Patents

Literature

35 results about "Shear strain rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer thick-film resistive paste, a polymer thick-film resistor and a method and an apparatus for the manufacture thereof

InactiveUS20050051360A1Low/insignificant dimensional and shape changeHigh solid contentPretreated surfacesLiquid/solution decomposition chemical coatingPolymer sciencePrinted circuit board

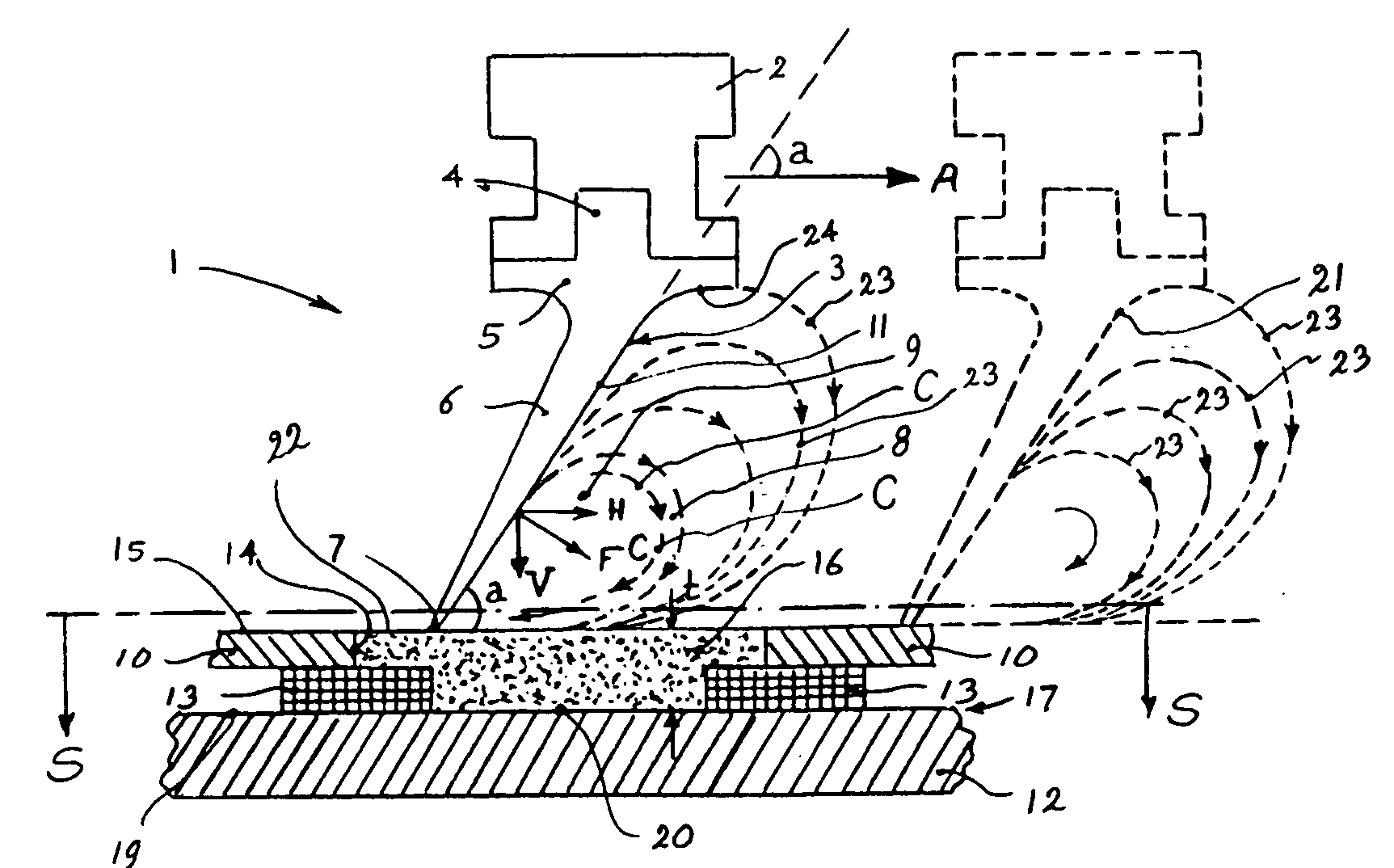

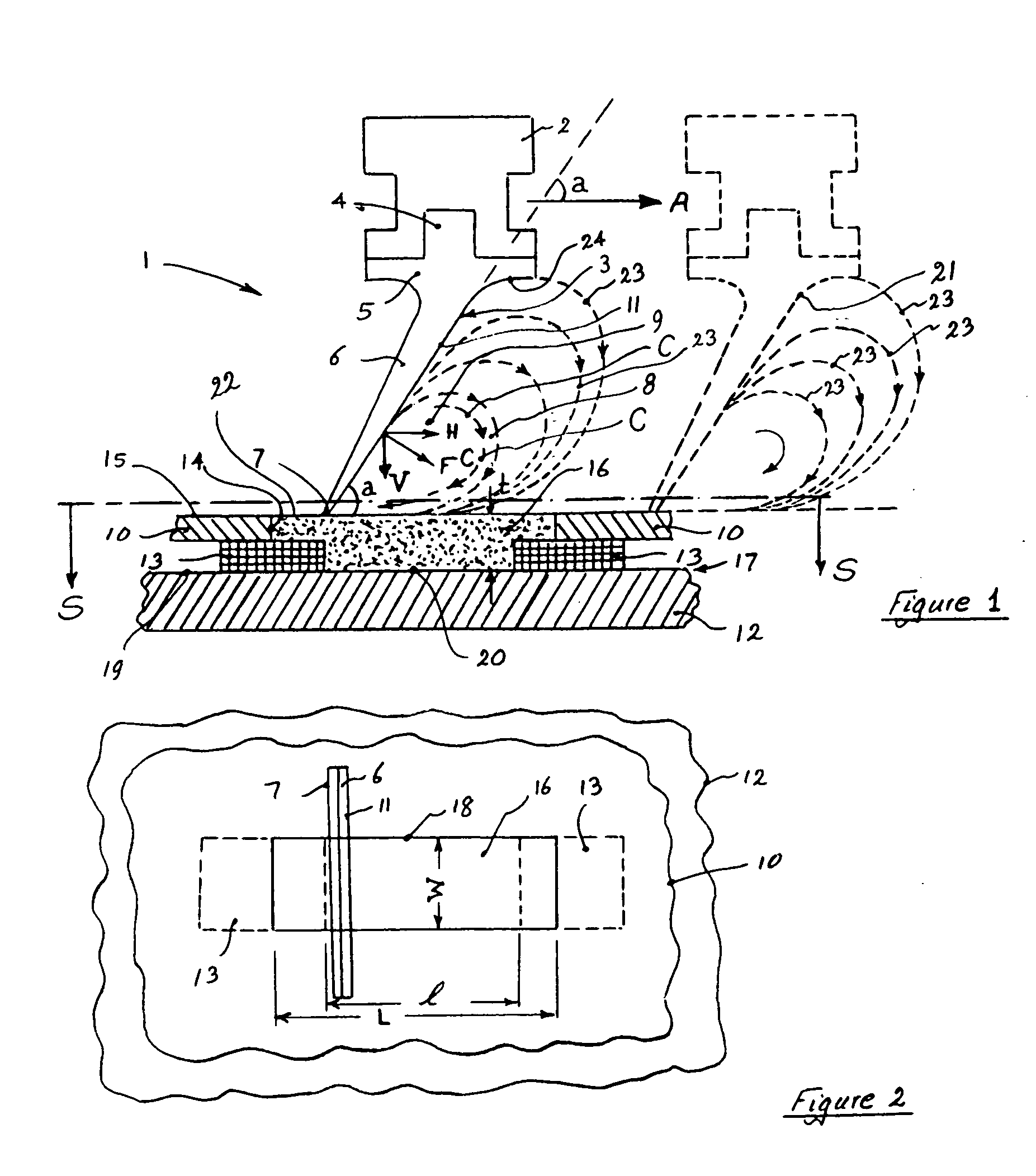

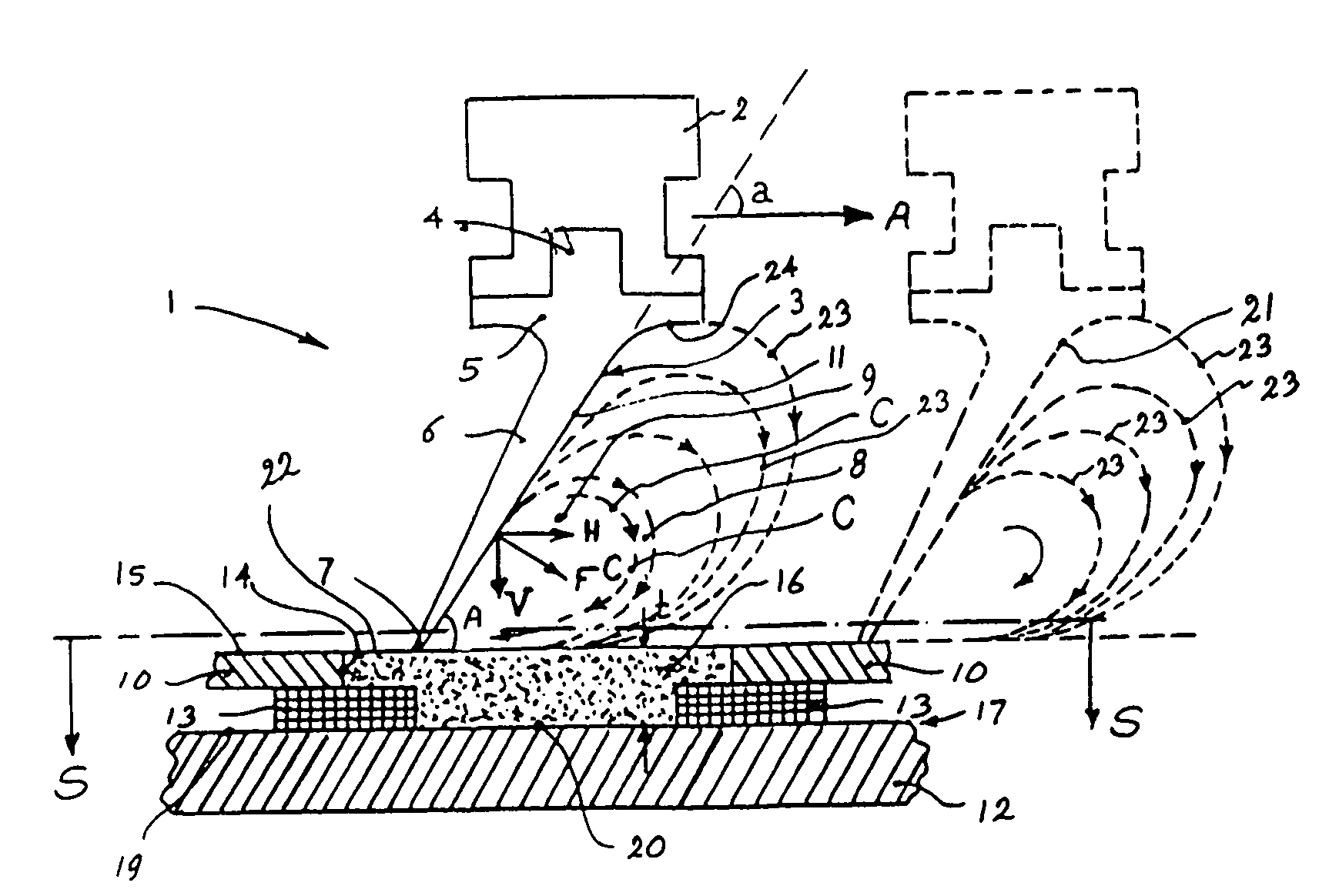

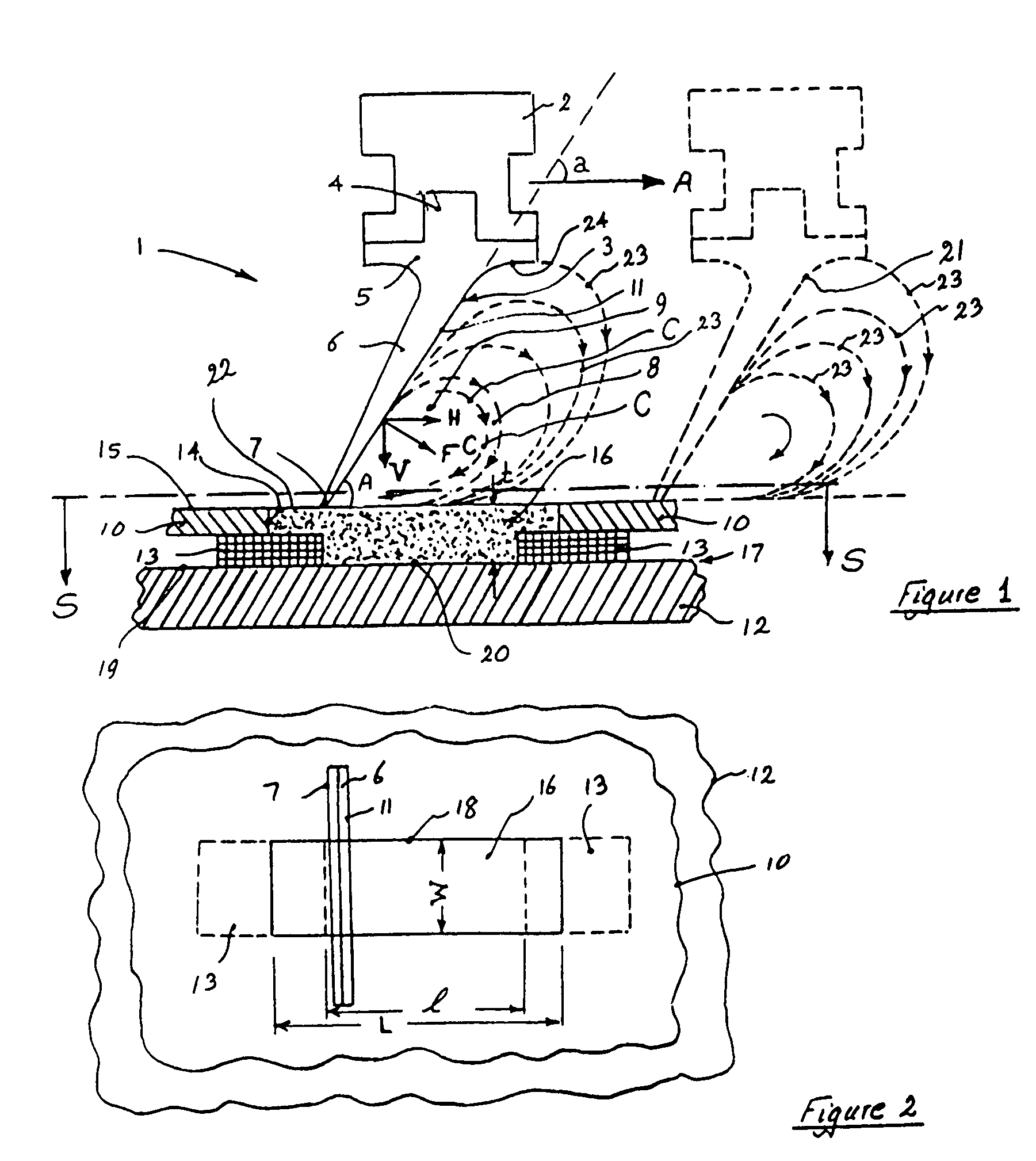

The present invention teaches formulations, apparatus and a method of applying high thixotropic index polymer thick-film resistive pastes for making polymer thick-film resistors with improved tolerances by providing a squeegee with a blade tilted at an angle of 10 to 85 to the surface of the printed circuit board thus causing a fluid rotational motion within the bead of the polymer thick-film resistive paste as the squeegee blade moves relative to the printed circuit board. This rotational motion increases the shear strain rate experienced by the paste within the bead and results in a more effective filling of the resistor-shaped cavity without including air bubbles, experiencing elastic recovery of the paste and, without surface fractures of the paste.

Owner:EMBED TECH

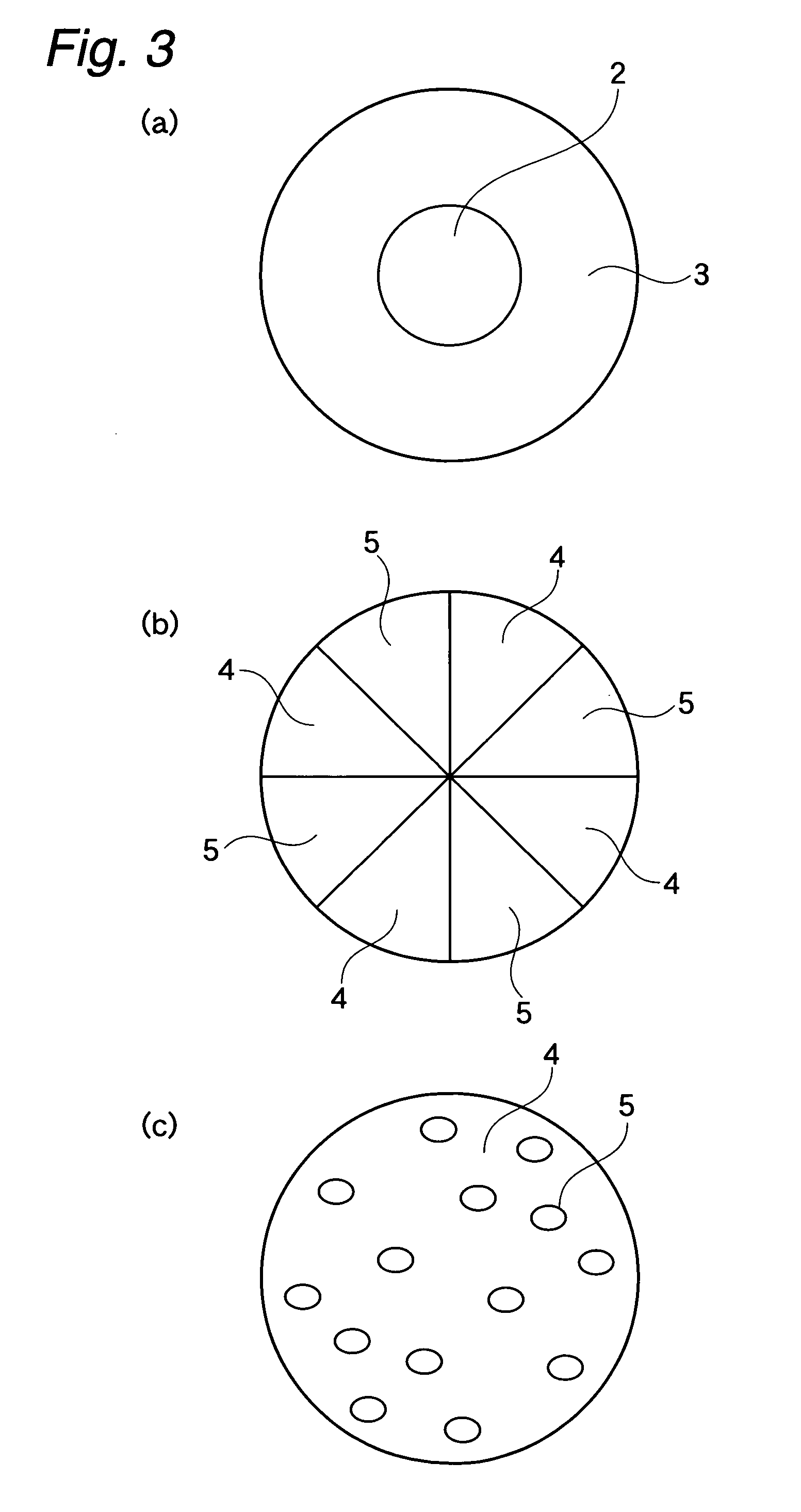

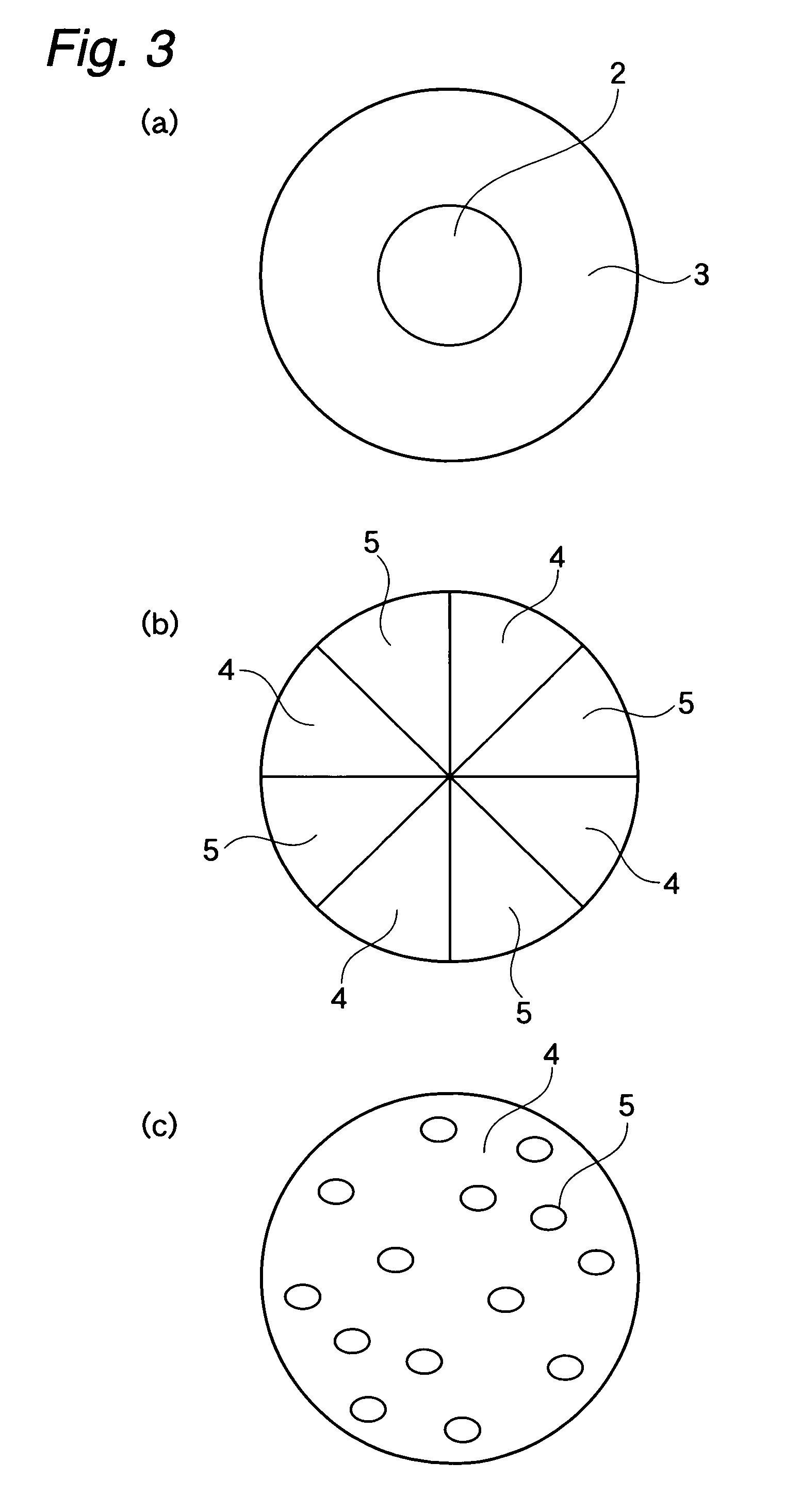

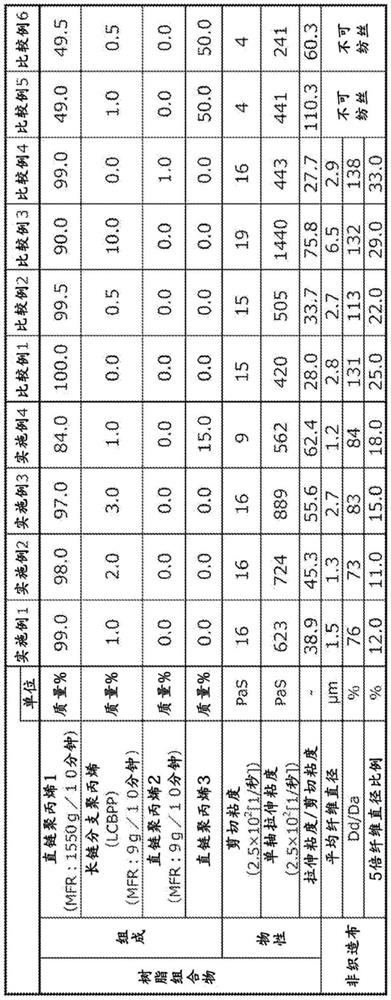

Nonwoven fabric capable of being elongated and composite nonwoven fabric comprising said nonwoven fabric laminated

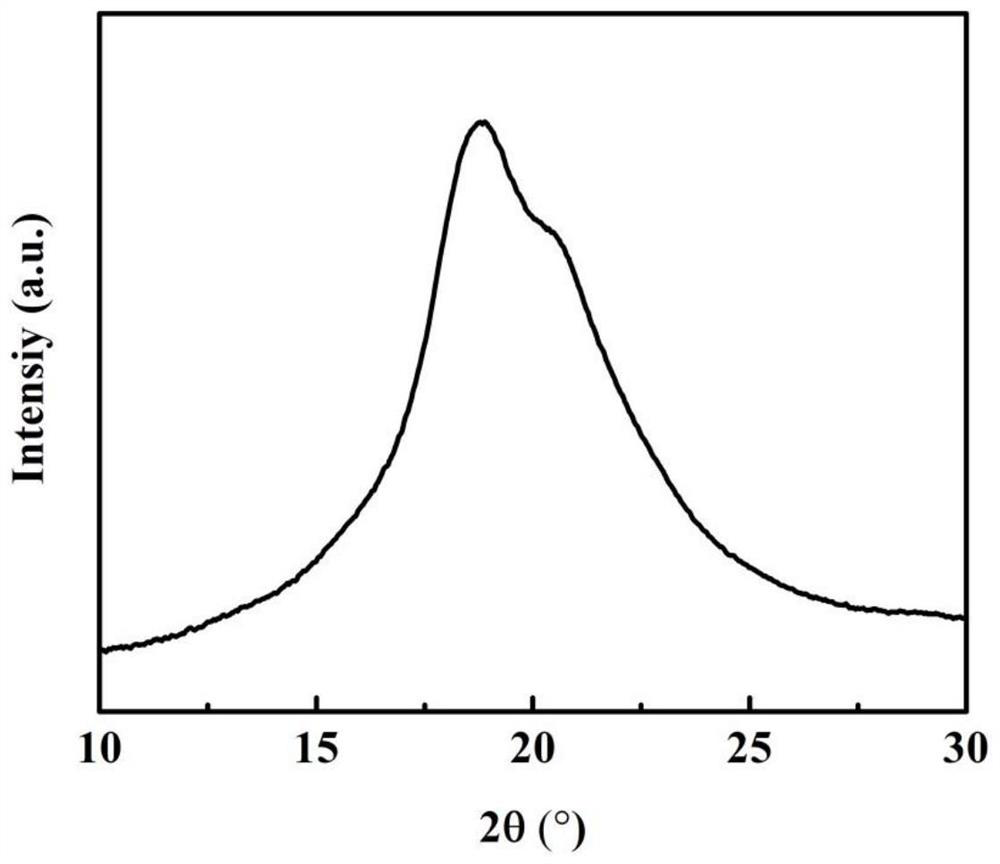

An extensible nonwoven fabric comprises a fiber comprising at least two olefin-based polymers. These olefin-based polymers are of the same kind and have different induction periods of strain-induced crystallization as measured at the same temperature and shear strain rate. A composite nonwoven fabric of the invention comprises at least one layer comprising the extensible nonwoven fabric.

