Patents

Literature

1598 results about "Lever pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

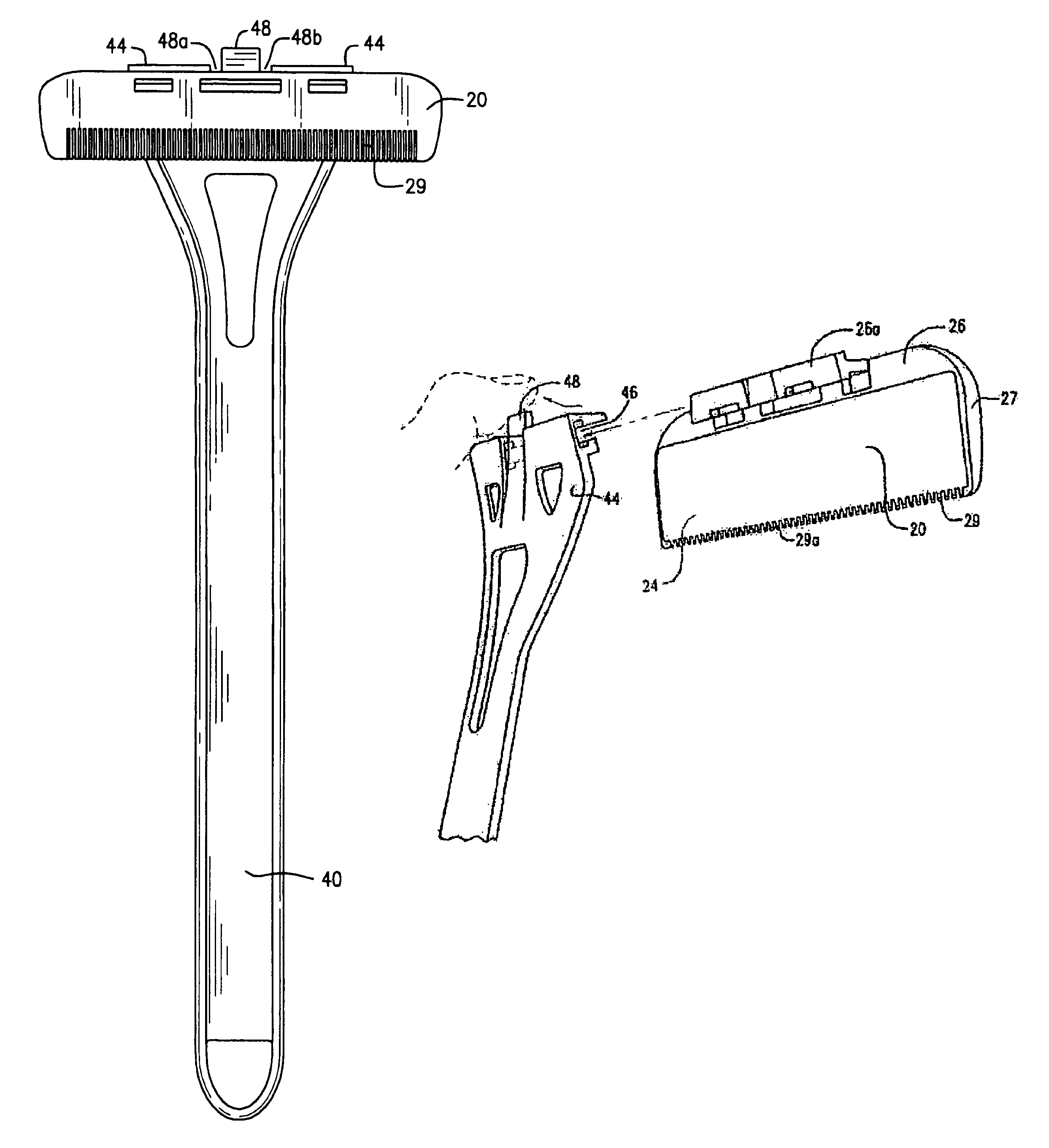

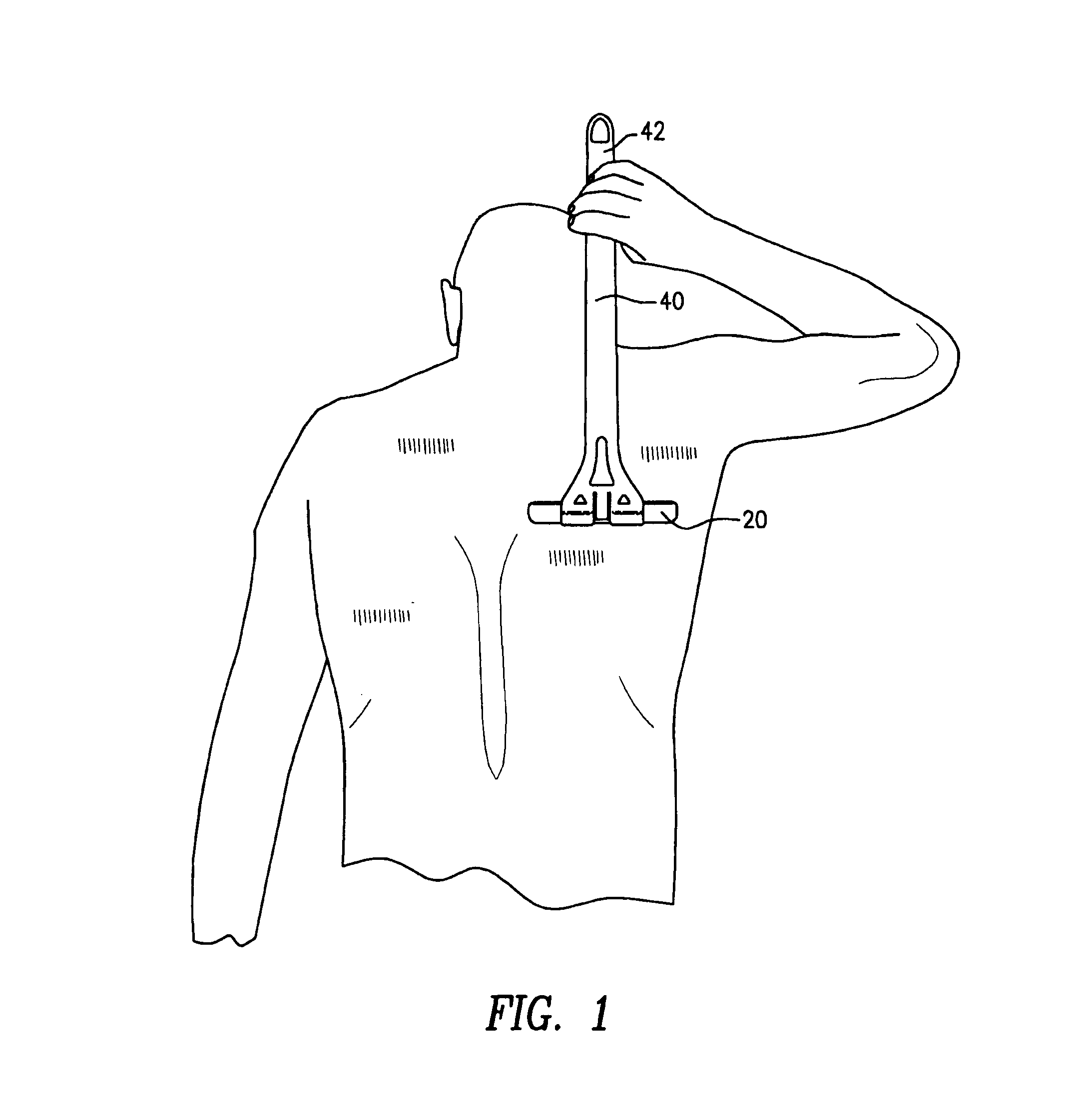

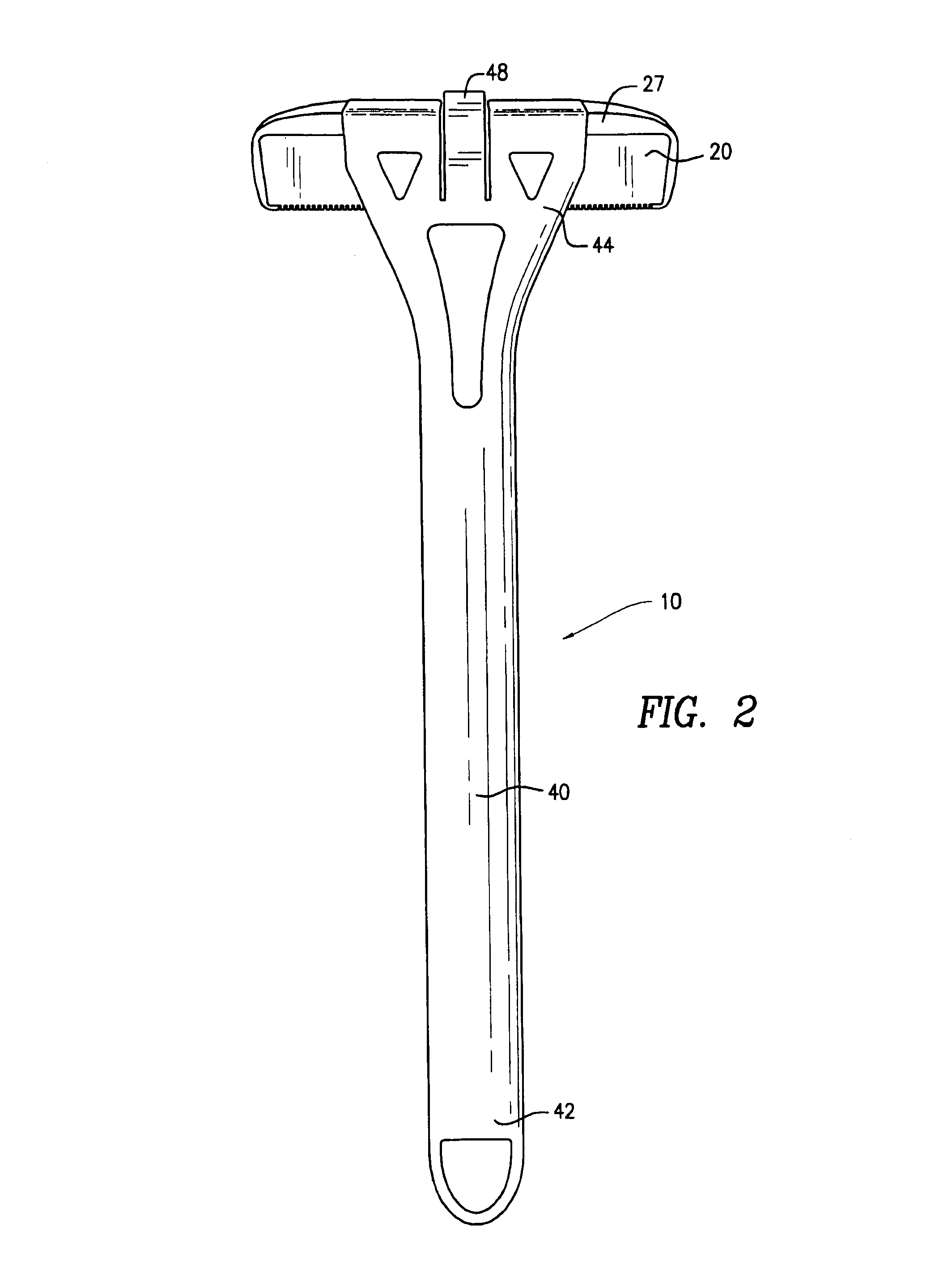

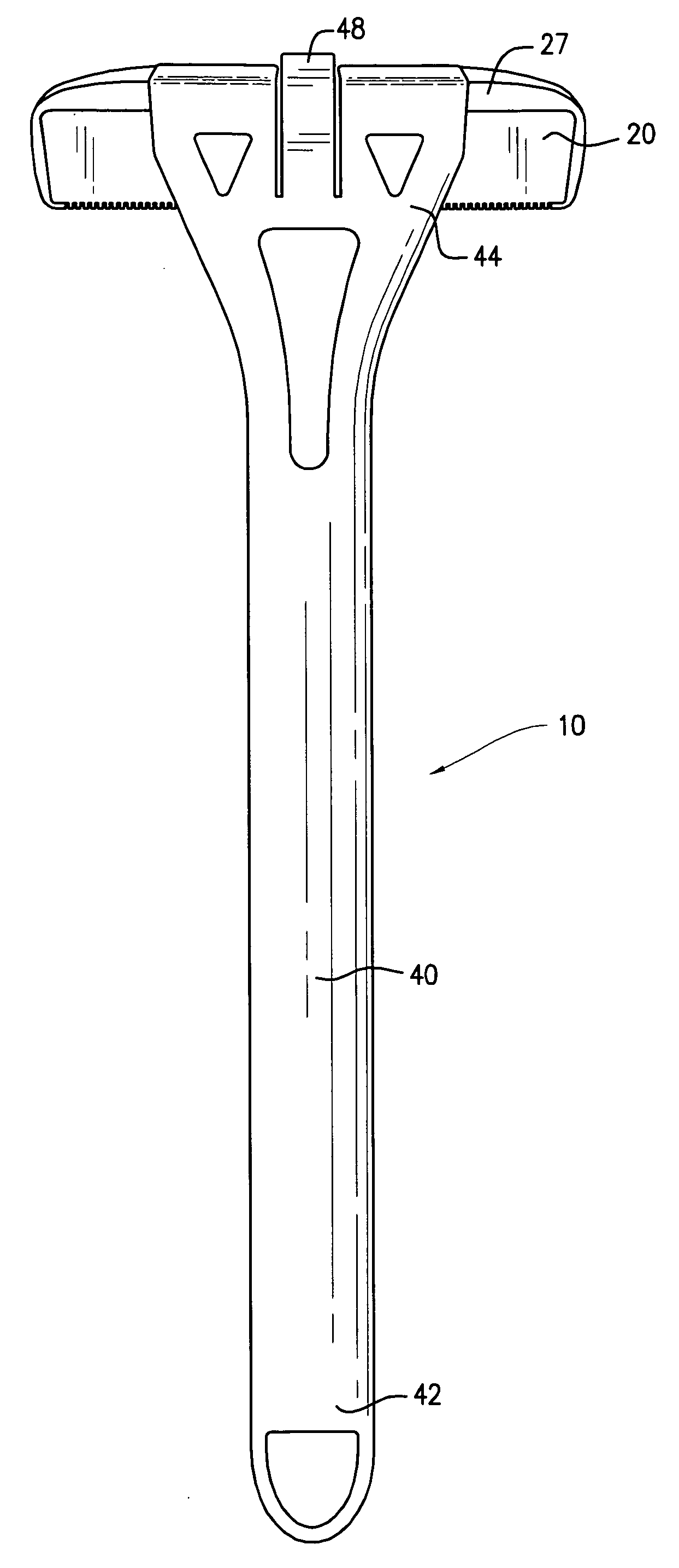

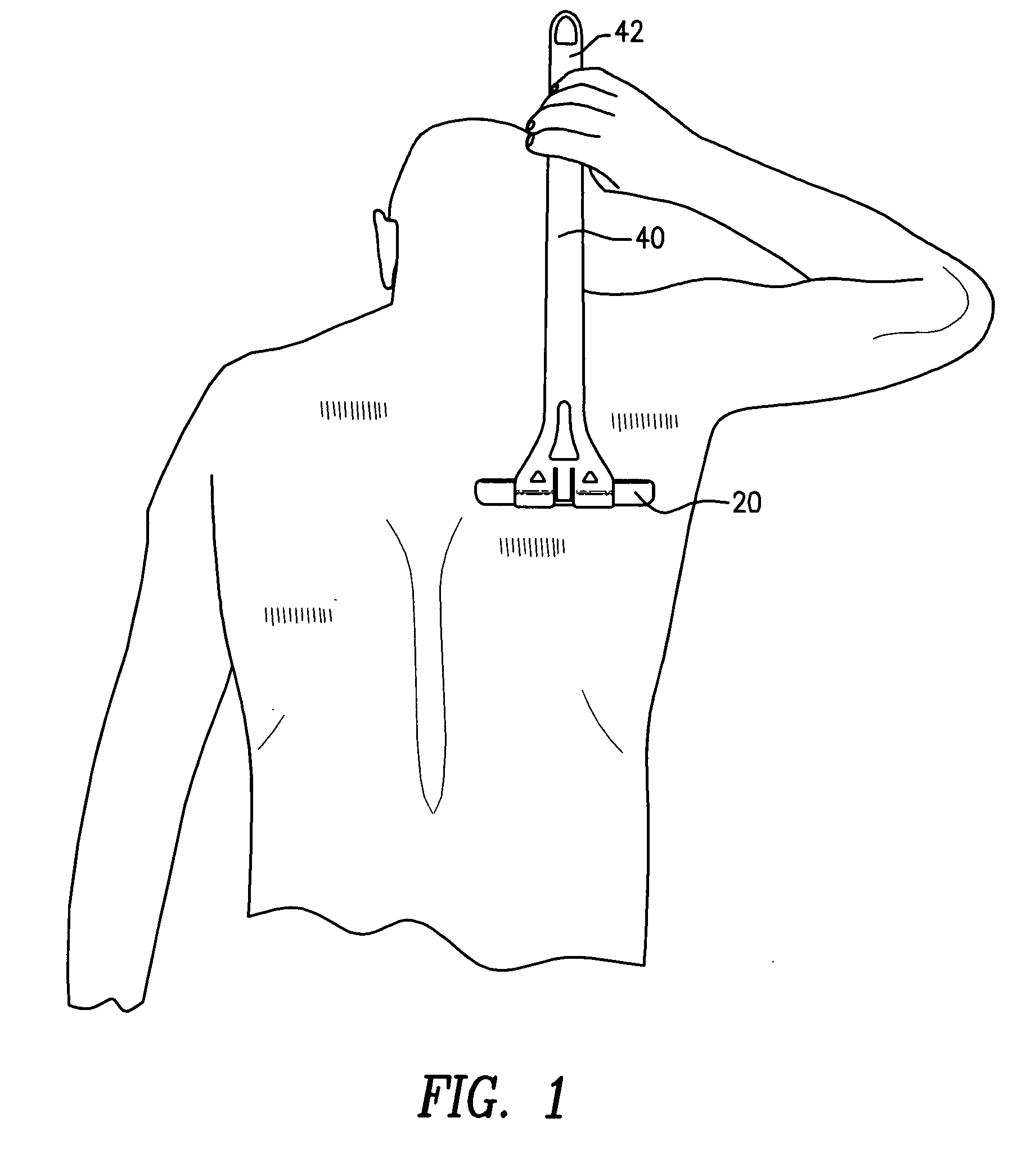

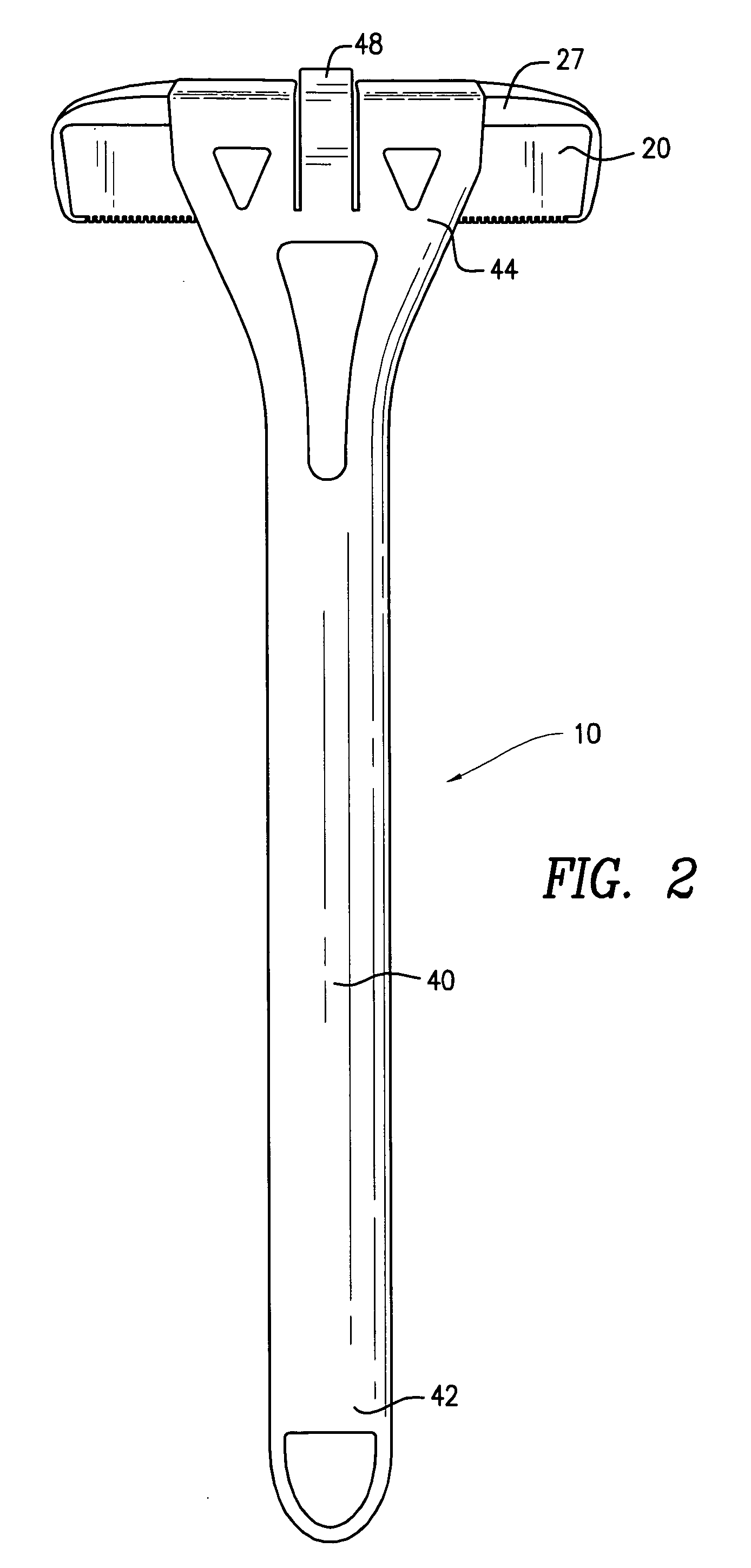

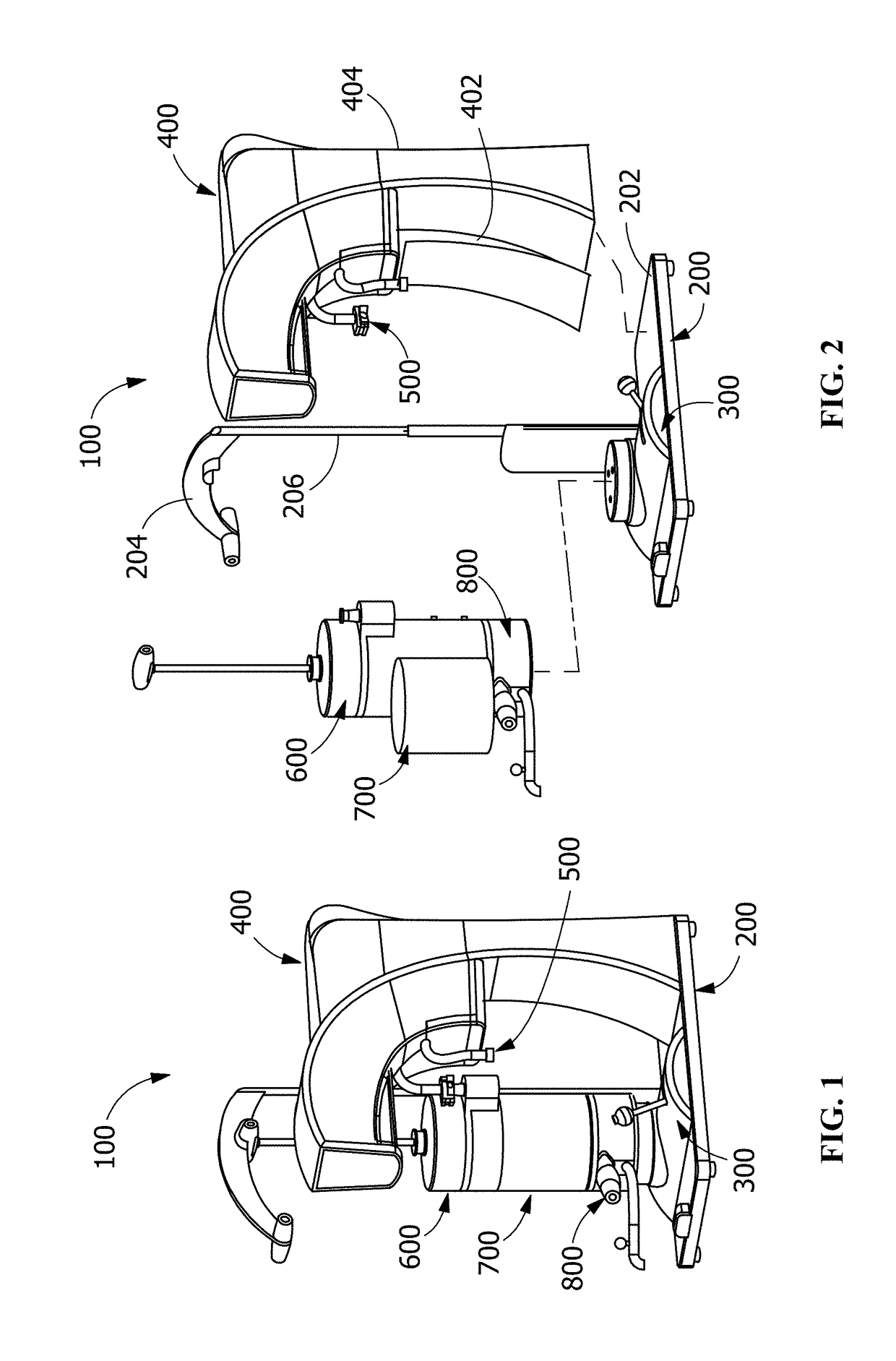

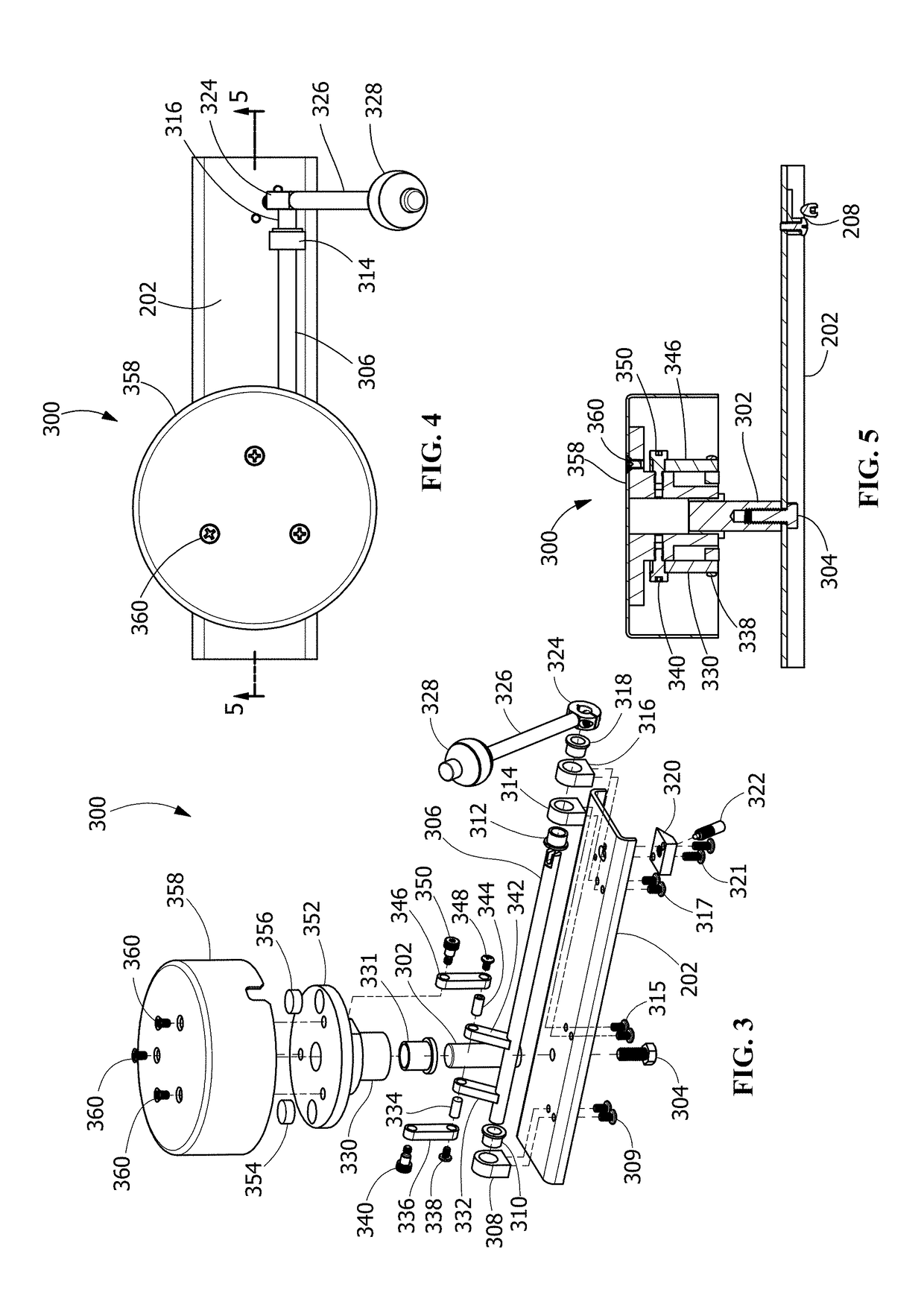

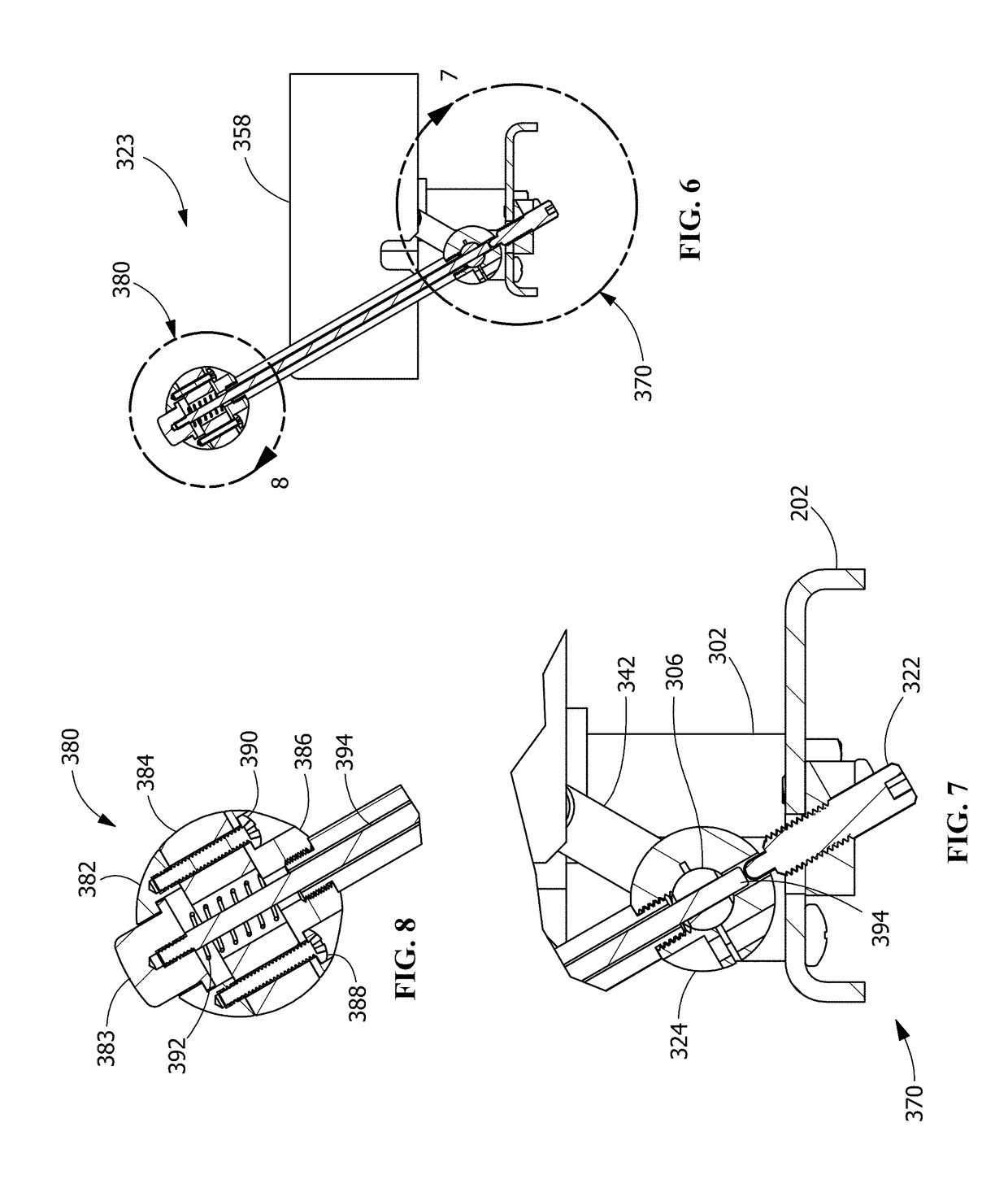

Back hair removal using comb and integrated blade

A method and apparatus of removing hair from the back, shoulders and arms of a man utilizes a device comprising a comb having teeth on a lower end and a blade embedded in the teeth so that a lower active edge of the blade does not reach a lower edge of the teeth and a s result there is no exposed blade and no skin irritation or safety concerns. A rigid or semi-rigid one-piece elongated handle, a proximal end of the handle having a channel shaped to slidably receive the upper end of the comb, the proximal end also having a lever pressing against the comb to hold the comb securely to the proximal end of the handle, the lever capable of being bent to release the comb. The device has a center of gravity approximately one-third of the way down the handle from the proximal end of the handle.

