Patents

Literature

498results about "Thick film resistors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

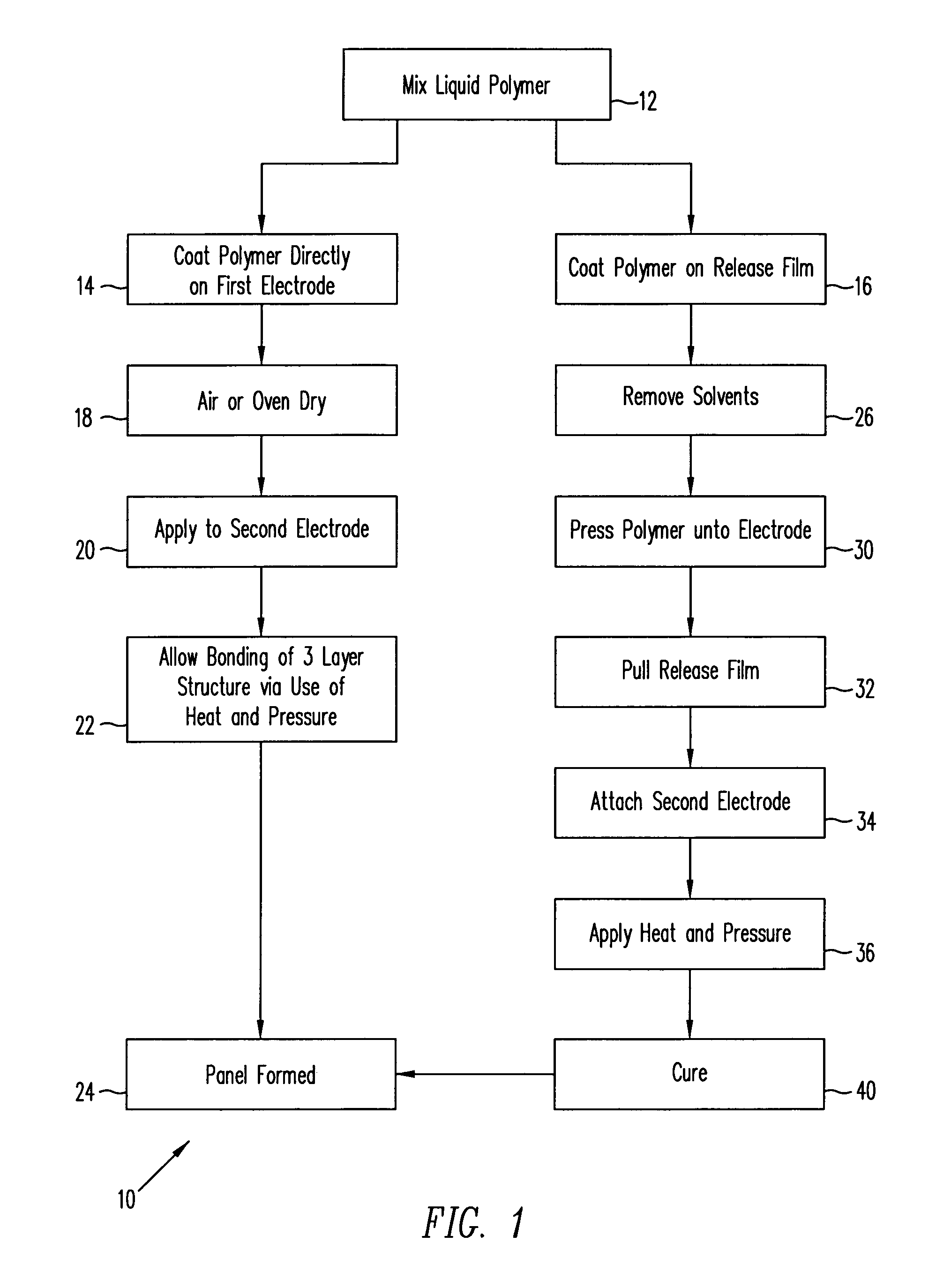

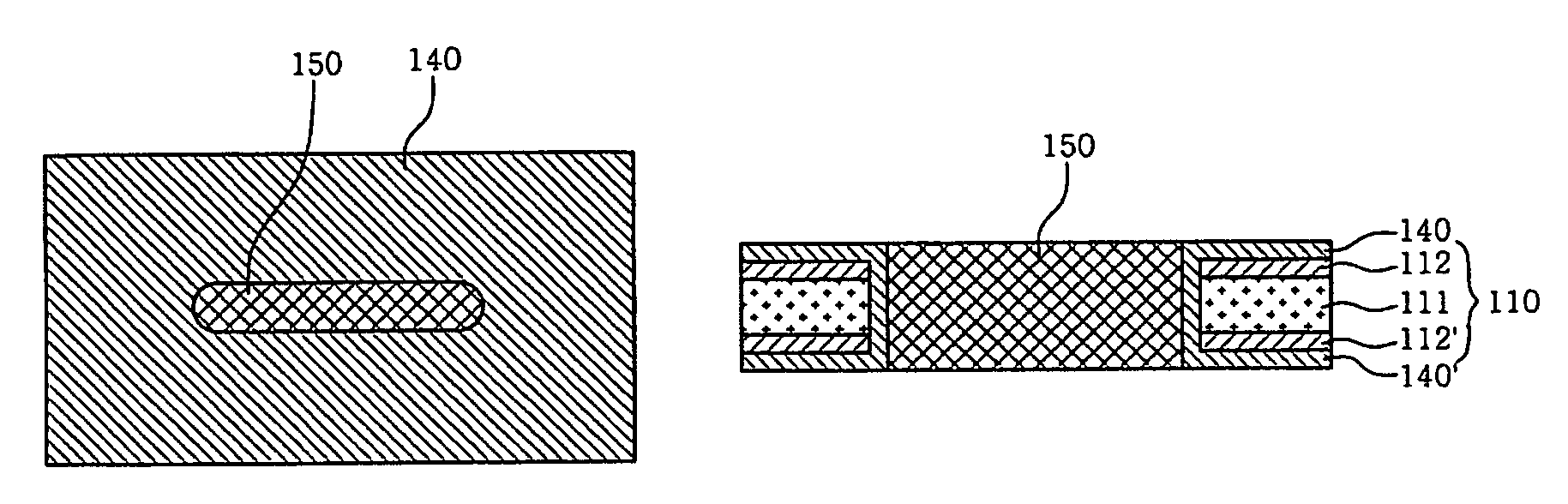

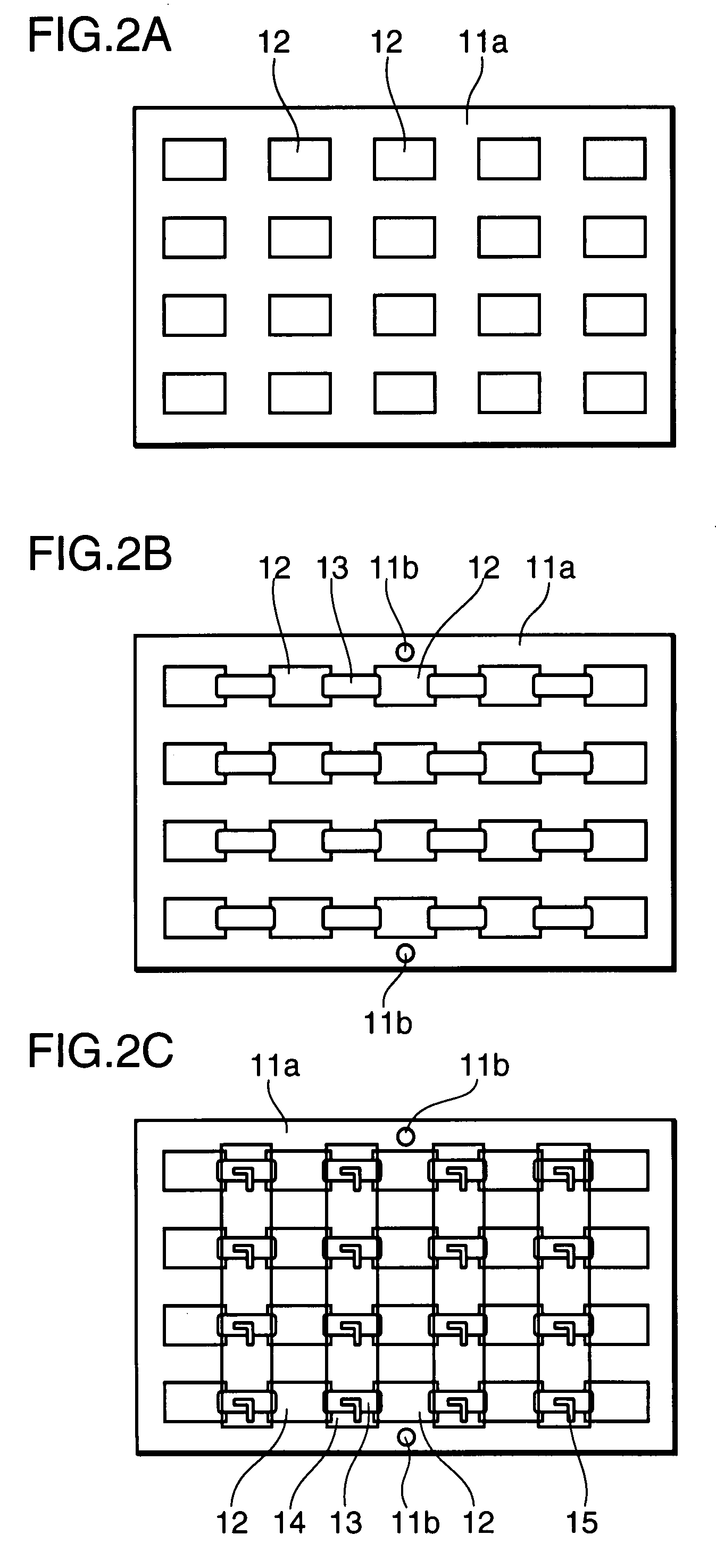

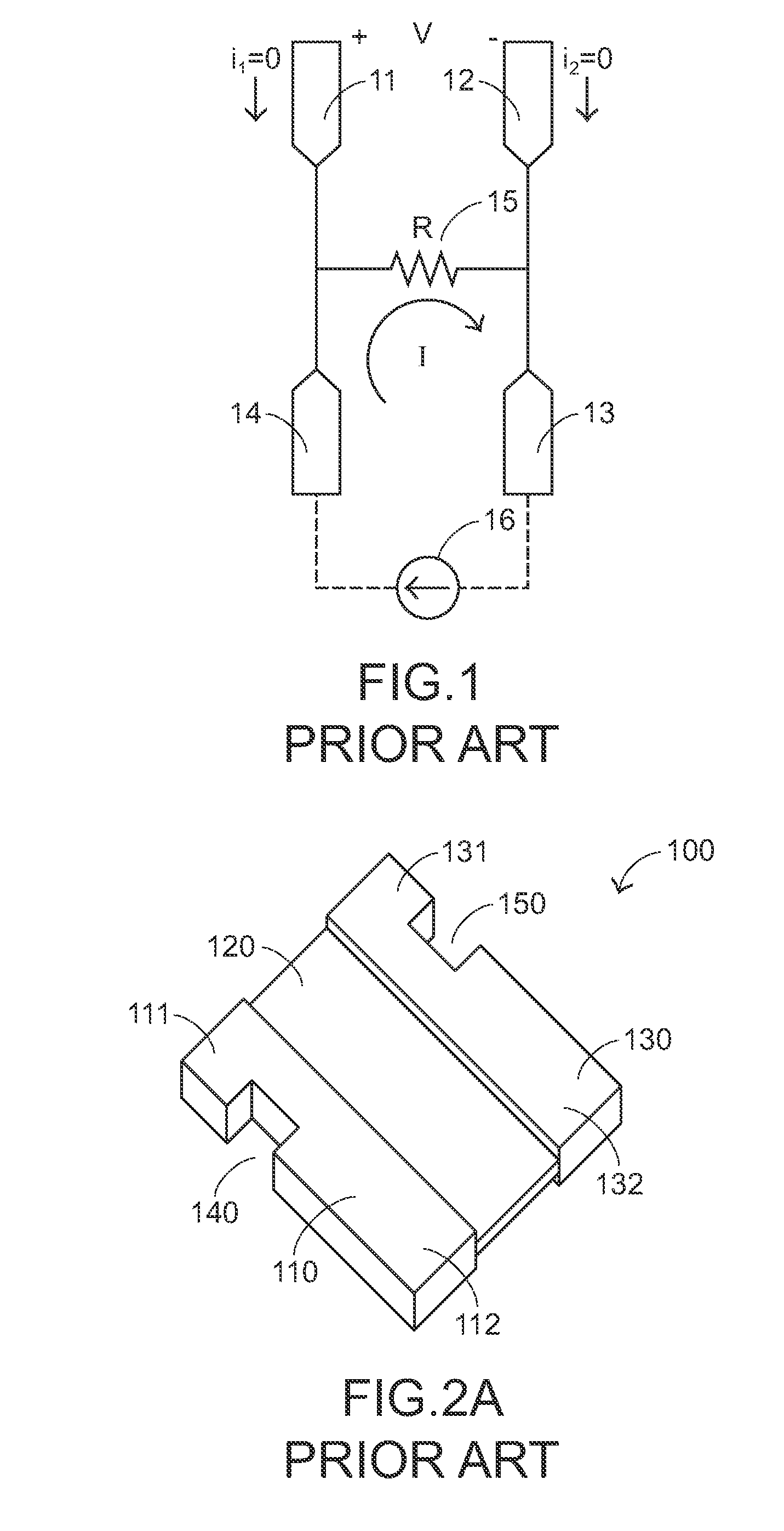

Method of manufacturing devices to protect election components

InactiveUS6981319B2Easy to customizeMake fastFuse device manufactureInsulating layers/substrates workingManufacturing technologyElectronic component

