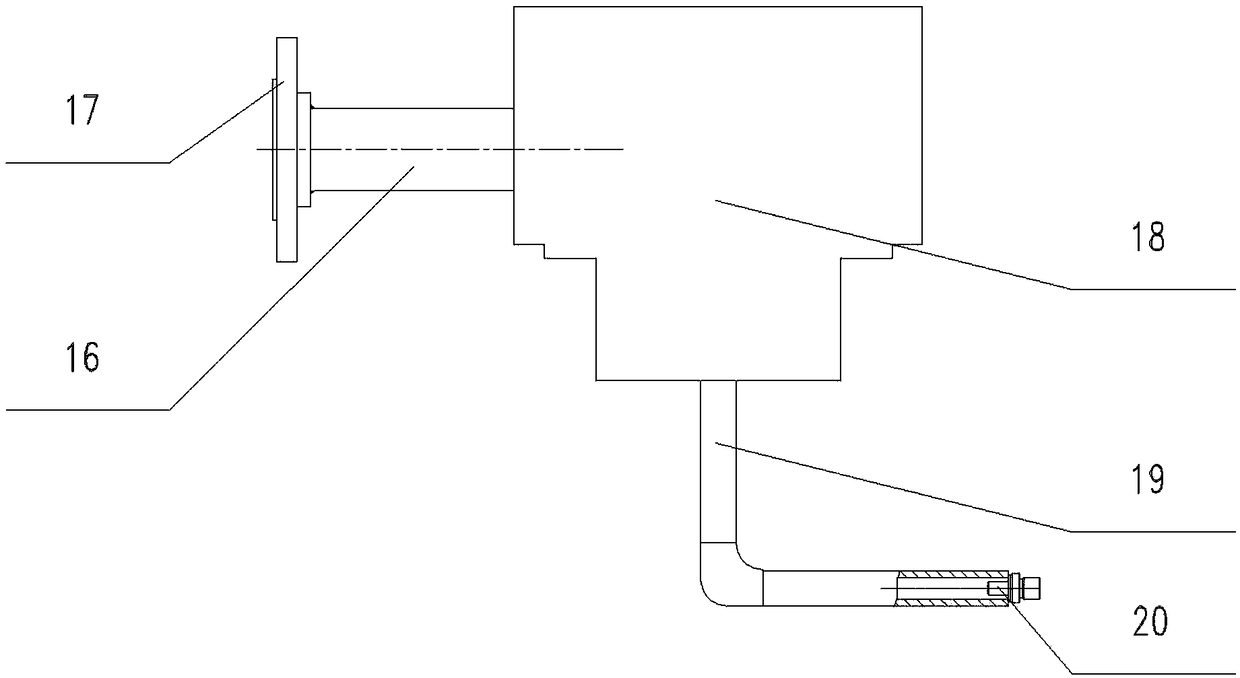

High-temperature sealing experimental device with continuously-adjustable sealing pressing force

InactiveCN108287044AReal-time read adjustmentCompression can be adjusted continuouslyMeasurement of fluid loss/gain rateMaterial thermal analysisControl systemEngineering

The invention discloses a high-temperature sealing experimental device with continuously-adjustable sealing pressing force. An experimental device support is mounted on anchor bolts. An experimental cavity is placed on the experimental device support. Two sealing cores are installed in the experimental cavity by cooperation to achieve sealing and pressurizing. A pressing force loading and adjusting system further transfers the pressing force to a sealing test piece through a sensor conduit, and achieves the precise adjustment of the pressing force by calibrating the pressing force in advance.Thereafter, a heating device is installed outside a test bench, and stable and continuous control of the temperature is realized by a control system, and a high-temperature-resistant platinum resistoris used for heating is used, thereby achieving high-temperature heating. The high-temperature sealing experimental device can test most sealing test pieces, and can control the continuous pressing force, measures the real-time compression amount, measures of the performance of the sealing test piece at different temperatures, and satisfies the requirements of different experimental conditions ofthe sealing test piece.

Owner:BEIJING UNIV OF CHEM TECH

Crispy fried stuffed bun, preparation method and pan dedicated therefor

InactiveCN1994095ASmall and exquisiteXuan soft and elasticBakery productsFood coatingFrying-pansFlavoring Agents

The invention relates to a method for producing fried bread, wherein said bread comprises skin and stuff. The stuff comprises 500g pork, 40-70g egg, 40-60g fecula, and 35-50g ginger, 70-85g flavoring agent, some green onion, and some water. The bottom of bread is thick with yellow skin. The invention also provides an aluminum pot, which can produce 300 breads at one time, with uniform temperature.

Owner:张友军

Seeding and shoulder expanding device and technique for single crystal rods and single crystal furnace

InactiveCN106435729AIncrease temperatureReduce radial temperature gradientPolycrystalline material growthBy pulling from meltMolten siliconSeed crystal

The invention discloses a seeding and shoulder expanding device and technique for single crystal rods and a single crystal furnace and belongs to the technical field of production of single crystal silicon. The seeding and shoulder expanding device for the single crystal rods comprises a hammer located above a crucible, wherein a conical reflection cover is fixed on the side wall of a connecting end, close to a seed crystal, of the hammer, the cone vertex angle is 150-180 degrees, and the conical surface faces molten silicon; the single crystal furnace comprises the seeding and shoulder expanding device for the single crystal rods; the seeding and shoulder expanding technique for the single crystal rods is performed by use of the single crystal furnace and comprises steps as follows: seeding: the rotating speed of the crucible is 8-12 rpm, the rotating speed of the seed crystal is 10-13 rpm, the seeding length is 120-200 mm, and the diameter of fine crystals is 4-8 mm; shoulder expanding: the rotating speed of the crucible is 10-12 rpm, the rotating speed of the seed crystal is 10-13 rpm, and the shoulder expanding pulling speed is 0.5-0.8 mm / min. The seeding and shoulder expanding success rate can be greatly increased, and the seeding and shoulder expanding time can be shortened.

Owner:YINGLI ENERGY CHINA

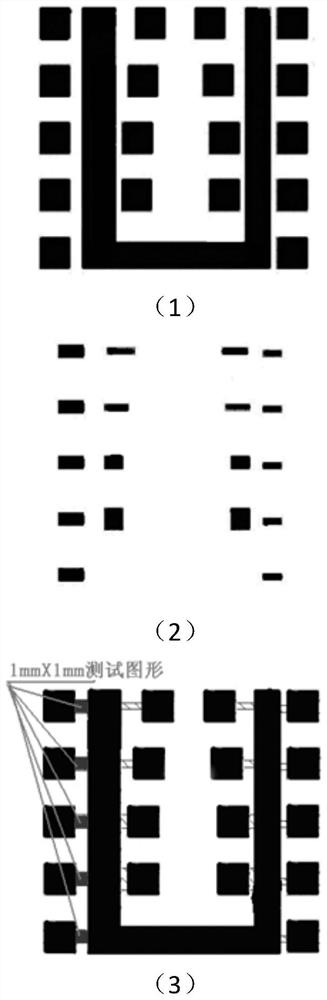

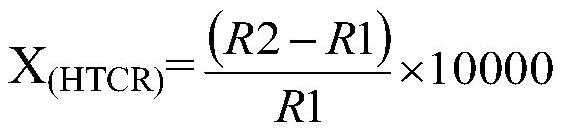

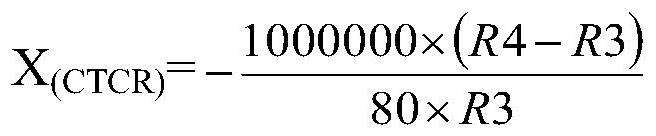

Thick-film resistance paste with electrostatic discharge resistance and low encapsulation change rate

ActiveCN111916248ASmooth temperature changeImprove resistance temperature change stabilityNon-conductive material with dispersed conductive materialThick film resistorsFilm resistanceGraphite

The invention discloses thick-film resistor paste and a thick-film resistor prepared from the thick-film resistor paste. A proper amount of graphdiyne is added into thick-film resistor paste in the form of a paste additive or a proper amount of graphdiyne is introduced into the thick-film resistor paste in the form of a glass powder additive. The thick-film resistor paste can be used for preparinga thick-film resistor which is stable in resistance temperature change and small in electrostatic discharge resistance and / or encapsulation change rate.

