Device for assembling contact spring of frame-type breaker

A frame circuit breaker and contact spring technology, used in emergency protection devices, manufacturing of emergency protection devices, circuits, etc., can solve the problems of personal injury, time-consuming and laborious, spring easily slipping out, etc., to reduce labor intensity, safe and convenient operation , The effect of convenient and quick embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

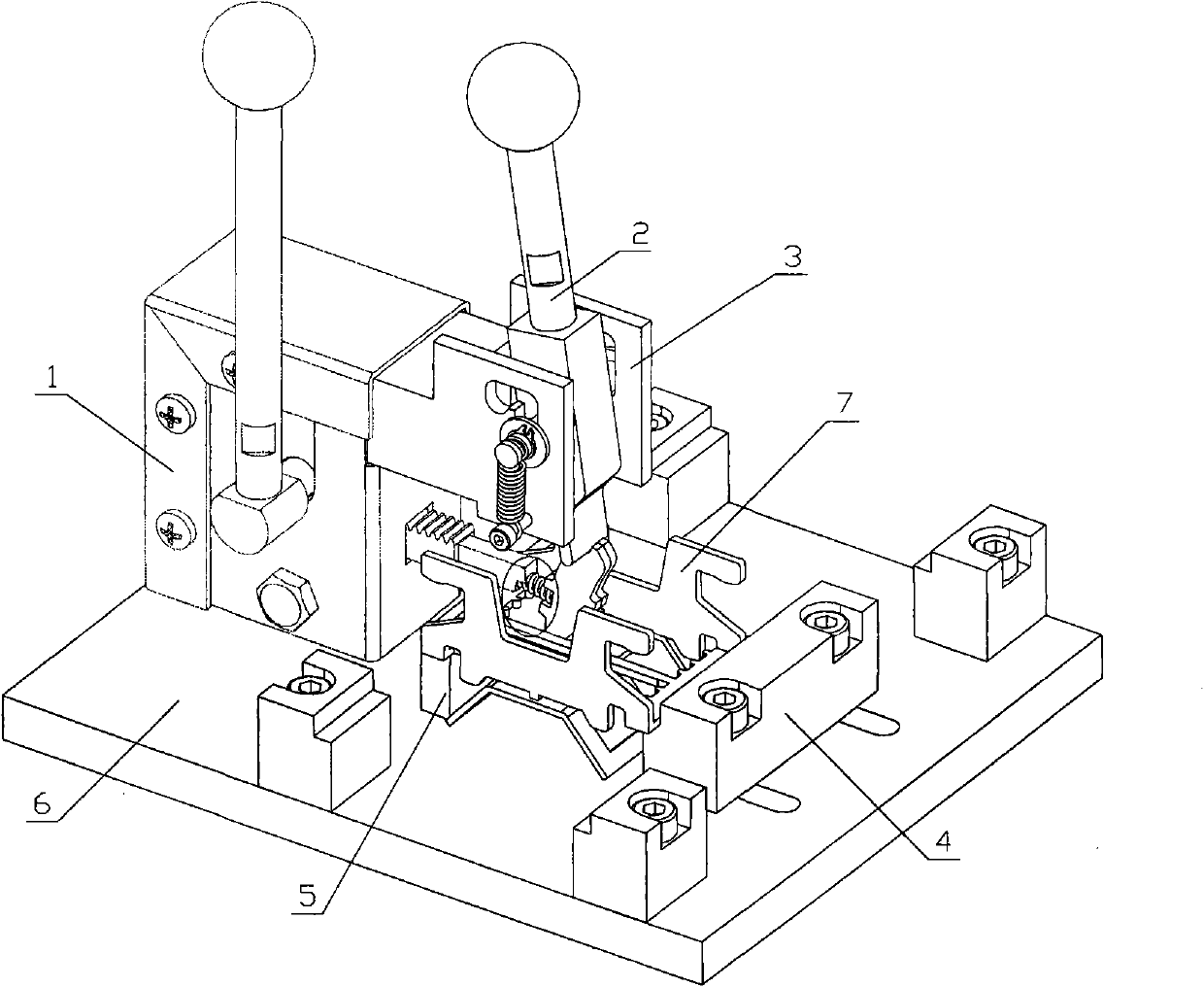

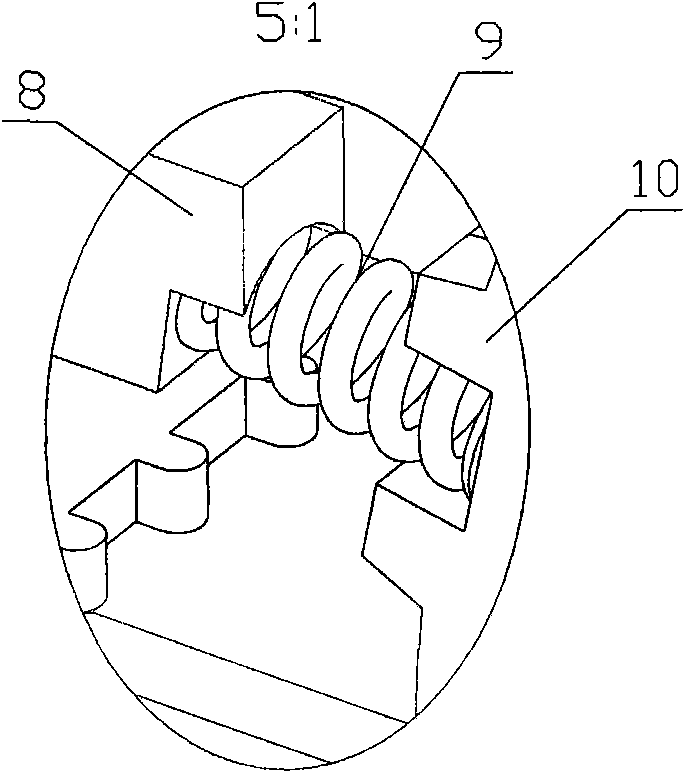

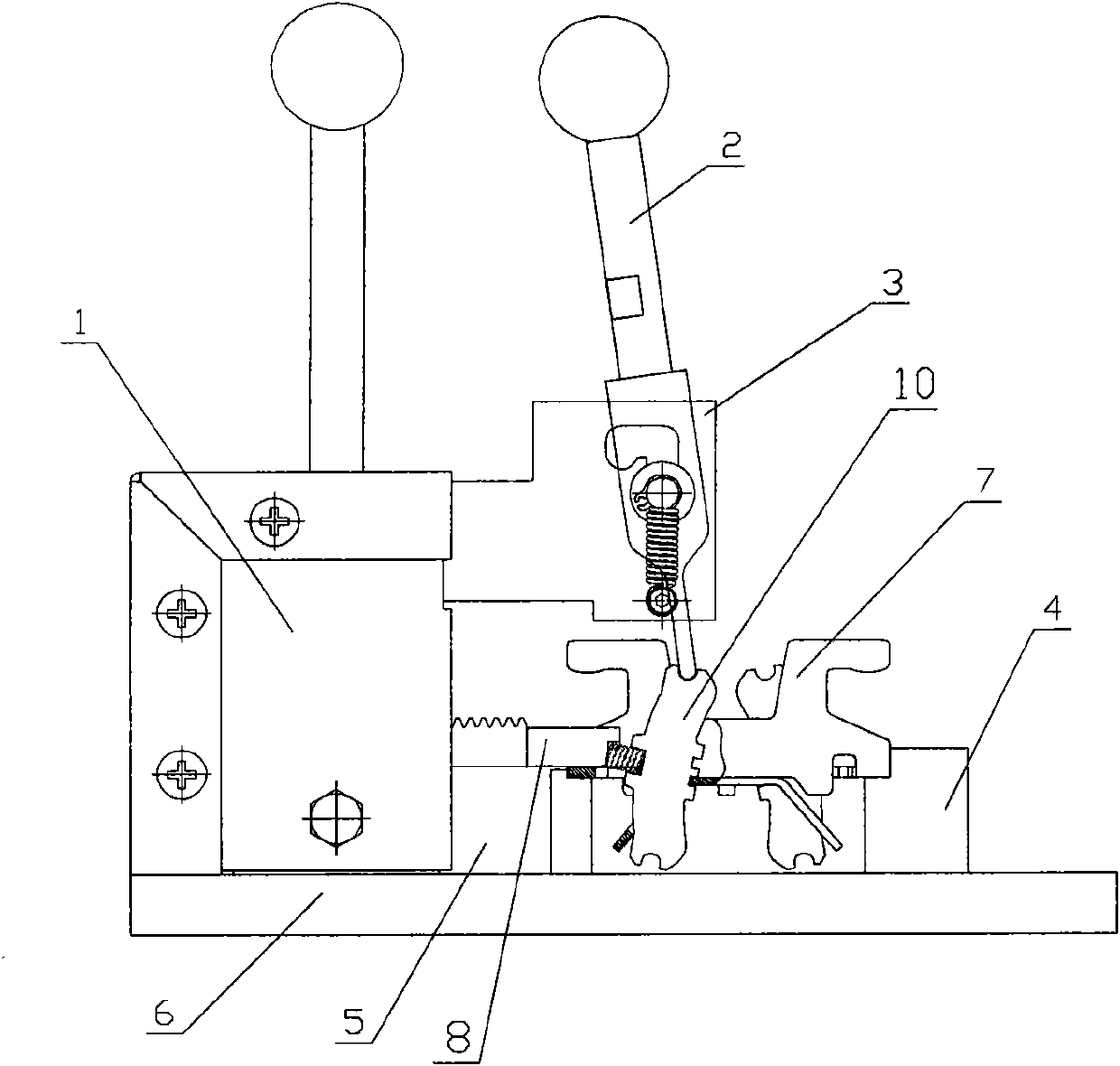

[0015] As shown in the figure, the contact spring assembly device of the frame circuit breaker of the present invention is composed of a bottom plate 6, a gear box 1, a pressure bar 2, a pressure bar bracket 3, a stopper 4, and a positioning block 5. The gear box 1, the stopper 4, The positioning blocks 5 are all fixedly installed on the base plate 6, the gear box 1 has a rack 8 extending out of the gear box 1, and a handle controls the sliding of the rack 8, the exposed end of the rack 8 is stepped, and the stepped surface is an inclined plane; The pressure rod bracket 3 is fixed on the side of the gear box 1 and is located above the exposed end of the rack 8. The pressure rod 2 is fixed in the middle of the pressure rod bracket 3 and can rotate around the fixed axis. The pressure rod bracket 3 has a "7" shaped groove. The fixed shaft of the bar 2 can slide along the "7" shaped groove, and the lower end of the bar 2 is an arc-shaped surface.

[0016] The action process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com