Owner:MITSUI CHEM INC

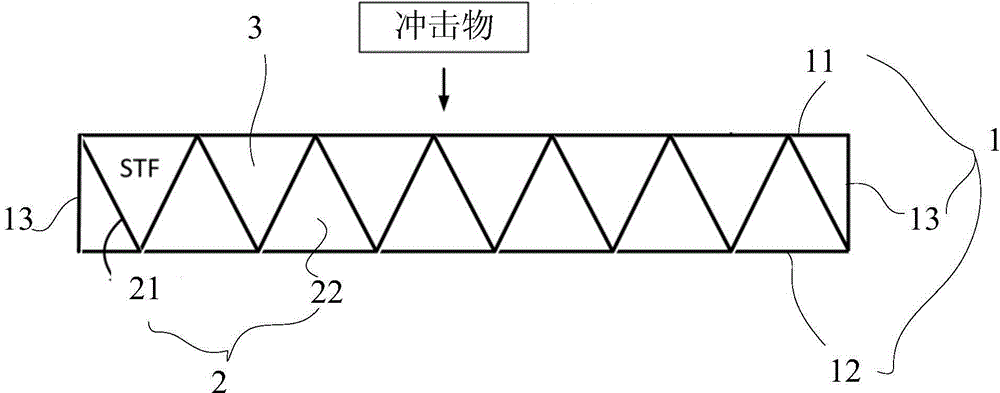

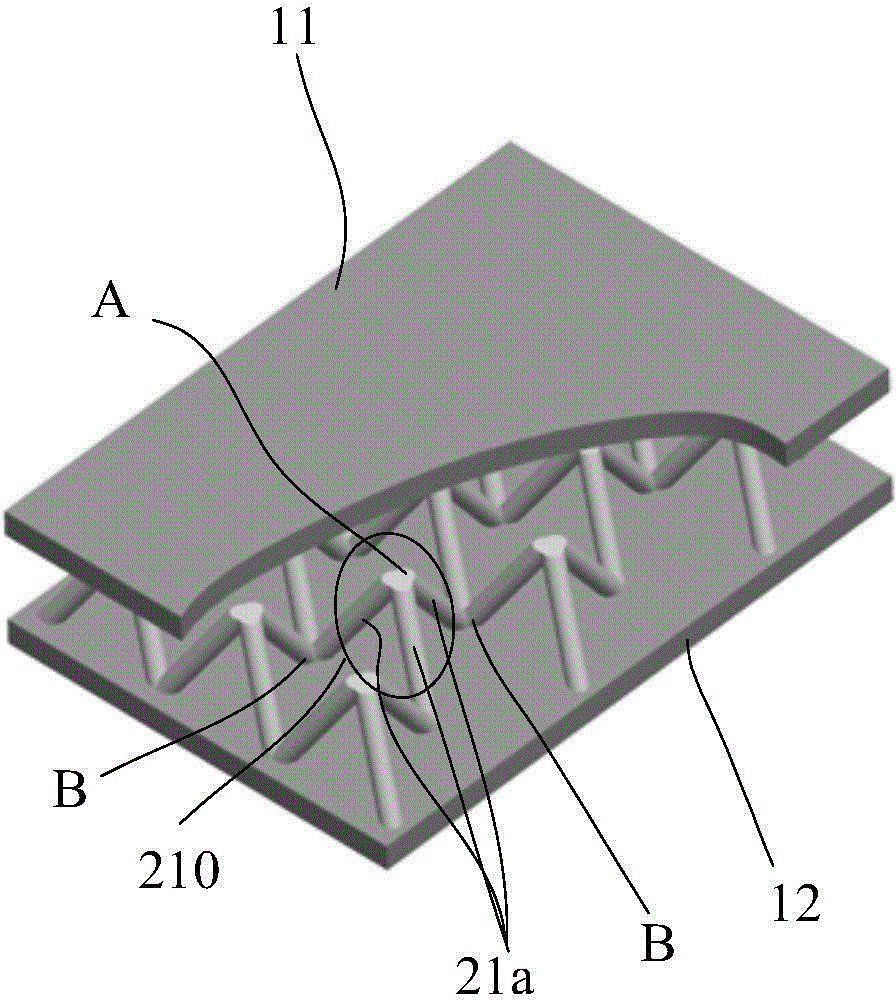

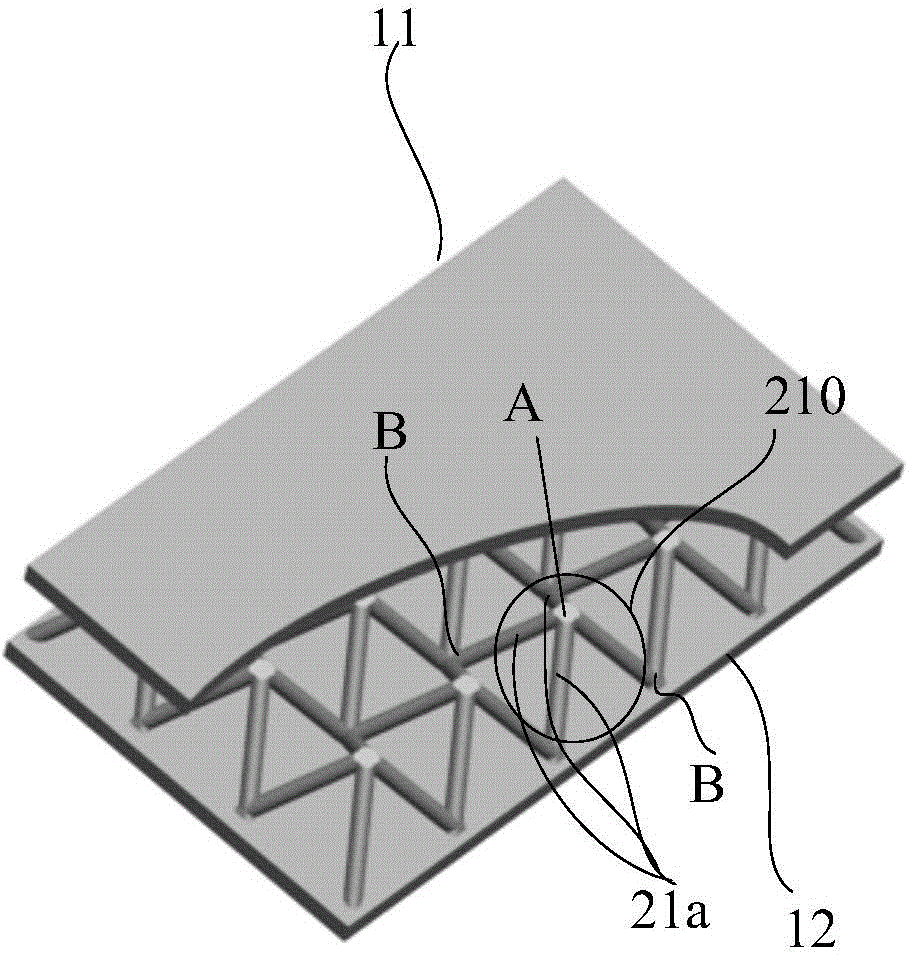

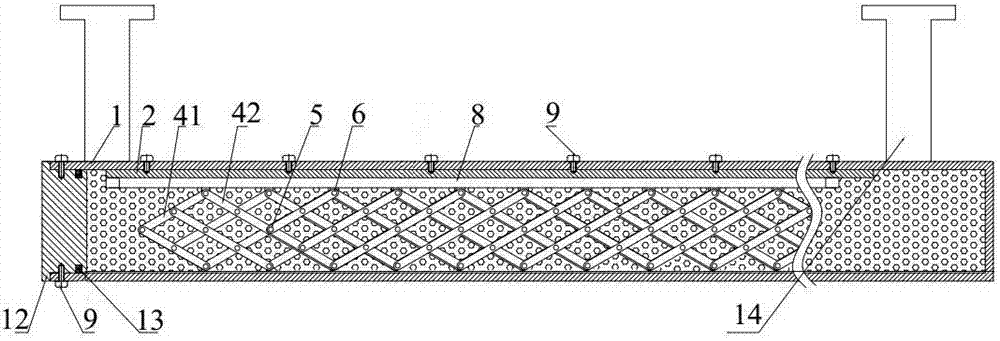

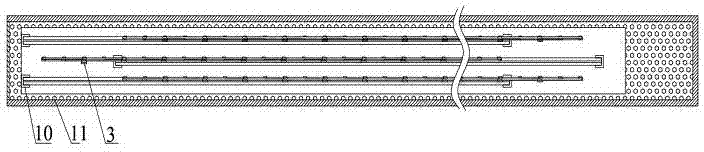

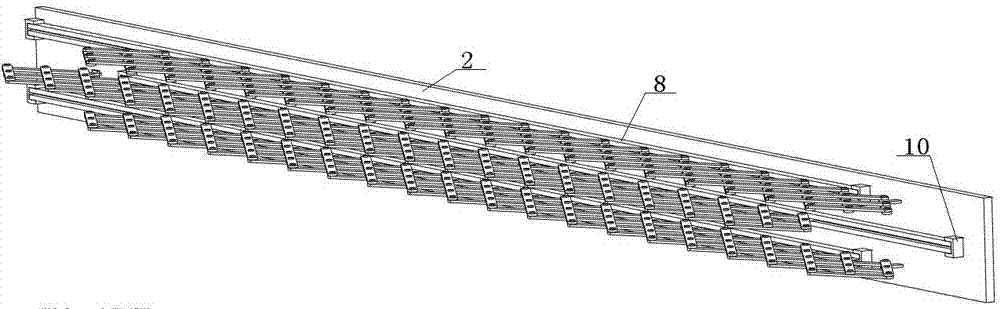

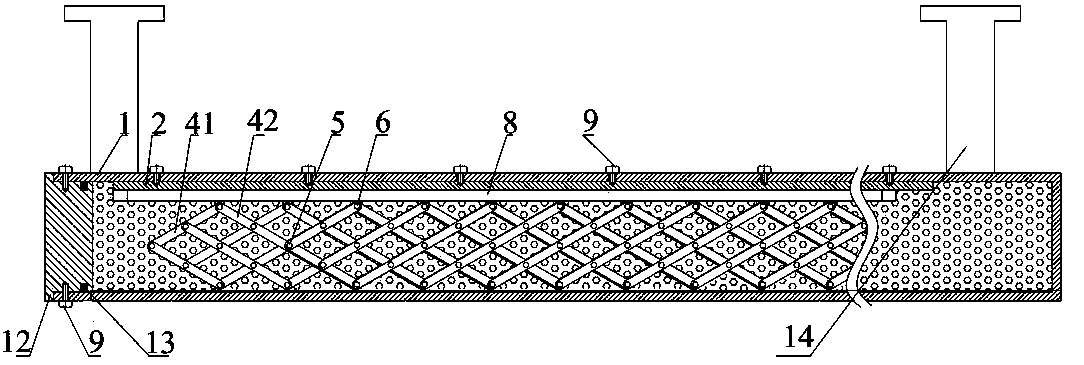

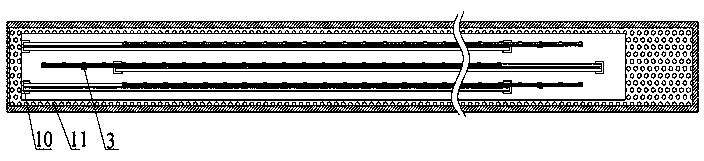

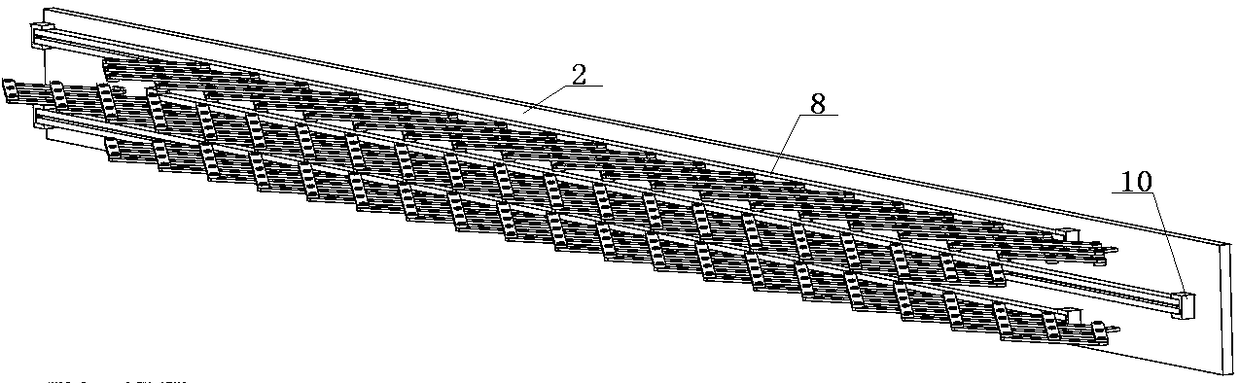

Sandwich energy-absorbing device

InactiveCN104476828AImprove energy absorptionHigh viscosityLayered productsNuclear engineeringEnergy absorption

The invention provides a sandwich energy-absorbing device which comprises an upper panel, a lower panel, lateral plates and a core plate layer, wherein the core plate layer is fed in a closed space formed by enclosing the upper panel, the lower panel and the lateral plates, and the core plate layer comprises core materials and a shear thickening fluid material fed between the core materials and / or fed between the core materials and the closed space. When an energy-absorbing device suffers from an action an external impact, structures of the upper panel, the lower panel, the lateral plates and the core materials rapidly deform, so that a quick shear action is applied to the shear thickening fluid material fed in a core plate, the viscosity of the shear thickening fluid material with a relatively high shear strain rate is rapidly improved, and thus impact energy is rapidly dissipated, and relatively high specific strength, specific stiffness and vibration resistance and energy absorption capabilities are achieved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Method of applying a polymer thick-film resistive paste for making polymer thick-film resistor having improved tolerances

InactiveUS7575778B2Low/insignificant dimensional and shape changeHigh solid contentPretreated surfacesLiquid/solution decomposition chemical coatingElectrical resistance and conductanceEngineering

The present invention teaches formulations, apparatus and a method of applying high thixotropic index polymer thick-film resistive pastes for making polymer thick-film resistors with improved tolerances by providing a squeegee with a blade tilted at an angle of 10° to 85° to the surface of the printed circuit board thus causing a fluid rotational motion within the bead of the polymer thick-film resistive paste as the squeegee blade moves relative to the printed circuit board. This rotational motion increases the shear strain rate experienced by the paste within the bead and results in a more effective filling of the resistor-shaped cavity without including air bubbles, experiencing elastic recovery of the paste and, without surface fractures of the paste.

Owner:EMBED TECH

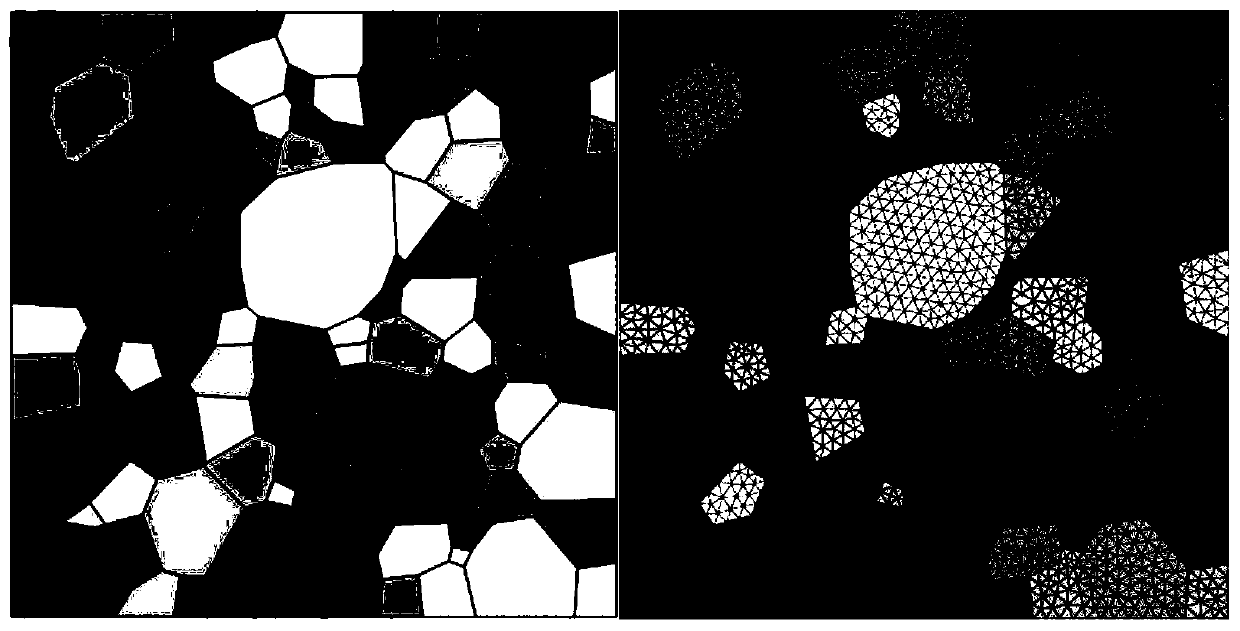

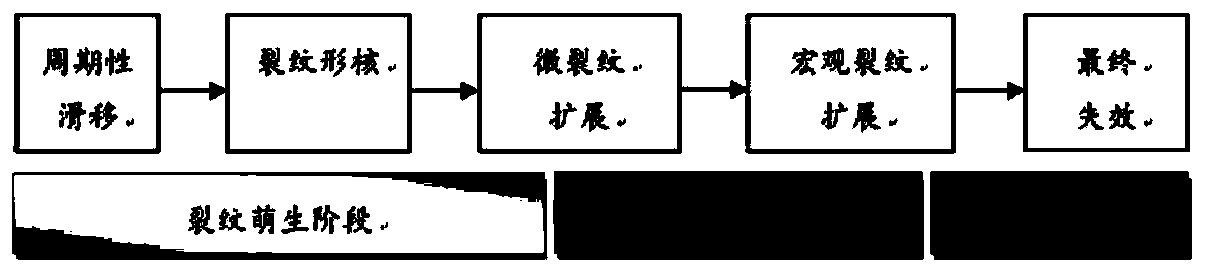

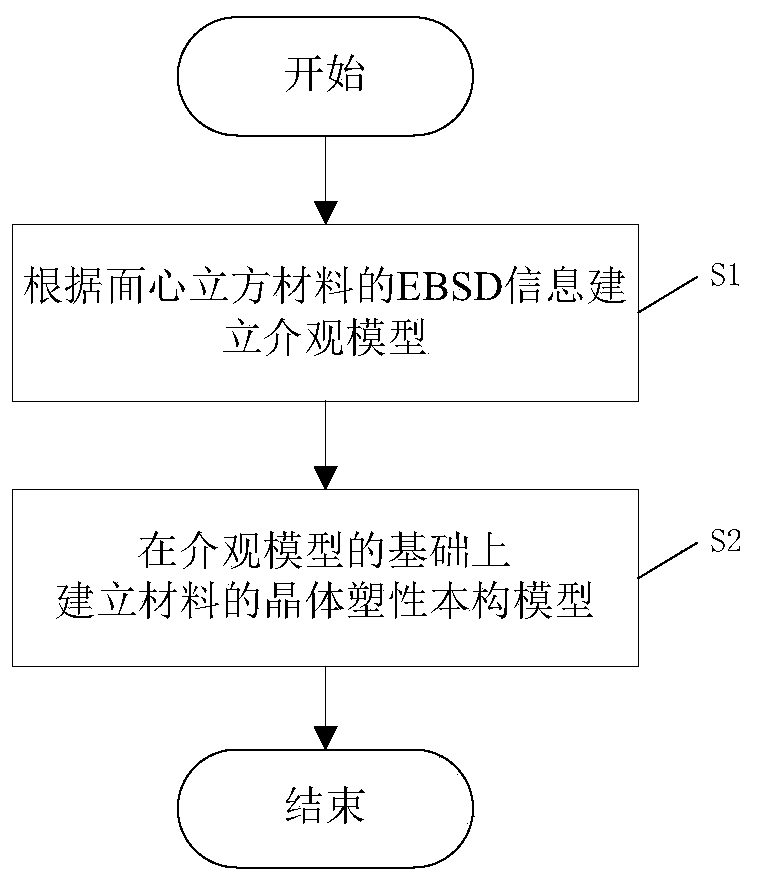

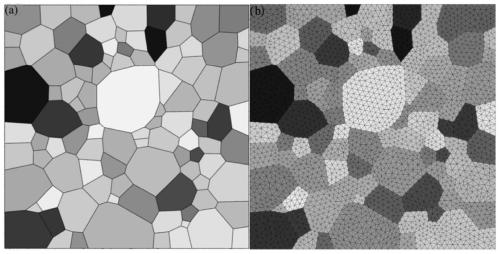

Method for establishing crystal plastic constitutive model in face-centered cubic material fatigue process

ActiveCN110222442ASolve the inability to consider mesoscopic plastic evolutionSolve the characteristicsDesign optimisation/simulationSpecial data processing applicationsBack stressMetallic materials

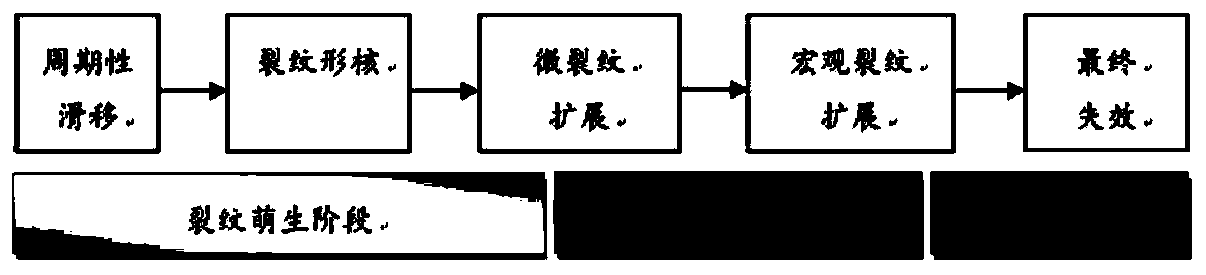

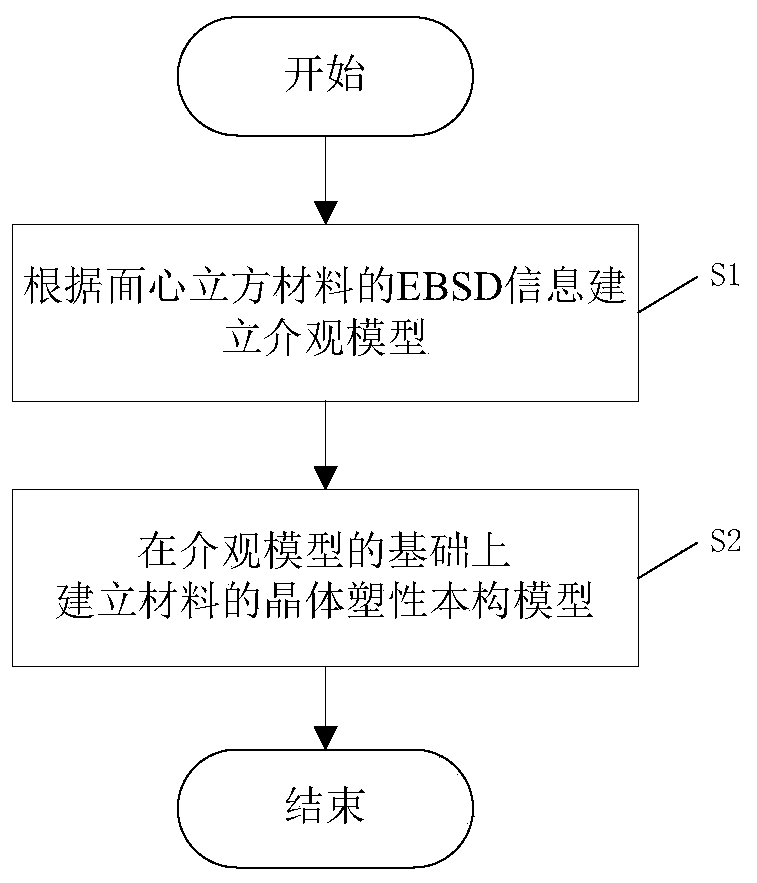

The invention discloses a method for establishing a crystal plastic constitutive model in a face-centered cubic material fatigue process. According to the method, the problem that mesoscopic scale plastic evolution and material microstructure characteristics cannot be considered in the process of calculating material damage and fatigue failure is solved, and a more accurate and innovative mesoscopic crystal modeling method, a crystal plastic constitutive model and related stable and efficient calculation methods are provided. According to the crystal plastic constitutive model and the calculation method, the normal direction and the sliding direction of the crystal sliding face are considered, the back stress effect is considered through the motion and isotropic hardening criterion, and finally the face-centered cubic metal material crystal plastic constitutive model of the crystal sliding and dislocation density and plastic shear strain rate function relation is established. The influence effect and contribution degree of the microscopic characteristics of the material on the damage and fatigue life of the material can be studied from the mesoscopic scale, important theoretical guidance and technical support are provided for studying the damage evolution and fatigue failure process of the material, and the method has important scientific significance and engineering application value.

