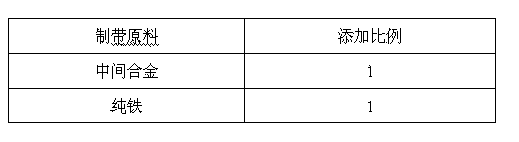

Patents

Literature

36results about How to "Fully alloyed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smelting method for high-Nb-TiAl based alloy

The invention provides a smelting method for a high-Nb-TiAl based alloy. According to the smelting method, titanium sponge, a niobium-titanium alloy and aluminum shots are used as raw materials and are pressed and welded to form a consumable electrode; the consumable electrode is smelted in a vacuum consumable electric arc furnace to obtain the high-Nb-TiAl based alloy. According to the smelting method, an electrode block is prepared by a manner of combining material mixing and material distribution; the vacuum consumable electric arc furnace is used for carrying out three times of smelting; after the materials are discharged from the furnace, the materials are slowly cooled by adopting a manner of sand burying treatment or annealing treatment so that the high-Nb-TiAl based alloy with uniformly-distributed components and no cracks can be obtained. The smelting method for the high-Nb-TiAl based alloy is simple in method and strong in maneuverability; with the adoption of the method, the high-Nb-TiAl based alloy with the uniformly-distributed components and no segregation or impurities can be produced.

