Coated fixture for stirring fork guide hole drilling machine

A technology of guide holes and fixtures, applied in drilling/drilling equipment, drilling templates for workpieces, parts of boring machines/drilling machines, etc., can solve problems such as poor efficiency, reduced precision, redesign and manufacturing, and reduce manufacturing Cost, the effect of increasing the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

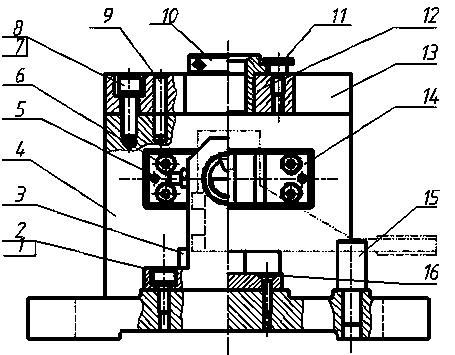

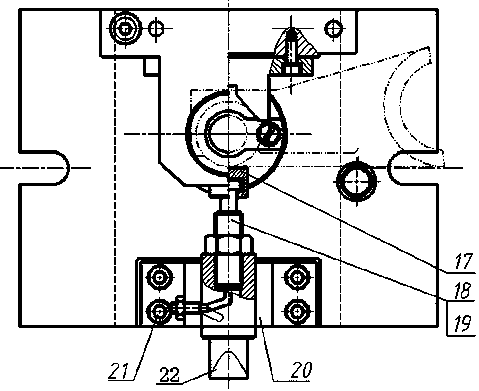

[0012] Such as figure 1 , shown in 2, the shift fork guide hole drilling jig with diamond-like coating of the present invention includes screw 1, washer 2, base 3, clamp body 4, positioning pin 5, bolt 6, hexagon socket head cap screw 7, washer 8 , positioning pin 9, drill sleeve 10, compression screw 11, bushing 12, pressure plate 13, V-shaped block 14, stop pin 15, screw 16, sleeve head 17, screw rod 18, nut 19, bracket 20, pressure plate 21, handle 22 .

[0013] The locating pin, the V-shaped block 14, the drill sleeve 10, and the inner wall of the retaining pin hole of the clamp body 4 are treated with a diamond-like coating, and the drill sleeve is located on the clamp platen 13, and the replaceable drill sleeve 10 is adopted, and the compression screw 11 is used for fixing. Add replaceable bushing 12 in the drill sleeve hole of pressing plate 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com