Owner:BAKBLADE LTD

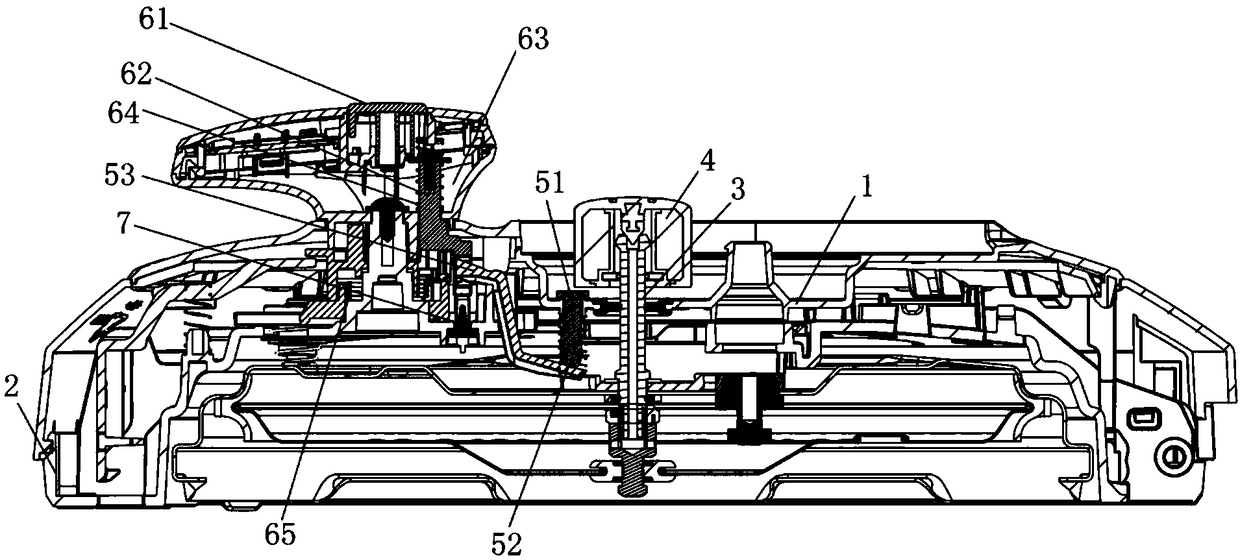

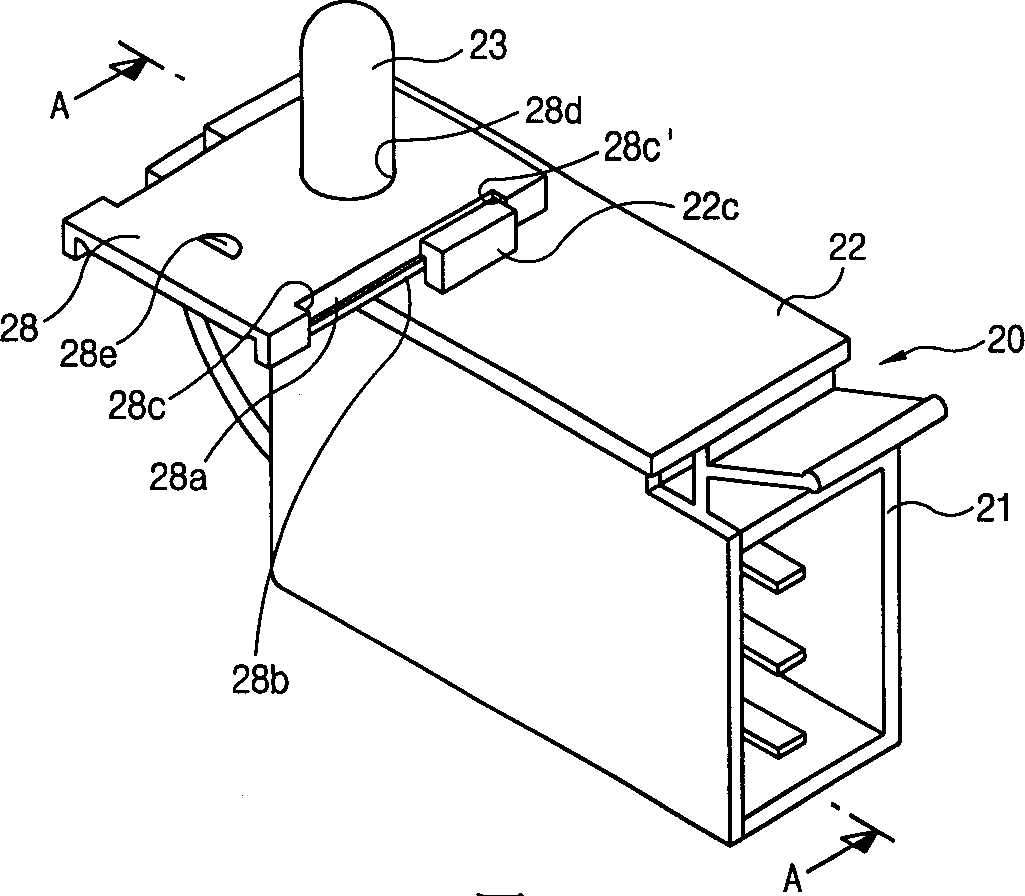

Exhaust device, pressure cooker cover and pressure cooker

ActiveCN106820957BEasy exhaust operationAchieve continuous exhaustPressure-cookersHome applianceEngineering

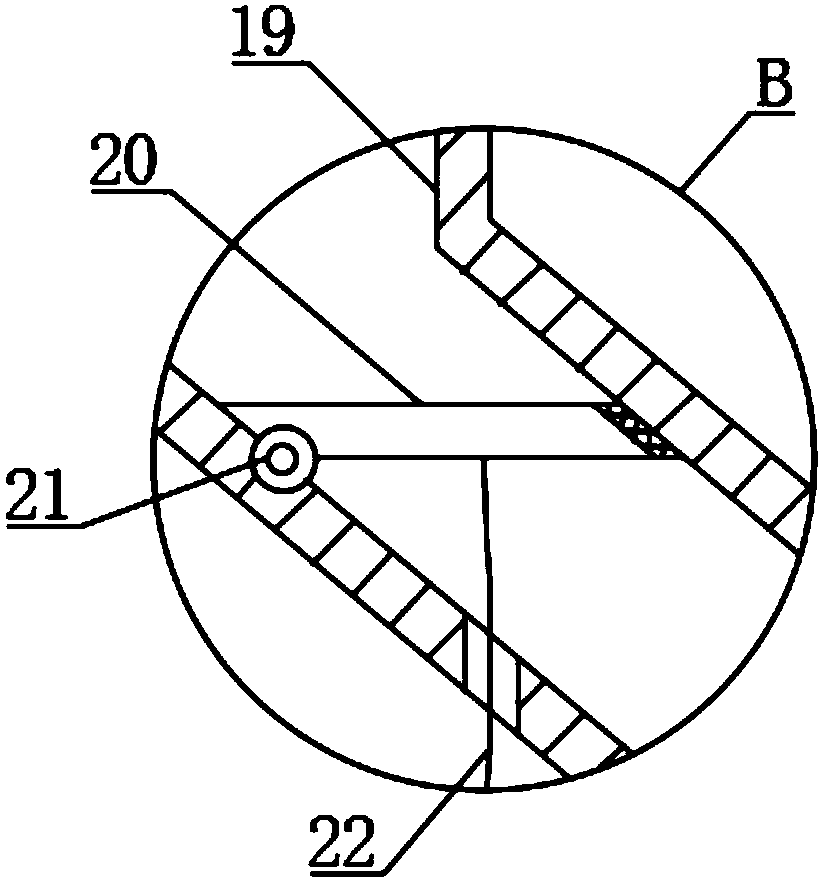

The invention relates to an air exhausting device, a pressure cooker cover and a pressure cooker, and belongs to the technical field of household appliances. The main technical scheme is that the air exhausting device comprises a relief valve, a jacking rod assembly and a control assembly, wherein the relief valve is buckled on an air exhaust pipe of the pressure cooker; the jacking rod assembly is used to jack up the relief valve; the control assembly comprises a control structure, a pressing rod and a limiting structure; the pressing rod can move to a set position under the control of the control structure to apply acting force to the jacking rod assembly, so that the jacking rod assembly jacks up the relief valve; the limiting structure is arranged on an inner cover of the pressure cooker cover, so as to limit the pressing rod to the set position; when the pressure cooker exhausts air, the control structure controls the pressing rod to move to the set position, and the limiting structure limits the pressing rod to the set position, so that the pressure cooker exhausts air continuously; after air exhausting of the pressure cooker is ended, the control structure controls the pressing rod to get away from the set position, so as to reset the relief valve. The air exhausting device, the pressure cooker cover and the pressure cooker are mainly used for facilitating a user to exhaust air out of the pressure cooker and reset the relief valve.

Owner:GREE ELECTRIC APPLIANCES INC

Self-feeding type stone crushing and screening device

The invention discloses a self-feeding type stone crushing and screening device, which comprises a base, a slide rail is arranged on the top of the base, and a rack and a crushing box are respectively slidably connected to the top of the slide rail through a slider; the crushing box is provided with a fixed extrusion plate , a number of sieve holes are evenly arranged on the fixed extrusion plate; support plates are arranged on the left and right sides of the top of the base, and a top plate is arranged on the top of the support plate, and the bottom of the top plate is connected to the second pulley through the rotation of the bracket, and the front surface of the second pulley is fixedly connected to a The driven gear, the bottom of the top plate is also fixedly connected with a deceleration motor through a bracket, the motor shaft at the front end of the deceleration motor is equipped with a driving gear, the top of the front end of the driven gear and the driving gear are all provided with a third pin shaft, and the third pin shaft is rotatably connected with an extrusion pin. The compression rod is hinged with a lifting extrusion plate at the bottom end of the extrusion rod. In the present invention, the lifting extrusion plate moves up and down through the meshing and rotation of the gears to extrude and pulverize the stone material, and the pulverization efficiency is high; the pulverized stones are screened through the sieve holes on the fixed extrusion plate.

Owner:李云

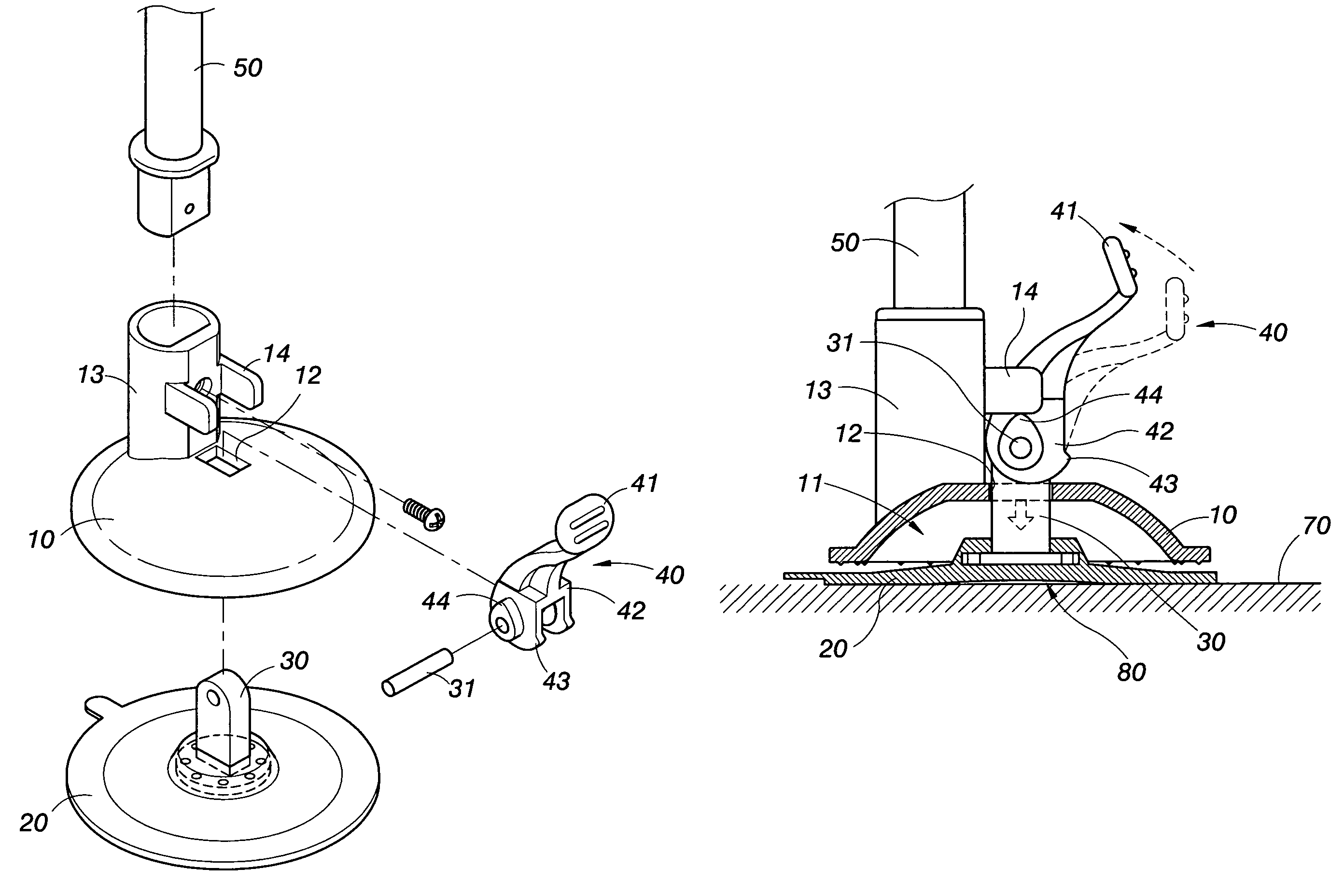

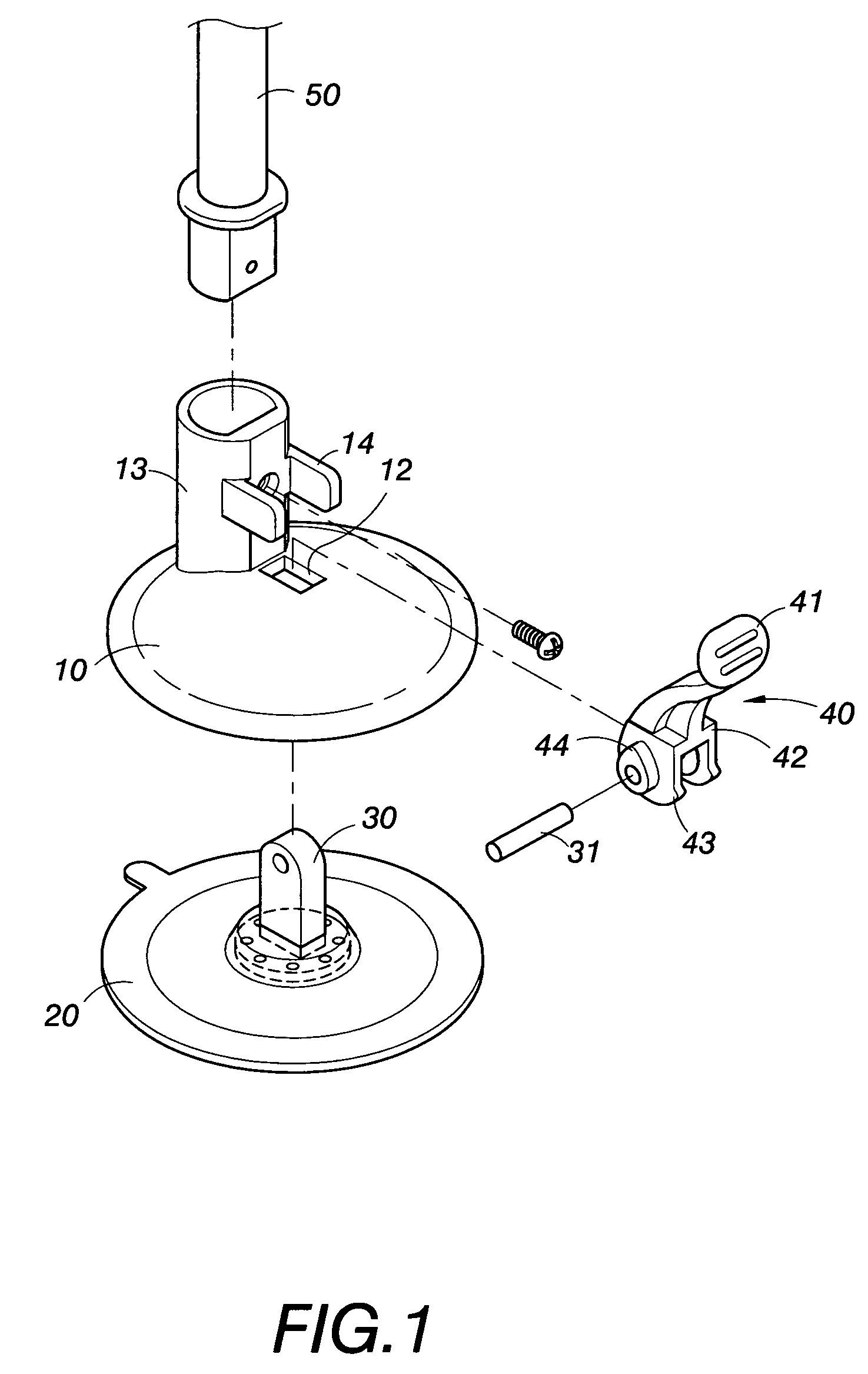

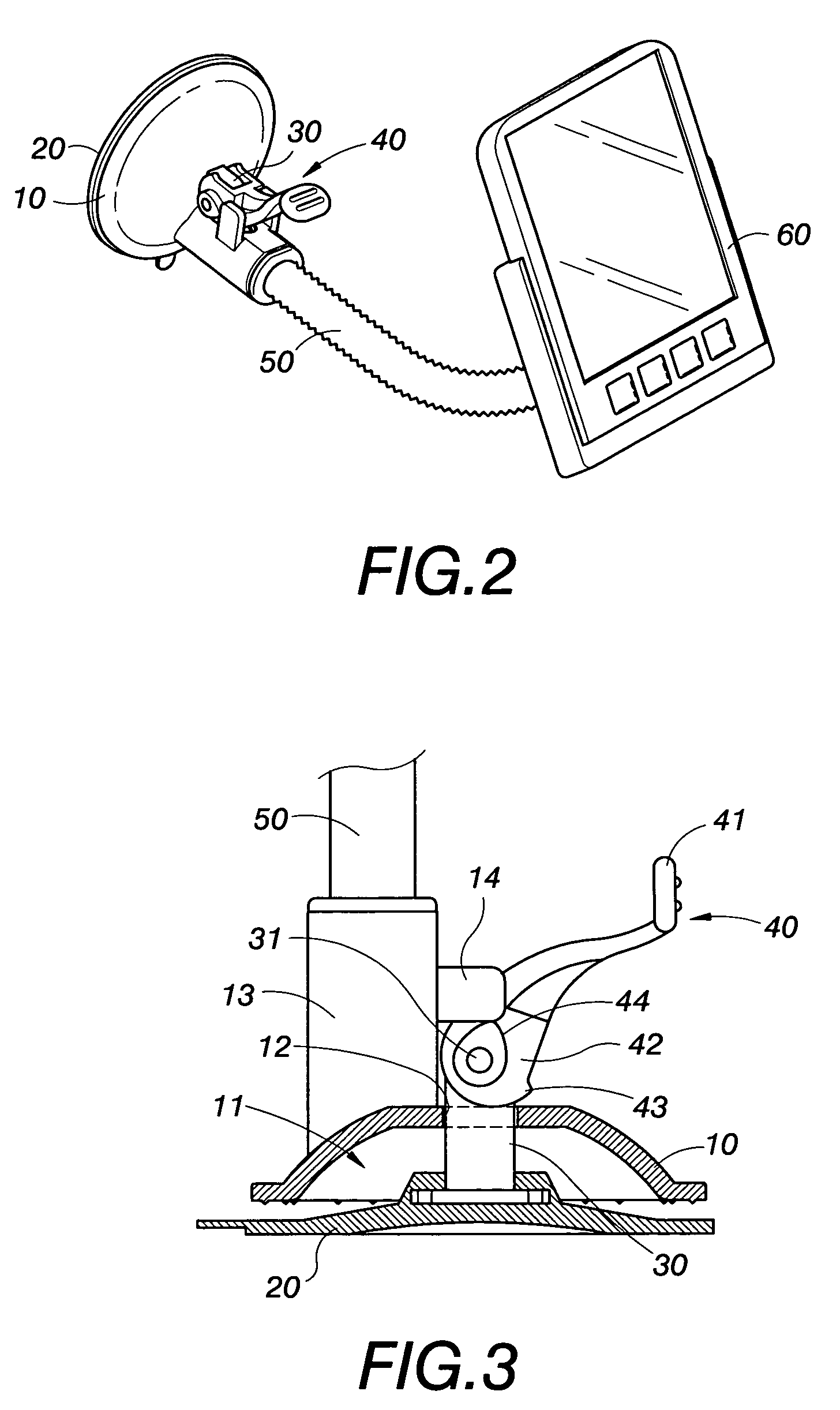

Suction disc unit

A suction disc unit, especially a suction disc unit that can be adsorbed on a smooth surface to support a hung article, it comprises a pressing lid, a suction disc, a link and a pressing rod; wherein the pressing rod at least has a first eccentric protruding portion and a second eccentric protruding portion; when the pressing lid is pulled up to make abutment of the suction disc against the smooth surface by pushing of the pressing rod, the air in the gap between the suction disc and the smooth surface is removed as much as it can; when the pressing rod is pressed down, the pressing lid abuts against the periphery of the suction disc, and the central portion of the suction disc is pulled up tight, the air pressure in the gap is much lower than that of the atmosphere to thereby induce a strong suction force, and thereby to increase the bearing strength of the suction disc unit.

Owner:COMART CORP

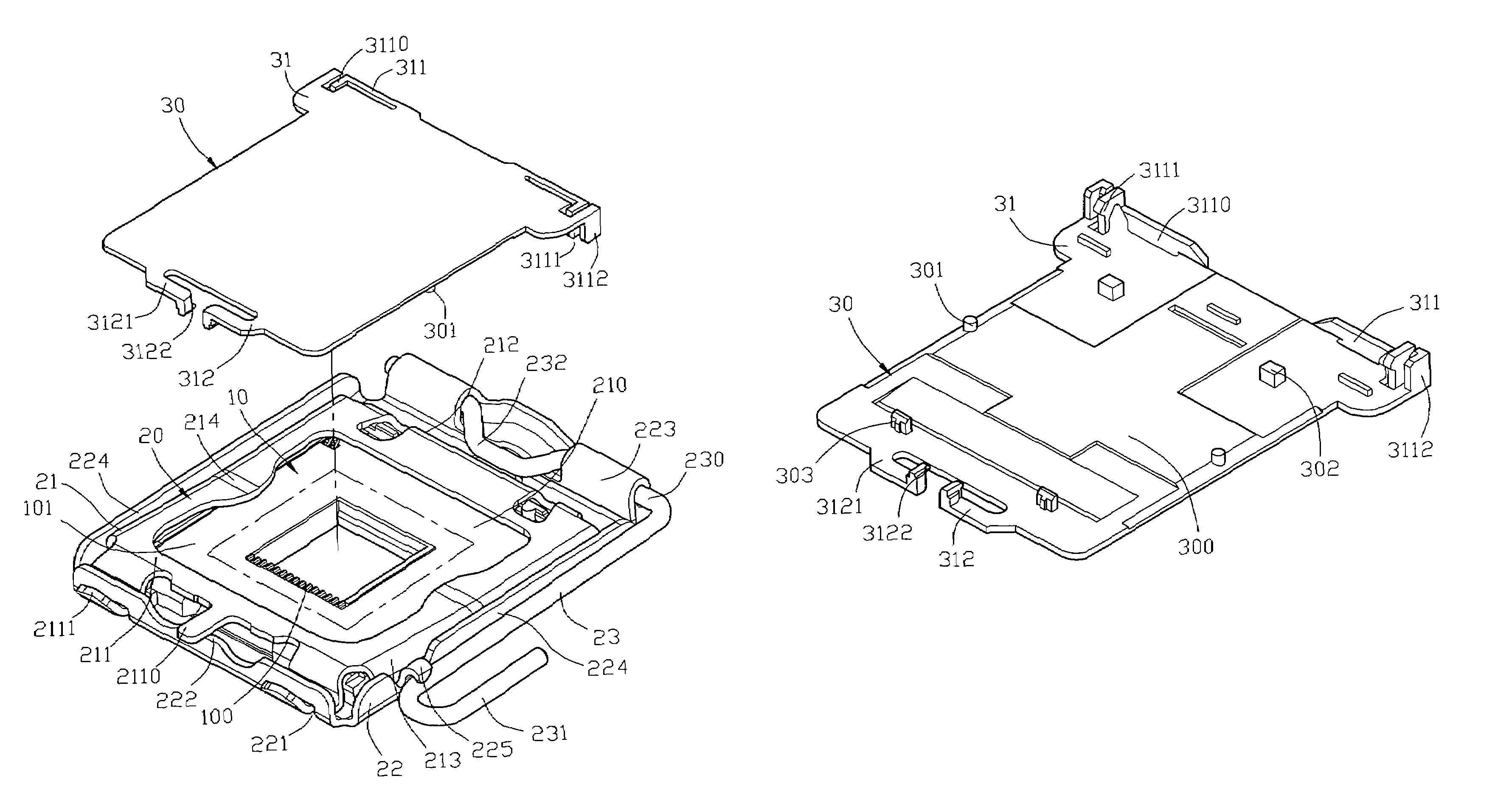

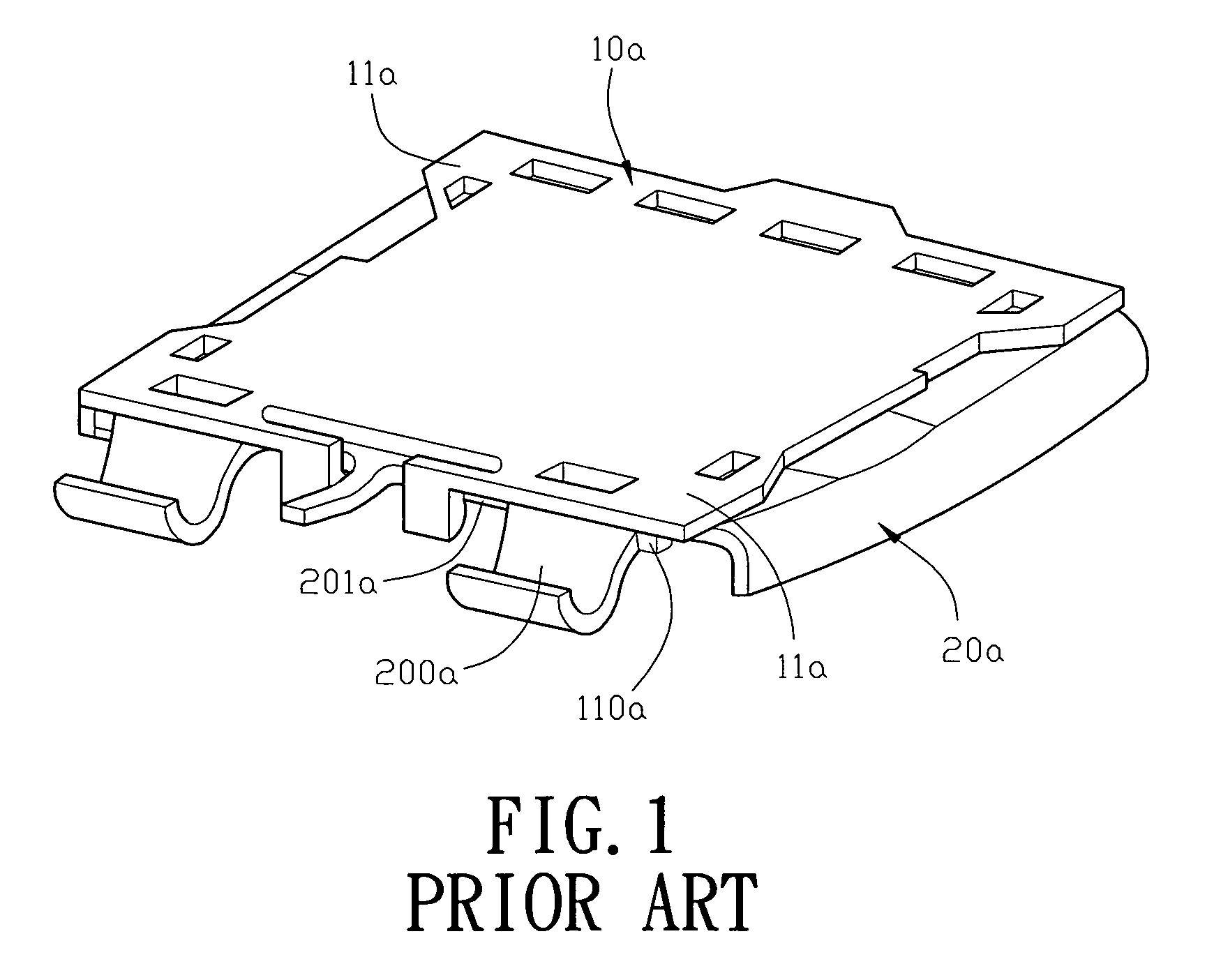

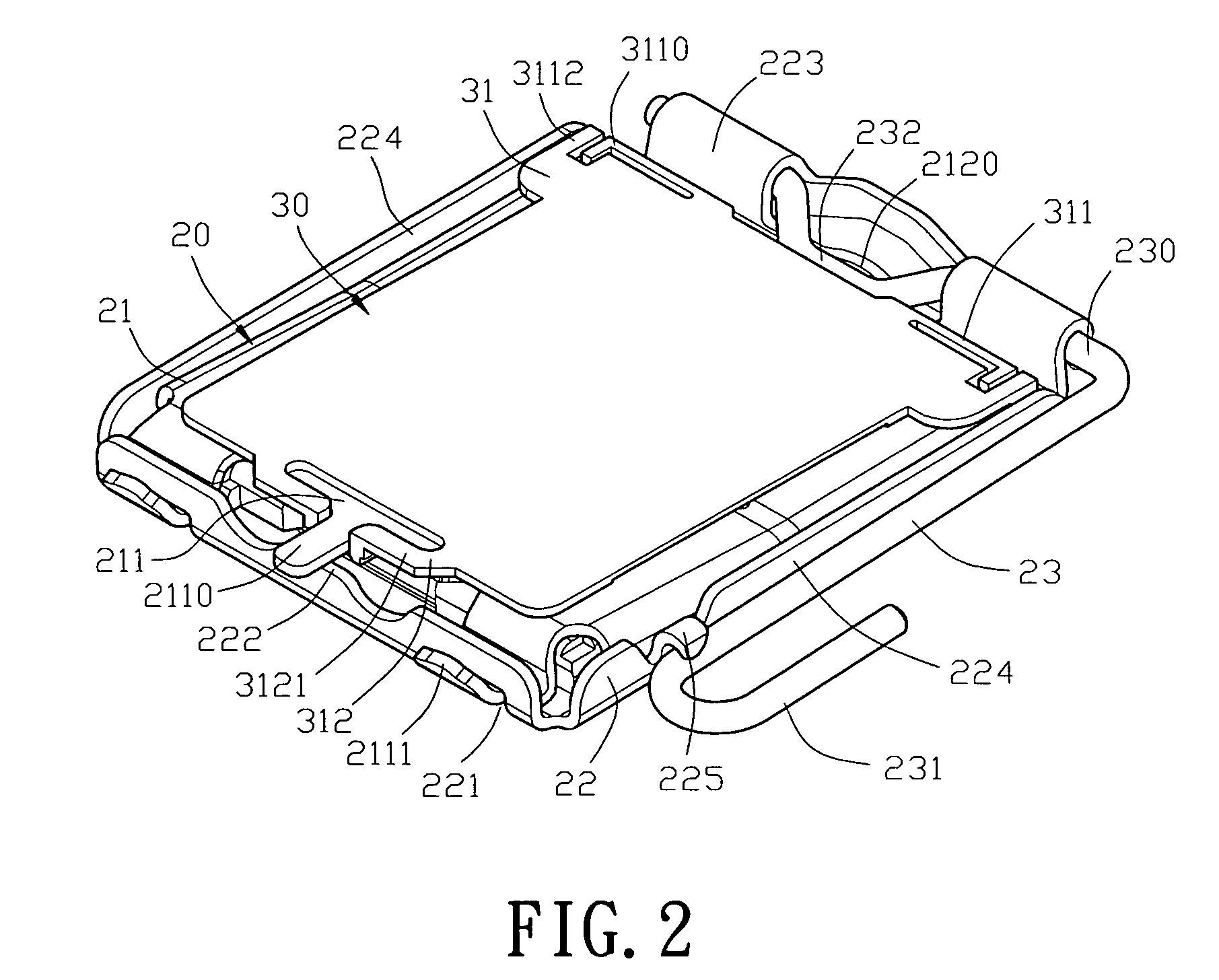

Electrical connector

ActiveUS7575449B1Save time at workEase of mass productionLive contact access preventionElectrical apparatus contructional detailsEngineeringElectrical connector

An electrical connector includes: a fastener having an upper cover, a lower cover and a lever, the upper cover having a first side and a second side opposite to each other, the first side extending to form two pivoting ends pivotingly connected to the lower cover, the second side extending to form a clipping portion, the lever pressing the clipping portion, the lever being pivotingly connected with the lower cover; a cover plate covering the upper cover, both ends of one side of the cover plate being provided with a protruding portion respectively on which a first positioning portion is provided for engaging with the second side of the upper cover, the other side of the cover plate being provided with a set of second positioning portions for engaging with the first side of the upper cover. Thus the production yield is increased, and it is suitable for mass production.

Owner:LOTES

Powder forming machine

The invention is a powder shaping machine which includes a force transmitting mechanism with two symmetric pressure, demoulding rod respectively fits with the pressing and demoulding cams. The connecting rod links together in turn a low mould plate, once and twice plate, pressing head base, and the soleplate. The once and twice pressing plate each has two pressing rods fitting with the pushing rod corresponds upon the low mould plate at the upper side and with the roller in the pressing block at the lower side. The pressing block fits with corresponding positive block fixed on the pressing head base. The cylinder linked with once, twice pressing plate fits with the cylinder on the flexural slipping mechanism base forming the mould stand pressing mechanism. The swing block links with the cylinder on the bridging arm and fits with the block fixed on the block box on the stand and the pushing rod on the bridging arm. The cylinder on the machine stand fits with the bridging arm forming the demoulding mechanism. The structure is simpler by leave off the original intermediate swing arm and the dual force transmitting mechanism transmits the force uniformly safely and stably especially suitable for large shaping machine of large tonnage with a product of uniform intensity at every steps.