Owner:SICHUAN UNIV

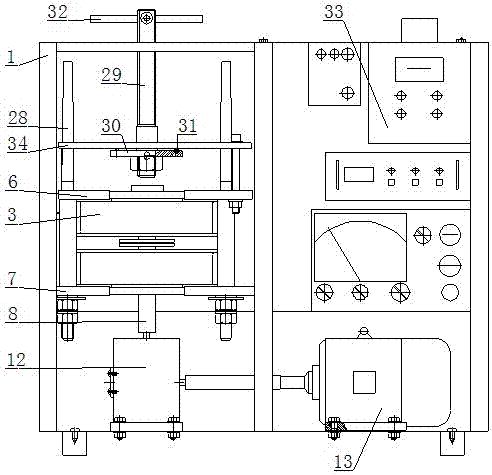

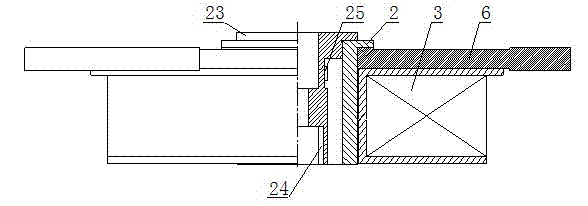

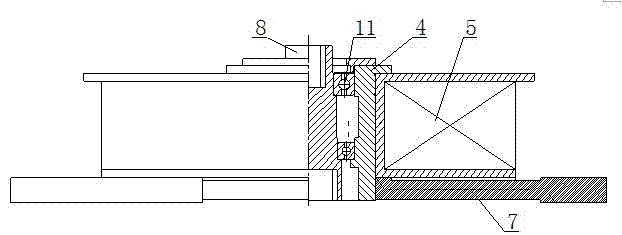

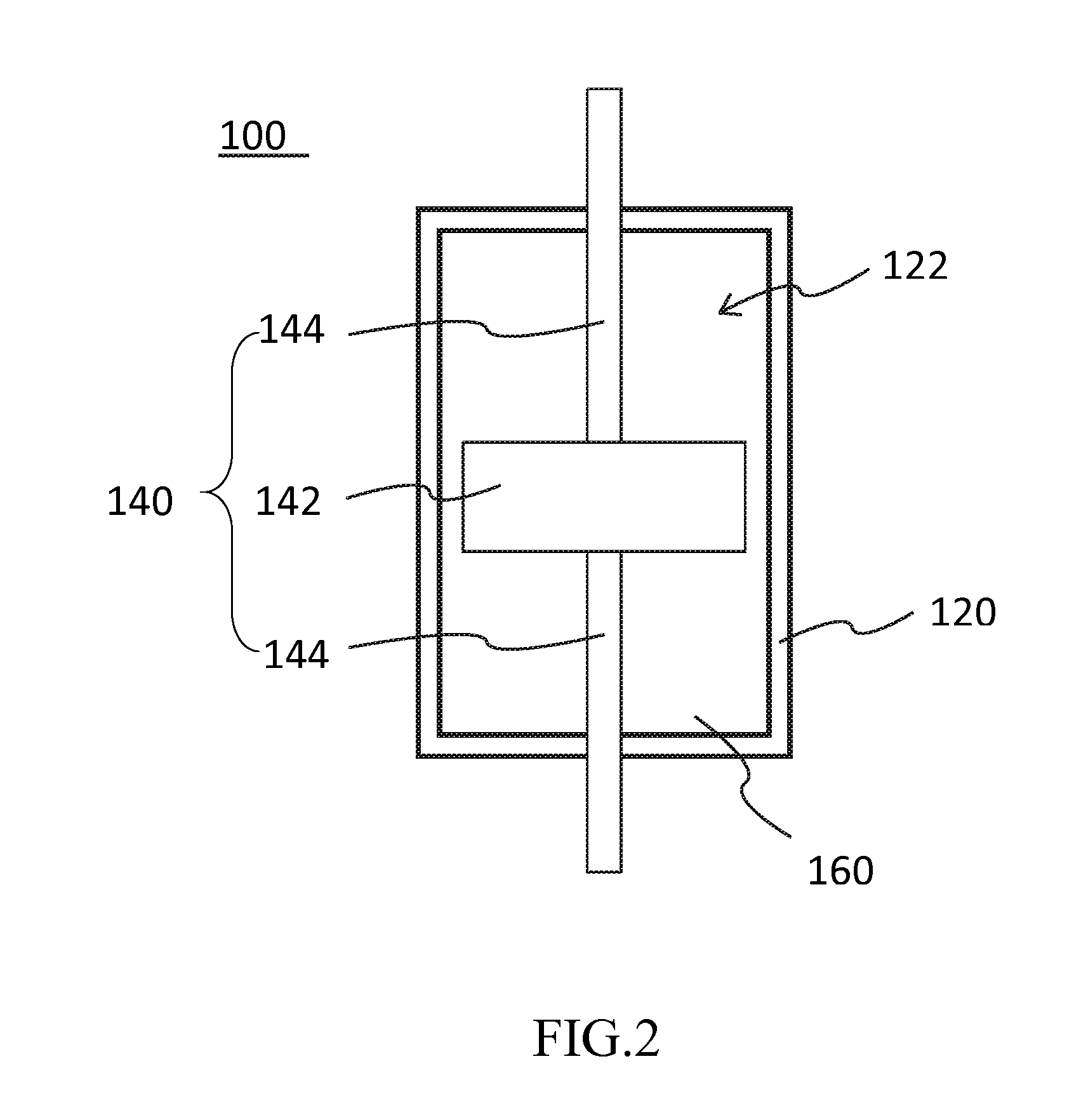

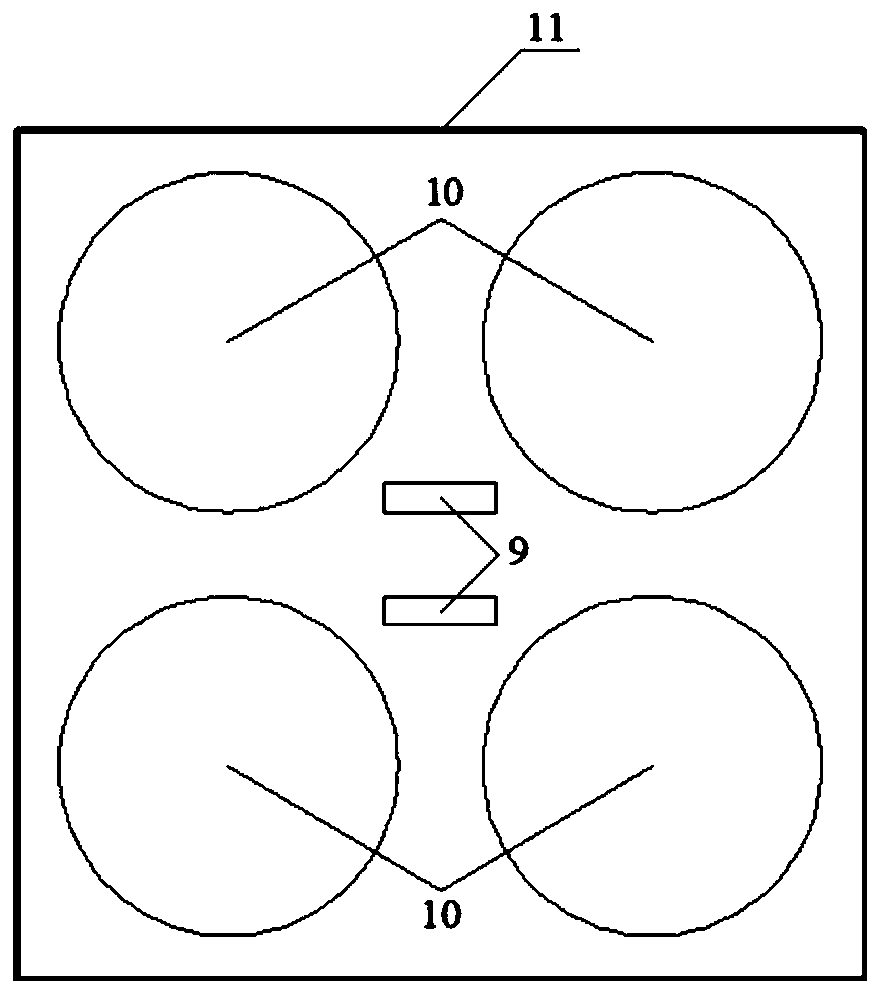

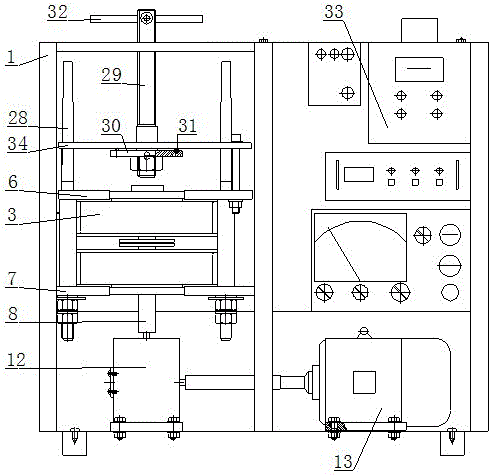

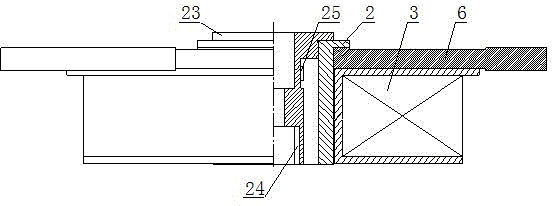

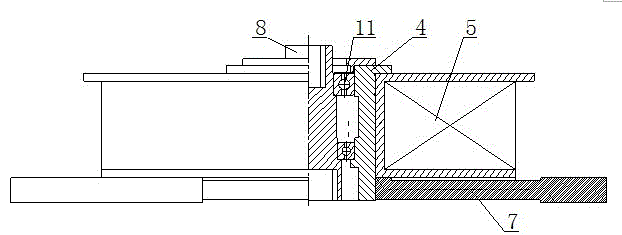

Horizontal annular slot type test device for magnetorheological material

InactiveCN102175576ATest performance parametersImprove interchangeabilityFlow propertiesMagnetic property measurementsShear stressControl system

The invention discloses a horizontal annular slot type test device for a magnetorheological material, which comprises a frame, wherein a magnetic field generating device, a shearing mechanism, a shearing strength detection mechanism, a warming and temperature detection mechanism, a lifting mechanism and a control system are arranged on the frame. Compared with the traditional test device, the horizontal annular slot type test device for magnetorheological material provided by the invention is additionally provided with the warming and temperature detection mechanism, so the device can be used for testing the influence of temperature on the magnetorheological liquid property. The three factors (temperature, magnetic field intensity and shearing strain rate) influencing the magnetorheological liquid and the change gradient of the three factors can be controlled, so the property parameters of the magnetorheological liquid can be more comprehensively detected. The shearing mechanism of the device can be used for furthest concentrating the shearing strength between a fixing ring and a shearing ring at the position of the magnetorheological liquid, thereby ensuring an accurate testing result and acquiring a better testing effect.

Owner:CHONGQING UNIV

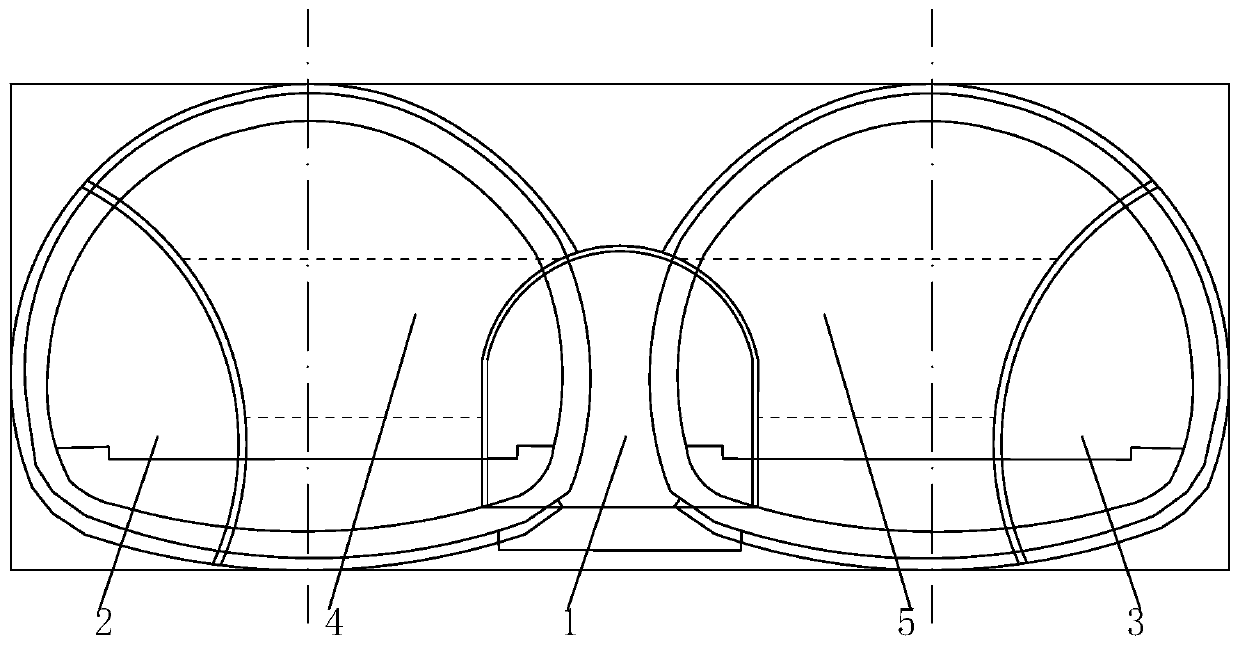

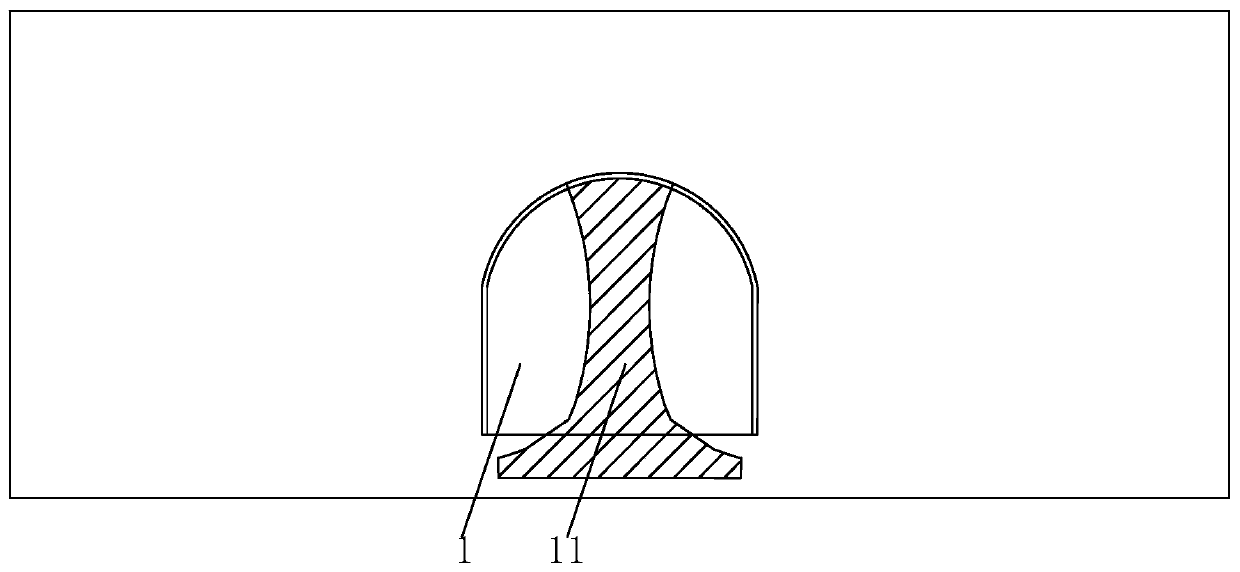

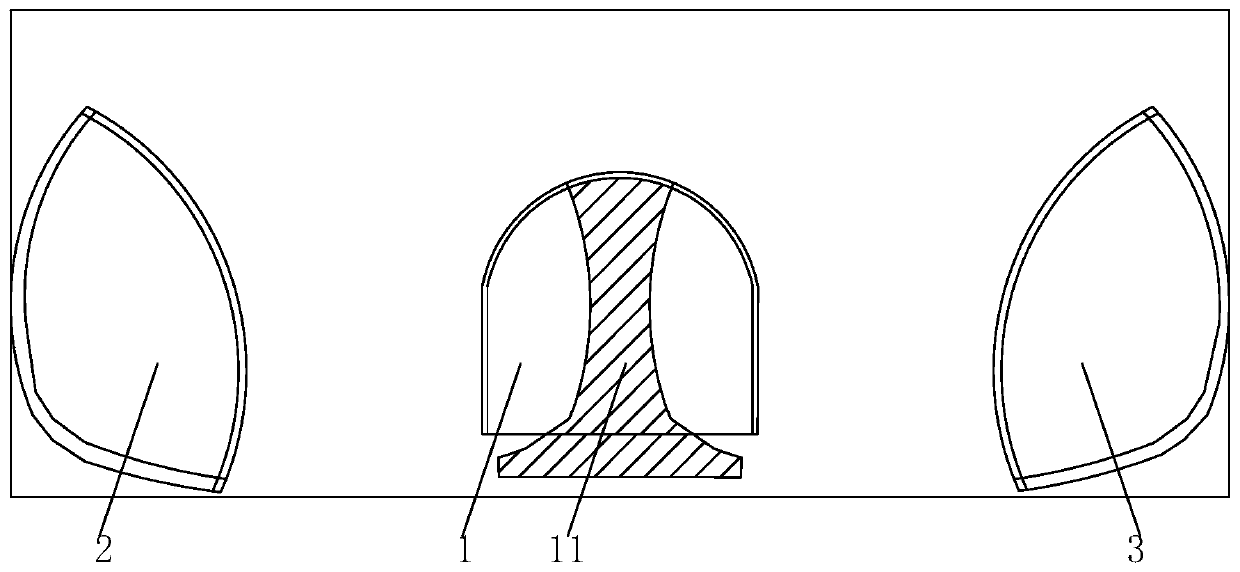

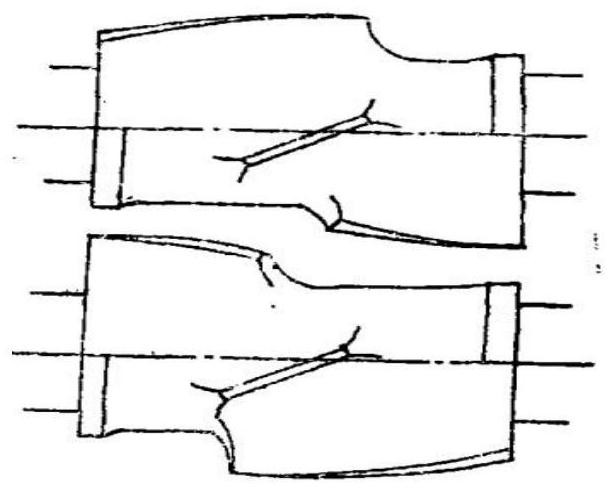

Five-hole excavation method for double-arch tunnel

ActiveCN111075454AReduce interactionEasy to excavateUnderground chambersTunnel liningArchitectural engineeringMutual influence

The invention relates to the technical field of double-arch tunnel excavation and provides a five-hole excavation method for a double-arch tunnel. In the method, firstly, excavation of a middle pilottunnel is carried out, and then excavation of a left wall pilot tunnel and a right wall pilot tunnel is carried out. Due to the large spacing between the three pilot tunnels, through the analysis of the shear strain rate and the plastic zone situation before and after the excavation of the three pilot tunnels, the mutual influence of the three pilot tunnels during the excavation process is very small, so that the three pilot tunnels can be constructed in parallel and the primary support can be applied in time, a certain support structure is provided for the excavation of the double-arch tunnelin advance, and the excavation of a main tunnel of the left tunnel and a main tunnel of the right tunnel is facilitated. According to the five-hole excavation method for the double-arch tunnel, a side form trolley can be used as a temporary reinforced supporting structure of the middle guide tunnel, so that a supporting structure is effectively provided, the pressure of a primary support of the left tunnel on a middle partition wall is avoided, the stability of the middle partition wall is ensured, and the side form trolley can be drove out when the secondary lining is constructed after the primary support of the tunnel is integrally formed, and finally the double-arch tunnel is formed.