Owner:西安宏星电子浆料科技股份有限公司

System and method for shutdown cooling of high-temperature gas cooled reactor nuclear power station

ActiveCN108278590AEasy to operateChange pressureLiquid degasificationNuclear energy generationNuclear powerInlet valve

The invention discloses a system and a method for shutdown cooling of a high-temperature gas cooled reactor nuclear power station. The system comprises an evaporator, an evaporator outlet valve set, asteam separator, an evaporator inlet valve set, a bypass valve set, a high-pressure heater, an auxiliary steam header, a condenser, a water feeding pump and a deaerator. The method comprises the following steps: 1) steam in the auxiliary steam header is introduced in a steam side of the high-pressure heater and the deaerator to increase the water feeding temperature in an inlet of the evaporator;2) the water feeding pressure in the inlet of the evaporator is adjusted by the water feeding pump; and the water injecting flow of the evaporator is controlled by an adjusting door in the inlet of the evaporator, so that the cooling speed of the evaporator is further controlled; and the pressure of the evaporator is controlled by an adjusting door in an outlet of the evaporator; 3) a working medium in the outlet of the evaporator is discharged into the steam separator; 4) the pressure of the steam separator is controlled by a bypass adjusting valve and auxiliary steam fed in the steam separator; and 5) water in the steam separator is recovered to the main deaerator to build a two-loop water cycle to cool the evaporator.

Owner:XIAN THERMAL POWER RES INST CO LTD

Preparation method of black tomato freeze-dried powder

PendingCN105053873AAvoid it happening againConducive to sublimationFood preservationFood shapingChlorine dioxideAutomatic control

The invention discloses a preparation method of a black tomato freeze-dried powder. The method adopting black tomatoes as a raw material comprises the following steps: choosing black tomatoes, removing impurities, disinfecting by using an aqueous solution of chlorine dioxide, cutting, pre-cooling, carrying out vacuum freeze-drying until the water content of the obtained material is 3.0-5.0%, and taking out the black tomatoes, wherein computer automatic control temperature programming is adopted in the vacuum freeze-drying process, the heating process is carried out according to a function of F=F1+(t / t1)3*(F2-F1), F is the heating medium temperature at the t moment after heating, t is 0 ~ t1, the unit of t is min, the total time t1 = 1020~1200min, an initial temperature F1 is 30~35DEG C, and a final temperature F2 is 50~55DEG C; and carrying out refrigeration crushing at a low temperature being smaller than -50DEG C to obtain the black tomato freeze-dried powder with the granularity being greater than 200 meshes. The black tomato freeze-dried powder is packaged by a silver paper bag, so the shelf life at normal temperature exceeds 1.5 years. The black tomato powder reserves nutritional substances and taste of fresh black tomatoes, and the above whole process is suitable for industrial production.