Owner:严培义 +1

Back hair removal using comb and integrated blade

A method and apparatus of removing hair from the back, shoulders and arms of a man utilizes a device comprising a comb having teeth on a lower end and a blade embedded in the teeth so that a lower active edge of the blade does not reach a lower edge of the teeth and a s result there is no exposed blade and no skin irritation or safety concerns. A rigid or semi-rigid one-piece elongated handle, a proximal end of the handle having a channel shaped to slidably receive the upper end of the comb, the proximal end also having a lever pressing against the comb to hold the comb securely to the proximal end of the handle, the lever capable of being bent to release the comb. The device has a center of gravity approximately one-third of the way down the handle from the proximal end of the handle.

Owner:BAKBLADE LTD

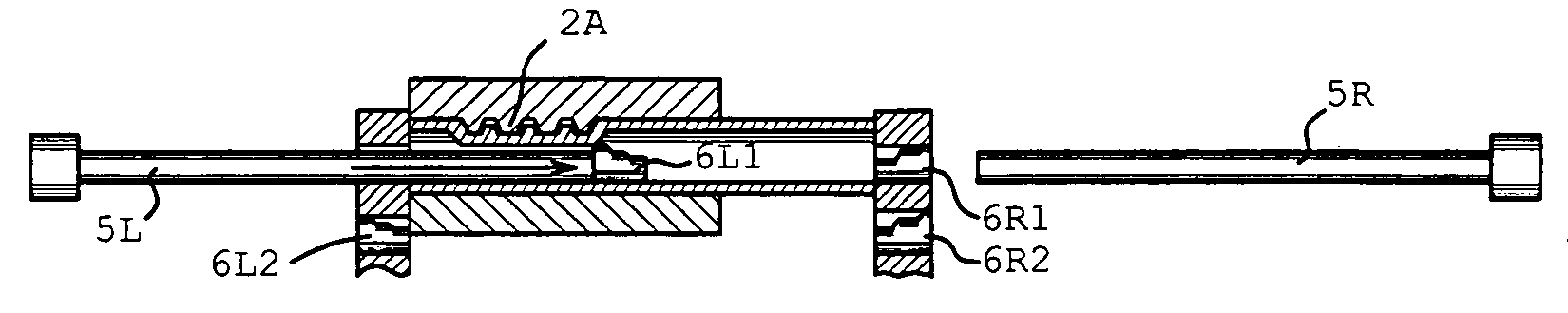

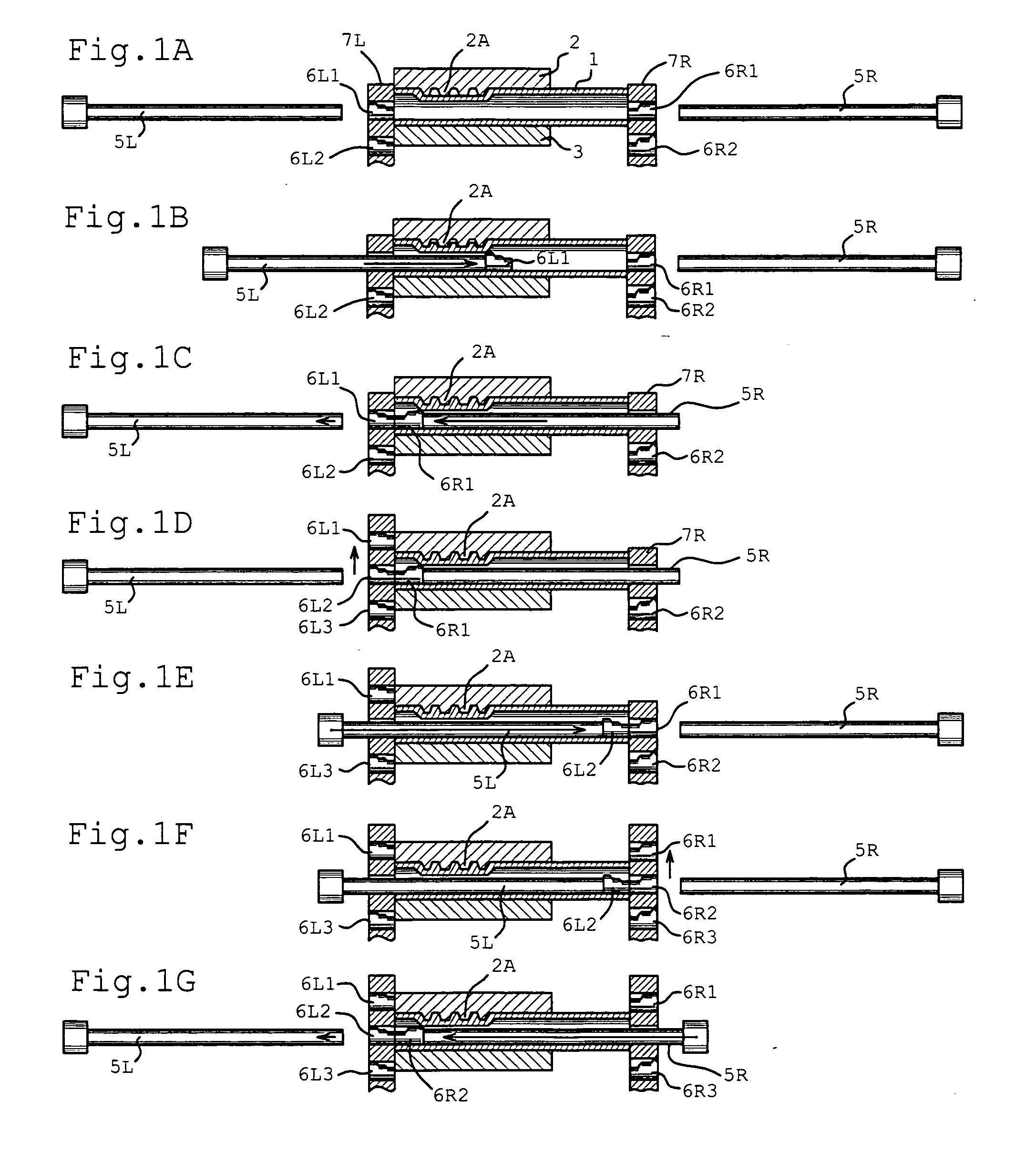

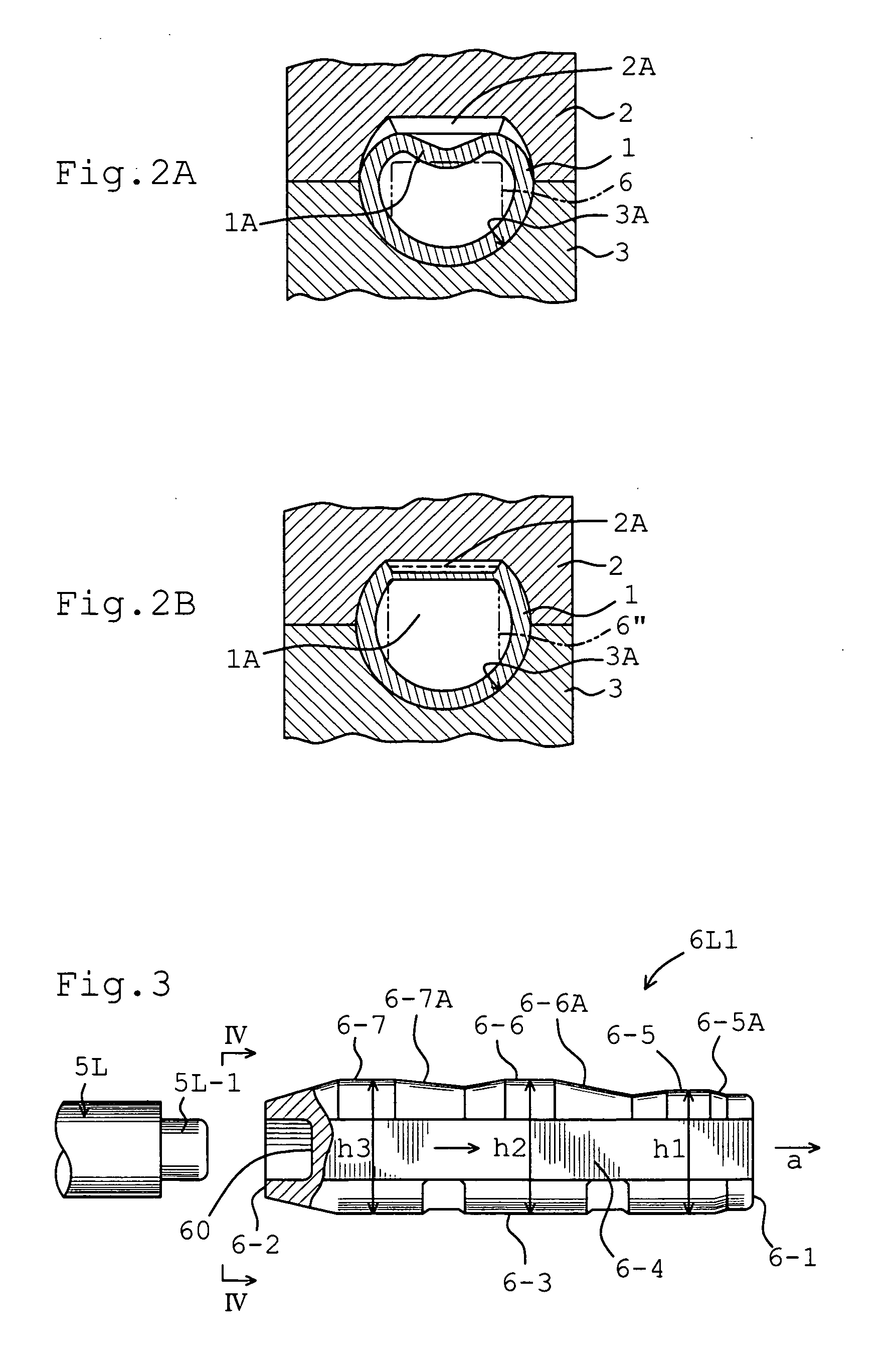

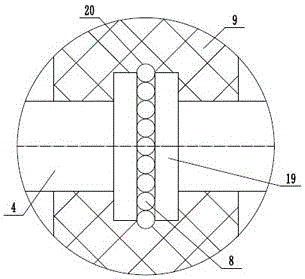

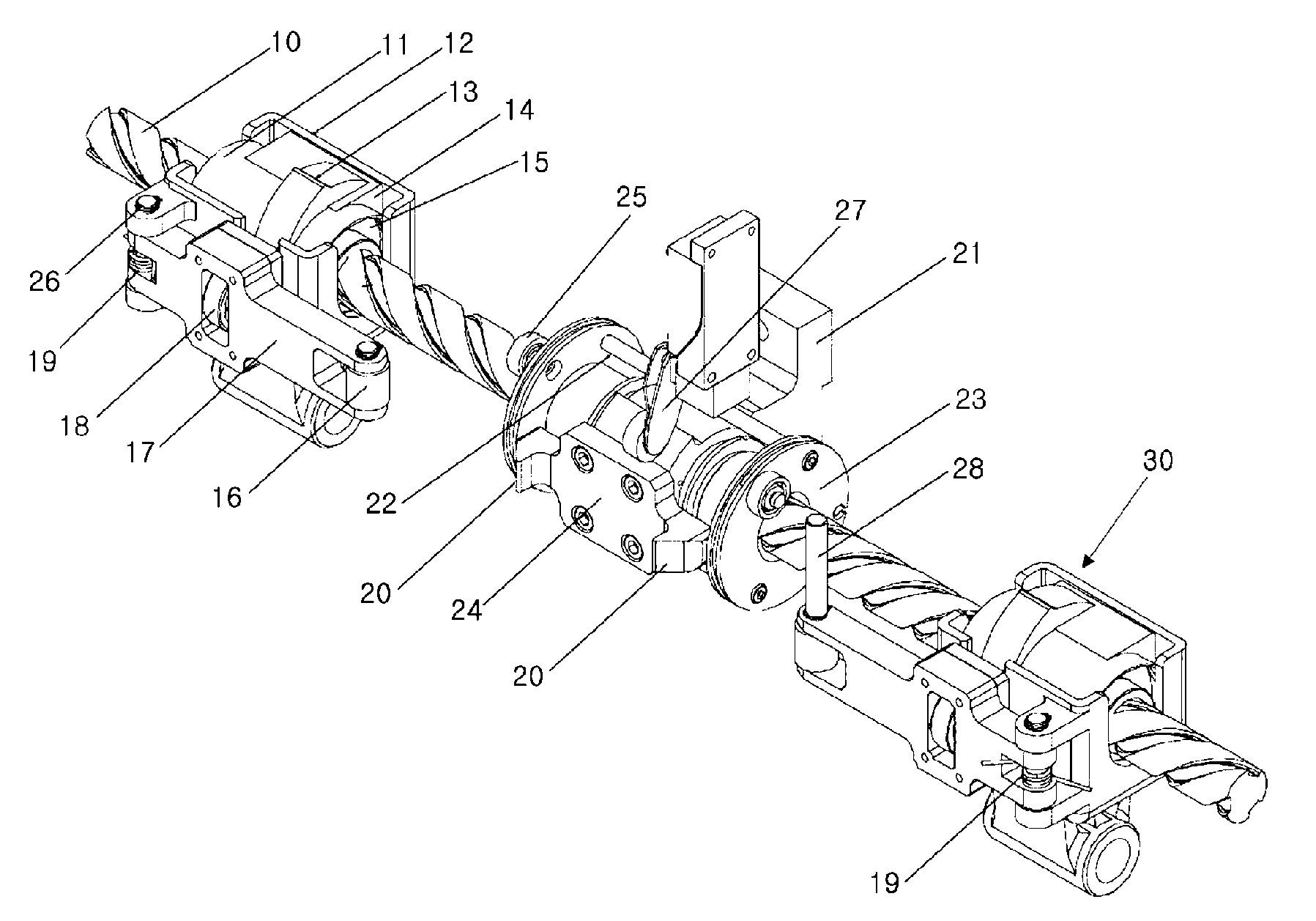

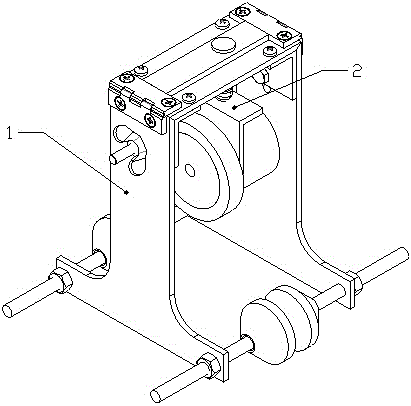

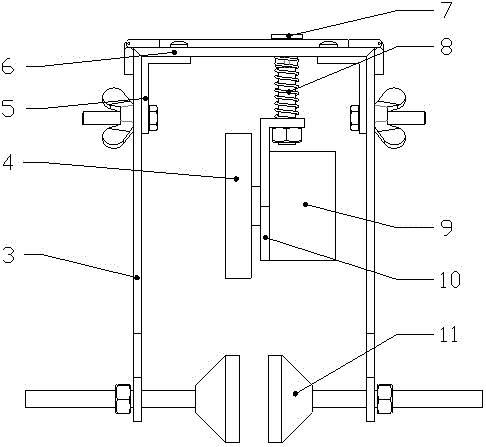

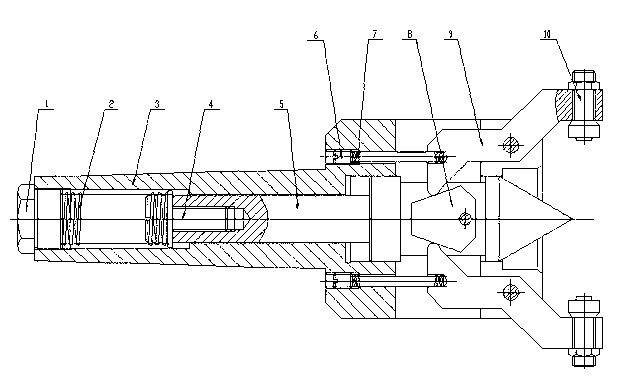

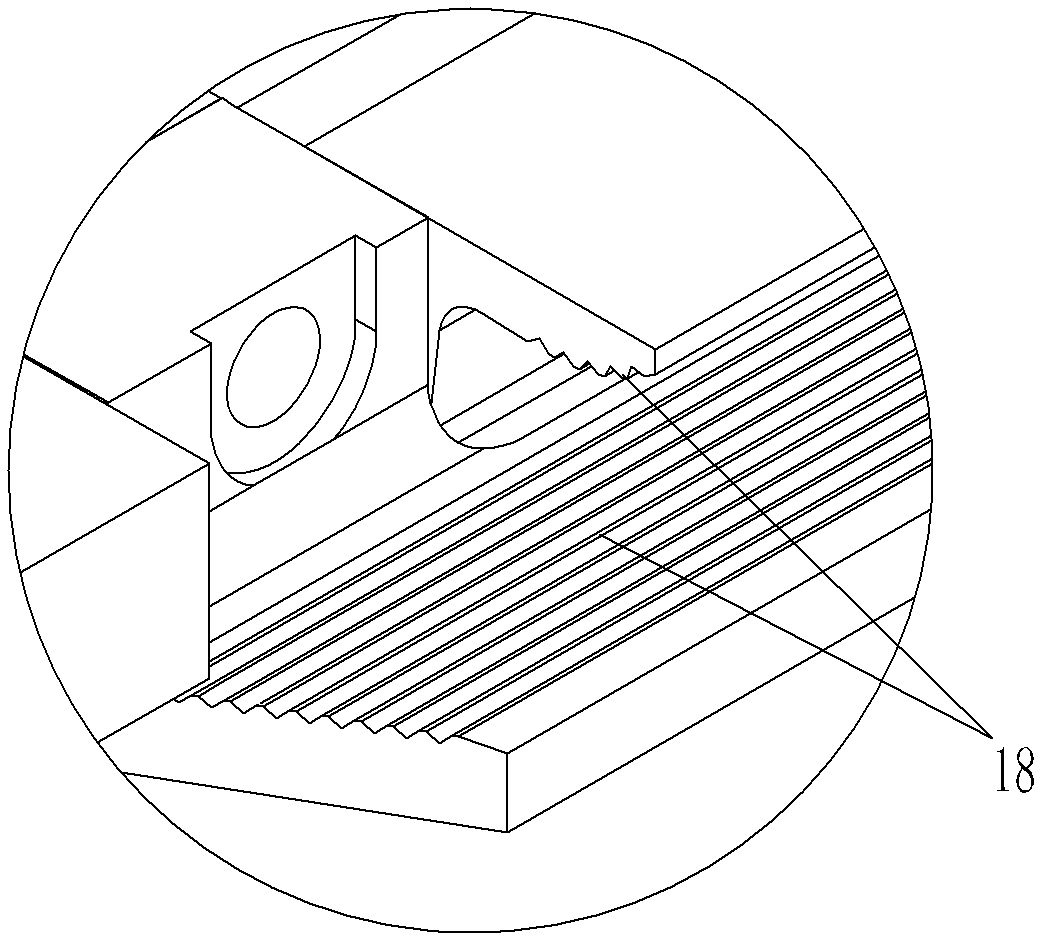

Method and apparatus for producing hollow rack bar and mandrel used for rack bar production

InactiveUS20060016238A1Low costLow running costNutsMetal-working apparatusEngineeringMechanical engineering

A system for forging a rack bar from a blank pipe. A blank pipe 1 is held between dies 2 and 3. Stockers 7L and 7R are arranged on respective sides of the die set. In the stockers 7L and 7R, left-handed shuttles 6L1, 6L2, 6L3, . . . 6Ln and right-handed shuttles 6R1, 6R2, 6R3 . . . 6Rn are stored. First, a left-handed presser rod 5L inserts the shuttles 6L1 to the blank pipe from the left-handed stocker 7L. Then, a right-handed presser rod 5R inserts the shuttles 6R1 to the blank pipe from the right-handed stocker 7R, causing the shuttles 6L1 to be entrained and returned to the left-handed stocker 7L. Vertical shift movement is alternately executed between the left-handed and right-handed stockers 7L and 7R, so that a shuttle of step-likely increased working height is selected for executing a working process.

Owner:MATSUOKA MINAKO +2

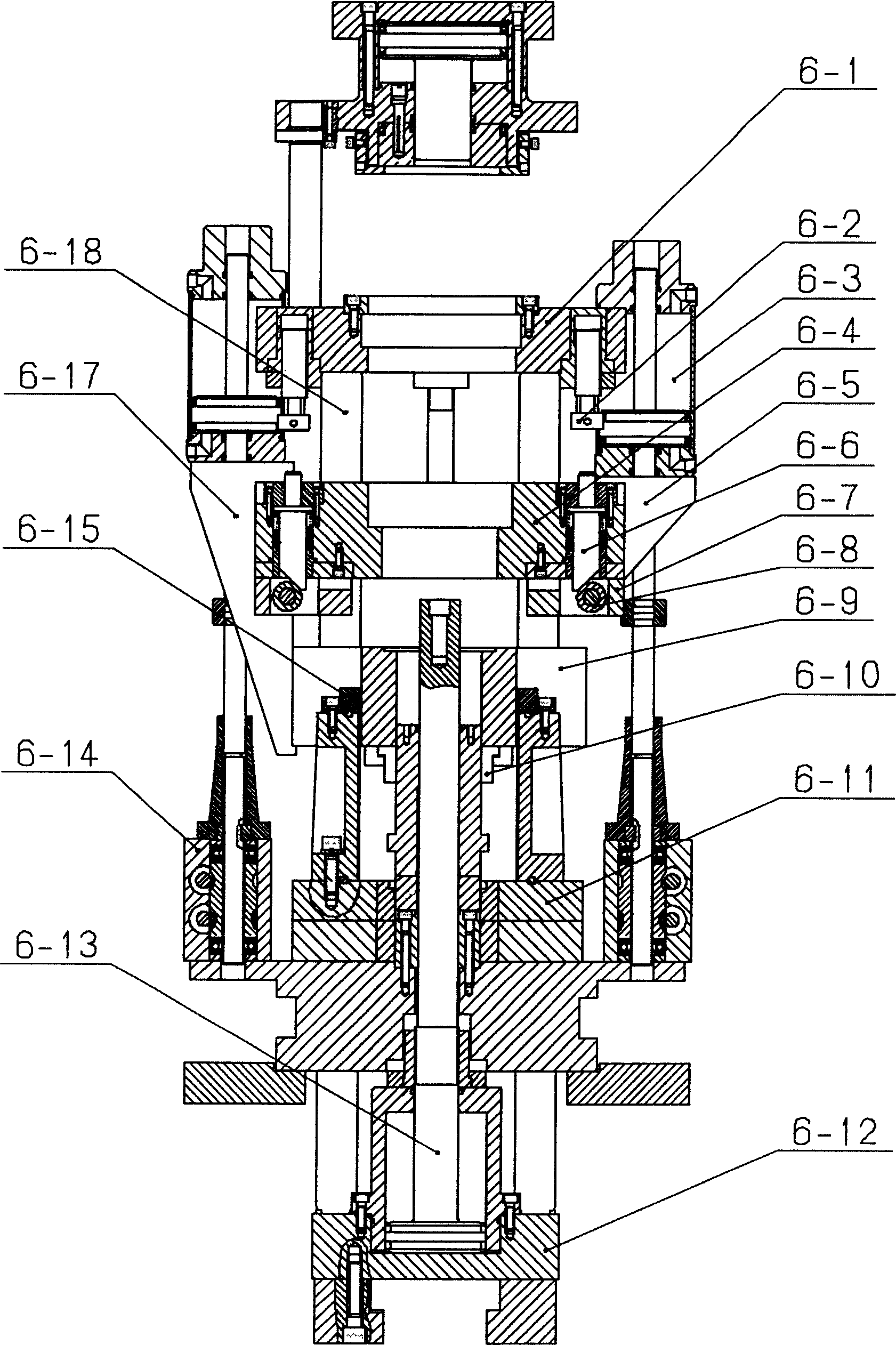

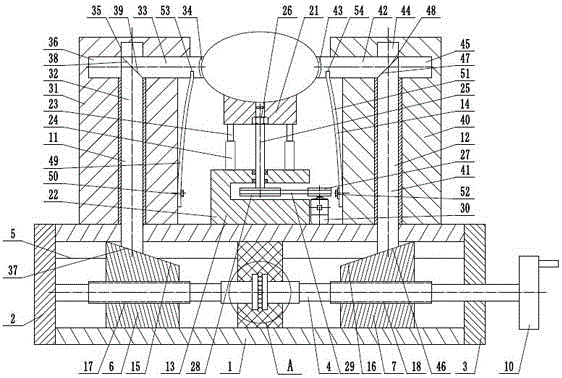

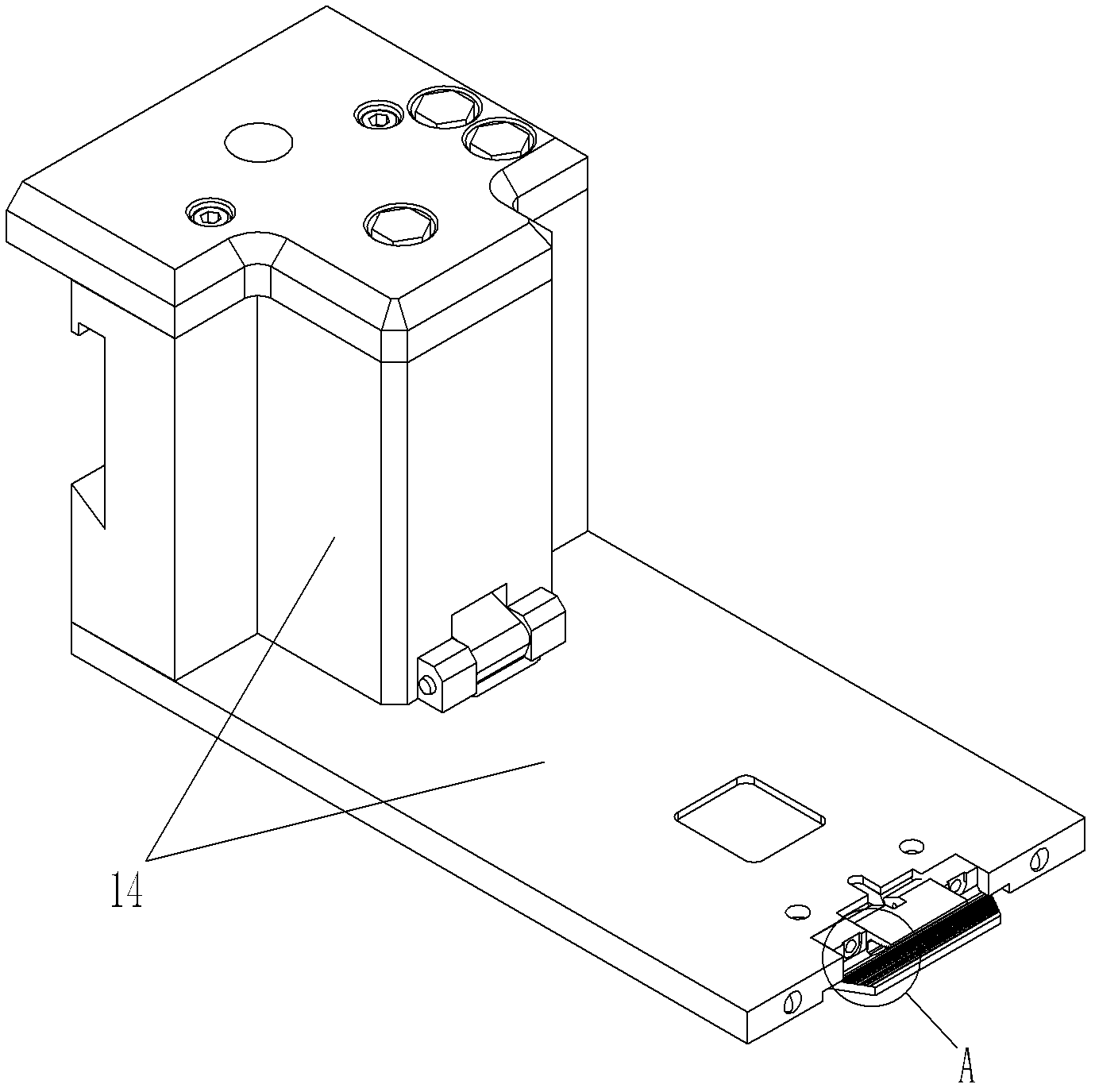

Centering clamping apparatus of ellipsoidal workpiece

PendingCN106826294APrevent axial slippageAchieve peace of mindPositioning apparatusMetal-working holdersLever pressingScrew thread

The invention provides a centering clamping apparatus of an ellipsoidal workpiece, which belongs to the technical field of a clamping device. The centering clamping apparatus comprises a screw, a left slide block, a right slide block, a left centering clamping assembly, a right centering clamping assembly, a height adjusting assembly and a return assembly, wherein both the left slide block and the right slide block can be arranged on a guiding seat in a sliding manner, a left threaded section of the screw is connected with the left slide block in a threading manner, a right threaded section of the screw is connected with the right slide block in a threading manner, a carrier frame of the height adjusting assembly is arranged on a fixed seat in an up-down sliding manner by virtue of a guide rod and a guide column, a left centering clamping assembly and a right centering clamping assembly are symmetrically arranged at the left side and the right side of the height adjusting assembly, the lower end of a left leaf spring of the return assembly is installed on a left supporting frame by virtue of a left nail, and the upper end of a right leaf spring is inserted into a right clamping groove of a right centering pressure rod. The centering clamping apparatus not only rapidly centers and clamps the ellipsoidal workpiece and is reasonable in structure, but also can be suitable for various models of ellipsoidal workpieces, and is high in universality.

Owner:全彬强

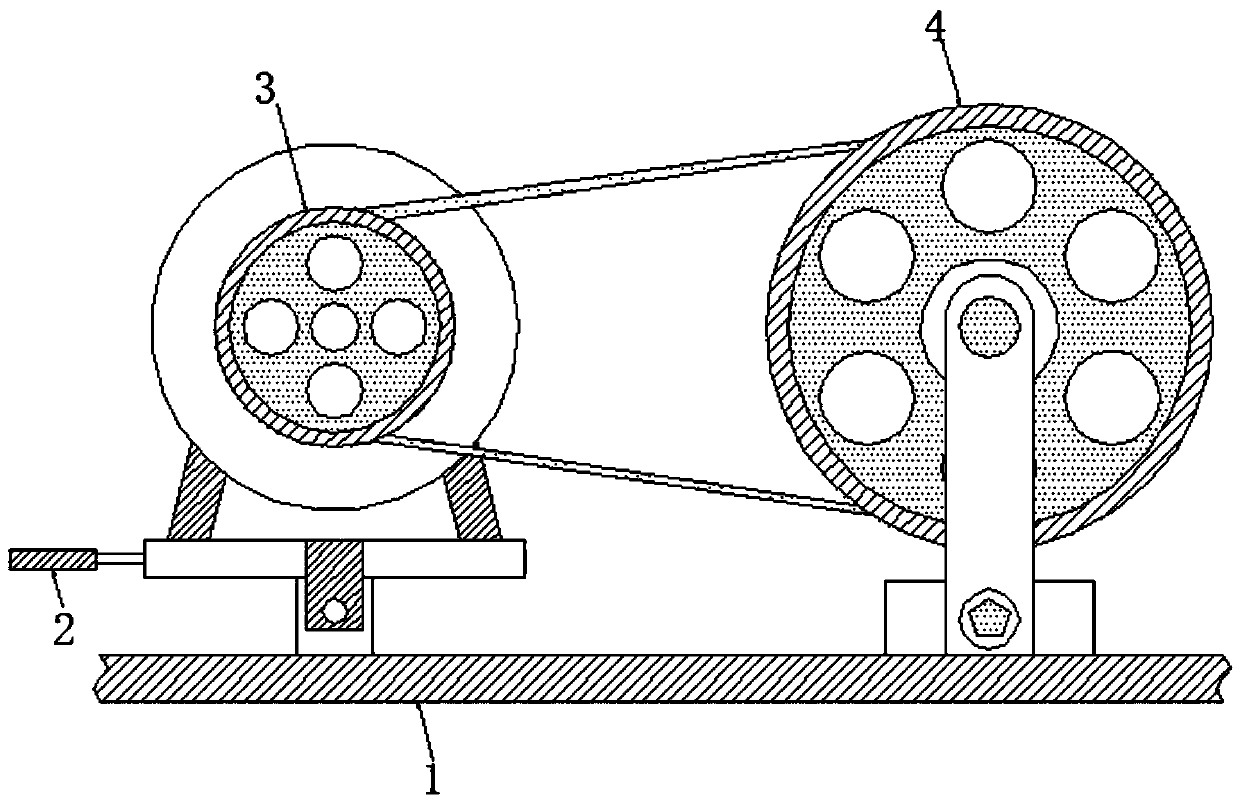

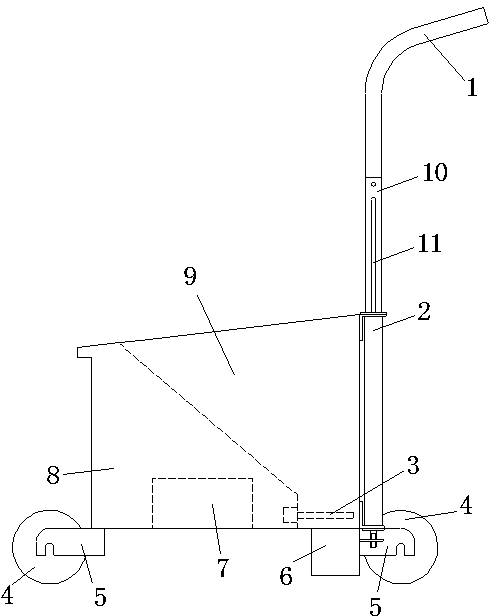

Winding device for ensuring coil thickness to be kept constant by thickness variation

The invention relates to the technical field of electric power, and further discloses a winding device for ensuring the coil thickness to be kept constant by utilizing the thickness variation. The winding device comprises a bottom plate, the upper portion of the bottom plate is movably connected with a pressing rod, the position of a first rotating wheel is controlled by the movement of the pressing rod, thereby, and the rotation of a second rotating wheel is controlled. Through cooperative use of a limiting plate and the pressing rod, the winding is automatically stopped when a set thicknessis reached, the thickness in the winding process is guaranteed to be kept constant, and the stability of the product is guaranteed; through cooperative use of a lower cutting rod and an upper cuttingrod, automatic cutting is carried out after quantitative winding is completed, the intelligence of the whole device is improved, and the working efficiency is improved; through cooperative use of a clamping plate, a gear and a cam, clamping is carried out synchronously in the shearing process, the coil is prevented from loosening after shearing, the coil is fixed; and through cooperation of a rotating shaft and a fixing block, and the rotating shaft can move left and right in the winding process, so that the winding is more uniform.