Owner:CHINA RAILWAY 19TH BUREAU GRP 3RD

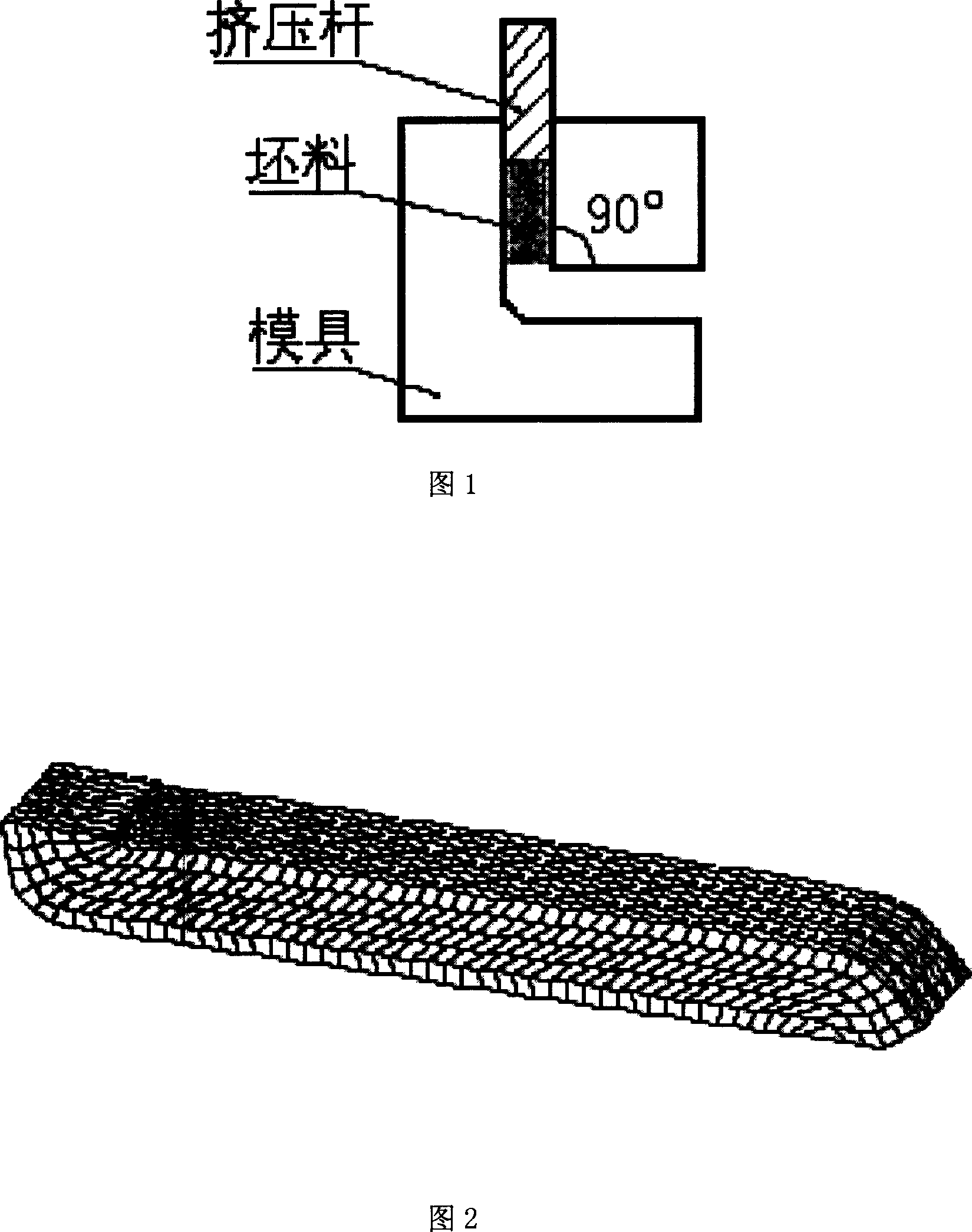

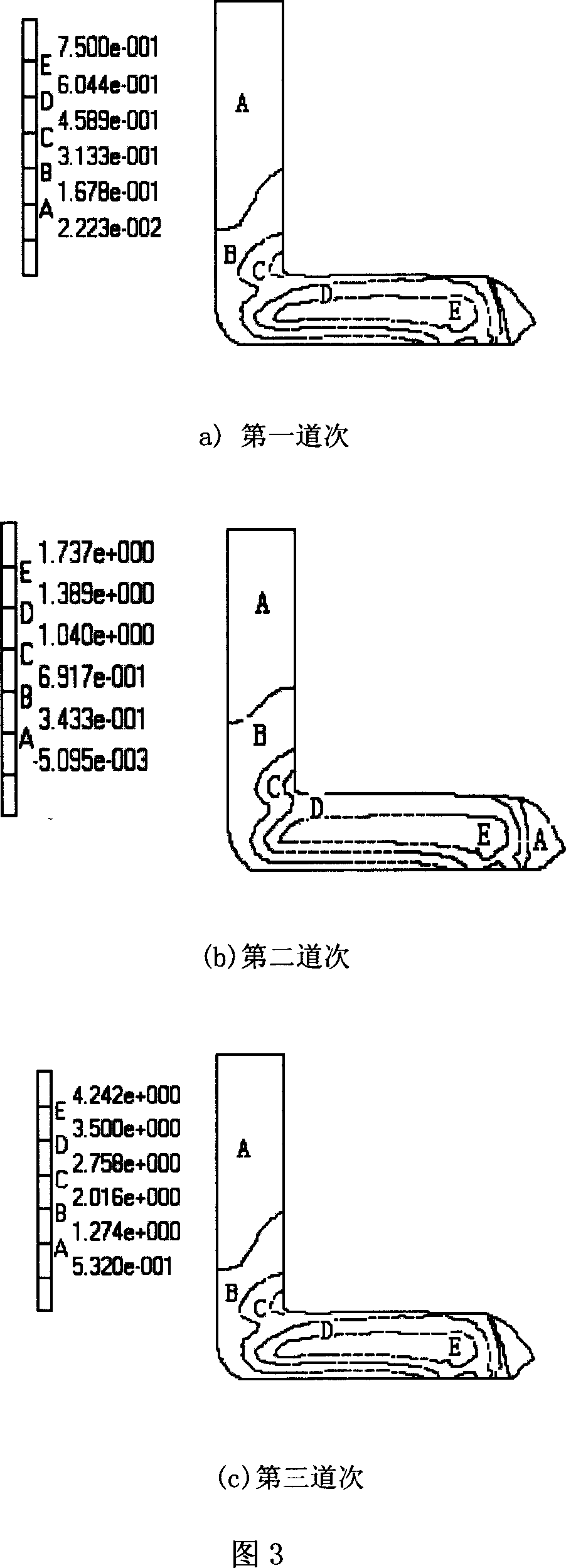

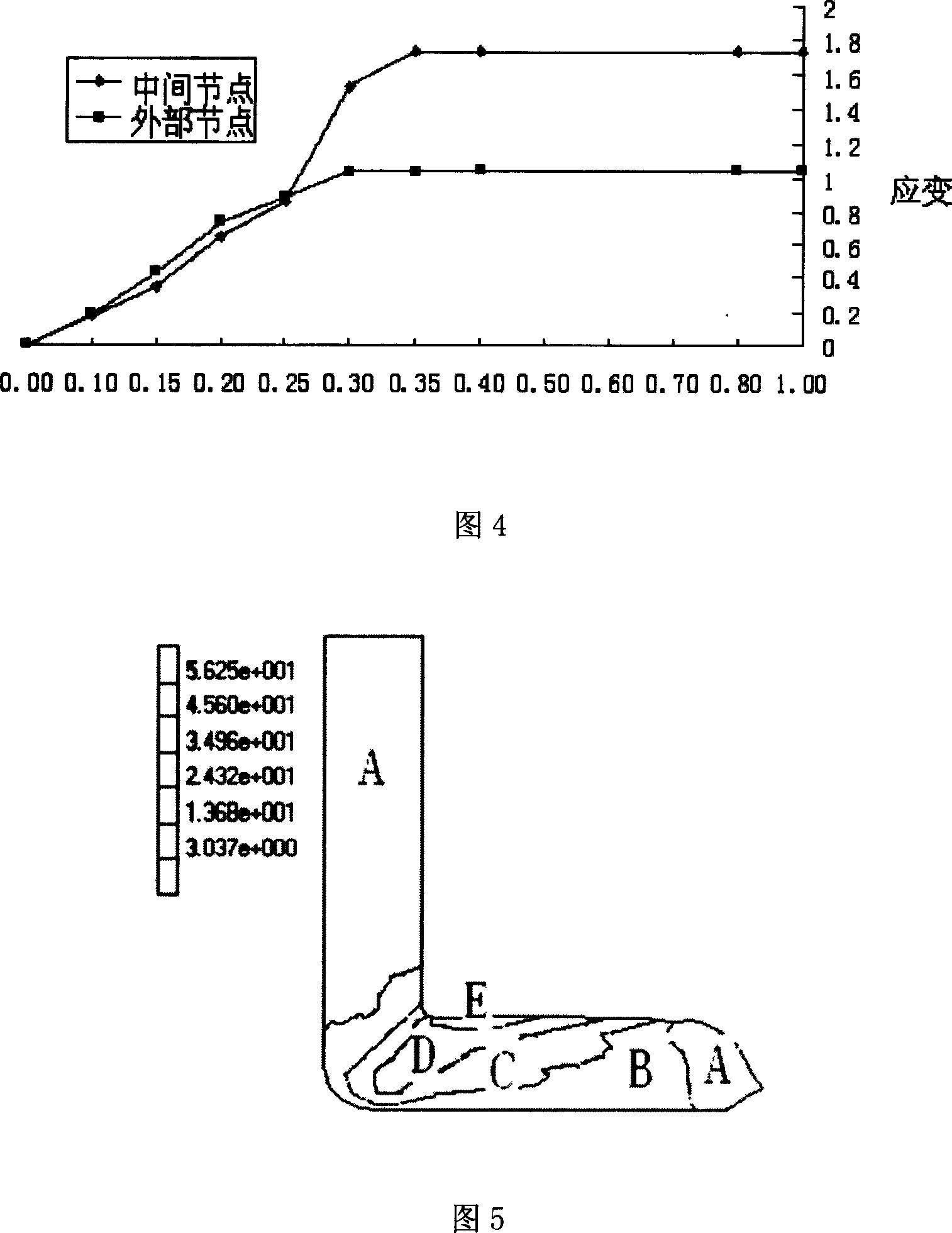

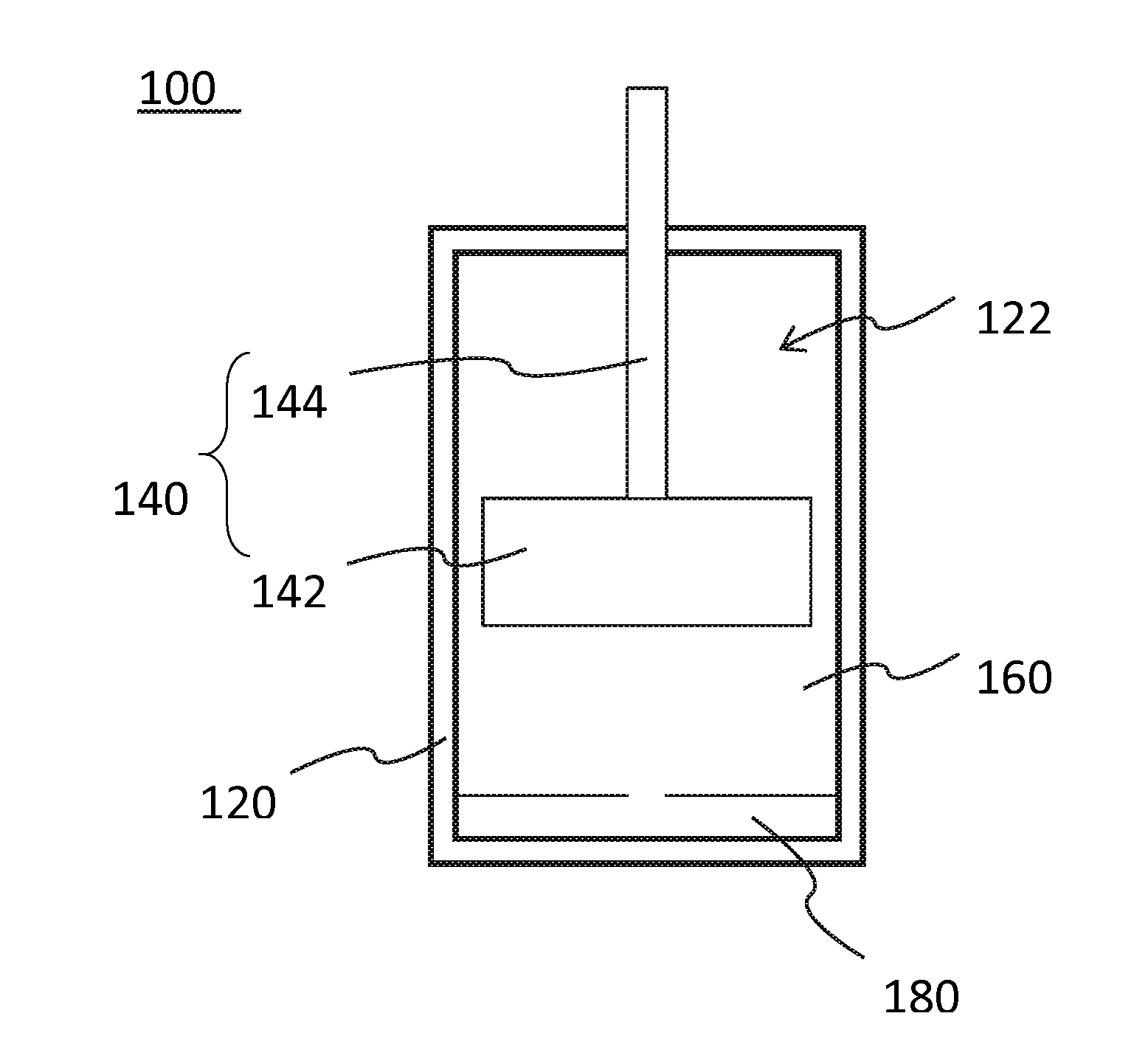

Method for determining grain size in equal channel angular pressing technology

InactiveCN101013453AMeet development needsImprove predictive abilitySpecial data processing applicationsShear stressCoupled differential equations

It's a method to determine the grain size in established channel angular extrusion process. First, analyze the displacement of finite element in established channel angular extrusion process, determine the node displacement through the center differential, compute the strain through the relationship between strain and displacement, get the stress in according to the elastic constitutive relationship, map to the grain slide project and line to get the crystal grain the shear stress within the grain and on the boundary, compute the shear stress within the crystal grain and on the boundary, if not exceed the critical shear stress, the grain size is not changed, or compute the new dislocation density and grain size; according to the dislocation coupled differential equations determine the dislocation density increment within the grain and on the boundary from corresponding shear strain rate, updating the dislocation density, and compute the grain size in current state through the dislocation density. The invention can get the grain size of extrusion material in repeated multiple times deformation processes, and provide the corresponding angle grain size extrusion, extruded times and other design parameters references to extrusion technology.

Owner:SHANGHAI JIAO TONG UNIV

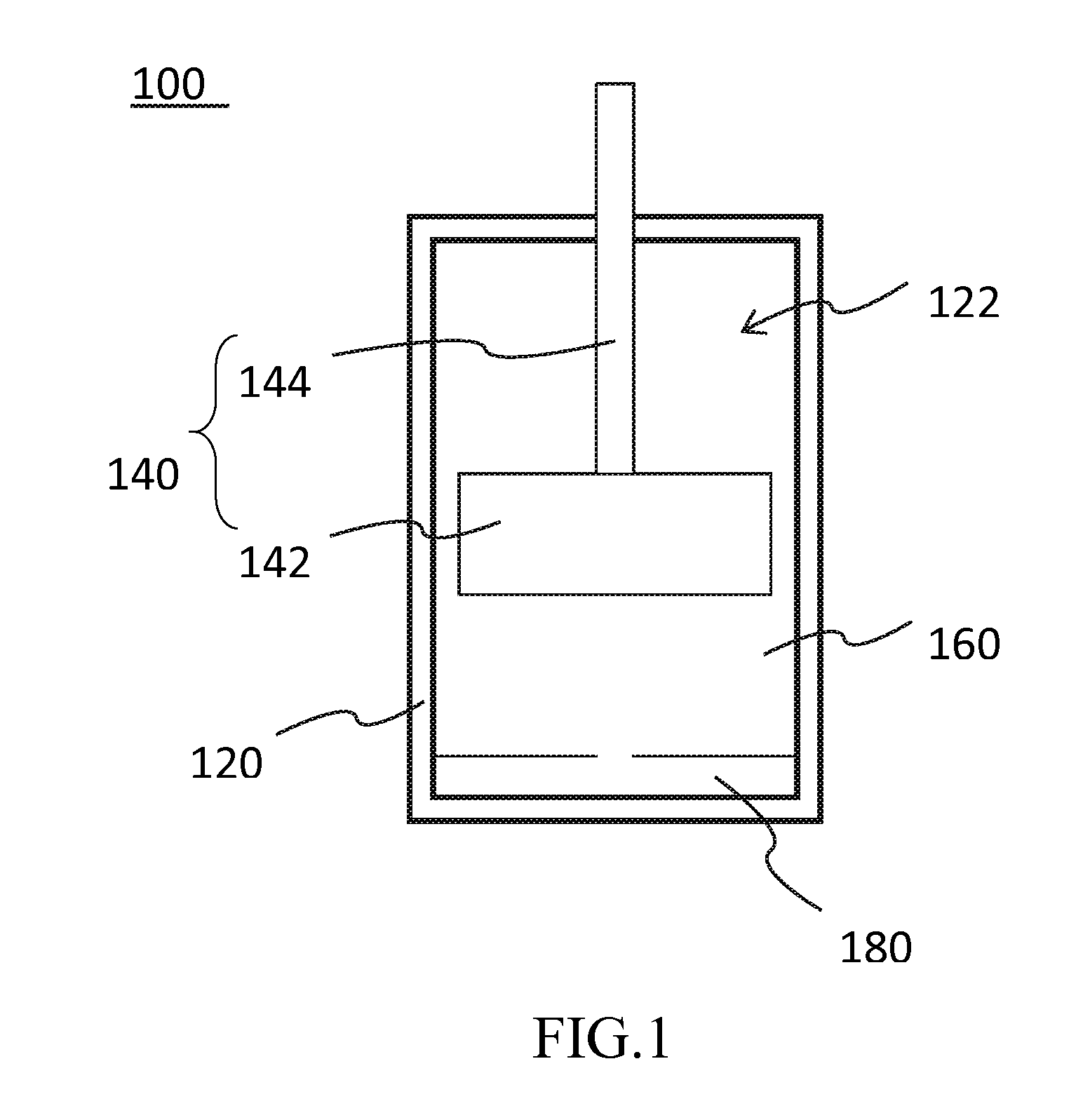

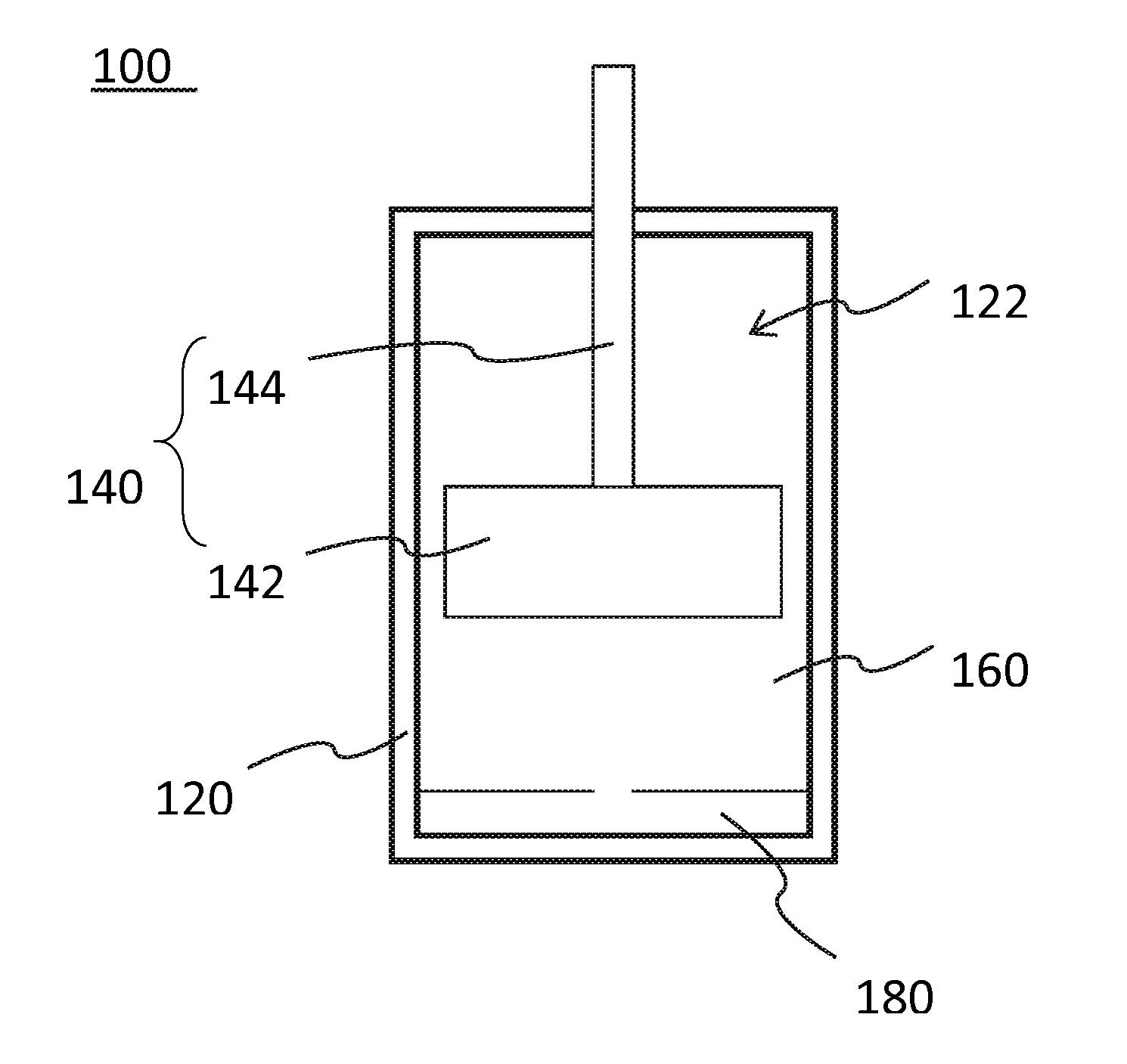

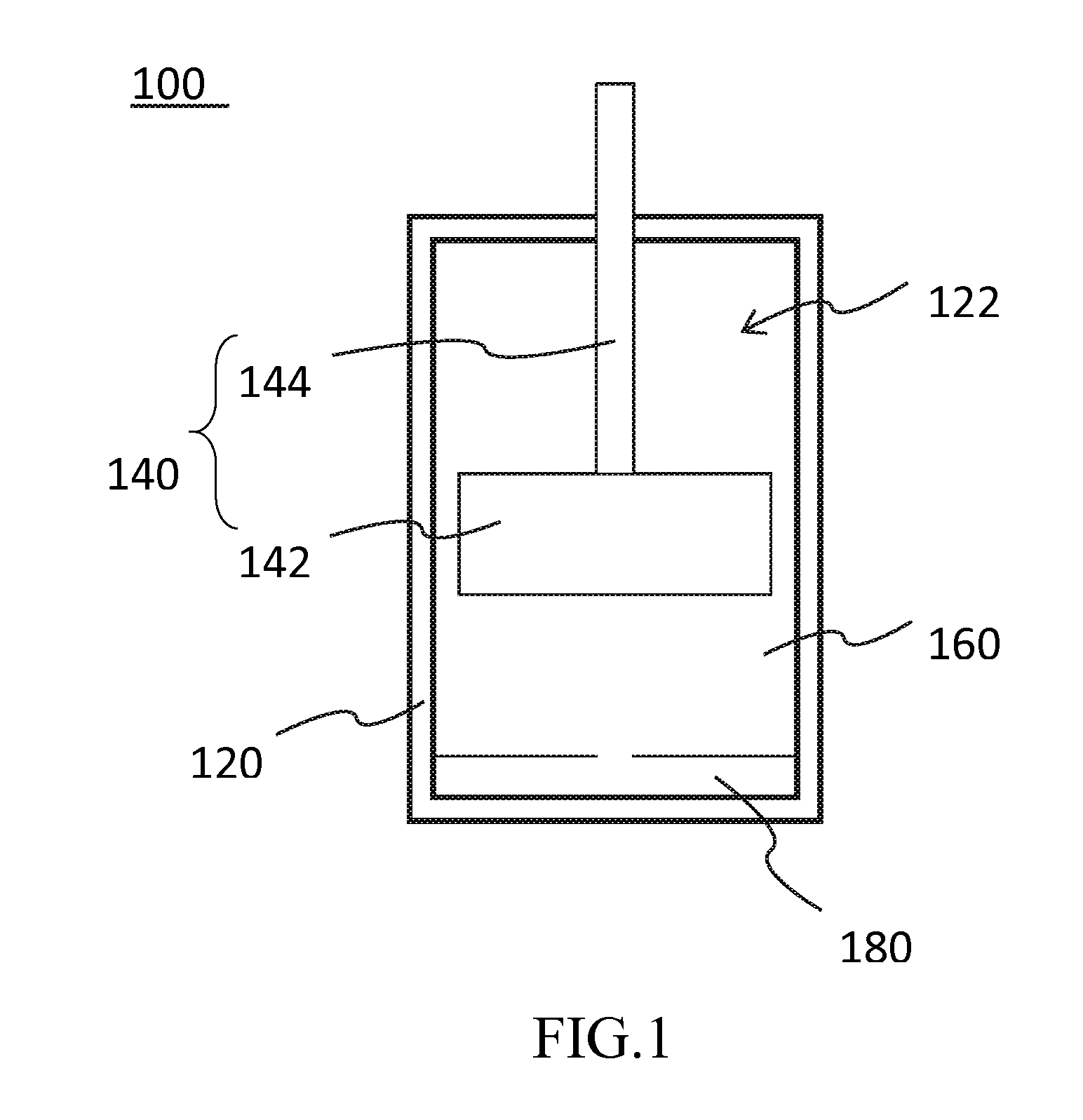

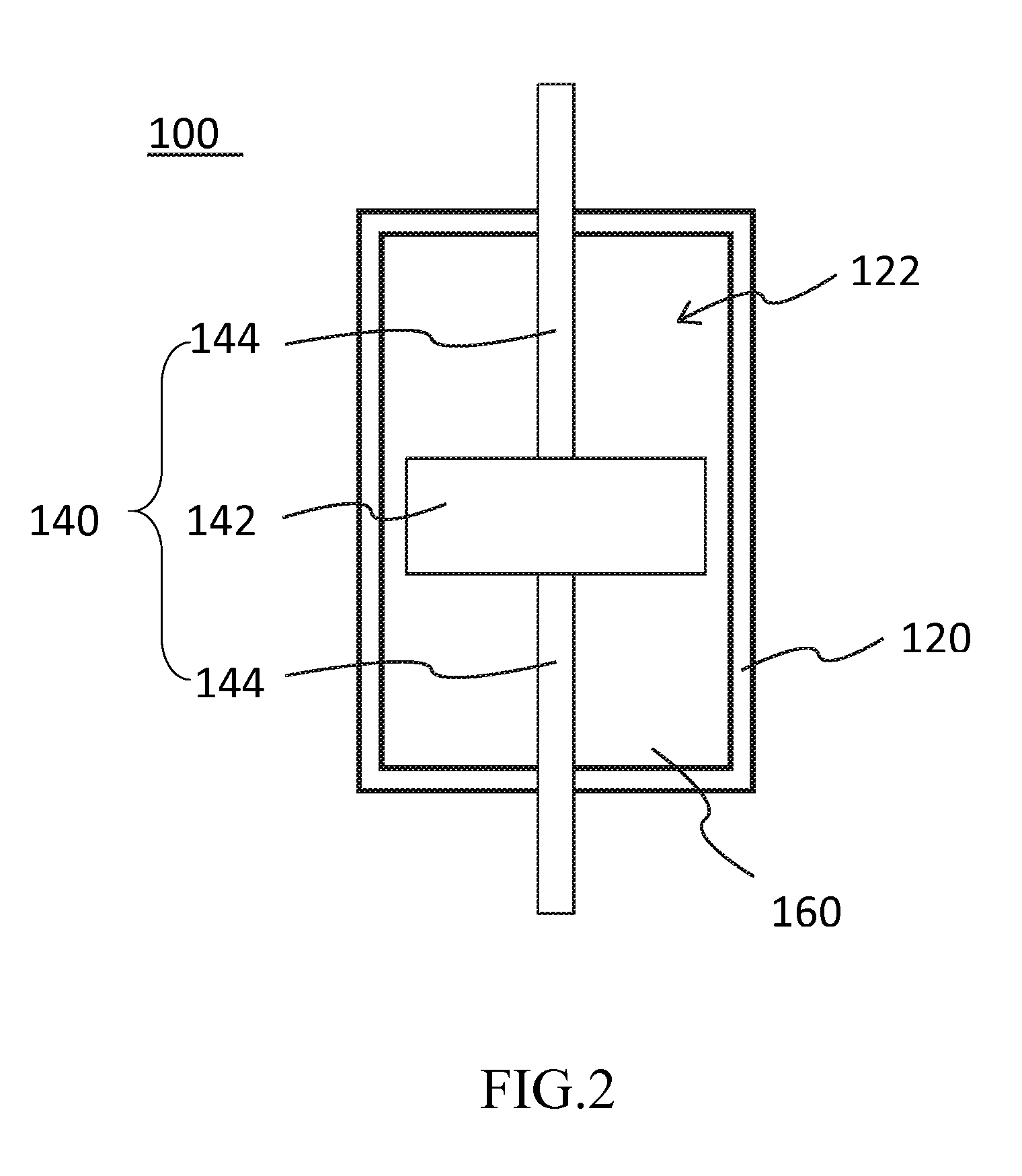

Micro-nano fluid damper

ActiveUS20150152933A1Impact absorption effectFacilitate conductionSpringsLiquid based dampersMicro nanoEngineering

A micro-nano fluid damper includes a sleeve, a piston assembly and a micro-nano fluid. The sleeve has an accommodating space. The piston assembly has a piston head and at least one piston rod. The piston assembly is movably disposed in the accommodating space. The piston rod extends out of the sleeve from a side of the piston head. The micro-nano fluid is filled between the sleeve and the piston assembly, and the micro-nano fluid flows in the accommodating space by the back-and-forth movement of the piston. When a shear strain rate of the micro-nano fluid is greater than 1 s−1, an exponent of velocity of the micro-nano fluid damper is less than 1, and the micro-nano fluid has a shear thinning threshold and a shear thickening threshold.

Owner:NAT APPLIED RES LAB

Extensible nonwoven fabric and composite nonwoven fabric comprising the same

An extensible nonwoven fabric comprises a fiber comprising at least two olefin-based polymers. These olefin-based polymers are of the same kind and have different induction periods of strain-induced crystallization as measured at the same temperature and shear strain rate. A composite nonwoven fabric of the invention comprises at least one layer comprising the extensible nonwoven fabric.