Owner:GUANGZHOU HUISHENGSENFENG AGRI SCI ANDTECH DEV CO LTD

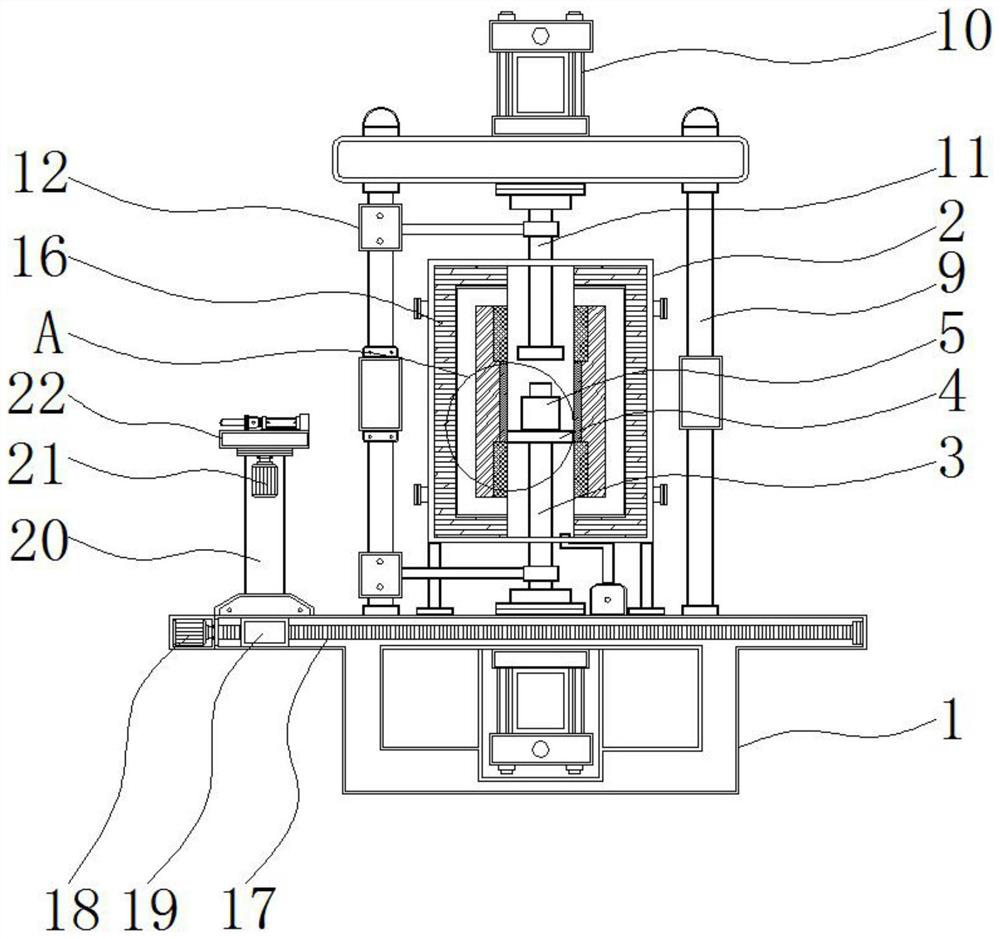

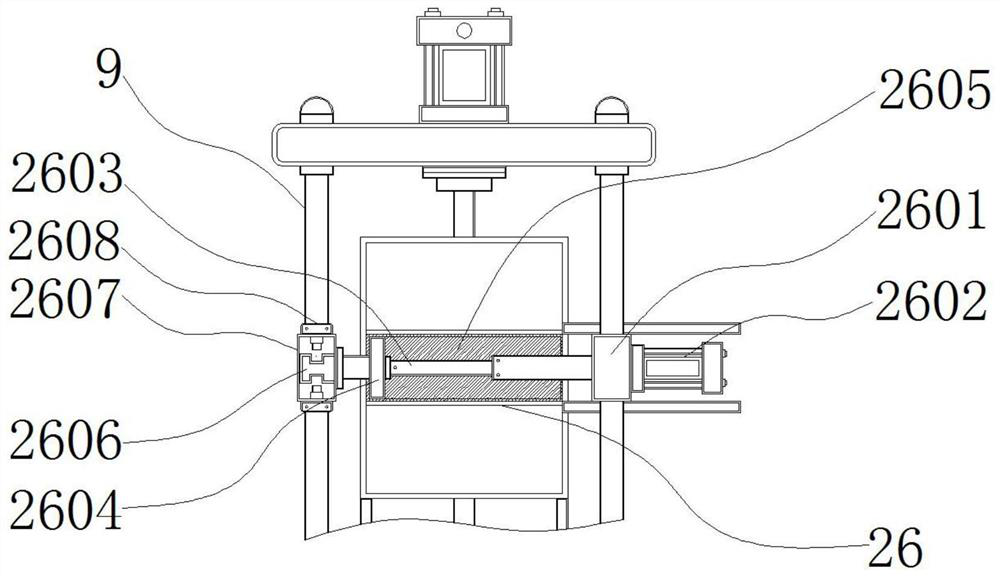

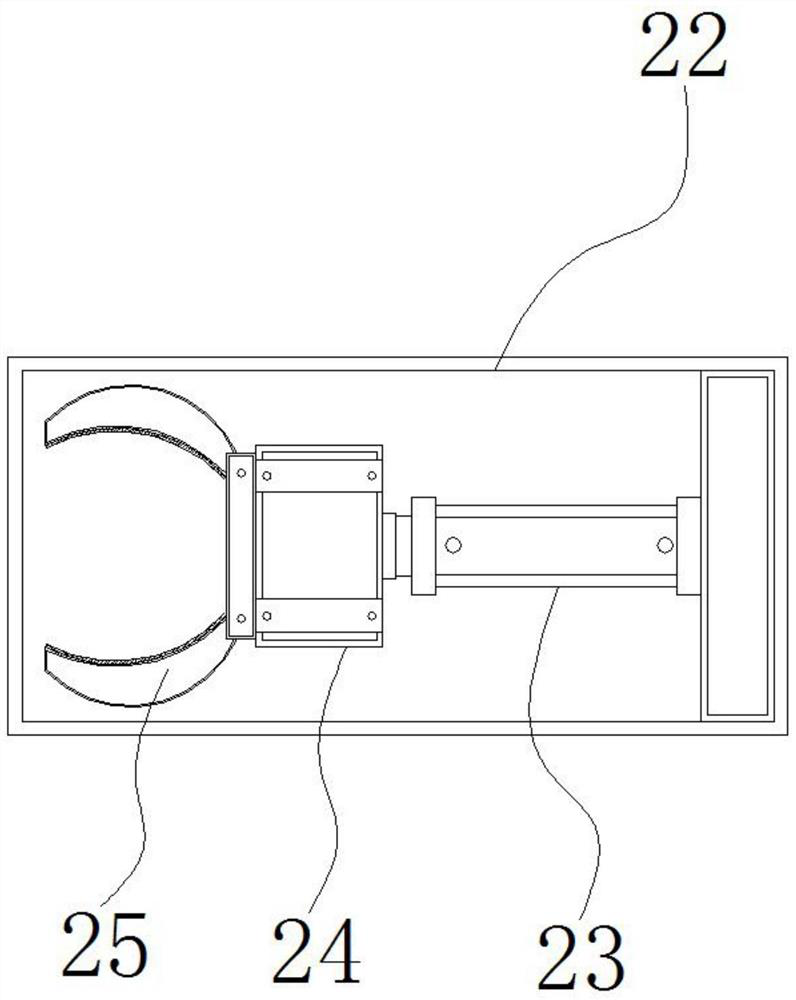

Oscillating hot-pressing sintering furnace with pressurizing auxiliary structure

The invention discloses an oscillating hot-pressing sintering furnace with a pressurizing auxiliary structure, and relates to the technical field of sintering furnaces. The oscillating hot-pressing sintering furnace specifically comprises a base and a sealing device, and a shell is arranged on the upper surface of the base. According to the oscillating hot-pressing sintering furnace with the pressurizing auxiliary structure, in the process of feeding a mold, a pneumatic block can be used for clamping the mold in an attached mode through a chuck, and slides to a tray along a lead screw througha moving rod and a sliding block, a second motor can drive a platform to rotate to an accurate direction, a first electric telescopic rod can immediately drive the clamped mold to be transferred to adesignated position on the upper surface of the tray for feeding treatment, and only the assembled mold needs to be placed at the mold position in the process, so that the operation is simple, follow-up correction by professionals is not needed, and potential safety hazards caused by misoperation are avoided; and the discharging process is similar, the chuck is driven by the first electric telescopic rod to discharge the sintered mold, manual touch is not needed in the process, and safety of workers is guaranteed.

Owner:湖南伊澍工业技术有限公司

Method for adjusting growth temperature of silicon carbide monocrystal

InactiveCN105970285AImprove operational safetyImprove product qualityPolycrystalline material growthBy pulling from meltCrystal rotationCrucible

The invention relates to a method for adjusting the growth temperature of a silicon carbide monocrystal. The method comprises the following steps: enabling a seed crystal and a crucible to be coaxial and to rotate in opposite directions; controlling the temperature field and temperature distribution of a melt by controlling the crystal rotation speed and the crucible rotation speed; enabling an induction coil to be fixed; adjusting the silicon carbide subliming plane to be in the highest point of an induction coil magnetic field all the time by lifting the crucible. The method is stable in temperature change and high in product quality.