Owner:柏仕海

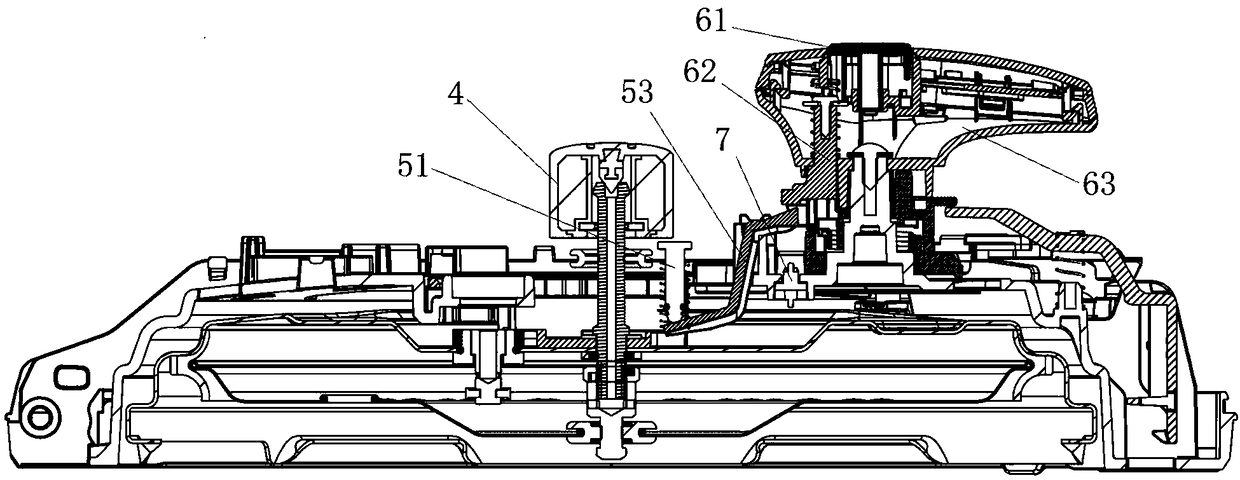

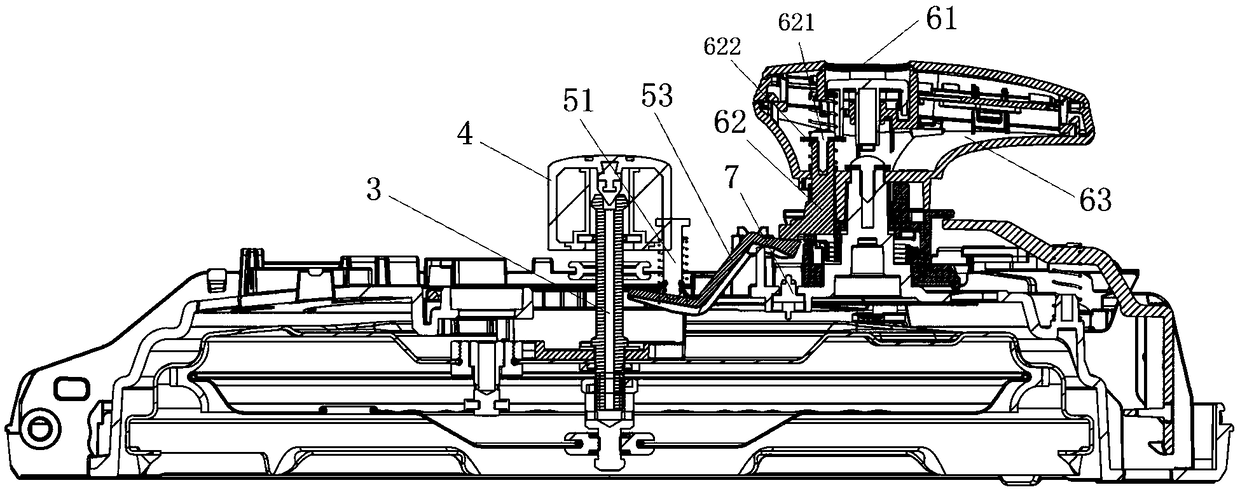

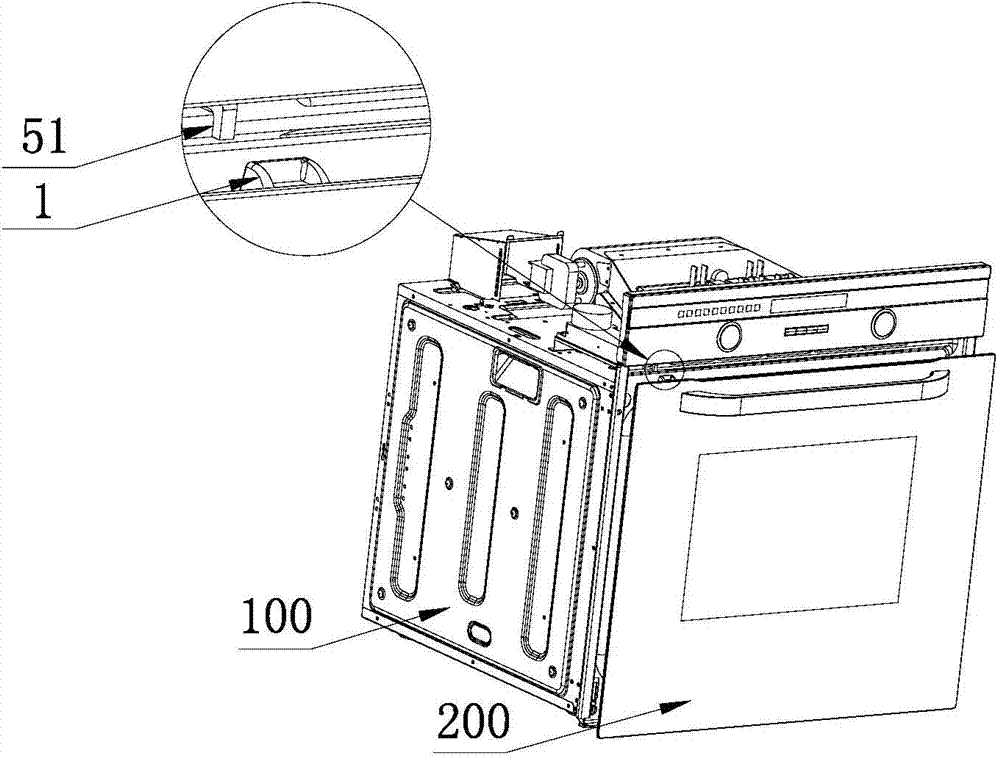

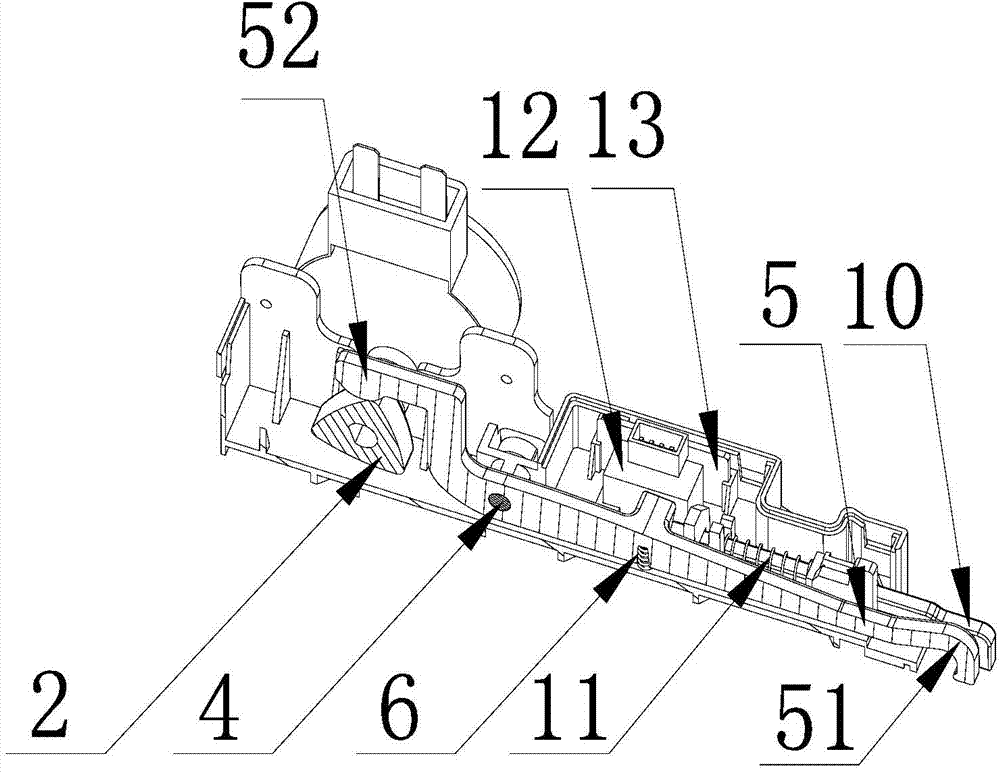

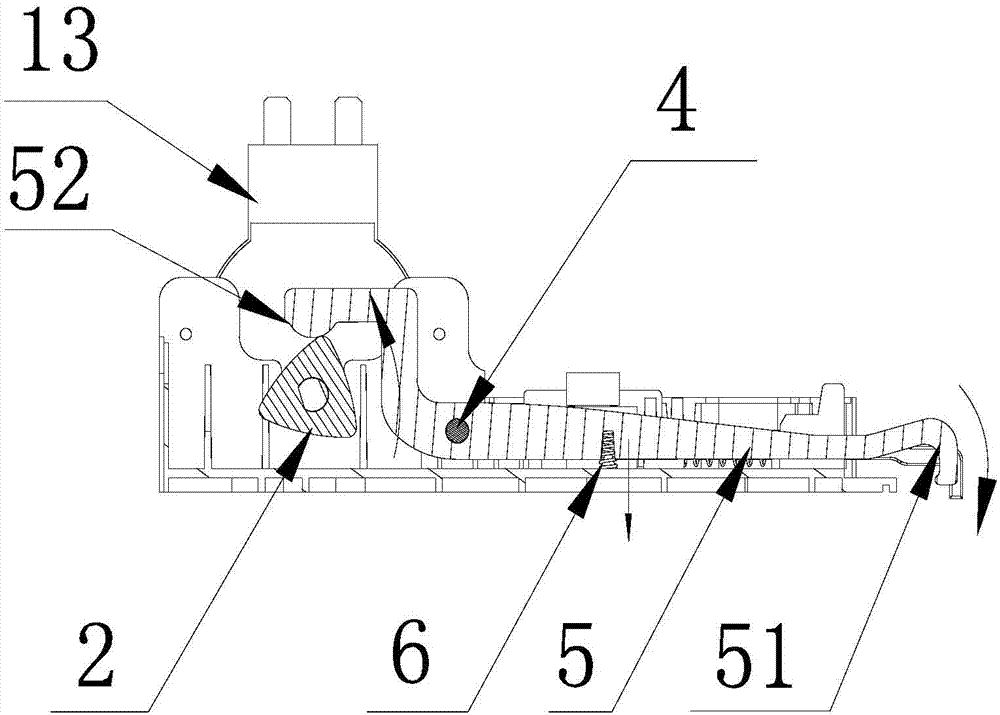

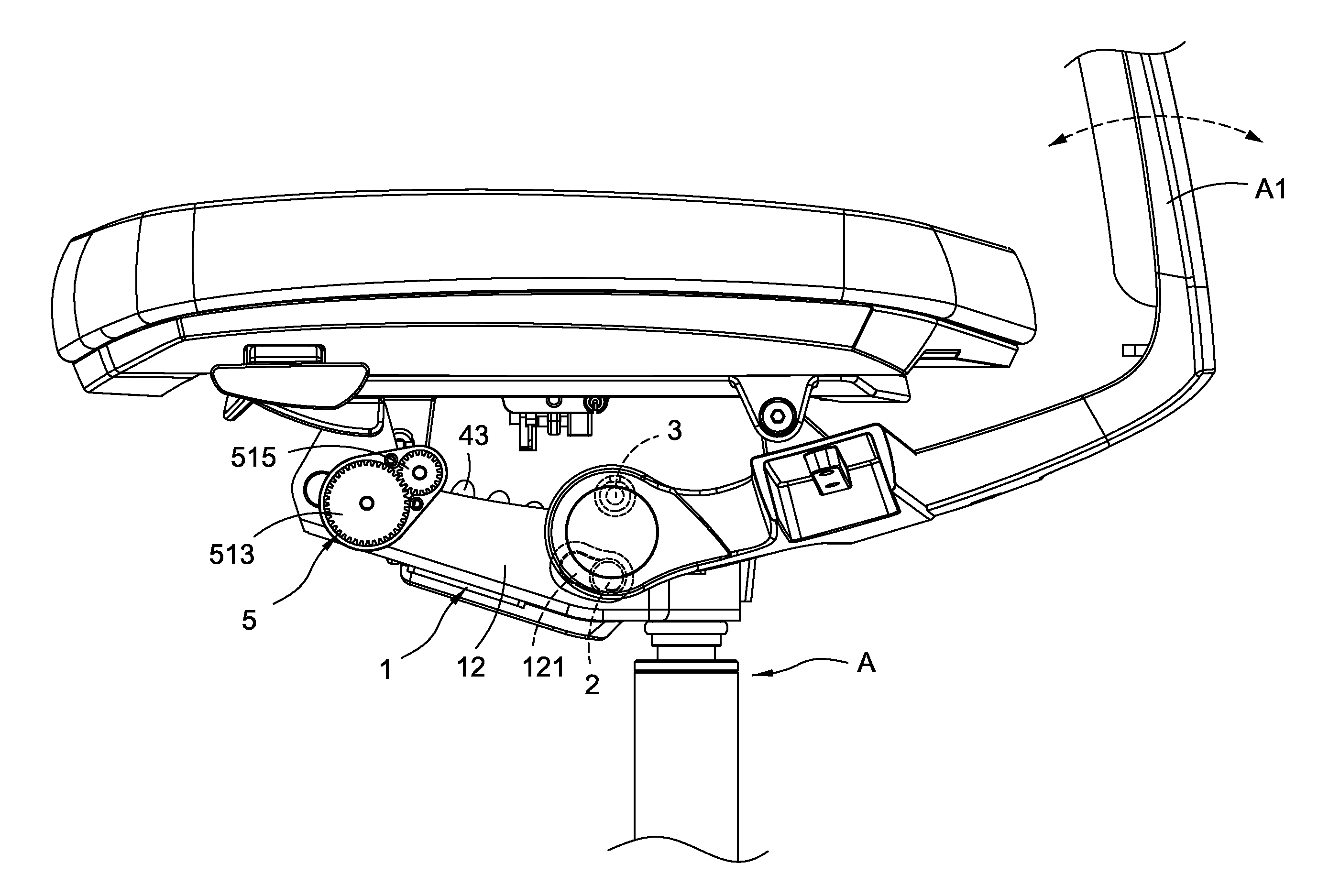

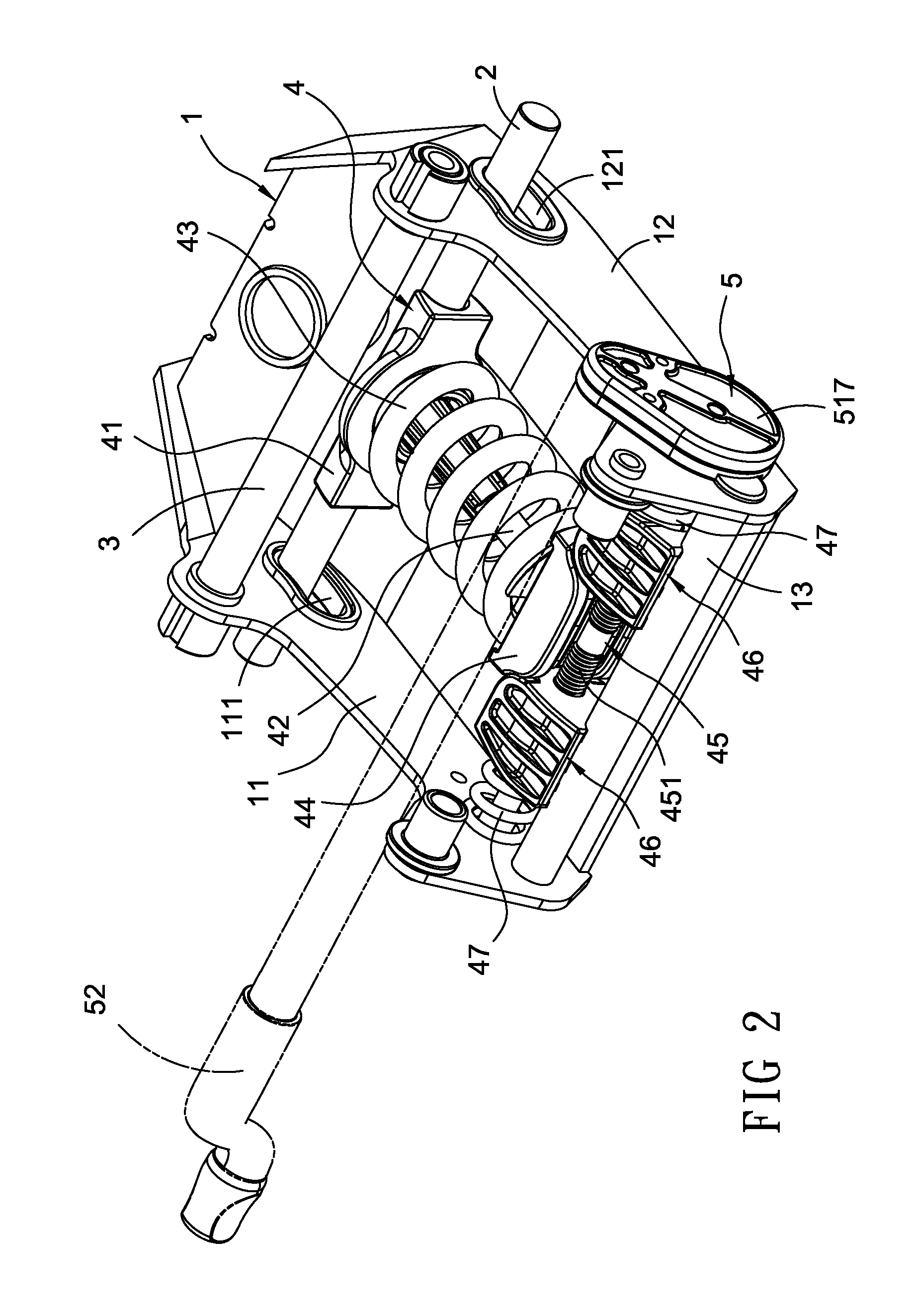

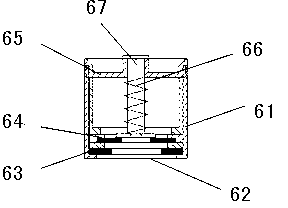

Door lock assembly and box-type electric appliance

ActiveCN104763259AImprove the reliability of safe operationSimple structureDomestic cooling apparatusLighting and heating apparatusElectricityEngineering

The invention discloses a door lock assembly and a box-type electric appliance. The door lock assembly comprises a lockset (1) and a lock catch unit, wherein the lock catch unit comprises a lock body, a cam oscillating mechanism and a locking lever mechanism; a locking lever (5) is connected with the lock body by virtue of a rotating shaft (4), and two ends of the locking lever can rotate around the rotating shaft; and one end of the locking lever refers to a locking end (51) extending towards the lockset, and the other end of the locking lever is matched with a cam (2), so that the locking lever can be locked or unlocked with the lockset under oscillation of the cam. The door lock assembly also comprises a trigger mechanism, wherein one end of a top pressing rod (10) and the locking end extend out in the same direction and can be contacted with the lockset, and the other end of the top pressing rod can push a micro switch (12) to be electrically connected with an induced circuit board (13) so as to generate a trigger signal. The door lock assembly disclosed by the invention is simple and compact in structure and attractive in appearance, the box-type electric appliance adopting the door lock assembly can acquire the trigger signal, and after the box door is closed and locked, the other operating modes are operated, and the safety operation reliability is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