Owner:MITSUI CHEM INC

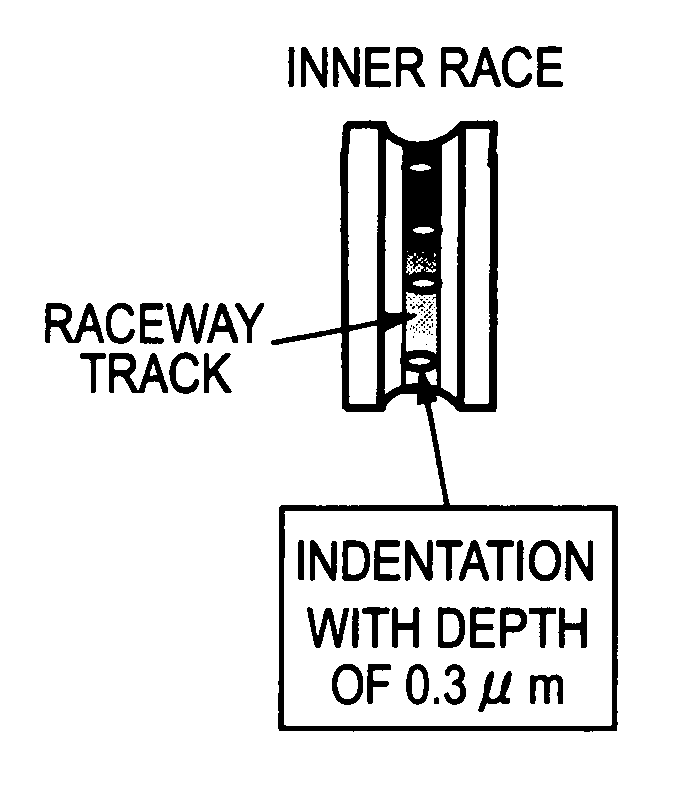

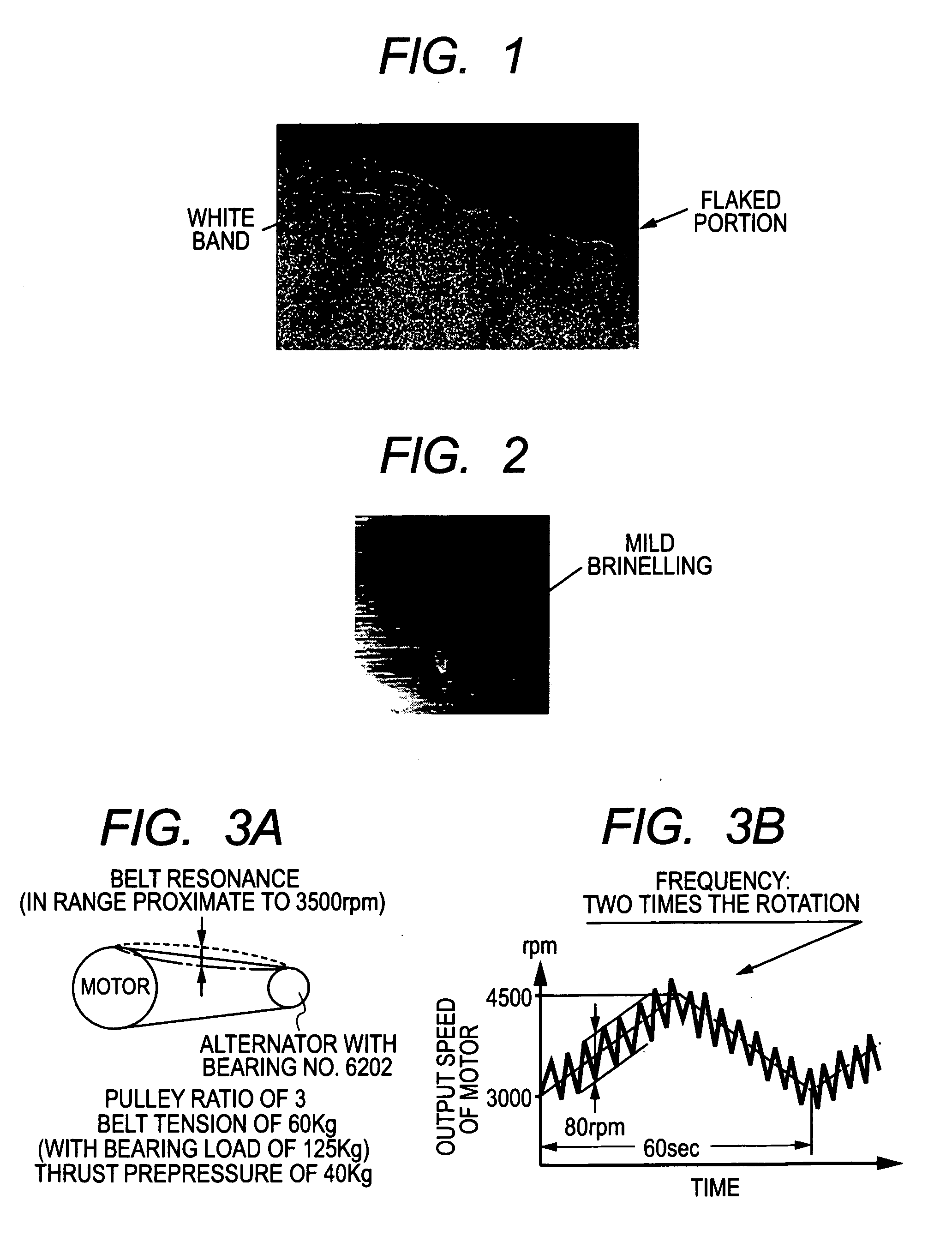

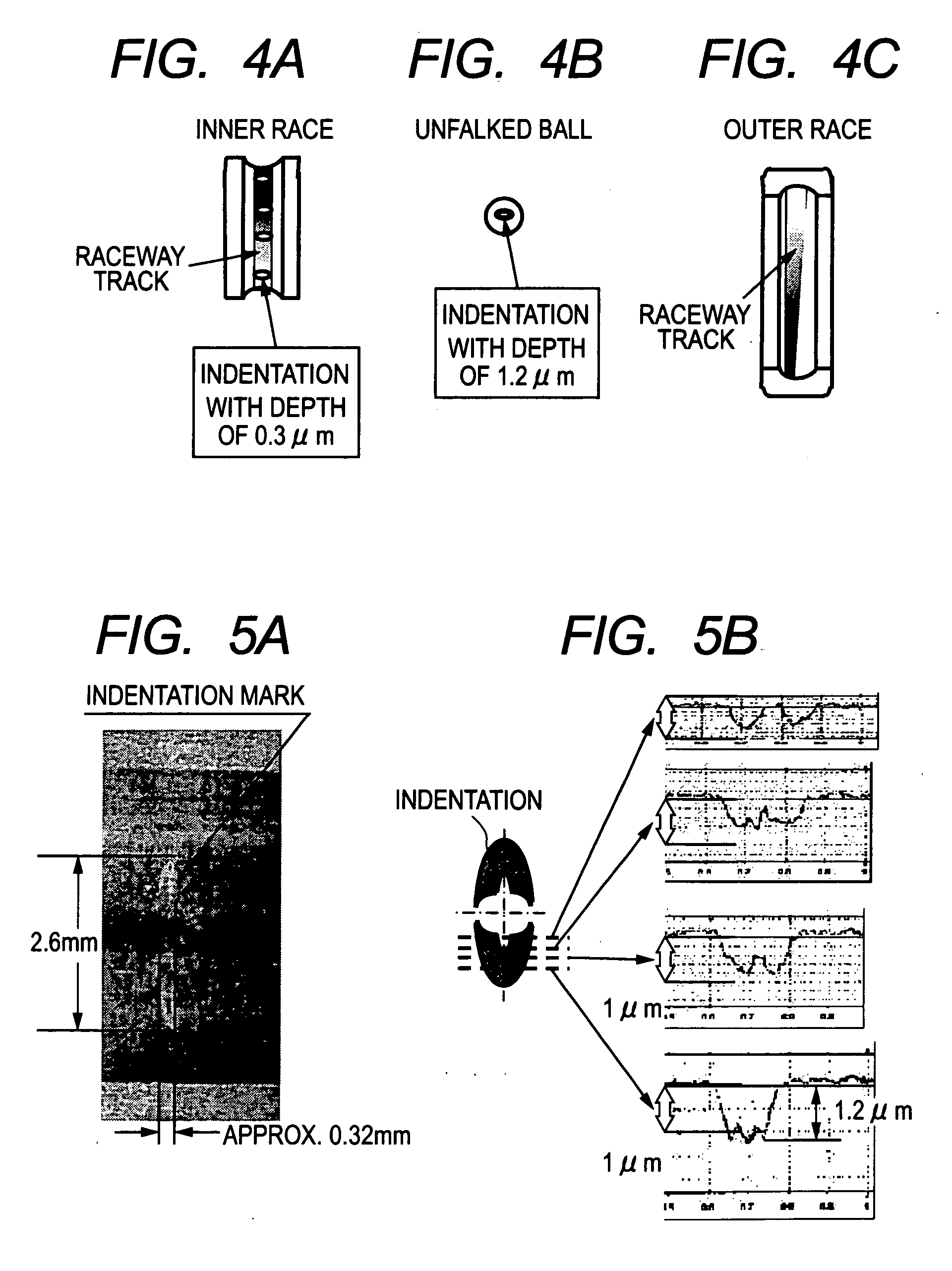

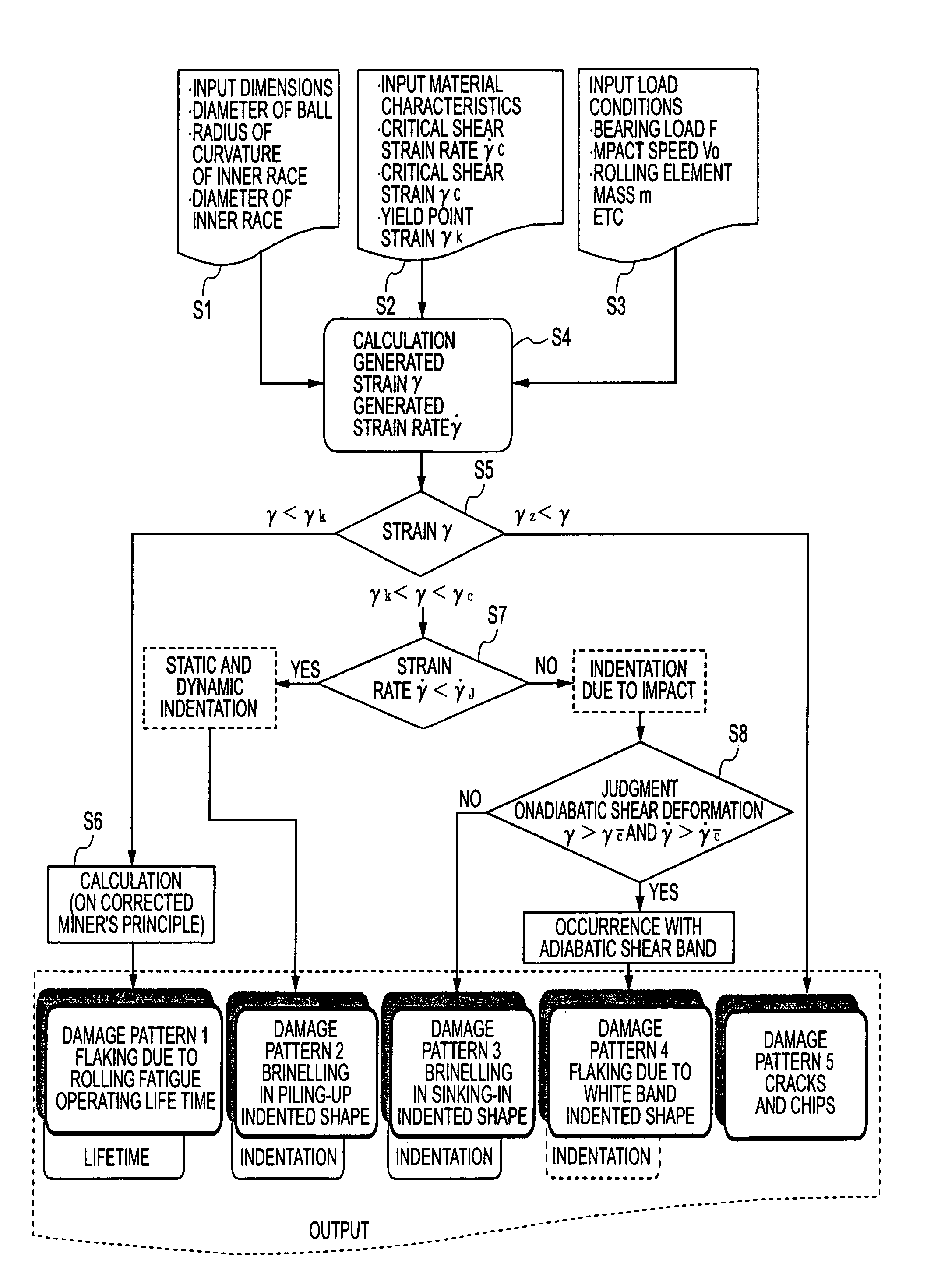

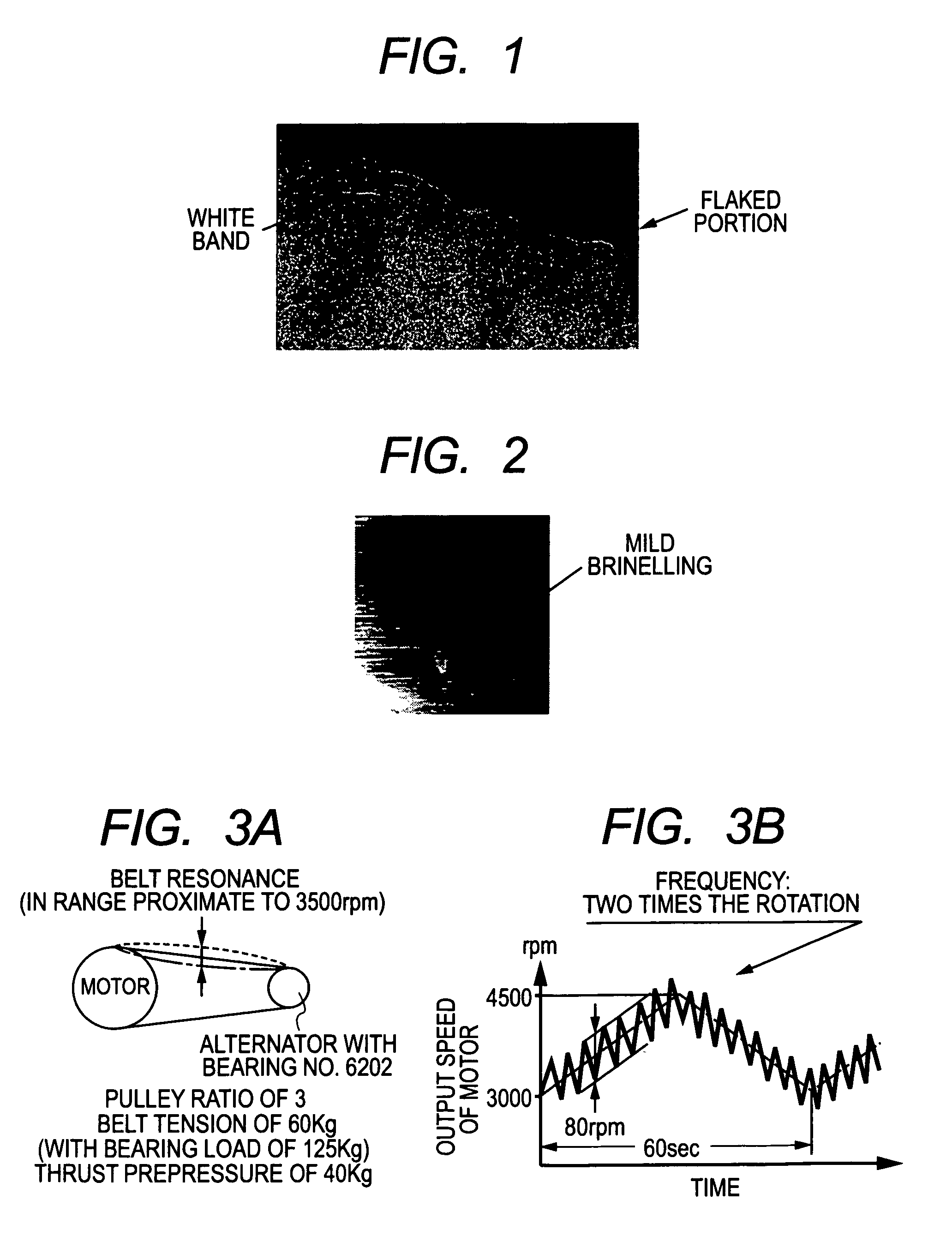

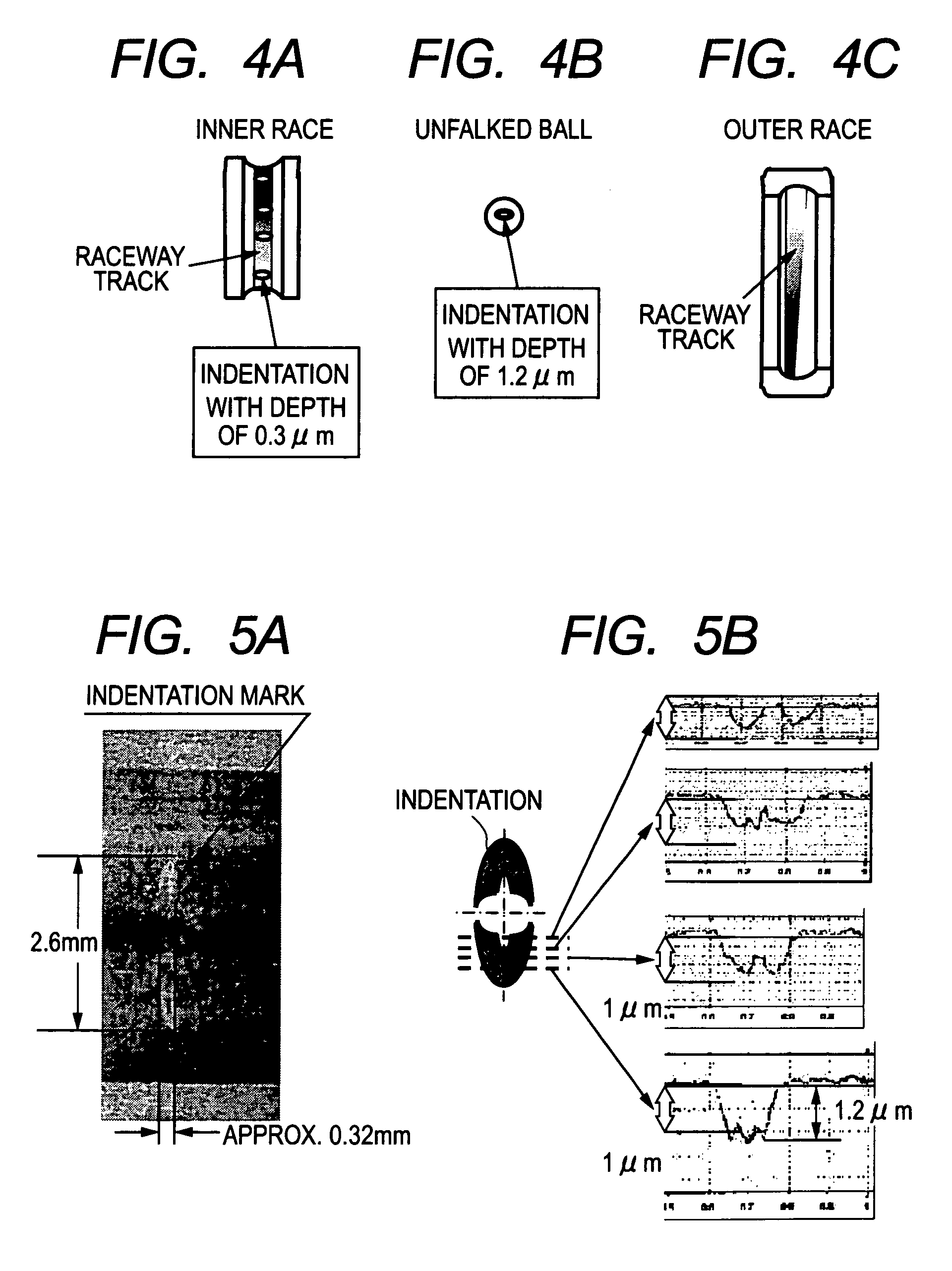

Apparatus and method for determining patterns of damage being caused in rolling contact element

InactiveUS20070044543A1Simple fashionAvoid damagePlug gaugesMachine bearings testingBrinellingAdiabatic shear band

A method of designing a roller bearing is disclosed upon clarifying mechanisms of damage patterns in respect of two kinds of brinelling, involved in the bearing, wherein white-banded flaking (brittle flaking) is a plastic instability phenomenon appearing under high-speed deformation accompanied by adiabatic shear deformation status with the resultant occurrence of adiabatic shear band (also called white band) inside material of the bearing. This enables all of the damage patterns to be determined upon making comparison between shear strain and shear strain rate, occurring inside the bearing, and discriminated values.

Owner:DENSO CORP

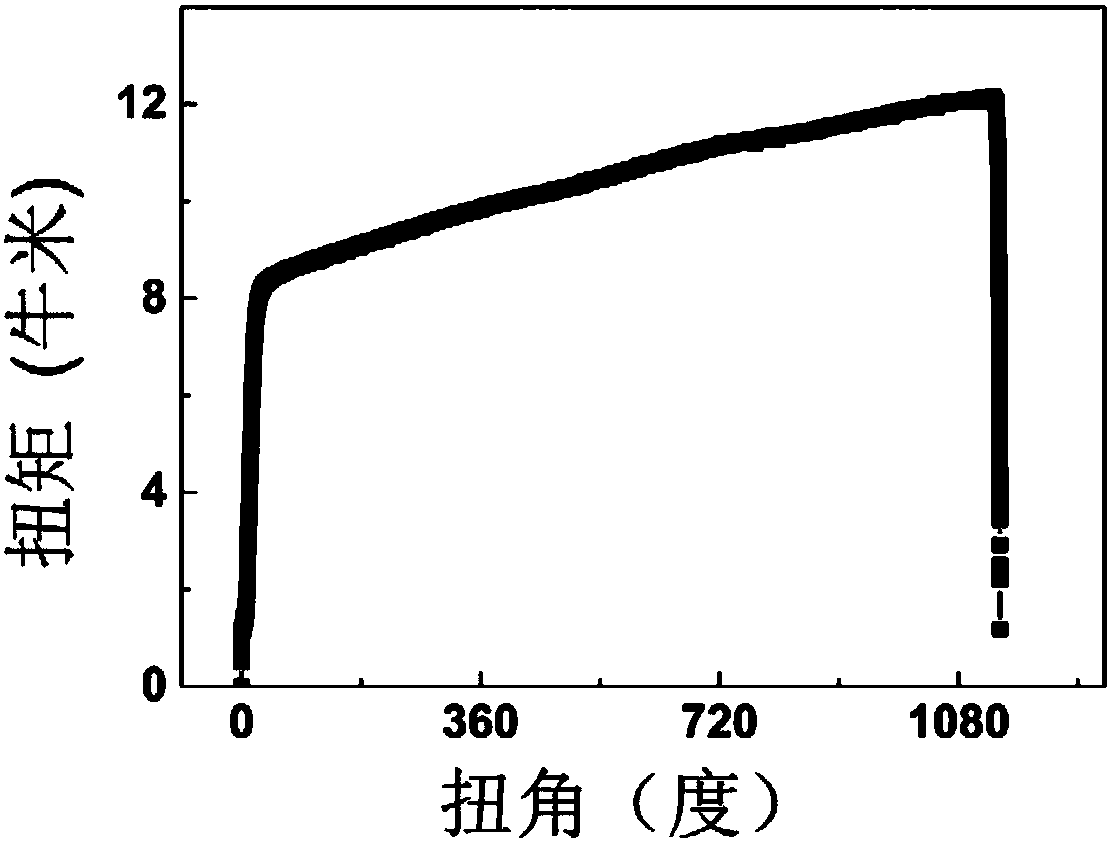

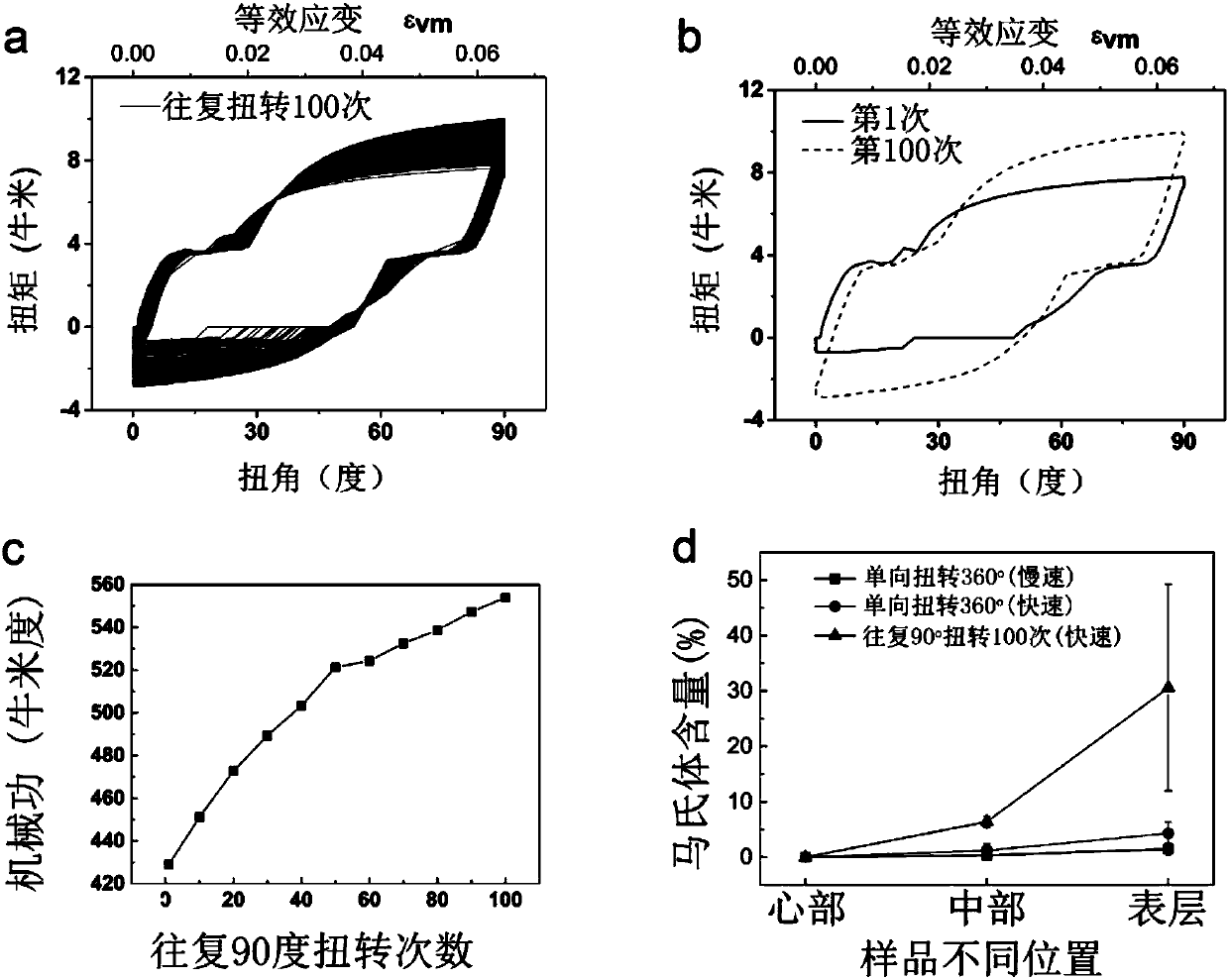

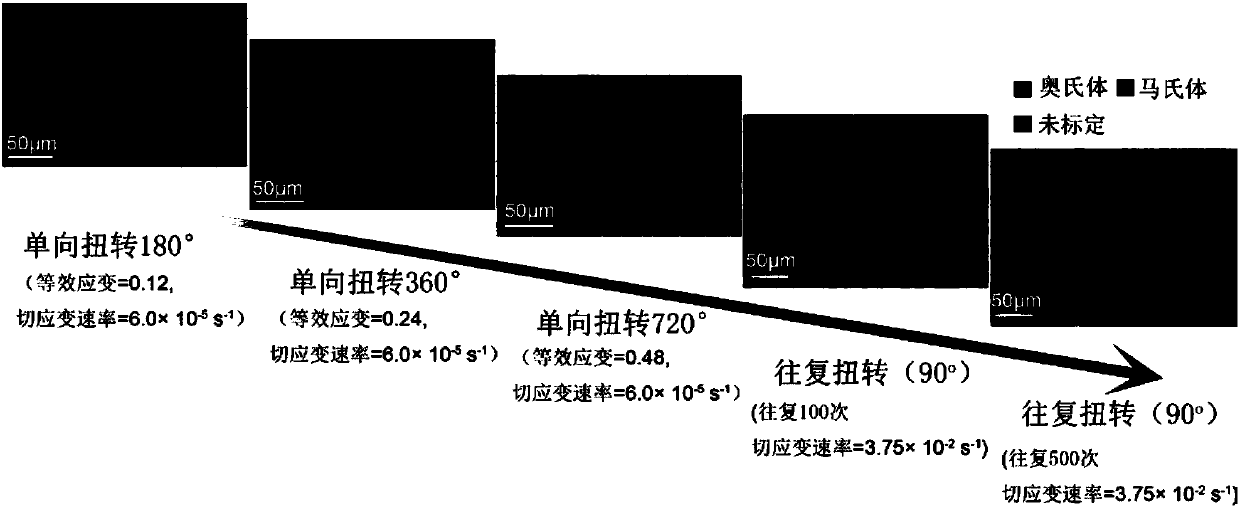

Preparing method for high-strength and high-toughness gradient martensite and austenite dual-phase steel

ActiveCN107893154AHinder dislocation movementHigh tensile strengthSurface layerUltimate tensile strength

The invention discloses a preparing method for high-strength and high-toughness gradient martensite and austenite dual-phase steel. The preparing method includes the step that the austenite steel is subjected to twisting and deforming treatment. By means of the preparing method, twisting and plastic deforming treatment is conducted on the austenite so that a martensite second phase distributed ina gradient manner can be formed in the austenite, the content of the martensite is gradually increased from the center part to the surface layer, and the tensile strength of the austenite steel is improved. In addition, the size of the martensite second phase is further refined, the content of the martensite on the surface layer is further increased and the tensile strength of the steel is furtherimproved according to the shearing strain deformation path, the shearing strain rate, the deformation temperature and the deformation amount of limited twisting treatment.