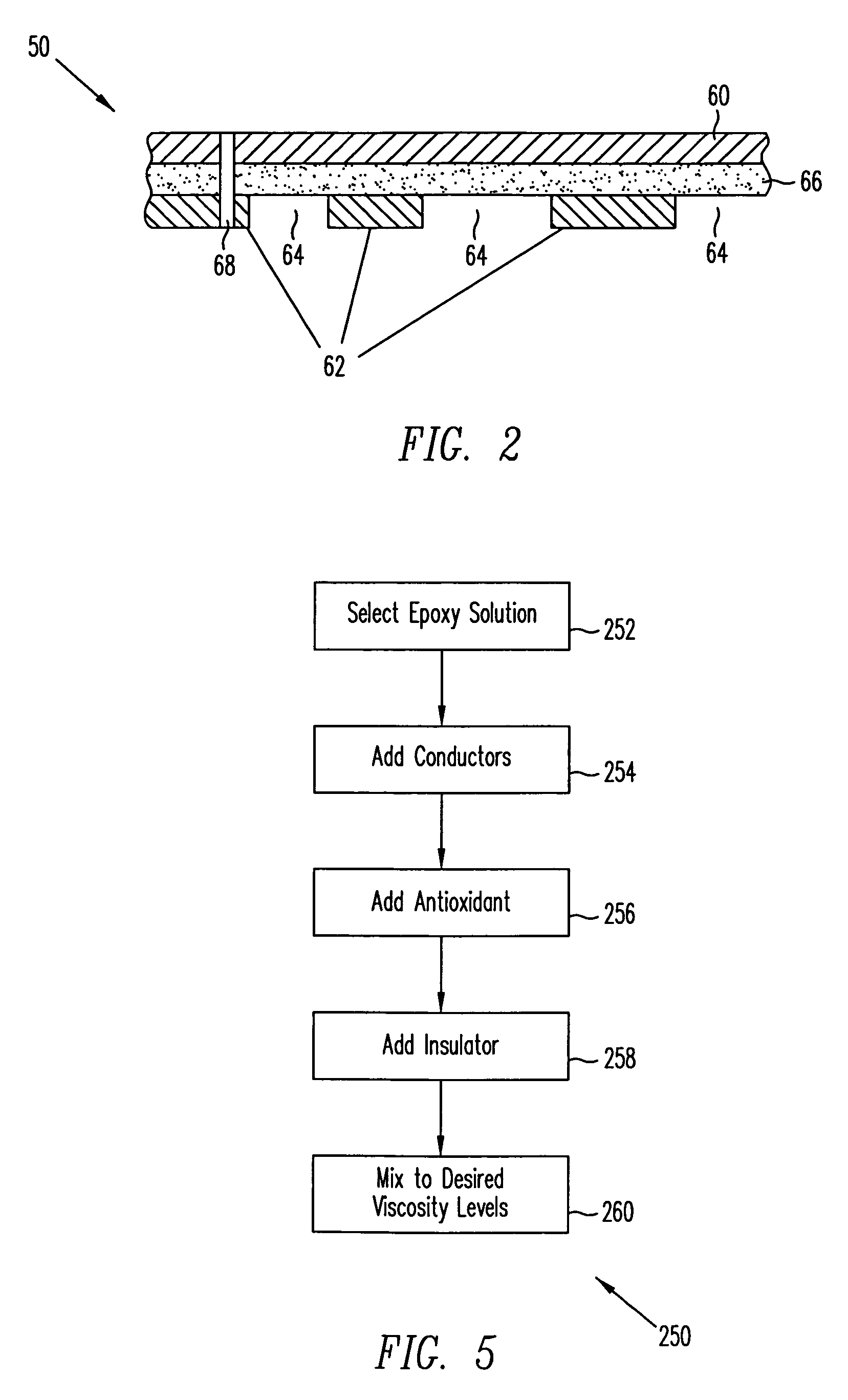

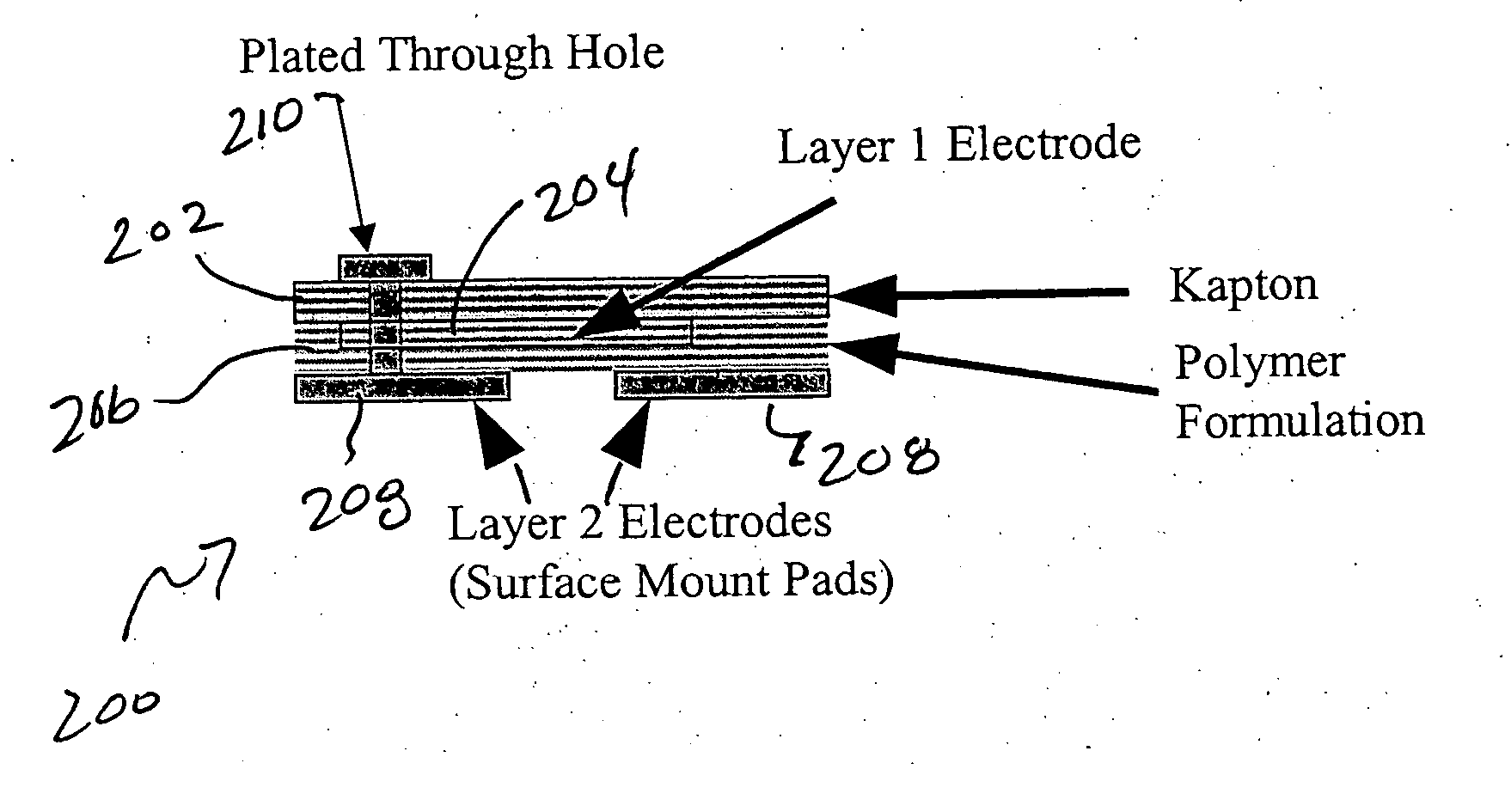

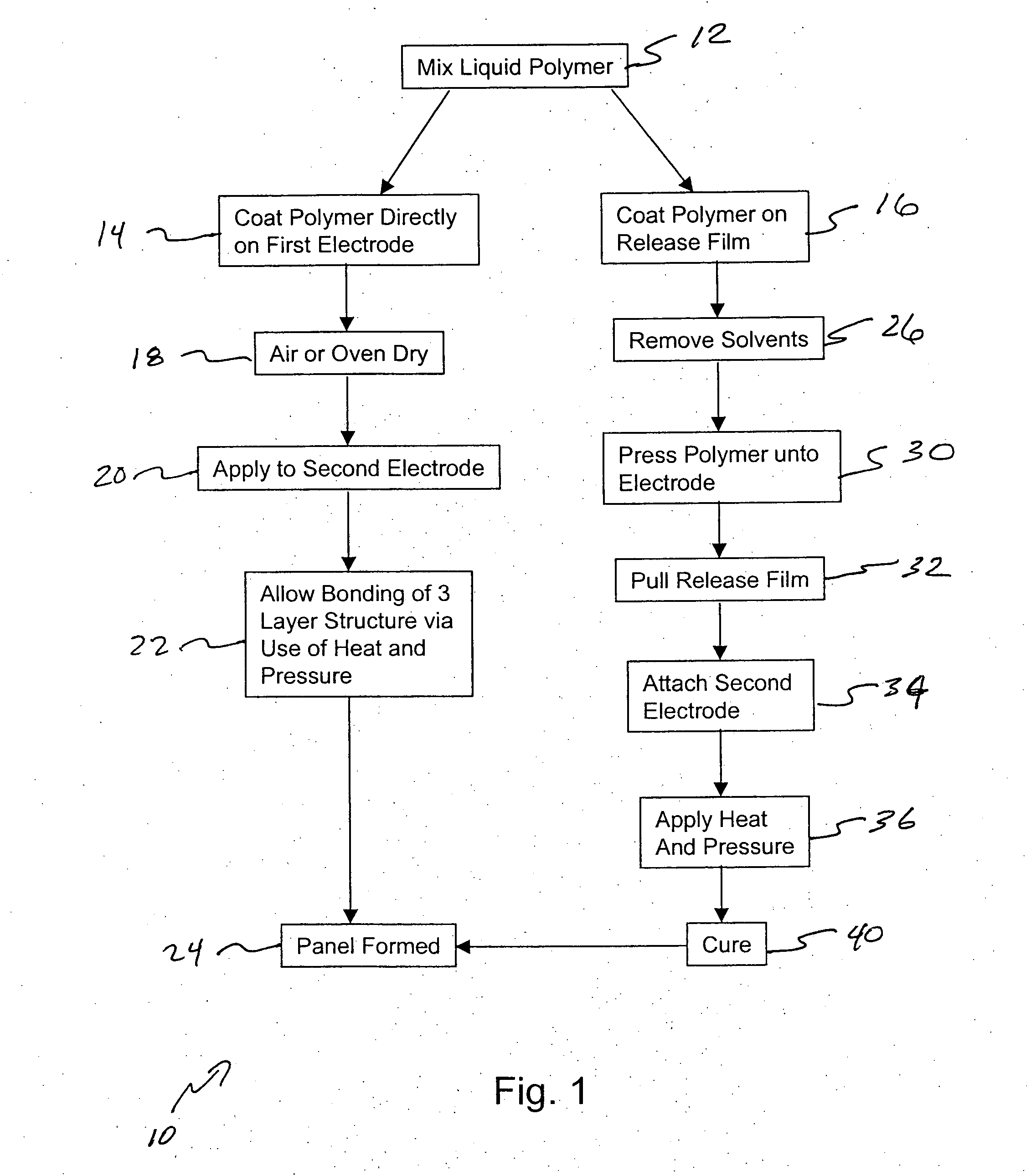

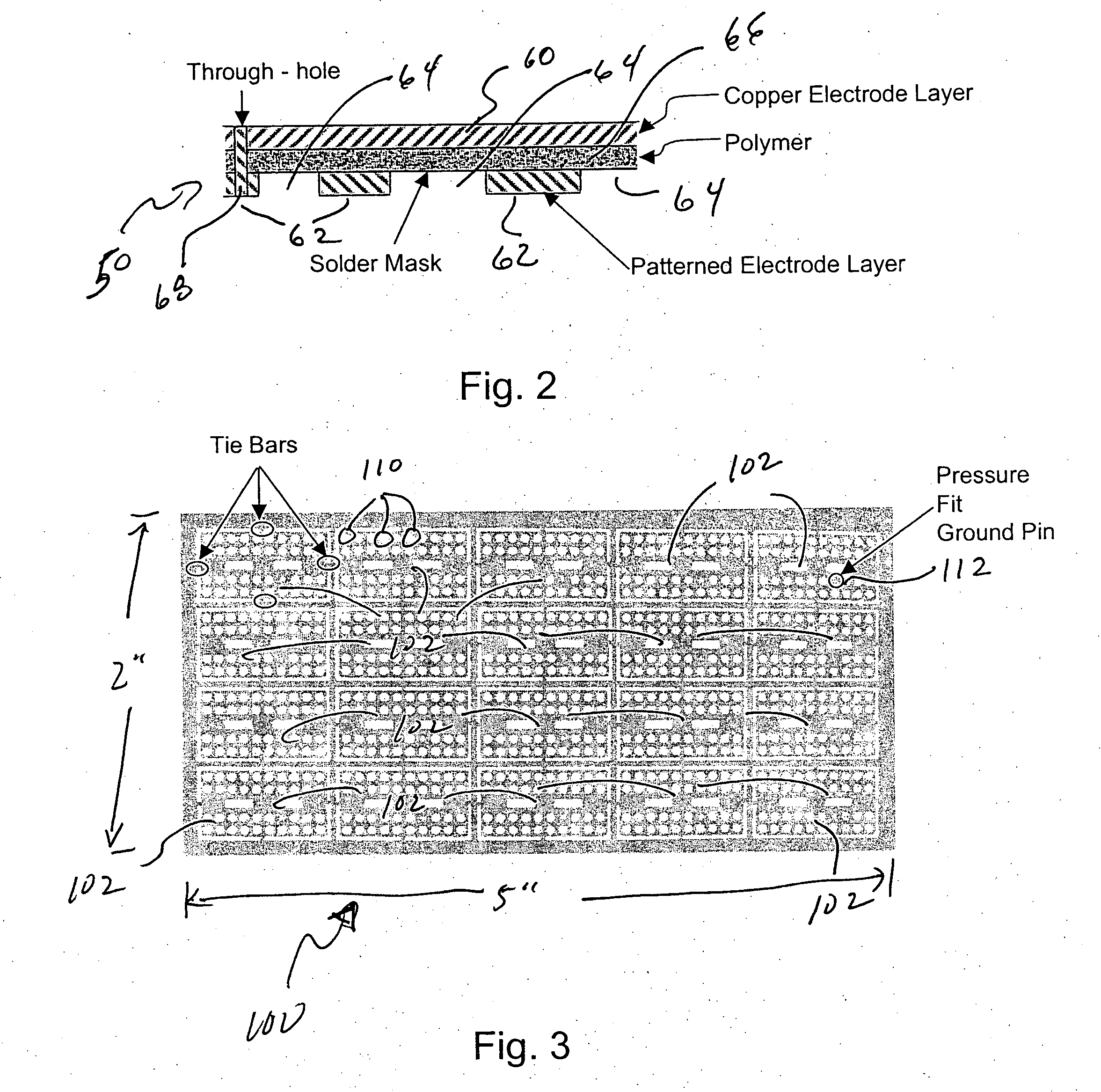

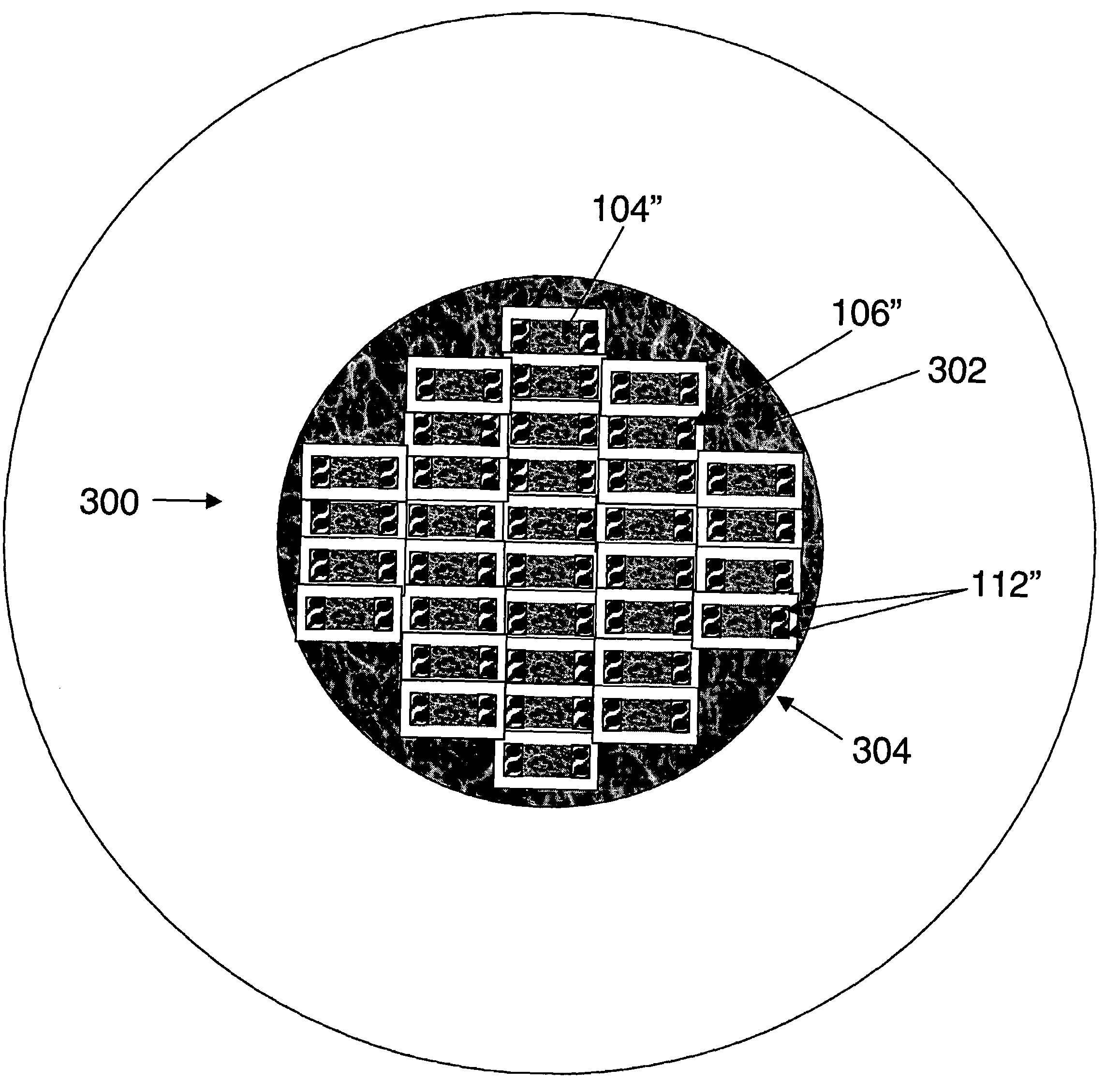

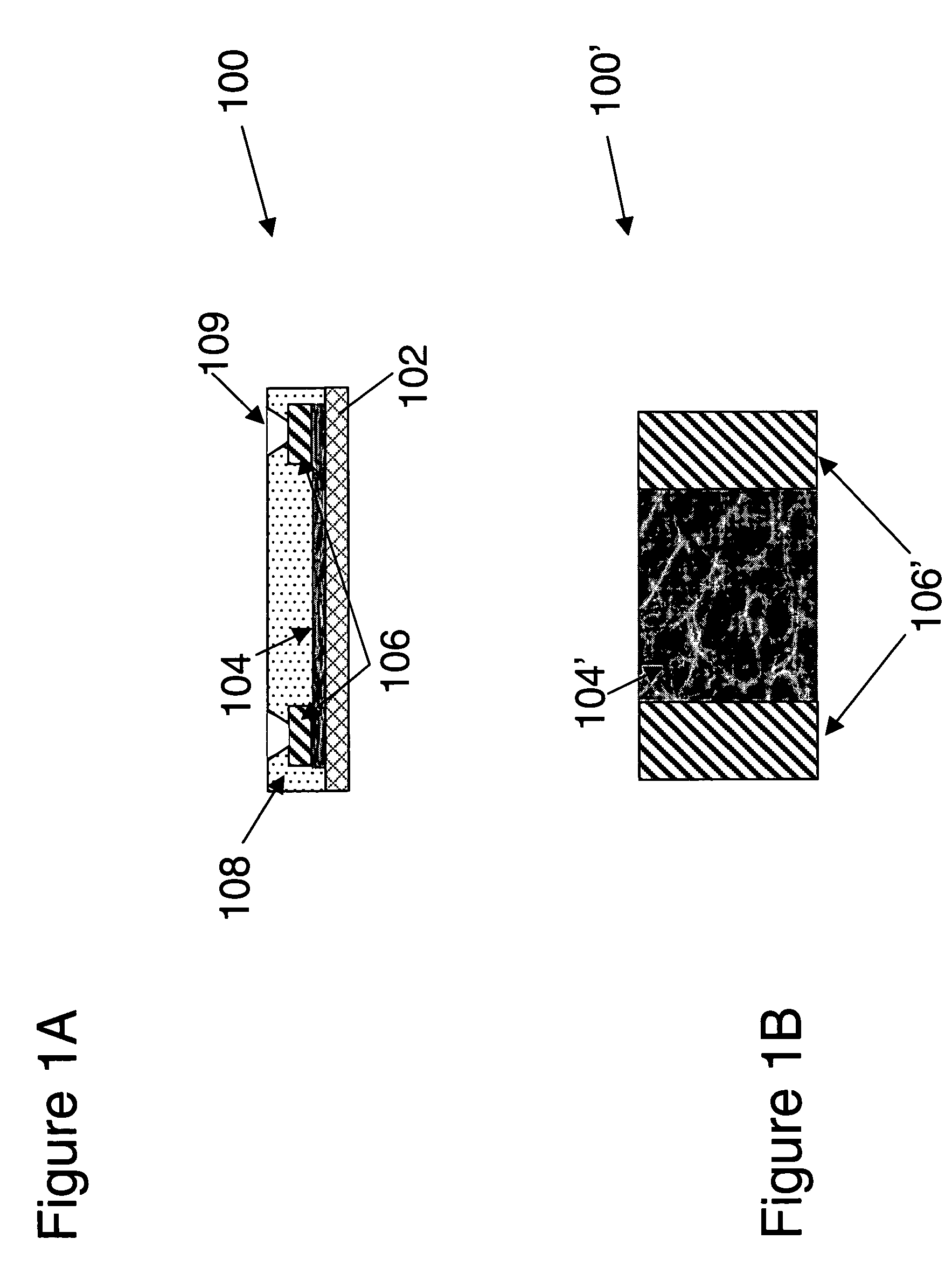

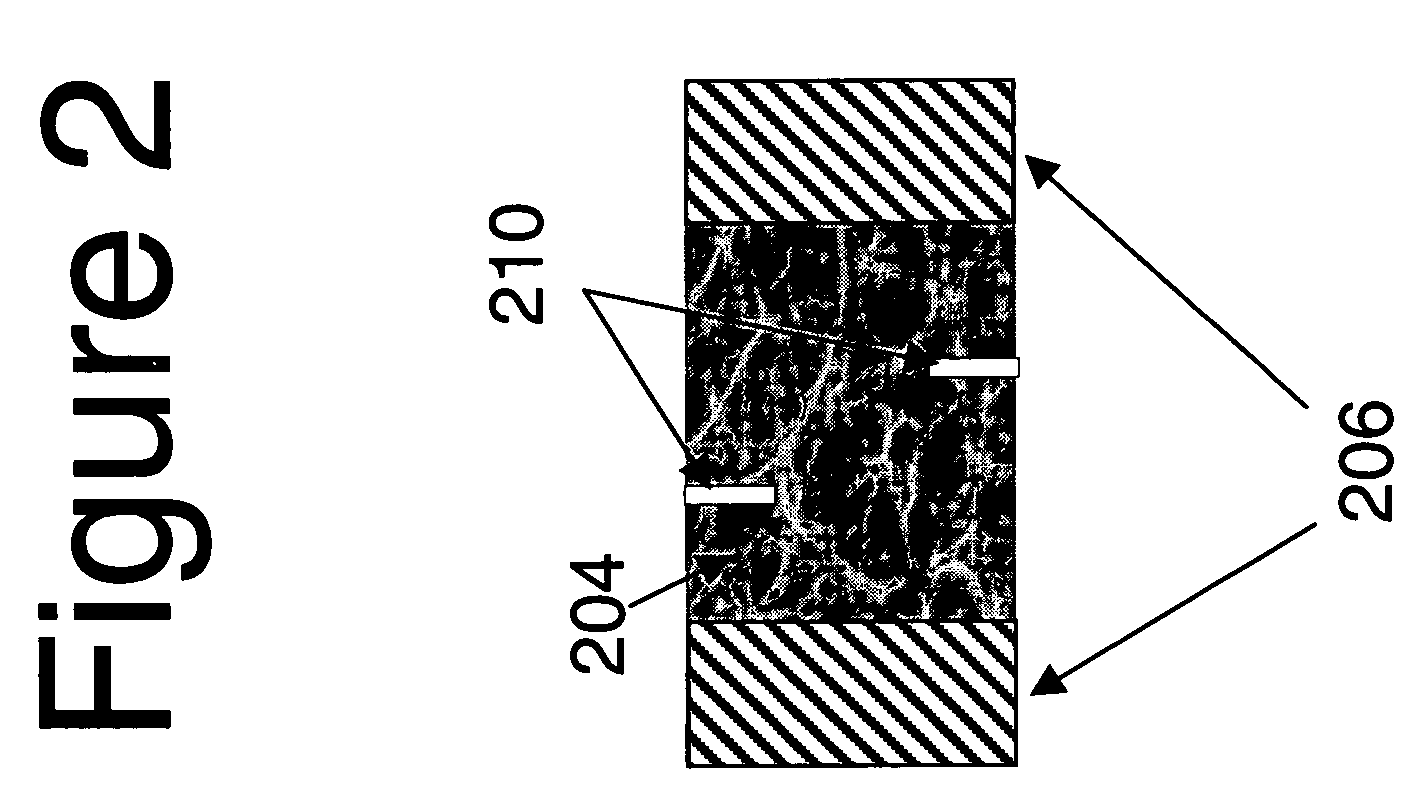

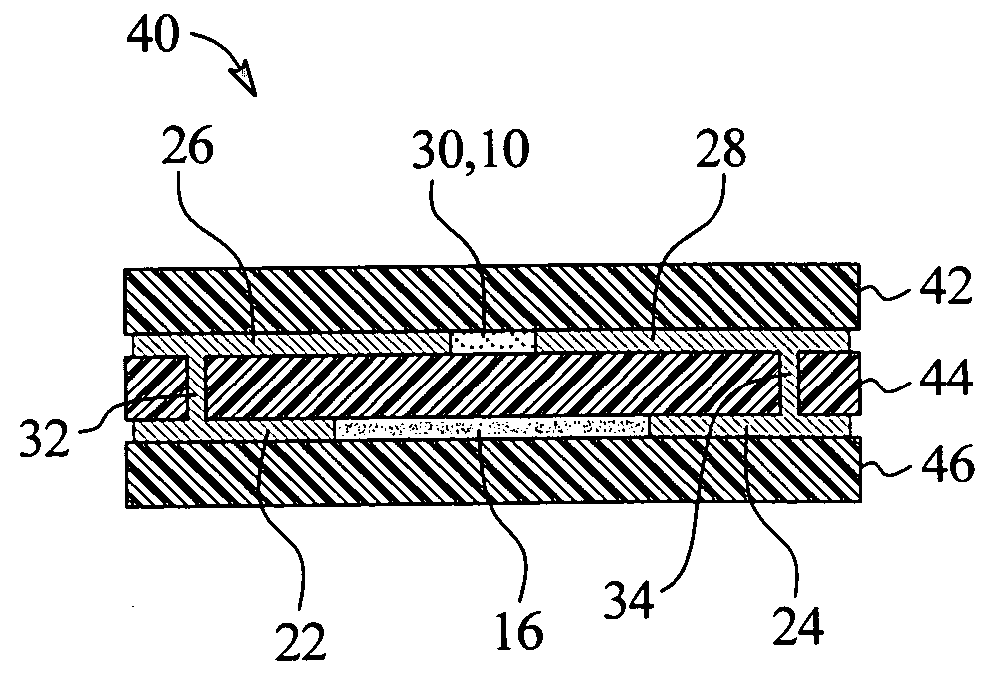

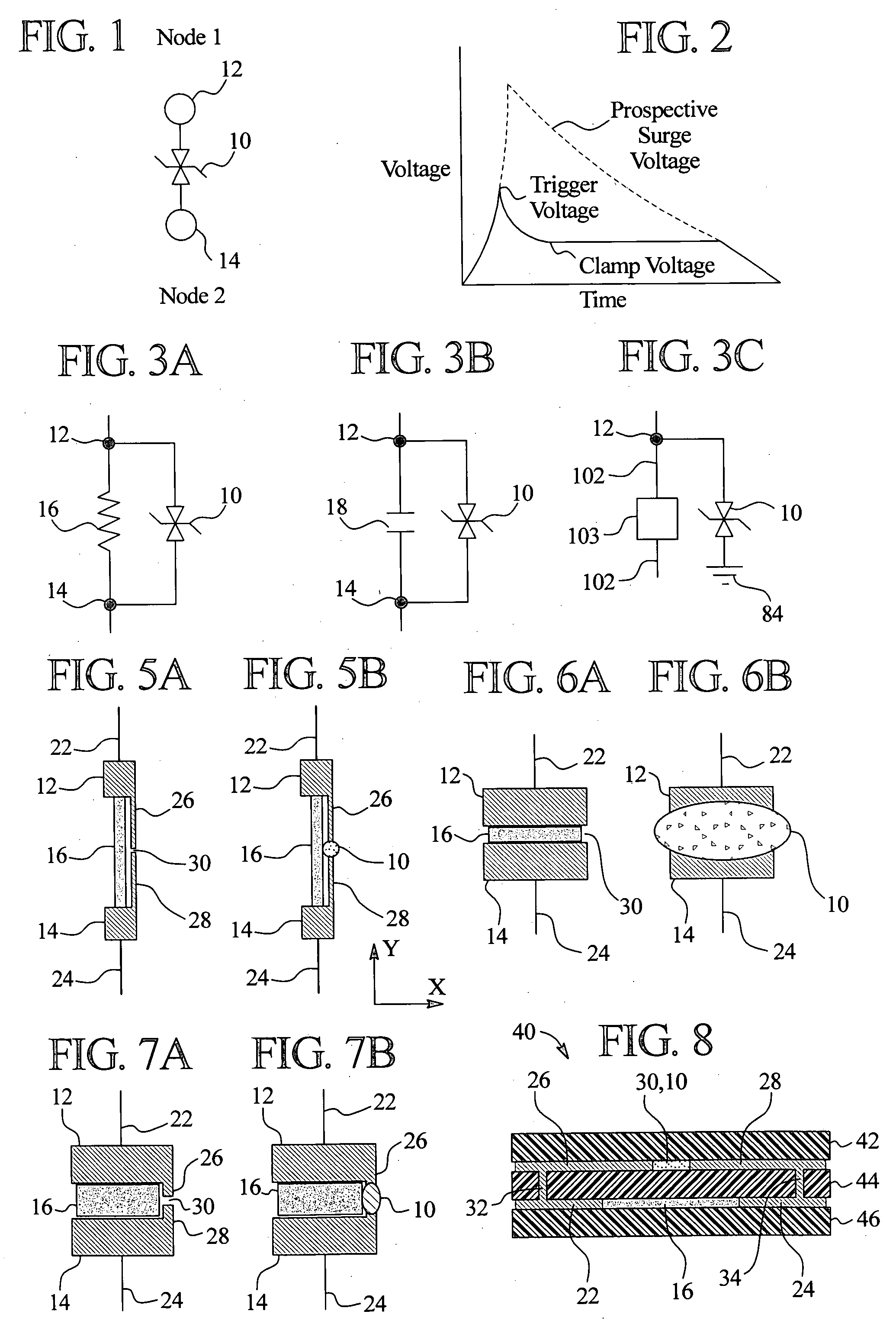

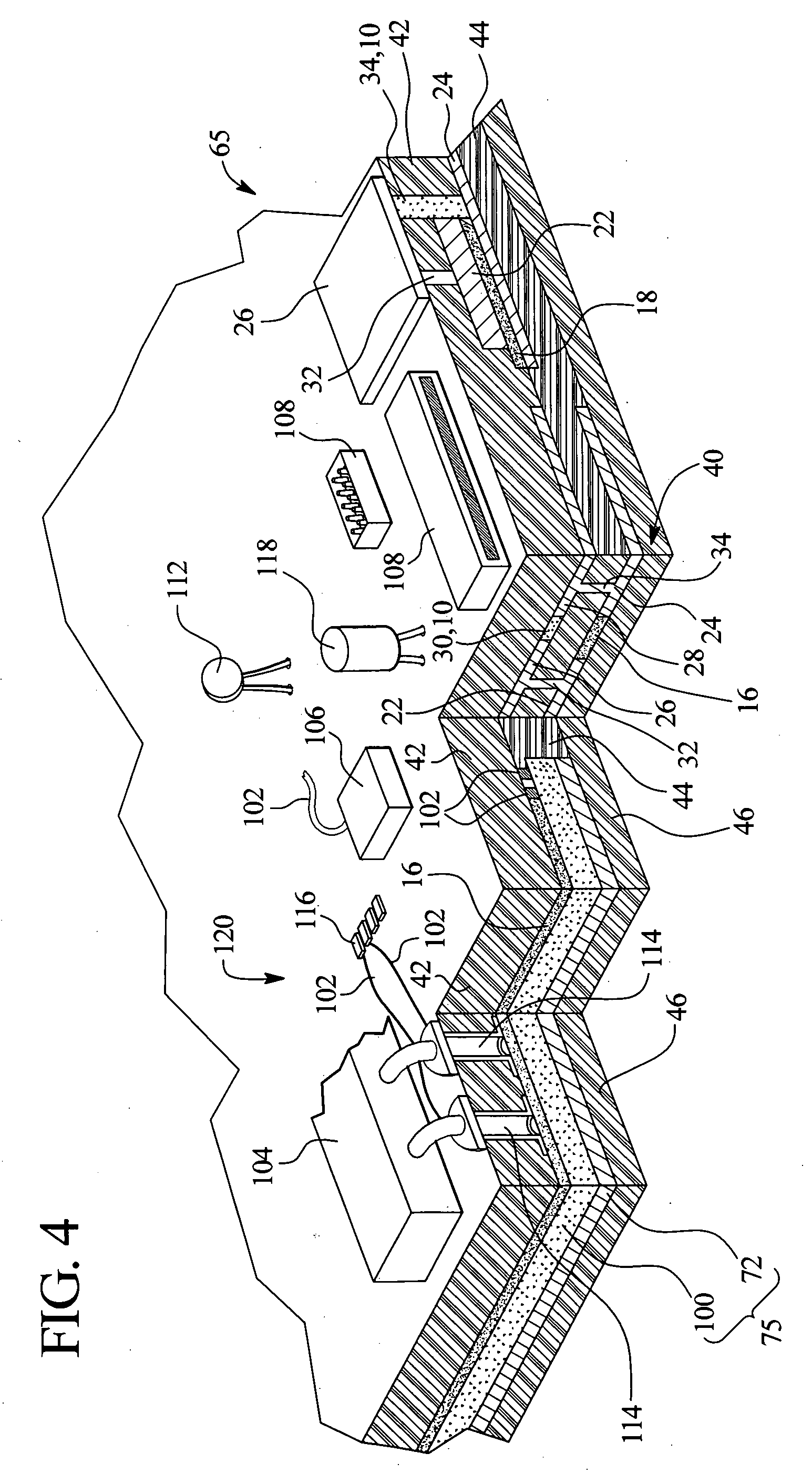

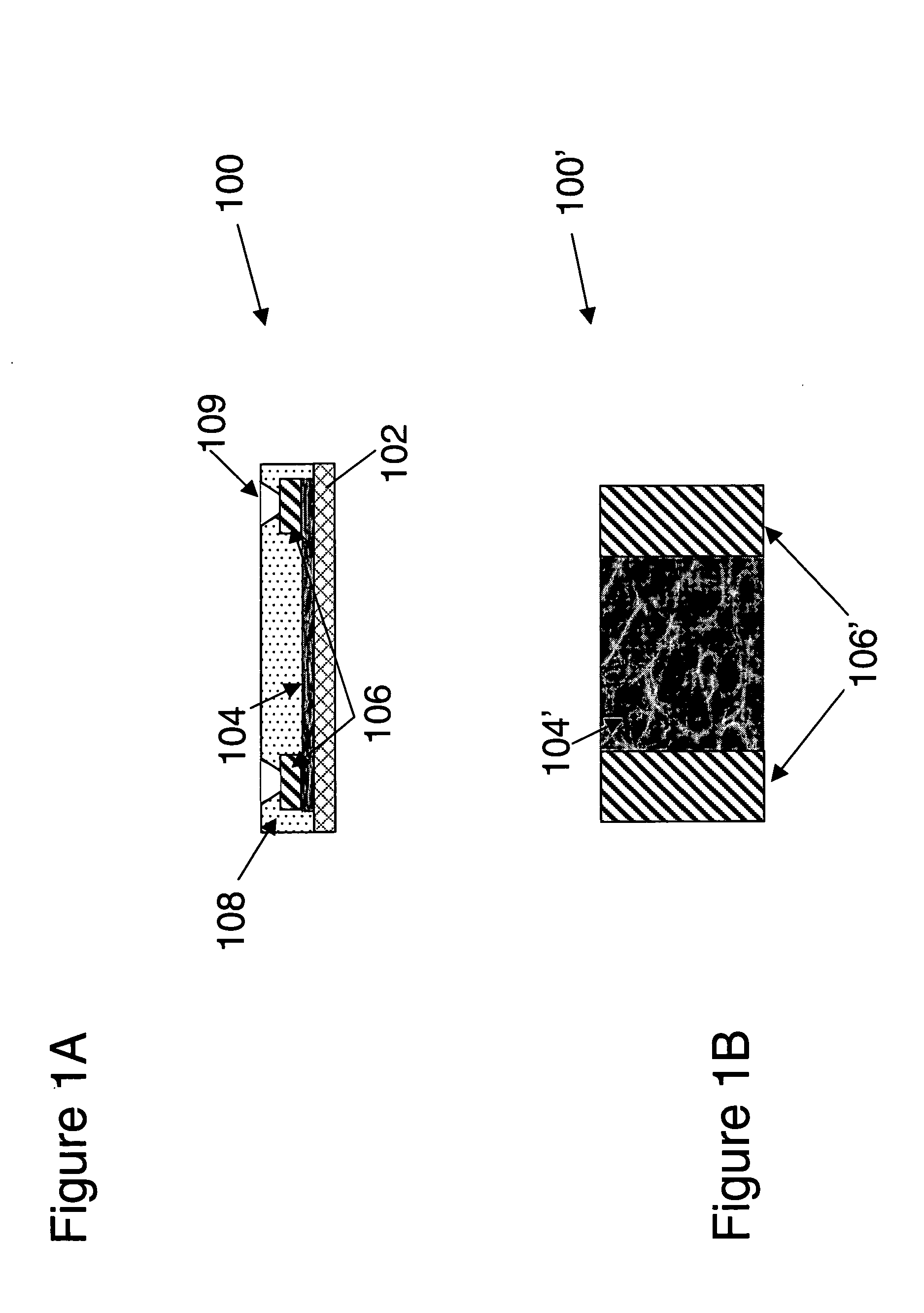

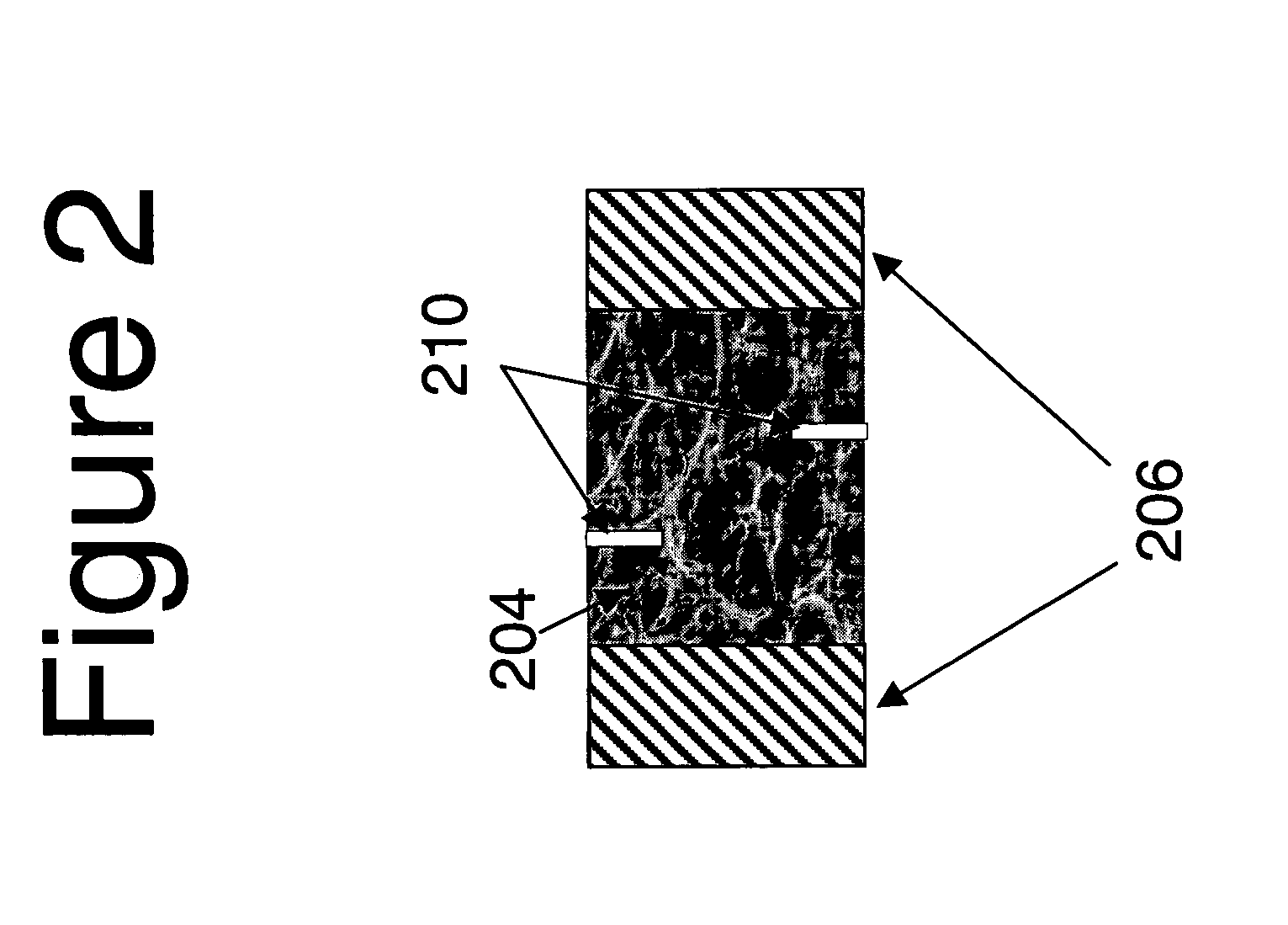

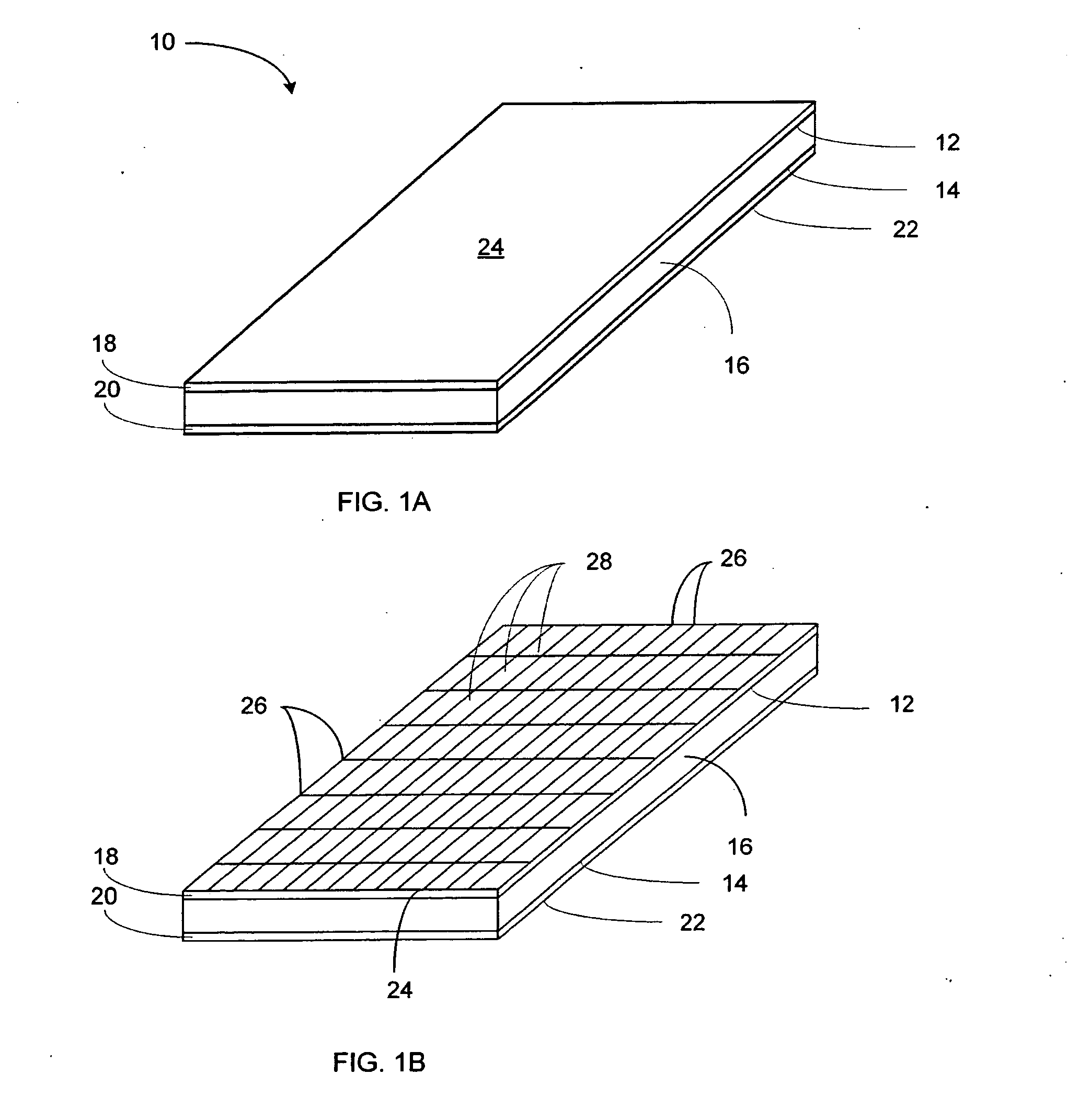

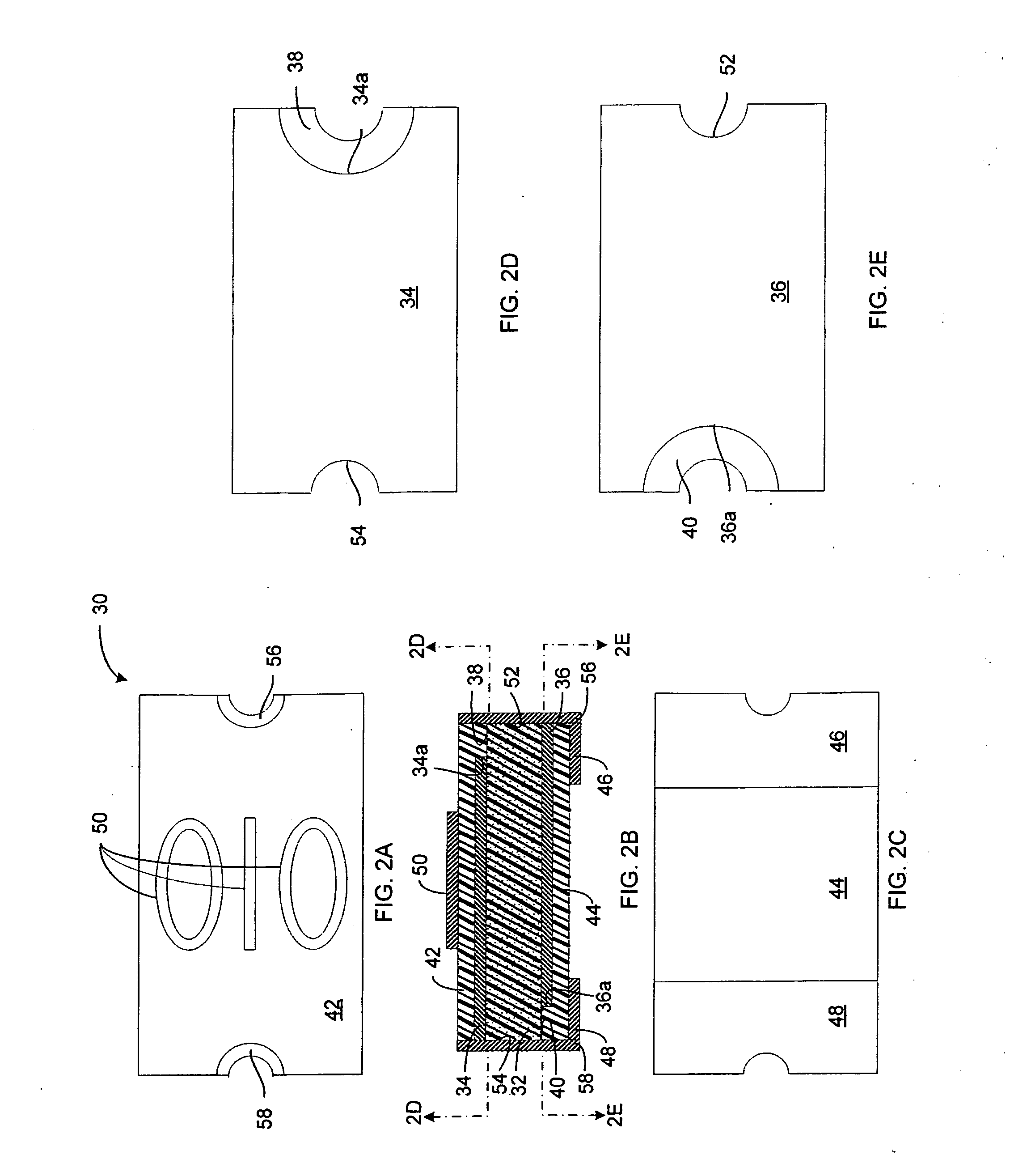

Devices capable of protecting electronic components during the occurrence of a disturbance event using printed circuit board manufacturing techniques. A three (3) layer structure is formed comprising a polymer-based formulation sandwiched between two electrode layers. The devices can be manufactured in panel form providing high quantities of devices which can be removed from the panel and applied directly to the component to be protected. Desired patterns can be formed on either one of the electrode layers by photo-etch techniques thereby providing a process that can be tailored to a large number of applications.

Owner:ELECTRONICS POLYMERS NEWCO

ESD protection devices and methods of making same using standard manufacturing processes

ActiveUS20050083163A1Easy to customizeMinimal effortInsulating layers/substrates workingPrinted resistor incorporationManufacturing technologyElectronic component

Devices capable of protecting electronic components during the occurrence of a disturbance event using printed circuit board manufacturing techniques. A three (3) layer structure is formed comprising a polymer-based formulation sandwiched between two electrode layers. The devices can be manufactured in panel form providing high quantities of devices which can be removed from the panel and applied directly to the component to be protected. Desired patterns can be formed on either one of the electrode layers by photo-etch techniques thereby providing a process that can be tailored to a large number of applications.

Owner:ELECTRONICS POLYMERS NEWCO

Resistive elements using carbon nanotubes

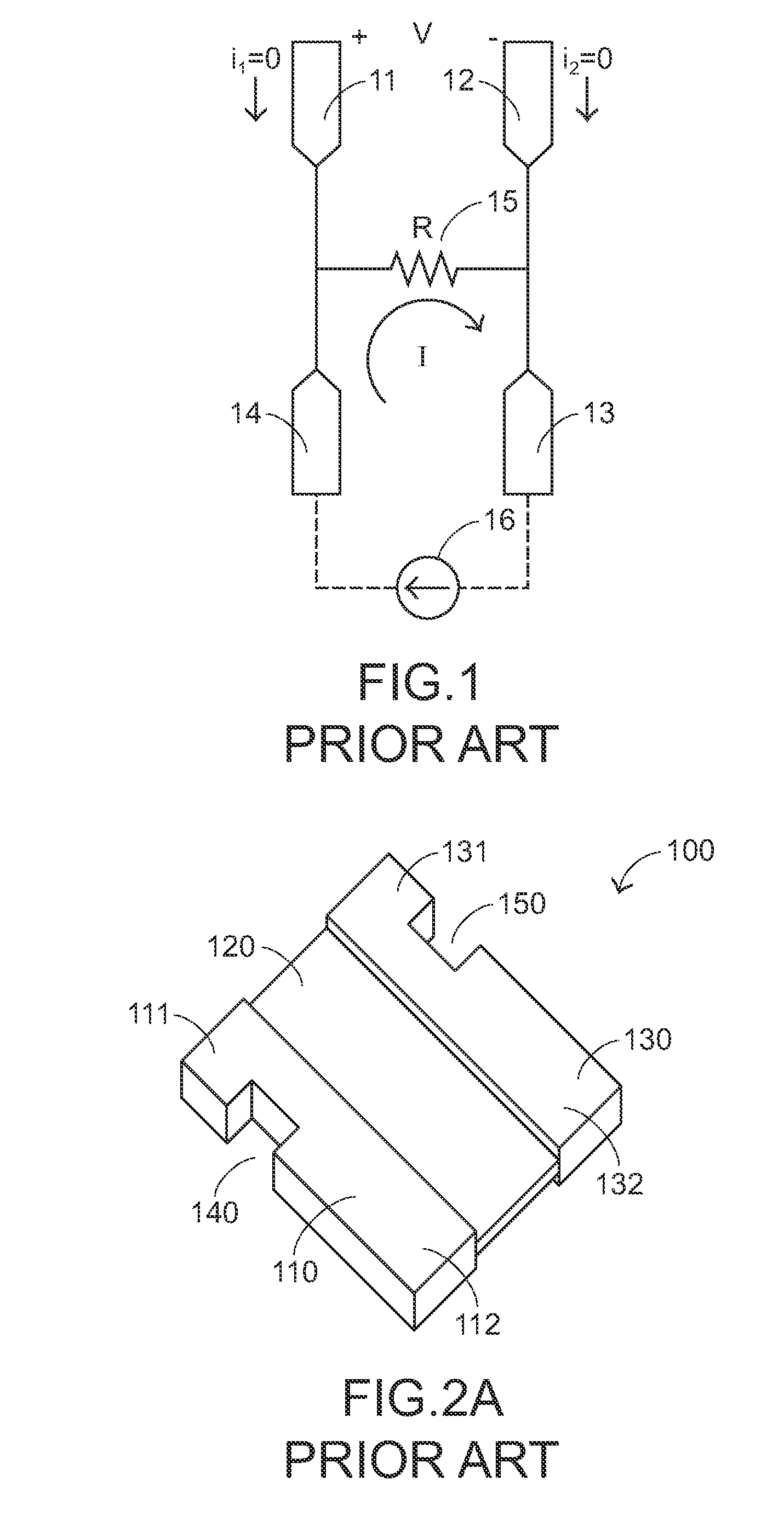

ActiveUS7365632B2Function increaseEasy parameter controlCurrent responsive resistorsSolid-state devicesBulk resistanceCarbon nanotube

Resistive elements include a patterned region of nanofabric having a predetermined area, where the nanofabric has a selected sheet resistance; and first and second electrical contacts contacting the patterned region of nanofabric and in spaced relation to each other. The resistance of the element between the first and second electrical contacts is determined by the selected sheet resistance of the nanofabric, the area of nanofabric, and the spaced relation of the first and second electrical contacts. The bulk resistance is tunable.

Owner:NANTERO

Electrostatic discharge protection for embedded components

InactiveUS20060152334A1Protection elementLow costPrinted circuit aspectsHigh voltage circuit adaptationsCapacitanceElectrical resistance and conductance

An improved electrical circuit that includes an embedded electrical component and an embedded voltage variable material (“VVM”) is provided. In one embodiment, the embedded VVM is provided as a voltage variable substrate, which is used in combination with an embedded electrical component, such as an embedded resistive material or an embedded capacitive material.

Owner:LITTELFUSE INC

Resistive nanocomposite compositions

InactiveUS20030100653A1Improve mechanical propertiesEasy to wearNanotechPrinted electric component incorporationScreen printingOrganic solvent

A resistive composition for screen printing onto a substrate. The resistive composition, based on total composition has a) 5-30 wt. % of polymer resin, b) greater than 0 up to and including 10 wt. % of thermosetting resin, c) 10-30 wt. % conductive particles selected from the group consisting of carbon black, graphite and mixtures thereof and d) 0.025 -20 wt. % carbon nanoparticles, wherein all of (a), (b), (c) and (d) are dispersed in a 60-80 wt. % organic solvent.