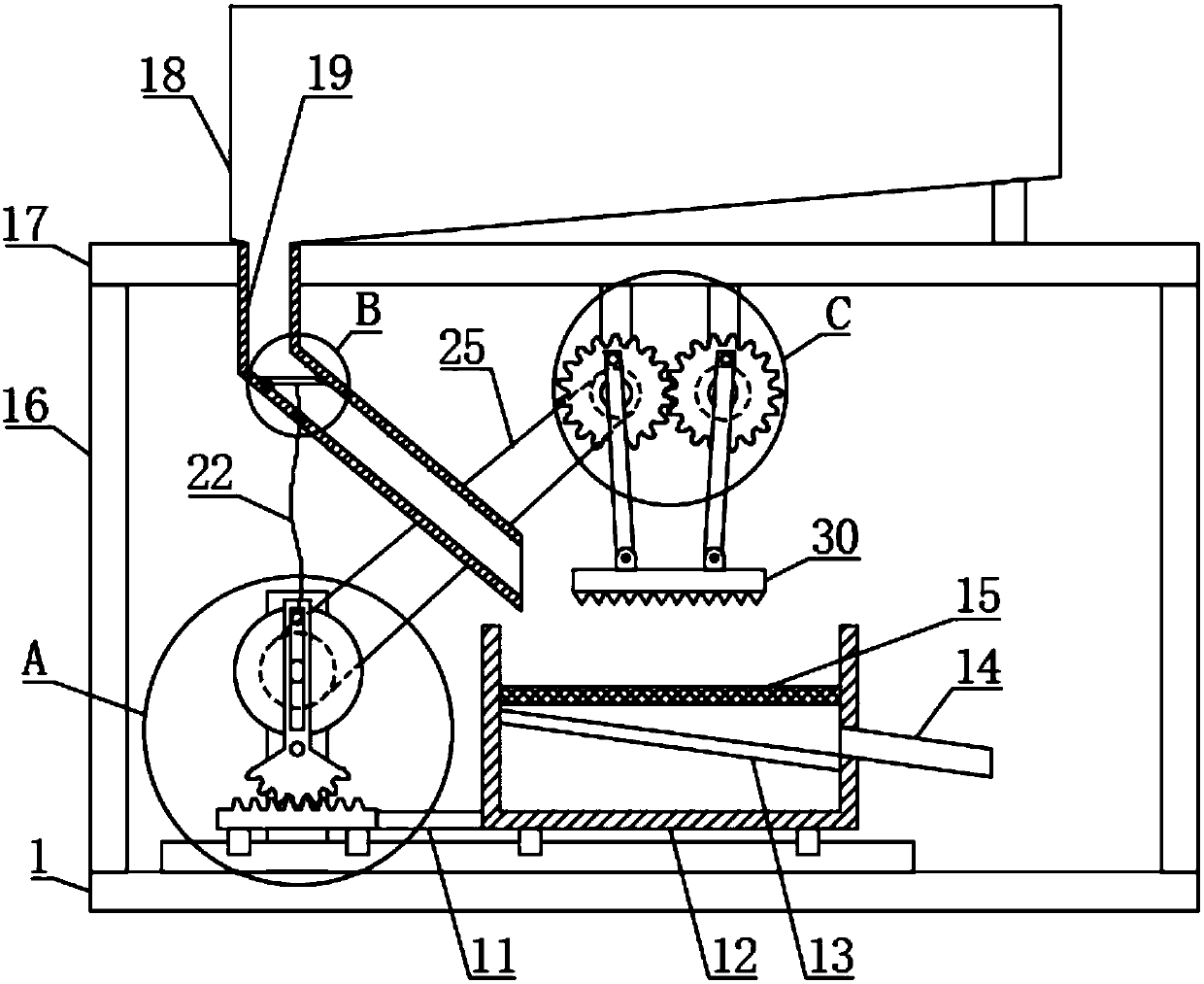

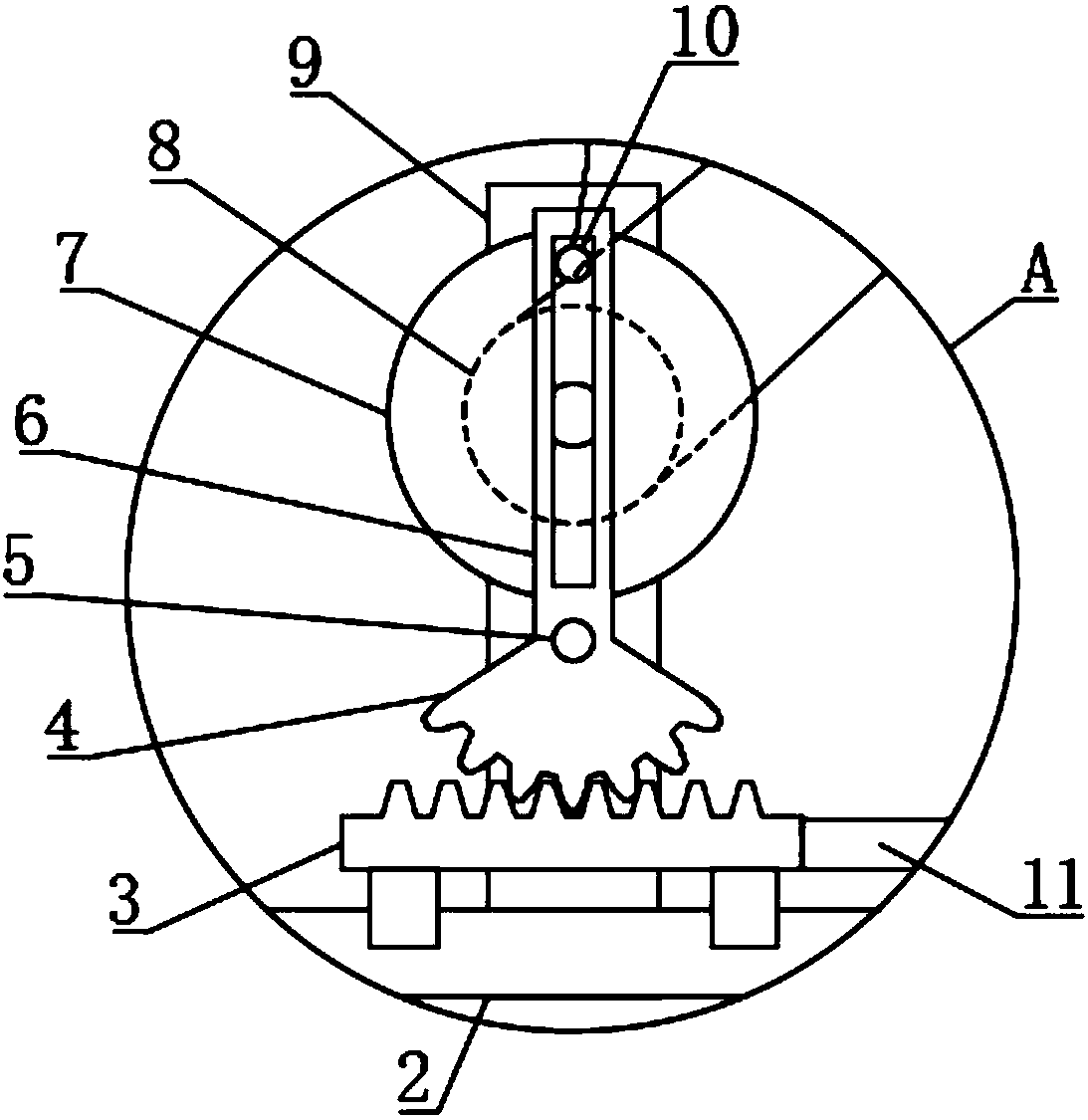

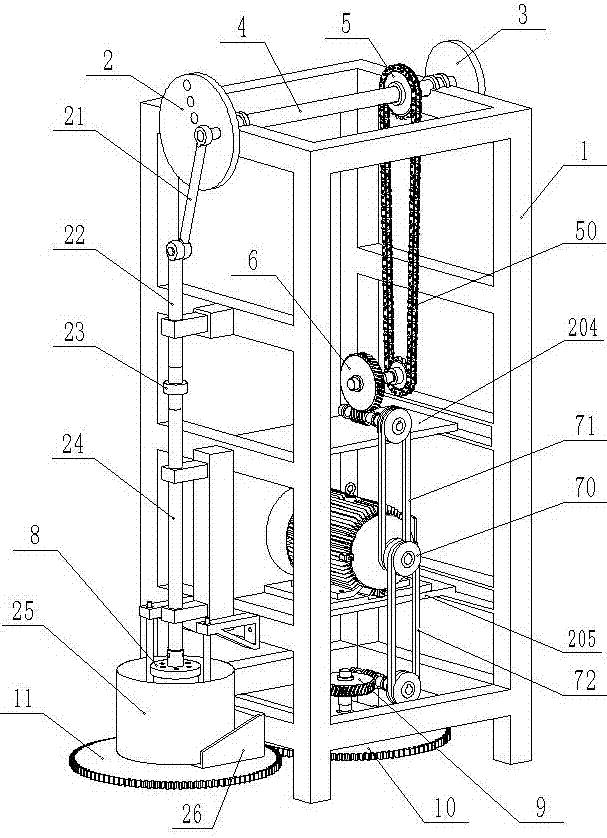

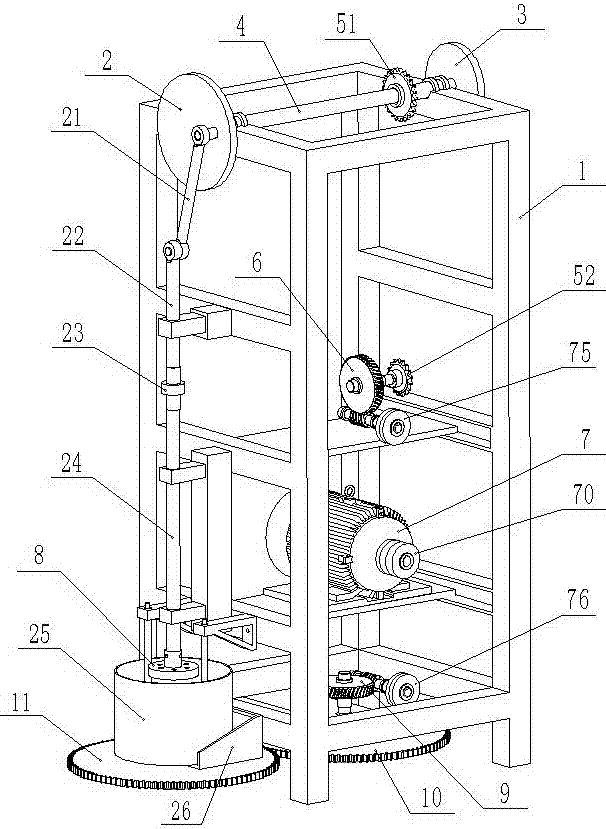

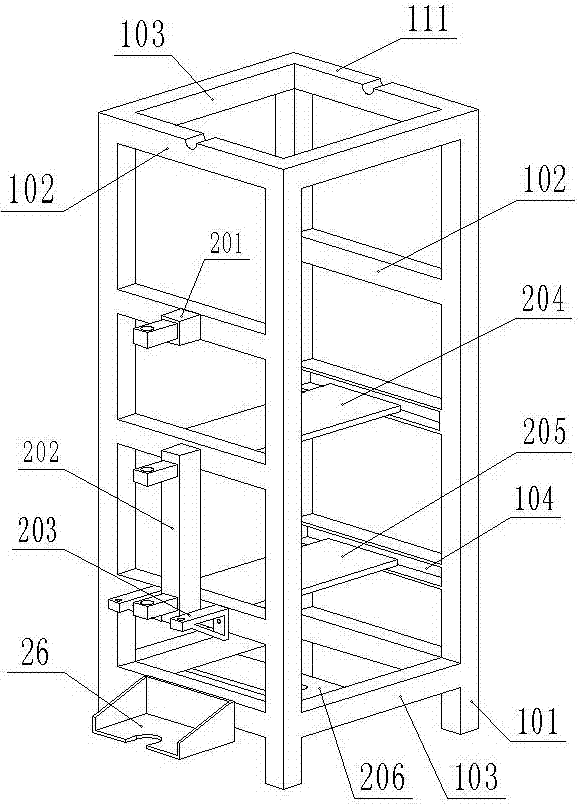

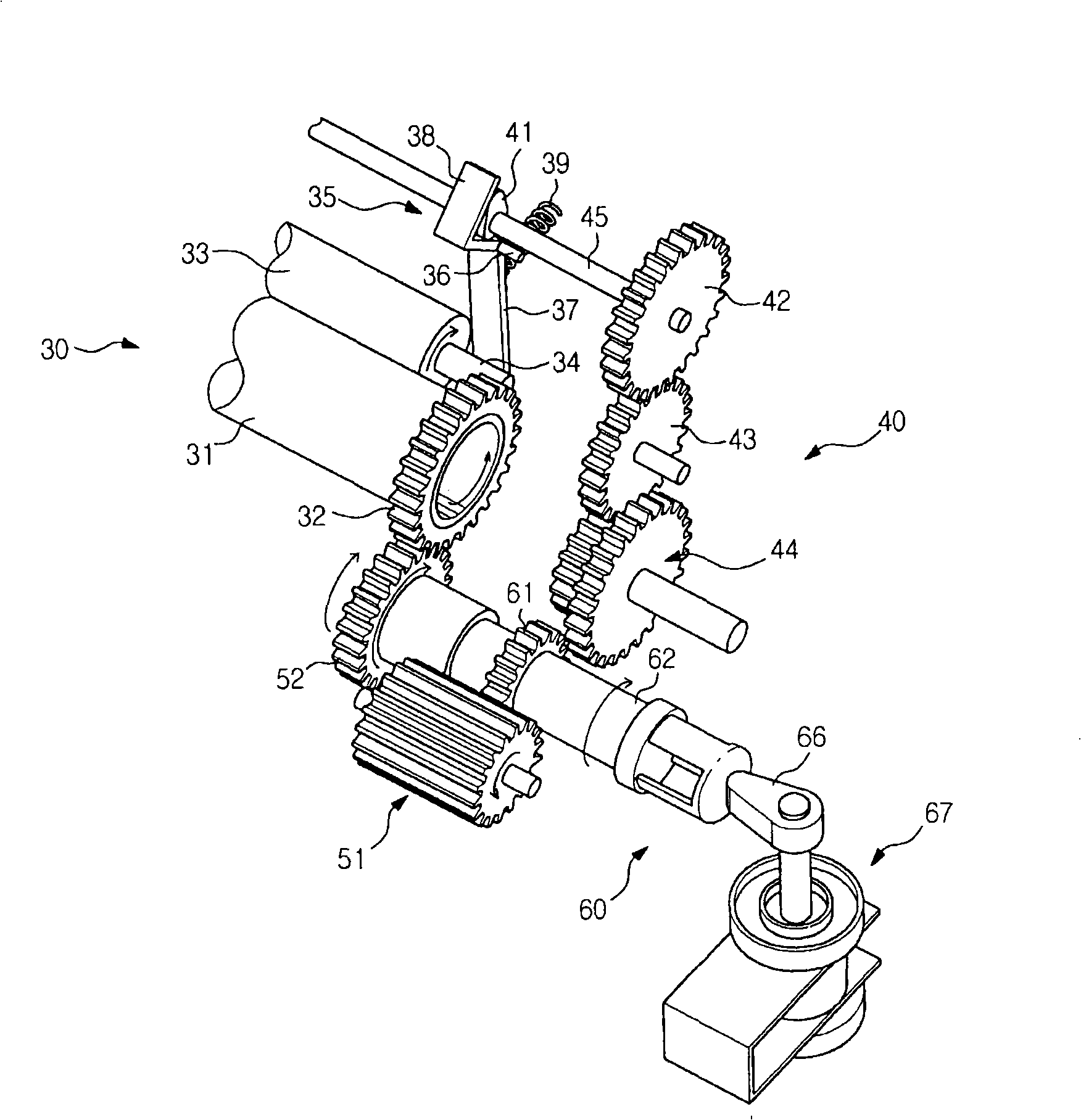

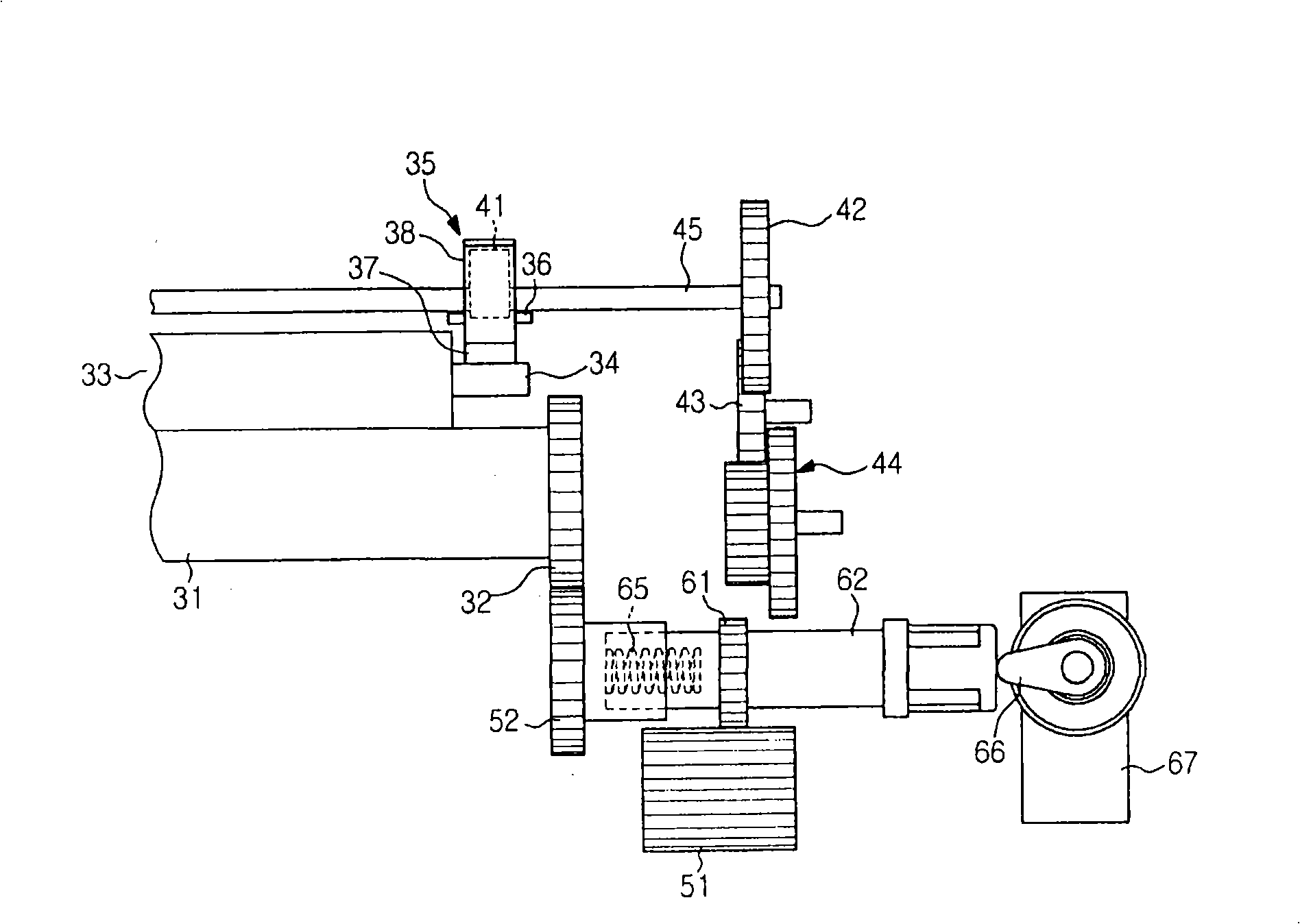

Full-automatic mechanical hammering type meat stuffing preparation machine

The invention relates to a full-automatic mechanical hammering type meat stuffing preparation machine. The meat stuffing preparation machine comprises a frame body (1), a rotating shaft (4), a crank rotating disc (2), a middle electric motor (7), a hammering device (8), a roller (25), an overload nut (23), a main driving device and a stirring device, wherein the hammering device (8) is arranged on the left side of the frame body (1), the rotating shaft (4) is arranged at the top of the frame body (1), and the crank rotating disc (2) is fixedly mounted on the rotating shaft (4); a middle worm gear mechanism (6) comprises an upper worm gear (61) and an upper worm (62); a big chain wheel (51) and a small chain wheel (52) are sleeved with a transmission chain (50); an upper belt wheel (75) and a main belt wheel (70) are sleeved with an upper conveying belt (71); a driving gear (10) is arranged at the lower end part of a shaft body of a lower worm gear (91); the main driving device comprises a connecting rod (21), a push rod (22) and a pressure rod (24), and the hammering device (8) is fixedly mounted at the bottommost end of the pressure rod (24); and the roller (25) is arranged at the lower end of the hammering device (8); and a driven gear (11) is arranged at the lower end of the roller (25). Therefore, by utilizing the full-automatic mechanical hammering type meat stuffing preparation machine, people can relatively conveniently and flexibly make fibriform meat stuffing.

Owner:宫文峰

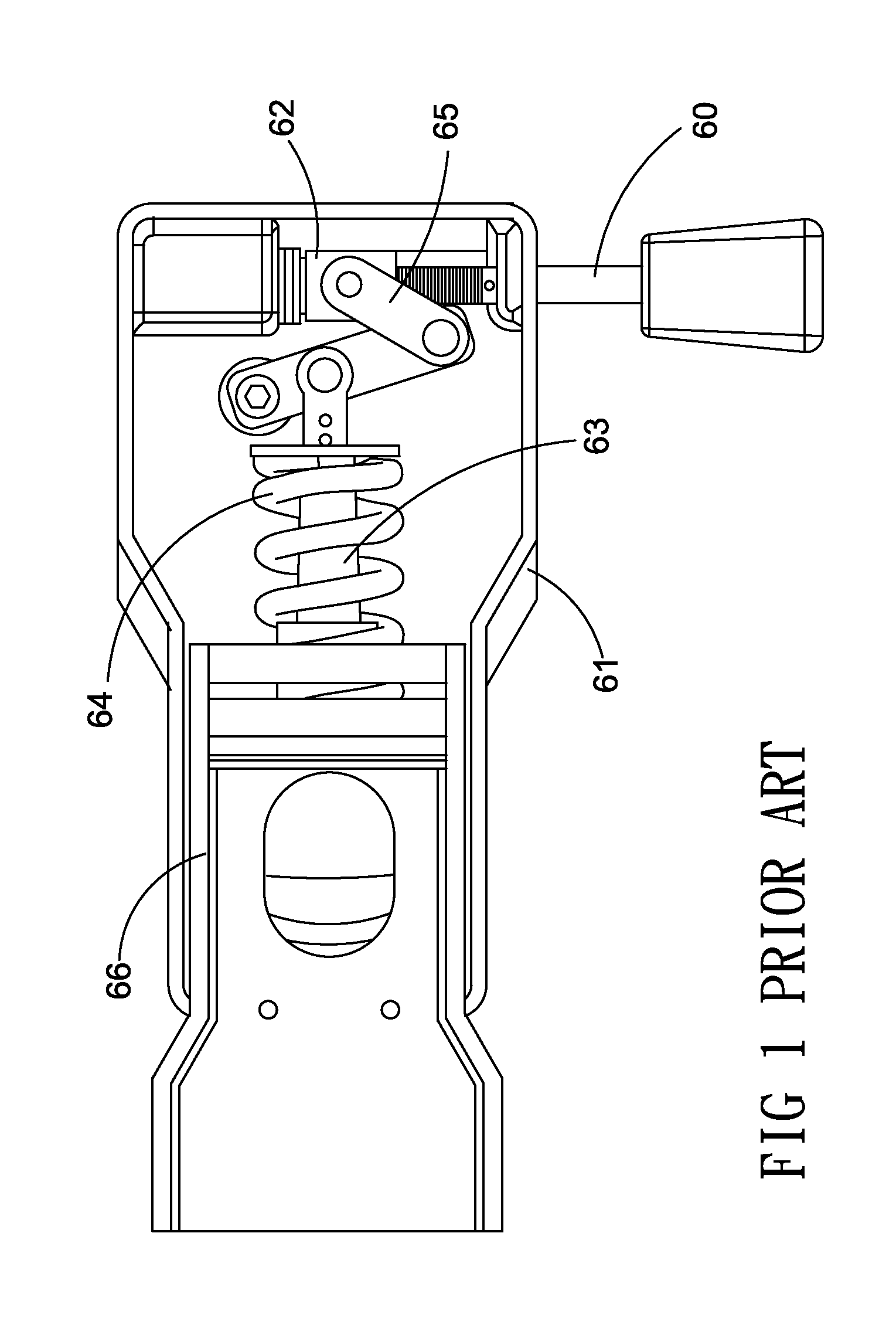

Electrical door-locking device

InactiveUS8661733B2Simple structureReduces dangerVehicle locksNon-mechanical controlsEngineeringLever pressing

Owner:THE KOREA DEV BANK

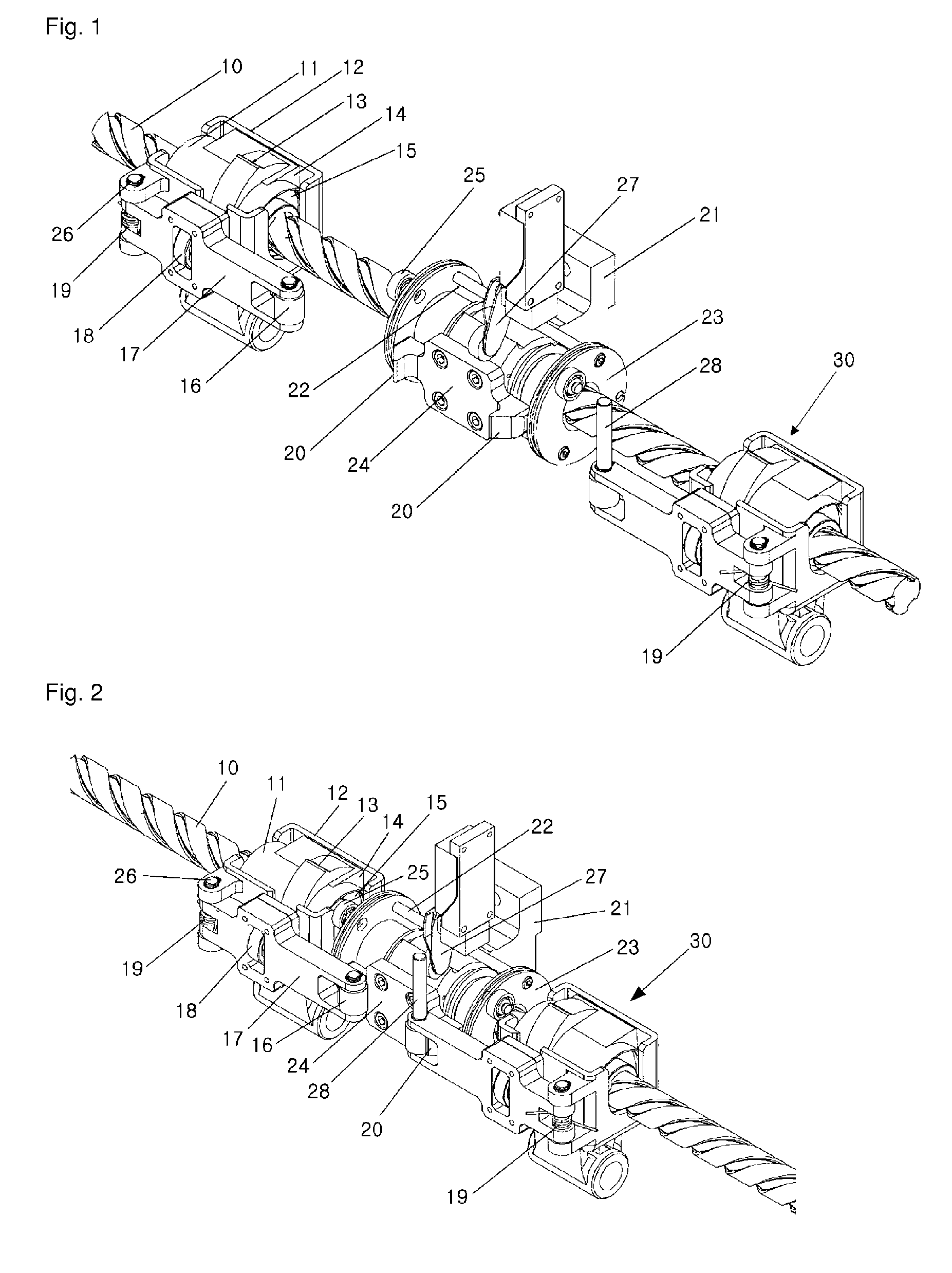

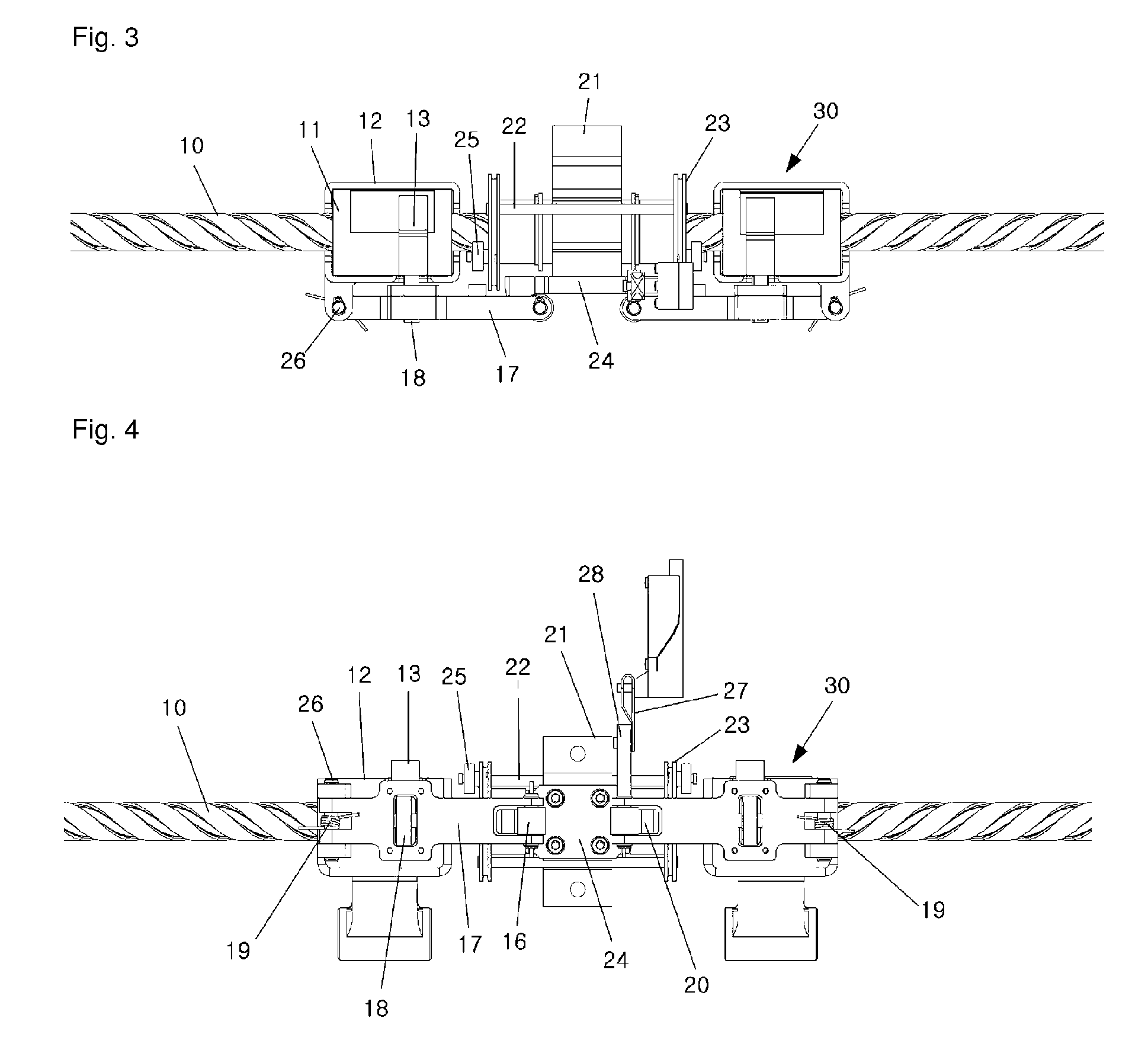

Escalator hand strap speed measuring clamp

InactiveCN103910276AMeet the clamping requirementsAbsorb uncertain shocksLinear/angular speed measurementEscalatorsEngineeringLever pressing

The invention provides an escalator hand strap speed measuring clamp. The escalator hand strap speed measuring clamp comprises a clamp part and an elastic pressing part; the clamp part is connected with the elastic pressing part through a pressing rod which penetrates a transverse board; the clamp part comprises the transverse board, two side boards and four universal hooves, the side boards are fixed on two sides of the transverse board through hinges, and each universal hoof penetrates the two side boards during usage and is fastened through fastener butterfly nuts; the elastic pressing part comprises an encoder, a mounting plate, a compressed spring and the pressing rod. According to the escalator hand strap speed measuring clamp, the two side boards can be mutually closed and the encoder can completely contact with a hand strap so that the clamping firmness of the speed measuring clamp can be greatly improved.

Owner:SHANGHAI UNIV

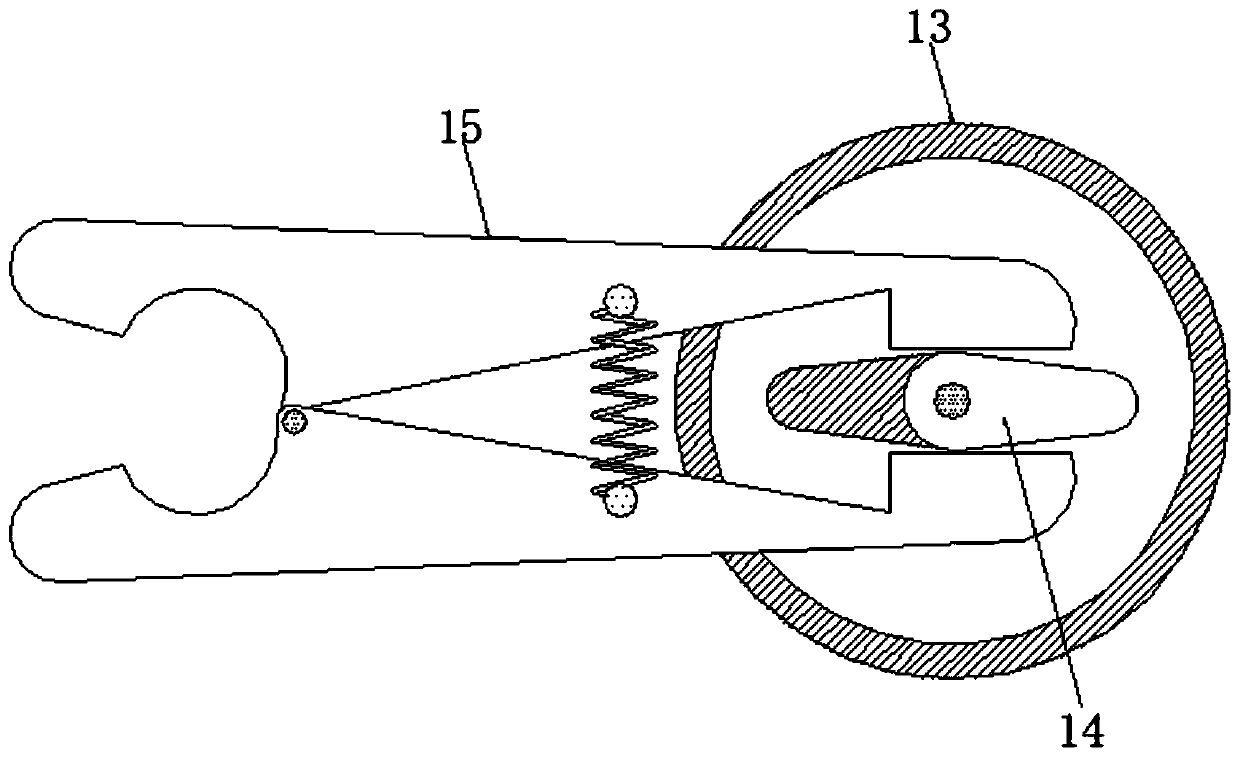

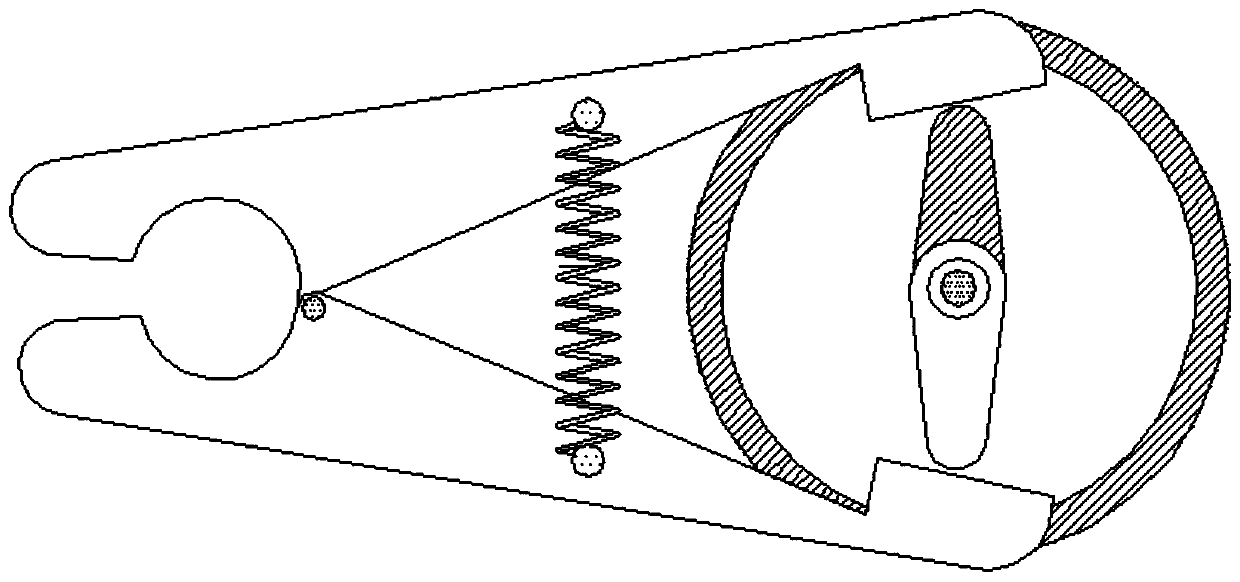

Self-tightening type centering drive plate

InactiveCN103009163AEasy to operateHigh precisionPositioning apparatusMetal-working holdersEngineeringLever pressing

The invention provides a self-tightening type centering drive plate. The self-tightening type centering drive plate comprises a Morse cone, wherein a drive plate apex is arranged in the Morse cone; the drive plate apex is fixedly connected through an adjusting screw, a top tension spring and compression screws; the drive plate apex is connected to a floating block through a pin; the Morse cone is connected with a lever pressing plate through another adjusting screw, another spring and another pin; the contact of the lever pressing plate is in sliding contact with the floating block; the lever pressing plate is fixedly connected with a pressing head through a screw thread; and the drive plate apex precisely matches the Morse cone, and the fit clearance is 0.005-0.01 mm. The self-tightening type centering drive plate, disclosed by the invention, has the advantages of operation convenience, high precision, low labor intensity and high working efficiency; and the longitudinal separation of a tail seat is only necessary to adjust when work-pieces with different lengths are machined.

Owner:YANTAI HAIDE MACHINE TOOL

Flexible tilt adjustment device for a chair back

Owner:DONGGUAN KENTEC OFFICE SEATING

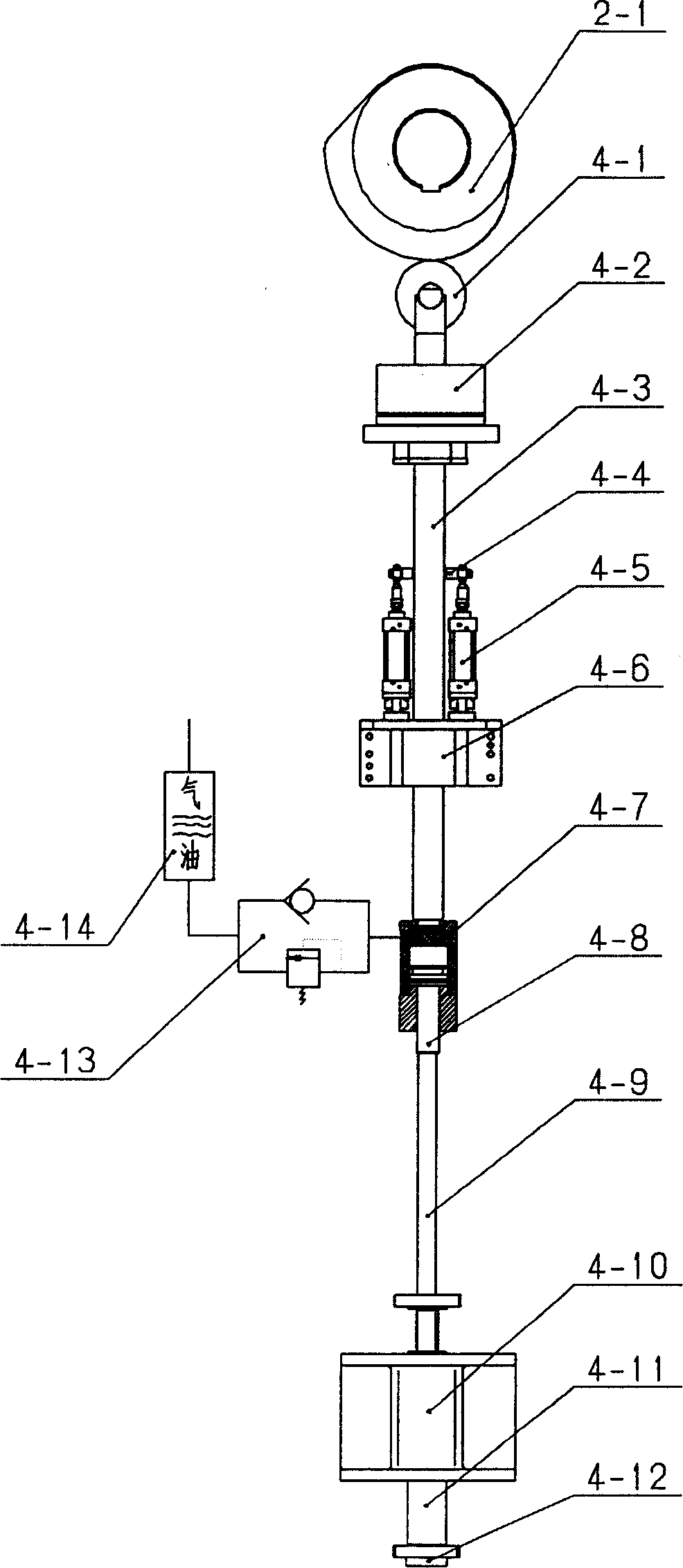

Pull-down type press-in device for axle housing bolt

ActiveCN102773688ANo human action requiredProcess safetyMetal working apparatusEngineeringLever pressing

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Panel feeding clamp

ActiveCN102513866AStable clamping forceReliable clamping forceMetal working apparatusCrankClassical mechanics

The invention discloses a panel feeding clamp, which comprises a base for external installation, a pincer seat with one end fixed on the base, a substrate fixed on the base, a compression bar with the middle hinged with the other end of the pincer seat and an external casing. The compression bar is provided with a pincer opening end and a non-pincer opening end, wherein the pincer opening end andthe pincer seat form a pincer opening, and the non-pincer opening end is controlled by a driving mechanism to achieve opening or closing of the pincer opening, the driving mechanism comprises a cylinder arranged on the pincer seat and a spring assembly arranged on the substrate, the cylinder is connected with the spring assembly, the casing is rotatably provided with a C-shaped crank arm, one endof the crank arm is hinged to a connection portion of the cylinder and the spring assembly, the other end of the crank arm is hinged to a connection plate capable of sliding along the surface of the pincer seat, and elasticity effects of the spring assembly drive the connection plate to move close to the compression bar to enable the pincer opening to clamp a panel through the crank arm. When thecylinder applies reverse force on the crank arm, the crank arm drives the connection plate to move far away from the compression bar to enable the pincer opening to open. The clamp force is stable and reliable, has no damage to the surface of the panel, and avoids influences of power-down, decompression or pressure oscillation.

Owner:爱克(苏州)机械有限公司

Oiling machine

InactiveCN104259042ASimple structureImprove oiling efficiencyLiquid surface applicatorsCoatingsOil and greaseThermodynamics

The invention discloses an oiling machine. The oiling machine comprises a rack and an oiling device, wherein an oil storage cavity is arranged in the rack, an electrical heating element is arranged at the bottom of the oil storage cavity, and the oiling device is arranged under the bottom of the rack and is positioned right below the oil storage cavity, so that liquid fat in the oil storage cavity can enter the oiling device conveniently; a sleeve is arranged at the rear end of the rack, a pressure level is arranged in the sleeve, a pressure spring is arranged between the pressure level and the sleeve, the pressure level can move in the sleeve along a vertical sliding groove up and down, and the lower part of the pressure level is connected with an oiling cavity of the oiling device; when the pressure level is pressed downwards, the oiling cavity can be nested with a bolt assembly or a bolt required to be oiled; according to the scheme disclosed by the invention, the oiling machine can be pushed to move on a rail by an operator, when the bolt assembly is planned to be oiled, the pressure level is pressed downwards, and then the bolt assembly can be sleeved into the oiling cavity for oiling; and the oiling machine has a simple structure and high oiling efficiency and can perform construction conveniently.