Owner:SOUTHWEST UNIVERSITY

Apparatus and method for determining patterns of damage being caused in rolling contact element

InactiveUS7577555B2Avoid mechanical damageNo errorPlug gaugesMachine bearings testingBrinellingAdiabatic shear band

A method of designing a roller bearing is disclosed upon clarifying mechanisms of damage patterns in respect of two kinds of brinelling, involved in the bearing, wherein white-banded flaking (brittle flaking) is a plastic instability phenomenon appearing under high-speed deformation accompanied by adiabatic shear deformation status with the resultant occurrence of adiabatic shear band (also called white band) inside material of the bearing. This enables all of the damage patterns to be determined upon making comparison between shear strain and shear strain rate, occurring inside the bearing, and discriminated values.

Owner:DENSO CORP

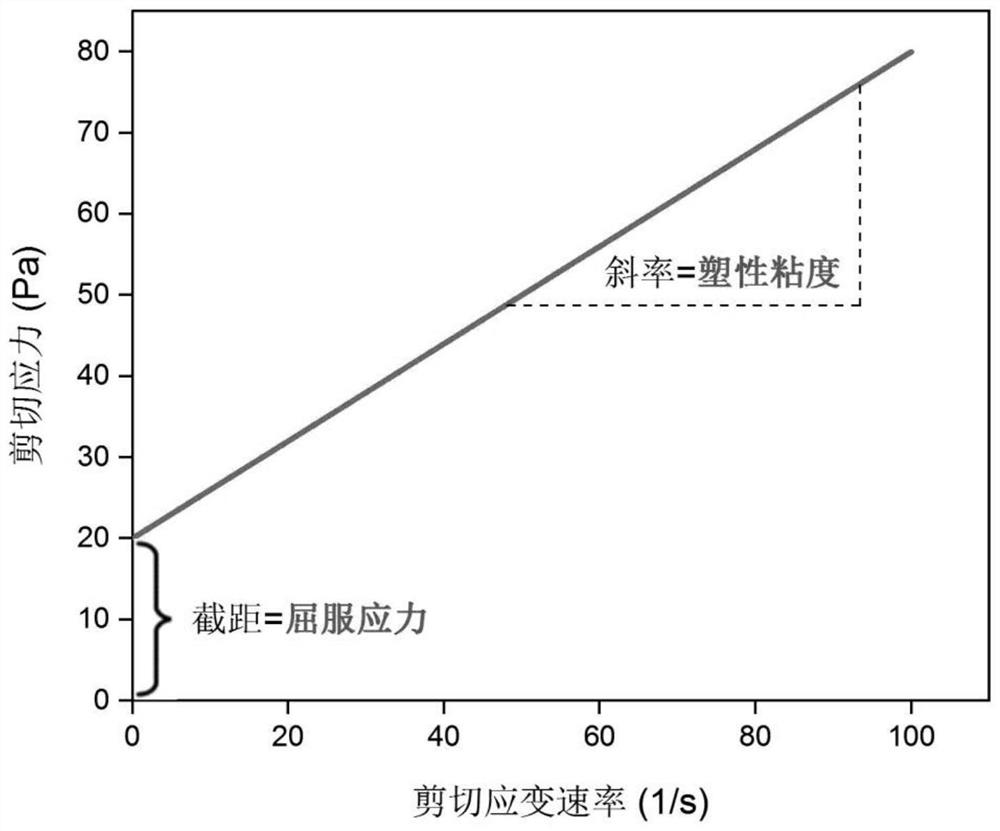

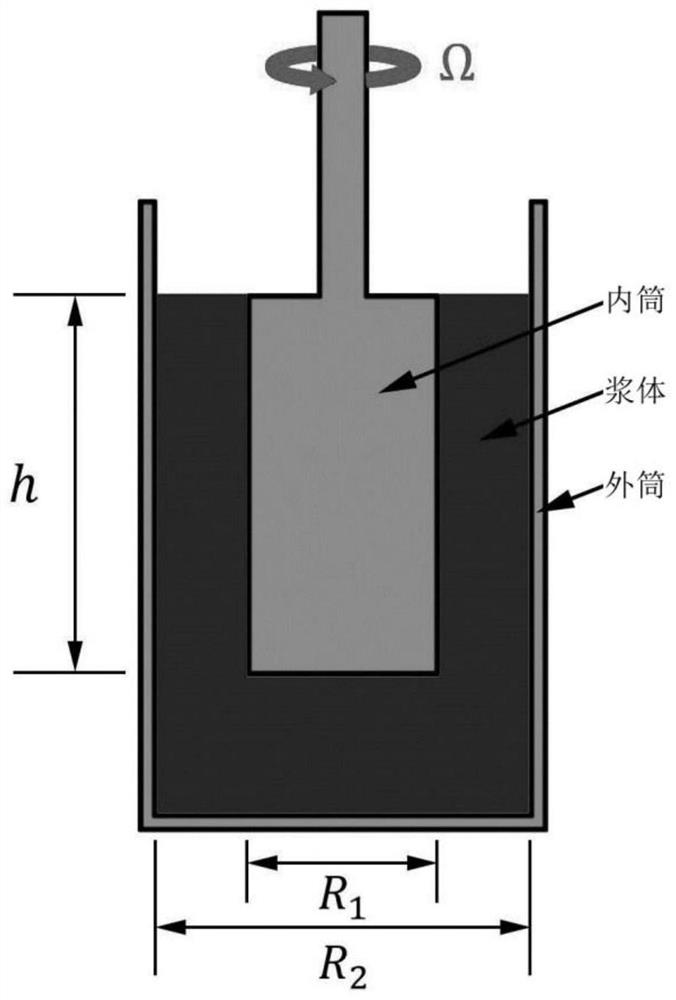

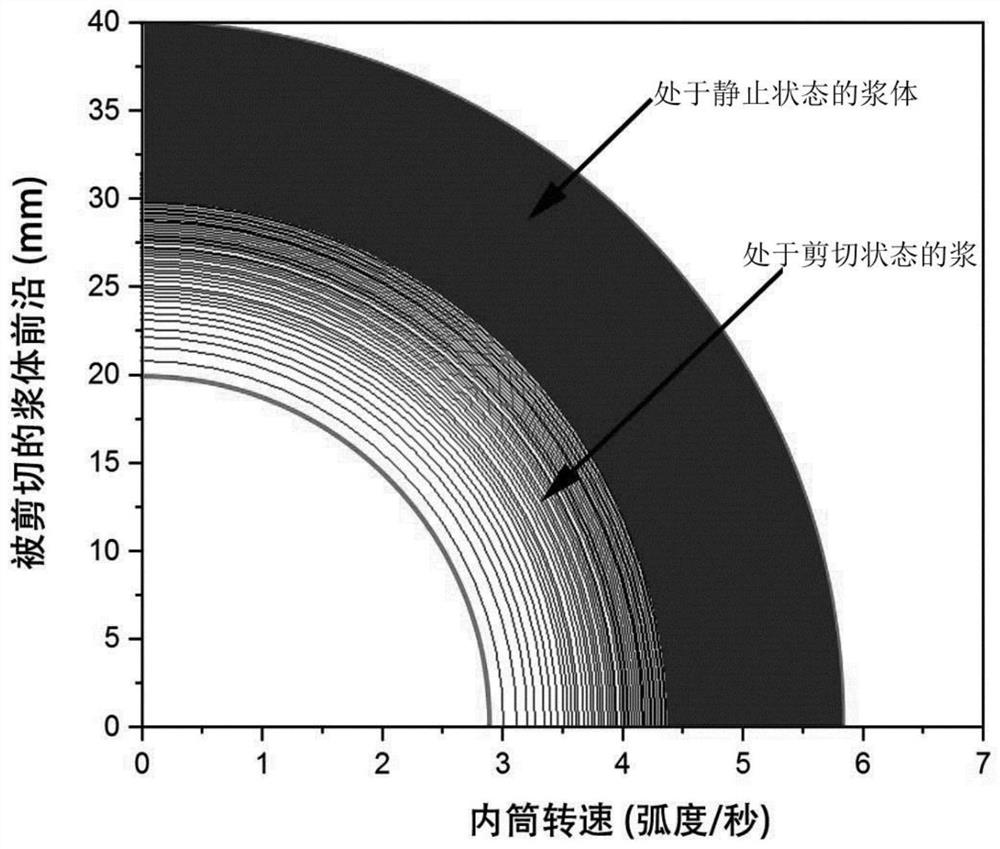

Cement-based material Bingham rheological parameter analysis method

The invention provides a cement-based material Bingham rheological parameter analysis method. A nonlinear rotating speed-torque relation obtained by a coaxial double-cylinder rheometer in a partial shearing state is reasonably converted into a linear shearing stress-shearing strain rate relation, and Bingham rheological parameters of the cement-based material are obtained essentially. On one hand,when the rotating speed of the inner barrel is accelerated to a partial shearing state and disappears, relative slippage between the inner barrel and slurry or between the outer barrel and the slurryat a high rotating speed and testing errors caused by radial flowing of the slurry due to centrifugal force of the inner barrel are avoided, and side effects caused by increasing of the rotating speed of the inner barrel are effectively avoided; and on the other hand, a nonlinear rotating speed-torque curve is utilized to realize accurate solution of the Bingham rheological parameters of the cement-based material.

Owner:TSINGHUA UNIV +2

Micro-nano fluid damper

ActiveUS9422997B2Facilitate conductionHigh viscositySpringsLiquid based dampersMicro nanoEngineering

Owner:NAT APPLIED RES LAB

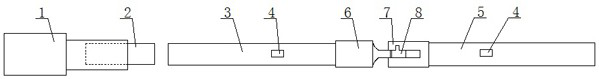

Method for testing interfacial shear strength of marine clad steel plate

ActiveCN112229705ASmall sizeGuaranteed reliabilityMaterial strength using single impulsive forceLever pressingStrain gauge

The invention discloses a method for testing interfacial shear strength of a marine clad steel plate, which uses a separated Hopkinson pressure lever for testing, and the dynamic test method mainly comprises the following steps: designing a sample, a loading piece and a clamping piece, respectively connecting the loading piece and the clamping piece with an incident rod and a transmission rod of the separated Hopkinson pressure lever by threads, and placing the sample in a sample loading block; adjusting the punch to be coaxial with the composite layer of the sample, erecting a high-speed camera system, and taking the punch as an observation area; starting a loading system of the separated Hopkinson pressure rod to carry out a test, and recording strain information through strain gauges adhered to the incident rod and the transmission rod to calculate the dynamic shear strain rate and the dynamic shear strength at the interface. By the adoption of the dynamic test method, effective dynamic loads can be applied to the clad steel plate, the interface shear strength value can be calculated, and necessary technical guarantee is provided for effective testing of the interface performance of the clad steel plate.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

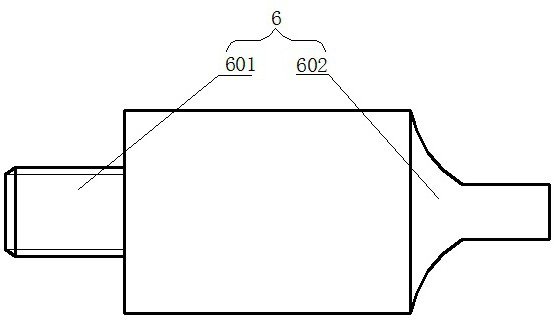

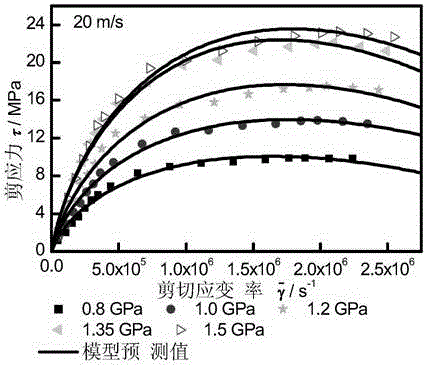

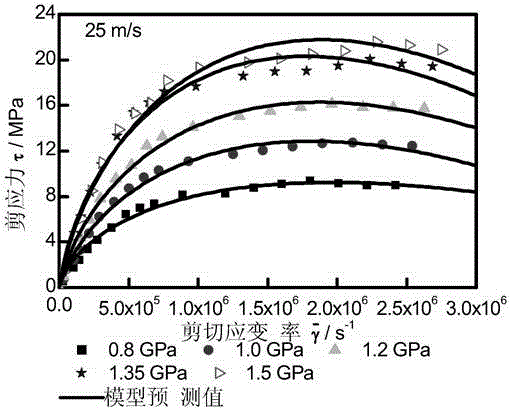

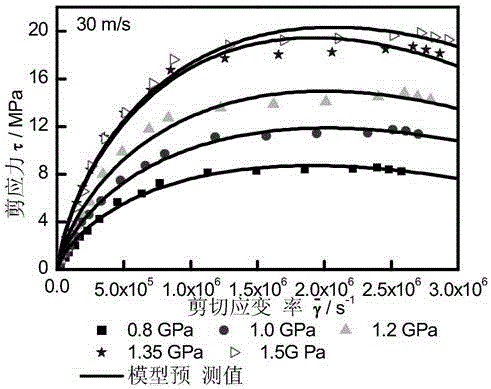

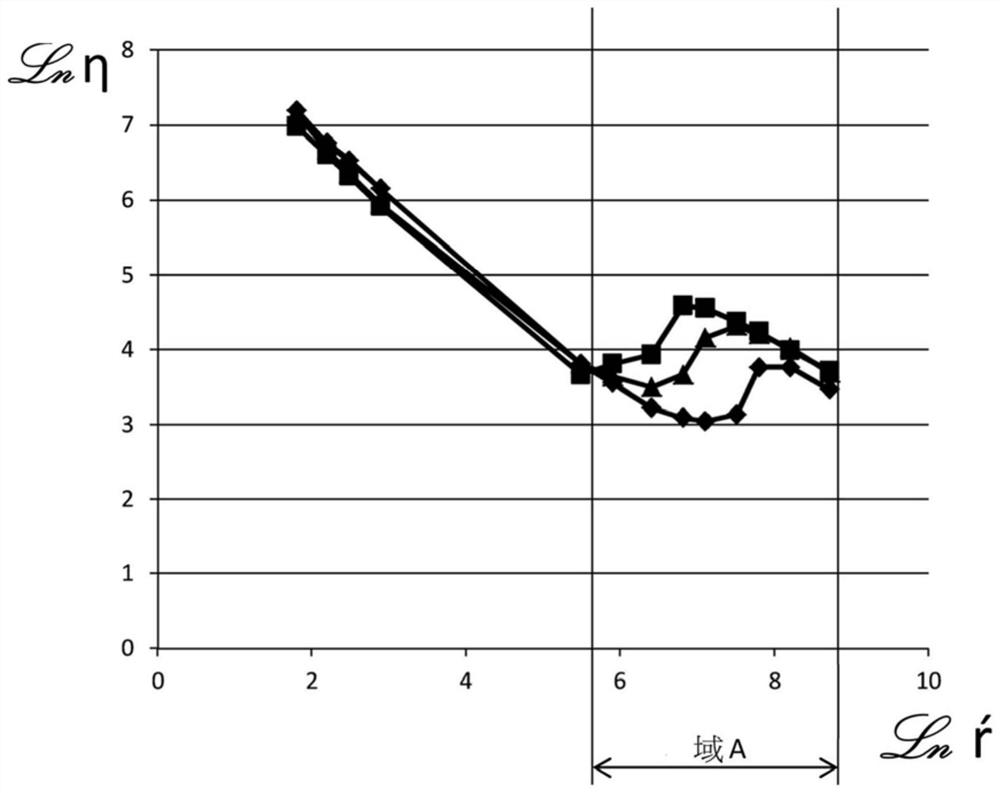

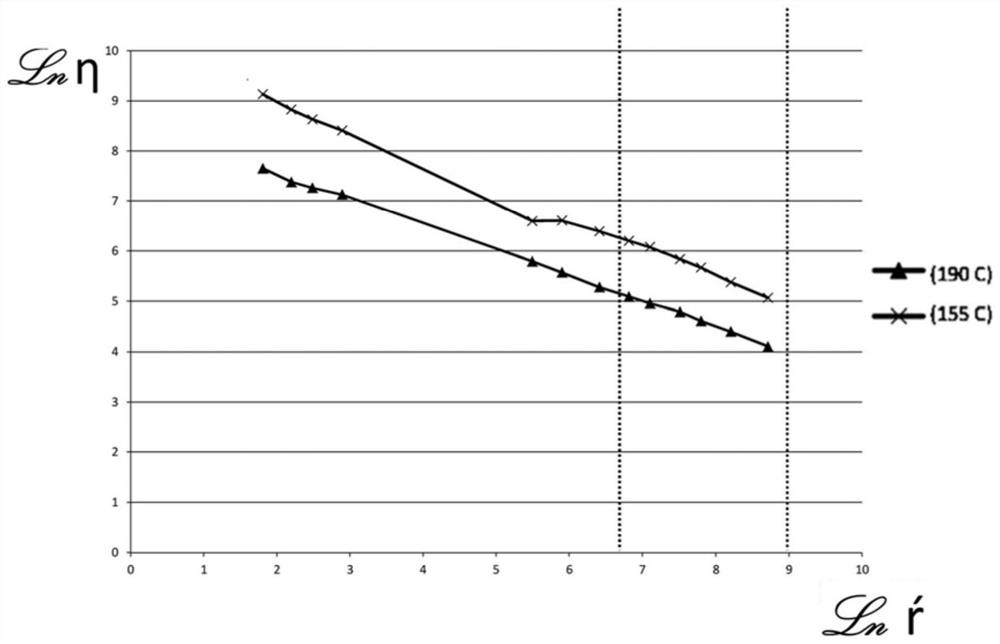

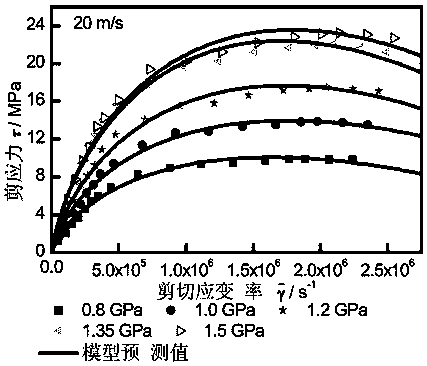

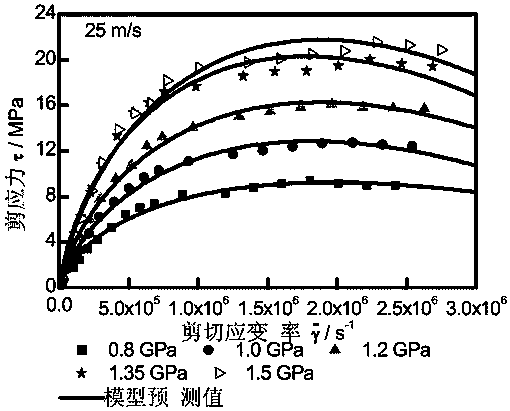

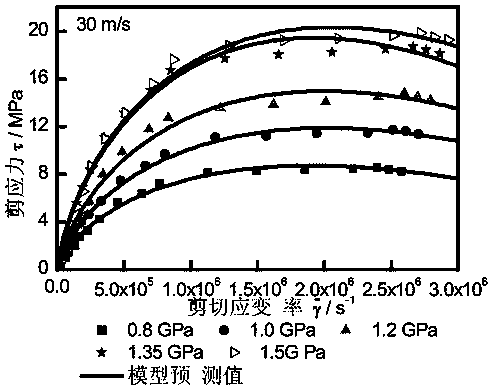

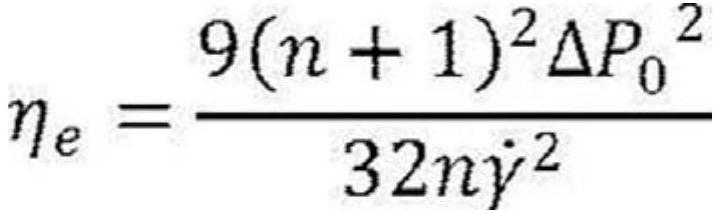

Ultrahigh shear strain rate lubricating grease rheological model

ActiveCN106769666AEasy to buildHigh precisionFlow properties on non-Newtonian fluidsLithiumEngineering

The invention discloses an ultrahigh shear strain rate lubricating grease rheological model. The formula is shown in the description. The model is convenient to construct, parameters on which the model is based are easy to obtain, the model is measured on an ultrahigh shear train rate rheometer, and it is verified that the model has high precision and is especially suitable for rheological data with the shear strain rate from 0 to 3.5*106 s<-1> and even higher. The model has high applicability, and is suitable for solving lubricating grease shear strain between any two contact parts rolling relatively and sliding. After the model is built, the model can be used for solving the friction force of lubricating grease integrally, and the friction force of the lubricating grease is an important parameter necessary for lubricating grease research and development and bearing design. The model has high applicability especially on complex lithium-based grease.

Owner:QILU UNIV OF TECH

Vehicle bumper

The invention discloses a vehicle bumper. The vehicle bumper comprises a packaging layer, a mounting plate, a fixing ring, a forward lever, a reverse lever, a short rotating shaft, a long rotating shaft, a T-shaped sliding block, a guide rail, a fastening screw, an STF, an end cover, an anti-collision beam support frame and a shear effect increasing device. The vehicle bumper has the characteristic of superior cushion protection performance, can be widely applied the field of collision protection of vehicles to reduce the casualty rate of personnel and property loss. By combining STF and multi-link structure, the good energy absorption characteristic of the STF is used and the kinetic characteristic of a multi-link structure is also used so that when shock occurs, other STFs around are driven to participate in the energy consumption process, the utilization efficiency of the STFs is improved, and energy absorption efficiency of the STF is greatly improved. The STF has a sensitive and rapid response to the shear strain rate so that the bumper can make a high energy consumption response at the moment the bumper is shocked, the protective performance of the structure is improved and the complexity of the whole structure is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A Meshing Shear Variable Gap Hexalobular Rotor

ActiveCN112123617BImprove the mixing effectTo achieve the purpose of shearing and tearingRubber materialEngineering

The invention belongs to the technical field of internal mixer rotors, and relates to a meshing and shearing variable-gap hexagonal rotor, which is installed on an internal mixer and used for mastication and mixing of rubber. It consists of a rotor body and six rotor bodies. The front and rear rotors are meshed and connected by ribs and returning glue threads. When in use, the front and rear rotors are sleeved on the screw. The screw absorbs the advantages of the meshing and shearing mixing rubber, overcomes the shortcomings of each other, and strengthens the rubber in the rubber. The axial movement in the mixing chamber improves and strengthens the shear capacity between the ridge peak and the wall of the mixing chamber; with sufficient shear force, a high shear strain rate is achieved, and sufficient rubber movement ensures The uniformity of the mixing and dispersion of the rubber material is ensured. At the same time, the setting of the glue return thread can prevent the rubber material from overflowing in the internal mixer. Compared with the standard four-edged rotor, a short edge is added on one side of the front rotor and the rear rotor, which is beneficial The backflow of the rubber material makes the lateral movement of the rubber material in the mixing chamber more obvious, which is more conducive to the mixing of the rubber material.