Owner:西安超晶科技股份有限公司

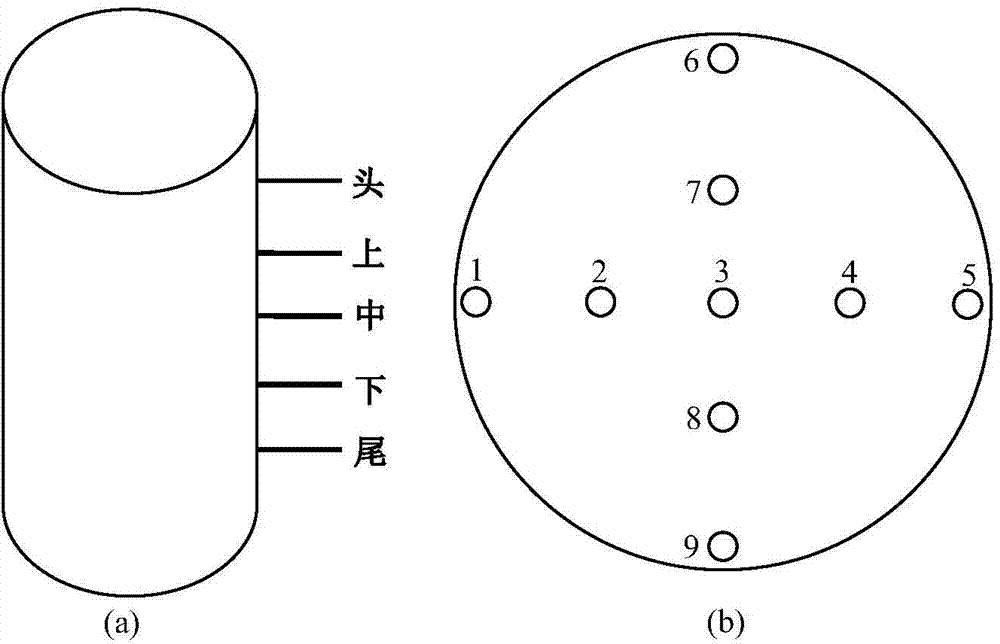

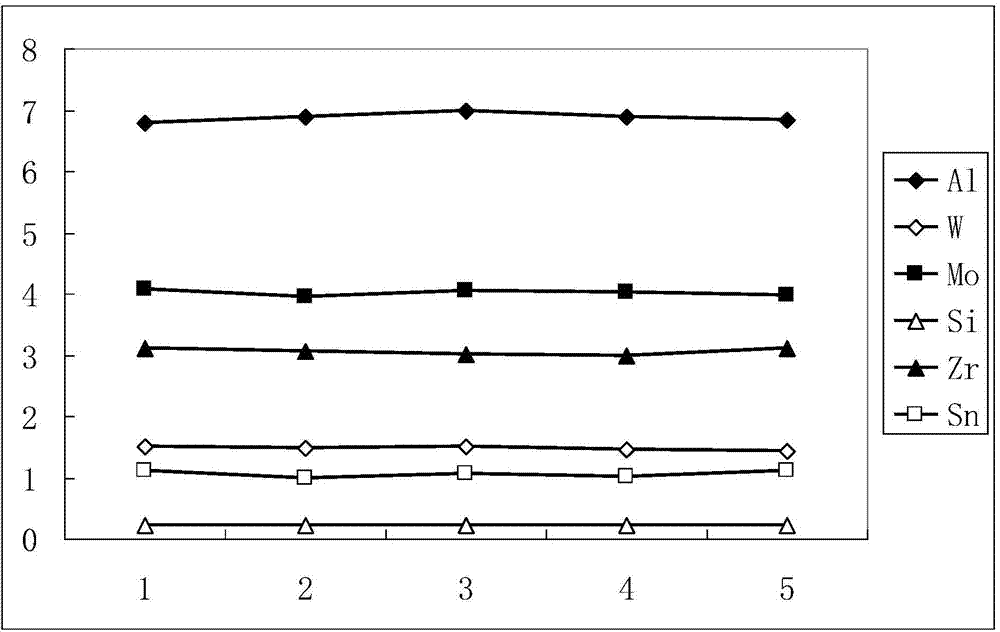

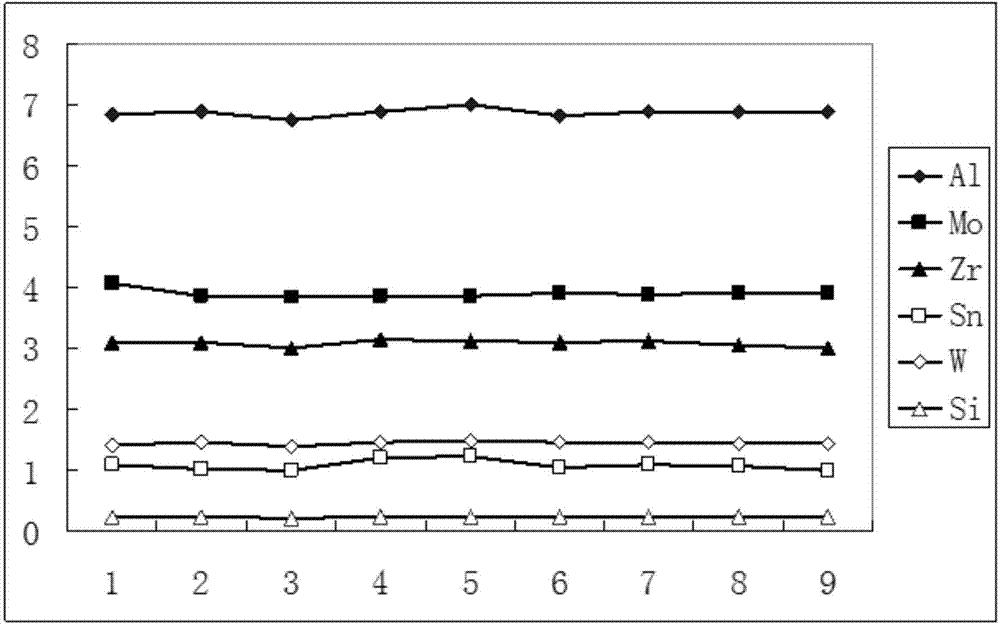

Preparation method for high-uniformity WSTi62441S titanium alloy ingot

The invention discloses a preparation method for a high-uniformity WSTi62441S titanium alloy ingot. The preparation method comprises the following steps of mixing 6.0 to 7.0 mass percent of Al, 1.0 to 2.5 mass percent of Sn, 3.5 to 4.5 mass percent of Mo, 3.0 to 4.5 mass percent of Zr, 0.20 to 0.25 mass percent of Si, 0.4 to 1.5 mass percent of W and the balance of Ti based on the total amount of 100 percent, performing electrode pressing and welding on the mixture to obtain a consumable electrode, and performing vacuum smelting on the consumable electrode for many times to obtain the high-uniformity WSTi62441S titanium alloy ingot. According to the preparation method, the problems of composition segregation, poor controllability in the content of impurities and an interstitial element and poor batch stability of the conventional preparation method are solved, the prepared WSTi62441S titanium alloy ingot is uniform in element composition and high in batch stability, and the preparation method is applied to the industrial production of WSTi62441S titanium alloy ingots in specifications of Phi560 to Phi720mm.

Owner:西部超导材料科技股份有限公司

A kind of anti-oxidation iron-based superalloy and preparation method thereof

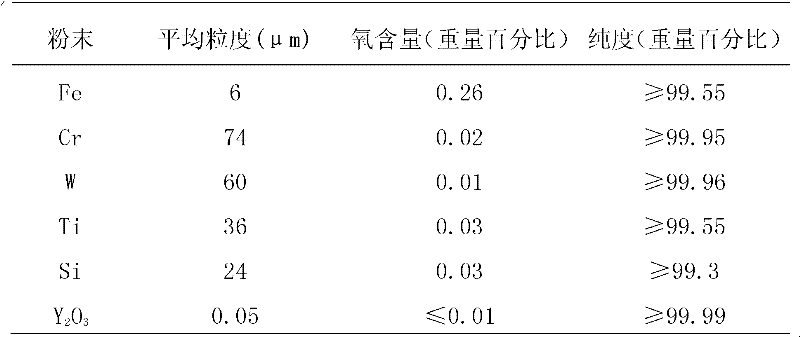

InactiveCN102286694AIncrease working temperatureIncrease productivityNuclear fusionOxidation resistant

