Method for testing interfacial shear strength of marine clad steel plate

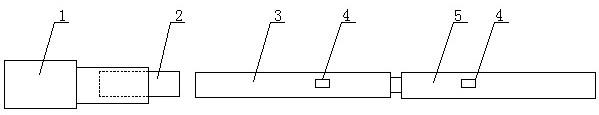

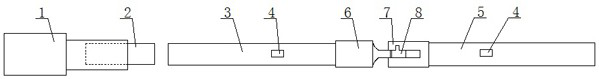

A technology of interfacial shear strength and clad steel plate, which is applied in the direction of testing material strength, strength characteristics, and measuring devices using a single impact force. Strain rate, improve the test success rate, ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0053] A method for testing the interfacial shear strength of a marine composite steel plate, comprising the steps of:

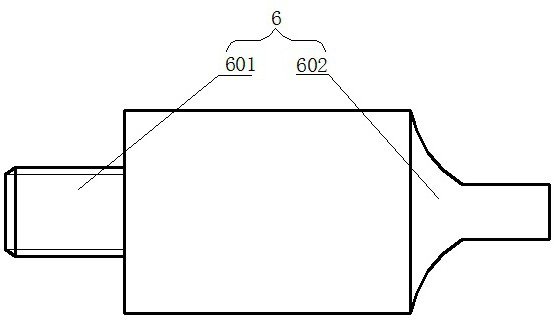

[0054] (1), processing sample, loading part and clamping part, in detail, described sample comprises mutually parallel basic layer and compound layer from bottom to top, and compound layer and basic layer are cuboid shape, and the long L1 of compound layer 801, Width W1, height H1 are 2cm, 6cm, 2cm respectively, length L2, width W2, height H2 of base layer 802 are 8cm, 6cm, 4cm respectively, the distance between the right side wall of compound layer 801 and the right side wall of base layer 802 5cm; the loading part 6 includes a first threaded part 601 for connecting the loading part 6 with the incident rod 5 and a punch 602 for impacting the base layer of the sample with the same center line; the clamping part 7 It includes a second threaded part 701 for connecting the clamping member 7 with the transmission rod 5 with the same center line and a sample load...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com