Owner:QINGDAO UNIV OF SCI & TECH

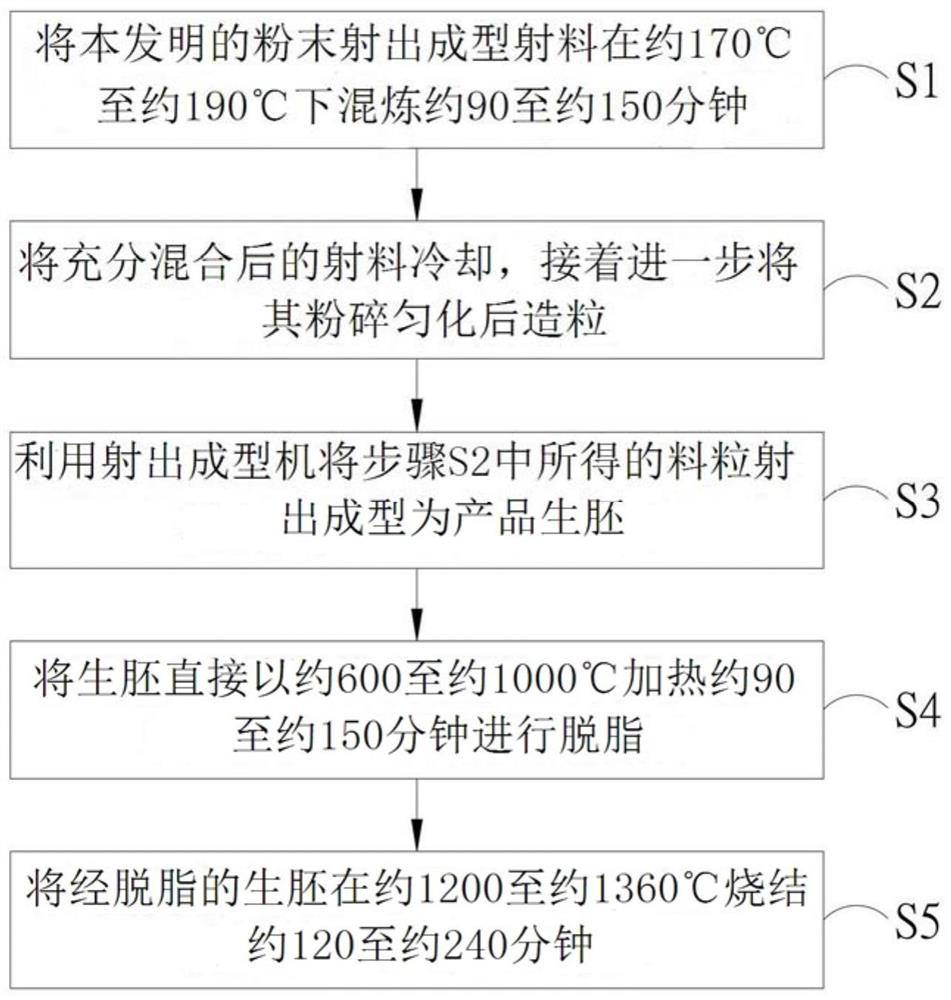

Improved powder injection molding shot, product manufactured therefrom, and product manufacturing method

ActiveCN107755702BPrevent or reduce the phenomenon of separationMaintain strengthTransportation and packagingMetal-working apparatusPolyoxymethylenePolymer science

The invention provides an improved powder injection molding shot, its manufactured product and product manufacturing method, wherein the improved powder injection molding shot includes: sinterable powder and a binder, the binder includes a hydrocarbon wax, a surfactant, Polyolefin compounds, polyoxymethylene, and rheology modifiers. The powder injection molding shot of the present invention contains a rheological modifier to reduce the powder injection molding shot from becoming an expansion fluid in the high shear strain rate (high shear rate) region, thereby maintaining a high injection rate. In the case of speed, increase the quality of the product.

Owner:CHENMING MOLD IND CORP

Establishment Method of Rheological Model of Ultra-high Shear Strain Rate Grease

ActiveCN106769666BEasy to buildHigh precisionFlow properties on non-Newtonian fluidsLithiumEngineering

The invention discloses an ultrahigh shear strain rate lubricating grease rheological model. The formula is shown in the description. The model is convenient to construct, parameters on which the model is based are easy to obtain, the model is measured on an ultrahigh shear train rate rheometer, and it is verified that the model has high precision and is especially suitable for rheological data with the shear strain rate from 0 to 3.5*106 s<-1> and even higher. The model has high applicability, and is suitable for solving lubricating grease shear strain between any two contact parts rolling relatively and sliding. After the model is built, the model can be used for solving the friction force of lubricating grease integrally, and the friction force of the lubricating grease is an important parameter necessary for lubricating grease research and development and bearing design. The model has high applicability especially on complex lithium-based grease.

Owner:QILU UNIV OF TECH

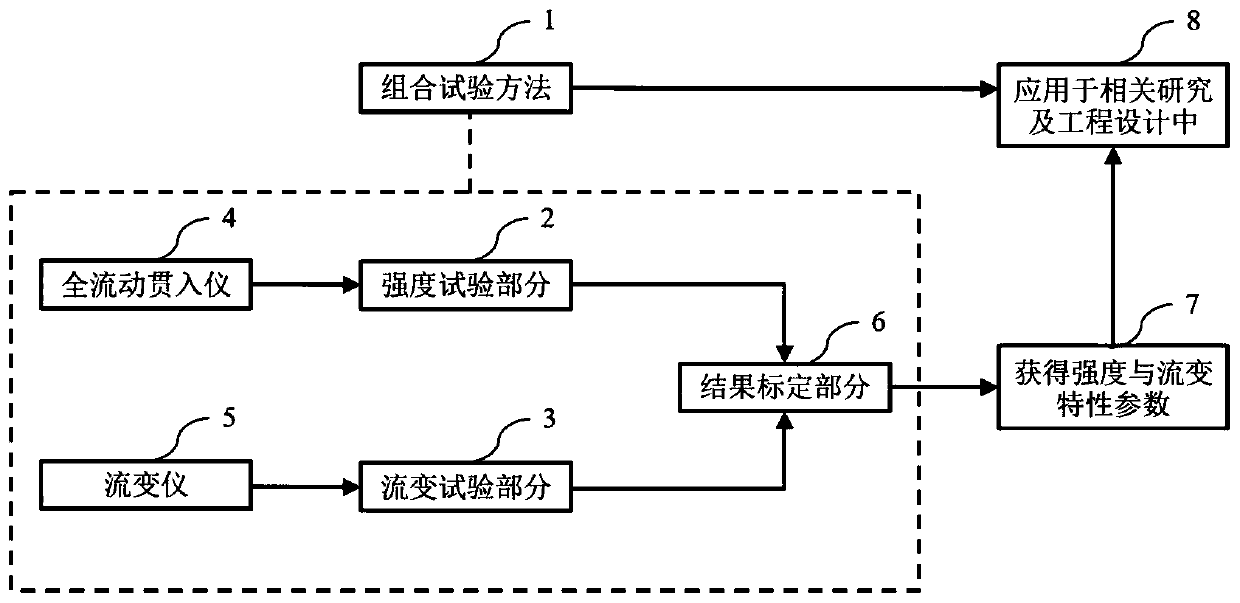

Combined test method for testing strength and rheological properties of marine ultra-soft soil

InactiveCN110749724AReliable strength test resultsWide range of shear strain rate testingEarth material testingCombined testSoil science

The invention discloses a combined test method for testing strength and rheological properties of marine ultra-soft soil, and belongs to the technical field of offshore engineering. The method is based on the advantages of a full-flow penetrometer in the aspect of strength test and the advantages of a rheometer in the aspect of shear strain rate test, the method comprises the following steps of: respectively testing a marine ultra-soft soil sample by adopting two types of devices; and calibrating a strength result measured by the rheological test part by taking a strength value measured by thestrength test part under the reference shear strain rate as the standard strength, and correcting the strength curve measured by the rheological test part according to the calibration result, therebyobtaining the strength and rheological property parameters of the marine ultra-soft soil. The test method provided by the invention has the characteristics of the reliable strength test result (whichcan be as low as 0.001 kPa), the wide shear strain rate test range (which can exceed 100s-1 or is less than 0.001s-1), the rich test parameters (undrained shear strength, sensitivity, yield stress and viscosity) and the like, and technical reference is provided for the mechanical property test of the marine ultra-soft soil in offshore engineering.

Owner:DALIAN UNIV OF TECH +1

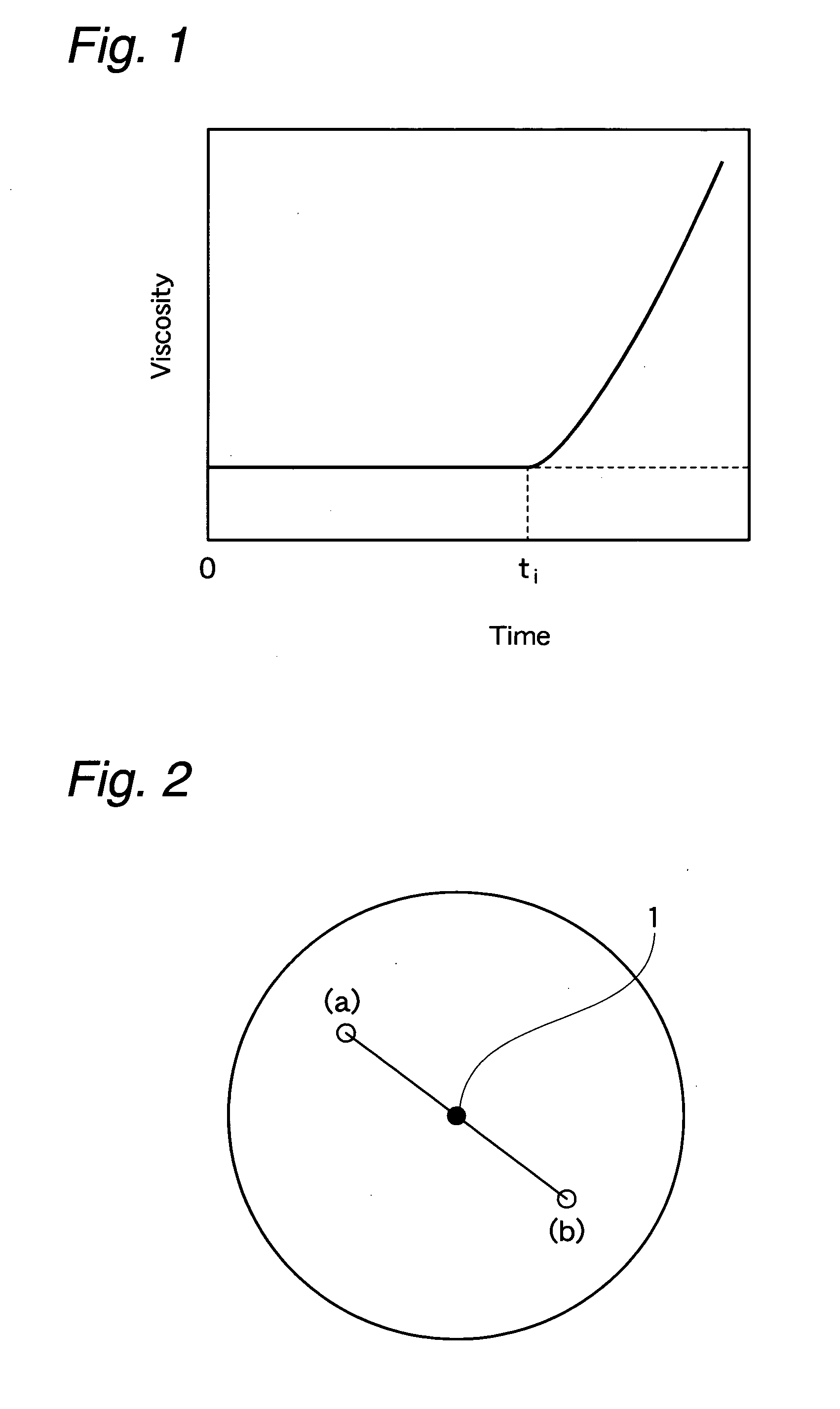

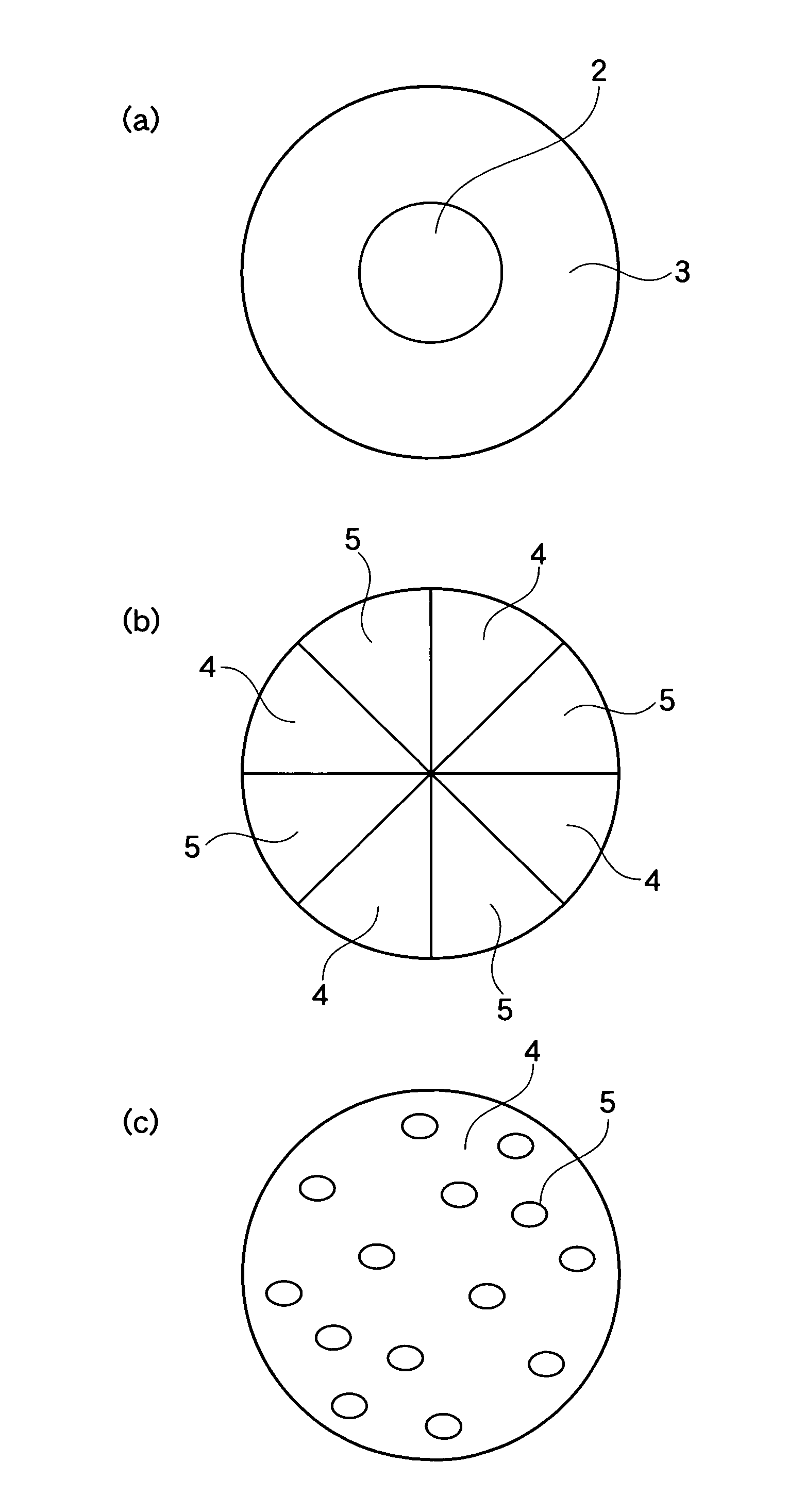

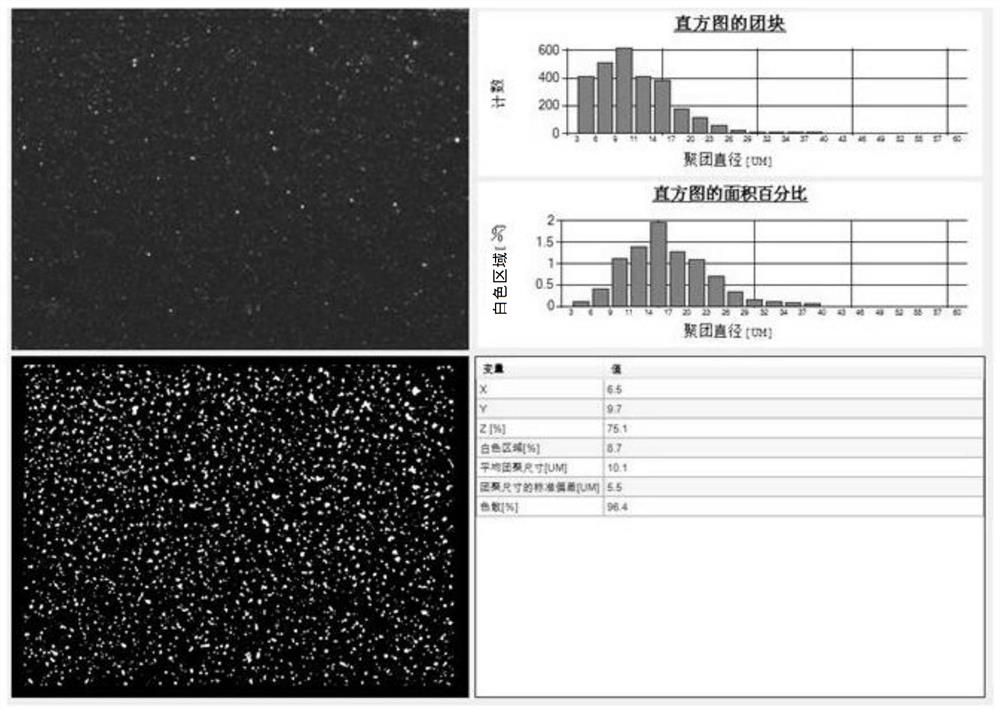

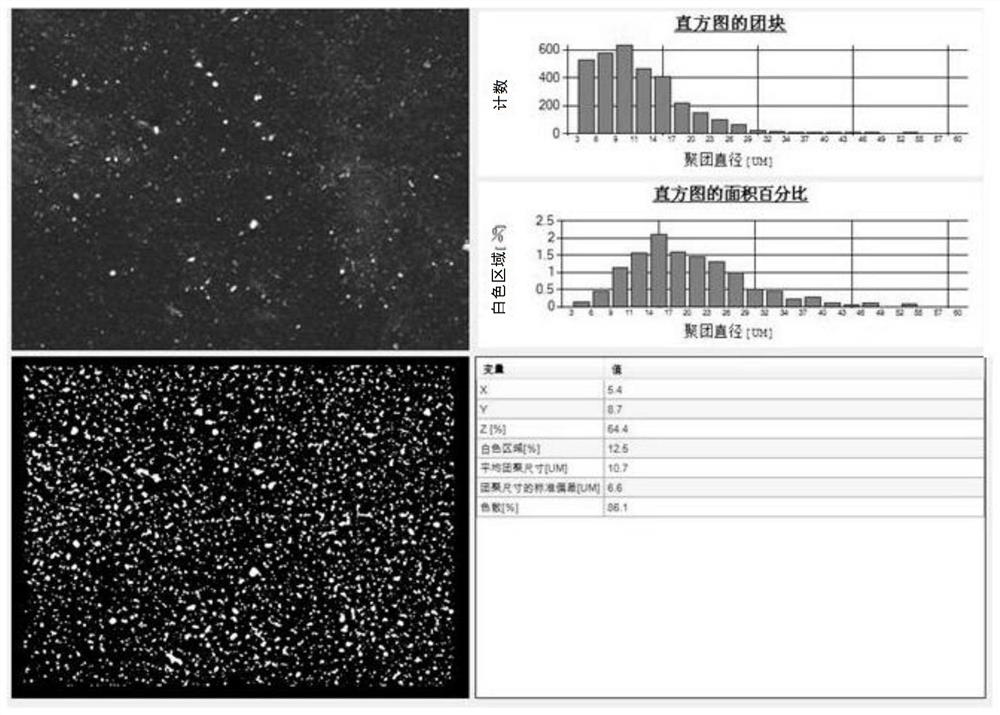

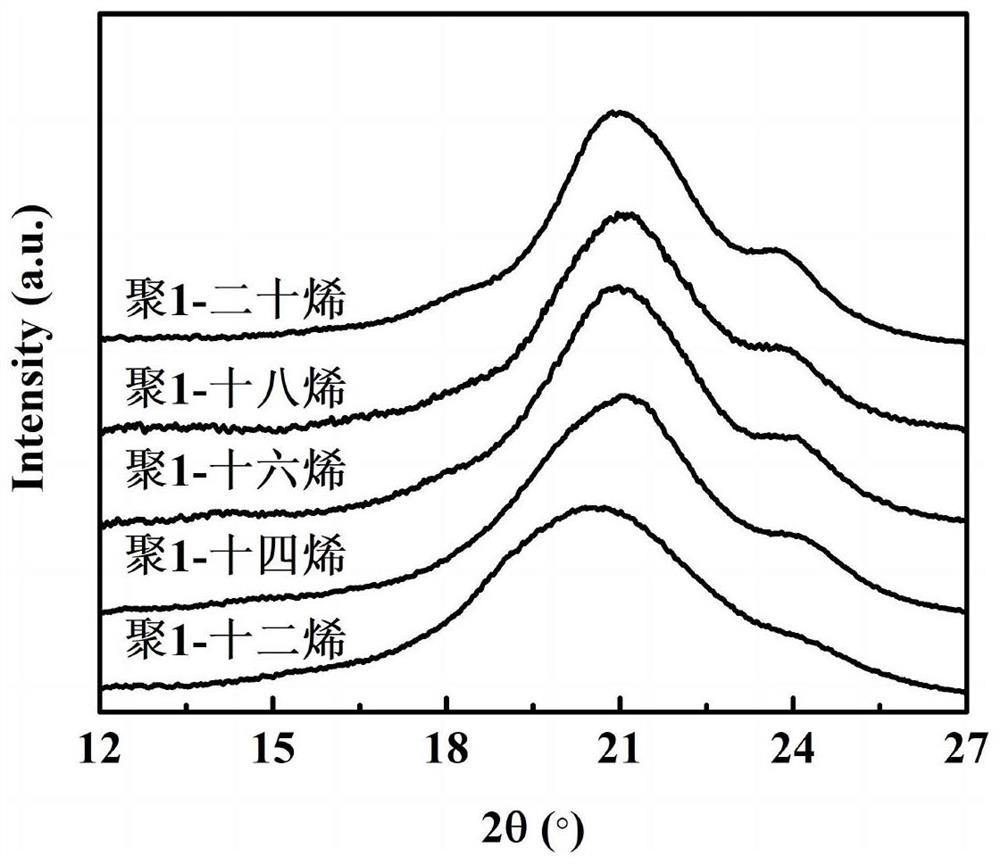

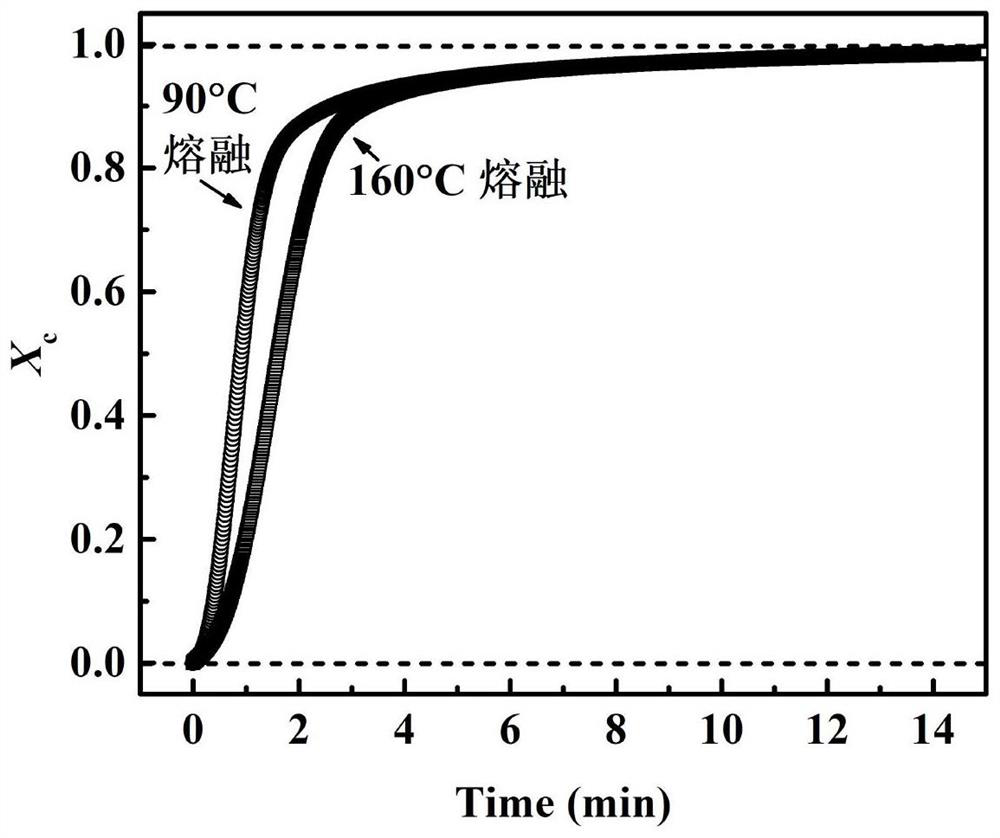

A method for regulating the crystallization of α-olefin homopolymer by processing conditions

ActiveCN114133588BPromote rapid formationImprove processing efficiencyIsothermal crystallisationPolymer science

The invention discloses a method for controlling the crystallization of α-olefin homopolymer through processing conditions, and belongs to the technical field of polymer crystallization. The long-chain α-olefin homopolymer with 12-20 carbon atoms is heated to 160°C and kept for 10 minutes, and the temperature is lowered so that the long-chain α-olefin homopolymer crystallizes to obtain the initial sample; then the temperature is raised to 45-160°C to melt and Keep warm for 1-3600s, then cool down to an isothermal temperature of 10-75°C at 10°C / min; apply a shear strain rate of 0-5s ‑1 , a flow field with a shear time of 0‑5s, and crystallization at the isothermal crystallization temperature. In the present invention, there are obvious differences in the crystallization time of long-chain α-olefin homopolymers under different processing conditions, which shows that processing conditions have a greater impact on the crystallization time of long-chain α-olefin homopolymers, and provides a basis for improving processing and molding efficiency. a feasible solution.

Owner:TIANJIN UNIV

Non-woven fabric and filter

ActiveCN111918995AImprove capture efficiencyMembrane filtersFiltration separationExtensional viscosityFiber

A non-woven fabric comprising fibers, wherein the fibers have a uniaxial elongational viscosity of 430 Pa*s to 1200 Pa*s as measured at 160 DEG C, with a 2.5*102(1 / sec) elongation strain rate, and theproportion of the uniaxial elongational viscosity (Pa*s) to the shear viscosity (Pa*s) as measured at 160 DEG C, with a 2.5x102(1 / sec) shear strain rate, is 35 to 65.