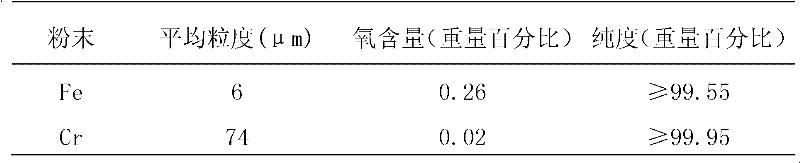

An anti-oxidation iron-based superalloy and a preparation method thereof, which belong to superalloys and a preparation method thereof, solve the problem of unsatisfactory oxidation resistance of existing iron-based superalloys under high-temperature conditions, so as to improve serviceability and broaden high-temperature application fields. The anti-oxidation iron-based superalloy of the present invention has the composition mass percentages of: 12%≤Cr≤14%, 2%≤W≤3%, 0.3%≤Ti≤0.4%, 0.2%≤Si≤2%, 0.25%≤ Y2O3≤0.3%, the balance is Fe; it is made by mechanical alloying, molding and vacuum sintering, and the matrix of the final sintered body is α-(Fe, Cr) single-phase solid solution with uniformly distributed oxides in the matrix. The invention has high production efficiency and low cost, and the prepared anti-oxidation iron-based superalloy has reduced oxidation weight gain and improved anti-oxidation ability under the atmospheric condition of 850°C; the tensile strength at room temperature is ≥600MPa, and the elongation rate is ≥25%, which meets the requirements of automobiles. Requirements for the use of high-temperature structural parts such as engines and gas turbines, nuclear fission fuel cladding tubes, and first wall structural materials of nuclear fusion reactors.