Owner:JIANGSU BAIR PHOTOELECTRIC EQUIP CO LTD

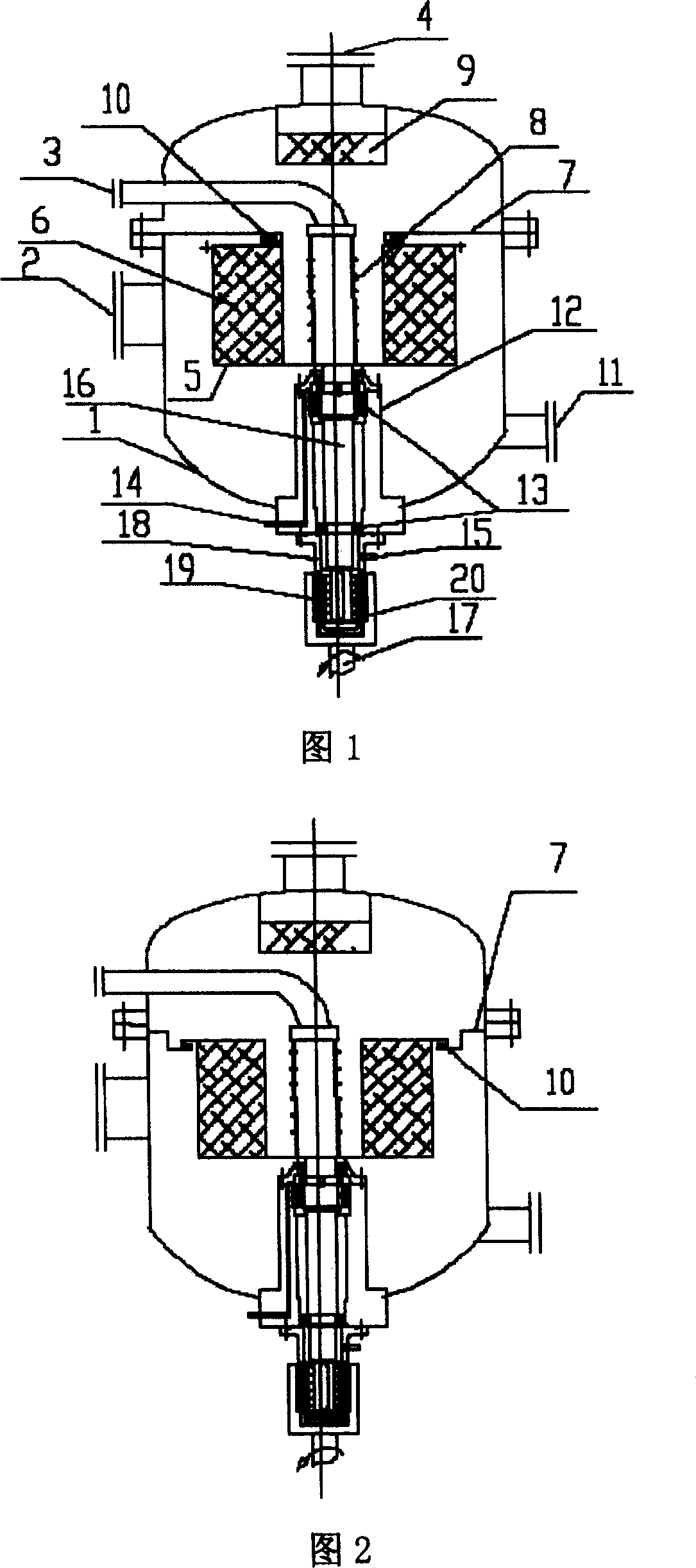

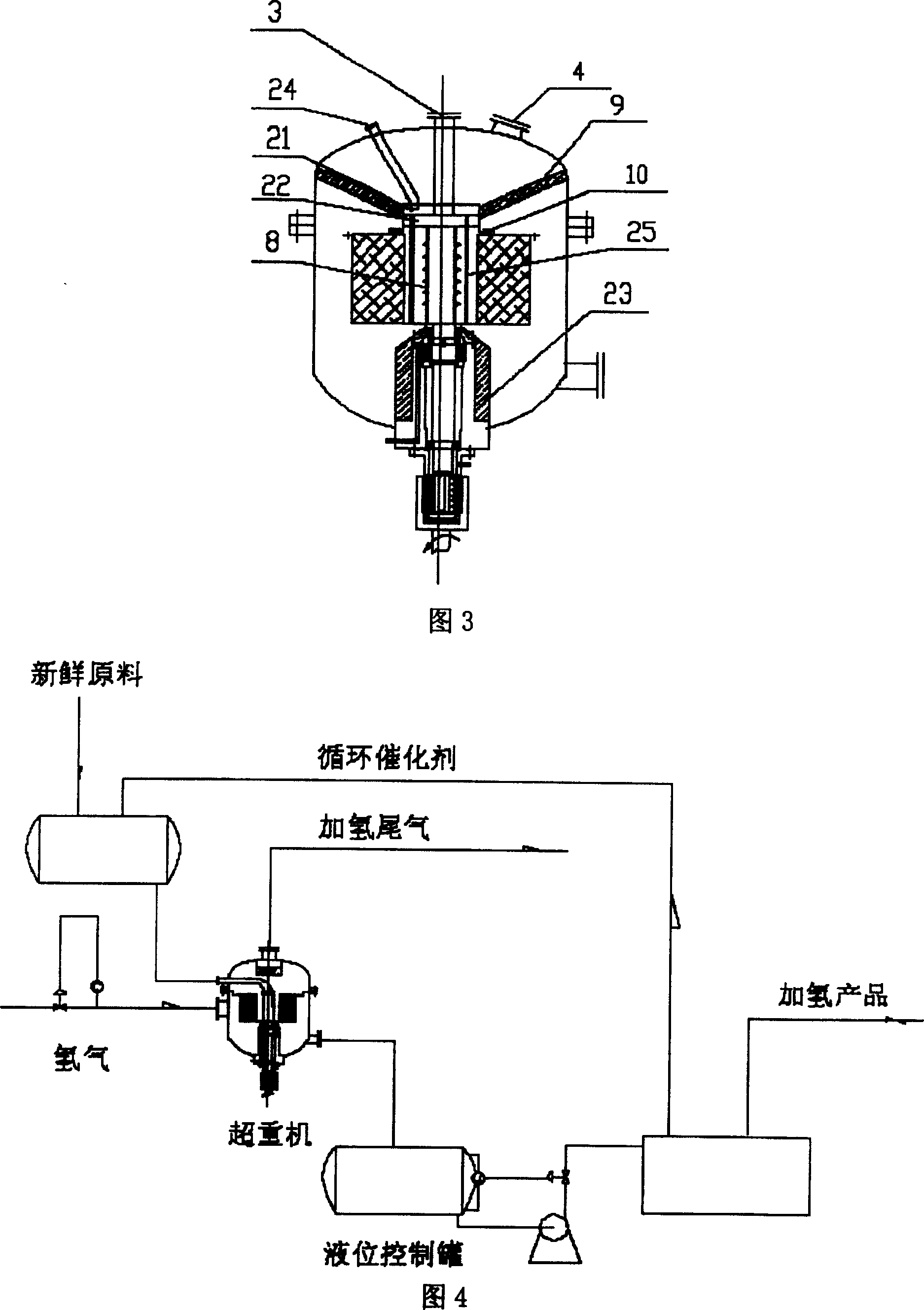

Method for conducting catalytic reaction in ultragravity field

ActiveCN1327945CEasy to prepareExtended regeneration cycleChemical/physical/physico-chemical moving reactorsEmulsionActive component

The present invention discloses a method for making catalytic reaction in supergravitational field. Said method includes the following steps: after the heterogeneous catalyst is formed into liquid phase, it can be used for making catalystic reaction, and said reaction is made in the supergravitational rotary bed reactor, in which the described liquid phase formation is characterized by that the active component of catalyst is dissolved in the liquid phase reaction material or solvent to form homogeneous mixture or dispersed in the liquid phase reaction material or solvent to form emulsion

Owner:CHINA PETROLEUM & CHEM CORP +1

Coriolis mass flowmeter including an inner pipe made of fluororesin and outer pipe having fibers

InactiveUS7861603B2Reduce the overall diameterReduced elutionVolume meteringDirect mass flowmetersFiberElastic modulus

A Coriolis flowmeter includes an oscillator for oscillating a fluid pipe that forms a flow path for allowing a measurement fluid to flow; first and second detectors that are disposed to be spaced apart from each other along the flow path of the fluid pipe so as to detect a state of oscillation of the fluid pipe; and a calculator for calculating a mass flow rate of the measurement fluid that passes through the flow path of the fluid pipe on the basis of a relative amount of the states of oscillation that are detected by the first and second detectors. The fluid pipe includes an inner pipe made of a fluororesin whose inner circumferential surface is in contact with the flow path, and an outer pipe having fibers that are arranged in order to surround an outer circumferential surface of the inner pipe and a resin that is cured in a state of close adhesion between the fibers arranged in order, and having an elastic modulus larger than that of the inner pipe.