Owner:苏州路云机电设备有限公司

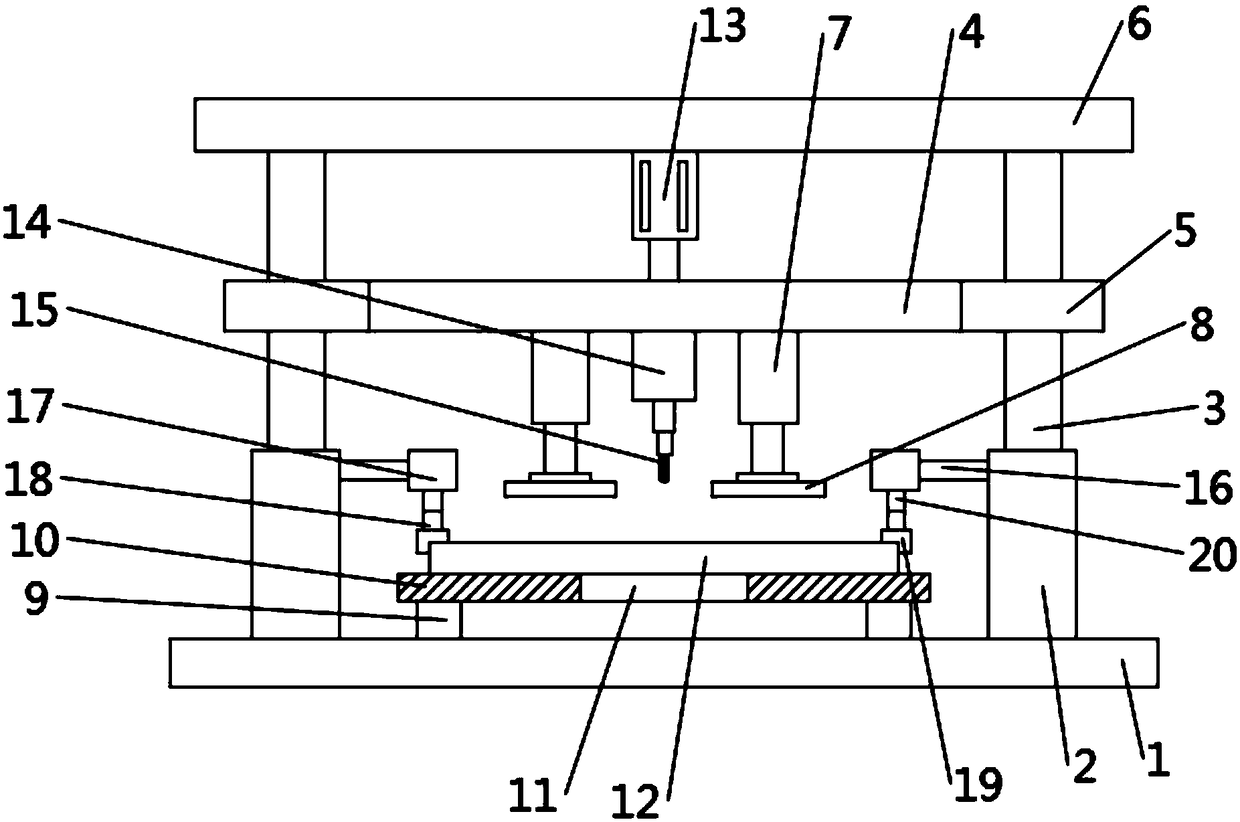

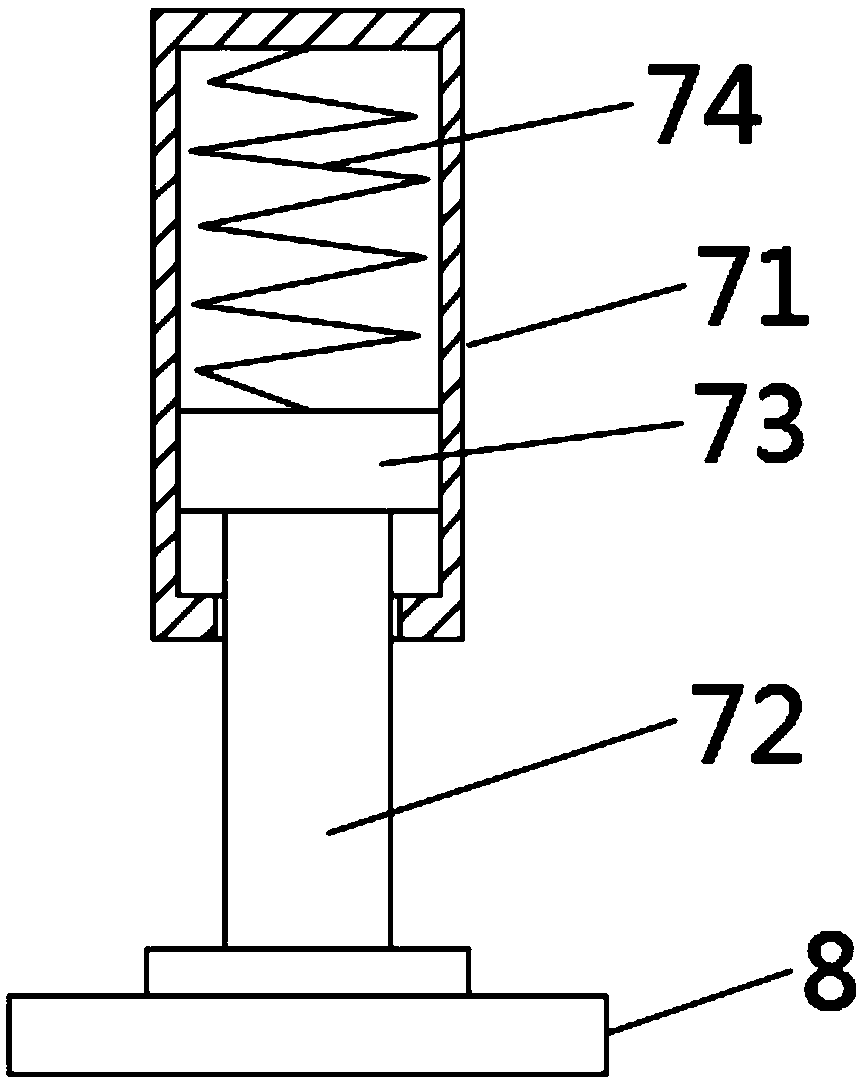

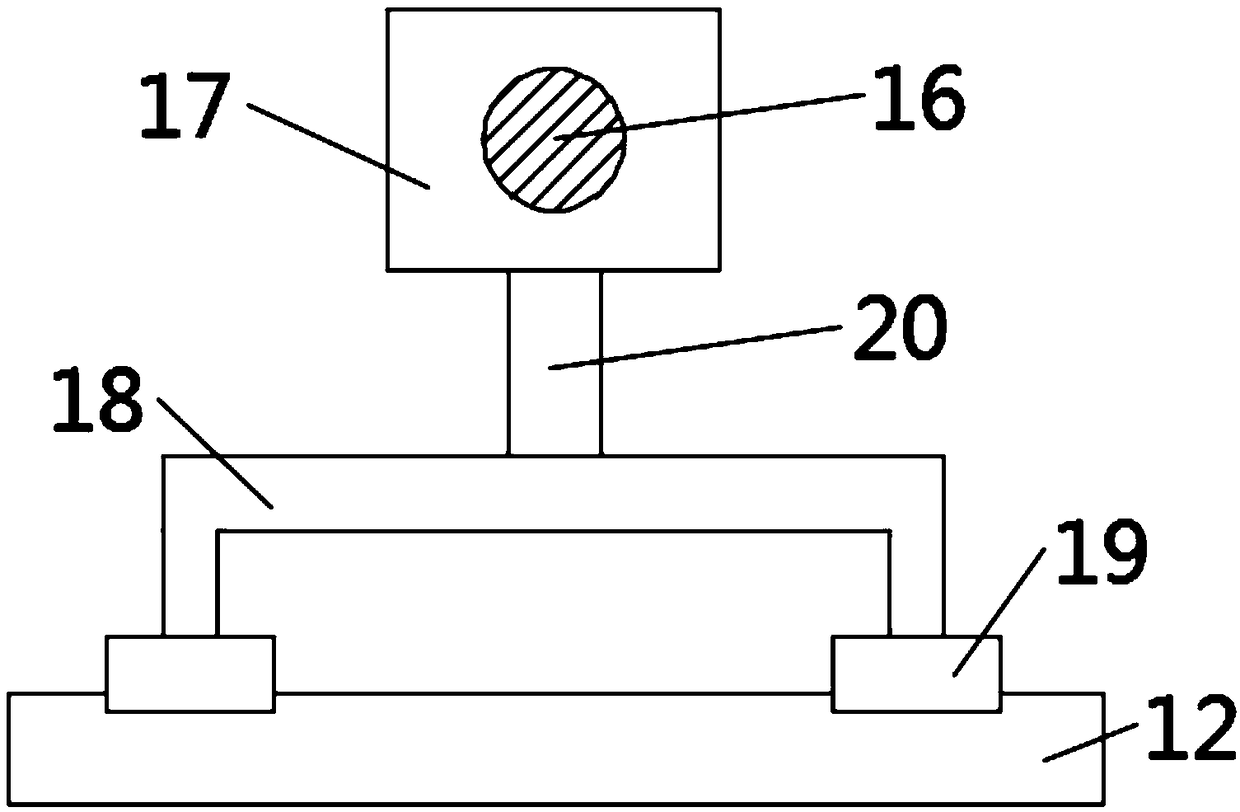

Drilling equipment for automobile parts

InactiveCN108943134AGuaranteed stabilityEasy resetMetal working apparatusElectric machineryTelescopic cylinder

The invention discloses drilling equipment for automobile part processing. The drilling equipment comprises a supporting base, a supporting stand column, a guide sliding rod, a lifting platform, a workpiece groove, a first electric telescopic cylinder, a drilling motor and a clamping device. according to the drilling equipment, a pressing rod is driven by a second electric telescopic cylinder to move down, a supporting connecting rod is driven by the pressing rod to move down, and thus an automobile part is clamped and fixed through a clamping block. The lifting platform is pushed by the firstelectric telescopic cylinder to move down, a lifting sleeve plate slides down relatively to the guide sliding rod at the moment, further a drilling bit rotating at high speed contacts with the automobile part, and drilling operation is completed. In addition, when the lifting platform moves down, the automobile part needing to be drilled is compressed further by a pressing block on an elastic compression component, so that the stability of the automobile part is ensured. Moreover, by the arrangement of a supporting spring, the lifting platform is conveniently reset.

Owner:HEFEI LIANSEN YUTENG NEW MATERIAL TECH DEV CO LTD

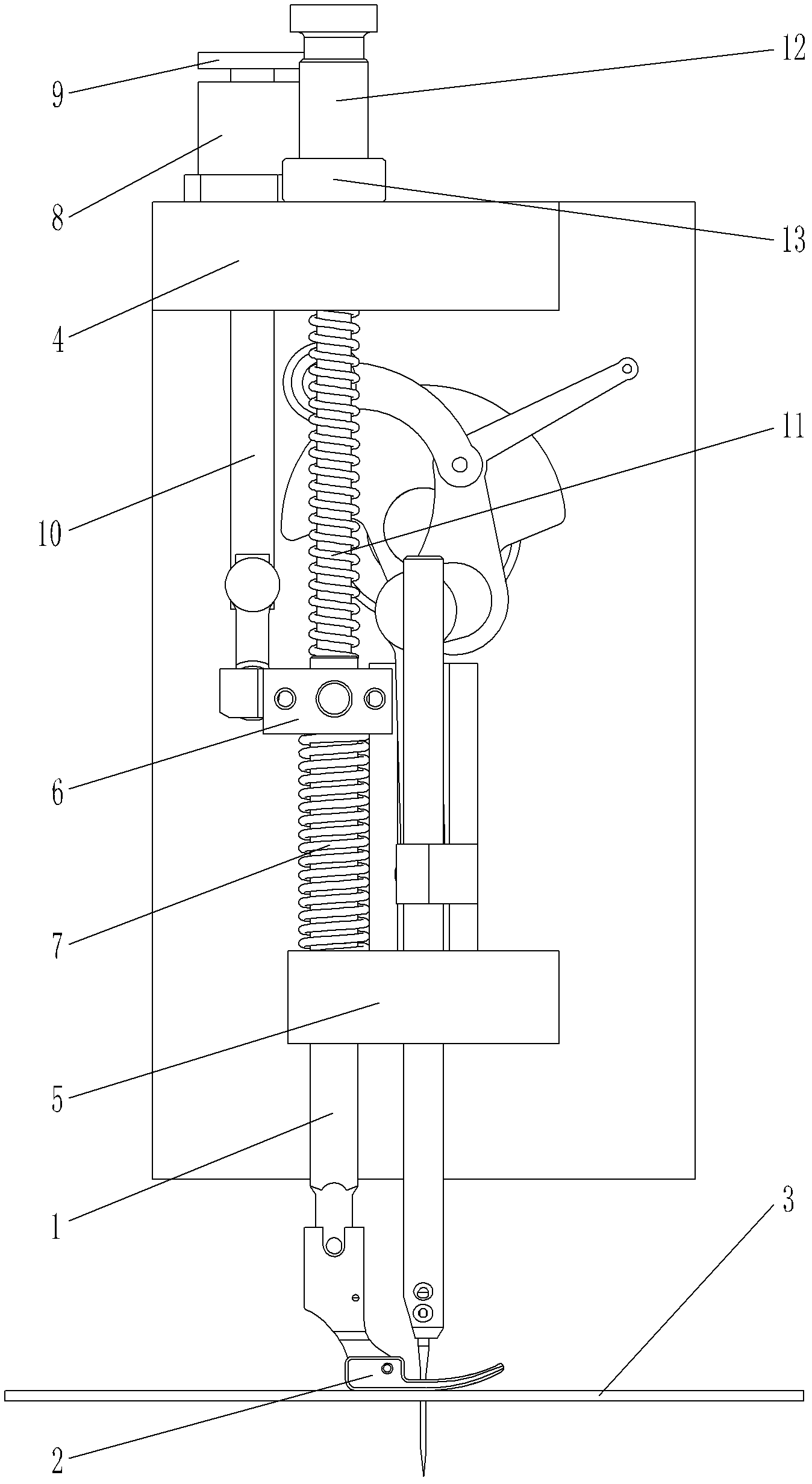

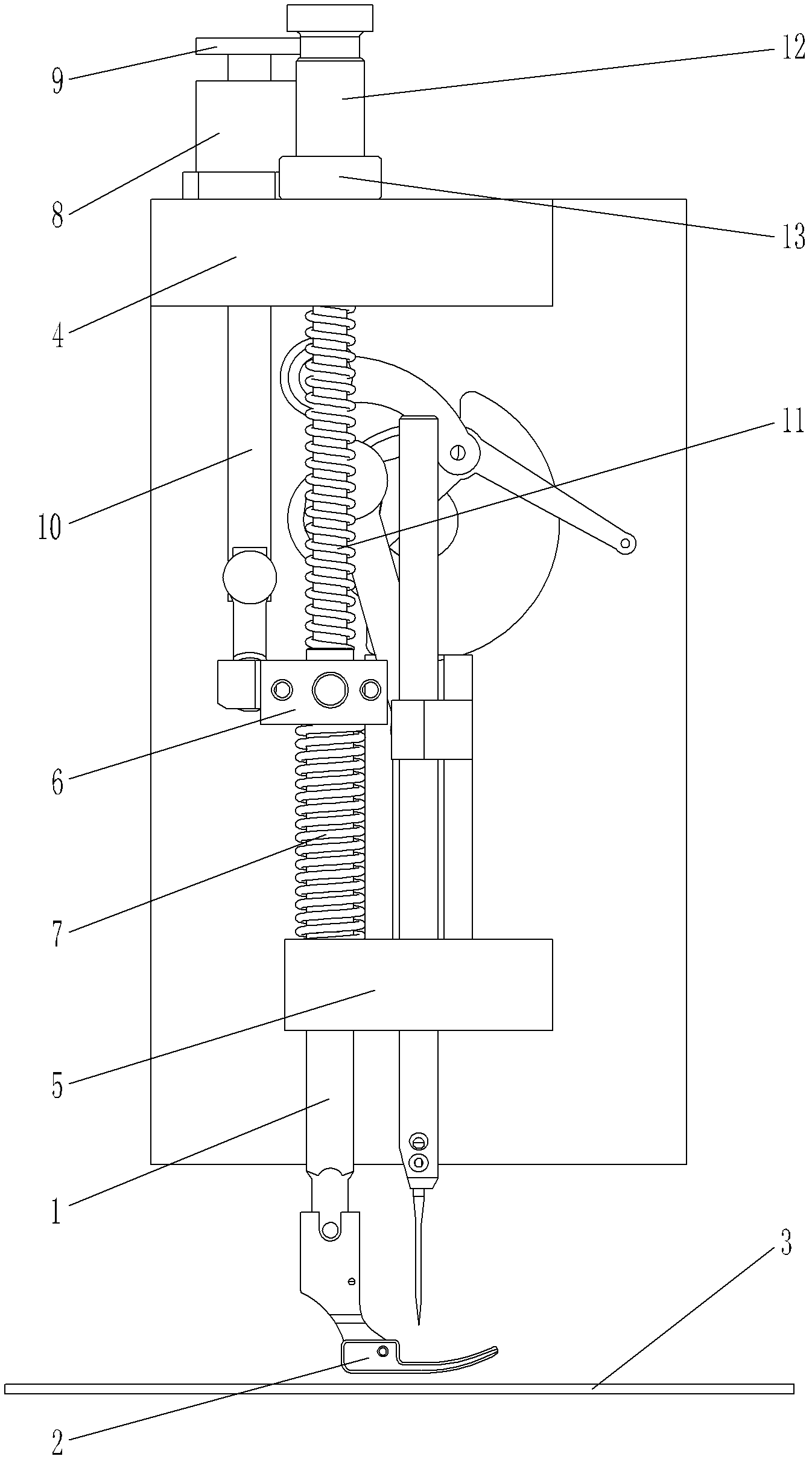

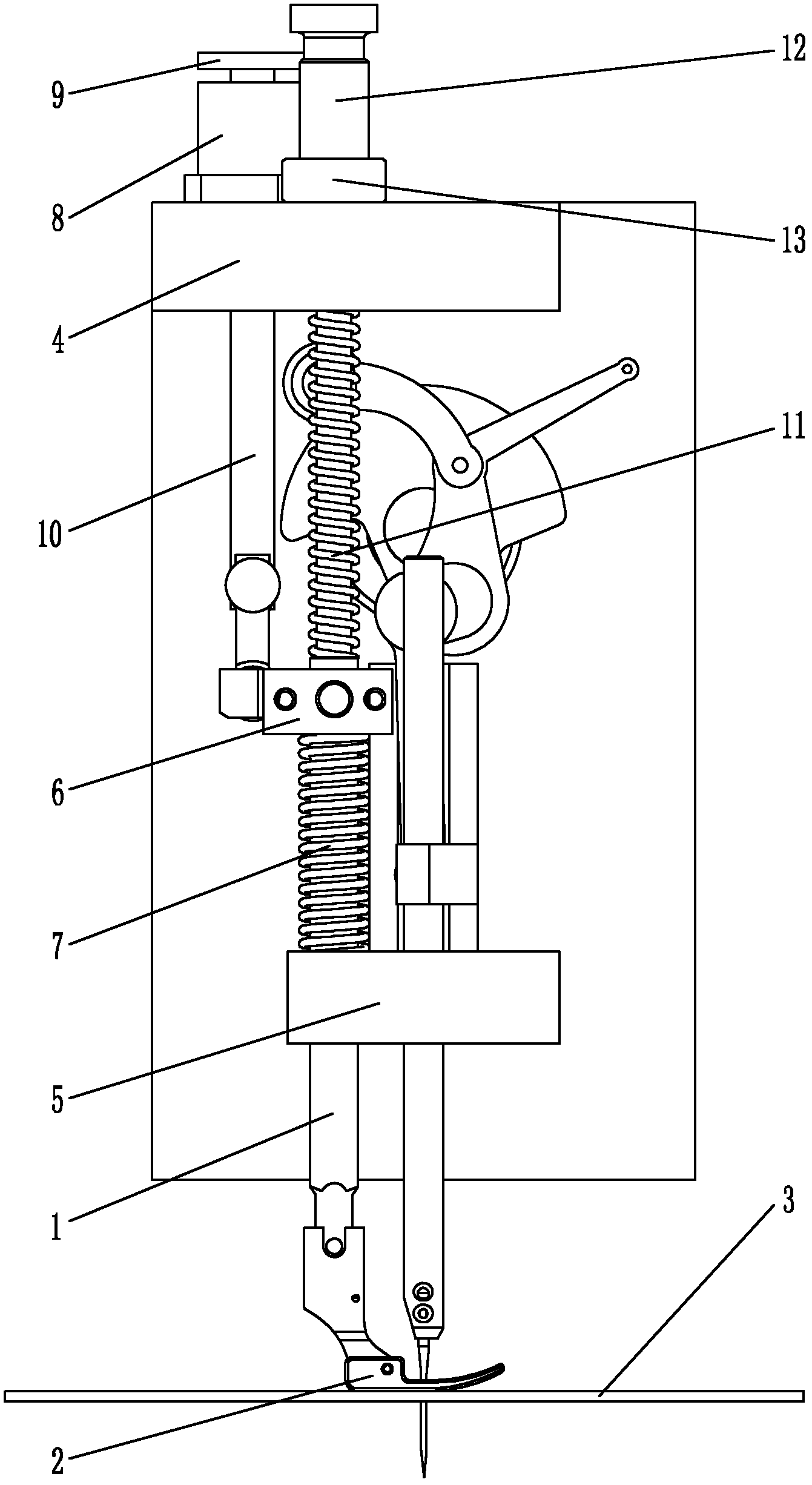

Intelligent cloth pressing device

The invention discloses an intelligent cloth pressing device which comprises a liftable pressure rod vertically arranged on a housing, wherein the lower end of the pressure rod is provided with a presser foot, a working platform is arranged below the presser foot, a control drive mechanism used for controlling the pressure rod to drive the presser foot to lift is arranged between the pressure rodand the housing, the control drive mechanism comprises a pressing part used for controlling the pressure rod to drive the presser foot to descent, and a resetting part used for controlling the pressure rod to drive the presser foot to upwards restore to the original position. The pressure rod is intelligently controlled through attraction between an electromagnet and an attraction body and an elastic element to drive the presser foot to lift in a reciprocating manner, a larger downward pressure is applied to a fabric to be sawn during spurting so that stable spurting is ensured; and when the fabric is sent, the pressure foot is upwards lifted under the action of the elastic element so that the fabric is ensured to be smoothly sent, thus the intelligent cloth pressing device is safety and reliability in action, and is suitable for popularization and use on a sewing machine.

Owner:ZHEJIANG ZOJE SEWING MACHINE

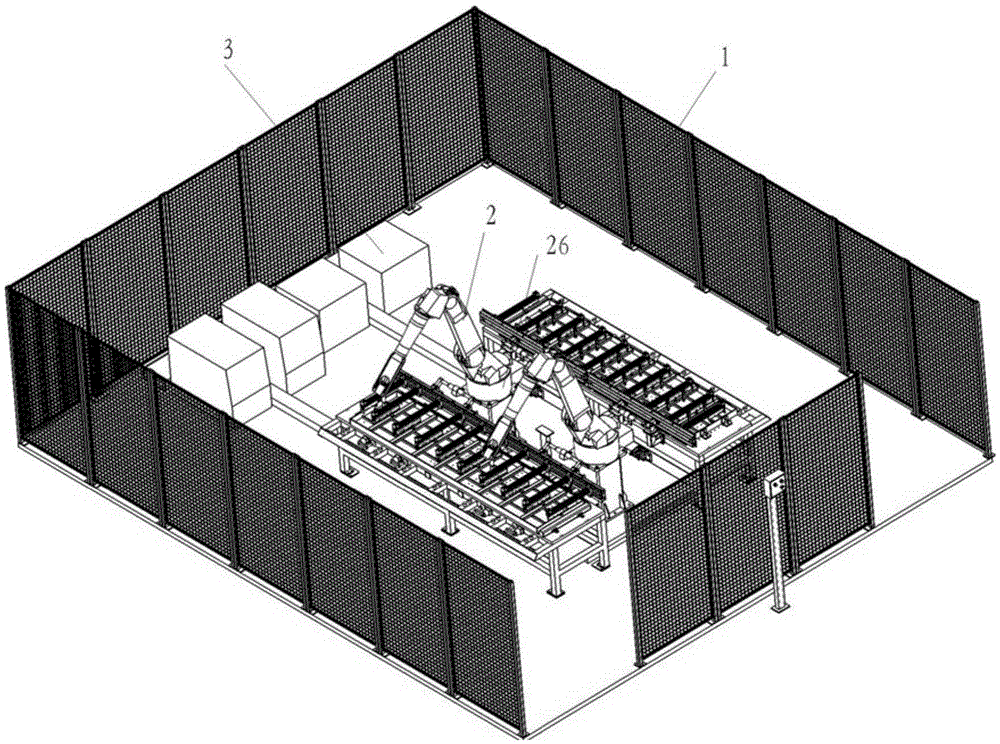

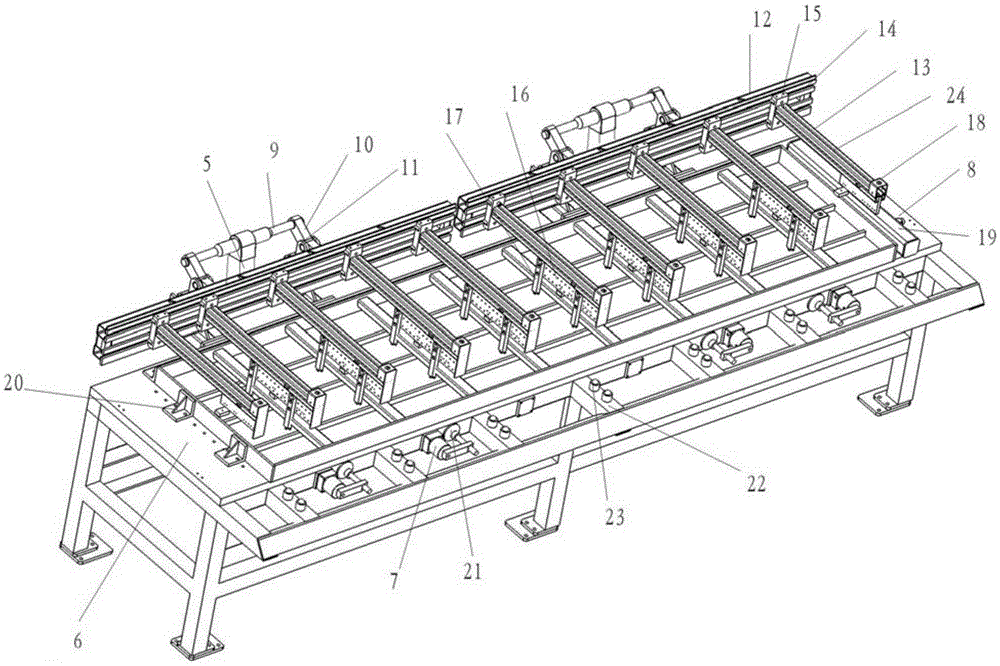

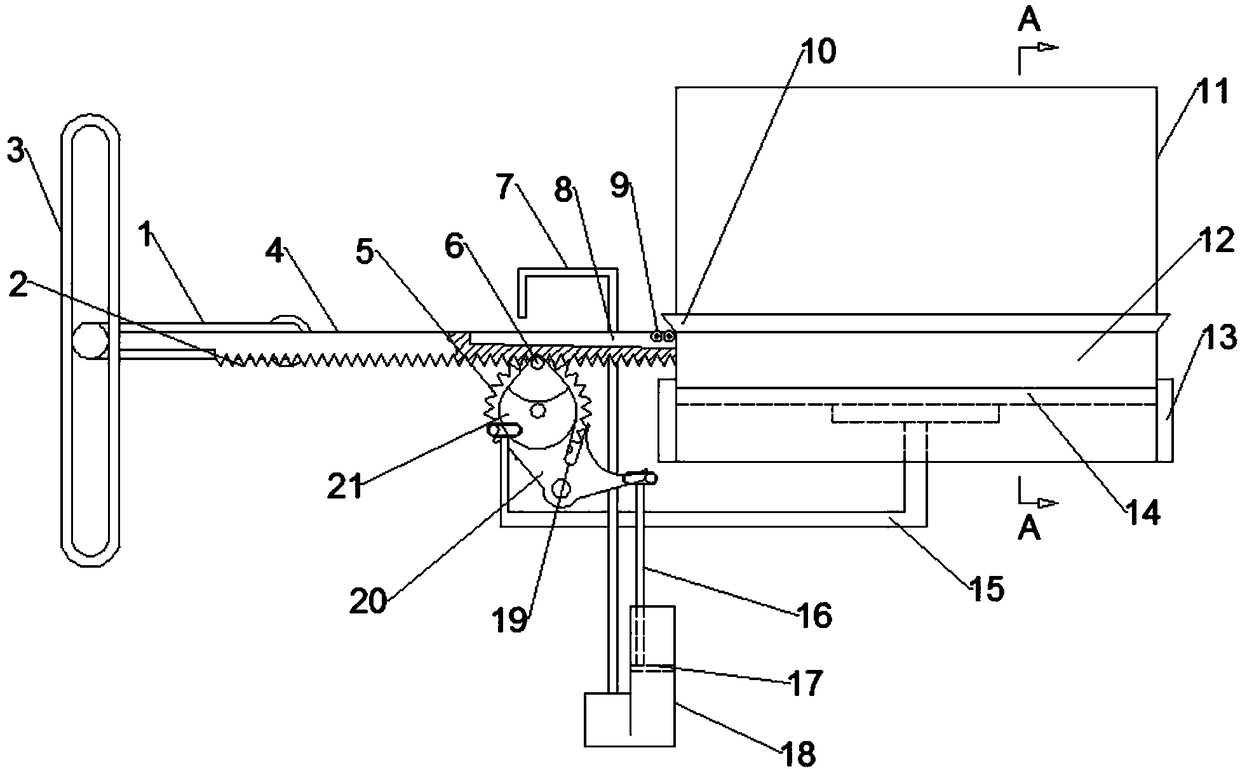

Aluminum template welding system

ActiveCN105345335ABeautiful and does not affect workImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesFixed frameEngineering

The invention relates to the technical field of welding devices, in particular to an aluminum template welding system. The aluminum template welding system comprises a protective fence, a welding manipulator, an air pump and support fixing mechanisms, wherein the protective fence is arranged outside the welding manipulator, the air pump and the support fixing mechanisms; the support fixing mechanisms comprise ejecting cylinders, working tables, rotating cylinders and side cylinders; the ejecting cylinders are fixed at the back sides of the working tables; piston rods of the ejecting cylinders are connected with cross shafts; the two ends of the cross shafts are respectively hinged with one ends of pressing rods; the other ends of the pressing rods are connected with transverse fixed frames; the transverse fixed frames are provided with longitudinal fixed frames; the lower parts of the longitudinal fixed frames are fixedly provided with fixed plates; the fixed plates are provided with vertical pressing cylinders; and limiting support blocks are respectively arranged at the left sides and the back sides of the working tables. The system welds an aluminum template through the automatic welding manipulator, and adopts two sets of support fixing mechanism to perform the reciprocating welding in turns so as to improve the working efficiency.