Owner:HUAZHONG UNIV OF SCI & TECH

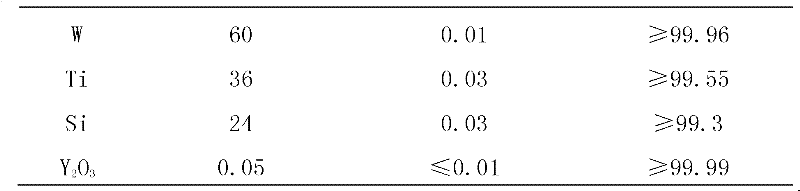

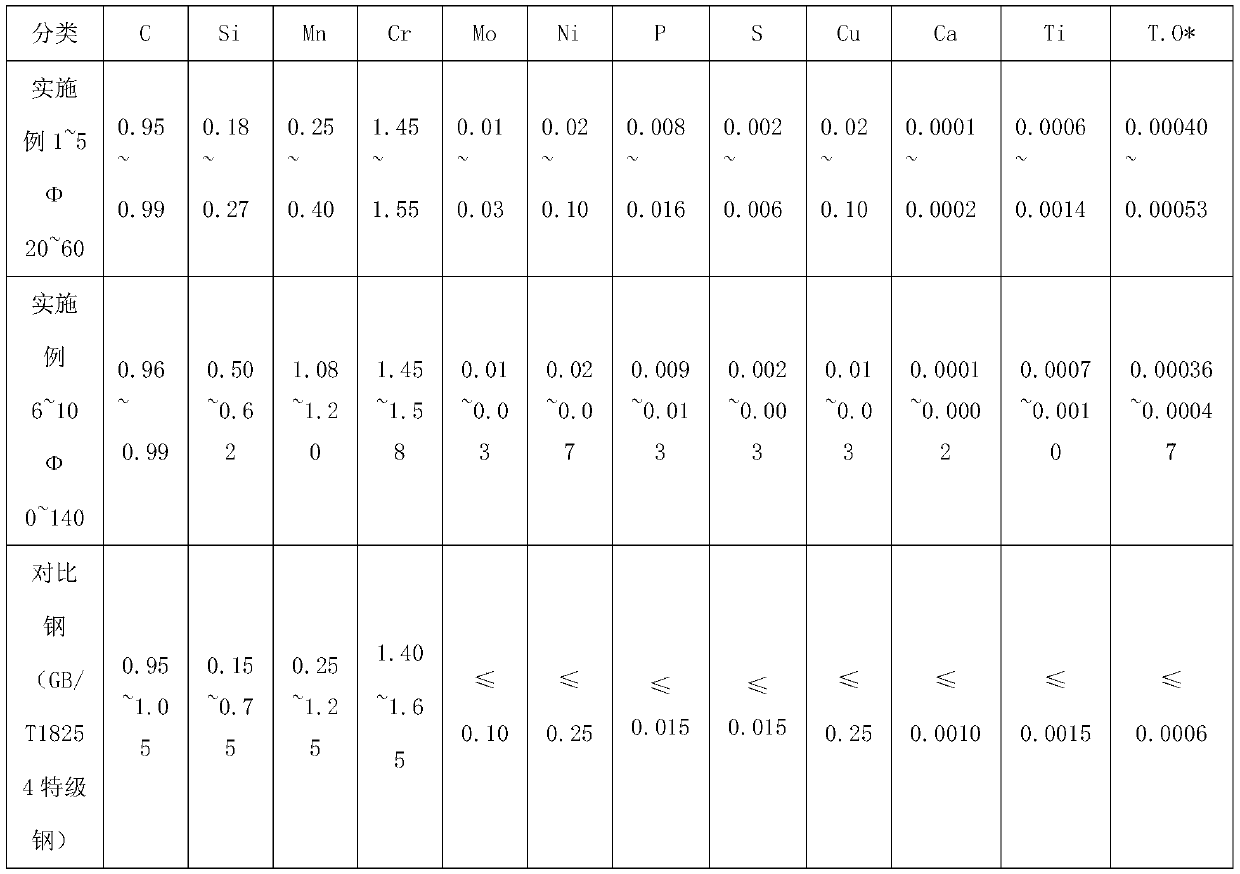

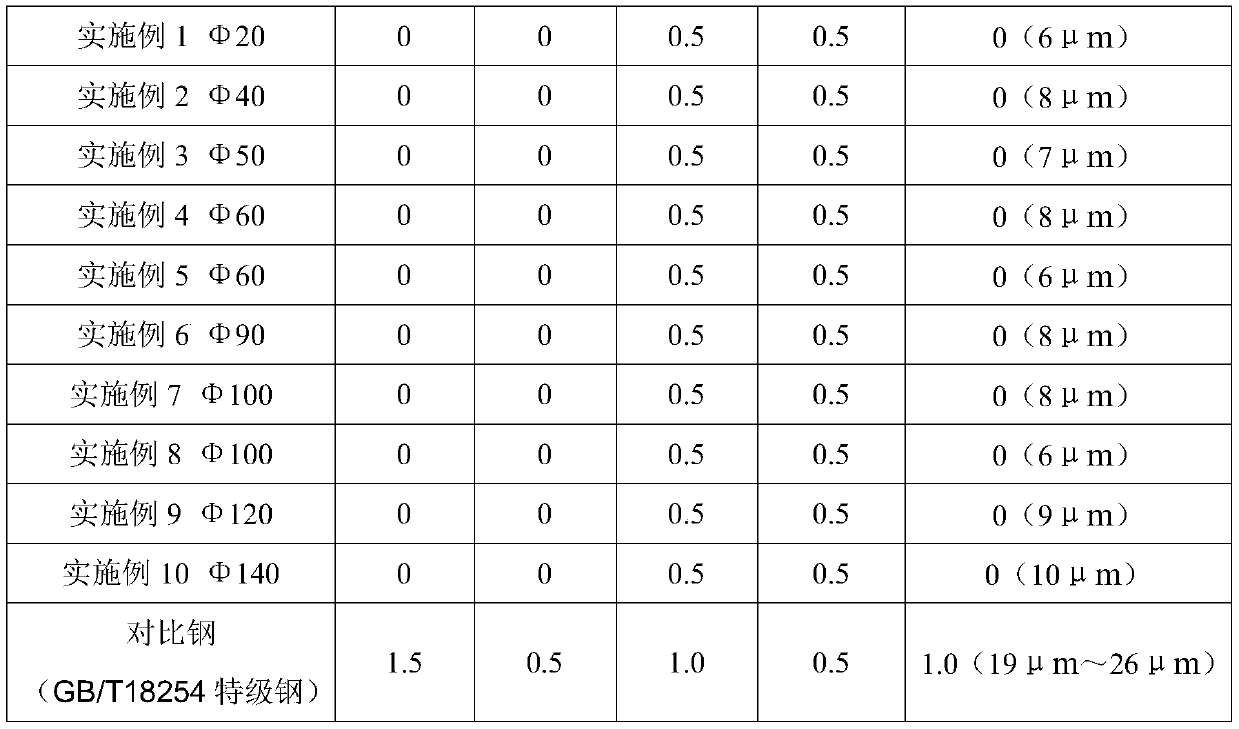

External refining method for refining high-carbon chromium bearing steel inclusion particles

The invention relates to an external refining method for refining high-carbon chromium bearing steel inclusion particles. The method comprises the procedures of material control, BOF, RS, LF, RH, CC and rolling, BOF blowing oxygen decarbonization is further controlled, and the final carbon content ranges from 0.15% to 0.80%. More than 0.5 kg / t aluminum is added to molten steel during steel tappingaccording to an aluminum oxygen equilibrium diagram, so that the oxygen content in the steel after steel tapping is reduced to 30 ppm or below, and the steel tapping temperature is controlled to range from 1600 DEG C to 1700 DEG C. RS drossing operation is carried out after BOF converter smelting steel tapping, and slag in a steel ladle is removed. Refining slag is added during LF refining, the molar fraction of CaO in the refining slag is controlled to range from 40% to 60%, the aluminum content in the steel is controlled to range from 0.03% to 0.07%, and the oxygen content during steel tapping is controlled to be below 10 ppm, and the steel tapping temperature ranges from 1550 DEG C to 1610 DEG C. Argon stirring is carried out in the whole RH vacuum degassing process, and the vacuum state below 100 Pa is kept for 10 min or longer. A continuous casting process which is high in efficiency and low in cost and saves energy is adopted, the production process is perfected, the critical process is optimized, and the particles of fragile DS inclusion of the product are finer.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Method for recycling ladle slag