Owner:KEYENCE

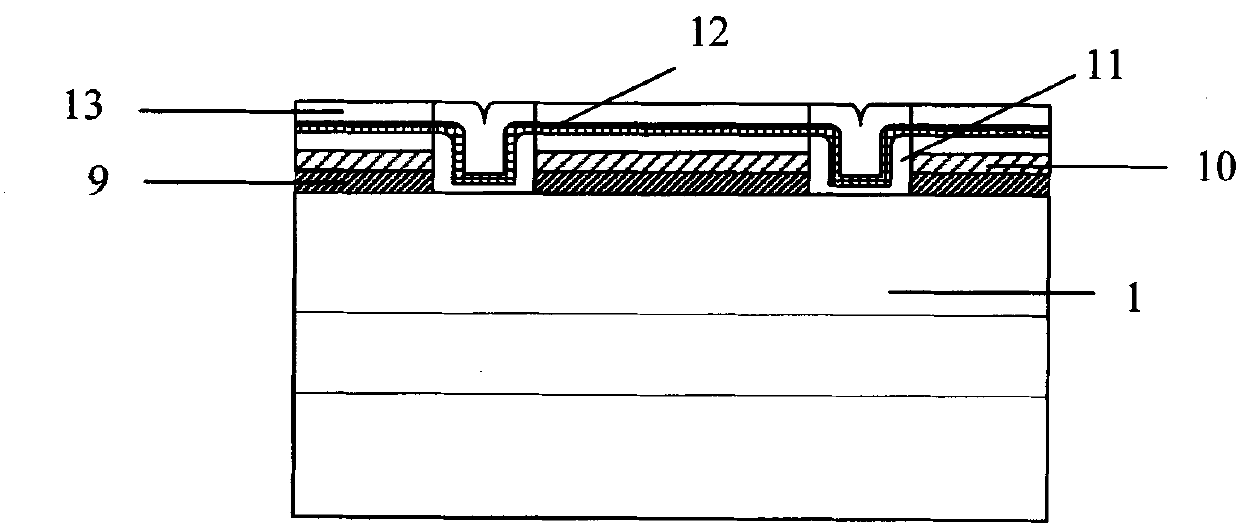

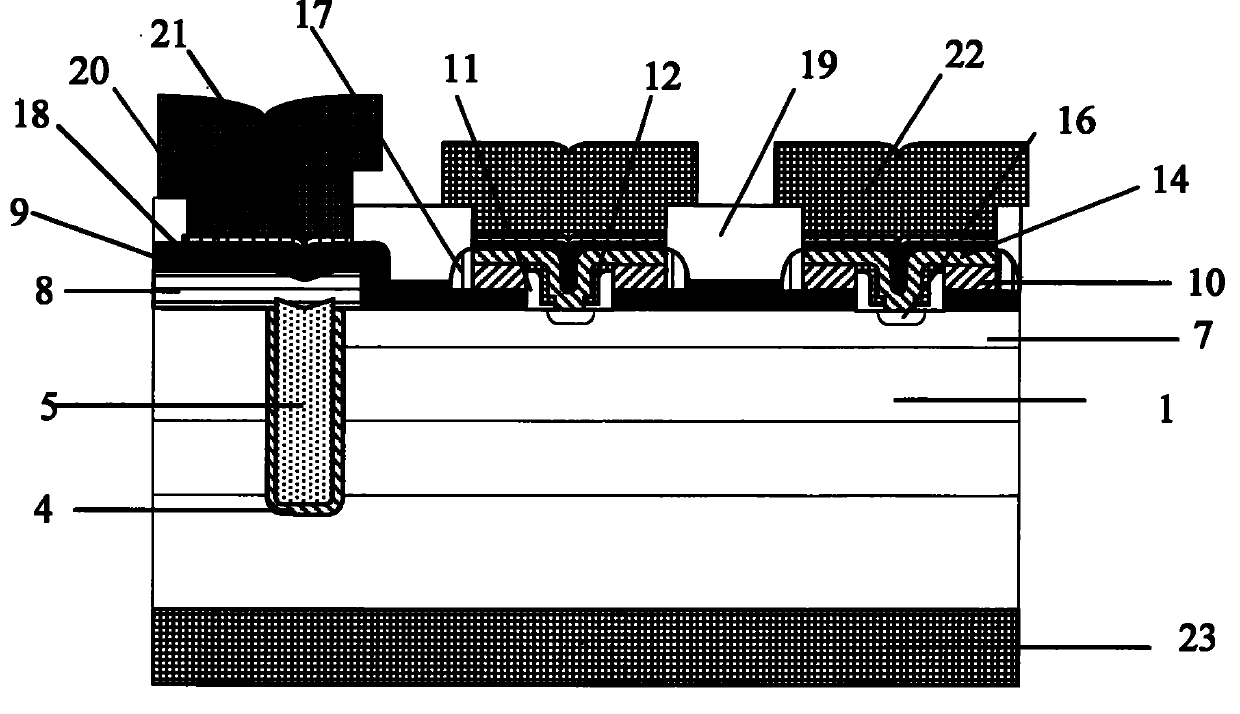

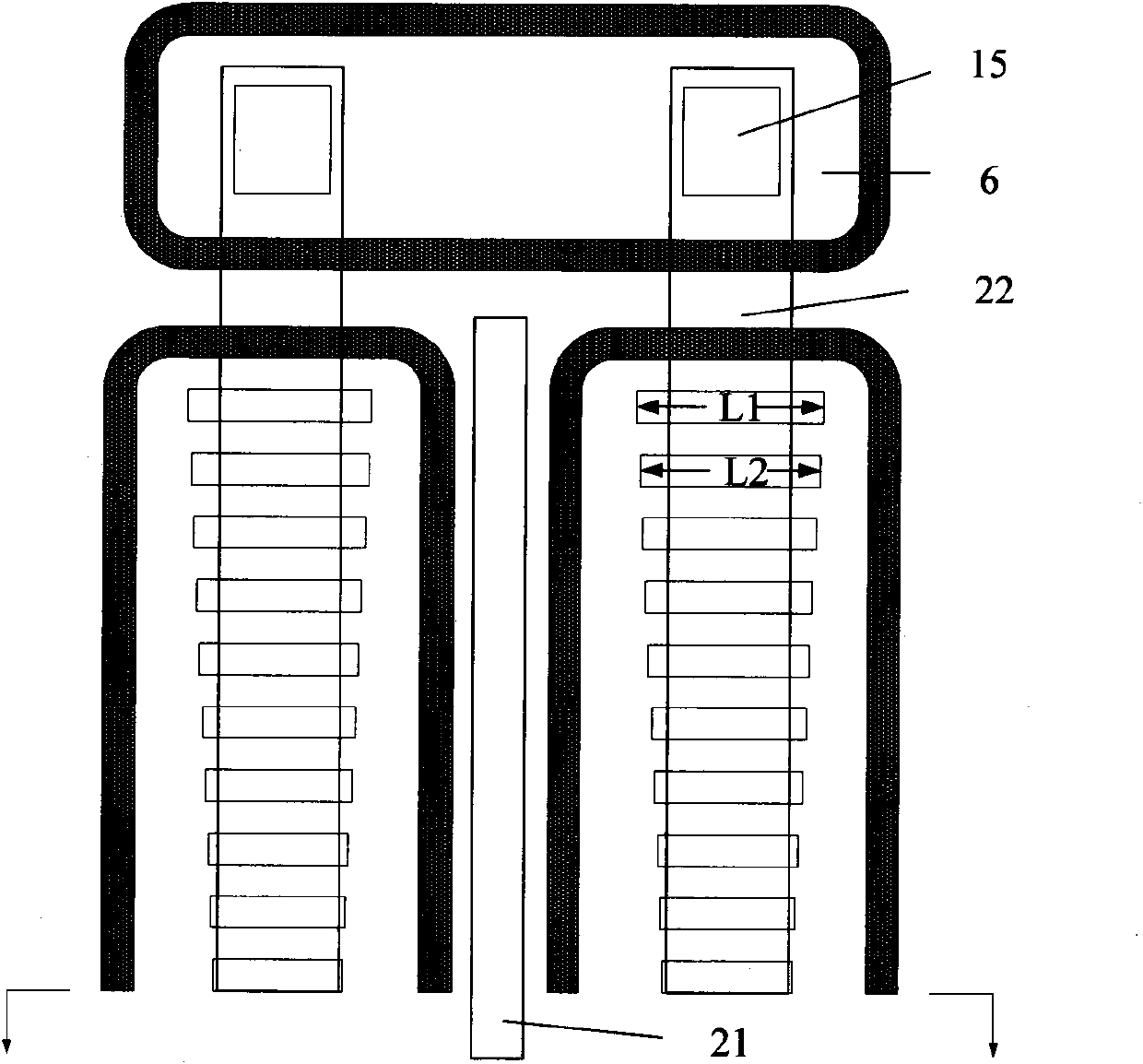

Method for manufacturing microwave power device by using double level polysilicon device structure

InactiveCN101950722AImproved power output characteristicsHighly integratedSemiconductor/solid-state device manufacturingAutocollimationEngineering

The invention discloses a method for manufacturing a microwave power device by using a double level polysilicon device structure. The method of the invention adopts a deep groove isolation technique and inhomogeneous thermal design, realizes the acinaceous cellular structure, adopts outer base region composite plate to carry out photoetching, vertically etches a monox dielectric layer and outer base polycrystalline silicon to obtain the outer base region window of the ratio change of the length and the like, and forms a compound L-shaped side wall capable of adjusting the length of an emitting electrode by means of autocollimation in the outer base region window. In the invention, the emitting electrode polycrystalline silicon composite plate is adopted to carry out photoetching, the emitting electrode polycrystalline silicon and the dielectric layer are vertically etched by utilizing autocollimation, the selective side wall protection technology is combined, under the scale of the deep submicron, and the polycrystalline silicon refractory metallic silicide with low film resistivity is realized by means of autocollimation, thereby avoiding the short circuit connection of two types of polycrystalline silicon leads, reducing the restriction of parasitic components of the interconnected leads on improving the characters of the microwave power device under the graph scale of submicron and deep submicron, thereby improving the overall performance of the microwave power device and the microwave performance thereof.