Owner:CTS CORP ELKHART

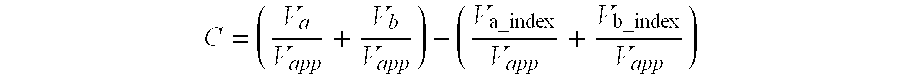

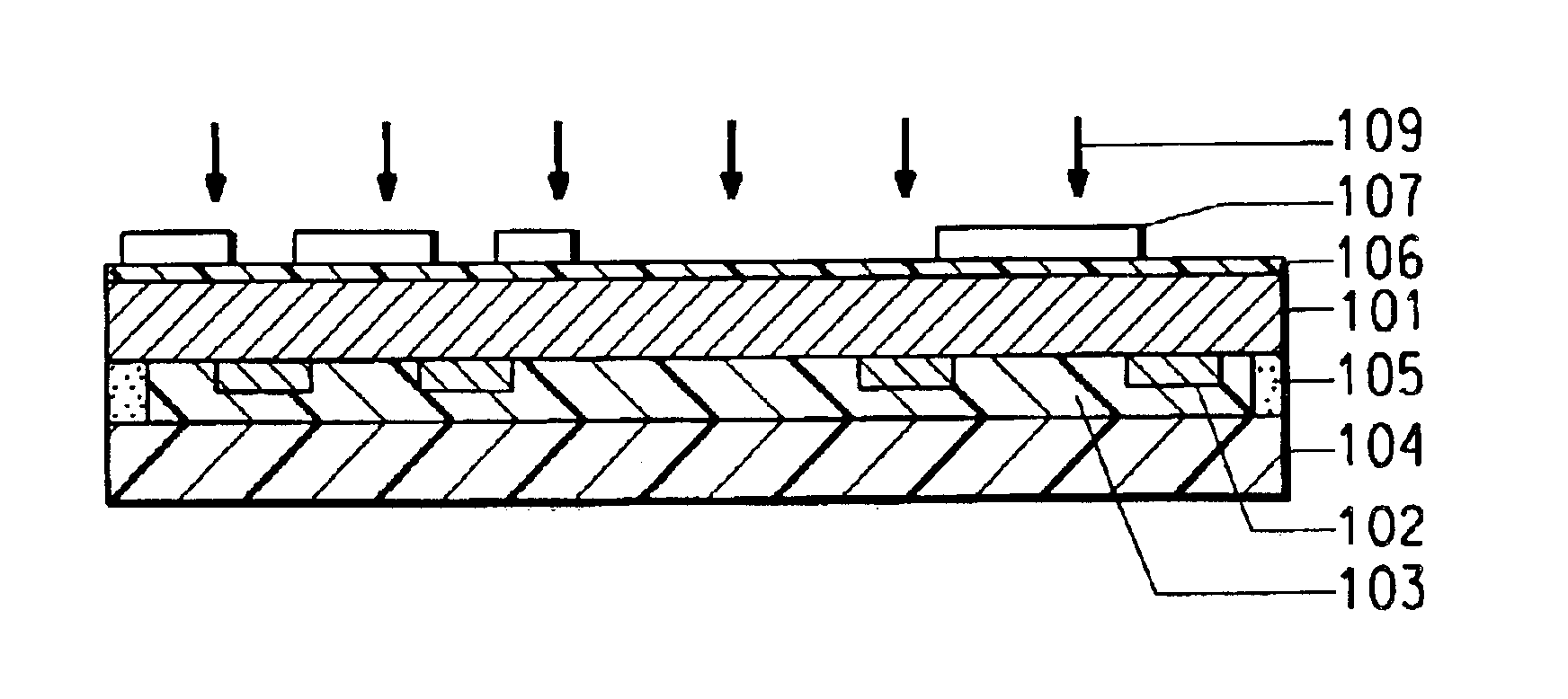

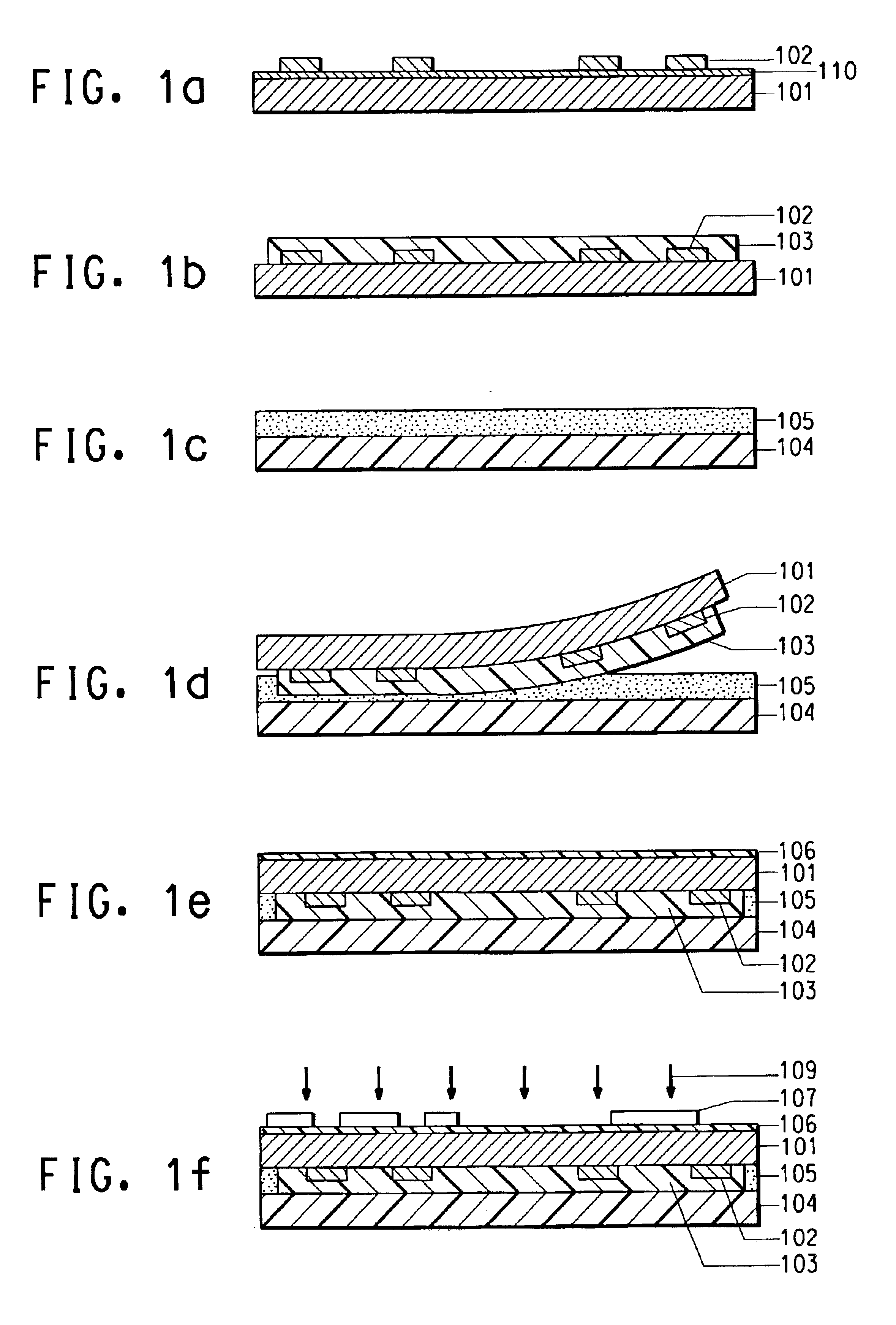

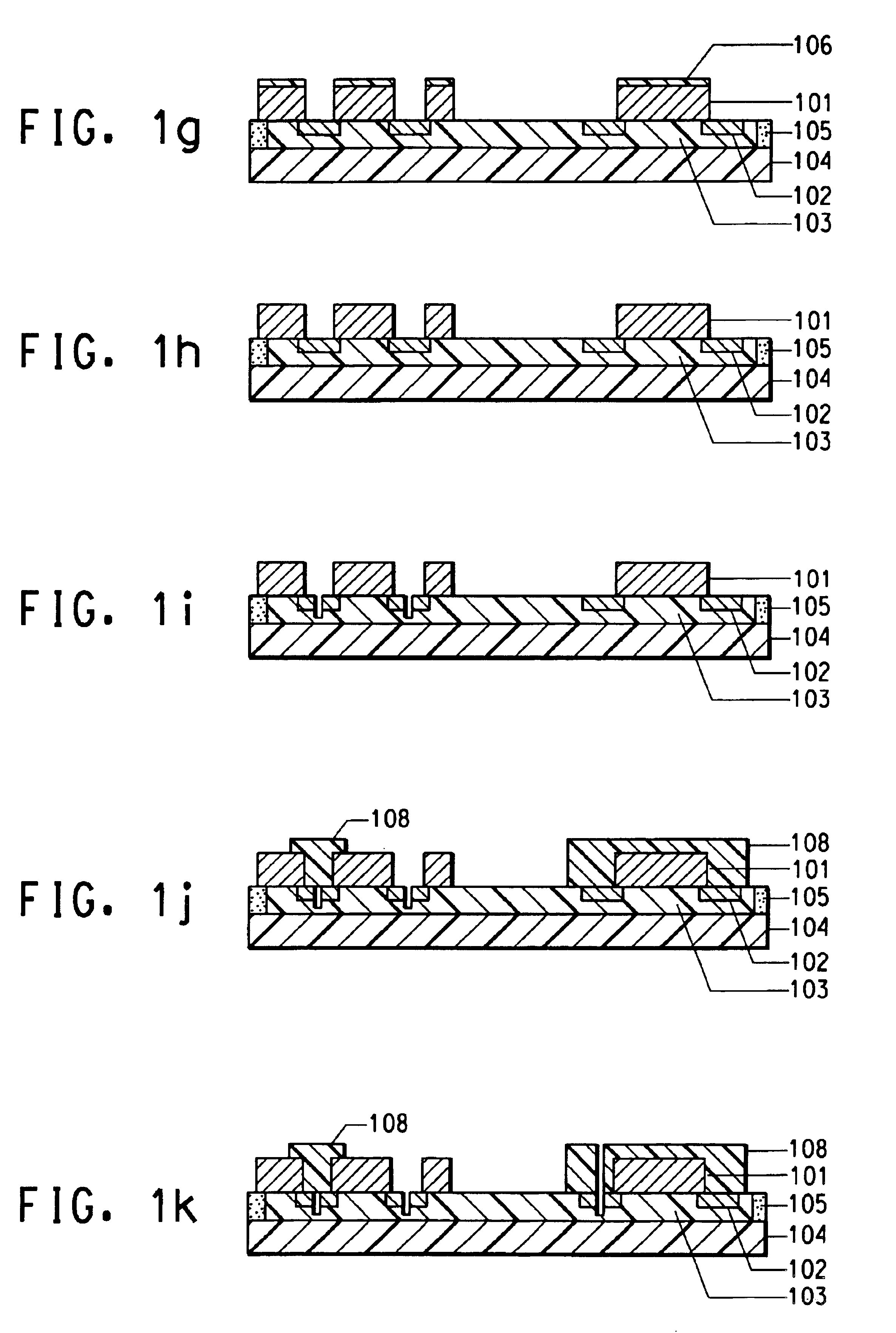

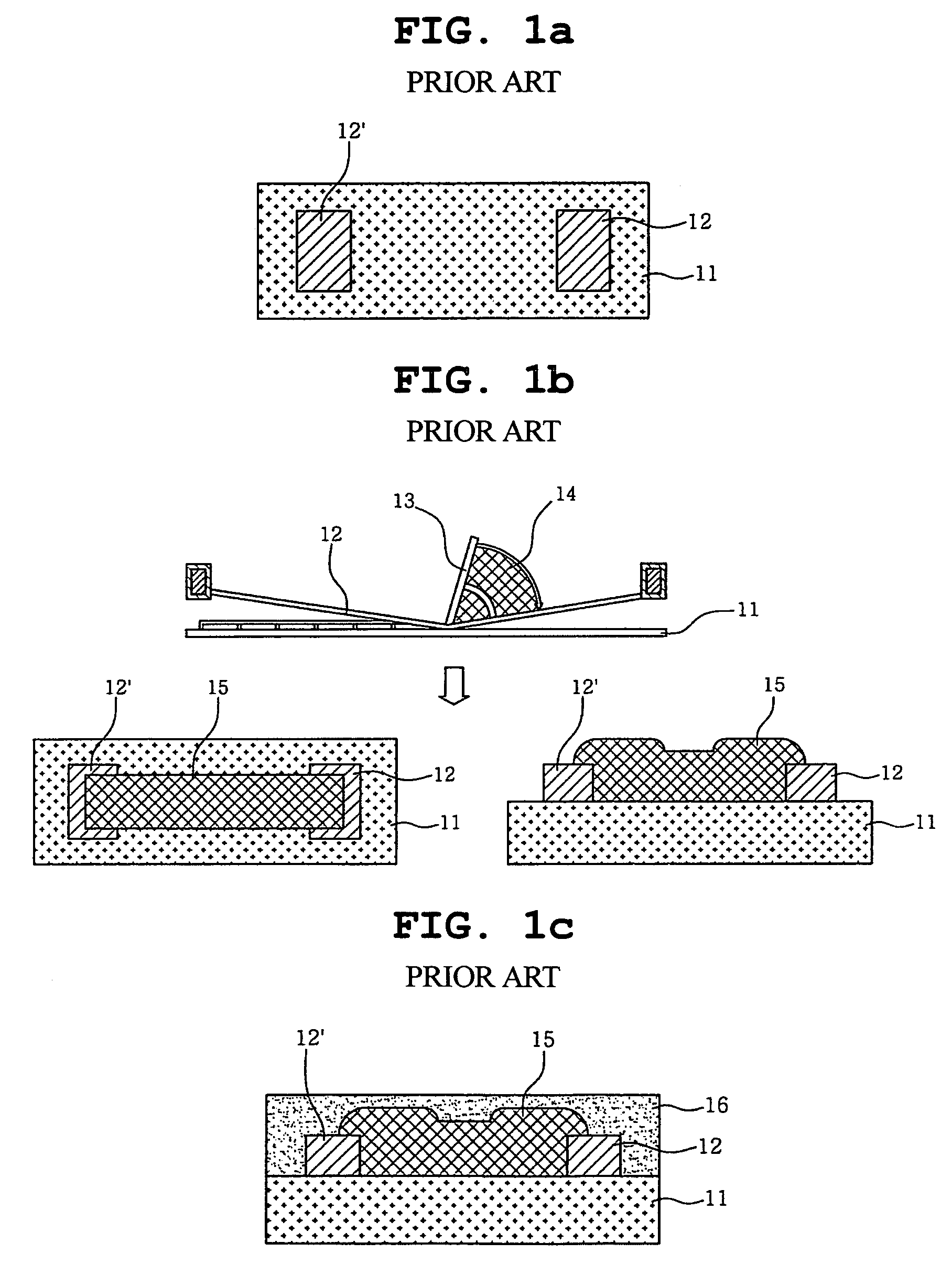

Method to embed thick film components

InactiveUS6860000B2Printed circuit assemblingInsulating substrate metal adhesion improvementEngineeringMetallic substrate

The invention is directed to a method to embed a thick film resistor composition into a printed wiring board comprising the steps of applying a reinforcing composition onto a resistor composition disposed on a metallic substrate forming an assembly wherein the resistor composition is at least partially coated with the reinforcing composition; processing the assembly; and applying the assembly onto at least one side of an organic substrate forming a component wherein the organic substrate is at least partially coated with an adhesive layer and wherein the reinforcing composition side of the assembly is embedded into the adhesive layer. The reinforcing composition allows laser trimming of the fired resistor and also eliminates cracking during lamination steps of the invention.

Owner:CHEMTRON RES

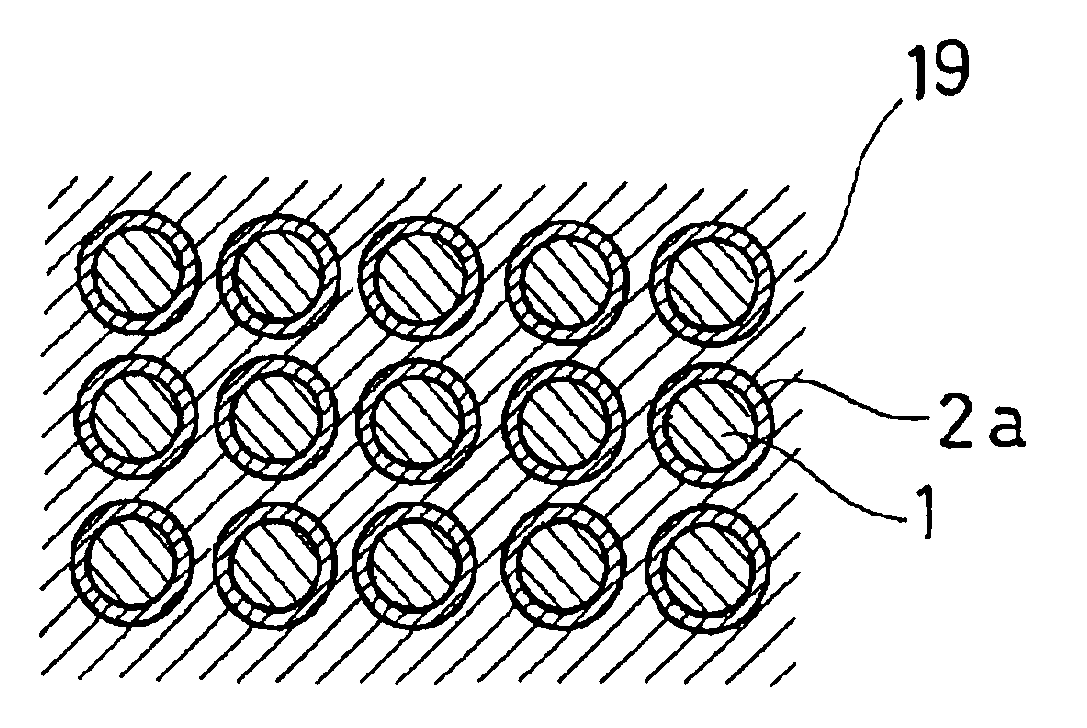

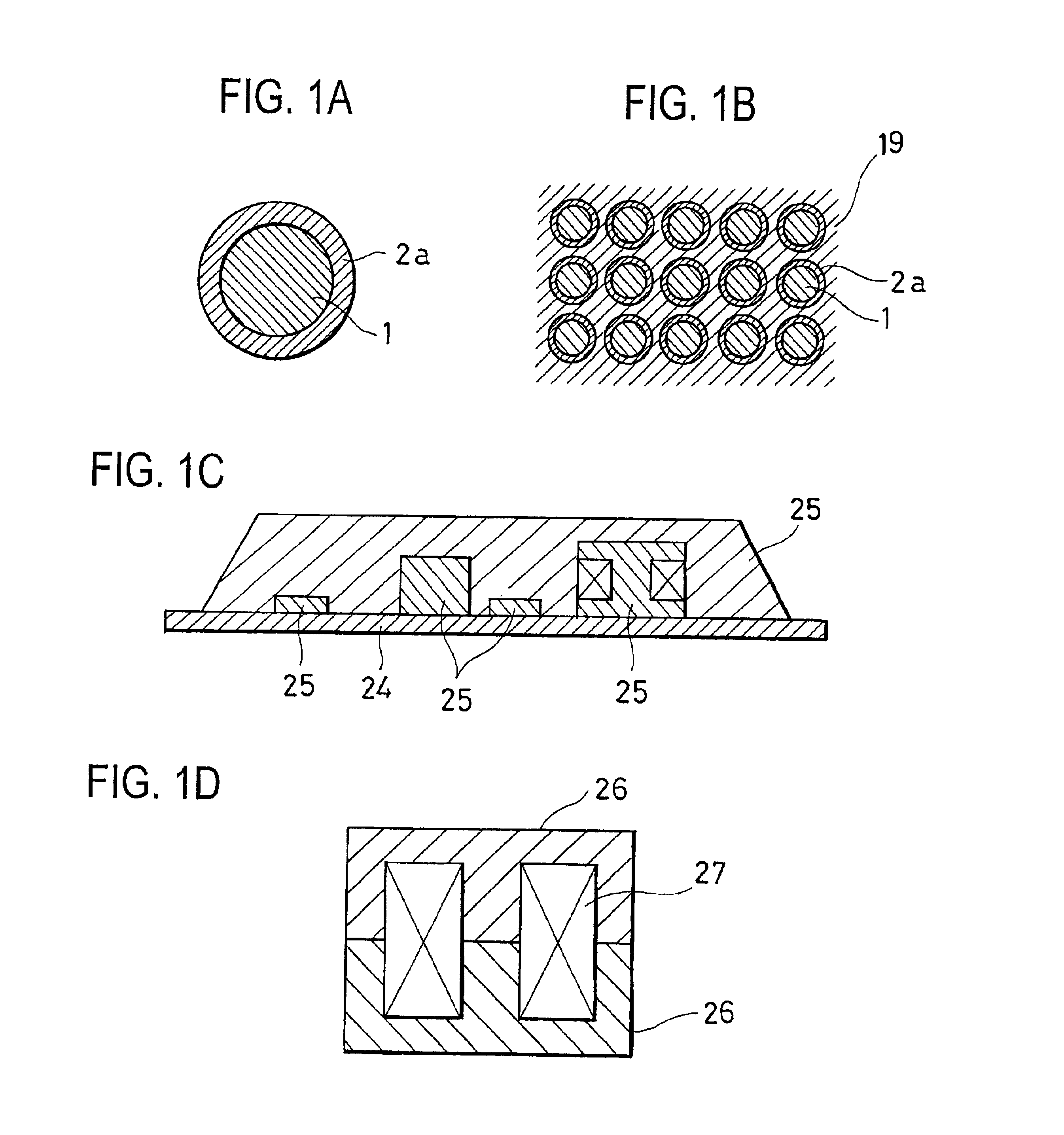

Composite magnetic material and magnetic molding material, magnetic powder compression molding material, and magnetic paint using the composite magnetic material, composite dielectric material and molding material, powder compression molding material, paint, prepreg, and substrate using the composite dielectric material, and electronic part

InactiveUS7060350B2High parts strengthIncrease resistanceRadiating elements structural formsRecord information storageCompression moldingMetal particle

A composite magnetic material including a resin and generally spherical magnetic metal particles of at least one type dispersed in the resin and consisting essentially of single crystal grains, the metal particles having a mean particle size of 0.1 to 10 μm and each having an insulating coating layer at least partially coated thereon.

Owner:TDK CORPARATION

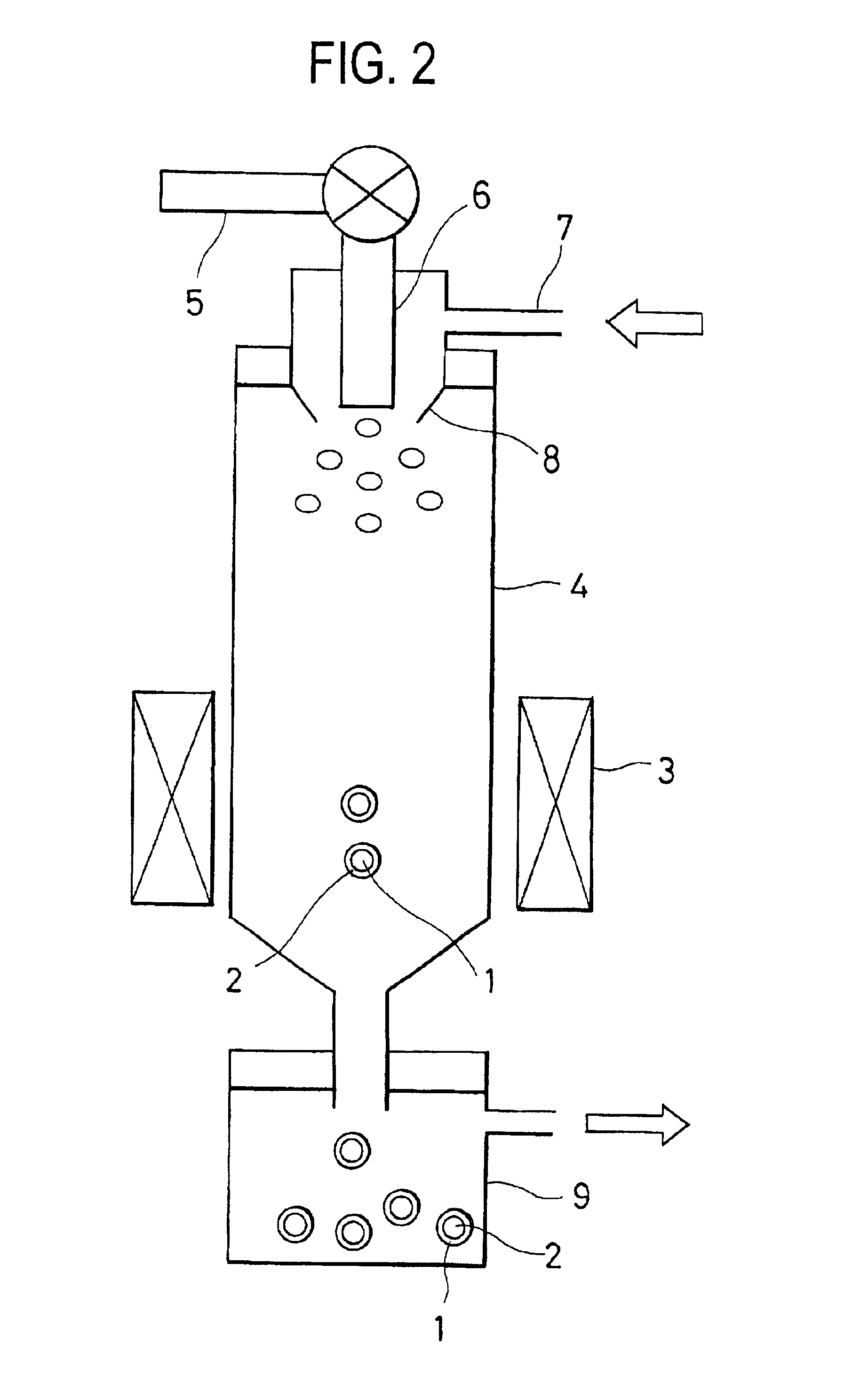

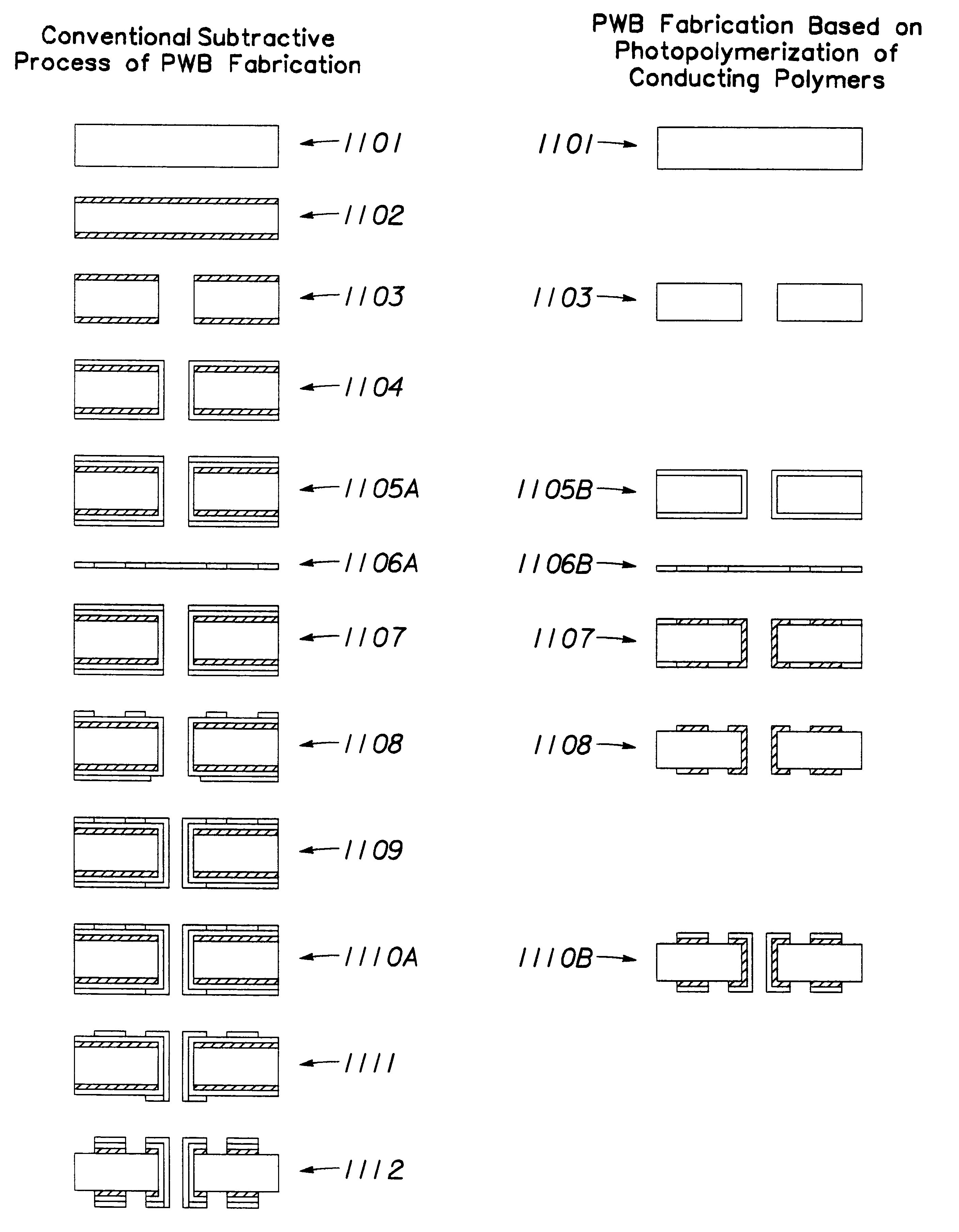

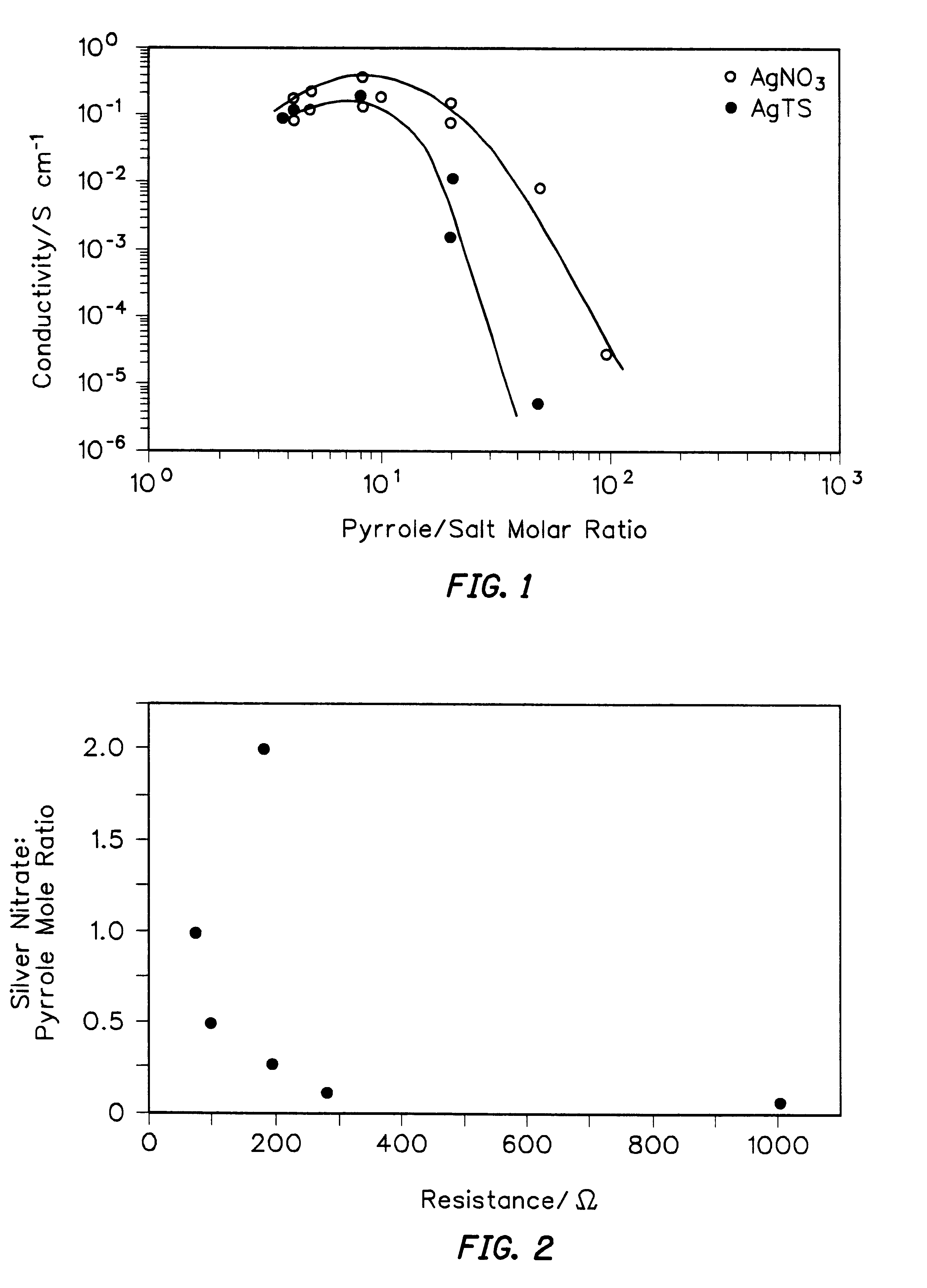

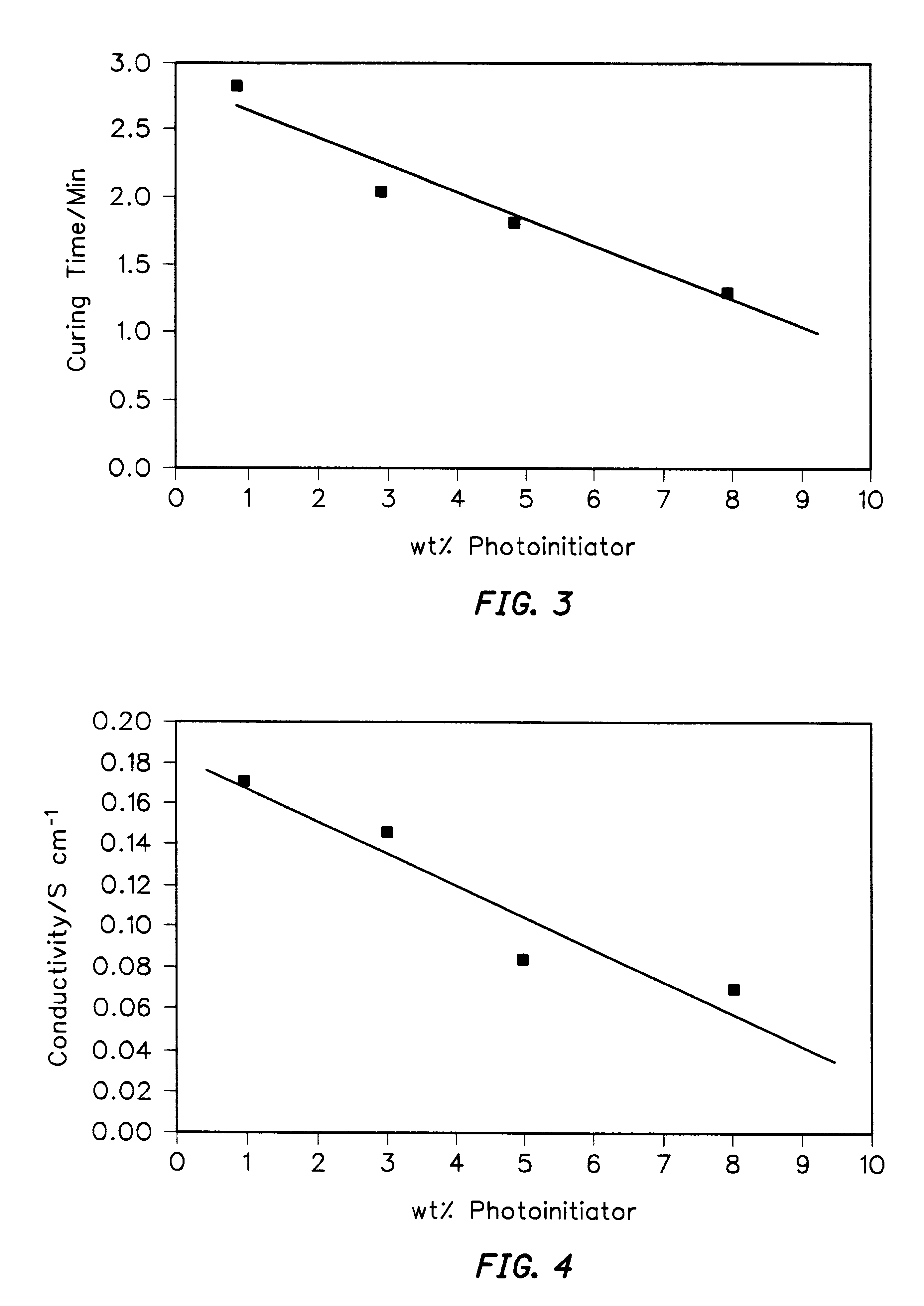

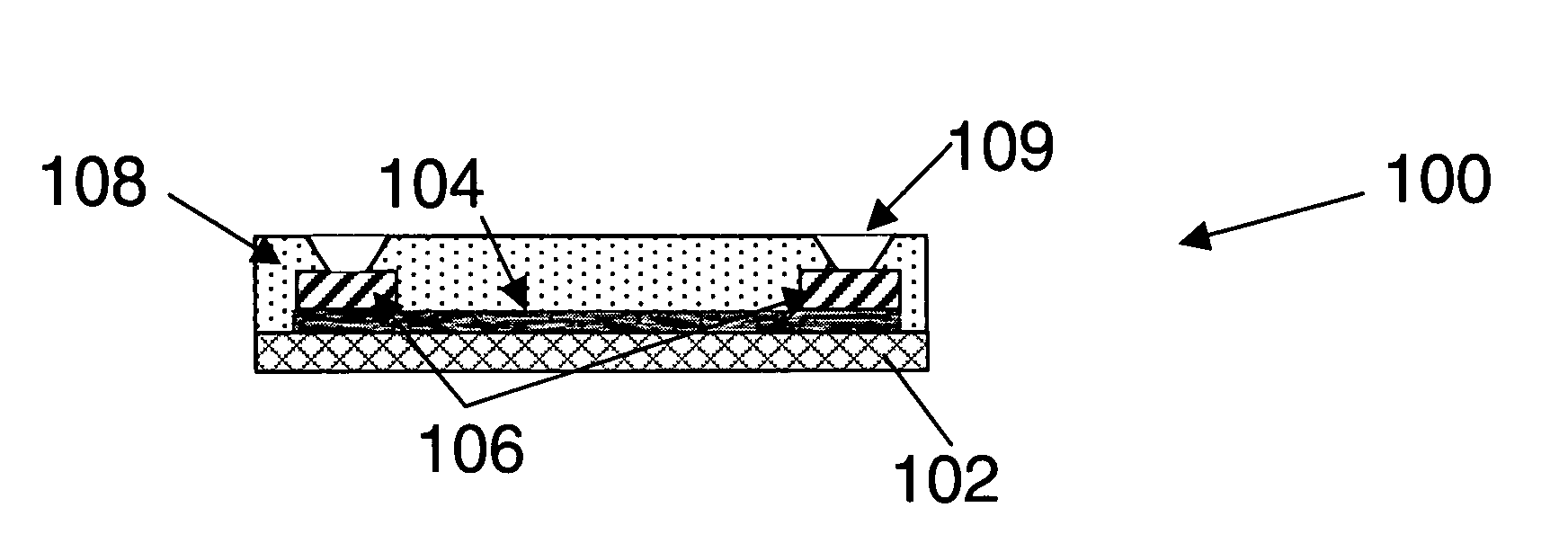

Method of forming electronically conducting polymers on conducting and nonconducting substrates

InactiveUS6210537B1Magnetic/electric field screeningPhotomechanical apparatusConductive polymerLaser light

The present invention provides electronically conducting polymer films formed from photosensitive formulations of pyrrole and an electron acceptor that have been selectively exposed to UV light, laser light, or electron beams. The formulations may include photoinitiators, flexibilizers, solvents and the like. These solutions can be used in applications including printed circuit boards and through-hole plating and enable direct metallization processes on non-conducting substrates. After forming the conductive polymer patterns, a printed wiring board can be formed by sensitizing the polymer with palladium and electrolytically depositing copper.

Owner:LYNNTECH

Resistive elements using carbon nanotubes

ActiveUS20070236325A1Easy parameter controlFunction increaseCurrent responsive resistorsSolid-state devicesBulk resistanceCarbon nanotube

Resistive elements include a patterned region of nanofabric having a predetermined area, where the nanofabric has a selected sheet resistance; and first and second electrical contacts contacting the patterned region of nanofabric and in spaced relation to each other. The resistance of the element between the first and second electrical contacts is determined by the selected sheet resistance of the nanofabric, the area of nanofabric, and the spaced relation of the first and second electrical contacts. The bulk resistance is tunable.