Owner:MITSUI CHEM INC

a vehicle bumper

The invention discloses a vehicle bumper. The vehicle bumper comprises a packaging layer, a mounting plate, a fixing ring, a forward lever, a reverse lever, a short rotating shaft, a long rotating shaft, a T-shaped sliding block, a guide rail, a fastening screw, an STF, an end cover, an anti-collision beam support frame and a shear effect increasing device. The vehicle bumper has the characteristic of superior cushion protection performance, can be widely applied the field of collision protection of vehicles to reduce the casualty rate of personnel and property loss. By combining STF and multi-link structure, the good energy absorption characteristic of the STF is used and the kinetic characteristic of a multi-link structure is also used so that when shock occurs, other STFs around are driven to participate in the energy consumption process, the utilization efficiency of the STFs is improved, and energy absorption efficiency of the STF is greatly improved. The STF has a sensitive and rapid response to the shear strain rate so that the bumper can make a high energy consumption response at the moment the bumper is shocked, the protective performance of the structure is improved and the complexity of the whole structure is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

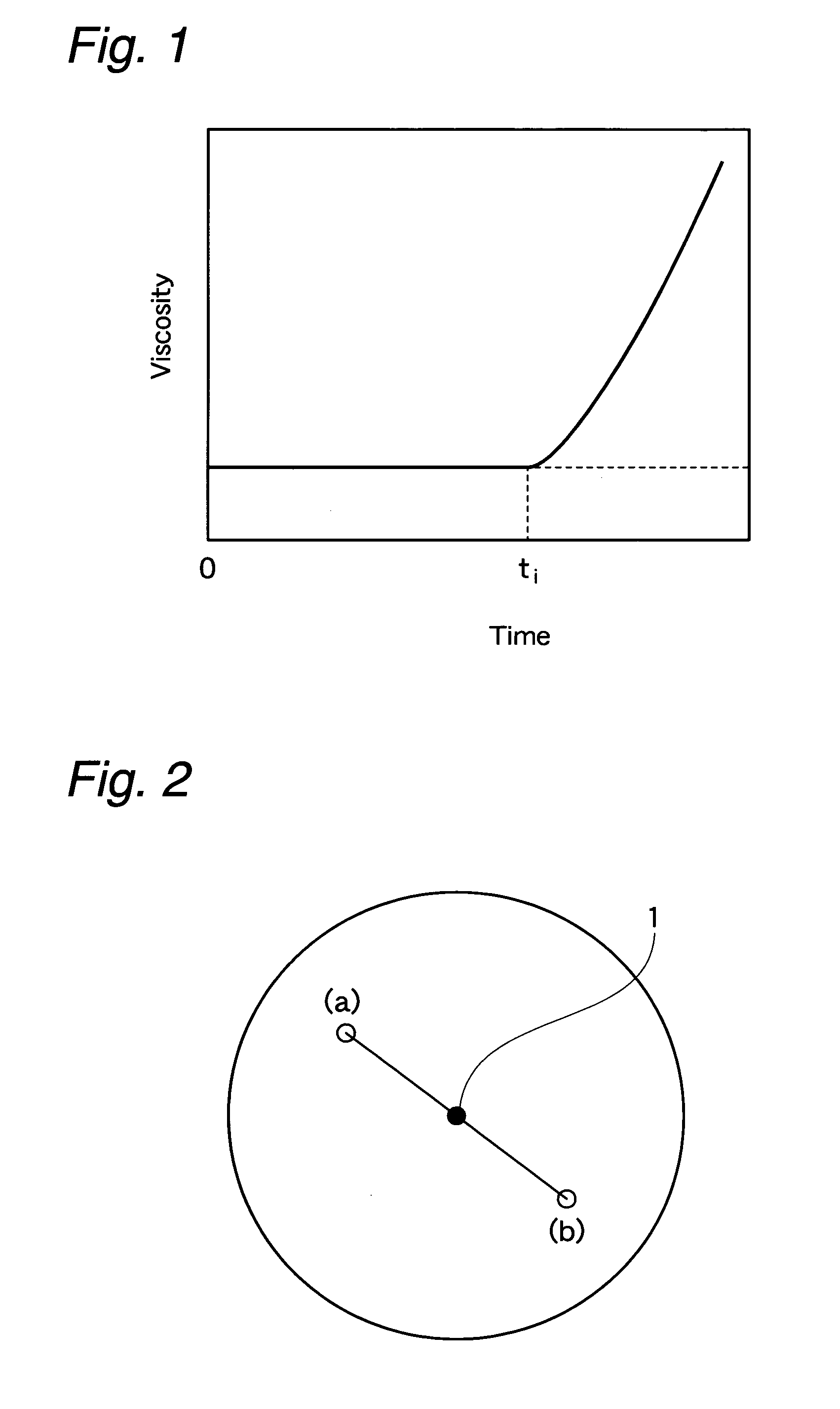

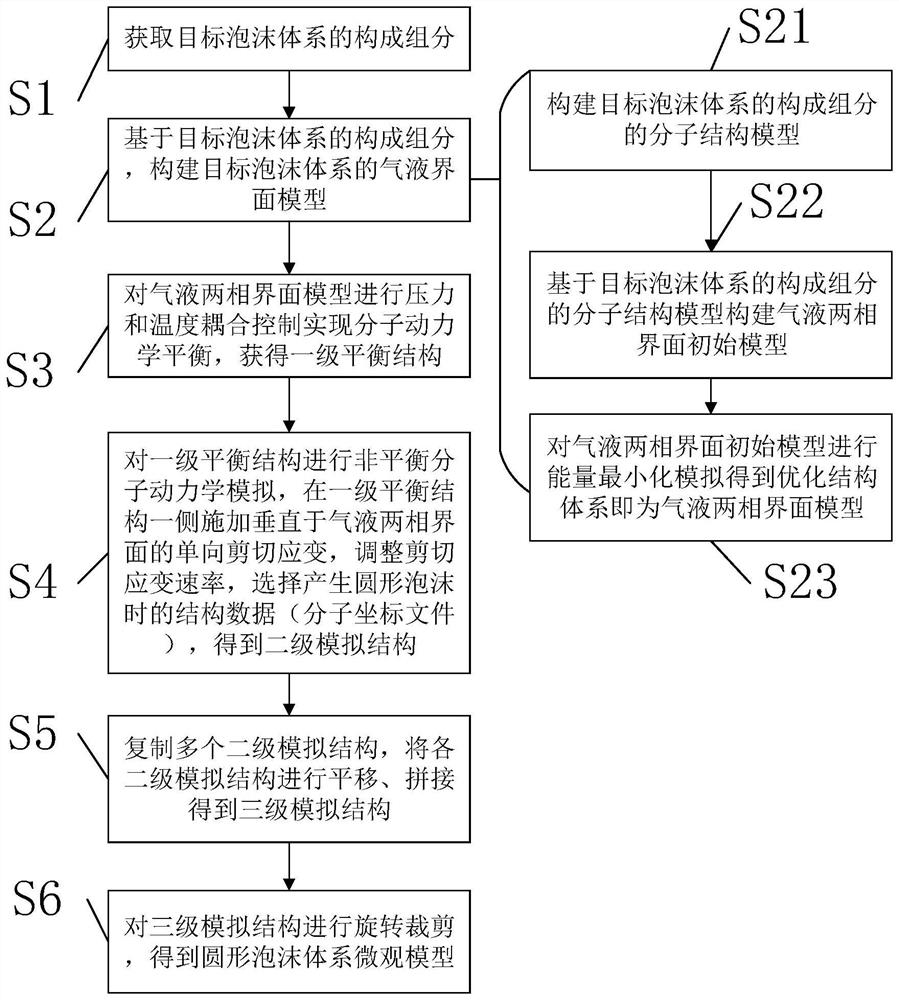

Establishment method of foam system microscopic model

PendingCN114283894AQuick buildEfficient constructionComputational theoretical chemistryInstrumentsDynamic balanceNonequilibrium molecular dynamics

The invention provides a method for establishing a foam system microscopic model. The method comprises the following steps: obtaining components of a target foam system; constructing a gas-liquid two-phase interface model of the target foam system based on the components of the target foam system; performing pressure and temperature coupling control on the gas-liquid two-phase interface model to realize dynamic balance to obtain a first-stage balance structure; performing non-equilibrium molecular dynamics simulation on the first-stage equilibrium structure, applying one-way shear strain perpendicular to a gas-liquid two-phase interface to one side of the first-stage equilibrium structure, adjusting the shear strain rate, and selecting structural data when circular foam is generated to obtain a second-stage simulation structure; copying a plurality of second-level simulation structures, translating the second-level simulation structures, and splicing to obtain a third-level simulation structure; and rotating and cutting the three-stage simulation structure to obtain the micro model of the circular foam system.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for establishing crystal plastic constitutive model of face-centered cubic material in fatigue process

ActiveCN110222442BImprove compatibilityImprove portabilityDesign optimisation/simulationSpecial data processing applicationsBack stressMetallic materials

Owner:SICHUAN UNIV

Horizontal annular slot type test device for magnetorheological material

InactiveCN102175576BTest performance parametersImprove interchangeabilityFlow propertiesMagnetic property measurementsShear stressControl system

The invention discloses a horizontal annular slot type test device for a magnetorheological material, which comprises a frame, wherein a magnetic field generating device, a shearing mechanism, a shearing strength detection mechanism, a warming and temperature detection mechanism, a lifting mechanism and a control system are arranged on the frame. Compared with the traditional test device, the horizontal annular slot type test device for magnetorheological material provided by the invention is additionally provided with the warming and temperature detection mechanism, so the device can be usedfor testing the influence of temperature on the magnetorheological liquid property. The three factors (temperature, magnetic field intensity and shearing strain rate) influencing the magnetorheological liquid and the change gradient of the three factors can be controlled, so the property parameters of the magnetorheological liquid can be more comprehensively detected. The shearing mechanism of the device can be used for furthest concentrating the shearing strength between a fixing ring and a shearing ring at the position of the magnetorheological liquid, thereby ensuring an accurate testing result and acquiring a better testing effect.

Owner:CHONGQING UNIV

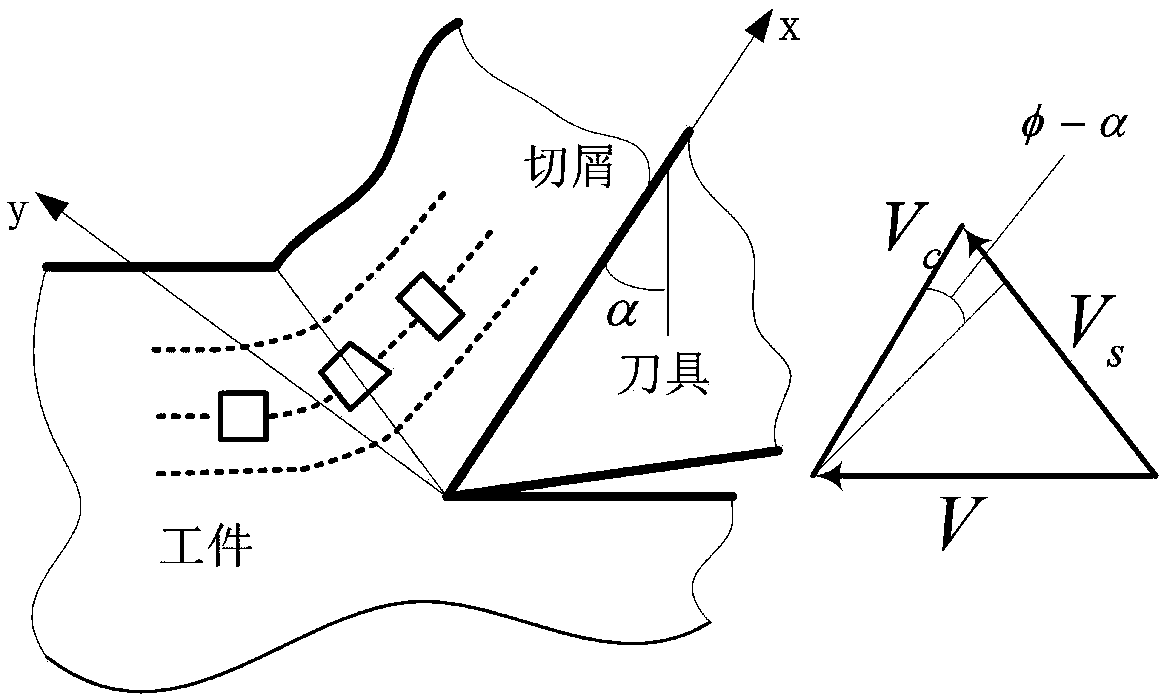

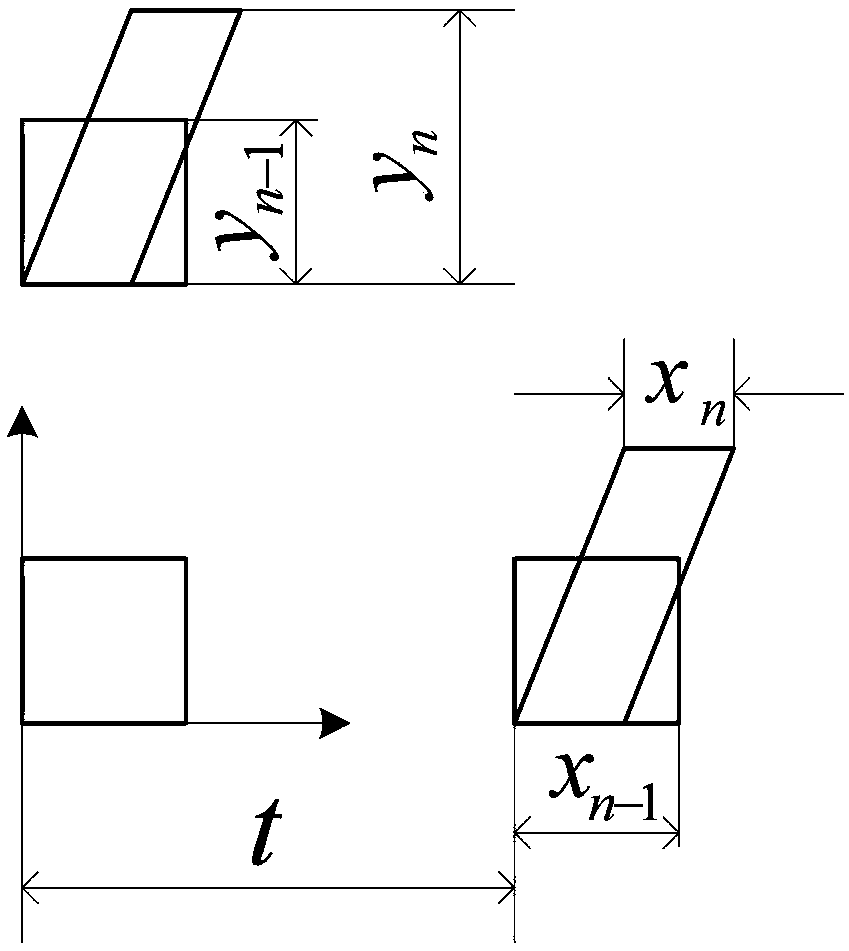

Method used for calculating cutting process strain rate based on grid flow difference

InactiveCN108426796AConvenient researchGood law of changeInvestigating machinabilitySlip lineEngineering

The invention discloses a method used for calculating cutting process strain rate based on grid flow difference. The method comprises following steps: the surface of a material to be measured is provided with grids via processing, from slip lines, grids of a certain area are subjected to slip for a certain period of time t, and deformation is caused with passing through a shearing plane, the length change of the grids at the certain period of time in the x direction is measured, and the deformation at the x direction is determined; time consumed in grid cutting deformation is determined basedon the moving distance of the grids along the x direction and the moving speed of cuttings along a front knife surface, and the strain rate distribution along the x direction is calculated; the abovesteps are repeated, and the cutting strain rate along the y direction is calculated. According to the method, shearing process is studied at the flowing angle, so that preferable study on the change rules of a plurality of physical parameters in cutting process is realized.

Owner:SHANDONG UNIV

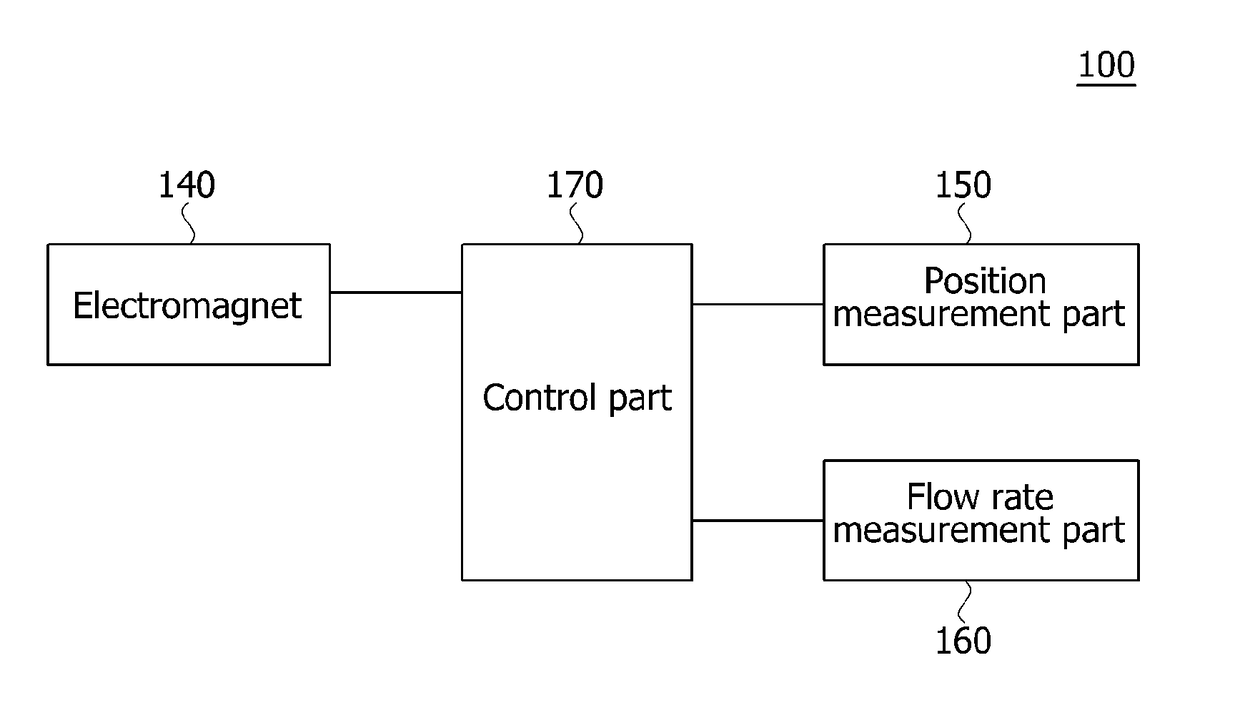

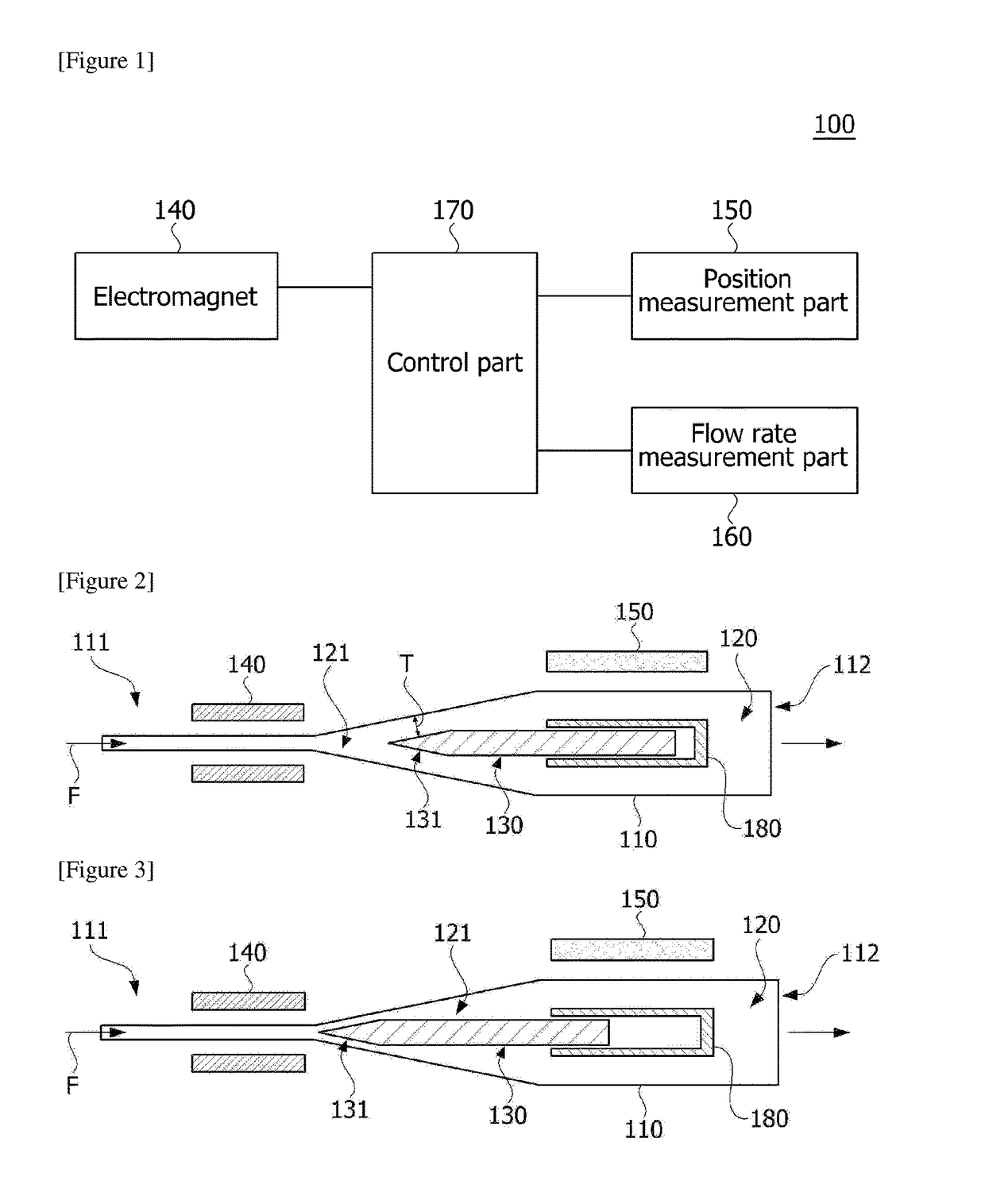

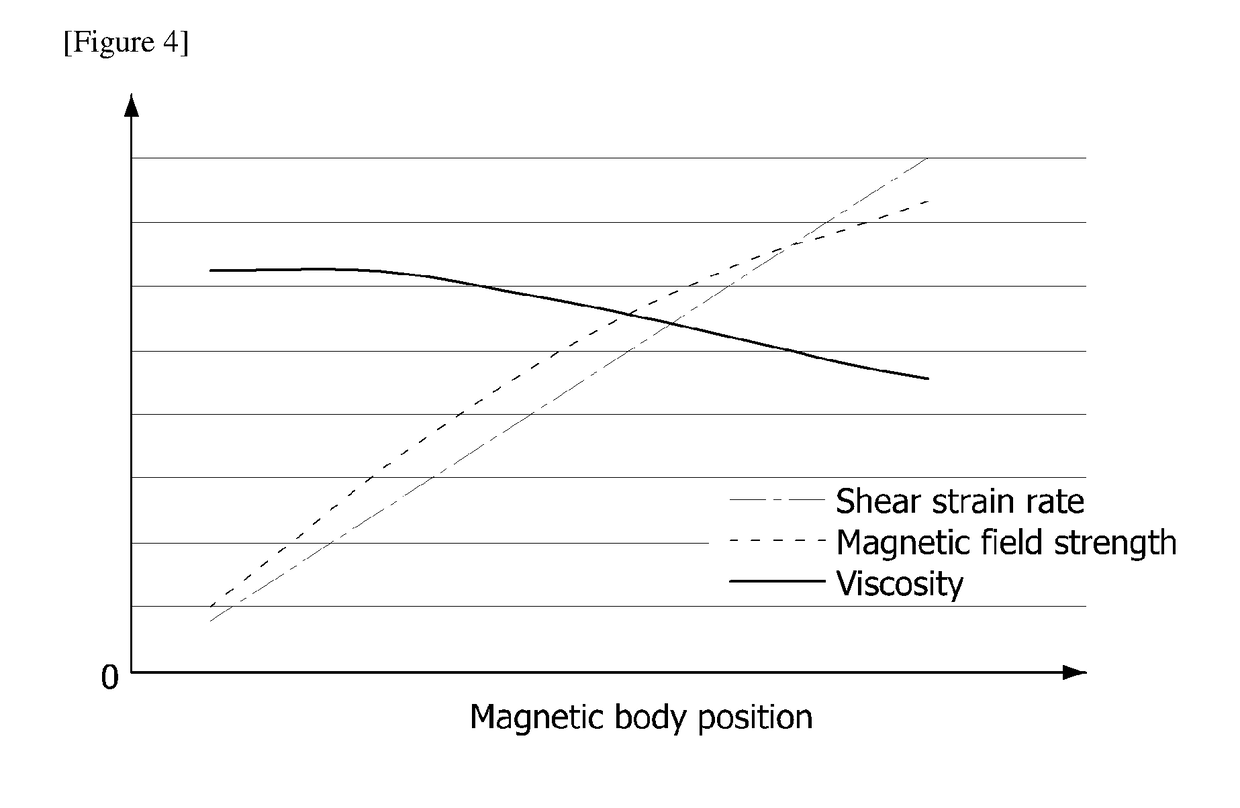

Viscosity measurement device

ActiveUS20170363452A1Change positionVolume/mass flow by electromagnetic flowmetersDirect flow property measurementMeasurement deviceUltimate tensile strength

The present invention relates to a viscosity measurement device. According to one aspect of the present invention, provided is a viscosity measurement device comprising: a housing which has an inlet port, an outlet port and a measurement space positioned between the inlet port and the outlet port; a magnetic body arranged in the measurement space; an electromagnet for moving the magnetic body; a position measurement part for measuring the position of the magnetic body; a flow rate measurement part for measuring the flow rate of fluid which flows in the measurement space; and a control part for measuring the viscosity of the fluid on the basis of the strength of a magnetic field generated by the electromagnet and the shear strain rate of the fluid which passes through the measurement space.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com