Owner:WUXI JINGKAI TECH

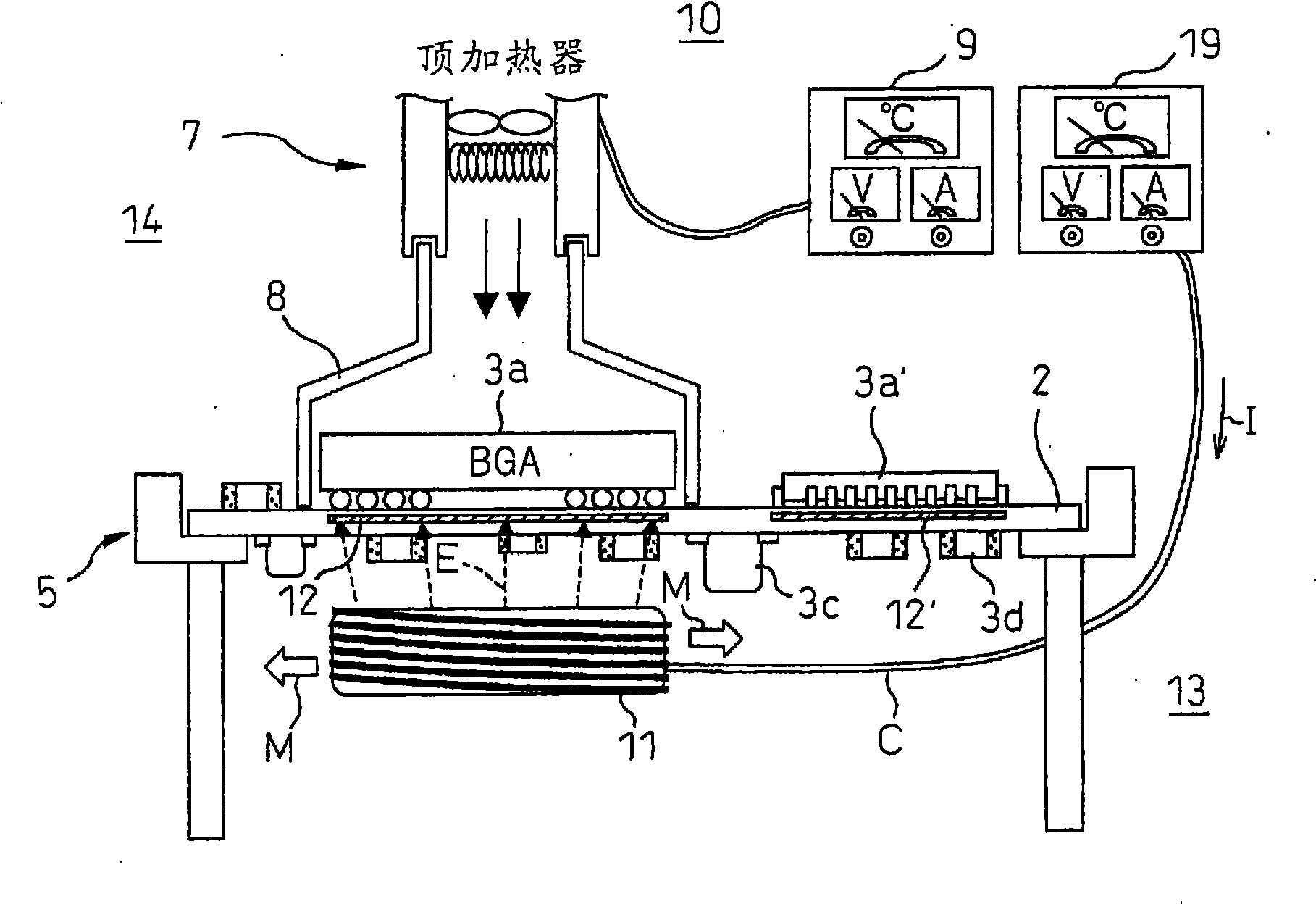

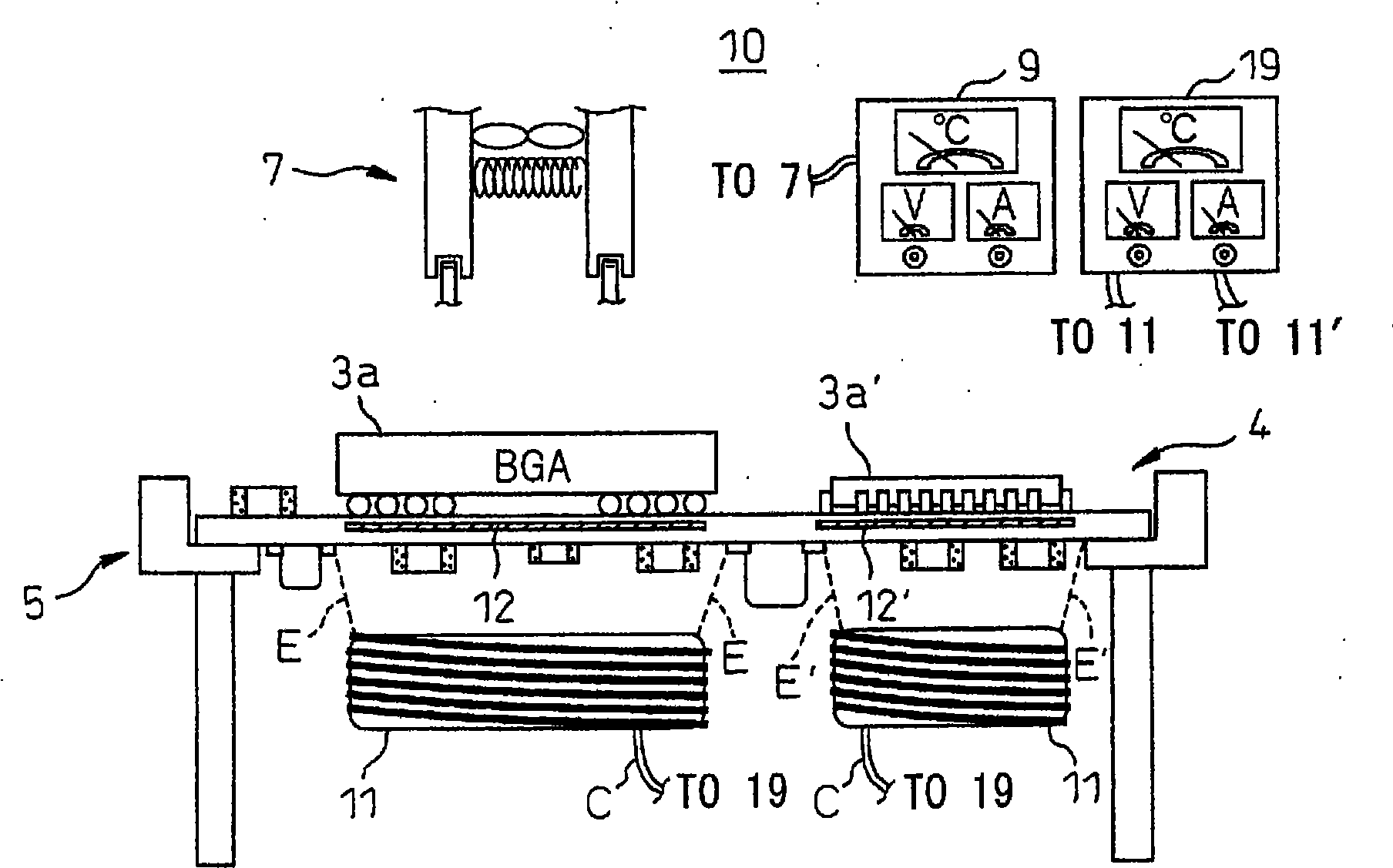

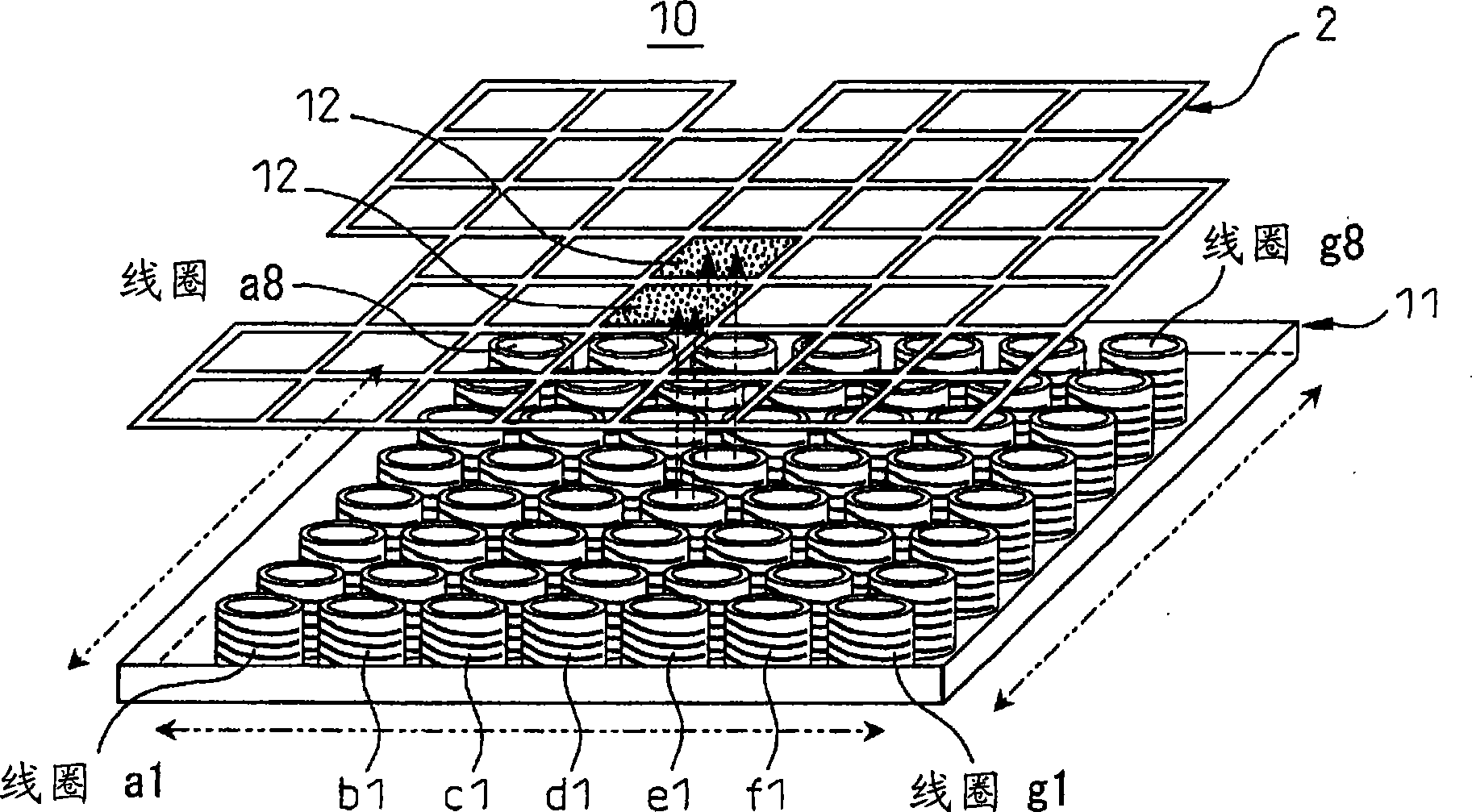

Method of repair of electronic device and repair system

InactiveCN101483978AWon't distortSuppression of distortionPrinted circuit assemblingHeating appliancesEngineeringElectromagnetic induction