Owner:NANTERO

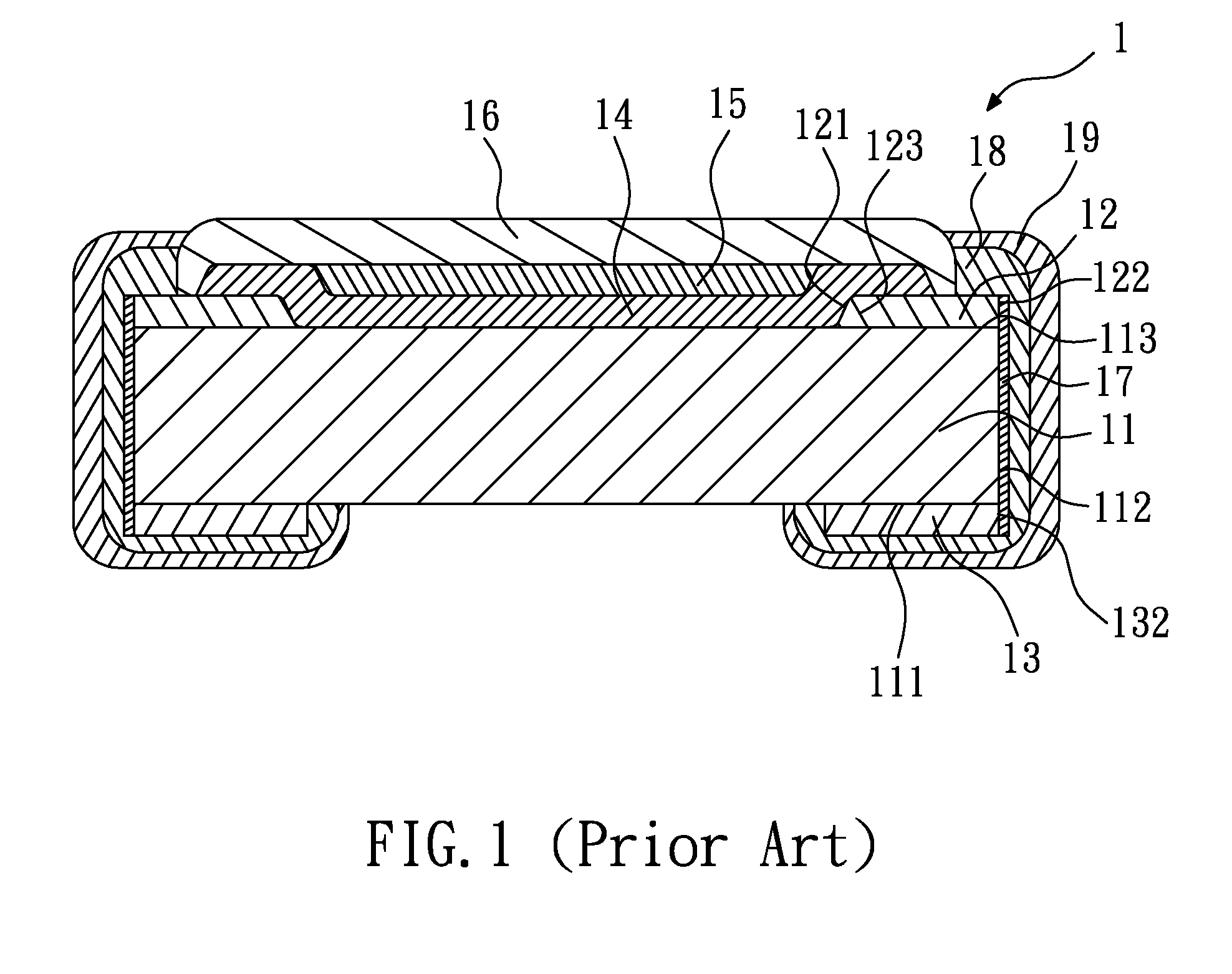

Chip resistor

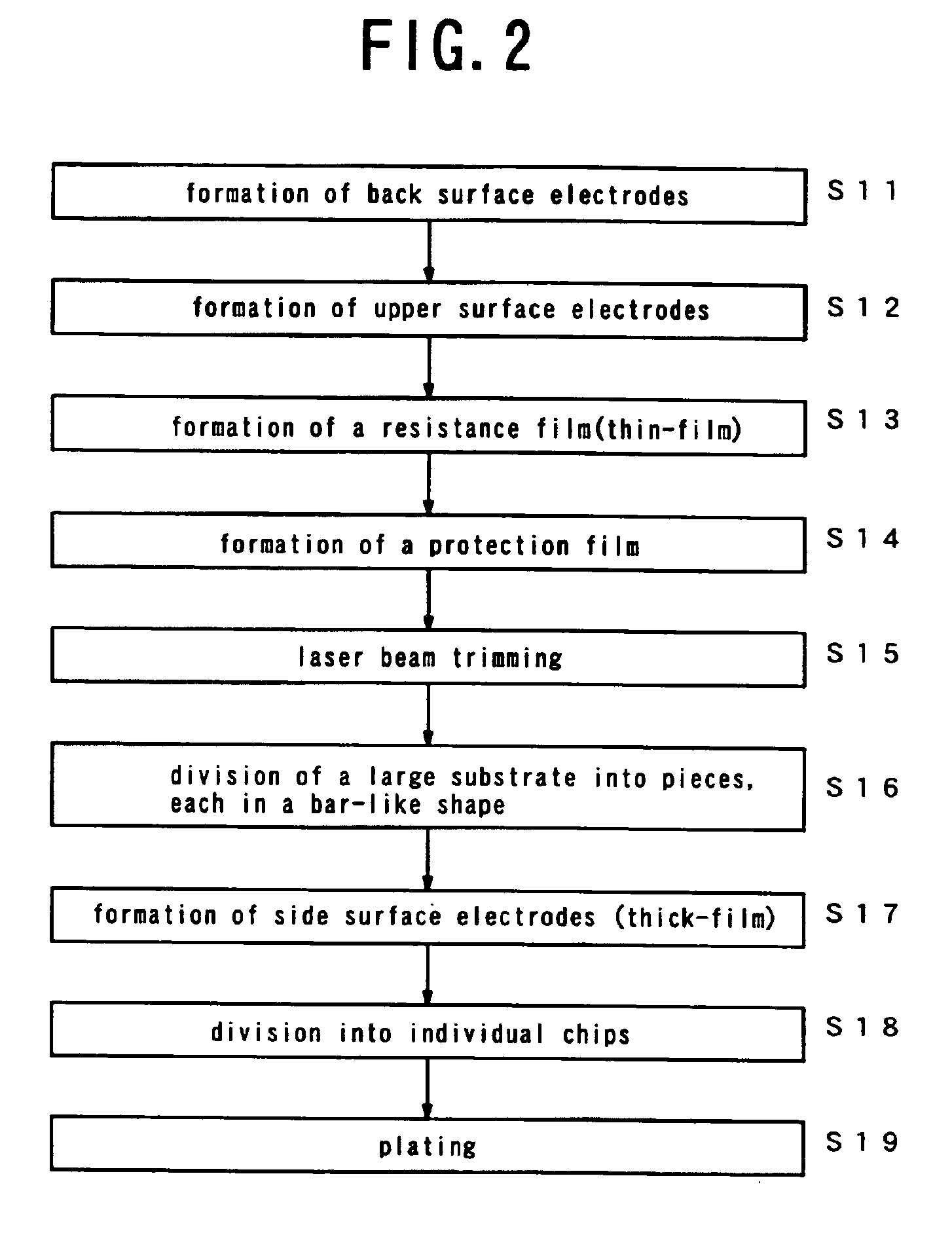

InactiveUS6943662B2Resistor chip manufactureResistor terminals/electrodesFilm resistanceChemical reaction

Resistance or side electrodes of a chip resistor is prevented from being lost due to chemical reaction with NaCl contained in human sweat and so on when human sweat, seawater, etc. are adhered thereto. The chip resistor comprises an insulating substrate, thick-film upper surface electrodes formed at opposite ends of the top surface of the insulating substrate, a thin-film resistance made of a constituent material not reacting with NaCl, and formed so as to be extended over the upper surface of the insulating substrate and respective portions of the upper surface of the thick-film upper surface electrodes, thick-film back surface electrodes formed at spots on the back surface of the insulating substrate, corresponding to the thick-film upper surface electrodes, respectively, and thick-film side surface electrodes connecting the thick-film back surface electrodes with respective portions of the thick-film upper surface electrodes, exposed out of the thin-film resistance, respectively.

