Manufacturing method of single-shaft strain GeOI wafer based on mechanical bending table

A manufacturing method and uniaxial strain technology, applied in the field of microelectronics, can solve the problems of silicon wafers being easily broken, complicated process steps, and long manufacturing cycle, and achieve small surface roughness, simple manufacturing process, and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Preparation of 3-inch uniaxially strained GeOI wafer

[0037] 1. GeOI wafer selection: 3-inch (100) or (110) wafer ((100) or (110) refers to a certain crystal surface of the GeOI wafer crystal surface), Si substrate thickness 0.4mm, SiO 2 The buried insulating layer is 500nm thick, and the top Ge layer is 500nm thick.

[0038] GeOI wafer diameter selection: the larger the diameter of the GeOI wafer, the smaller the minimum bending radius of the bend, the greater the strain of the obtained uniaxially strained GeOI wafer, and the final electron migration of the uniaxially strained GeOI wafer The enhancement of rate and hole mobility is also higher. For the SiO-based 2 For uniaxially strained GeOI wafers with buried insulating layers, GeOI wafers with different diameters from 3 inches to 8 inches can be selected according to the different processes of GeOI devices and circuits.

[0039] GeOI wafer crystal face and crystal orientation selection: for the te...

Embodiment 2

[0057] Embodiment 2: Preparation of 4-inch uniaxially strained GeOI wafer

[0058] 1. GeOI wafer selection: 4-inch (100) or (110) crystal plane, Si substrate thickness 0.55mm, SiO 2 The buried insulating layer is 300nm thick, and the top Ge layer is 50nm thick.

[0059] 2. Selection of bending radius of curvature: According to the selected GeOI wafer, the radius of curvature of the bending table is selected to be 0.75m.

[0060] 3. GeOI wafer bending process steps:

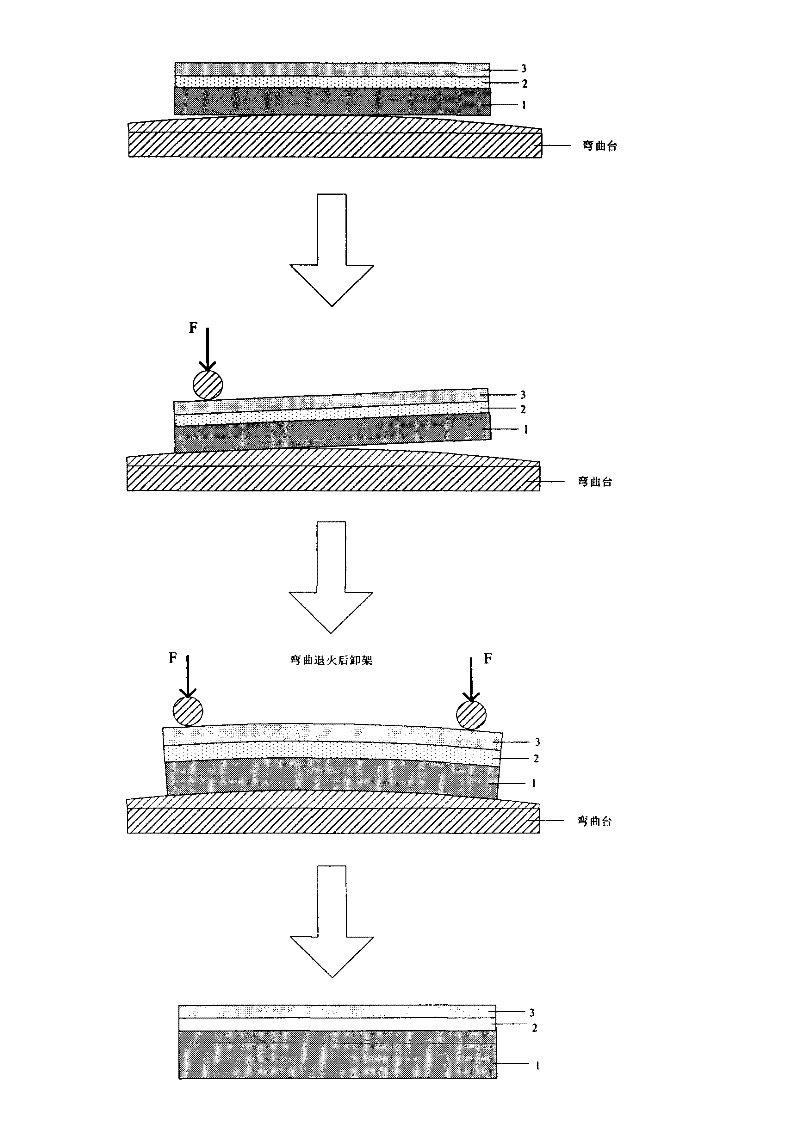

[0061] 1) Place the Ge layer on the top layer of the GeOI wafer upwards (or downwards) on a clean stainless steel arc-shaped bending table, and its or direction is parallel to the bending direction, such as image 3 or Figure 4 shown;

[0062] 2) Two cylindrical horizontal pressure bars on the bending table are placed horizontally at both ends of the GeOI wafer, 1 cm away from its edge;

[0063] 3) Rotate the ejector nut of one of the pressure rods on the bending table to fix one end of the GeOI wafer firs...

Embodiment 3

[0072] Embodiment 3: Preparation of 6-inch uniaxially strained GeOI wafer

[0073] 1. GeOI wafer selection: 6-inch (100) or (110) crystal plane, Si substrate thickness 0.68mm, SiO2 buried insulating layer thickness 1000nm, top Ge layer thickness 1000nm.

[0074] 2. Selection of bending radius of curvature: According to the selected GeOI wafer, the radius of curvature of the bending table is selected to be 0.5m.

[0075] 3. GeOI wafer bending process steps:

[0076] 1) Place the Ge layer on the top layer of the GeOI wafer upwards (or downwards) on an arc-shaped bending table, and its bending direction is parallel to the or direction, such as image 3 or Figure 4 shown;

[0077] 2) Two cylindrical horizontal pressure bars on the bending table are placed horizontally at both ends of the GeOI wafer, 1 cm away from its edge;

[0078] 3) Rotate the ejector nut of one of the pressure rods on the bending table to fix one end of the GeOI wafer first;

[0079] 4) Slowly turn the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bending radius | aaaaa | aaaaa |

| Bending radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com