A repair system which prevents heating of weakly heat resistant devices together and causing deterioration of the quality when preheating a first surface of the circuit board, wherein an electromagnetic induction material is buried in advance inside the circuit board near a specific electronic device envisioned as needed repair when becoming a defective electronic device in a production process and an electromagnetic coil emitting electromagnetic waves to an electromagnetic induction member in the vicinity of the repair device is provided and the heat generated by the electromagnetic induction member due to the electromagnetic waves enables the repair device to be heated and detached from the circuit board.

Owner:FUJITSU LTD

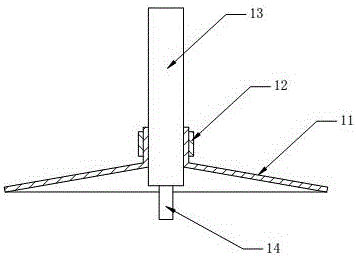

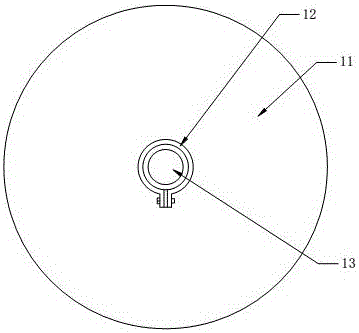

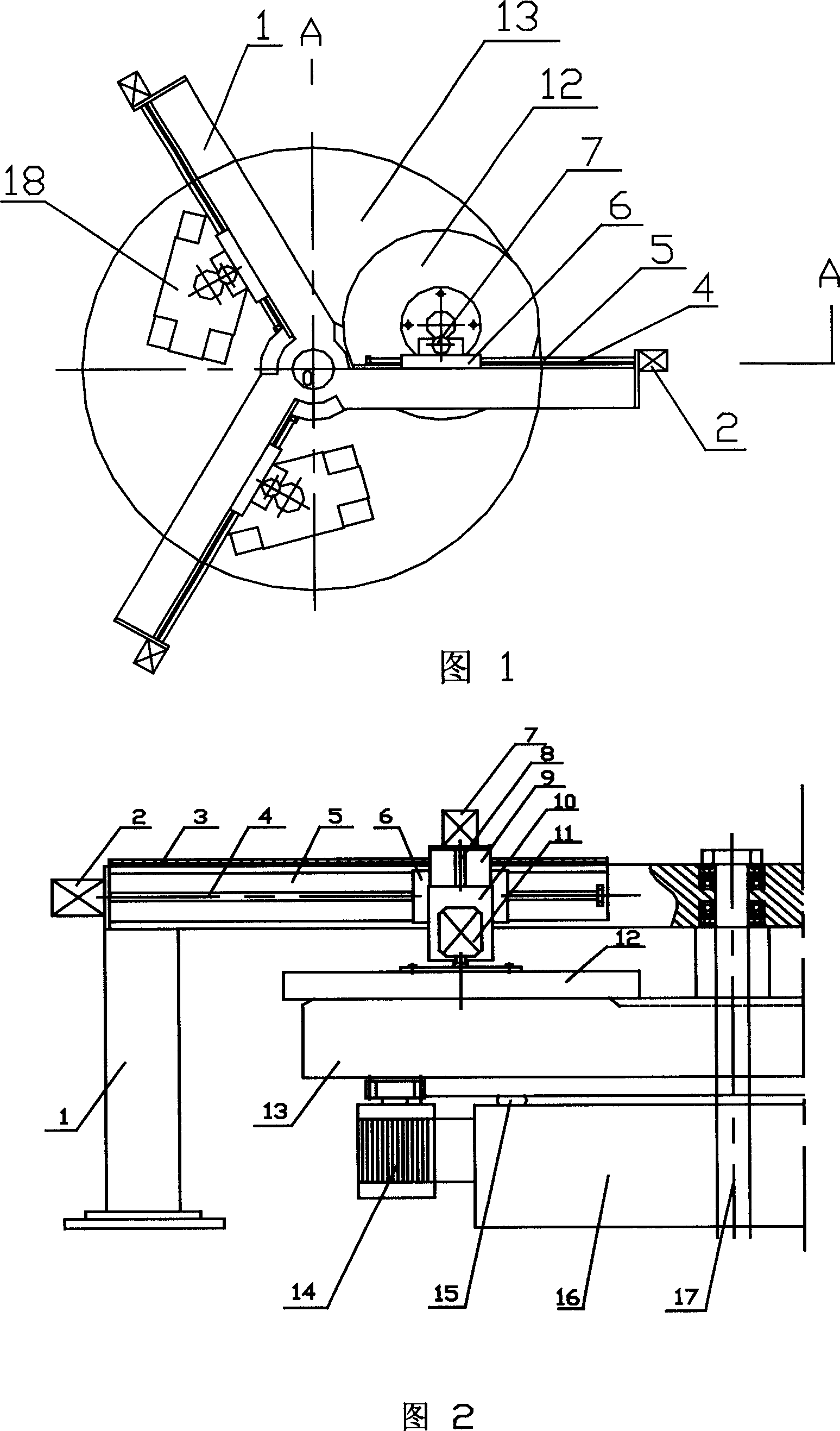

Automatic plate moving mechanism of large-diameter high-accuracy glass polishing machine

ActiveCN101096074ASmooth temperature changeSolve the deformationEdge grinding machinesGrinding machine componentsEngineeringMechanical engineering

The invention relates to an automatic disk-moving mechanism of large-diameter high-accuracy glass polisher, mainly comprising a large rotary disk. On the disk face of large rotary disk rubber disk is set and on the rubber disk finishing disk and workpeice disk are set. A three-foot scaffold is set at outside of the large rotary disk. Three horizontal beams of the scaffold are located above the large disk and are intersected with the large disk at the center. Radial disk-moving mechanism is set on each horizontal beam. The mechanism comprising a radial screw, a radial guide rail, a radial seat frame and step motor. Vertical lifting mechanism is set on each radial seat frame. The mechanism comprises a vertical screw, a vertical guide rail, a vertical seat frame and step motor, wherein a vertical seat frame is fixed with the center frame of finishing disk and other two vertical seat frame are fixed with the center frame of workpeice disk. Transmission mechanism for driving the finishing disk or the workpeice disk rotate is set on each vertical seat frame. The invention can improve producing efficiency and decrease industrial injury. The invention also conquers the deformation problem of rubber disk face and improves machining quality.

Owner:上海中晶企业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com