Owner:天津彼洋机器人系统工程有限公司

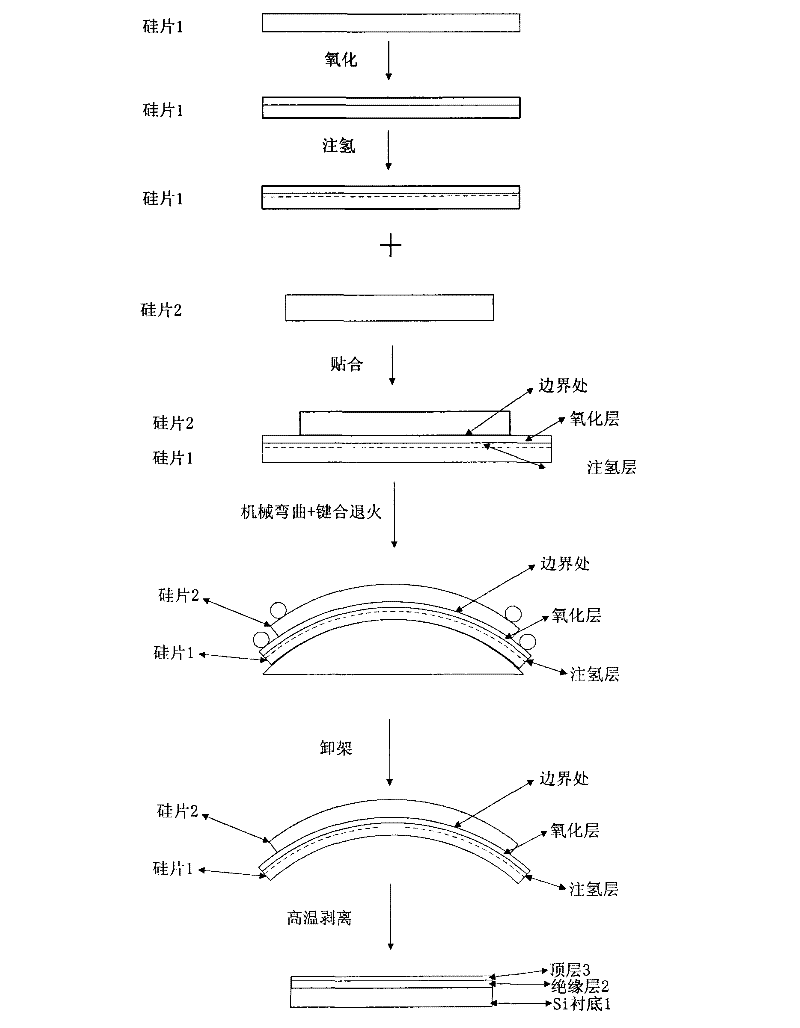

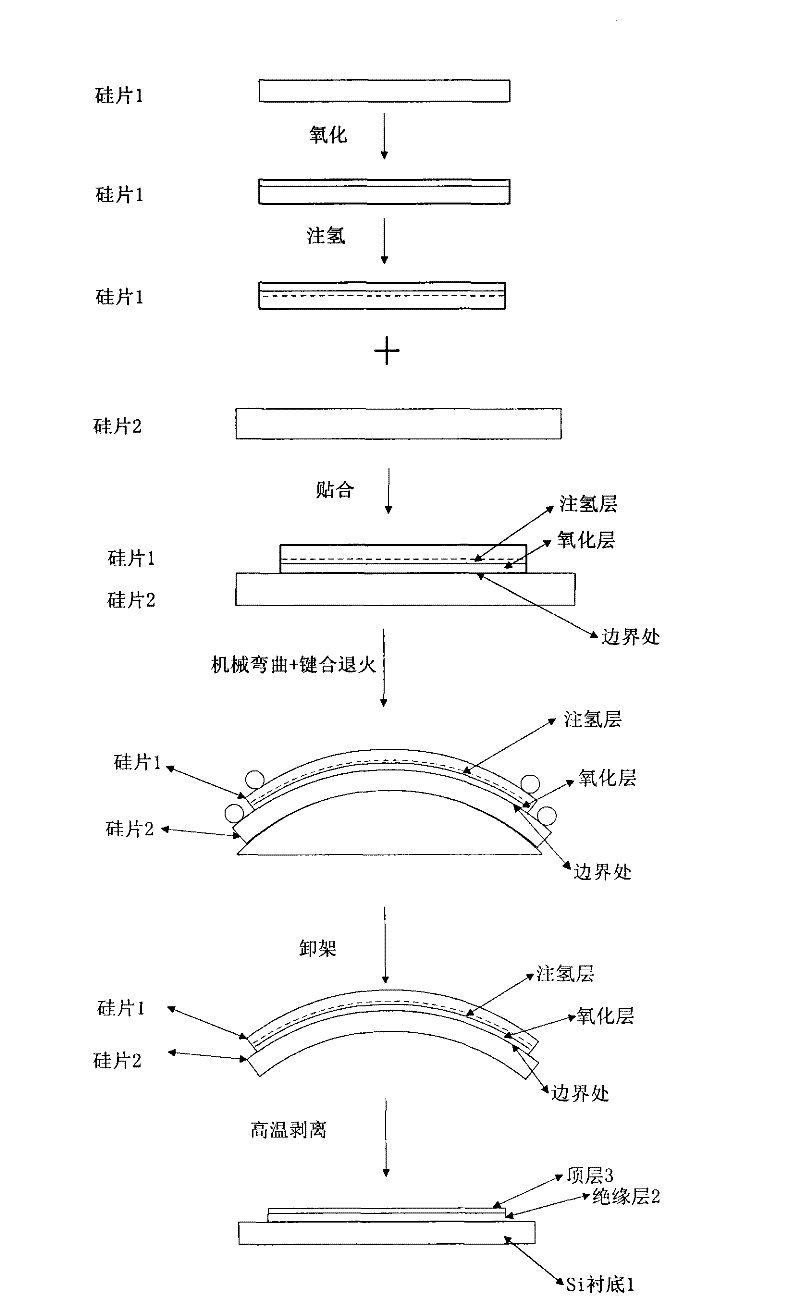

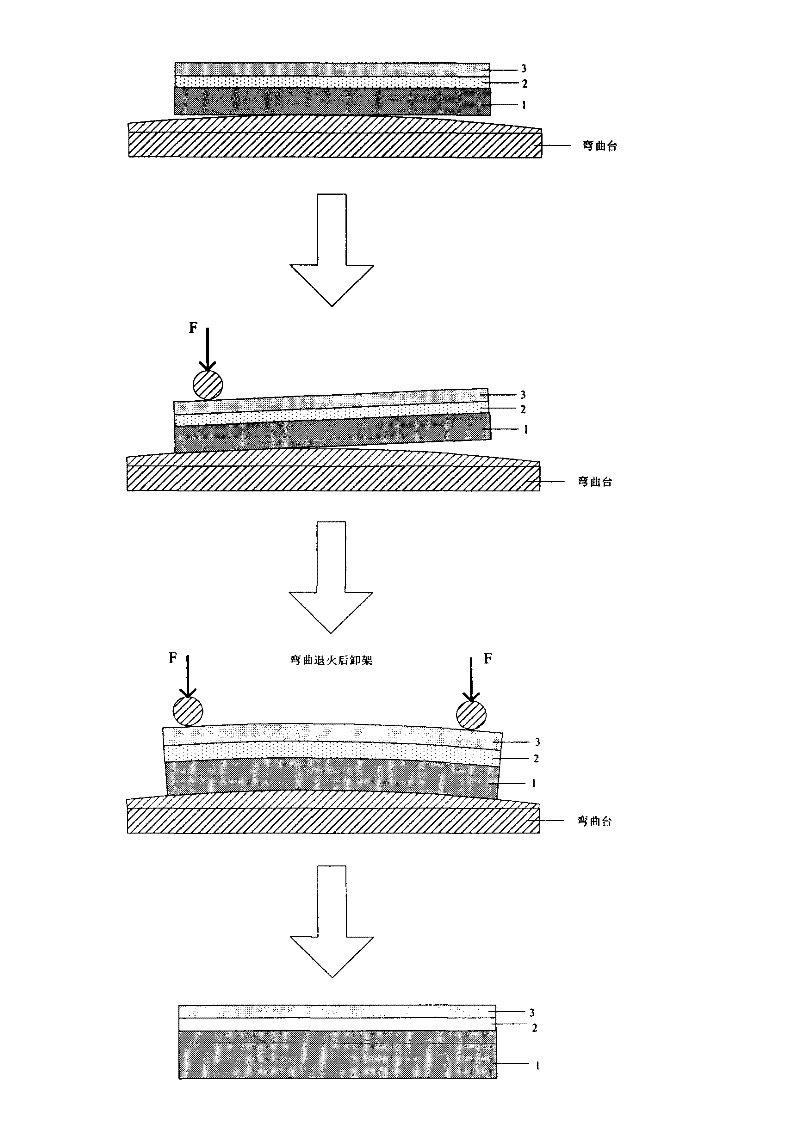

Manufacturing method of single-shaft strain GeOI wafer based on mechanical bending table

InactiveCN102403259ARaw materials are easy to getReduce process complexitySemiconductor/solid-state device manufacturingSurface roughnessRoom temperature

The invention discloses a manufacturing method of a single-shaft strain GeOI wafer based on a mechanical bending table, which comprises the following steps of: firstly, placing a Ge layer surface on the top layer of the GeOI wafer on the arc-shaped bending table downwards or upwards; secondly, respectively and horizontally placing two cylindrical stainless steel pressing rods at the two ends of the GeOI wafer which is 1cm away from the edge of the GeOI wafer; thirdly, slowly rotating nuts of the connected pressing rods, so that the GeOI wafer gradually bends along an arc-shaped tabletop till to be completely fitted with the arc-shaped tabletop; fourthly, placing the arc-shaped bending table carried with the GeOI wafer into an annealing furnace for annealing; fifthly, slowly cooling to the room temperature after the completion of the annealing and taking out the arc-shaped bending table carried with the GeOI wafer; and sixthly, rotating the nuts of the connected pressing rods and slowly lifting the pressing rods till the bent GeOI wafer restores the original shape. The invention has the following advantages that firstly, the raw materials are easy to obtain; secondly, the manufacturing cost is low; thirdly, the manufacturing process is simple; fourthly, the process temperature range is wide; fifthly, the yield rate is high; sixthly, the surface roughness is small; seventhly, the strain effect is good; and eighthly, the thermal property is good.

Owner:XIDIAN UNIV

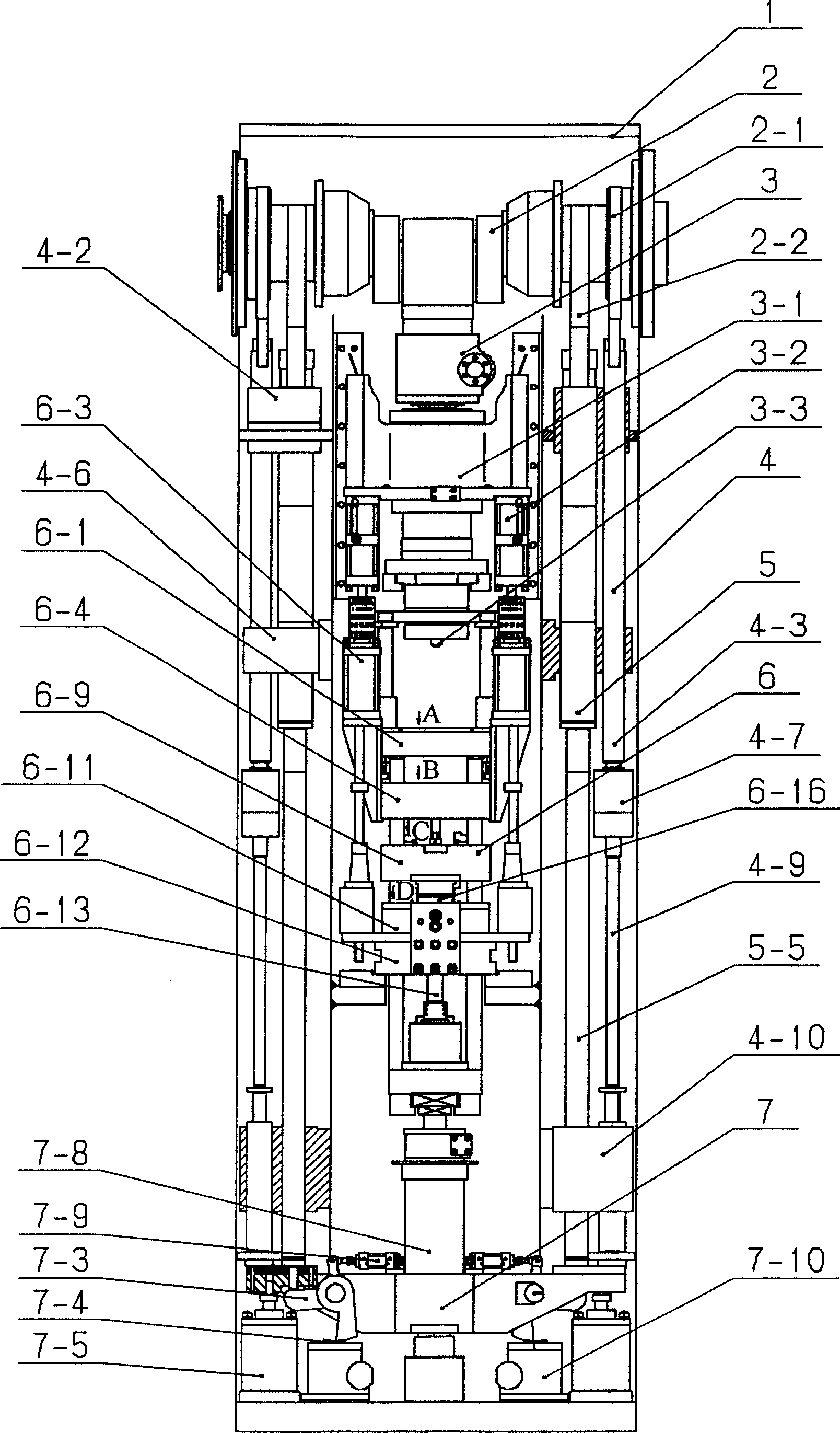

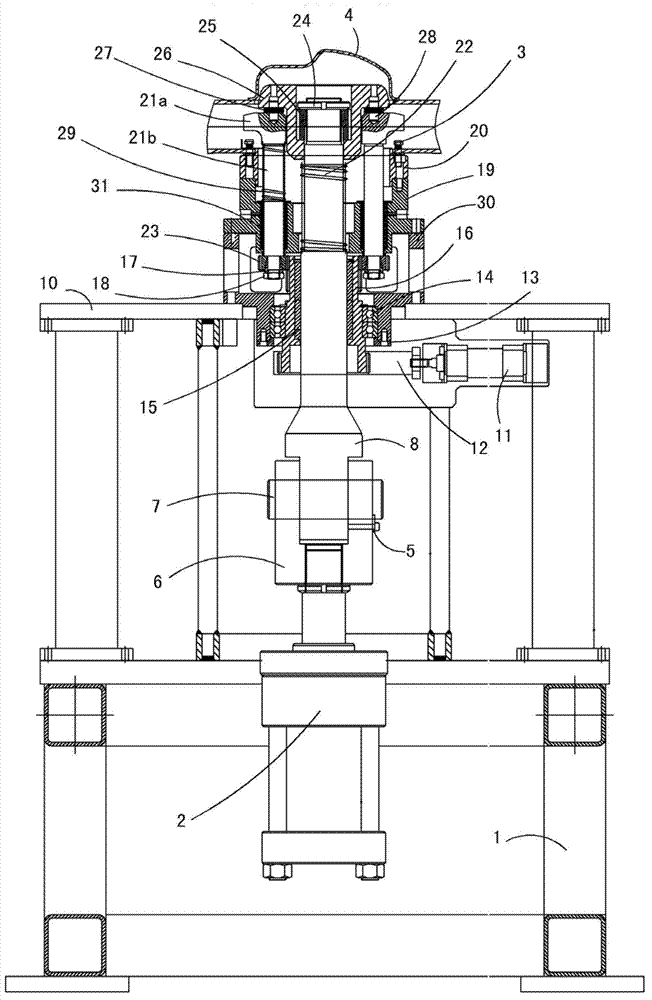

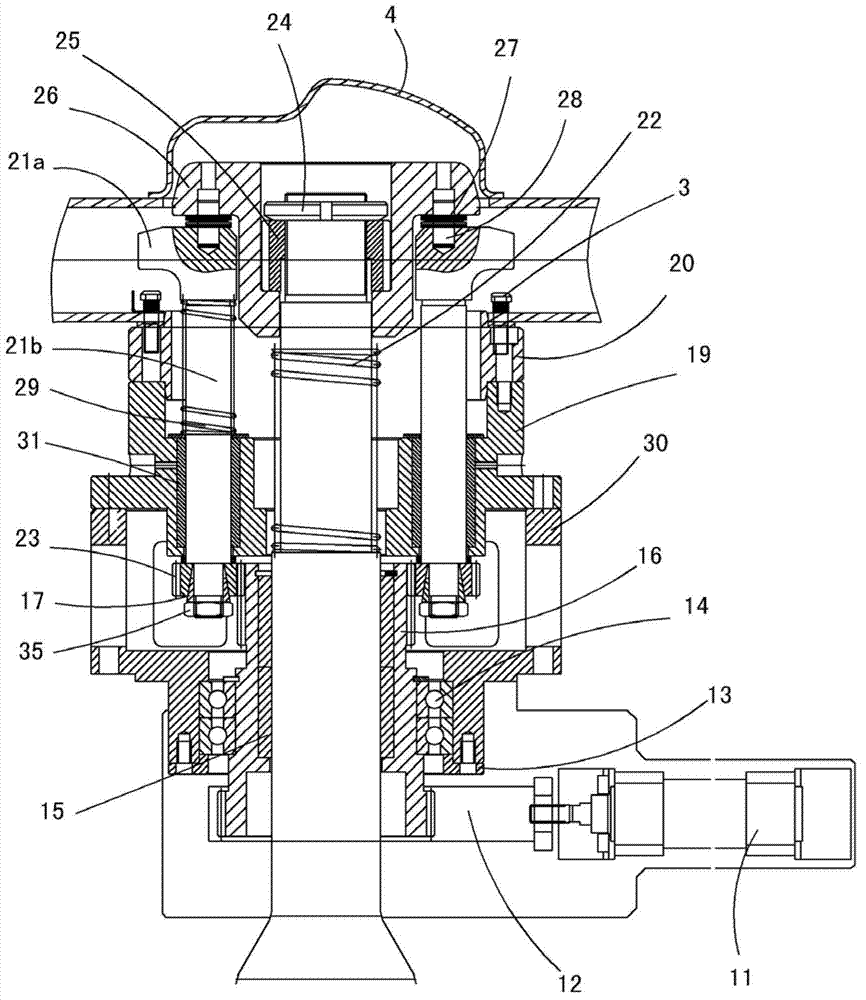

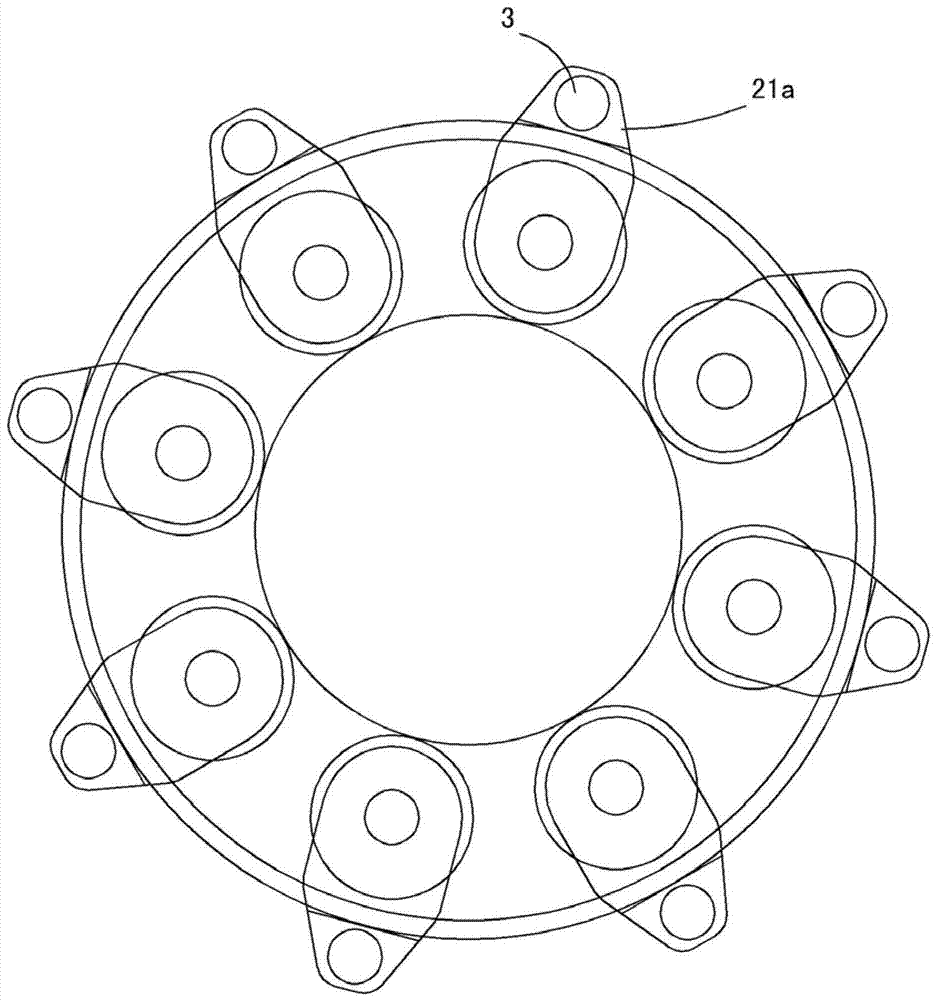

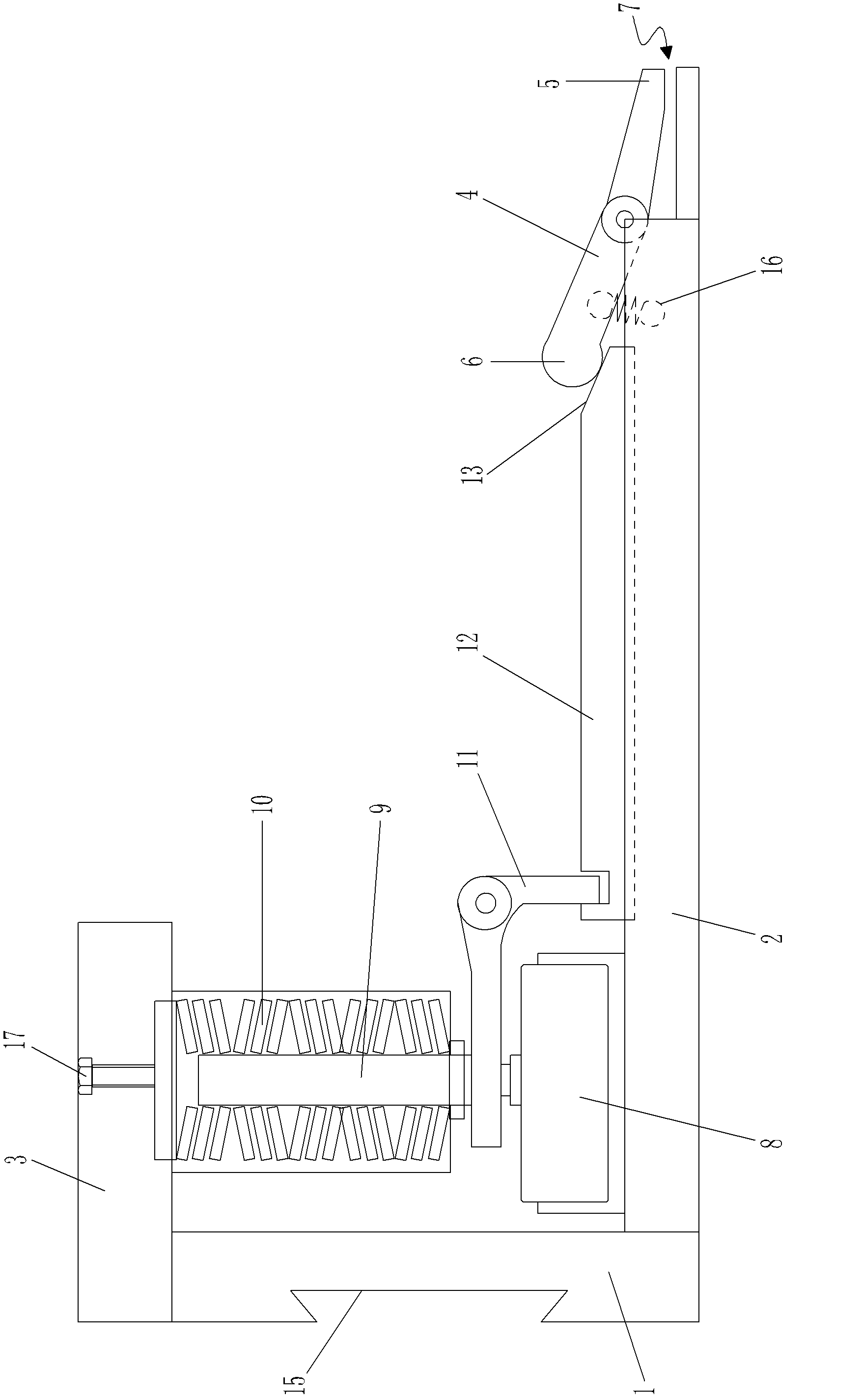

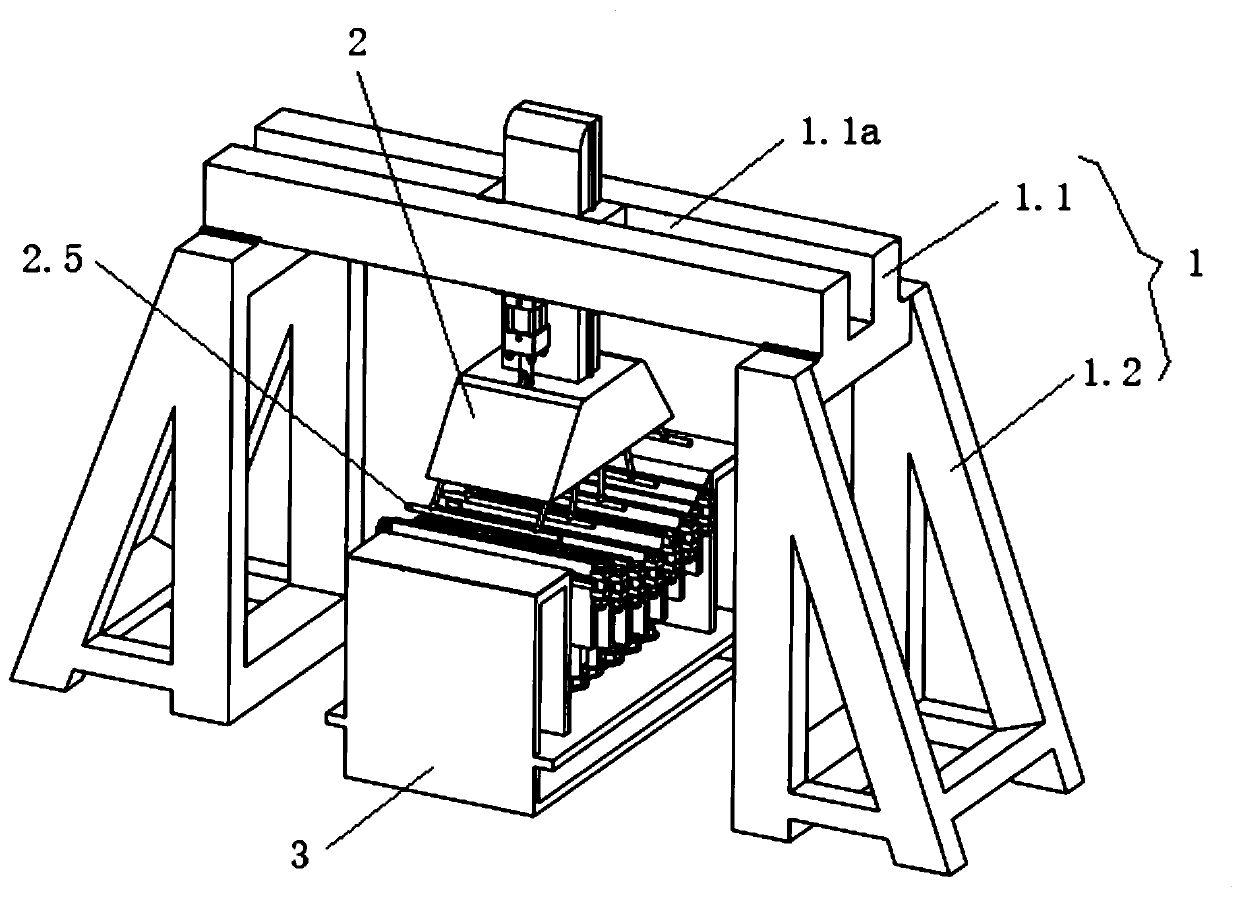

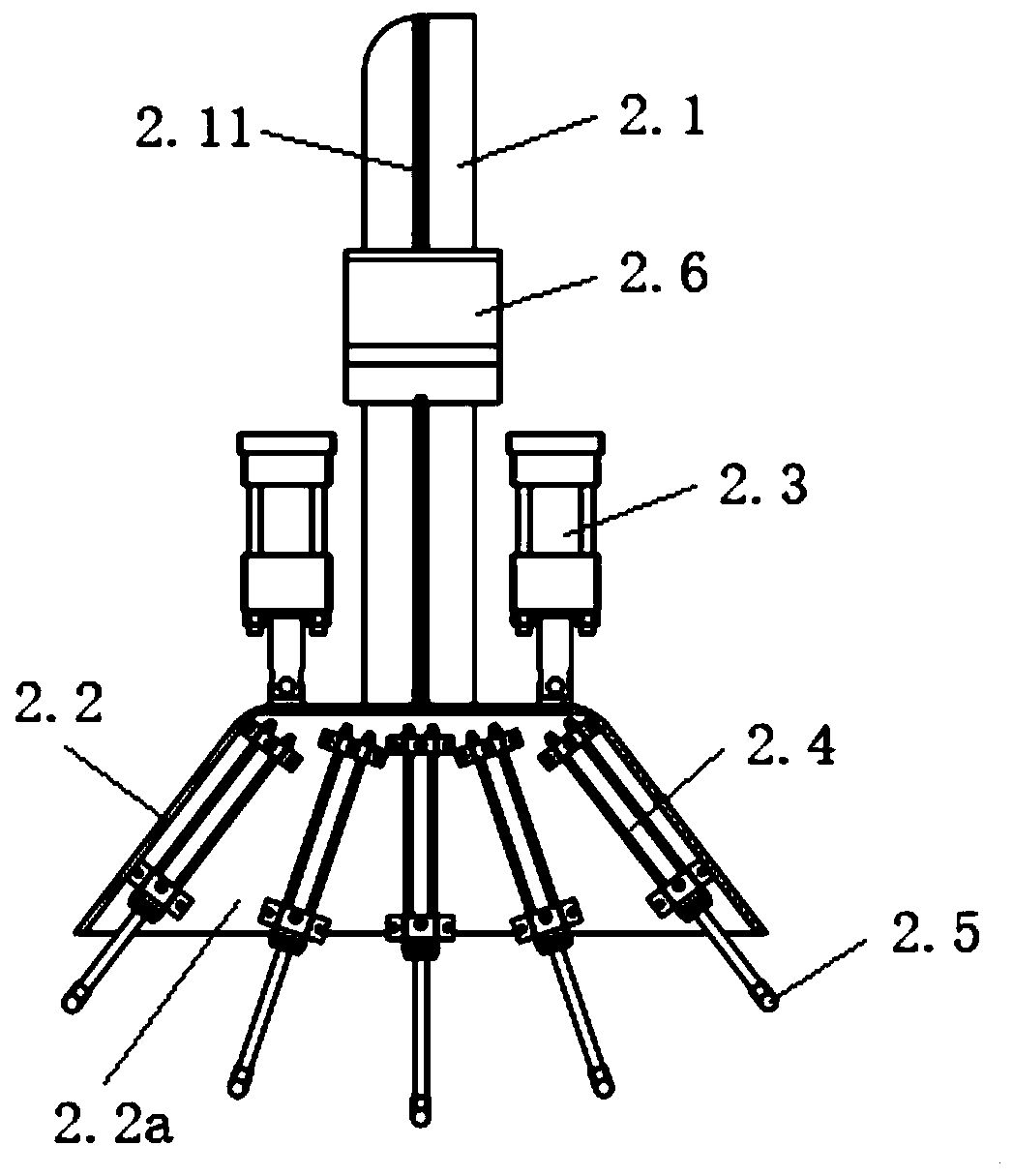

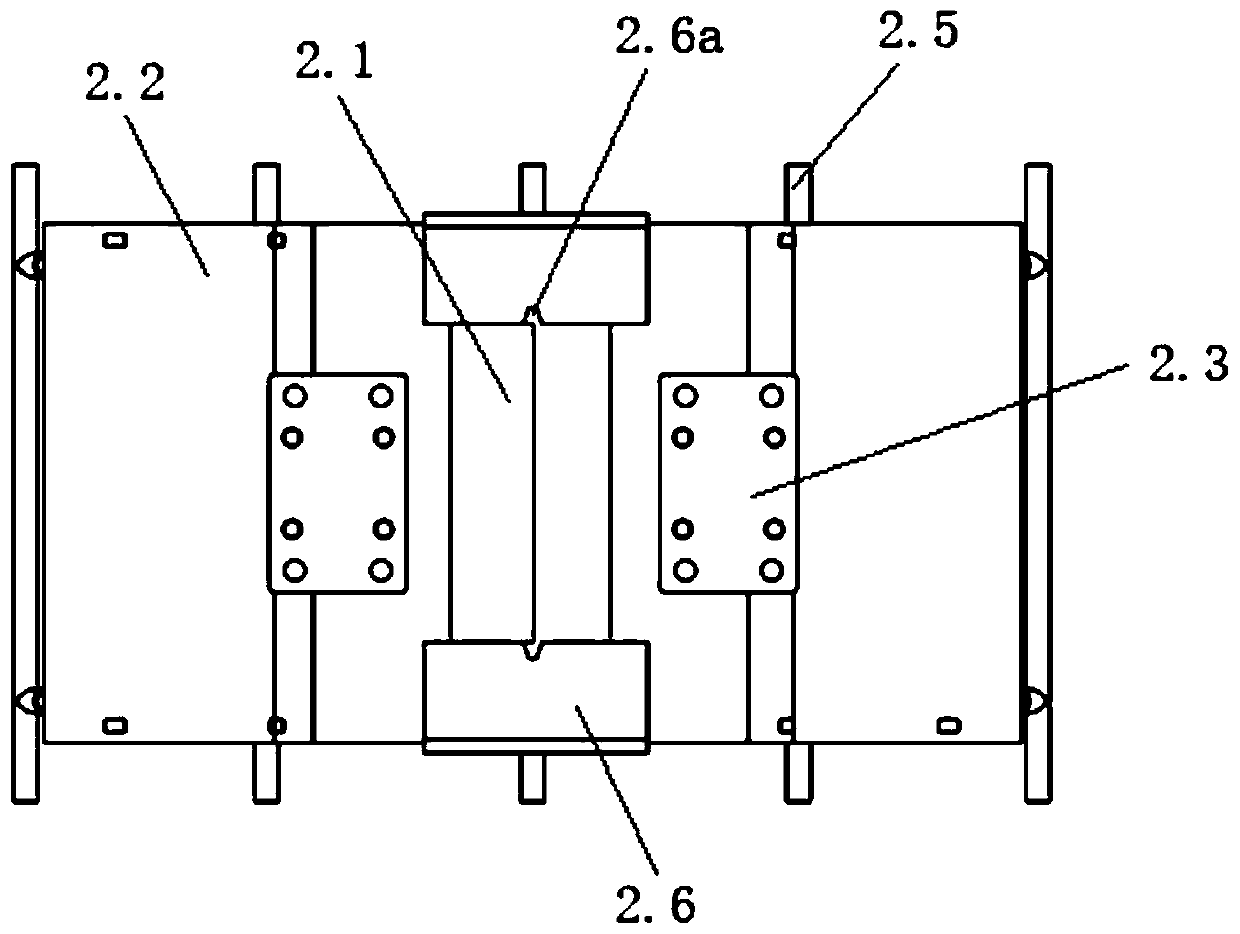

Mechanical loading creep age forming device

The invention discloses a mechanical loading creep age forming device. The mechanical loading creep age forming device comprises a rack, a loading device arranged on the rack and a mold arranged belowthe loading device; the loading device comprises a plurality of groups of loading hydraulic cylinders; the extending directions of the piston rods of two adjacent groups of loading hydraulic cylinders are different; the extending directions of the piston rods of the plurality of loading hydraulic cylinders in the same group are identical, and the lower ends of the plurality of piston rods are jointly connected with a pressing rod; and the mold comprises a mold-shaped plate and a plurality of supporting devices for supporting the mold-shaped plate. According to the mechanical loading creep ageforming device, the telescopic lengths of the piston rods of the different groups of loading hydraulic cylinders are controlled; the heights of the supporting devices can be adjusted, so that the curvature of a mold profile is adjusted; and therefore, the forming device can form multiple workpieces with different curvatures; a loading force is applied to a to-be-formed workpiece through the pressing rod, so that the possibility that internal defects are generated in the workpiece in a loading process is reduced. The mechanical loading creep age forming device has the advantages of simple structure, high operability, high practicability and stable quality of the formed workpiece.

Owner:CENT SOUTH UNIV

Paper box gluing device

ActiveCN108212664ALittle artificial influenceSmooth motionLiquid surface applicatorsCoatingsReciprocating motionCarton

The invention discloses a paper box gluing device and relates to the field of package. The paper box gluing device comprises a loading platform and a driving mechanism, wherein the loading platform isprovided with a gluing groove; the driving mechanism comprises a rocker arm; a sliding sleeve sleeves the rocker arm; the sliding sleeve is connected with a push rod; teeth are arranged at the bottomof the push rod; a glue groove is formed in the push rod; a gluing roller is arranged in the glue groove; a rotary gear is arranged below the push rod; the gear is engaged with the teeth; the gear iscoaxially fixedly provided with a cam; a pulling rod is fixed on the cam; a limiting wheel is coaxially fixed on the cam; one side, facing an eccentric end of the cam, of the limiting wheel is inwardconcave to form a semicircular groove; a swinging plate is arranged below the limiting wheel; the swinging plate is provided with a limiting groove and a pulling groove; the pulling rod is slidably arranged in the pulling groove; a glue barrel is arranged below the swinging plate; a piston plate is arranged in the glue barrel; the piston plate is provided with a pressing rod connected with the swinging plate; the glue barrel is connected with a glue outlet pipe. According to the paper box gluing device disclosed by the invention, the rotation of the rocker arm can drive the gluing roller to do transverse reciprocating motion and automatic gluing is carried out on the bottom of a paper box; the paper box does not need to be manually held to be subjected to manual gluing, so that manual influences are small, the running is stable and the gluing efficiency is high.

