Panel feeding clamp

A sheet material and material feeding technology, which is applied in metal processing and other directions, can solve problems affecting work efficiency and achieve the effect of stable clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

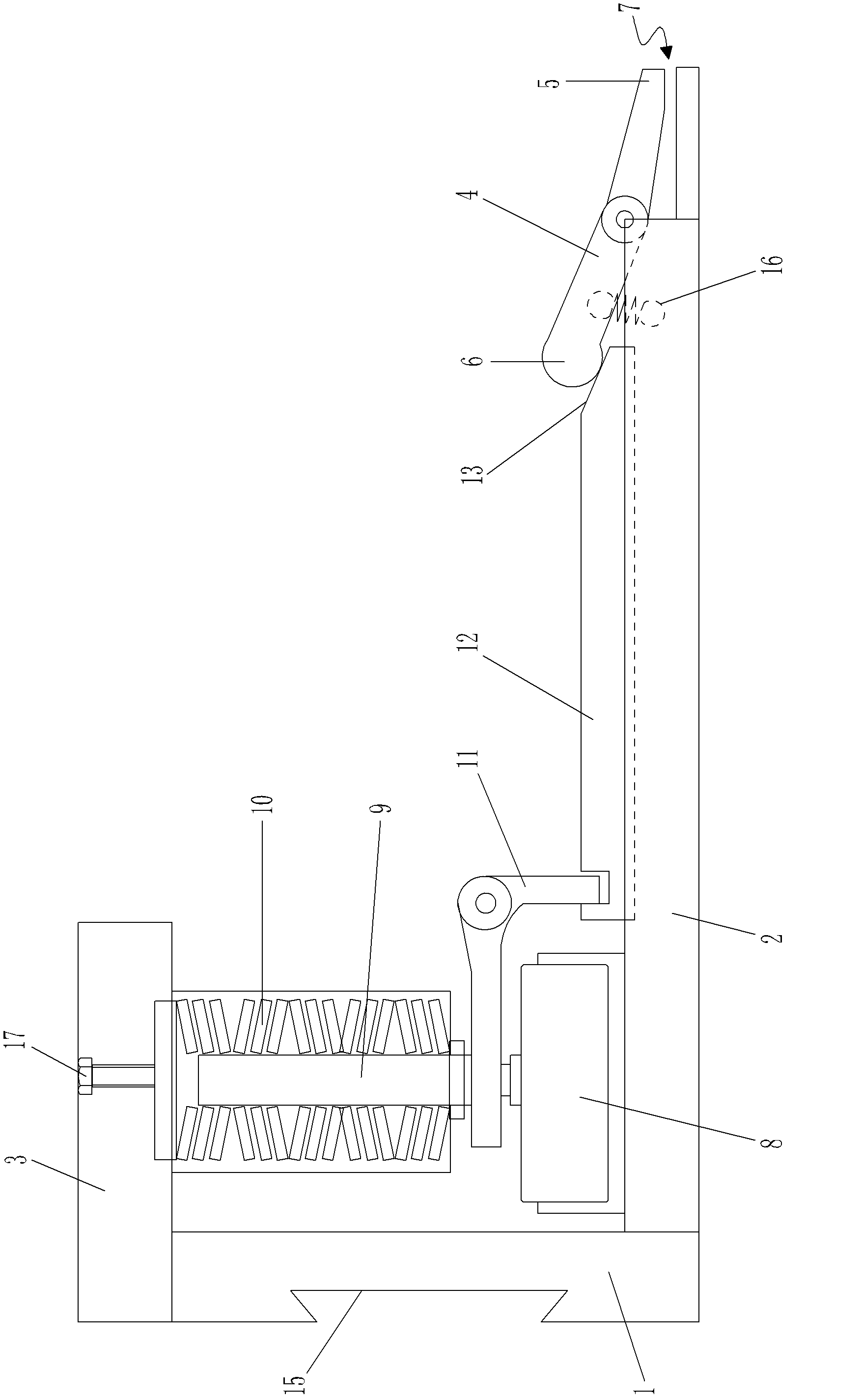

[0017] The technical scheme of the present invention is described in detail below in conjunction with the embodiment shown in the accompanying drawings:

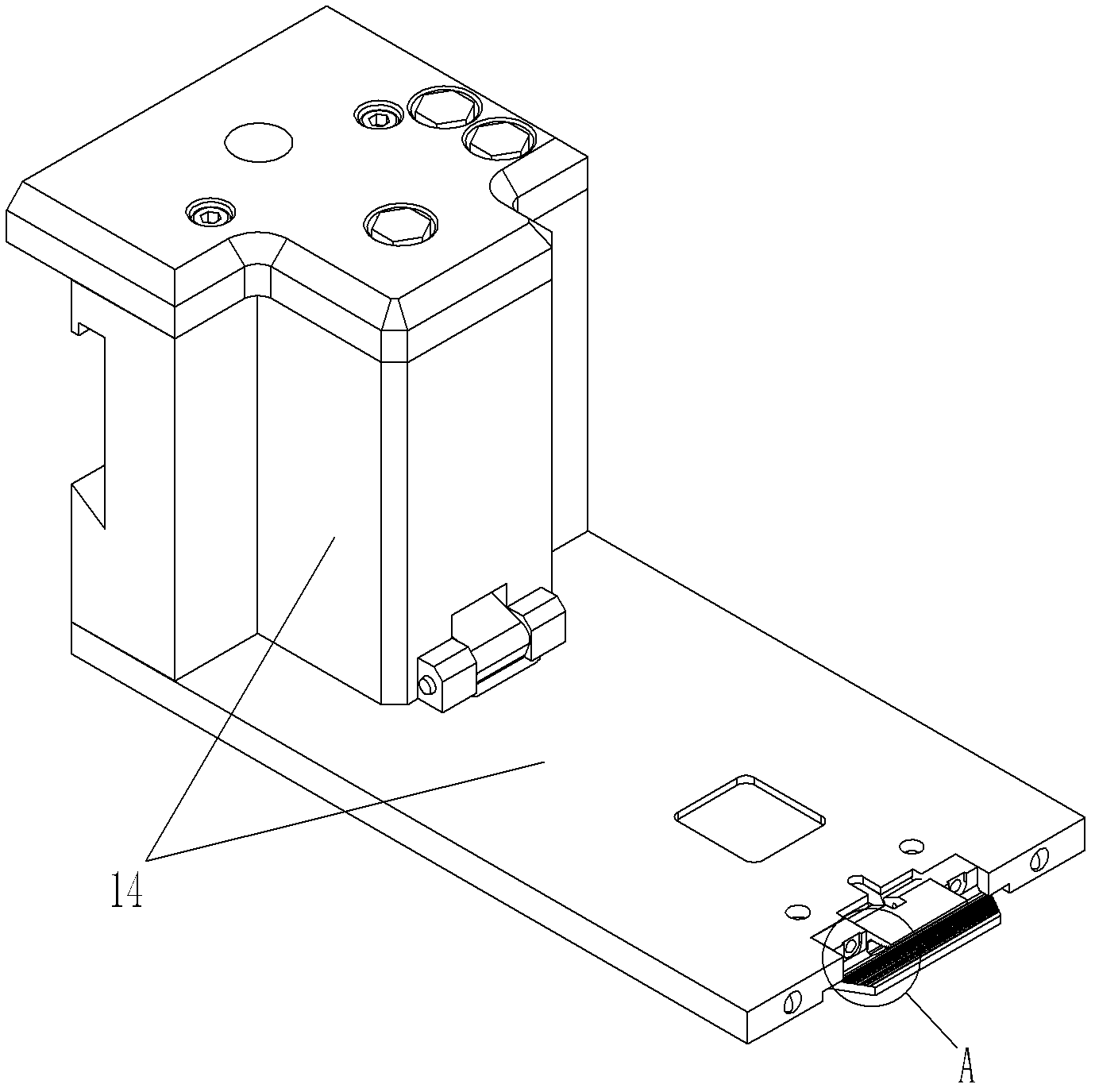

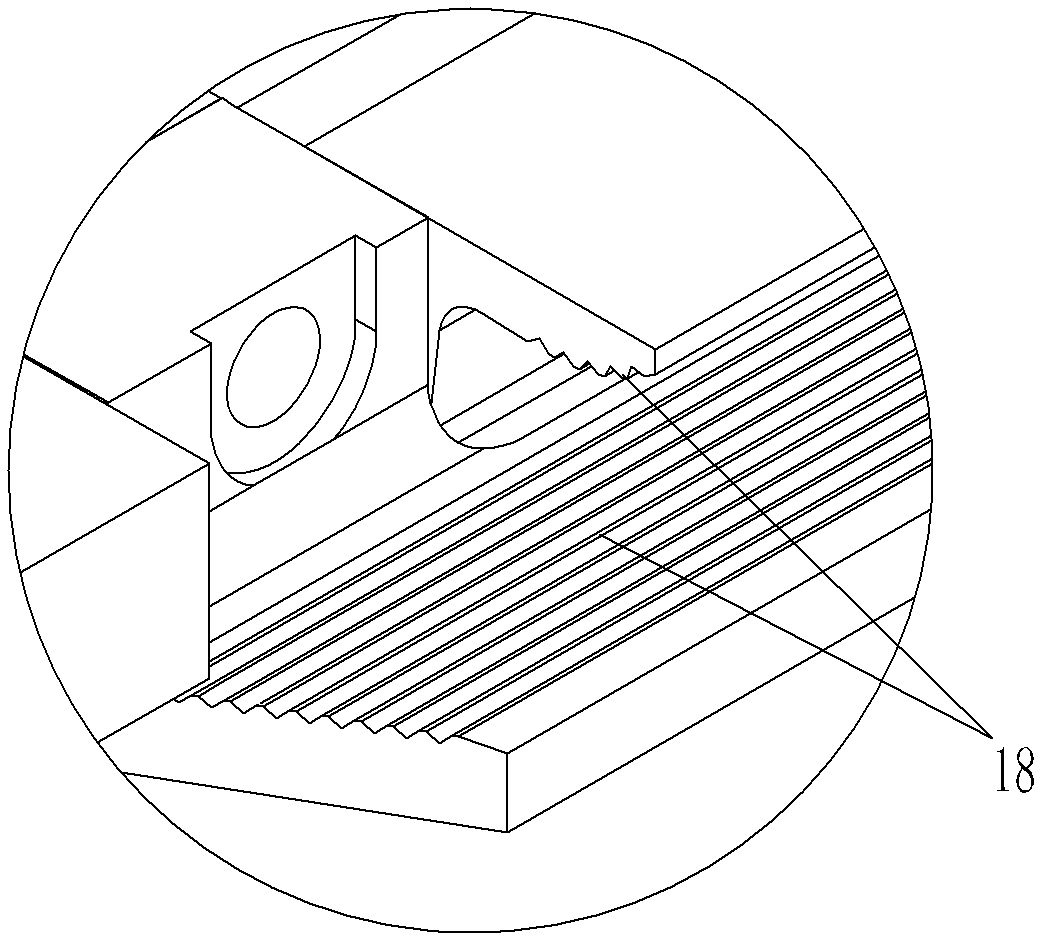

[0018] as attached figure 1 and attached figure 2 As shown, the plate feeding clamp of the present invention includes a base 1 for external installation, a clamp base 2 fixed on the base 1 at one end, a base plate 3 fixed on the base 1, and another hinged on the clamp base 2 in the middle. The pressure rod 4 at one end and the outer shell 14 are covered. The pressure rod 4 has a jaw end 5 forming the jaw 7 with the clamp base 2, and a non-pliers that realizes the opening or closing of the jaw 7 by the control of the driving mechanism. The mouth end 6, the driving mechanism includes a cylinder 8 arranged on the clamp base 2, a spring assembly arranged on the base plate 3, the cylinder 8 is connected with the spring assembly, and the force direction of the spring assembly is on the same line as that of the cylinder 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com