InactiveCN102337379AAvoid cloggingArgon blowing obstacleRecycling and recovery technologiesProcess efficiency improvementSlagAlloy

The invention provides a method for recycling ladle slag, comprising the following steps: carrying out solidification and fragmentation on the ladle slag, and then carrying out iron election, allowing residues after iron election as refining slag to contact with molten steel containing added alloy for LF refining. According to the invention, the recycle of the ladle slag is realized, and slag component in the recycle process can be accurately controlled, so that effect of refining of the molten steel is further improved; by adding the refining slag in the alloyed molten steel, the problem of argon blowing fault generated in tapping after adding the ladle slag in the empty ladle, and the time of refining of the molten steel is greatly reduced.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

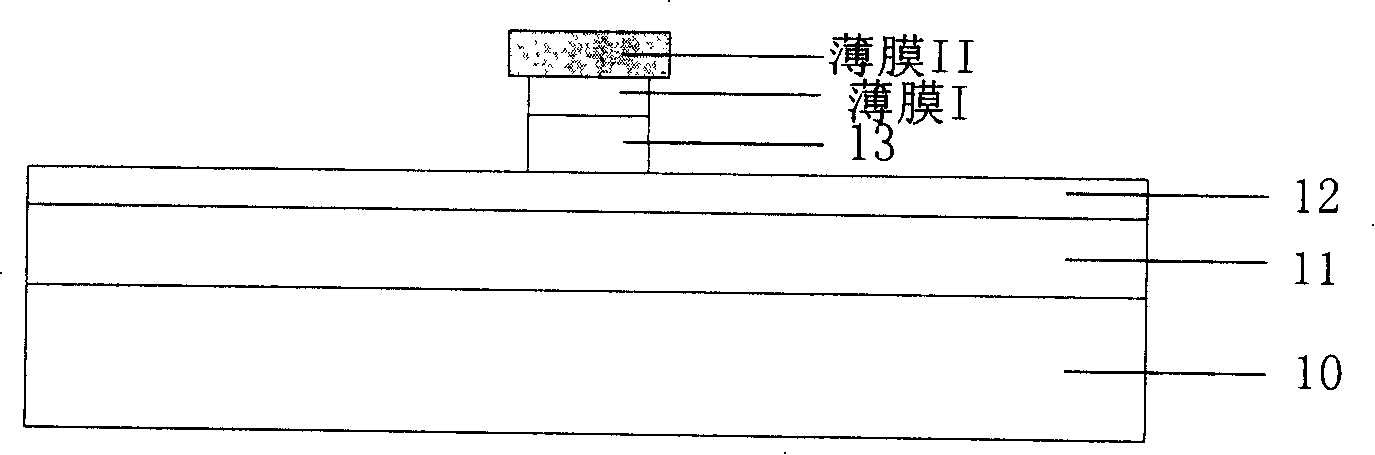

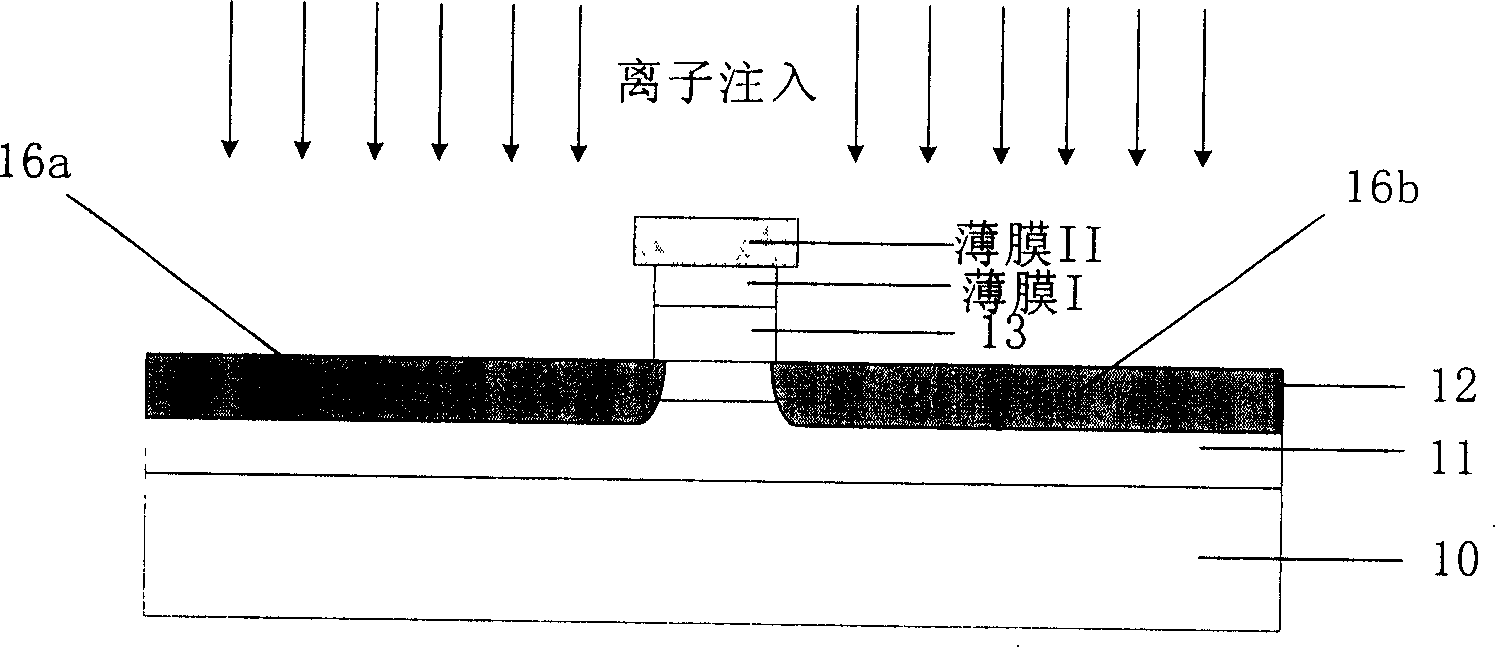

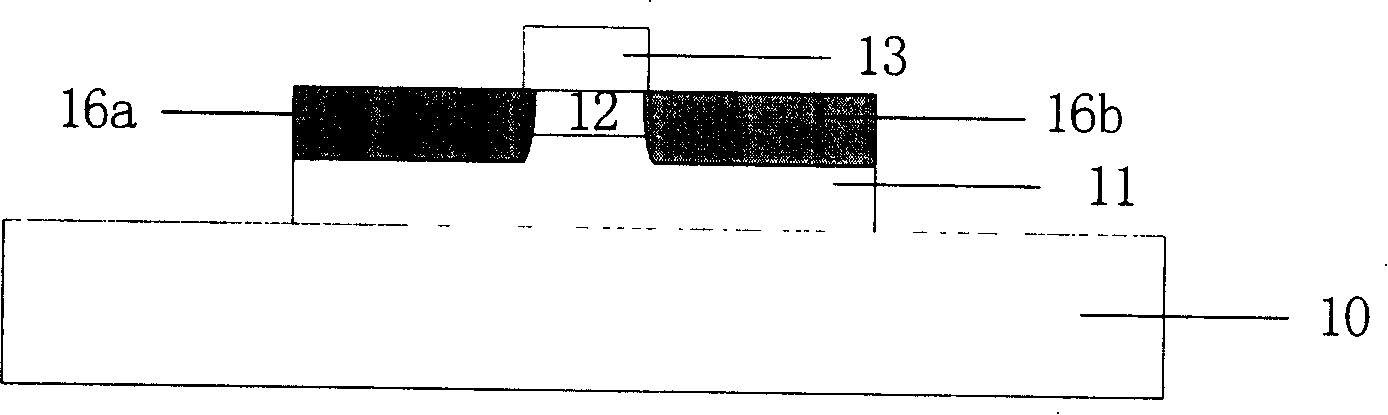

Heterojunction bipolar transistor and preparation method thereof

InactiveCN101207151AReduced series resistanceIncreasing the thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactOptoelectronics

The invention relates to a heterojunction bipolar transistor, which comprises a substrate, a first doping type of collecting electrode area on the substrate, the collecting electrode area comprises a collecting area and a collecting electrode contact area; a second doping type of base electrode area on the collecting electrode area ; a first doping type of emitting electrode area on the base electrode area, an emitting electrode area comprises an emitting area andanemitting electrode cap layer area; the electrode on the emitting electrode cap layer area, the base electrode area and the collecting electrode contact area;, the first doping type is contrary to the second doping type; and the doping type of the ion injected into the outer base area is identical to the second doping type. In the invention the outer base area is adulterated by combining the wet-etching self-aligning process and the ion implantation process, the effect is as following that the base series resistance is reduced, simultaneously the thickness of the base ohmic contact area is increased, the adequacy of alloy is ensured, and the rate of finished products is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