Owner:ROHM CO LTD

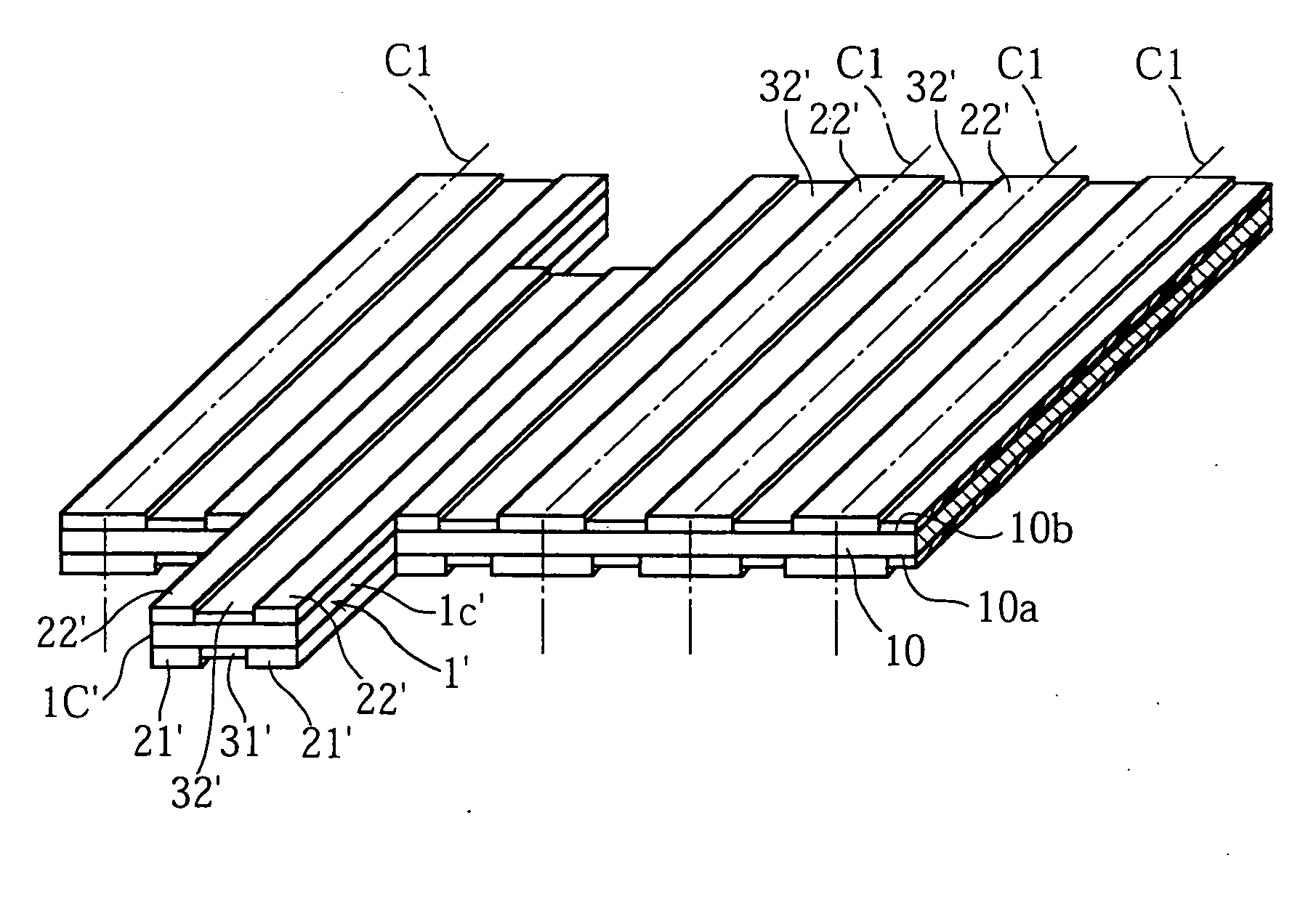

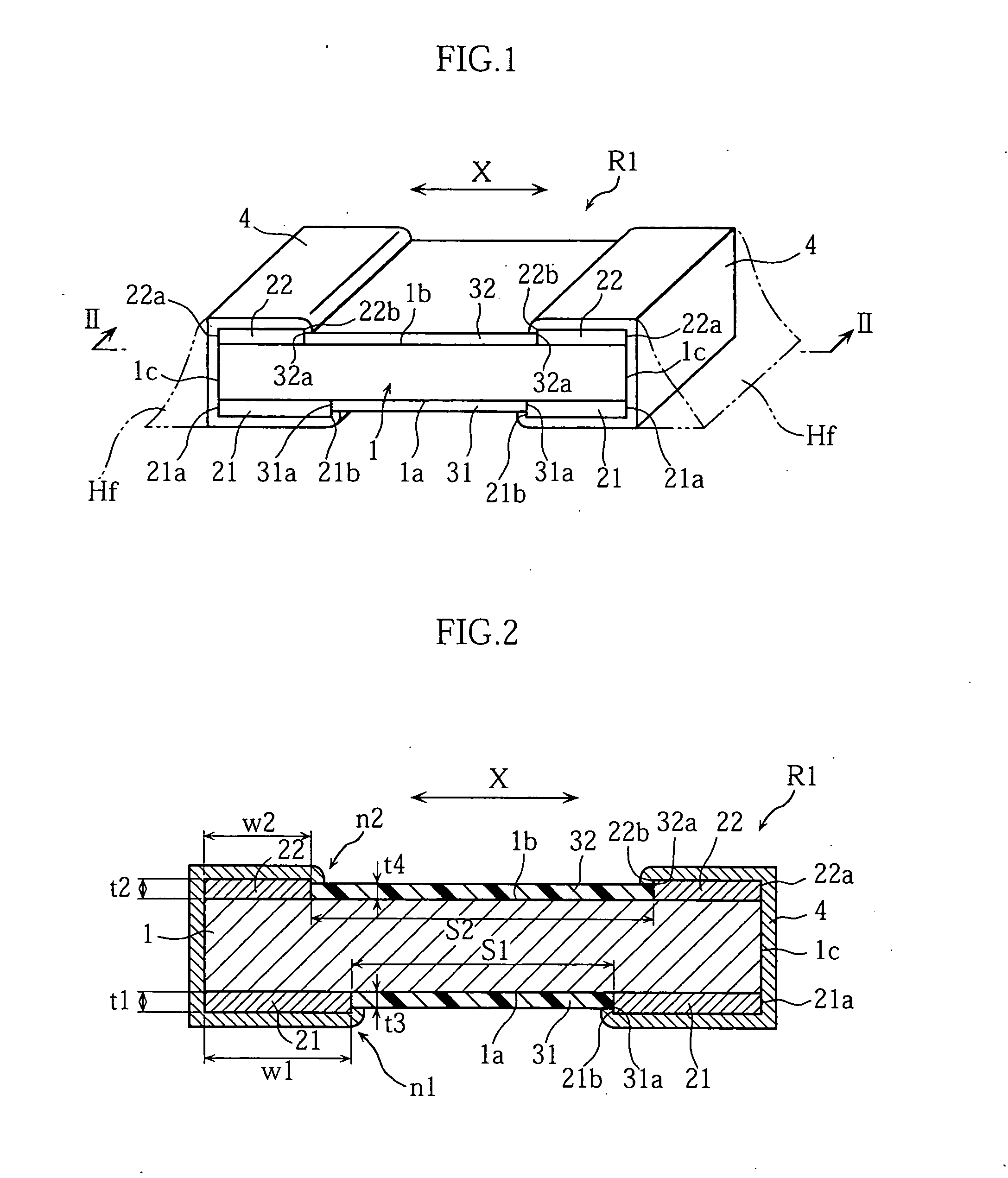

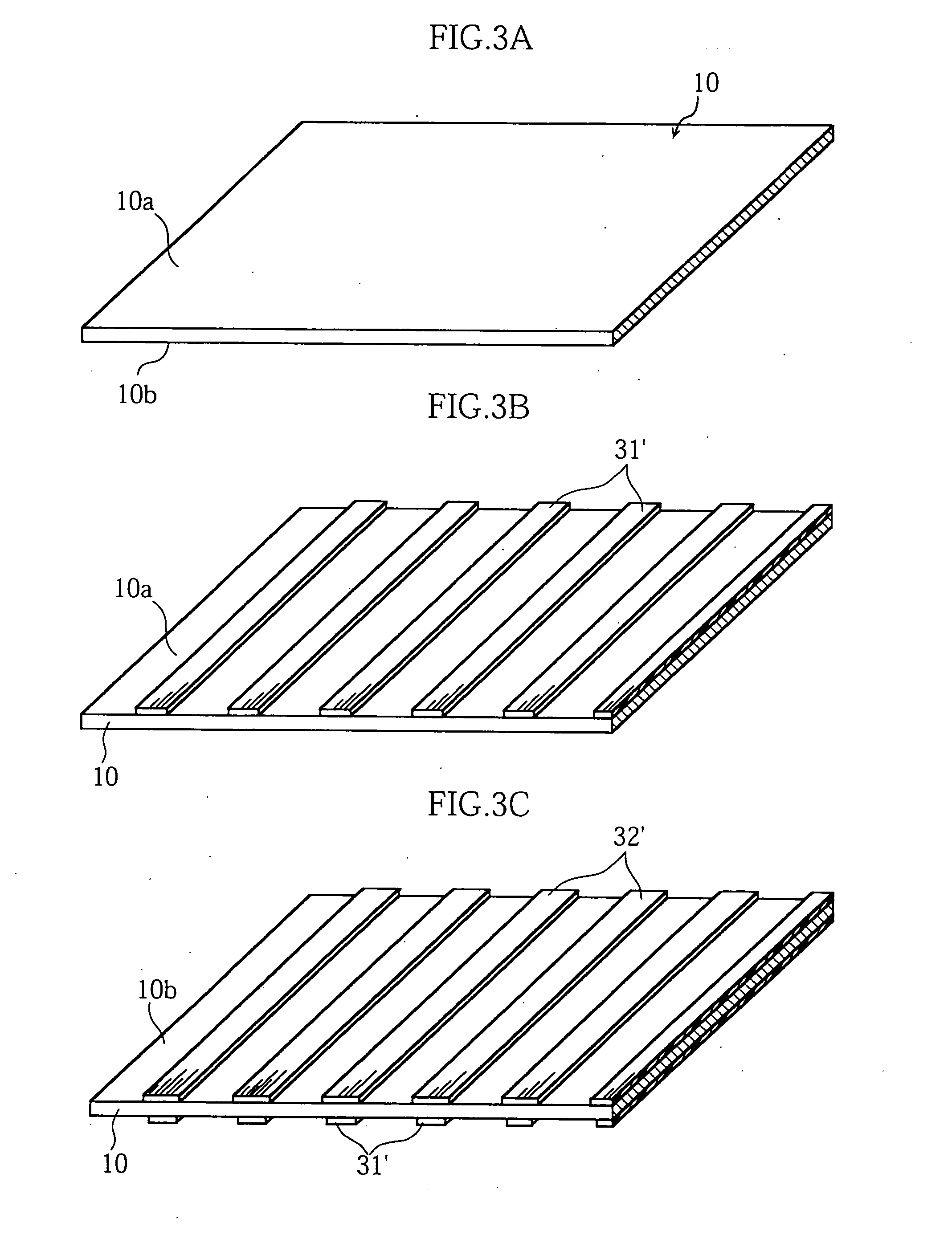

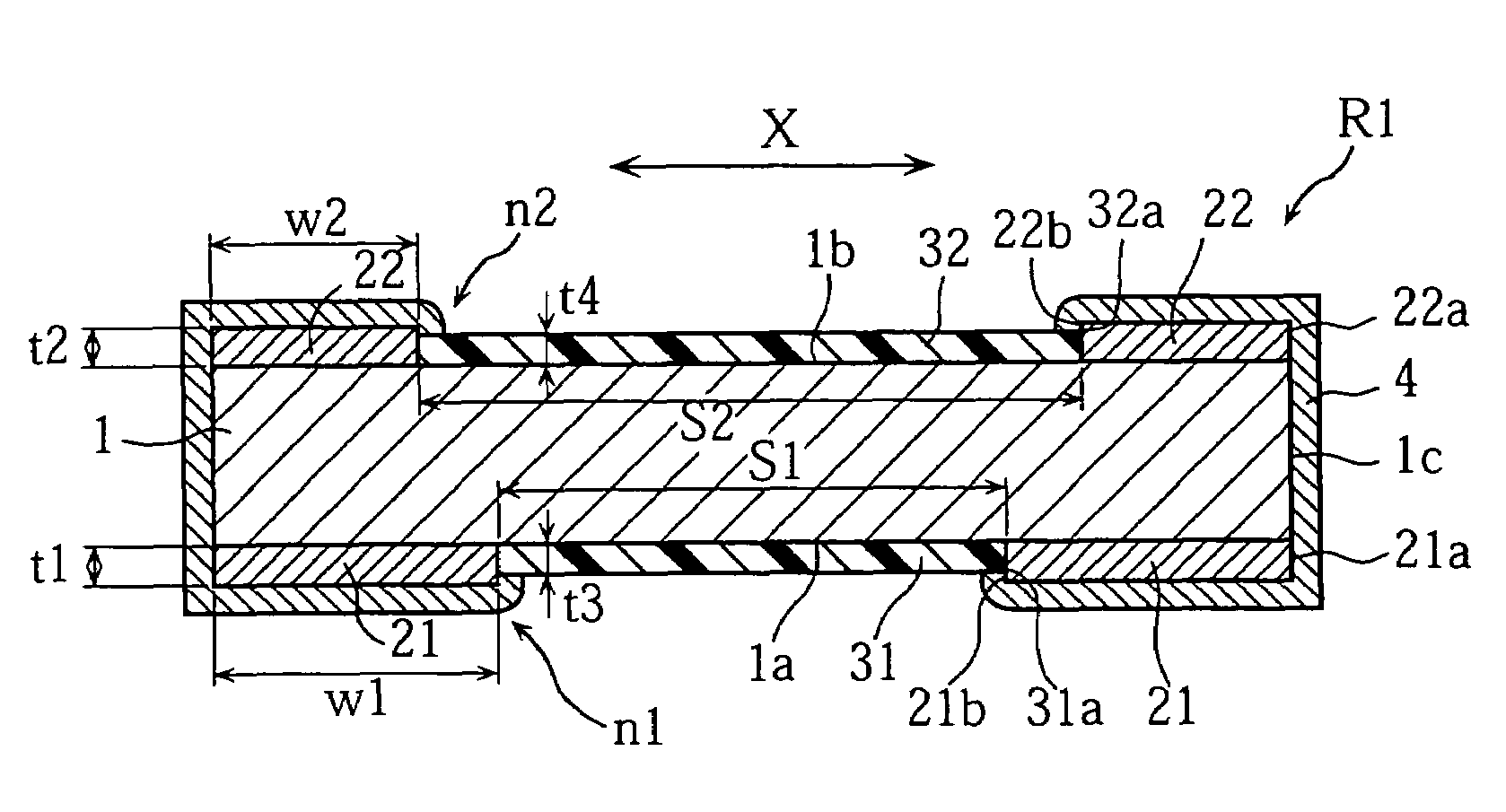

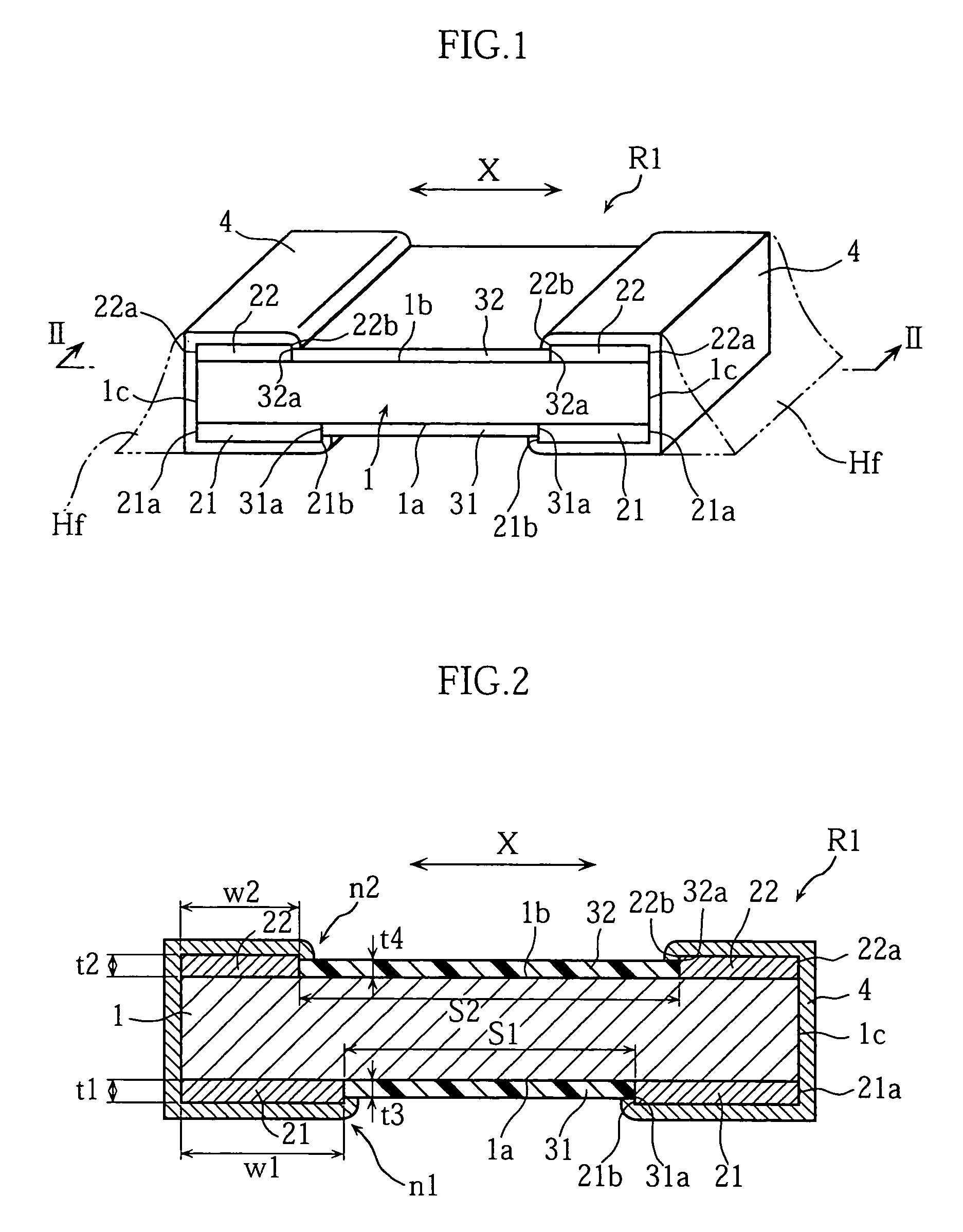

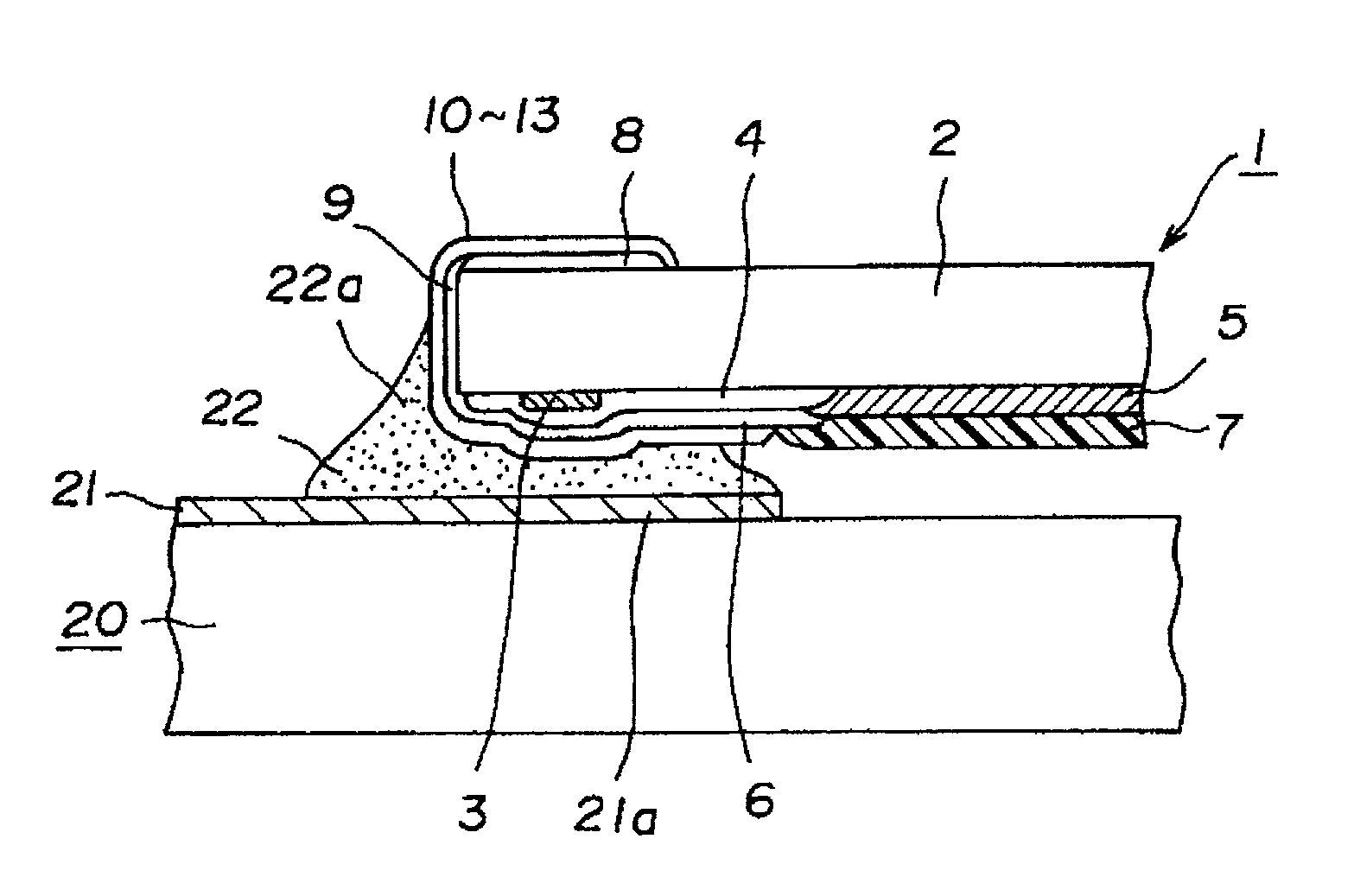

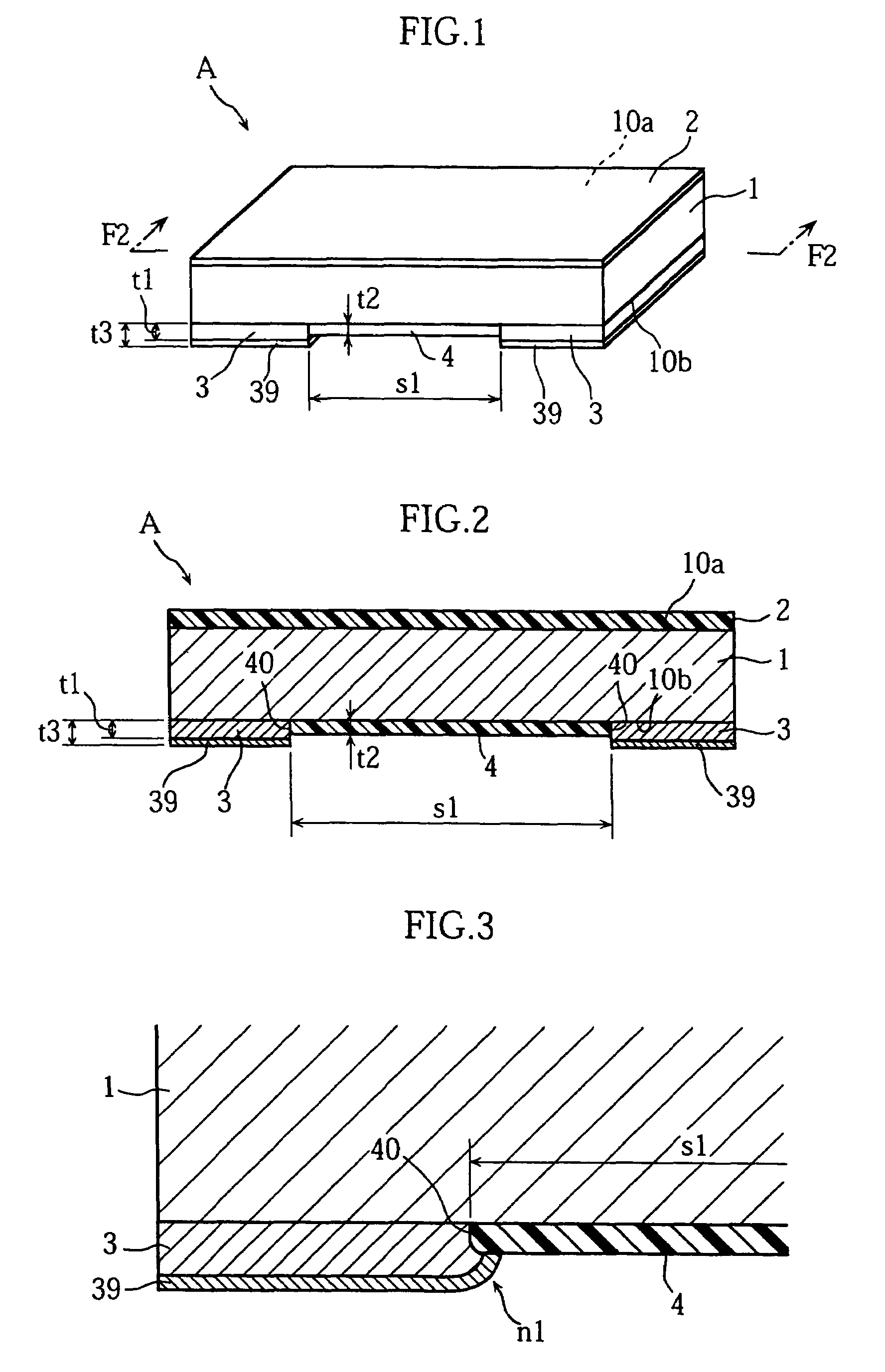

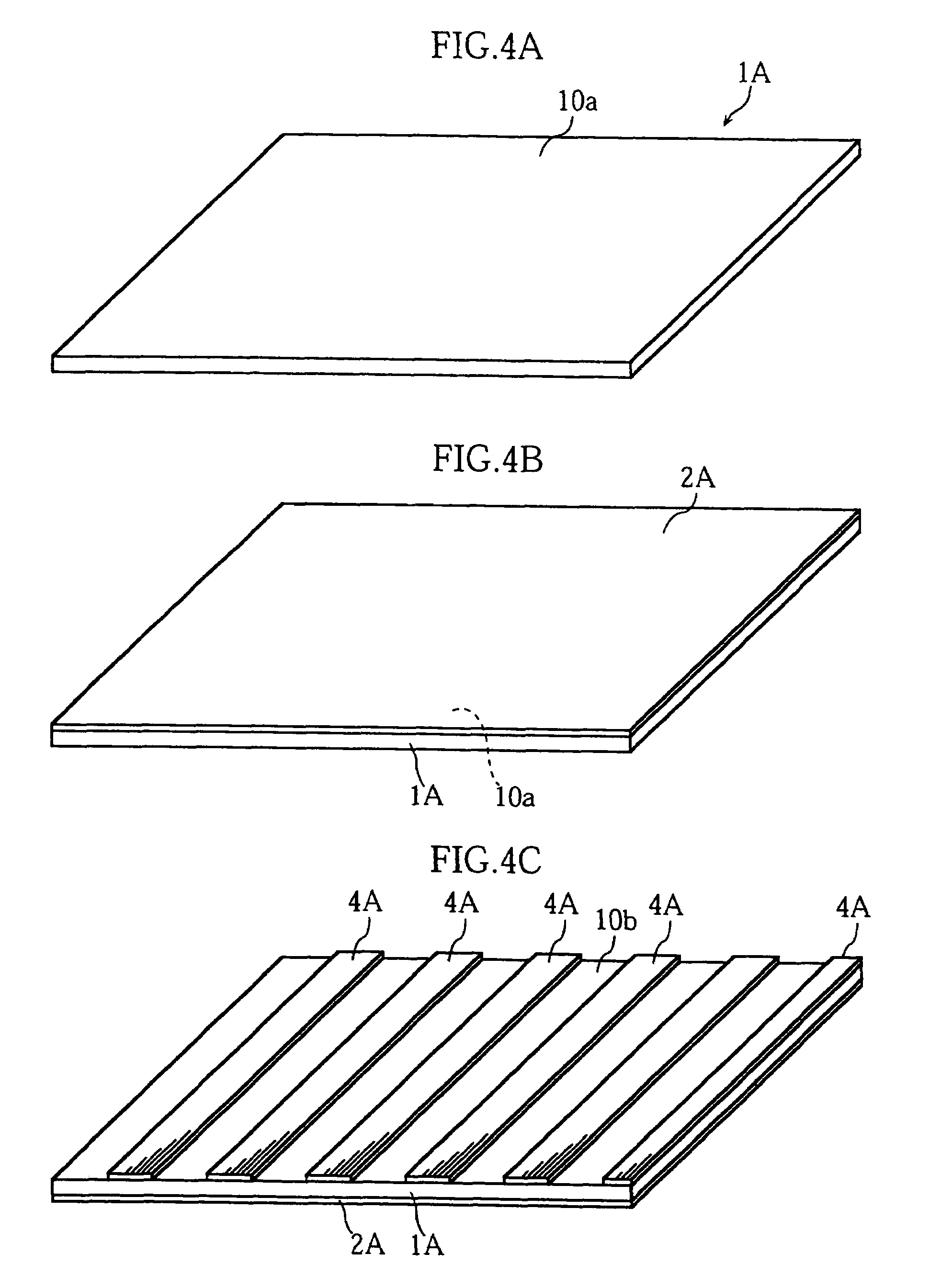

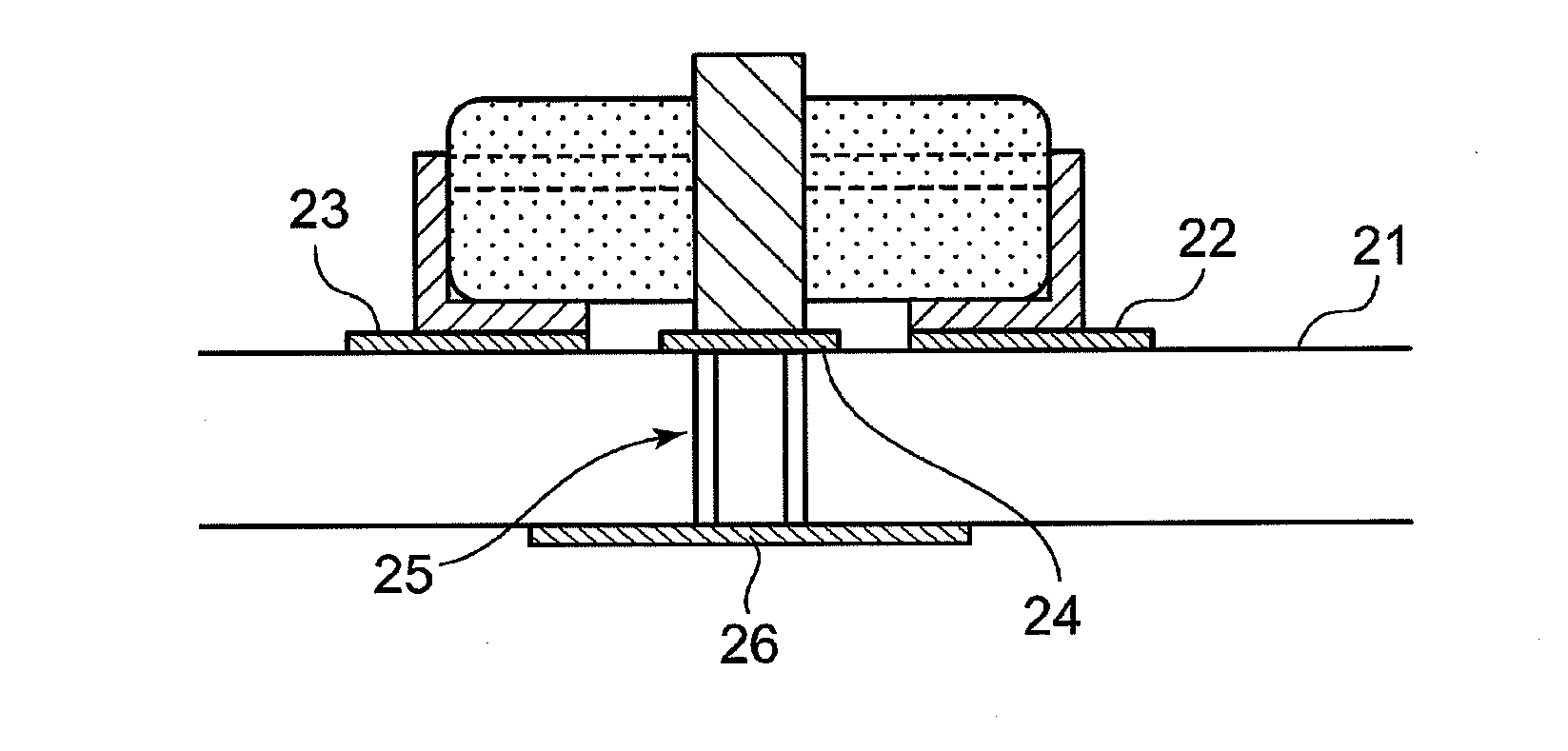

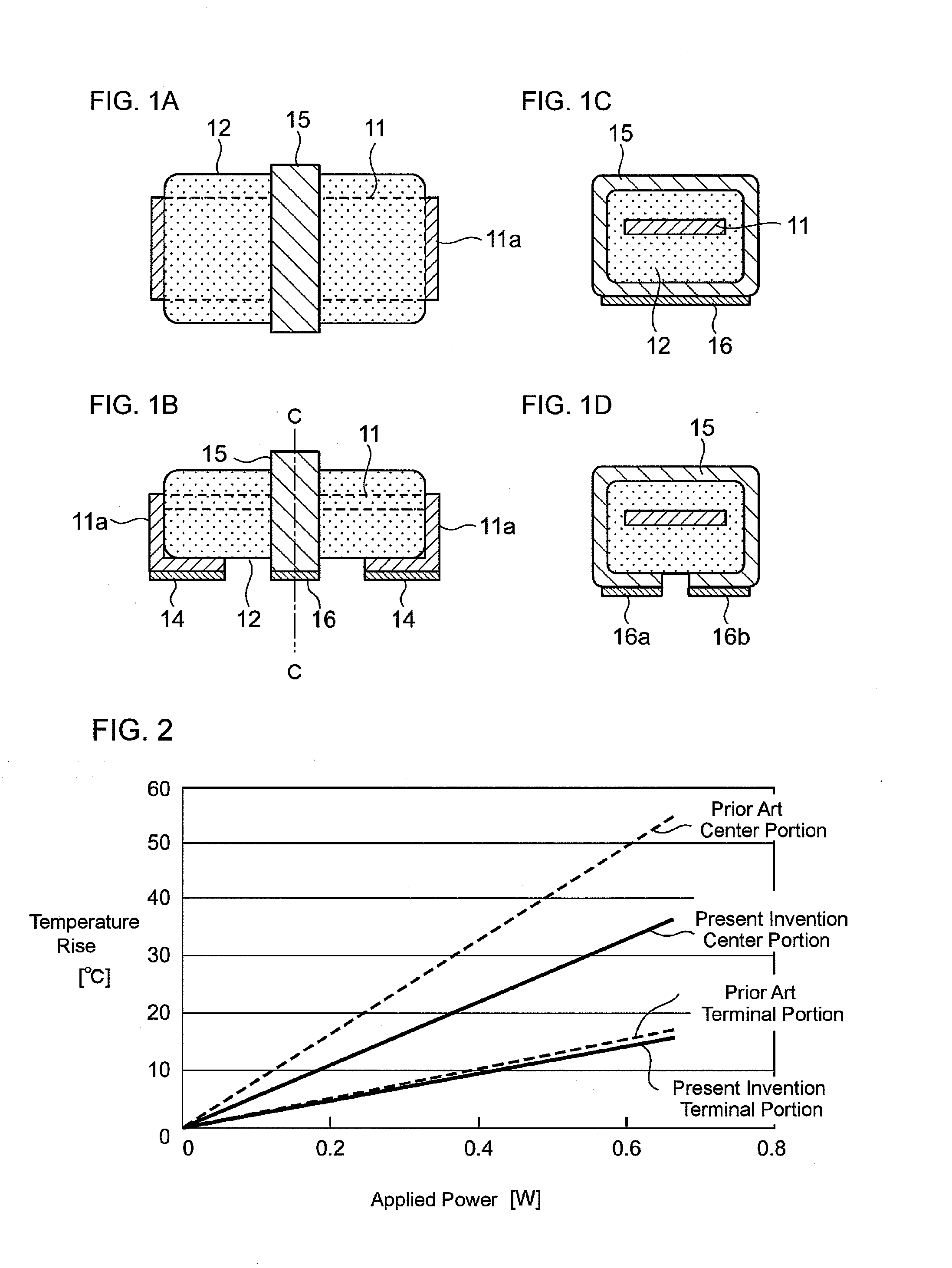

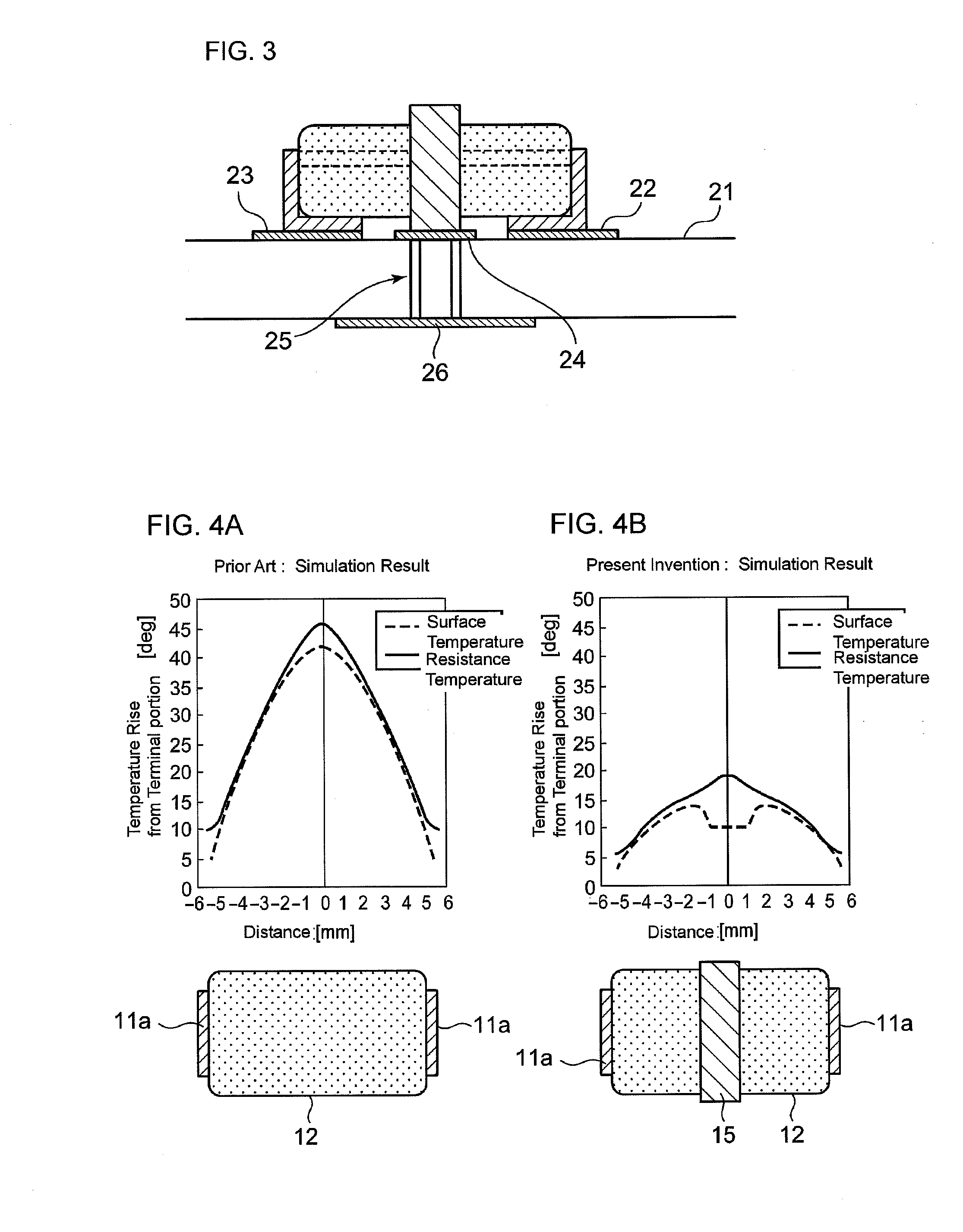

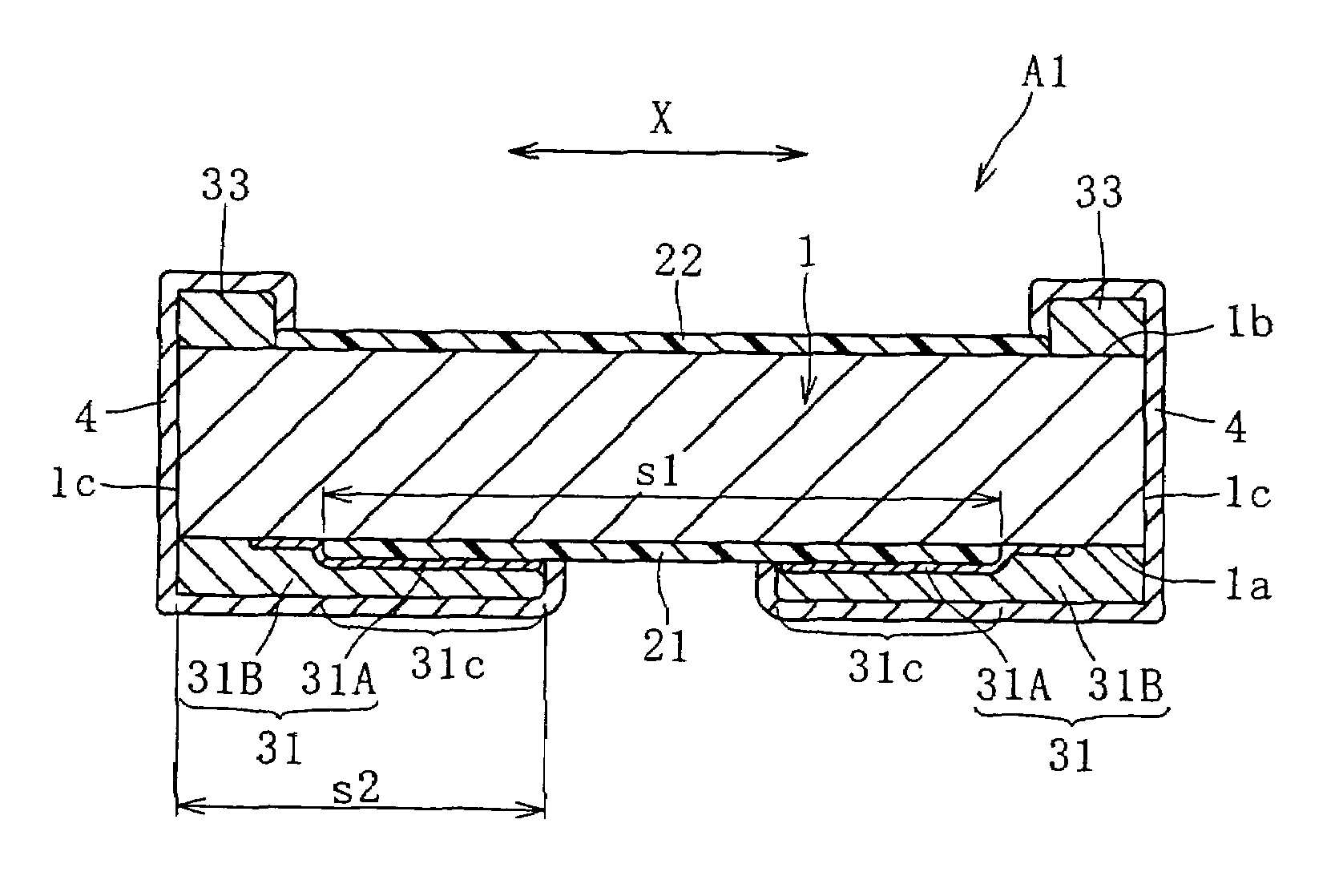

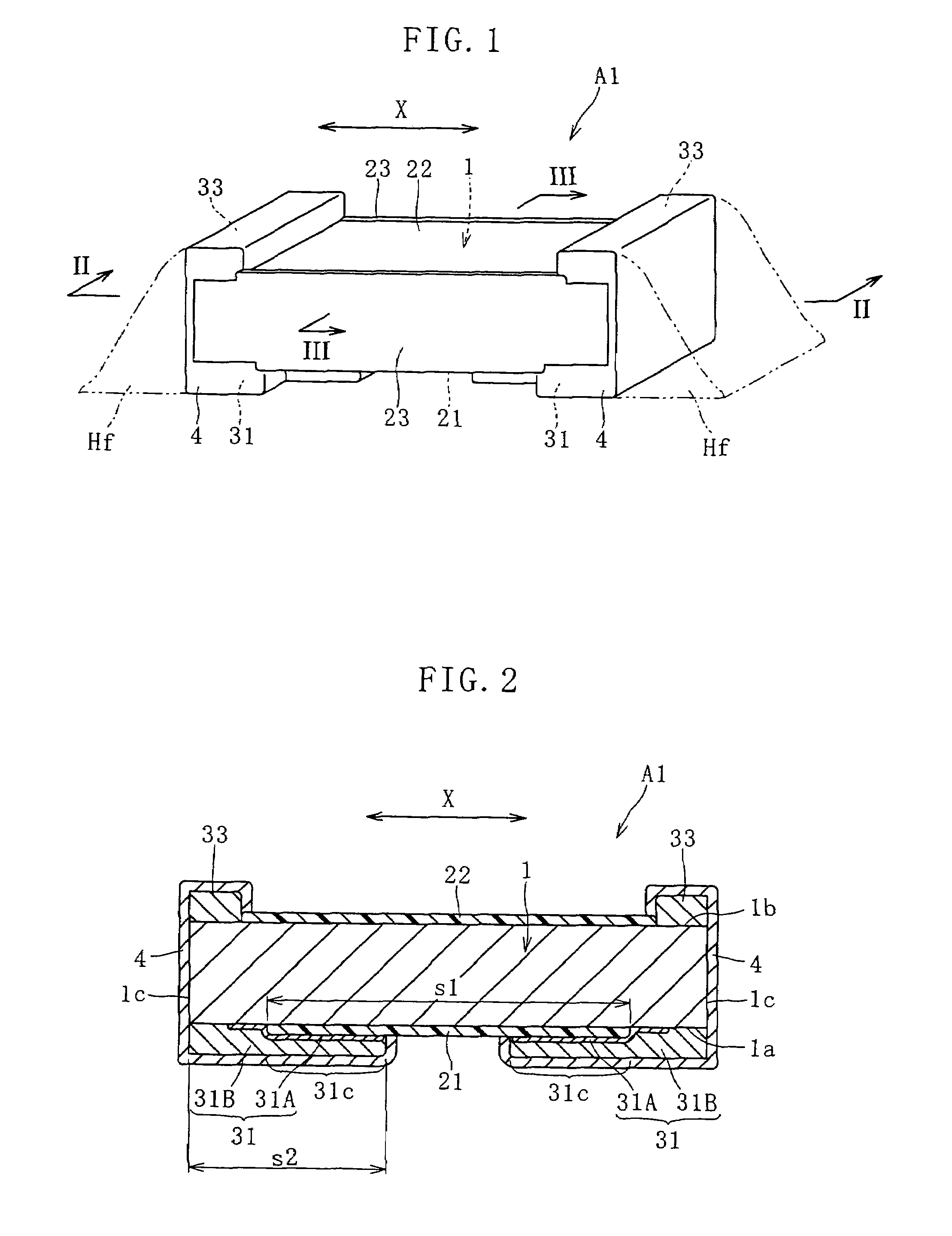

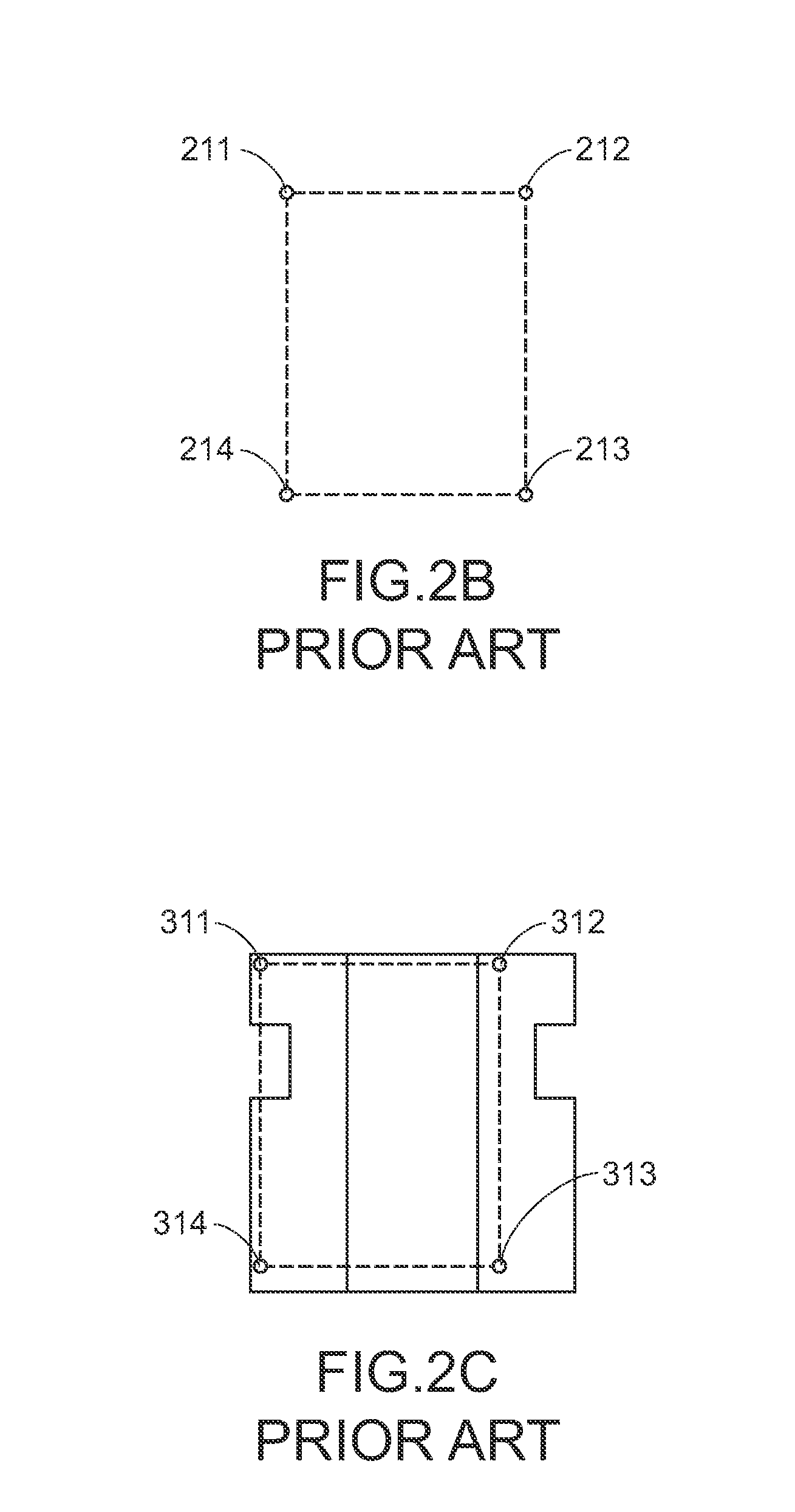

Chip resistor and method for manufacturing same

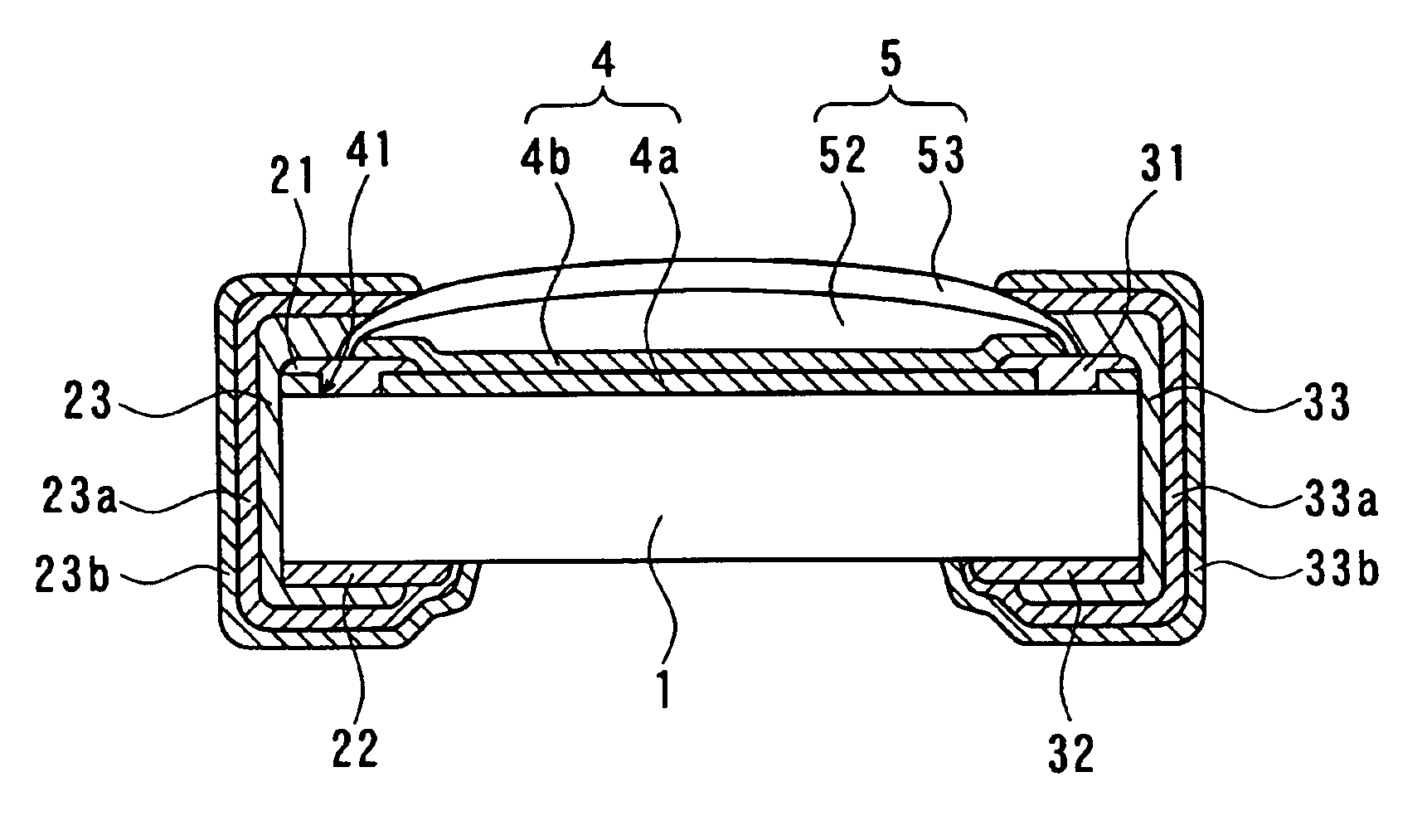

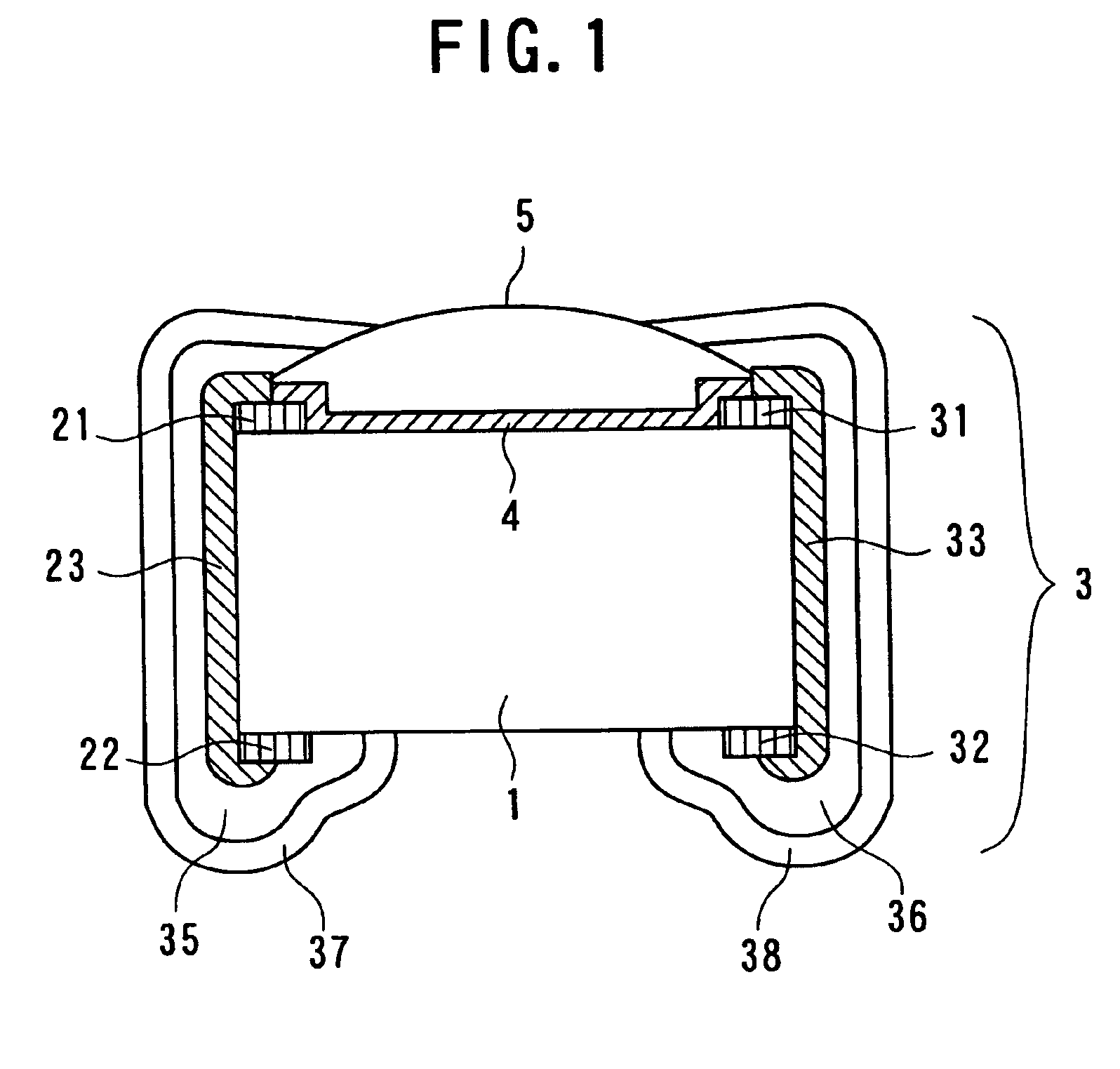

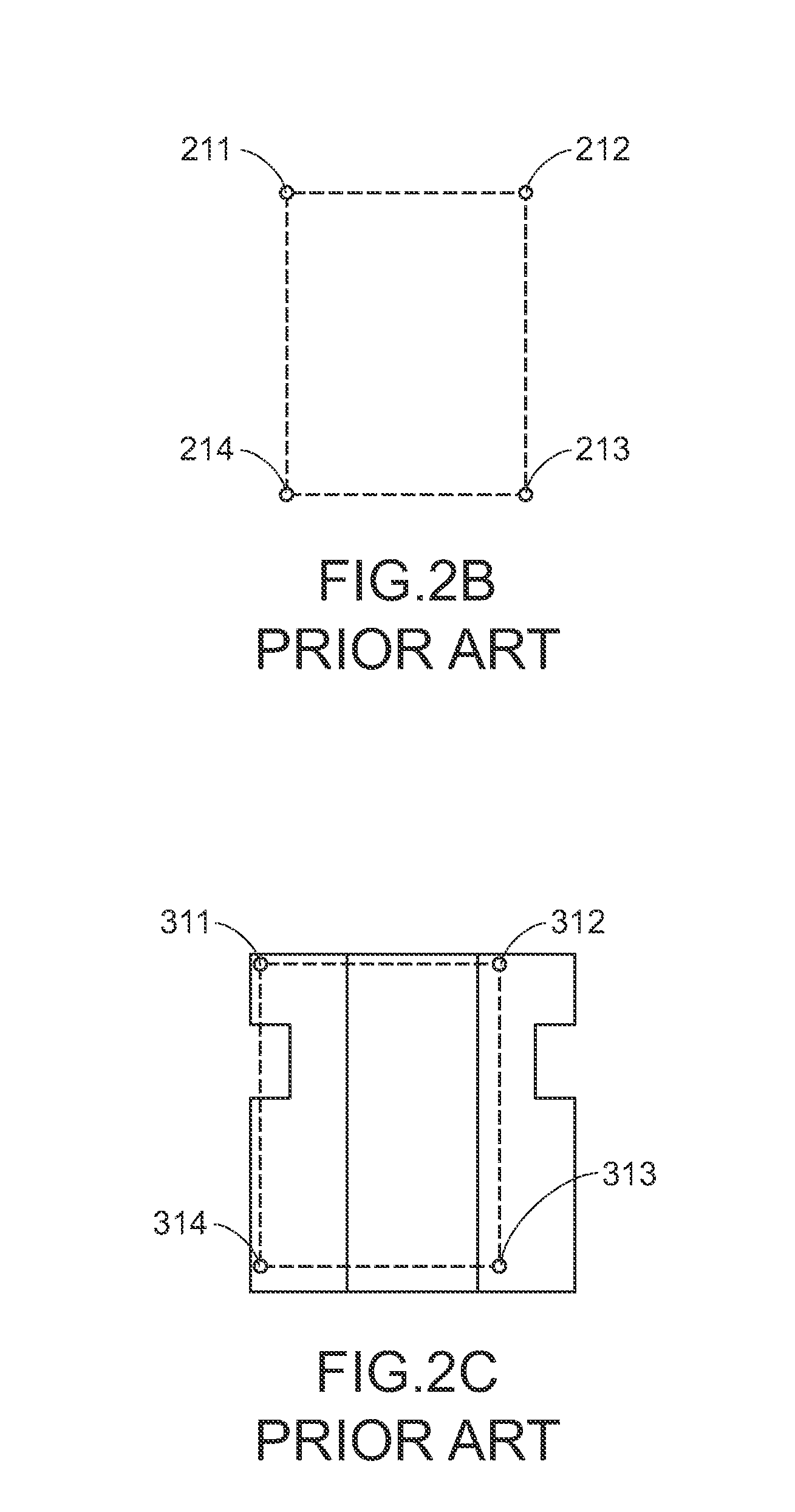

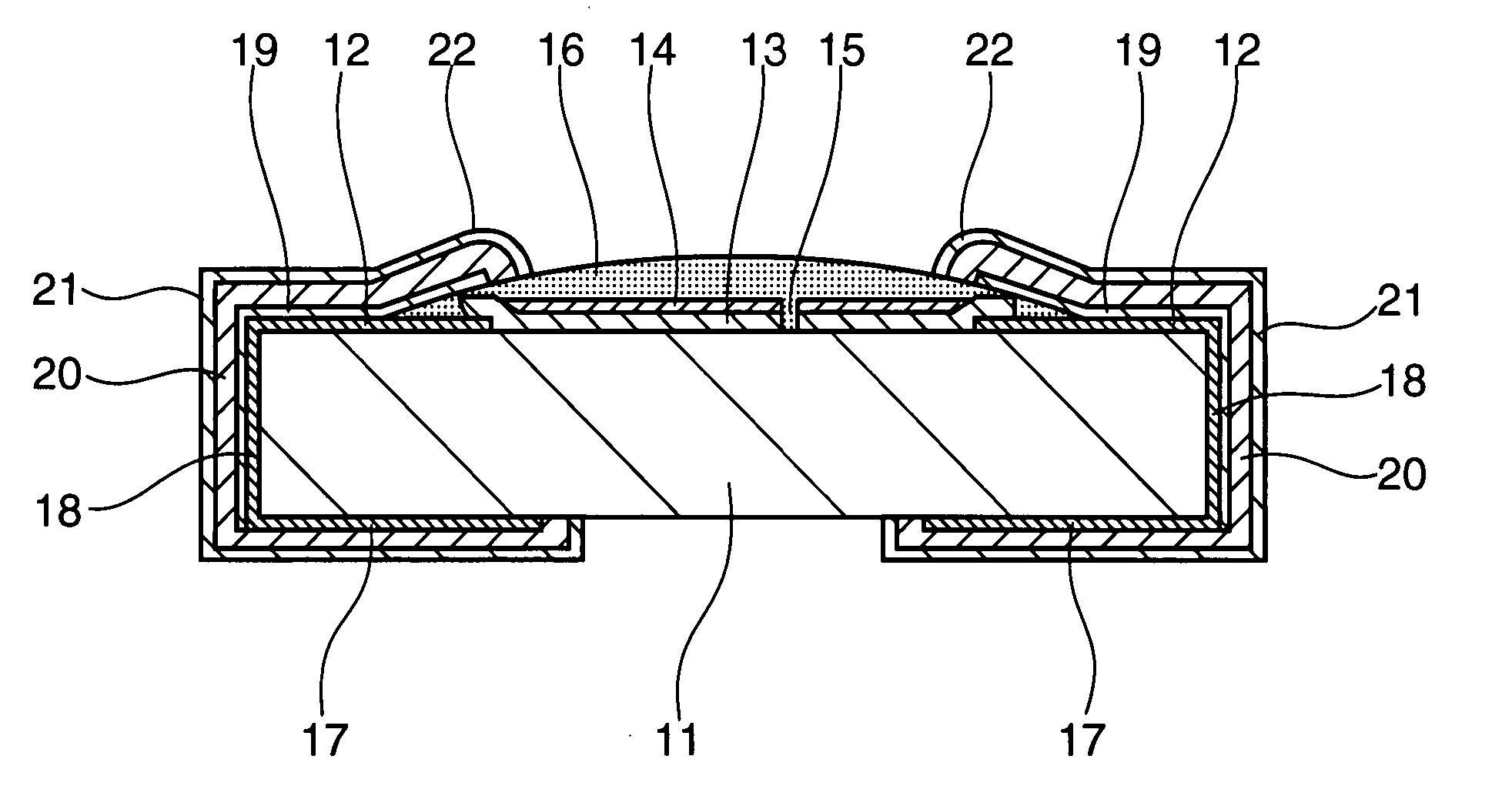

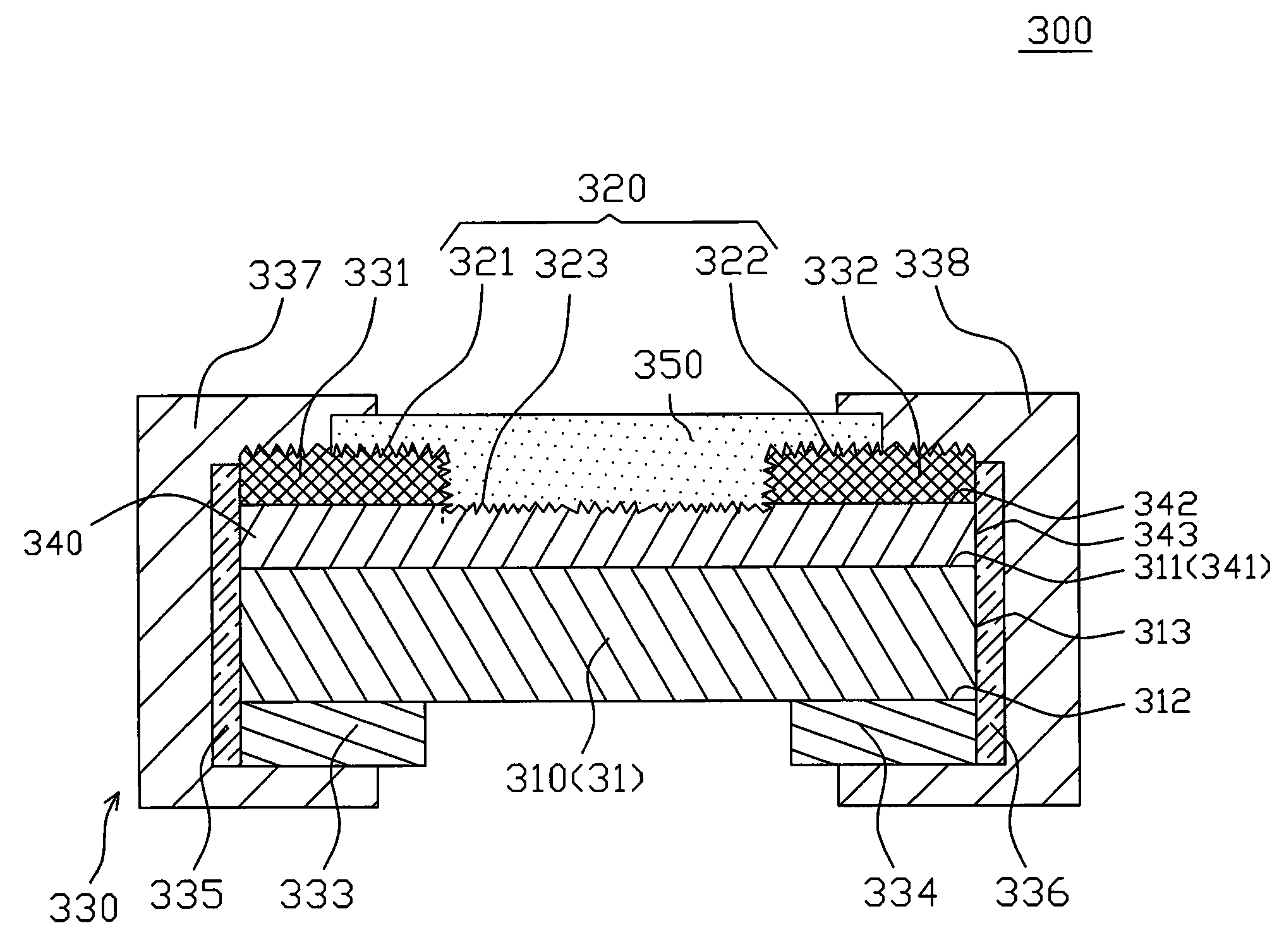

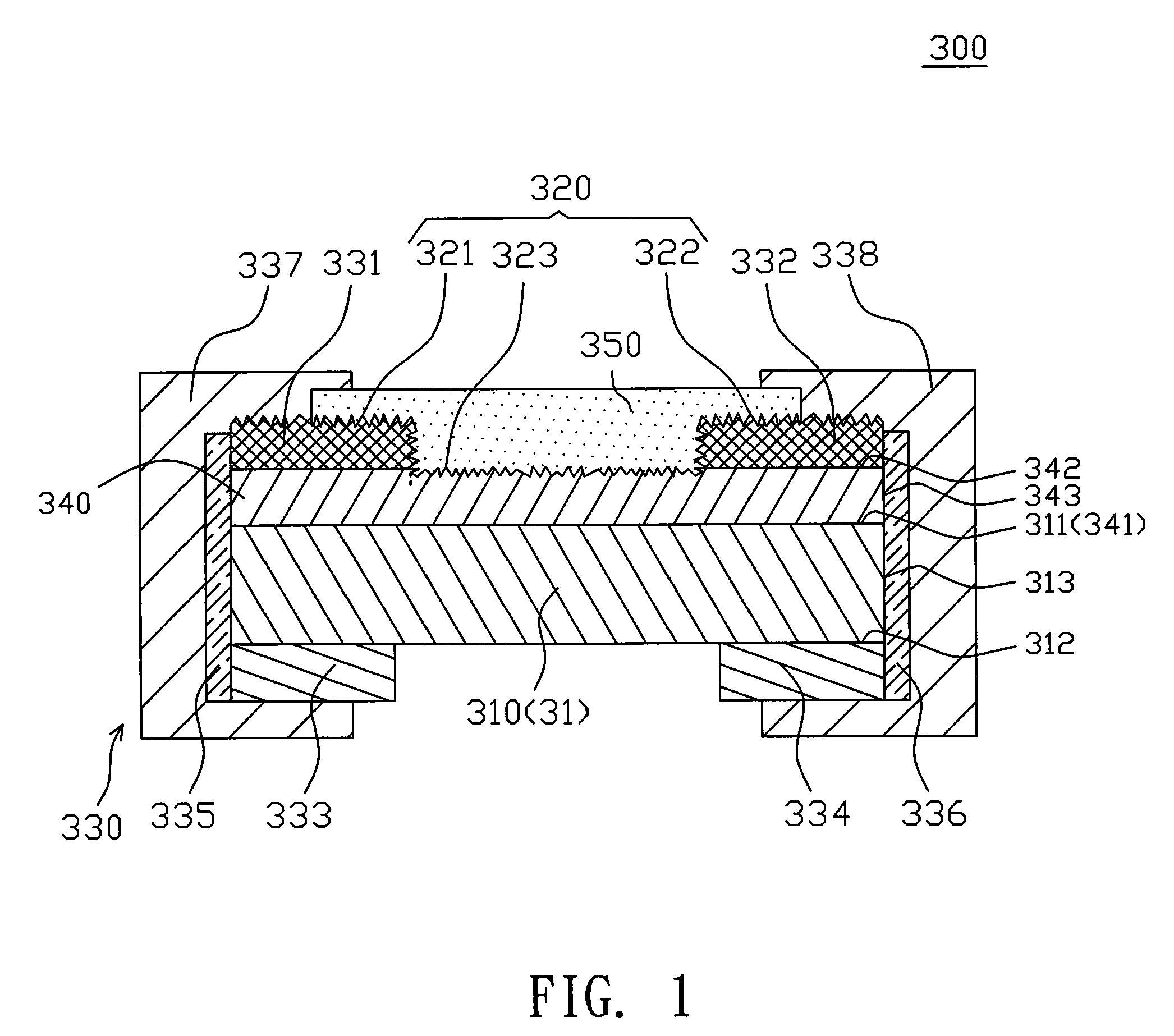

ActiveUS20060205171A1Small resistanceLow production costResistor chip manufactureResistor terminals/electrodesAuxiliary electrodeResistive element

A chip resistor (R1) includes a resistor element (1) having a first surface (1a) and a second surface (1b) opposite to the first surface. Two main electrodes (21), spaced from each other, are provided on the first surface (1a), while two auxiliary electrodes (22), spaced from each other, are provided on the second surface (1b). The auxiliary electrodes face the main electrodes (21) via the resistor element (1). The main electrodes (21) and the auxiliary electrodes (22) are made of the same material.

Owner:ROHM CO LTD

Chip resistor and method for manufacturing same

ActiveUS7326999B2Small resistanceLow production costResistor chip manufactureResistor terminals/electrodesAuxiliary electrodeBiomedical engineering

A chip resistor (R1) includes a resistor element (1) having a first surface (1a) and a second surface (1b) opposite to the first surface. Two main electrodes (21), spaced from each other, are provided on the first surface (1a), while two auxiliary electrodes (22), spaced from each other, are provided on the second surface (1b). The auxiliary electrodes face the main electrodes (21) via the resistor element (1). The main electrodes (21) and the auxiliary electrodes (22) are made of the same material.

Owner:ROHM CO LTD

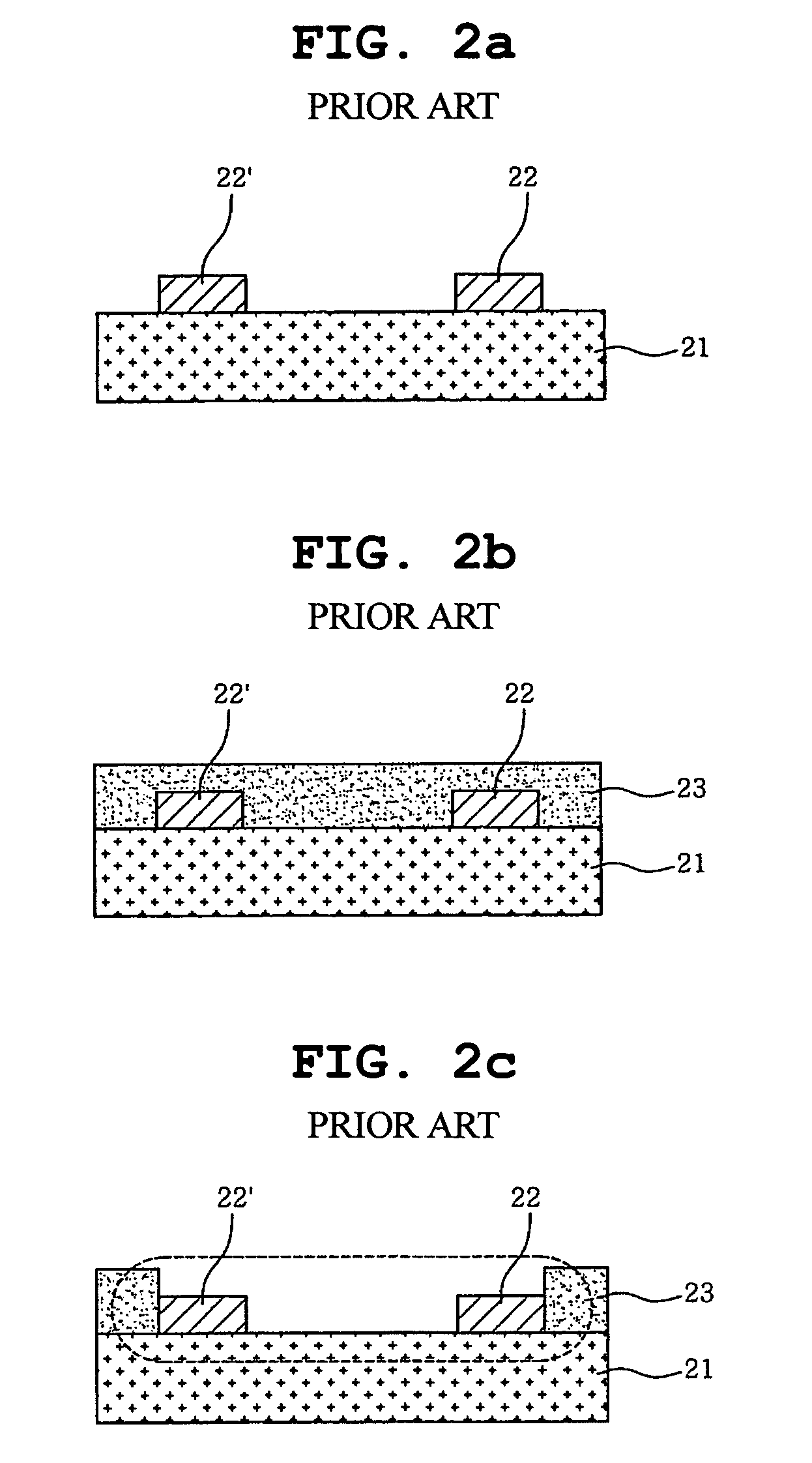

Printed circuit board including embedded resistor and method of fabricating the same

InactiveUS7277005B2Increase the number ofPrinted circuit aspectsSolid-state devicesConductive materialsPrinted circuit board

Disclosed is a PCB including an embedded resistor and a method of fabricating the same. The PCB includes a plurality of circuit layers in which circuit patterns are formed. A plurality of insulating layers is each interposed between the circuit layers. The embedded resistor is made of a resistive material and received in a receiving hole formed in the plurality of circuit layers and the plurality of insulating layers such that walls defining the receiving hole extends from one of the circuit layers to another circuit layer. The receiving hole has a closed section, and a conductive material is plated on the opposite walls of the walls defining the receiving hole.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

