Pull-down type press-in device for axle housing bolt

A press-in device, axle housing bolt technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of small cavity space, low production efficiency, inconvenient operation, etc., to achieve safe and reliable process, upper and lower parts Process quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

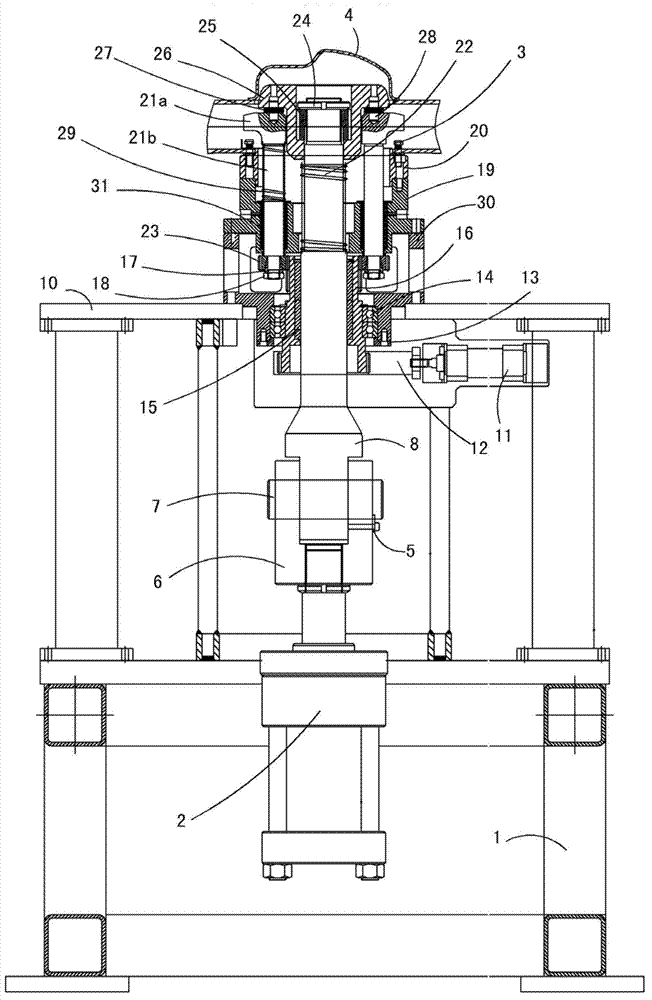

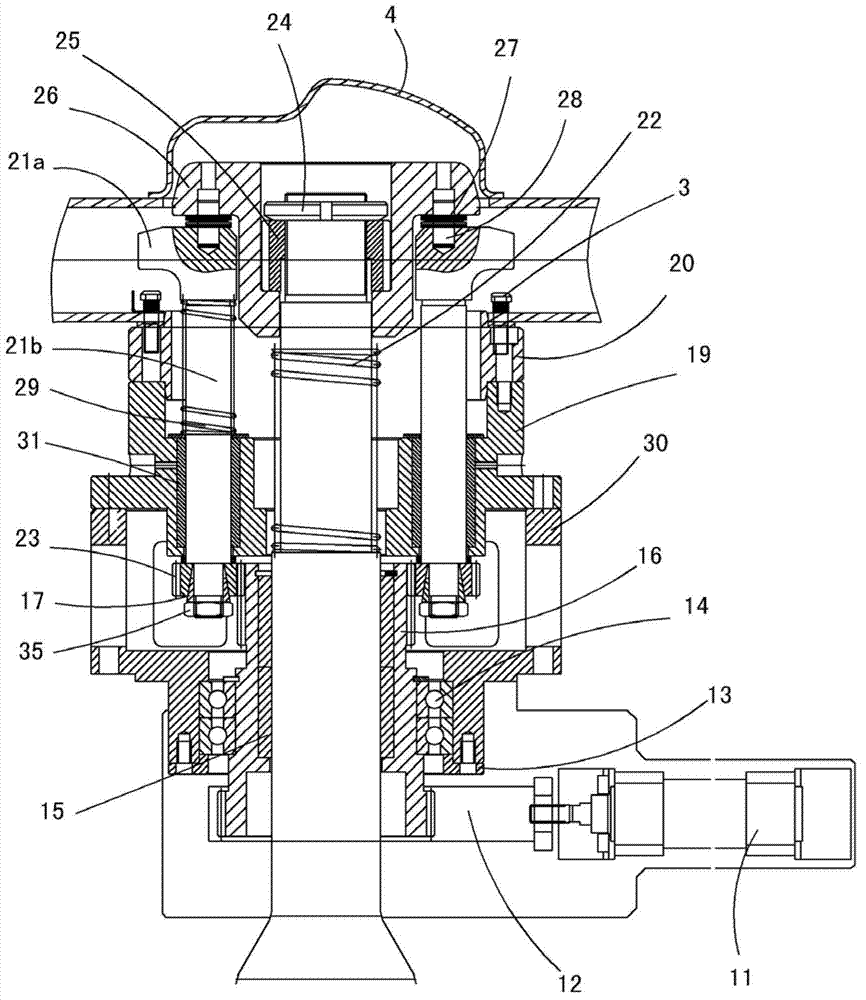

[0025] In this embodiment, the structure of the pull-down press-in device for axle housing bolts is set as follows:

[0026] The power cylinder 2 is fixedly arranged on the bottom frame 1, and the platform 10 is supported by a bracket on the bottom frame 1. The bottom end of the vertically arranged pull rod 8 and the piston rod of the power cylinder 2 on the same axis position The ends are connected, and the connectors therebetween are the joint 6 and the pin shaft 7. The anti-rotation piece 5 is fixedly arranged on the joint 6, and the anti-rotation piece 5 is inserted in the radial groove of the pin shaft 7 to prevent the rotation of the pin shaft 7.

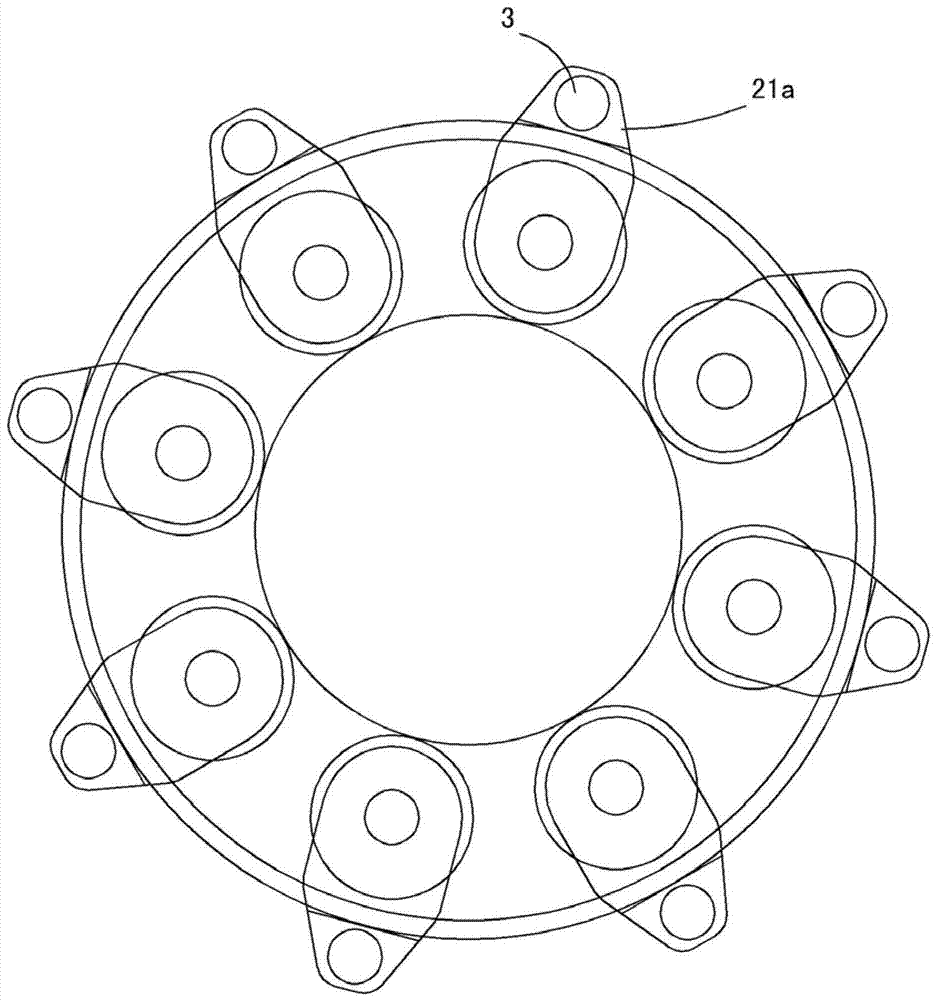

[0027] A horizontally telescopic telescopic mechanism 11 is arranged at the bottom of the platform 10, and the telescopic rod of the telescopic mechanism 11 can drive the rotor 16 sleeved on the outer periphery of the pull rod 8 to rotate through a transmission member 12, and the upper end of the rotor 16 is provided with perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com