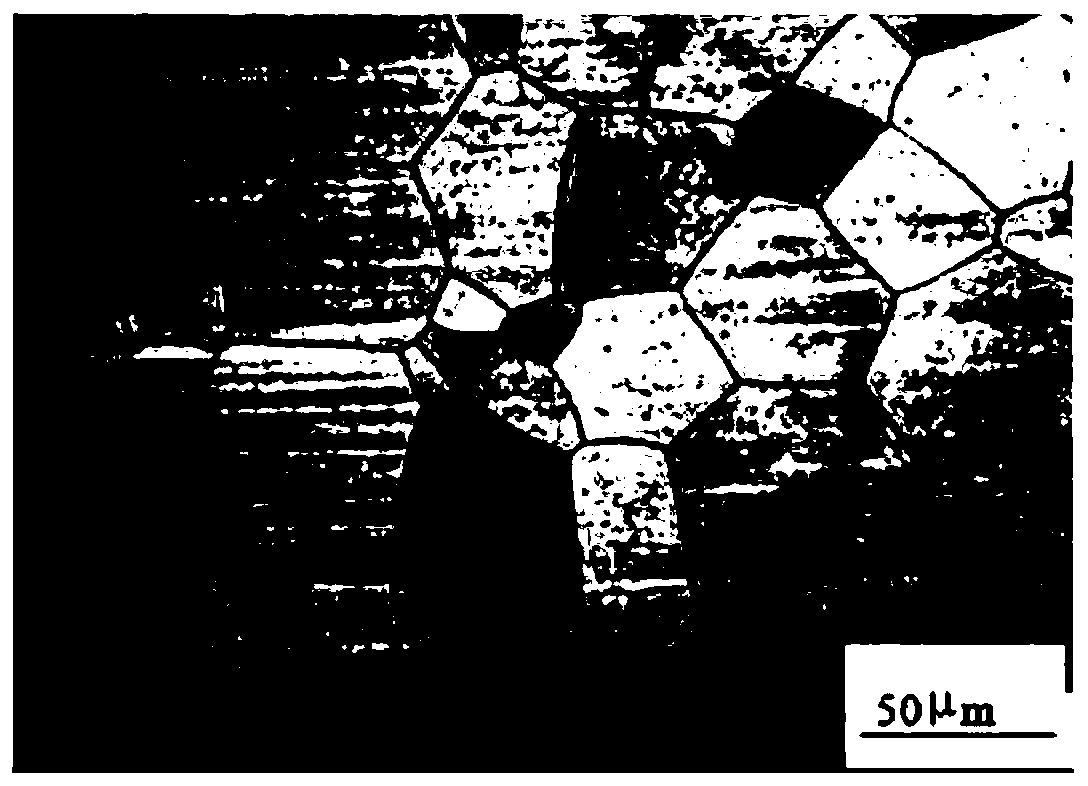

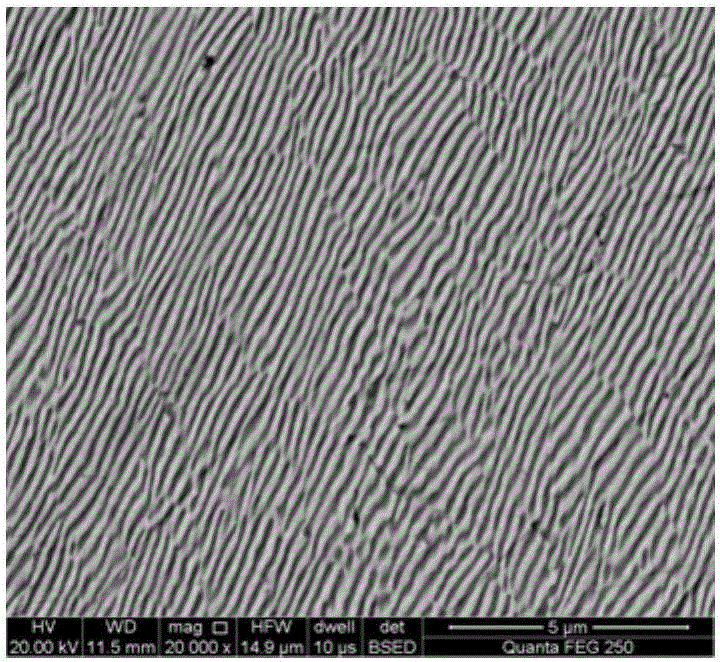

Preparation method for gold-tin eutectic alloy foil having uniform structure

The invention relates to a preparation method for a gold-tin eutectic alloy foil having a uniform structure. The preparation method comprises: accurately preparing a gold-tin alloy raw material with a tin mass percentage of 20% and a gold mass percentage of 80%; in a non-consumable electrical arc smelting furnace, under a vacuum degree of 10<-3> Pa, repeatedly carrying out smelting, electromagnetic stirring and cooling at least three times to obtain a gold-tin alloy casting ingot; and carrying out homogenization annealing on the casting ingot, and then carrying out multi-pass thermal compression to obtain the gold-tin eutectic foil. According to the present invention, the vacuum electrical arc smelting, the circular electromagnetic stirring and the cyclic thermal compression to prepare the whole lamellar eutectic structure, wherein the eutectic point component does not have the primary phase; and compared with the preparation method in the prior art, the preparation method of the prevent invention has the following characteristics that: the complete alloying is achieved, the strength is high, the weldability is good, other components are not added or the gold-to-tin ratio is not adjusted, the welding temperature and the welding performance are stable, the welding piece deformation and the force on the welding piece are uniform, the welding piece cracking condition is not easily generated, the yield is high, the production efficiency is much higher than the production efficiency of the electroplating method for preparing the gold-tin welding piece, the production cost is reduced, and the preparation method is suitable for mass production.