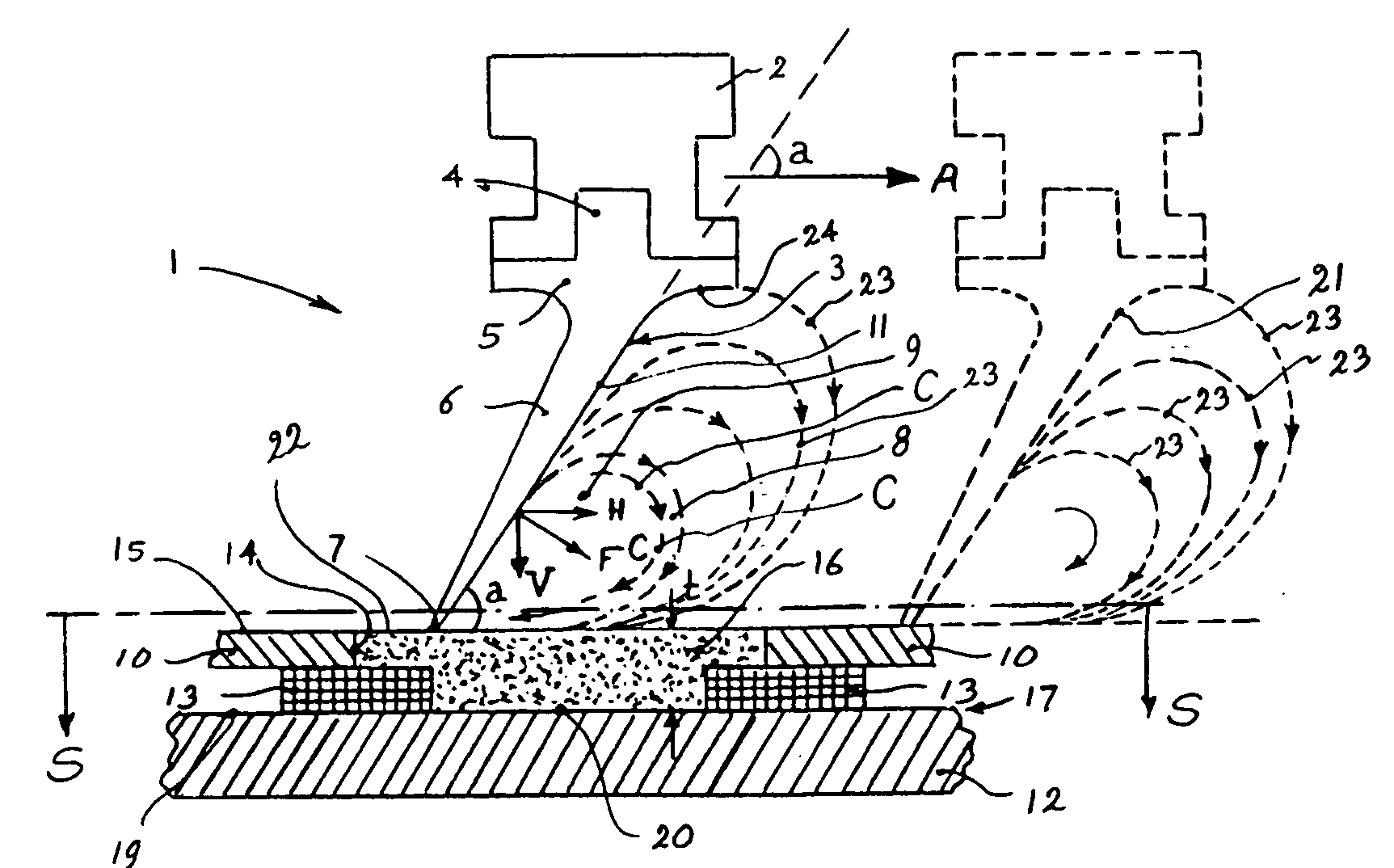

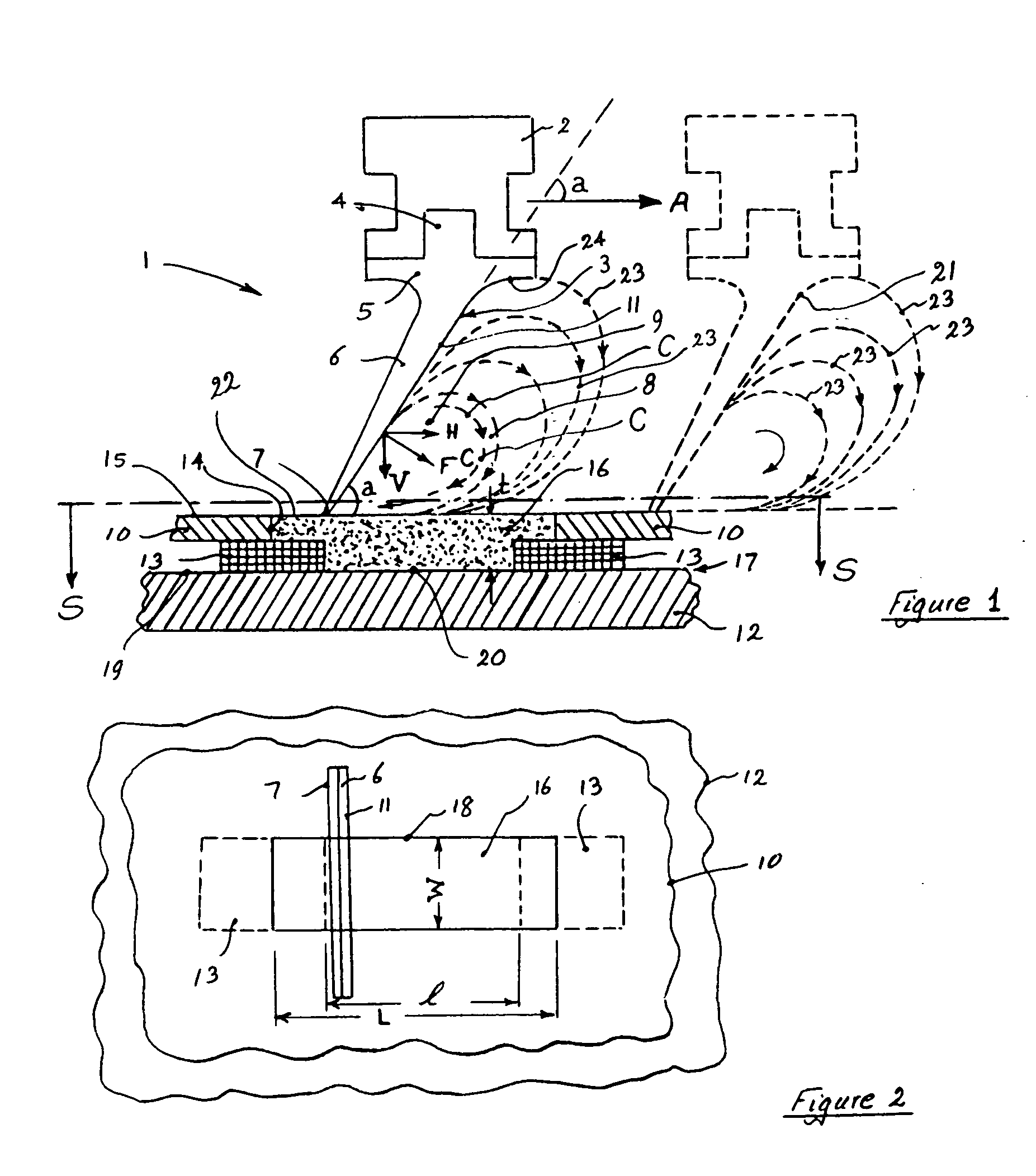

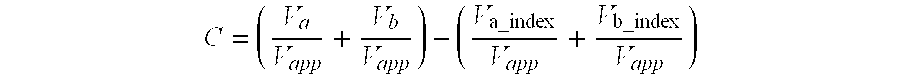

Polymer thick-film resistive paste, a polymer thick-film resistor and a method and an apparatus for the manufacture thereof

InactiveUS20050051360A1Low/insignificant dimensional and shape changeHigh solid contentPretreated surfacesLiquid/solution decomposition chemical coatingPolymer sciencePrinted circuit board

The present invention teaches formulations, apparatus and a method of applying high thixotropic index polymer thick-film resistive pastes for making polymer thick-film resistors with improved tolerances by providing a squeegee with a blade tilted at an angle of 10 to 85 to the surface of the printed circuit board thus causing a fluid rotational motion within the bead of the polymer thick-film resistive paste as the squeegee blade moves relative to the printed circuit board. This rotational motion increases the shear strain rate experienced by the paste within the bead and results in a more effective filling of the resistor-shaped cavity without including air bubbles, experiencing elastic recovery of the paste and, without surface fractures of the paste.

Owner:EMBED TECH

Resistive nanocomposite compositions

InactiveUS6617377B2Increased mechanical and wear and electrical and thermal propertyImprove material performanceNanotechPrinted electric component incorporationScreen printingOrganic solvent

A resistive composition for screen printing onto a substrate. The resistive composition, based on total composition has a) 5-30 wt. % of polymer resin, b) greater than 0 up to and including 10 wt. % of thermosetting resin, c) 10-30 wt. % conductive particles selected from the group consisting of carbon black, graphite and mixtures thereof and d) 0.025-20 wt. % carbon nanoparticles, wherein all of (a), (b), (c) and (d) are dispersed in a 60-80 wt. % organic solvent.

Owner:CTS CORP ELKHART

Chip resistor

InactiveUS7782174B2Lower resistanceReduce failure rateResistor detailsThick film resistorsCeramic substrateResistive element

Owner:KOA CORP

Chip resistor and manufacturing method therefor

ActiveUS7330099B2Easy to manufacturePrinted circuit assemblingResistor chip manufactureInsulation layerEngineering

Owner:ROHM CO LTD

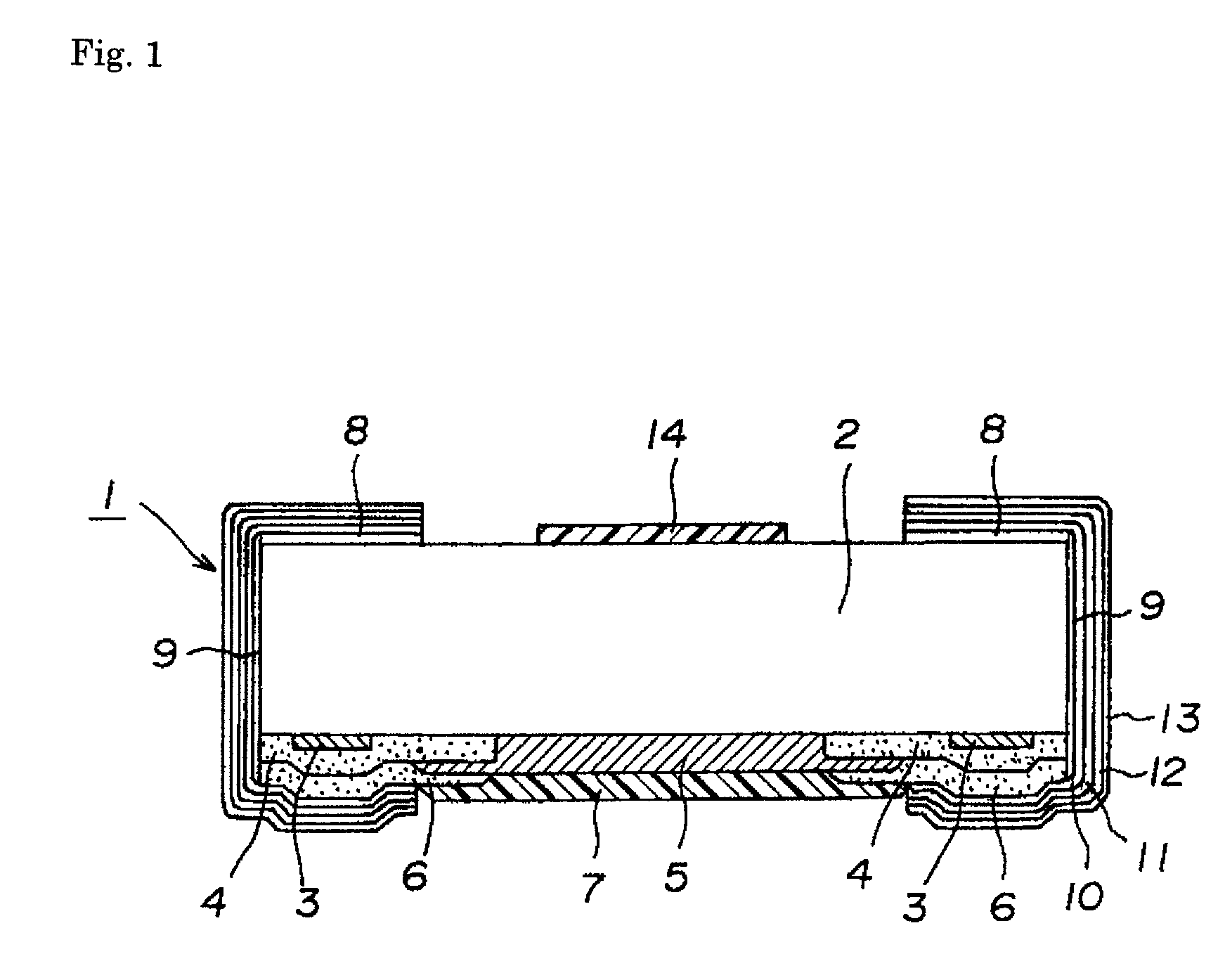

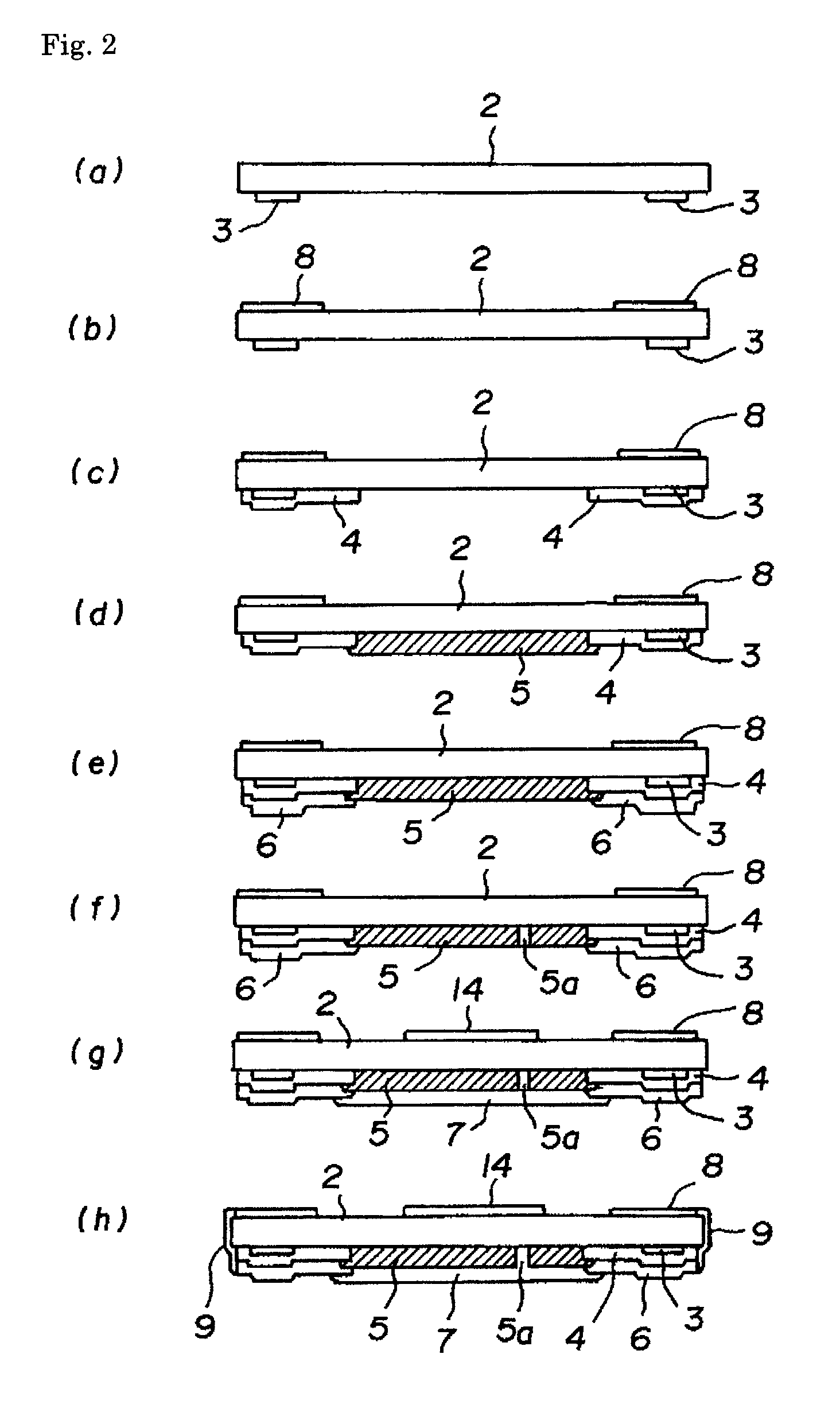

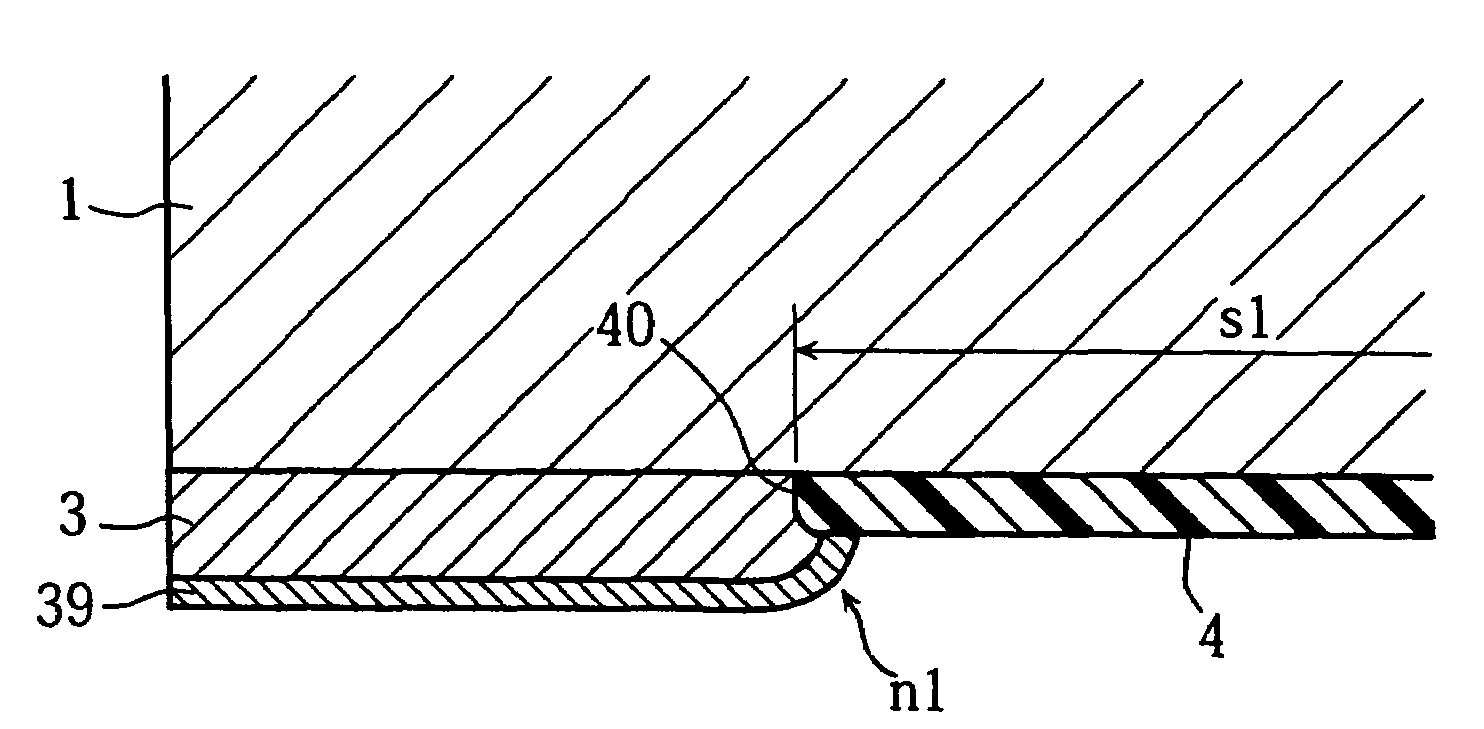

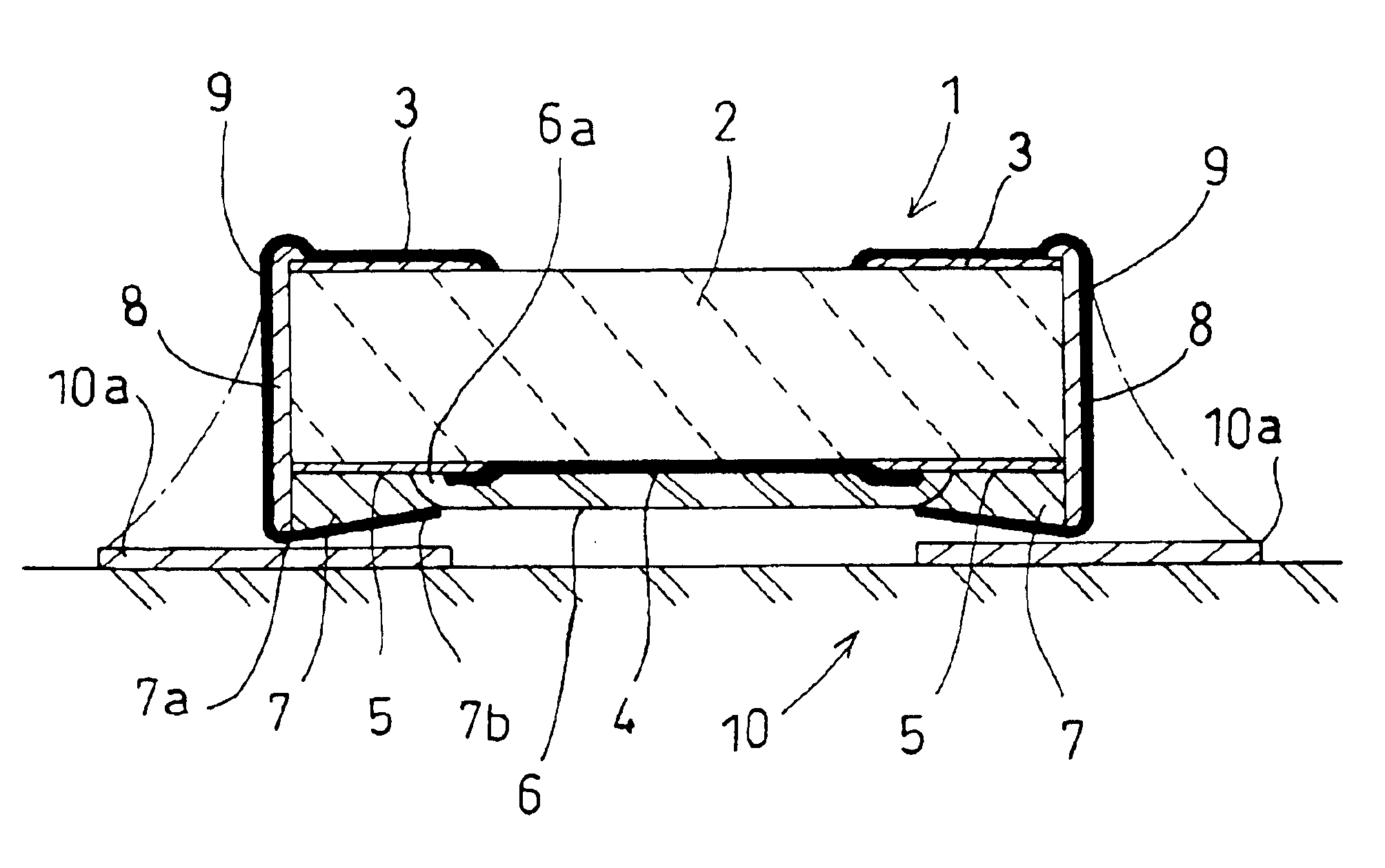

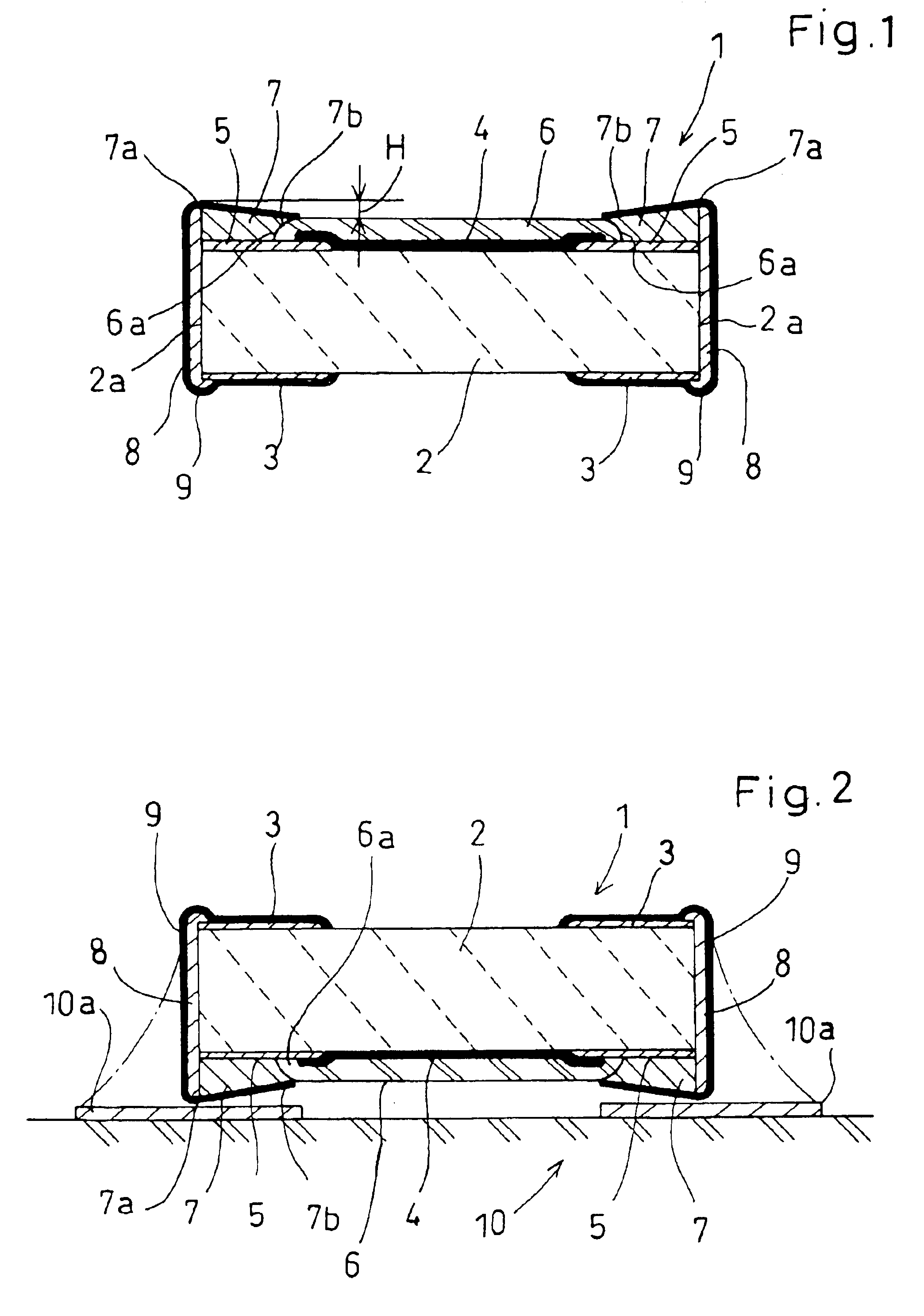

Chip resistor

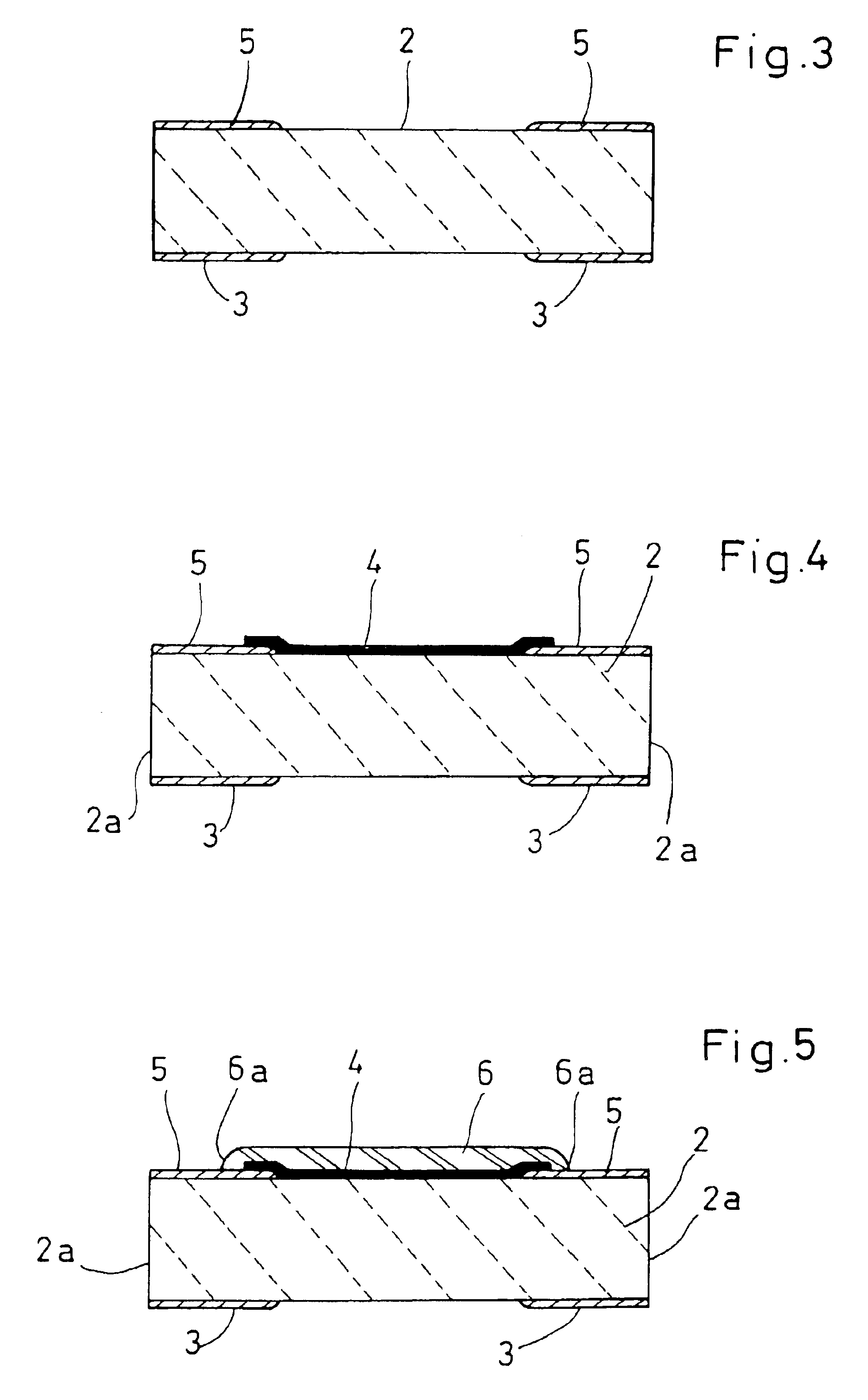

ActiveUS6856234B2Reduce manufacturing costPrevent rising of one endResistor chip manufactureResistor terminals/electrodesElectrical connectionElectrode