Owner:重庆云新包装有限公司

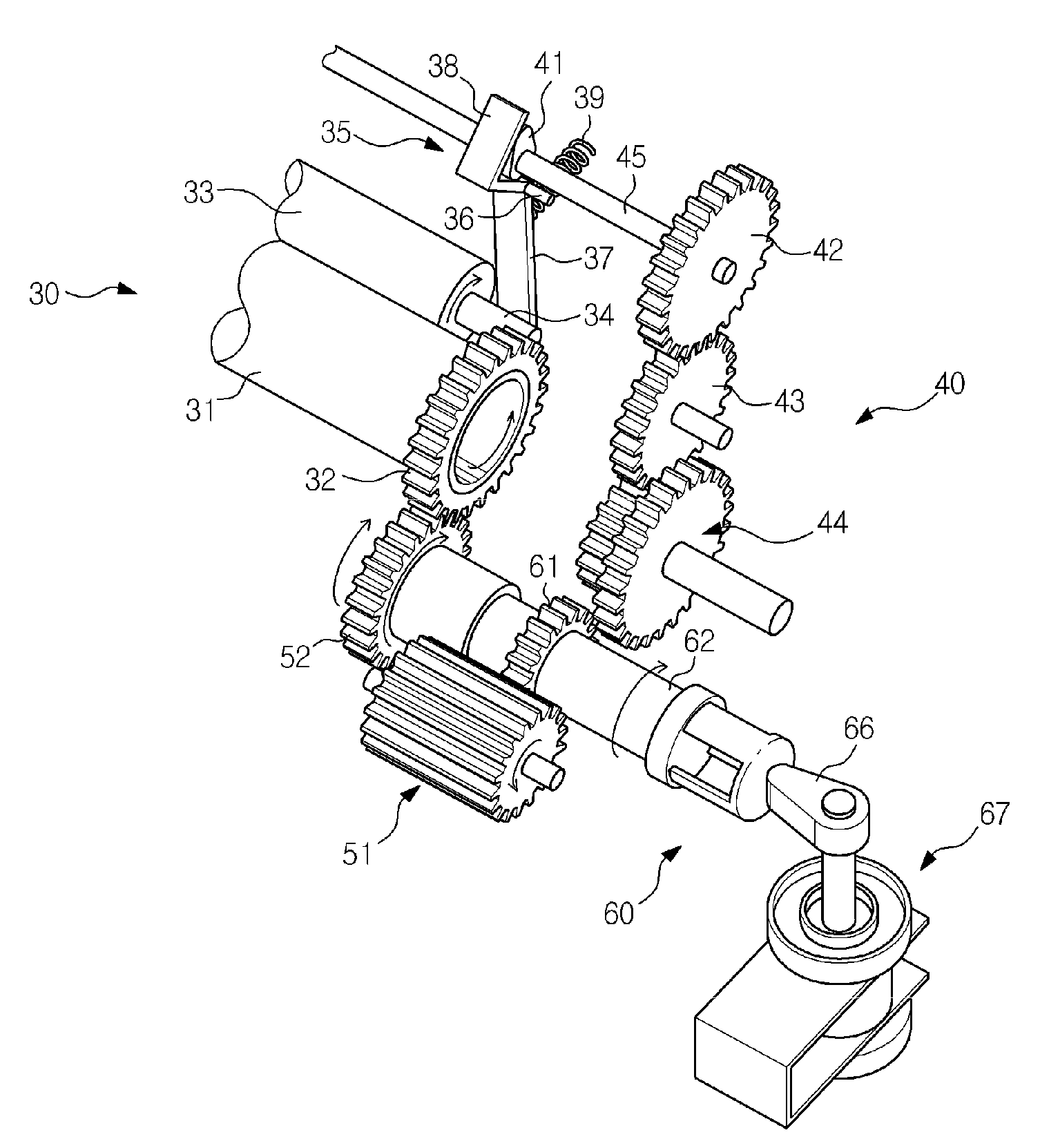

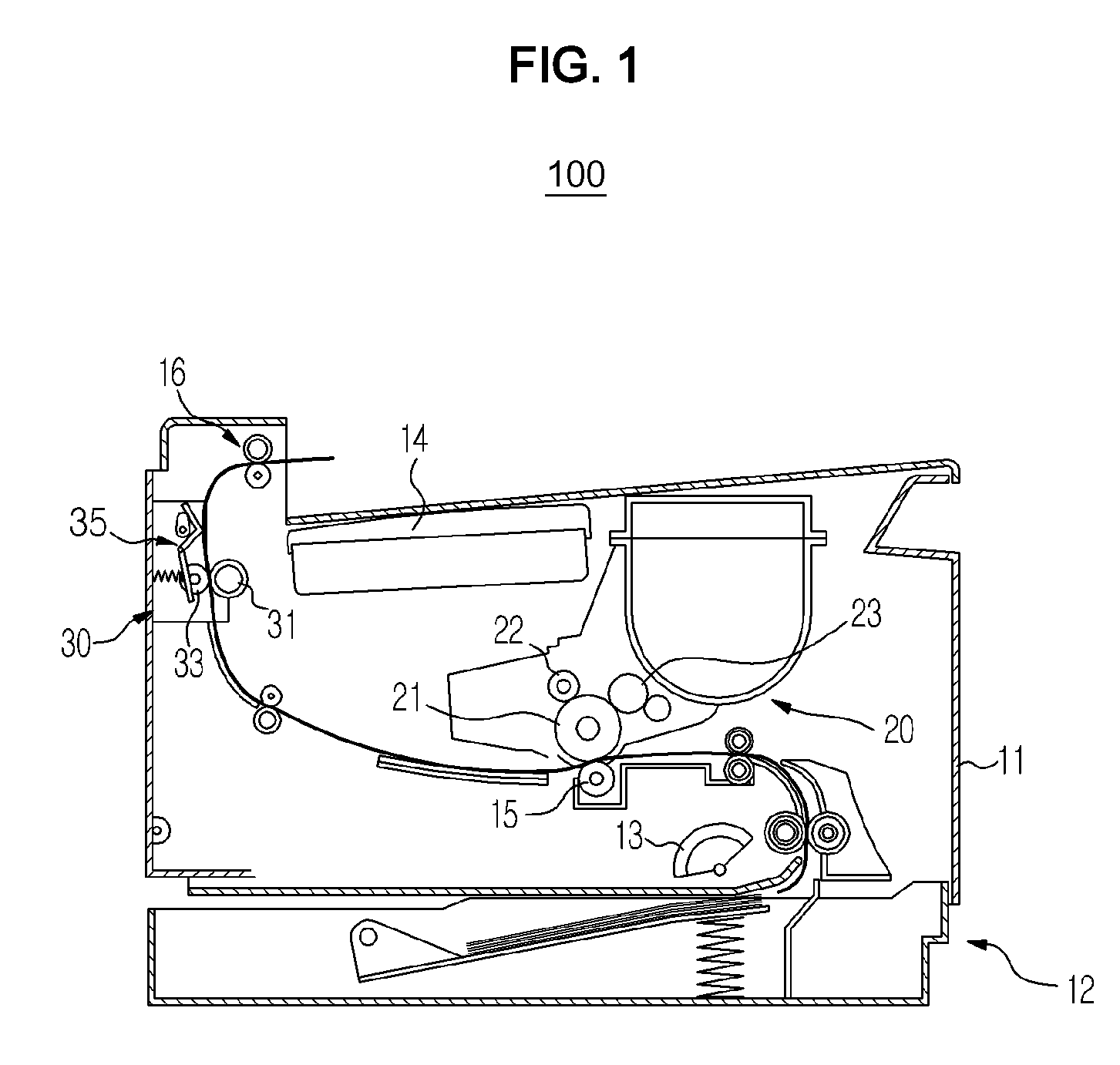

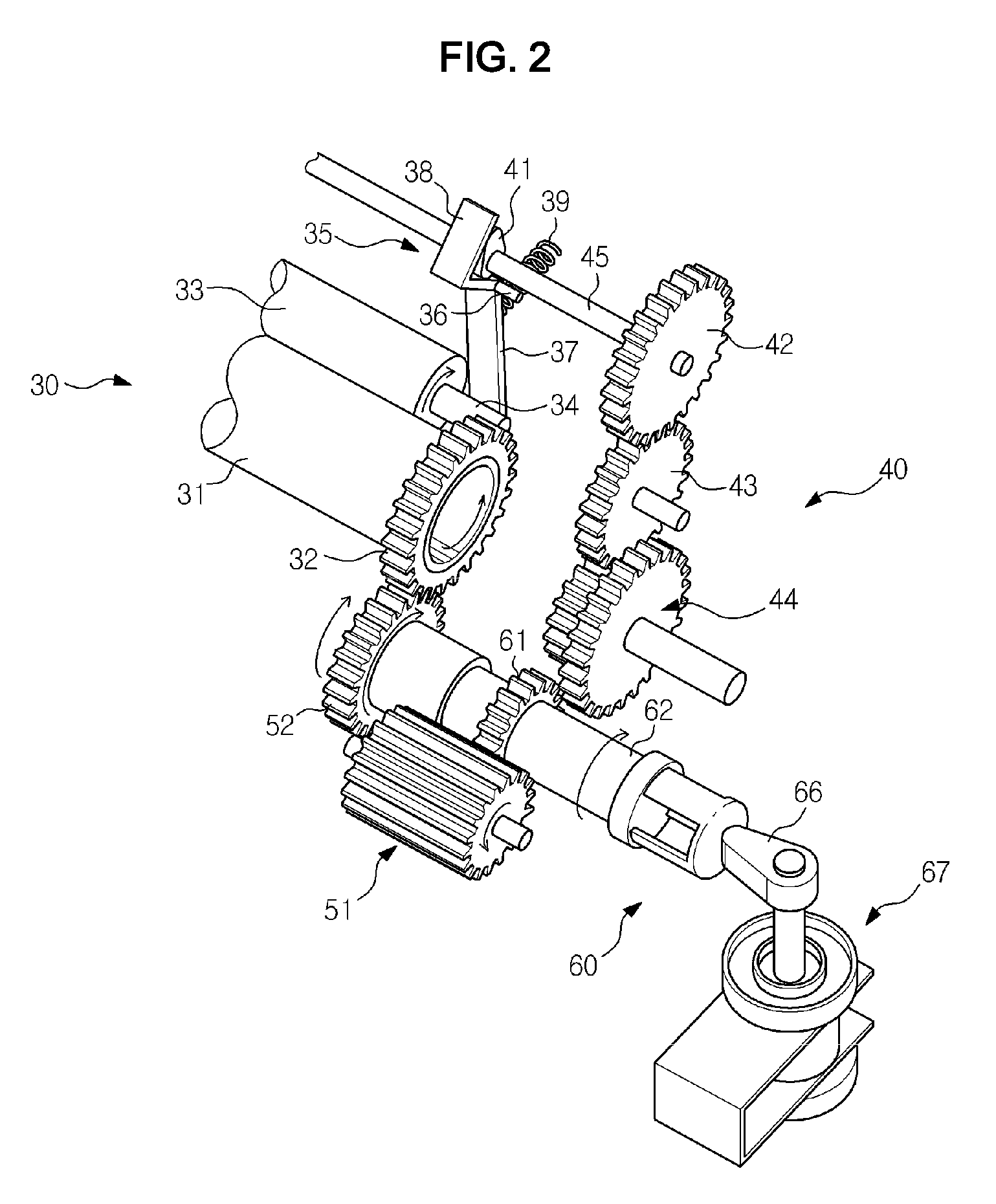

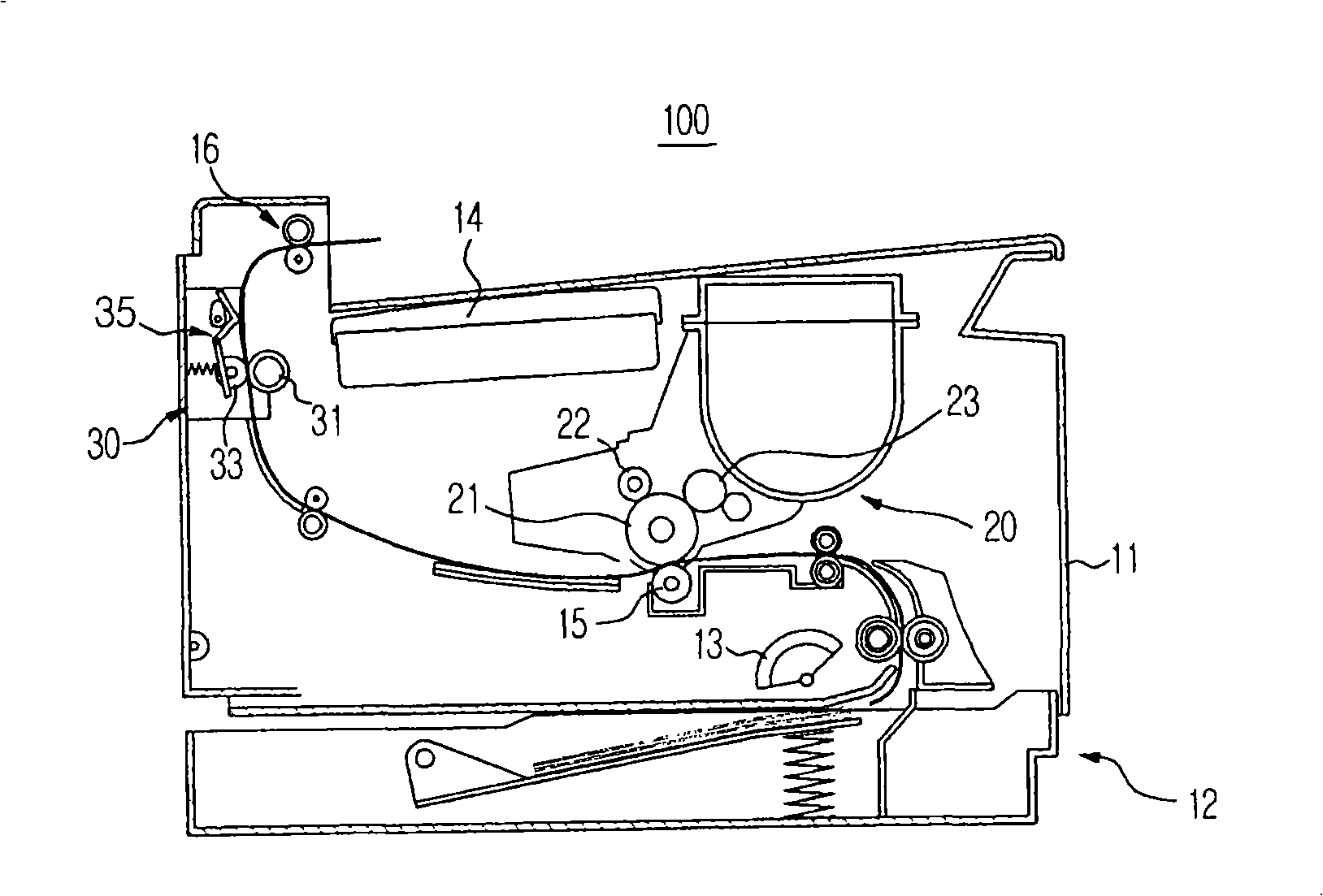

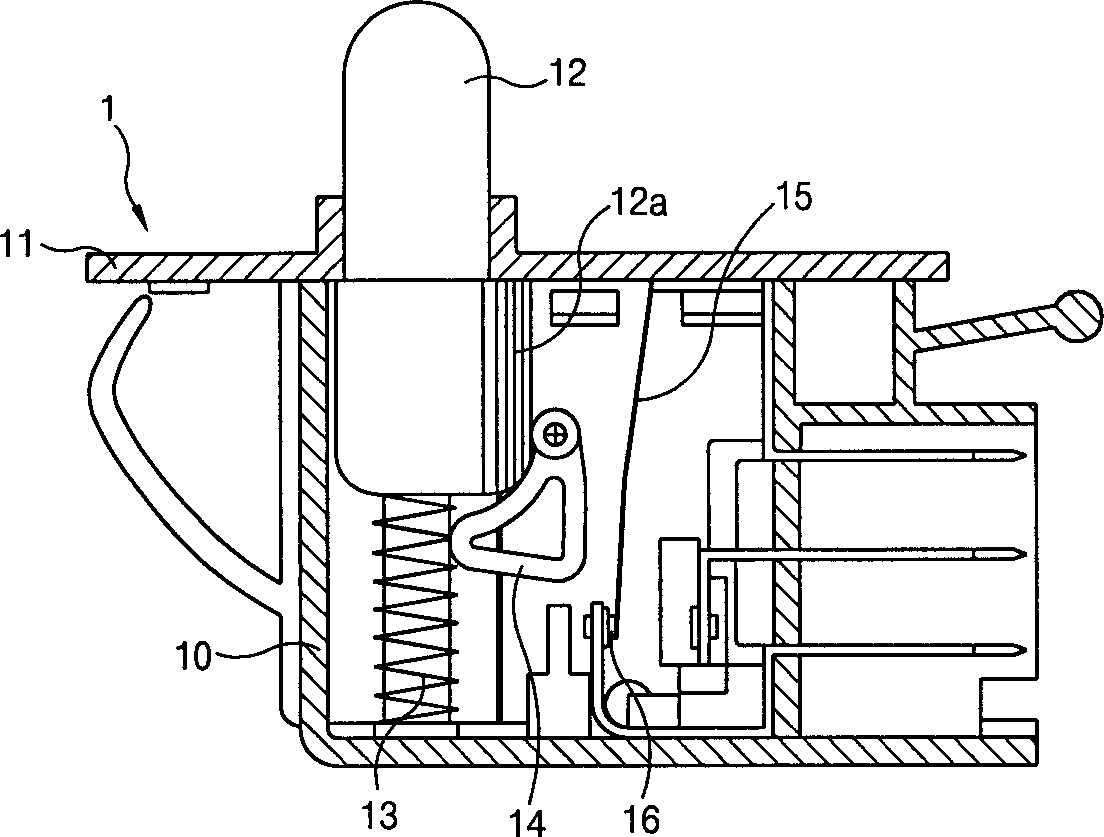

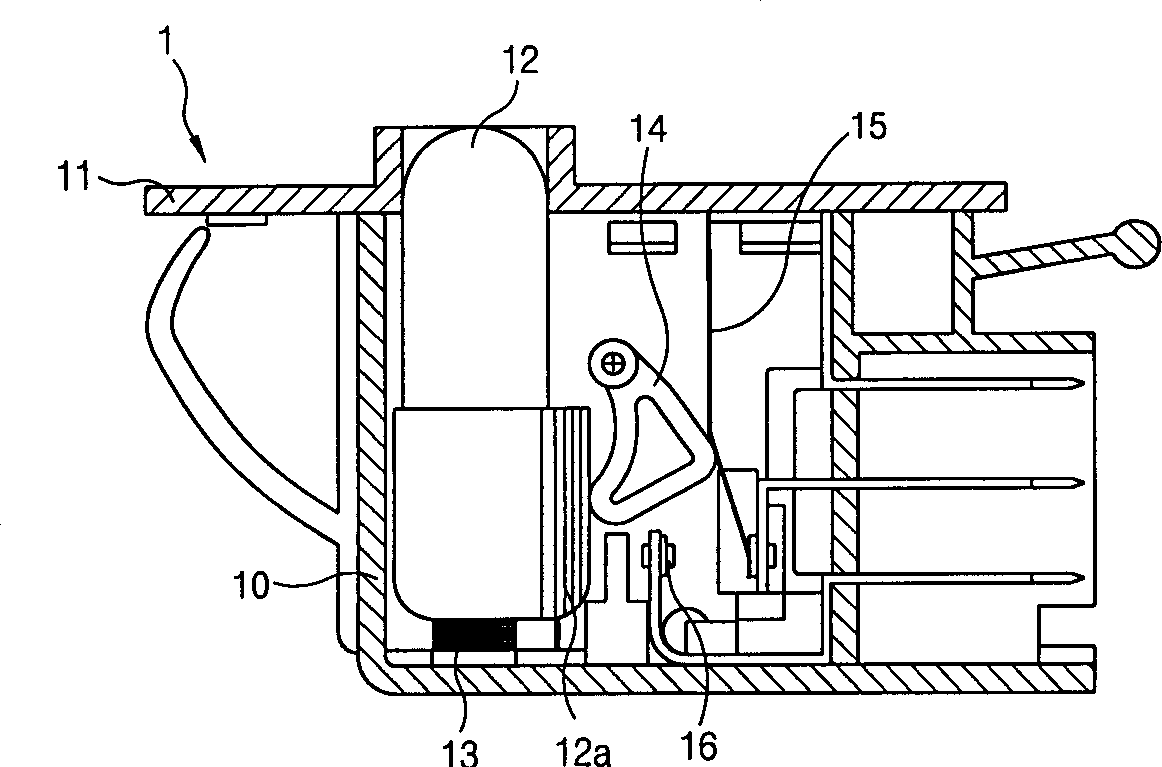

Image forming apparatus and fixing unit thereof

An image forming apparatus and a fixing unit thereof are disclosed. The fixing unit includes a heating roller, a press roller mounted in close contact with the heating roller to apply heat and pressure to the printable medium with the heating roller, a press lever to press the press roller toward the heating roller, a press spring connected to the press lever, a release device to operate the press lever to release pressing force exerted on the press roller, and a power conversion device to transmit driving power generated from a main driving source to drive the heating roller to the release device. Accordingly, since the press lever pressing the press roller to closely contact the heating roller can be operated by the driving power of the main driving source, the jammed printable medium can be easily removed.

Owner:SAMSUNG ELECTRONICS CO LTD

Commercial french press coffee brewing and dispensing system

A first coffee brewing and dispensing system that includes a removable grounds chamber assembly that includes a basin for holding ground coffee, an extendable dispensing spout, and a valve mechanism for opening and closing the dispensing spout; a brewing chamber assembly positioned on top of the removable grounds chamber assembly; and a lid / plunger assembly adapted to be inserted into the brewing chamber and removable grounds chamber, wherein the lid / plunger assembly includes a press rod, a handle mounted on the press rod, wherein the handle includes a trigger mounted therein, a lid mounted on the press rod below the handle, a wiper assembly mounted on the press rod below the lid; and a filter assembly mounted on the press rod below the wiper assembly, wherein the wiper assembly may be moved independently of the filter assembly by actuating the trigger in the handle.

Owner:SPITZLEY JULIE K

Image forming apparatus and fusing unit thereof

An image forming apparatus and a fixing unit thereof are disclosed. The fixing unit includes a heating roller, a press roller mounted in close contact with the heating roller to apply heat and pressure to the printable medium with the heating roller, a press lever to press the press roller toward the heating roller, a press spring connected to the press lever, a release device to operate the press lever to release pressing force exerted on the press roller, and a power conversion device to transmit driving power generated from a main driving source to drive the heating roller to the release device. Accordingly, since the press lever pressing the press roller to closely contact the heating roller can be operated by the driving power of the main driving source, the jammed printable medium can be easily removed.

Owner:SAMSUNG ELECTRONICS CO LTD

Switch for refrigerator door

A door switch for a refrigerator includes a case having a hole on one side; switch terminal units installed inside the case and making on / off operations of a circuit; a plunger for changing the on / off operations of the circuit mechanically while moving inward / outward of the case through the hole on the case; and a restriction means installed on the case for restricting the movement of the plunger, whereby a chamber light can be turned off even if the door of refrigerator is opened, and therefore power consumption of the refrigerator can be reduced.

Owner:LG ELECTRONICS INC

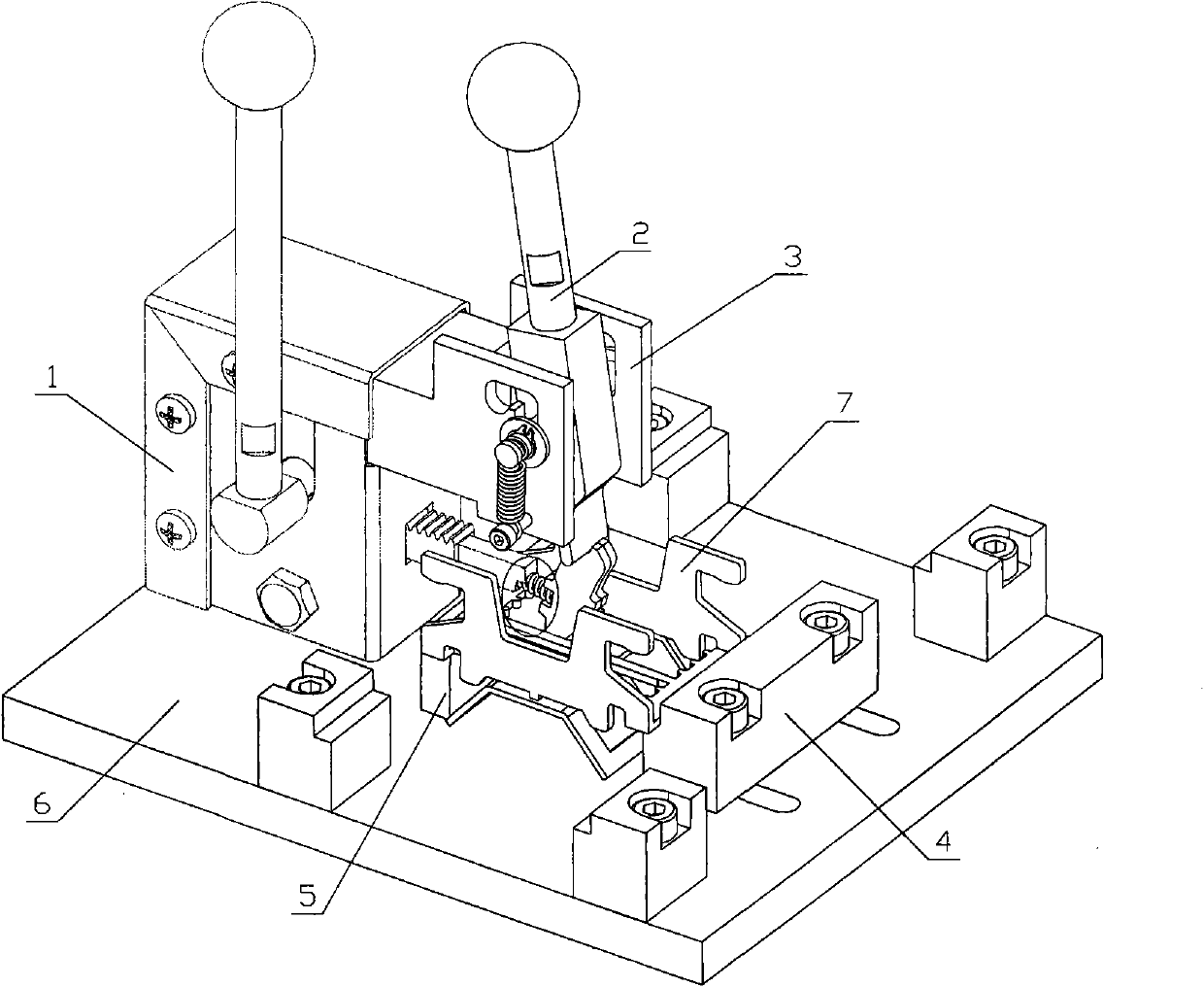

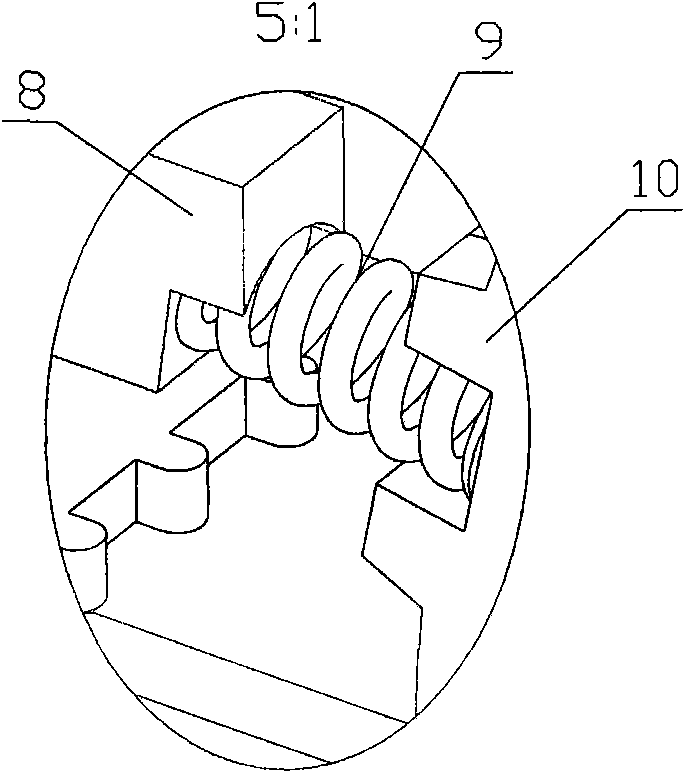

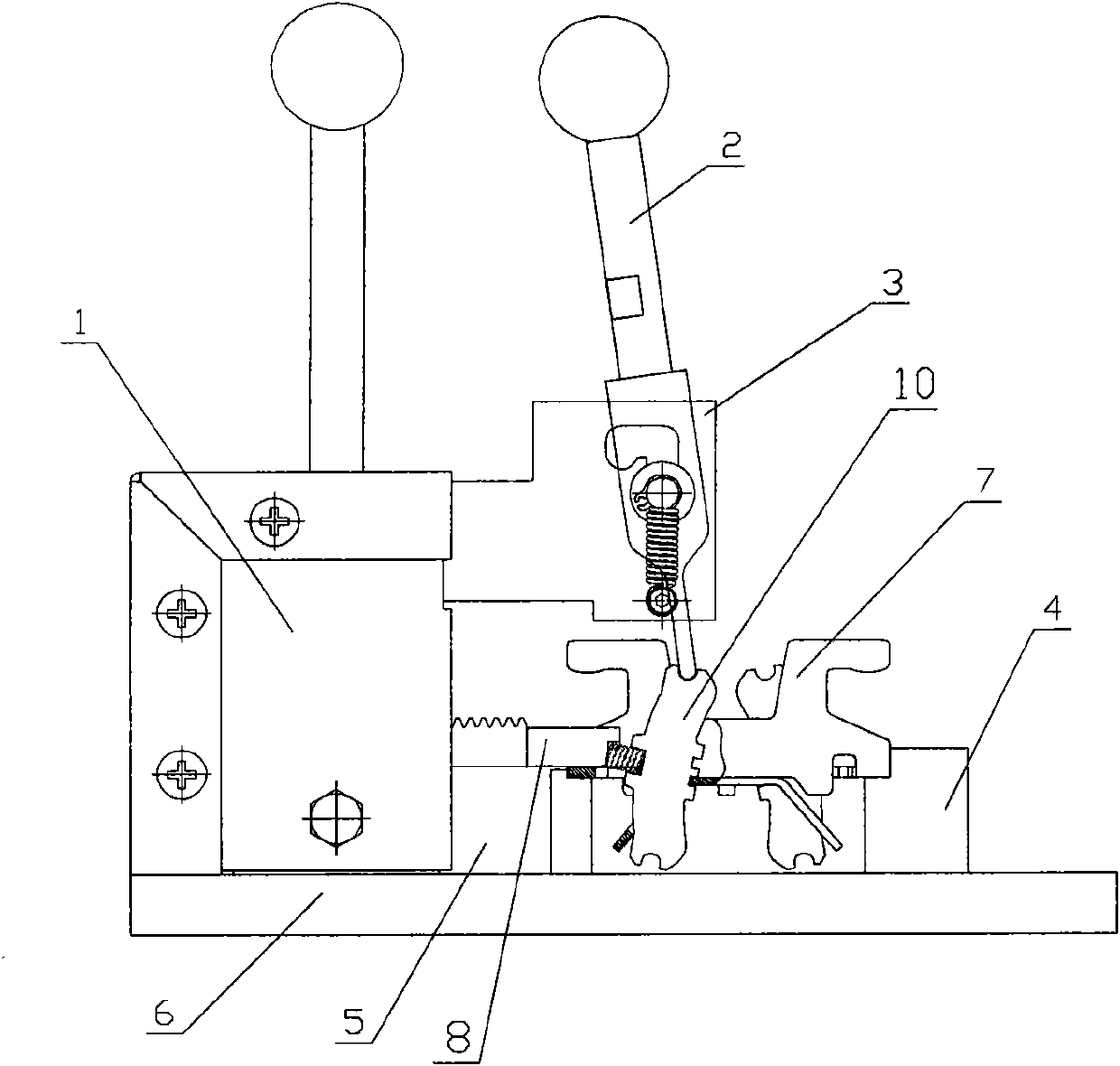

Device for assembling contact spring of frame-type breaker

InactiveCN102201299ASafe and convenient embeddedConvenient and fast embeddedEmergency protective device manufactureEngineeringStructural engineering

The invention discloses a device for assembling a contact spring of a frame-type breaker, which consists of a bottom plate, a gear box, a pressing rod, a pressing rod bracket, a stop block and a positioning block, wherein the gear box, the stop block and the positioning block are all fixedly assembled on the bottom plate; the gear box has a rack which extends out of the gear box and a handle which operates sliding of the rack, the exposed end of the rack is step-shaped, and the step-shaped surface is inclined; the pressing rod bracket is fixed on the later surface of the gear box and positioned above the exposed end of the rack; the pressing rod is fixed on the middle part of the pressing rod bracket and can rotate around a fixed shaft; the pressing rod bracket has a '7'-shaped groove; the fixed shaft of the pressing shaft can slide along the '7'-shaped groove; and the lower end part of the pressing rod has an arc surface.

Owner:江苏西门控电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com