A chip resistor includes an insulating substrate 2 in the form of a chip having an upper surface and an opposite pair of side surfaces, a resistor film 4 formed on the upper surface of the insulating substrate 2, a pair of upper electrodes 5 formed on the upper surface of the insulating substrate 2 to flank the resistor film 4 in electrical connection thereto, a cover coat 6 covering the resistor film 4, an auxiliary upper electrode 7 formed on each of the upper electrodes 5 and including a first portion 7a adjoining the relevant side surface of the insulating substrate 2 and a second portion 7b overlapping the cover coat 6, and a side electrode 8 formed on each of the side surfaces of the insulating substrate 2 and electrically connected to at least the upper electrode 5 and the auxiliary upper electrode 7. The first portion 7a of the auxiliary upper electrode 7 has an obverse surface positioned higher than an obverse surface of the second portion 7b for projecting above an obverse surface of the cover coat 6.

Owner:ROHM CO LTD

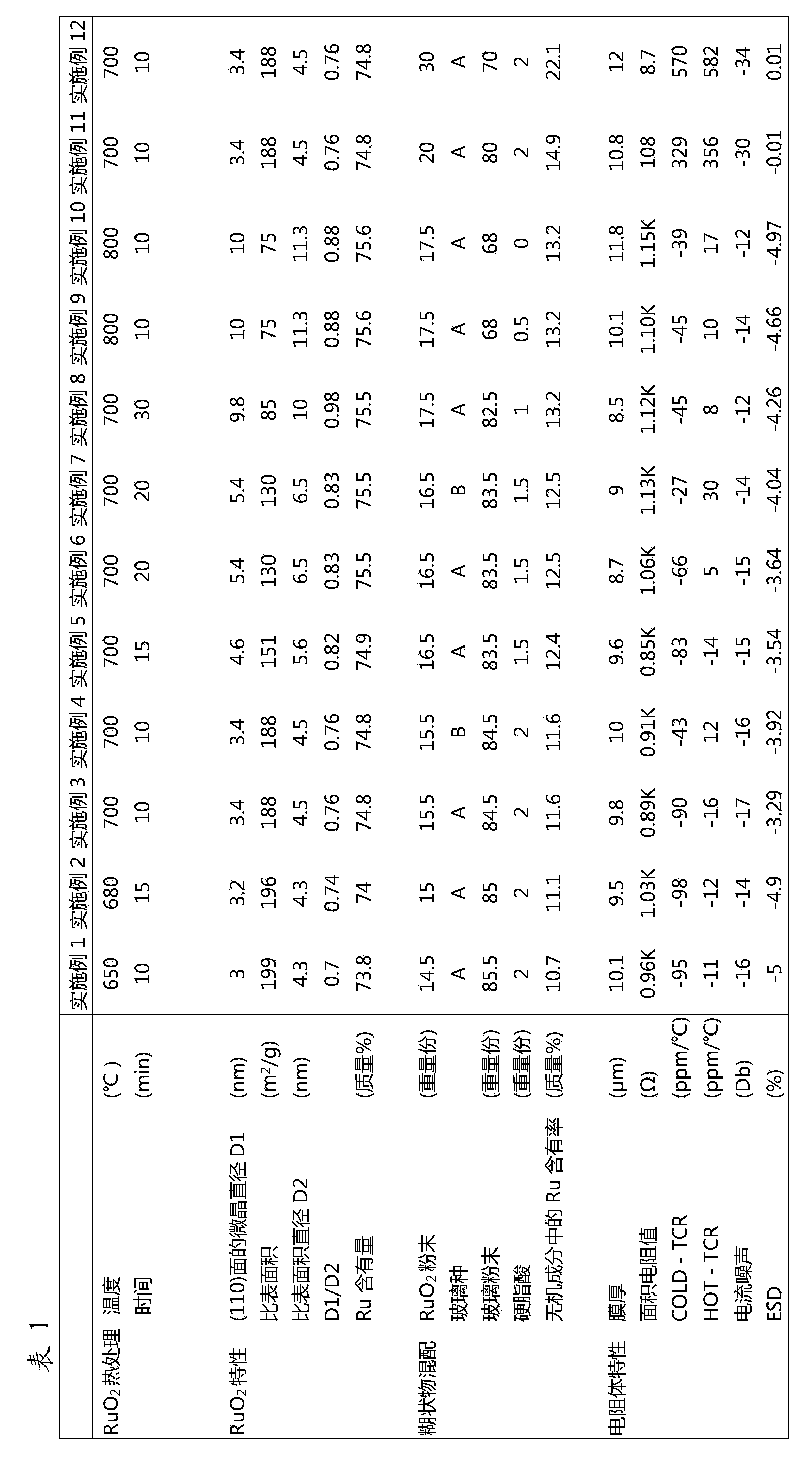

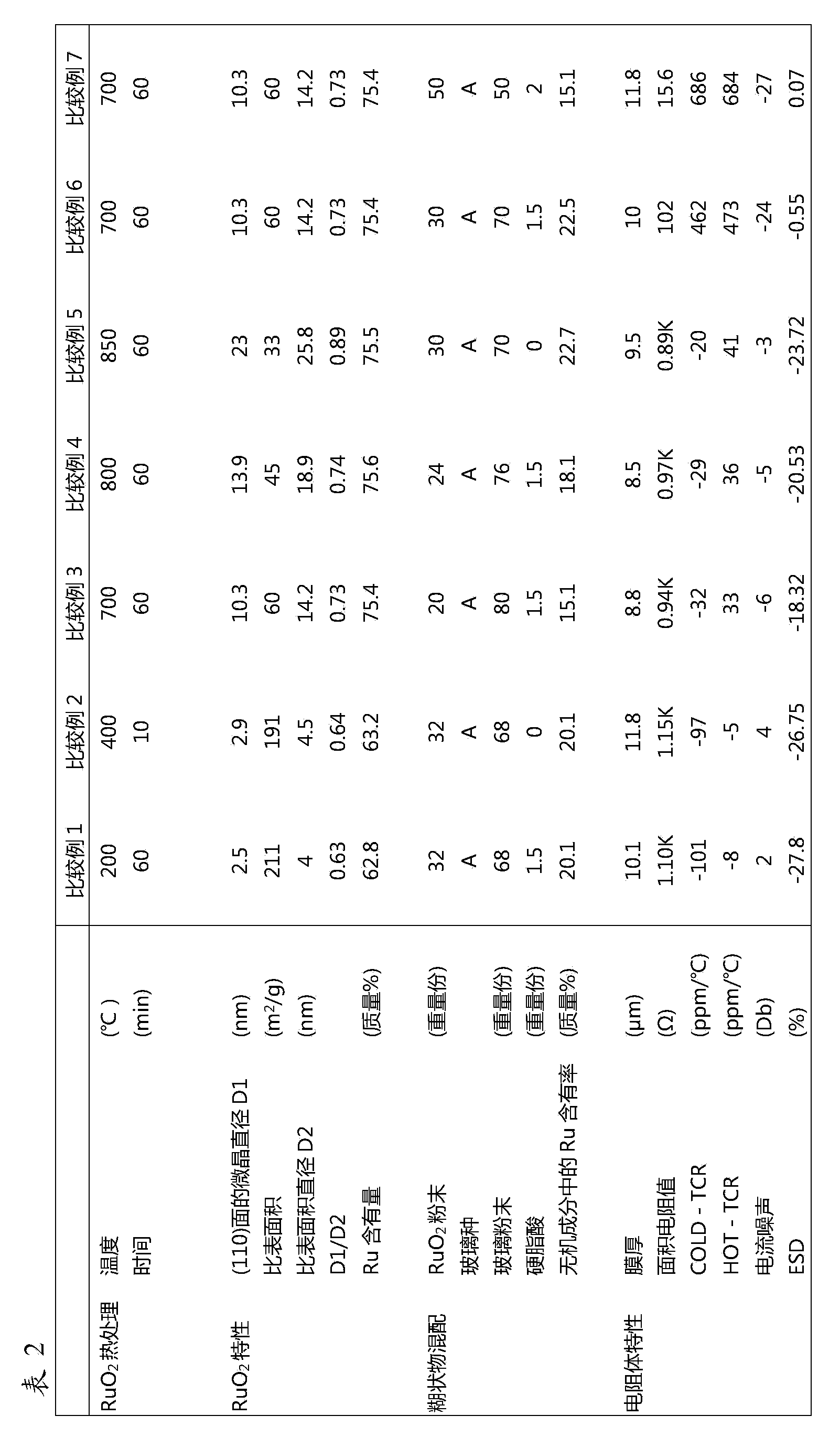

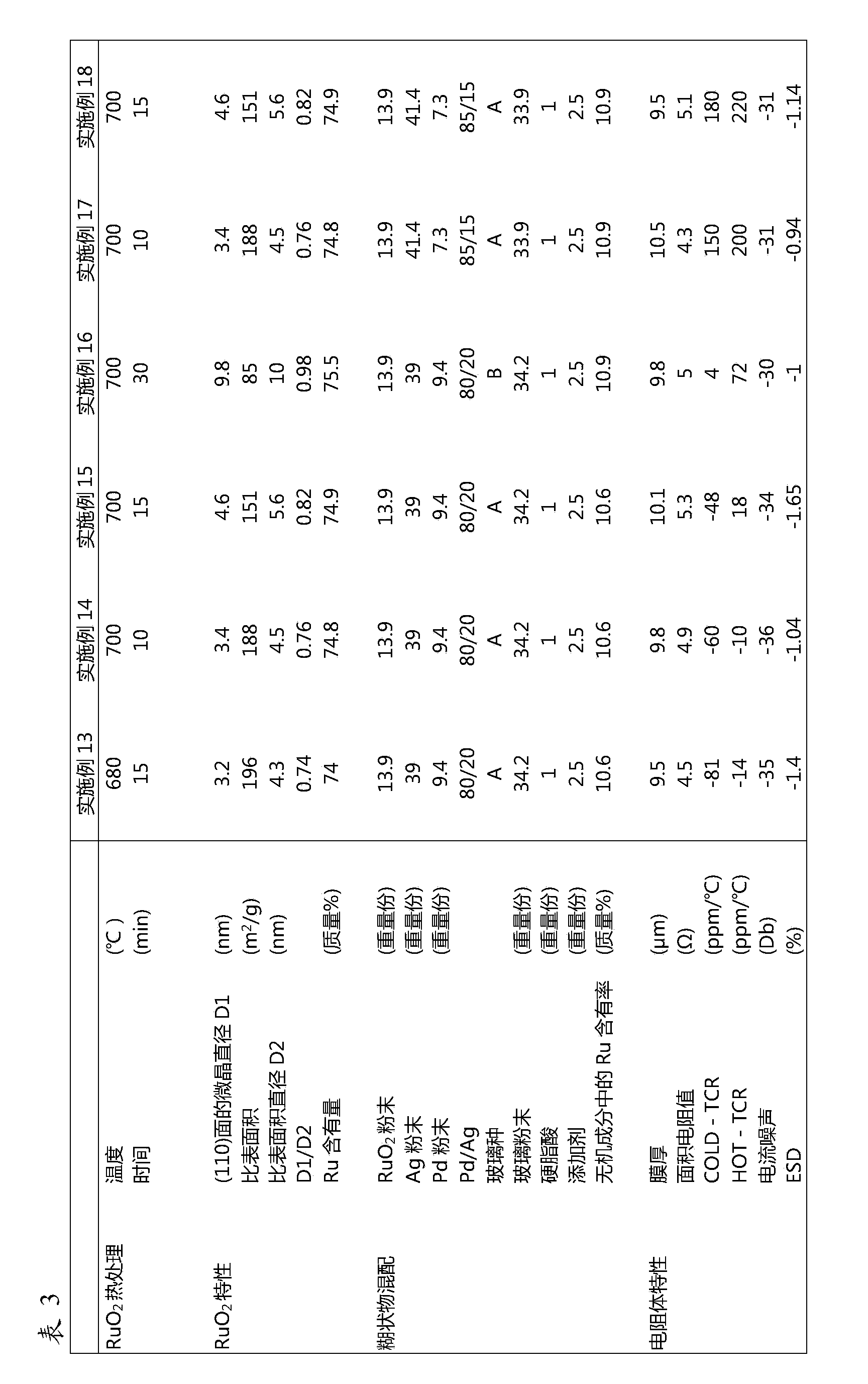

Ruthenium oxide powder, composition for thick film resistor elements using same, and thick film resistor element

ActiveCN103429537AInhibit growthHigh crystallinityRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesThick film resistorsX-rayEngineering

Provided are: a ruthenium oxide powder which is produced, at low cost, as a material for electronic components such as a chip resistor, a hybrid IC and a resistive network each having a sufficient performance, even if the ruthenium content thereof is low; a composition for thick film resistor elements, which uses the ruthenium oxide powder; and a thick film resistor element. Specifically provided are: a ruthenium oxide (RuO2) powder having a rutile crystal structure, which is characterized in that the crystallite diameter of the (110) plane as determined by an X-ray diffraction method is 3-10 nm and the Ru content is 73% by mass or more; a composition for thick film resistor elements, which is obtained by blending a glass powder and conductive particles that are formed of the ruthenium oxide powder as main constituent elements; and a thick resistor element paste, which is obtained by dispersing the composition for thick film resistor elements in an organic vehicle that contains a fatty acid, and which is characterized in that the content of the fatty acid is 0.1-10 parts by weight per 100 parts by weight of the ruthenium oxide.

Owner:SUMITOMO METAL MINING CO LTD

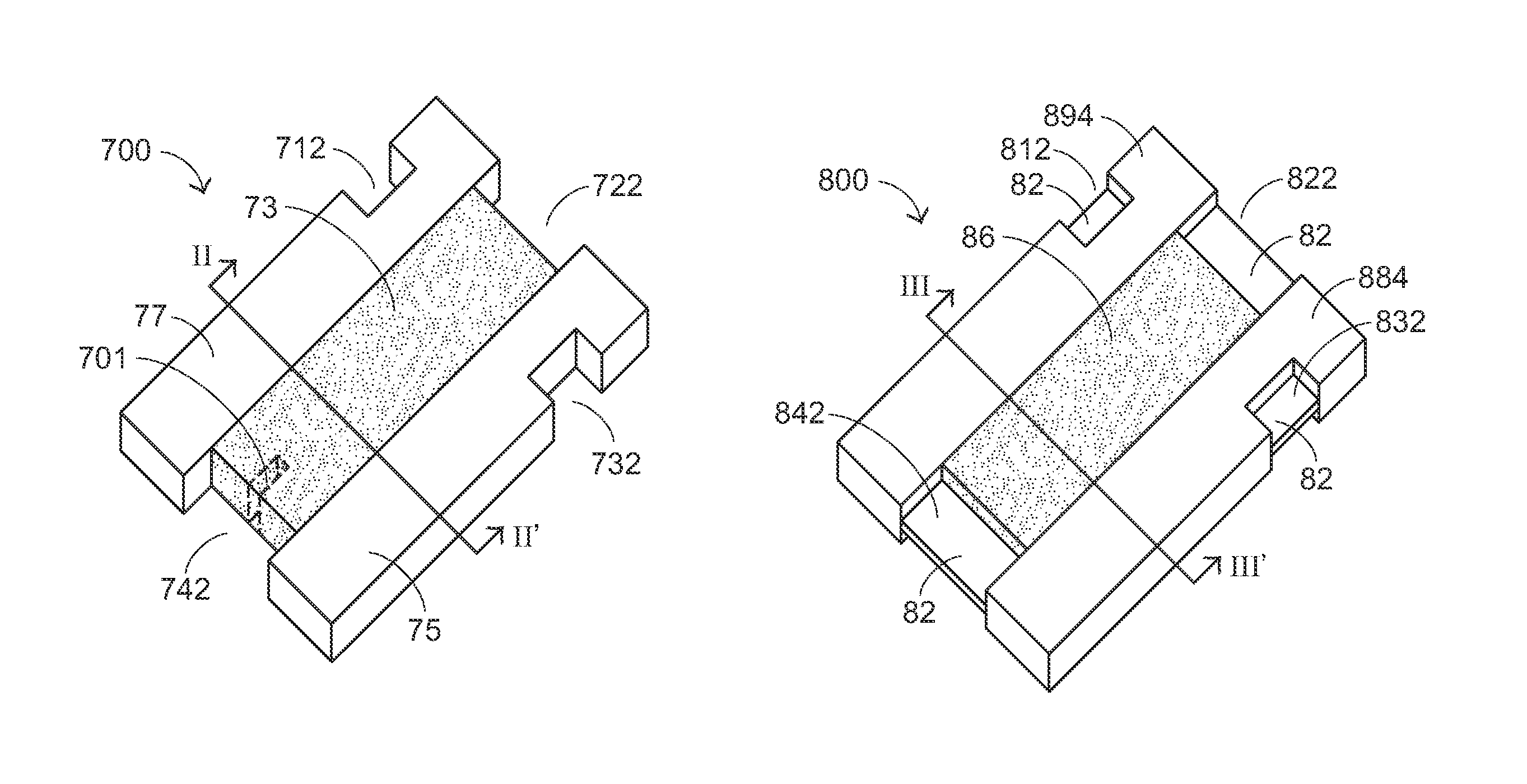

Resistor device

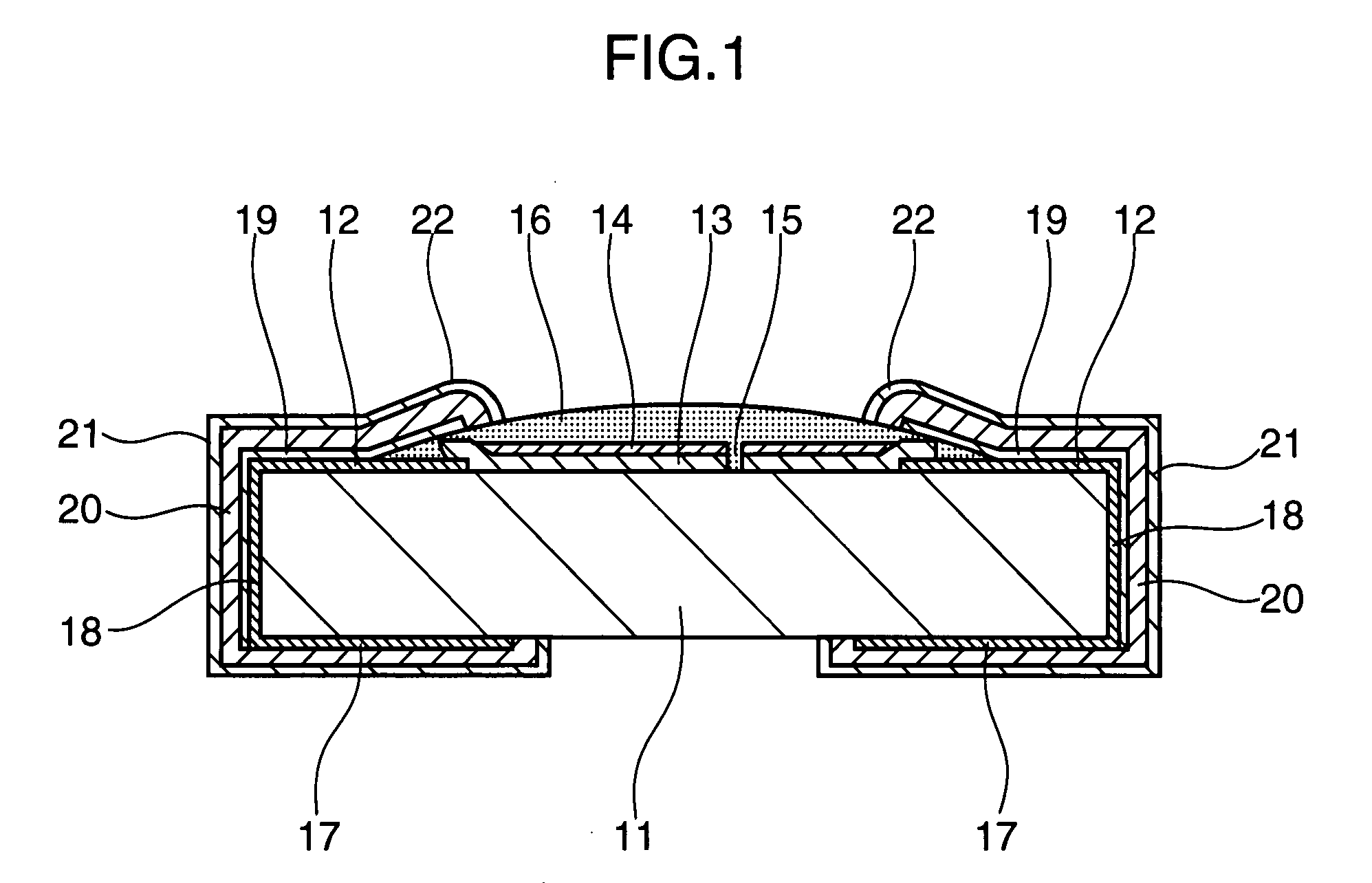

ActiveUS20100328021A1Effective absorptionIncreased power capacityEnvelope/housing resistor manufactureResistor terminals/electrodesElectrical resistance and conductanceSurface mounting

The resistor device is provided with a resistive plate (11) of metal plate material, which is used as a resistance body; a radiative plate (15) of metal plate material, which is spaced from the resistive plate and intercrossed on the resistive plate; a molded resin body (19), which encloses an intercrossing portion of the resistive plate and the radiative plate; terminal portions of the resistive plate (11a), which comprises so that both ends of the resistive plate extending from the molded resin body are bent along an end face and a bottom face of the molded resin body; and terminal portions of the radiative plate (15a), which comprises so that both ends of the radiative plate extending from the molded resin body are bent along an end face and a bottom face of the molded resin body. Accordingly, the surface-mountable resin-sealed metal plate resistor device is enabled to increase the power capacity drastically and to improve the reliability without changing most of the size.

Owner:KOA CORP

Resistor device and method for manufacturing same

ActiveUS20110063072A1Easy to doImprove accuracyCurrent responsive resistorsResistor mounting/supportingResistorElectrical and Electronics engineering

A resistor device includes a resistor plate having a first aperture, a second aperture, a third aperture and a fourth aperture respectively arranged on a first side, a second side, a third side and a fourth side thereof. A first electrode plate is coupled to the first side of the resistor plate and includes a first measurement zone and a second measurement zone disposed at opposite sides of the first aperture; and a second electrode plate is coupled to the third side of the resistor plate and including a third measurement zone and a fourth measurement zone disposed at opposite sides of the third aperture, wherein the first measurement zone and the third measurement zone are disposed at opposite sides of the second aperture, and the second measurement zone and the fourth measurement zone are disposed at opposite sides of the fourth aperture.

Owner:CYNTEC

Thick film circuit heating part based on minicrystal glass base plate and its making technology

ActiveCN101106842AEliminate magnetic pollutionImprove insulation performanceNon-conductive material with dispersed conductive materialResistor manufactureRare earthSlurry

The invention discloses a rare earth thick film circuit controllable electroheat (resistor) element based on microcrystalline glass substrate and the preparation method thereof. The element includes a substrate and a series of electric slurry. The electric slurry is formed on the substrate and includes packaging slurry and electrode slurry. Each kind of the electric slurry is composed of three parts: a functional phase, an inorganic binding phase and an organic carrier phase. The electric slurry also includes rare earth resistor slurry. Also disclosed includes a microcrystalline glass substrate, and formulas for packaging slurry, rare earth resistor slurry, and rare earth electrode slurry. The invention has the advantages of vertical heat transmission, uniform and controllable heating temperature field, rapid respond speed, high power density, strong thermal impact resistance, no magnetic leakage, green, environment protection, energy saving, and high safety and reliability.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

Middle temperature sintering thick-film resistance paste based on high-temperature-resistant flexible substrate and preparation method thereof

InactiveCN105976894AAvoid harmSolve urgent problemsNon-conductive material with dispersed conductive materialCable/conductor manufactureFilm resistanceOrganic solvent

The invention discloses middle temperature sintering thick-film resistance paste based on a high-temperature-resistant flexible substrate and a preparation method thereof. The thick-film resistance paste comprises an inorganic bonding phase, a composite function phase, a TCR regulator and an organic carrier. The inorganic bonding phase is formed by SiO2, Bi2O3, B2O3, P2O5, Al2O3, Li2O and CaF2; the composite function phase is formed by micron flake silver powders, micron spherical silver powders and nanometer silver powders; and the organic carrier is formed by organic solvents, macromolecule thickeners, high-temperature-resistant organic resin, surfactants, plasticizers, dispersants, antifoaming agents and thixotropic agents. The preparation method comprises the steps of preparation of the inorganic bonding phase, preparation of the composite function phase, preparation of the organic carrier and preparation of the resistance paste. The thick-film resistance paste is low in sintering temperature, short in sintering time, large in adhesive force, resistant to aging, high in flexibility, adjustable in square resistance, low and adjustable in resistance temperature coefficient and excellent in printing characteristic and sintering characteristic, and can be matched with the high-temperature-resistant flexible substrate.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

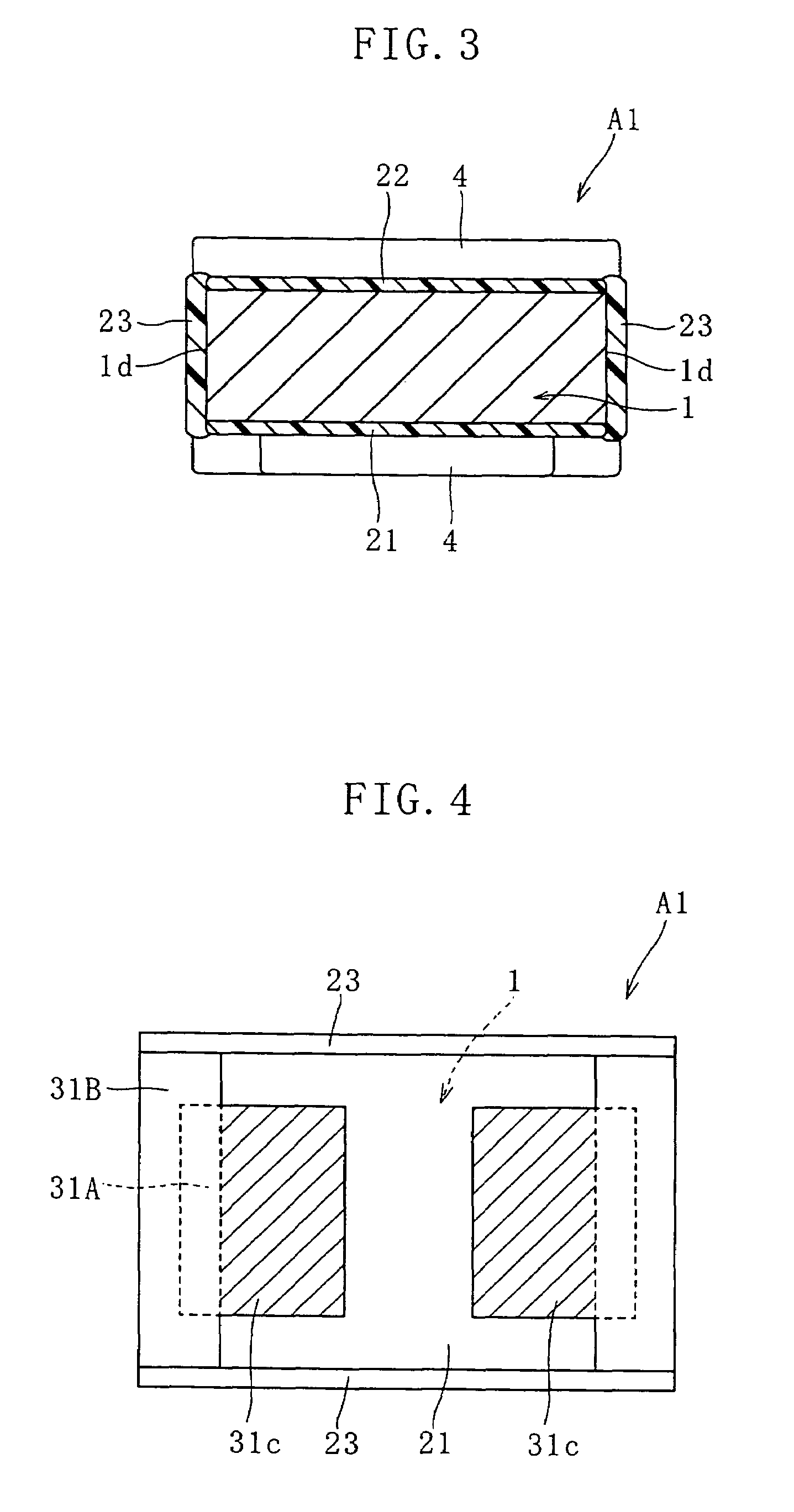

Chip-Shaped Electronic Part

ActiveUS20080094169A1Crack suppressionGood effectResistor chip manufactureCircuit arrangements on support structuresTectorial membraneEngineering

A chip-shaped electronic part includes: a substrate; a pair of upper surface electrodes formed on an upper surface of the substrate; a functional element formed to be electrically connected to the upper surface electrode pair; a pair of lower surface electrodes formed on a lower surface of the substrate at positions opposing the upper surface electrode pair; a pair of end surface electrodes formed on end surfaces of the substrate so that each of the end surface electrode pair is electrically connected to one of the upper surface electrode pair, and to one of the lower surface electrode pair corresponding to the one upper surface electrode; a protective film formed in such a manner as to cover at least the functional element; and a plated layer formed in such a manner as to cover at least each of the upper surface electrode pair, wherein the protective film or the plated layer has at least two points of application at which a load from above the substrate is exerted.

Owner:PANASONIC CORP

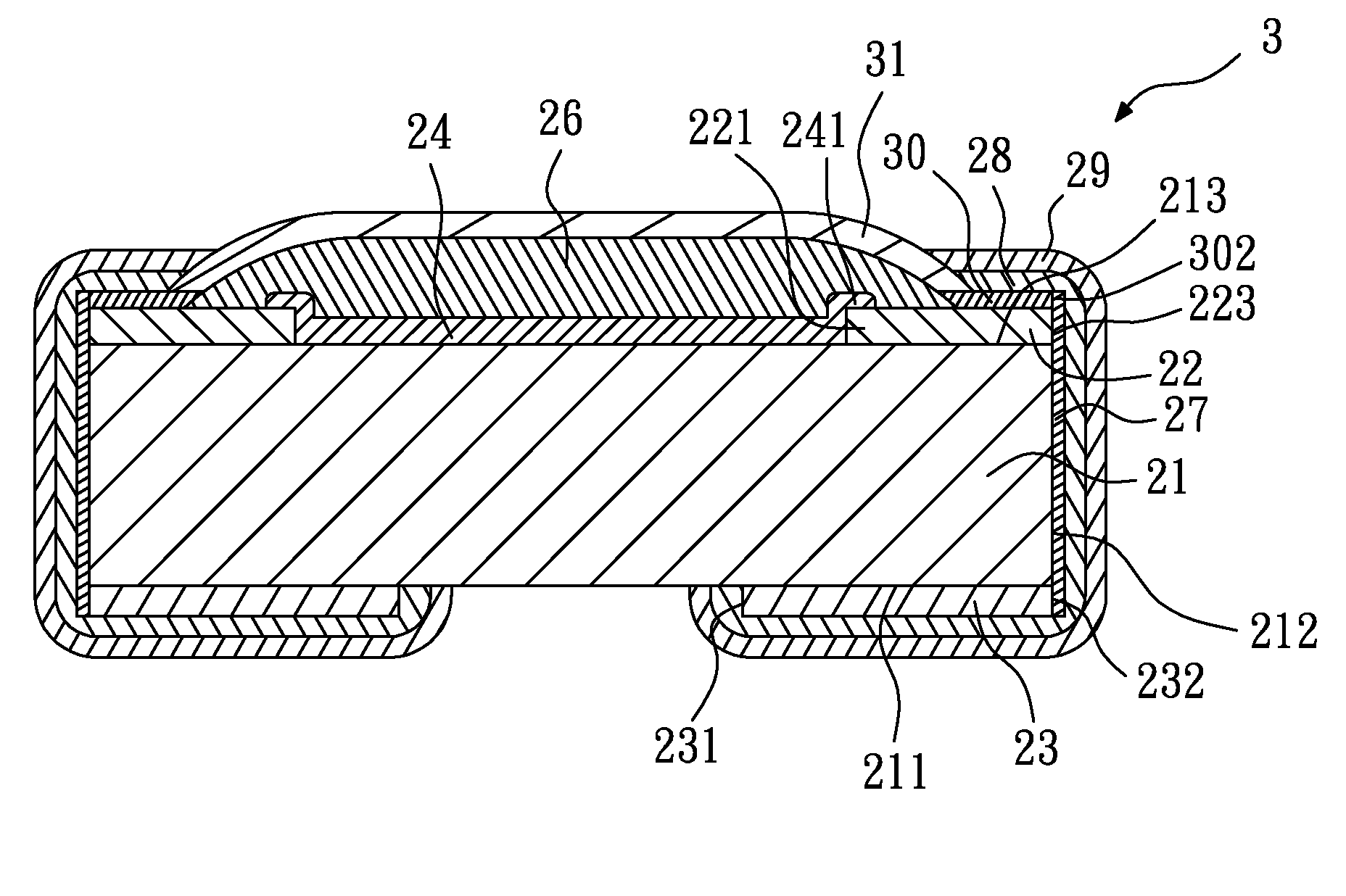

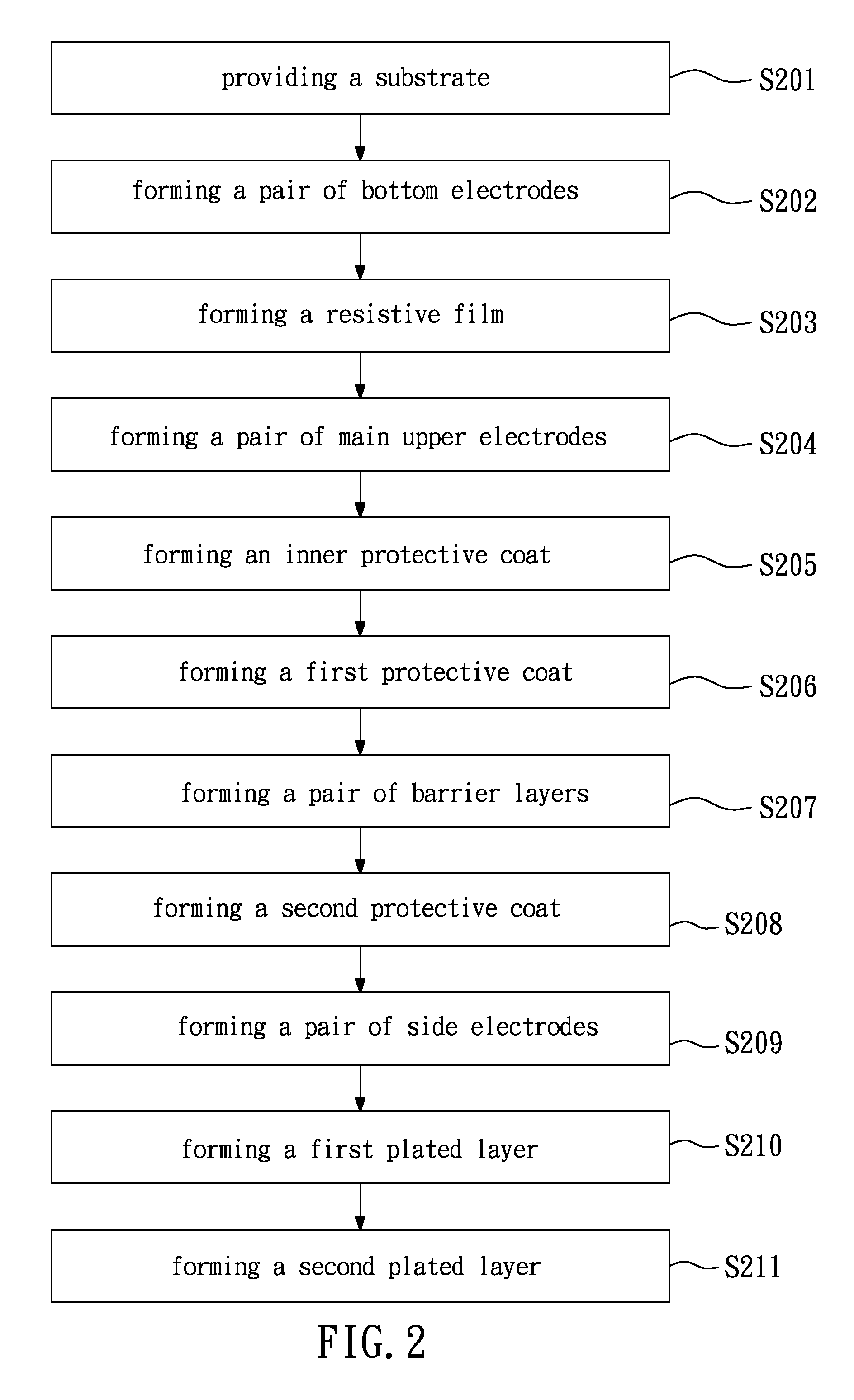

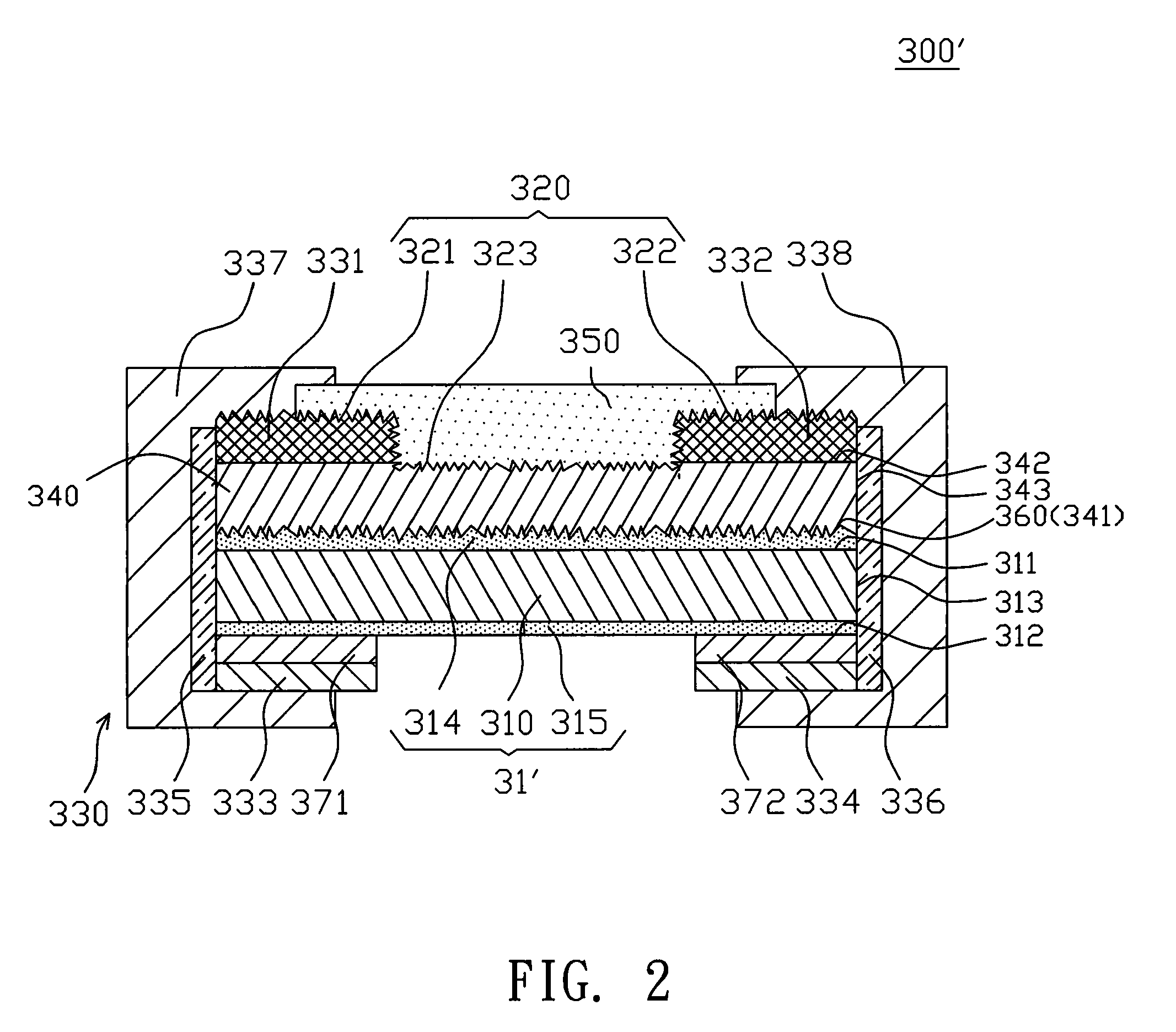

Chip resistor and method for making the same

ActiveUS20100201477A1Effective protectionEasily affectedResistor chip manufactureEnvelope/housing resistor manufactureCorrosionElectrical and Electronics engineering

The present invention relates to a chip resistor and method for making the same. The chip resistor includes a substrate, a pair of bottom electrodes, a resistive film, a pair of main upper electrodes, a first protective coat, a pair of barrier layers, a second protective coat, a pair of side electrodes and at least one plated layer. The first protective coat is disposed over the resistive film, and covers part of the main upper electrodes. The barrier layers are disposed on the main upper electrodes, and cover part of the first protective coat. The second protective coat is disposed on the first protective coat, and covers part of the barrier layers. The plated layers cover the barrier layers, the bottom electrodes and the side electrodes. As a result, the chip resistor features high corrosion resistance.

Owner:YAGEO CORP

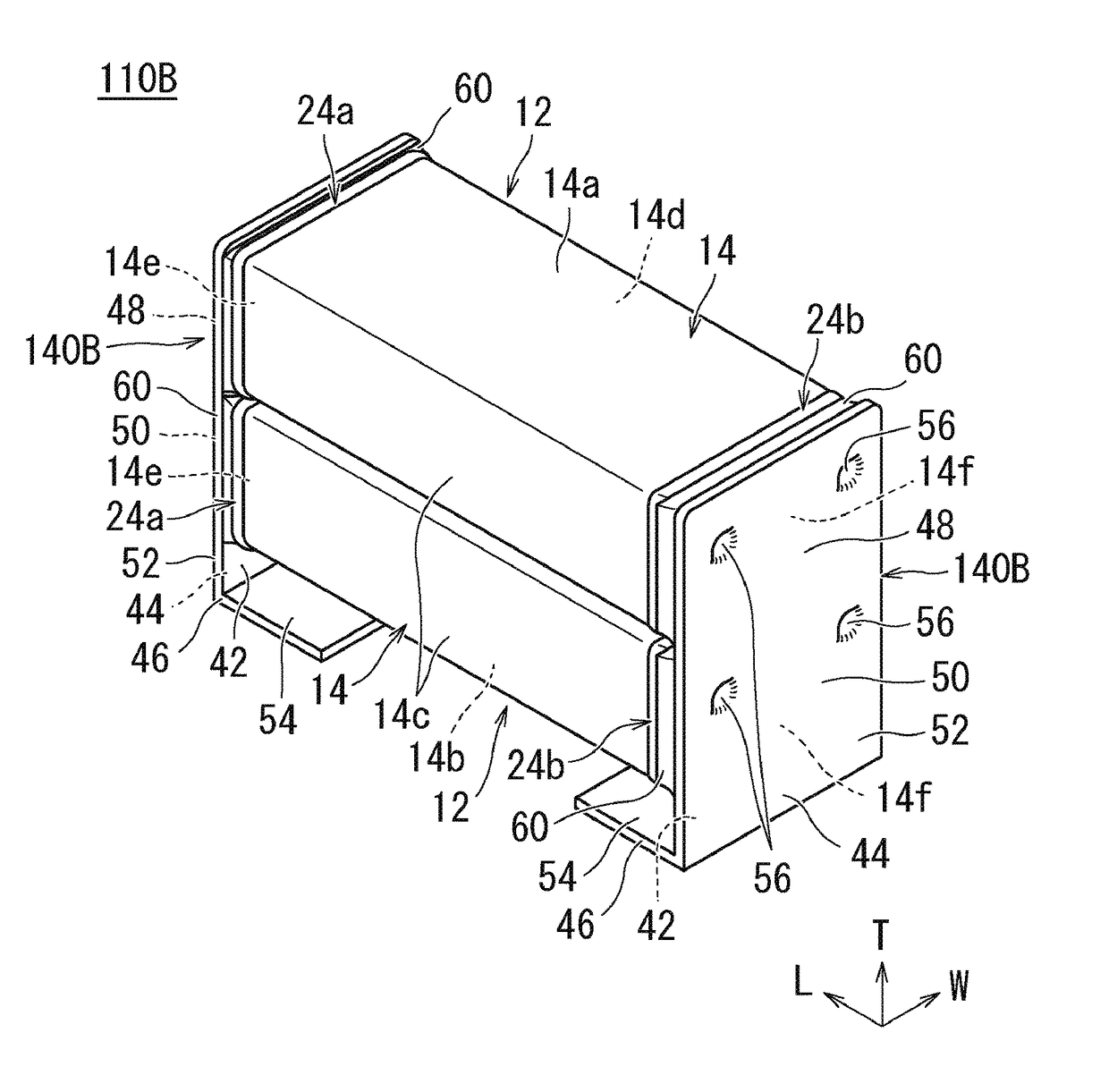

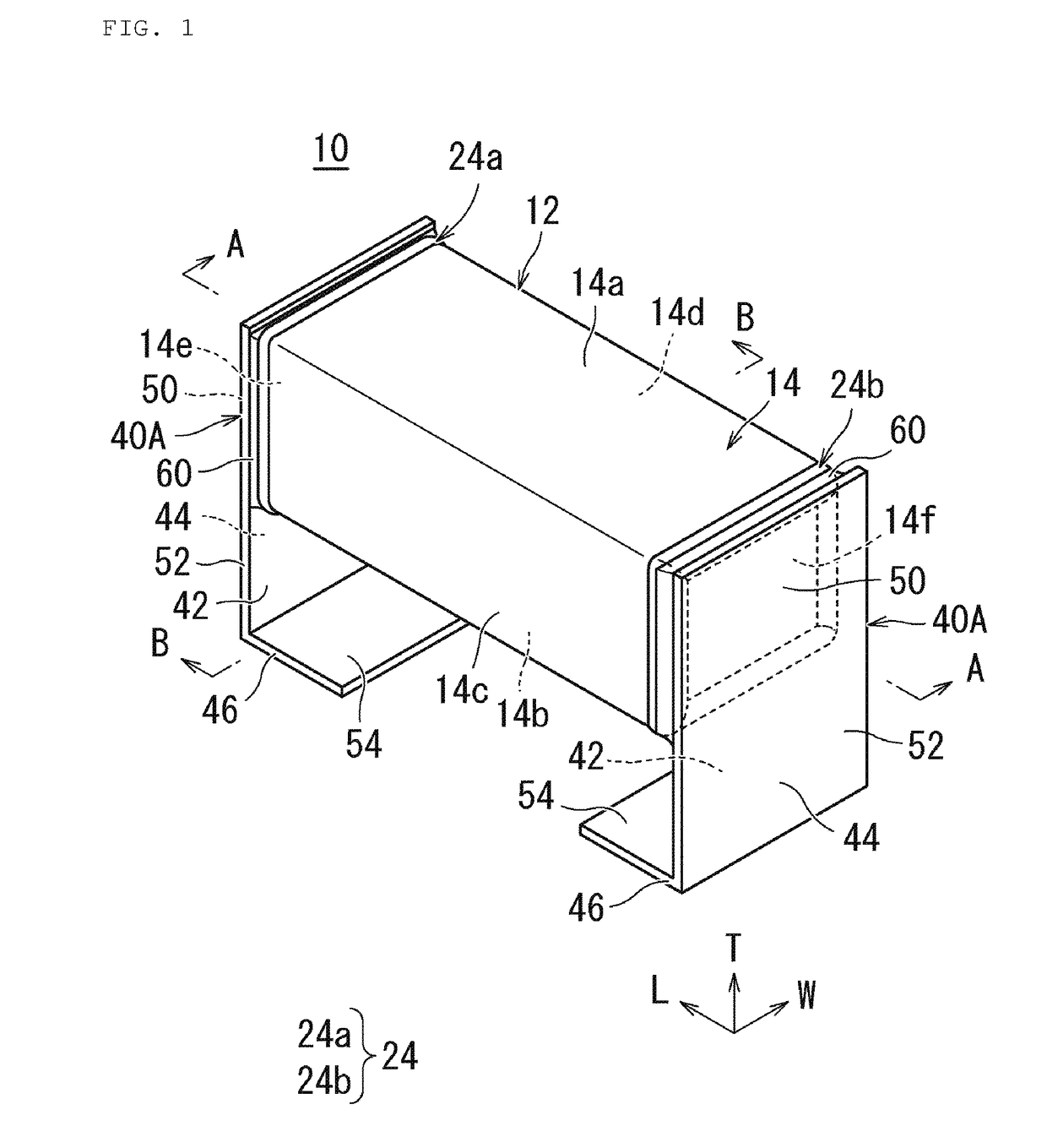

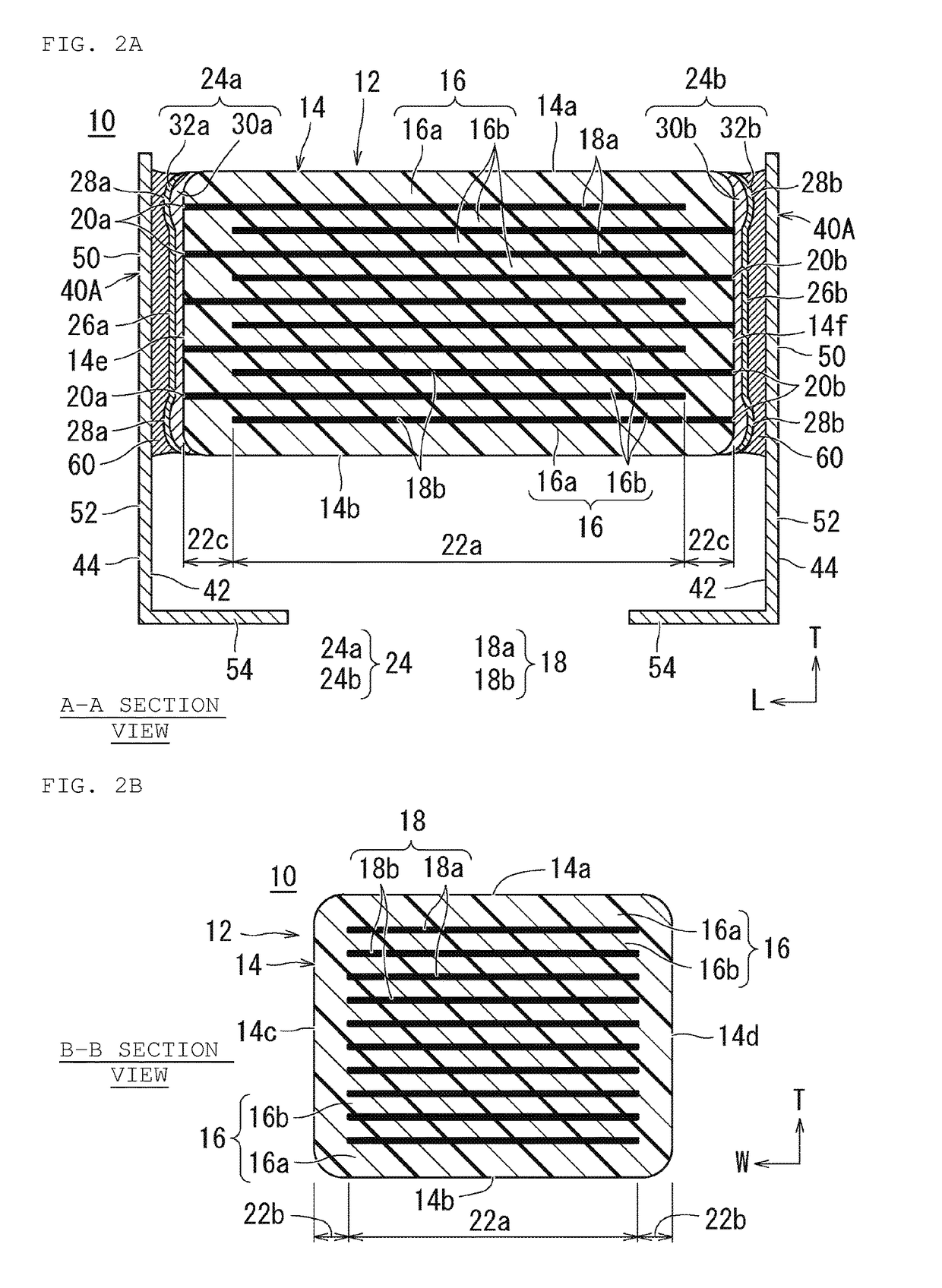

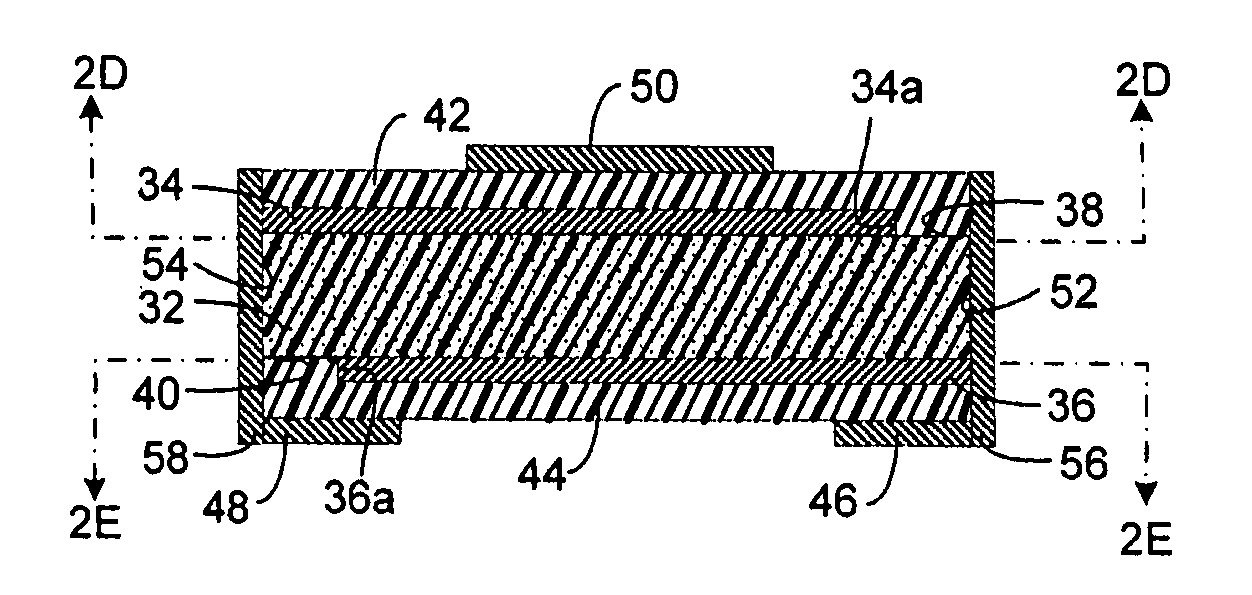

Multilayer ceramic electronic component

ActiveUS20180033556A1Reduce tensile stressAvoid it happening againFixed capacitor electrodesFixed capacitor dielectricElectronic componentMaterials science

A multilayer ceramic electronic component includes an electronic component body including a laminate and an external electrode, and a pair of metal terminals that are joined by a joining material. The pair of metal terminals includes a terminal joint portion, an extended portion and a mounting portion. The external electrode is provided only on both end surfaces of the laminate, and includes first and second external electrodes. The first external electrode and the second external electrode each include a saddle portion with a thickness larger than the thickness of a center portion of each end surface in the periphery of the first end surface and the second end surface of the laminate, respectively.

Owner:MURATA MFG CO LTD

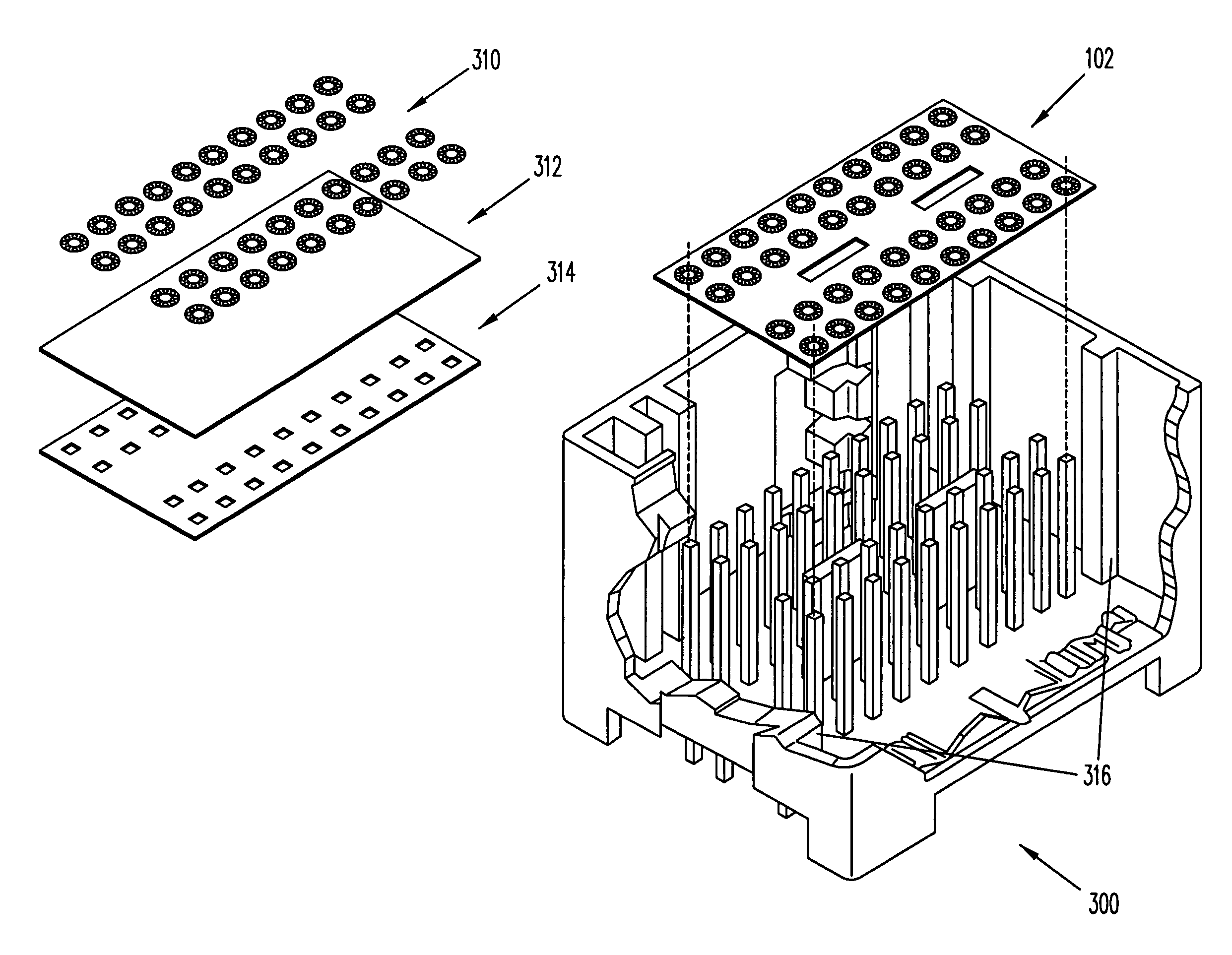

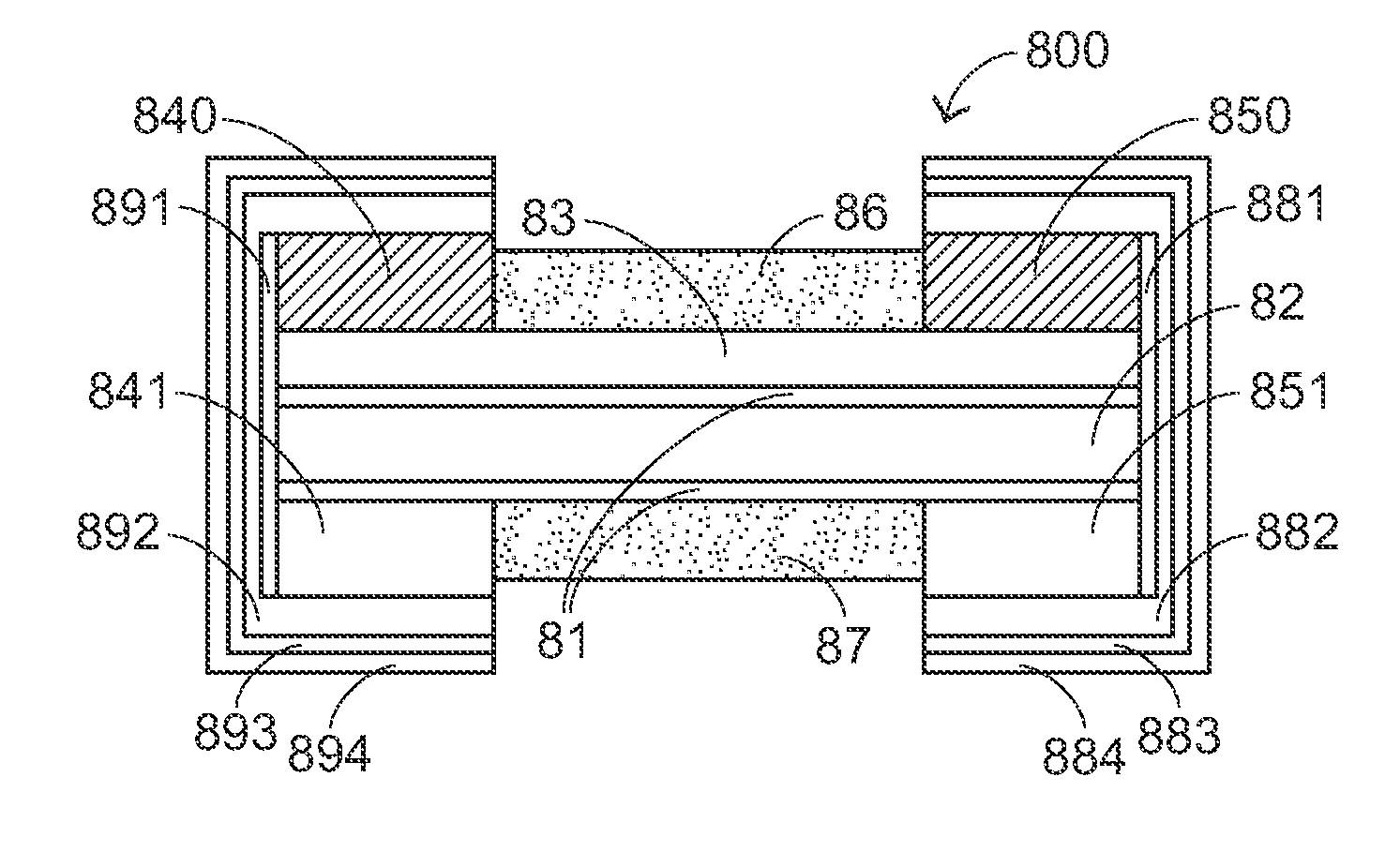

Conductive polymer electronic devices with surface mountable configuration and methods for manufacturing same

ActiveUS20110175700A1Envelope/housing resistor manufactureCurrent responsive resistorsInsulation layerElectrical conductor

Surface-mountable conductive polymer electronic devices include at least one conductive polymer active layer laminated between upper and lower electrodes. Upper and lower insulation layers, respectively, sandwich the upper and lower electrodes. First and second planar conductive terminals are formed on the lower insulation layer. First and second cross-conductors are provided by plated through-hole vias, whereby the cross-conductors connect each of the electrodes to one of the terminals. Certain embodiments include two or more active layers, arranged in a vertically-stacked configuration and electrically connected by the cross-conductors and electrodes in parallel. Several embodiments include at least one cross-conductor having a chamfered or beveled entry hole through the upper insulation layer to provide enhanced adhesion between the cross-conductor and the insulation layer. Several methods for manufacturing the present surface-mountable conductive polymer electronic devices are also provided.

Owner:BOURNS INC

Resistive component and method of manufacturing the same

ActiveUS20100039211A1Improve stabilityAdhesionResistor chip manufactureEnvelope/housing resistor manufactureElectrical resistance and conductanceOptoelectronics

A resistive component suitable for detecting electric current in a circuit and a method of manufacturing the resistive component are provided. The resistive component includes a carrier, a resistive layer, an electrode unit, an upper oxide layer and a protective layer. The resistive layer comprises copper alloy and is disposed on the carrier. The electrode unit is electrically connected to the resistive layer. The upper oxide layer is disposed on a part of a surface of the resistive layer and includes oxides of the resistive layer. The protective layer covers at least a part of the upper oxide layer.

Owner:CYNTEC

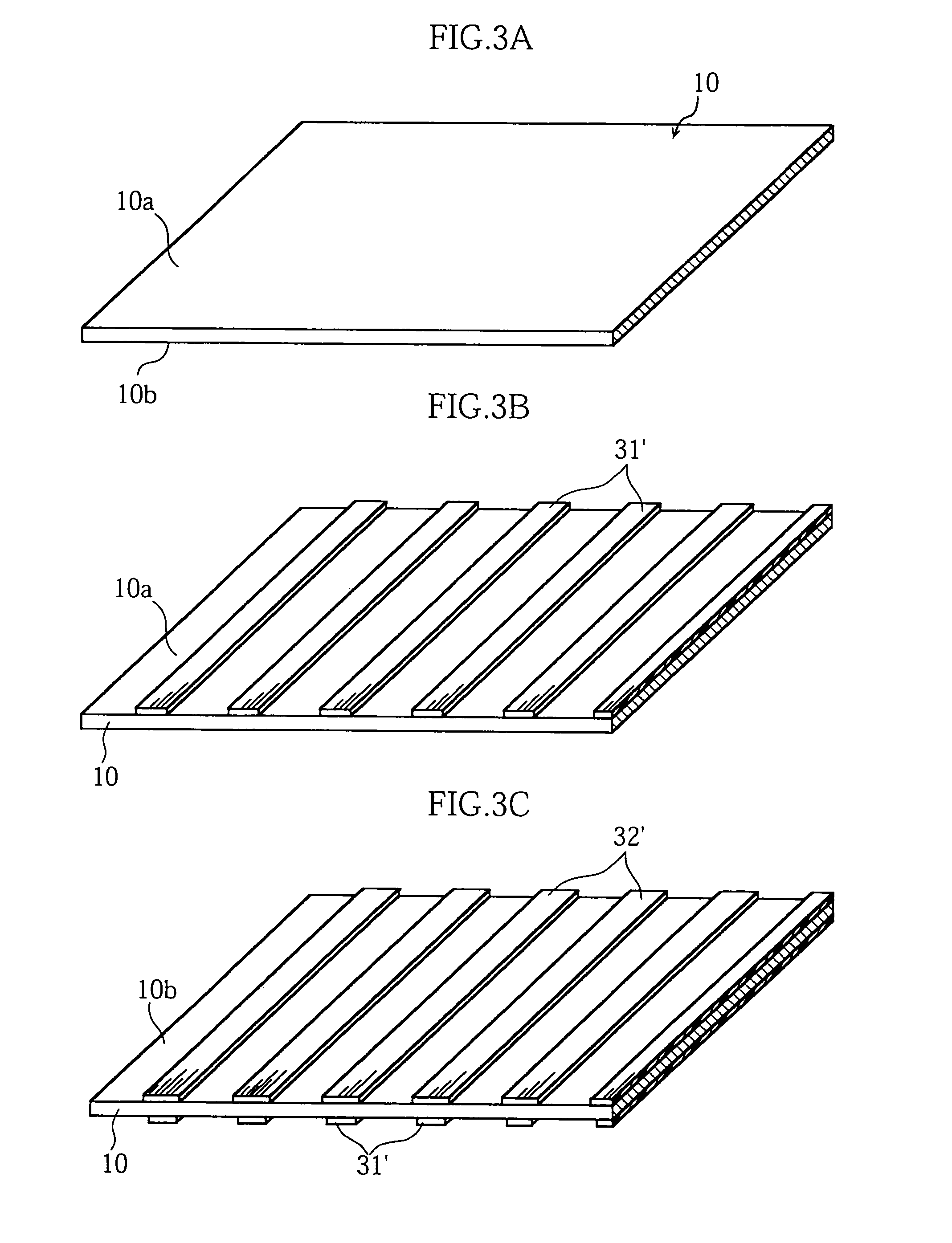

Chip resistor and manufacturing method thereof

ActiveUS7667568B2Making such a chip resistor efficiently and appropriatelyResistor chip manufactureResistor terminals/electrodesEngineeringElectrical and Electronics engineering

A chip resistor (A1) includes a chip-like resistor element (1), two electrodes (31) spaced from each other on the bottom surface (1a) of the resistor element, and an insulation film (21) between the two electrodes. Each electrode (31) has an overlapping portion (31c) which overlaps the insulation film (21) as viewed in the vertical direction.

Owner:ROHM CO LTD

Resistor device and method for manufacturing same

ActiveUS8183976B2Improve accuracyAdd supportCurrent responsive resistorsResistor mounting/supportingEngineeringResistor

A resistor device includes a resistor plate having a first aperture, a second aperture, a third aperture and a fourth aperture respectively arranged on a first side, a second side, a third side and a fourth side thereof. A first electrode plate is coupled to the first side of the resistor plate and includes a first measurement zone and a second measurement zone disposed at opposite sides of the first aperture; and a second electrode plate is coupled to the third side of the resistor plate and including a third measurement zone and a fourth measurement zone disposed at opposite sides of the third aperture, wherein the first measurement zone and the third measurement zone are disposed at opposite sides of the second aperture, and the second measurement zone and the fourth measurement zone are disposed at opposite sides of the fourth aperture.

Owner:CYNTEC

Popular searches

Circuit susbtrate materials Emergency protective arrangements for limiting excess voltage/current Protective switch operating/release mechanisms Varistors Line/current collector details Electrothermal relays Overvoltage circuit protection Circuit electrostatic discharge protection Conductive pattern formation Coupling protective earth/shielding arrangements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com