Owner:CENT SOUTH UNIV

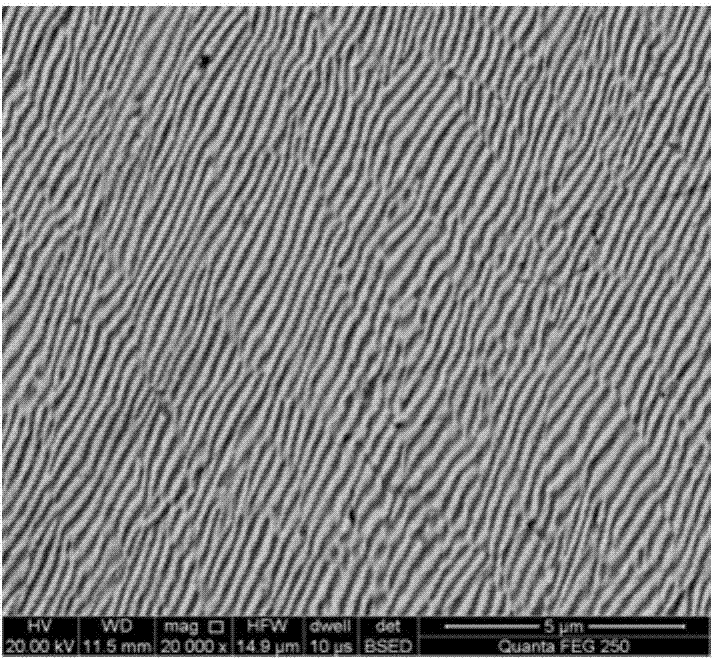

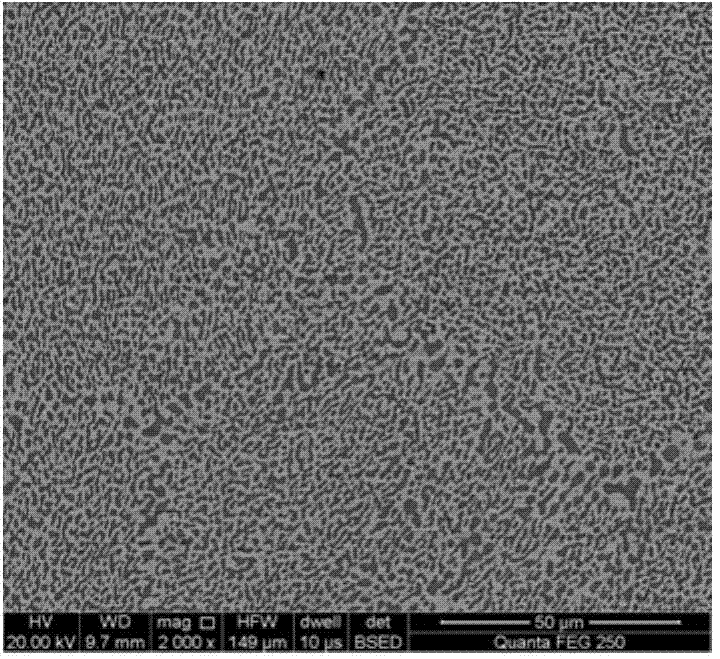

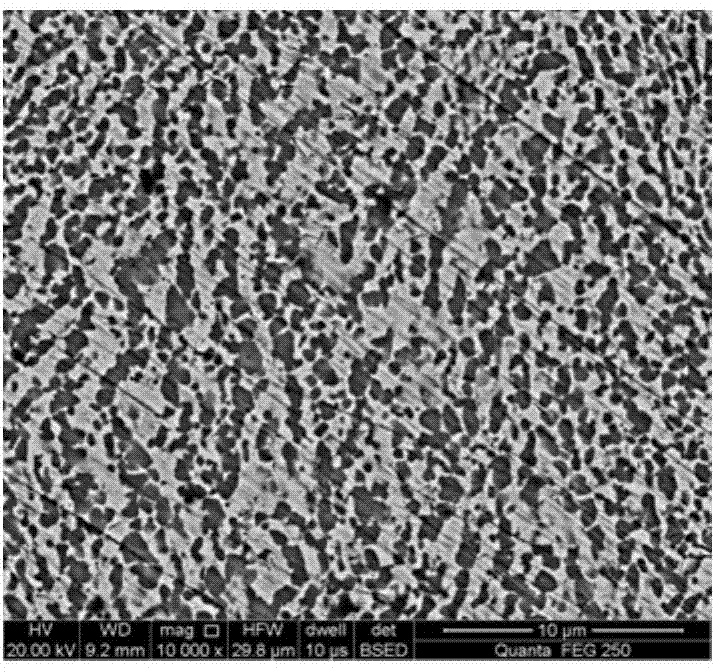

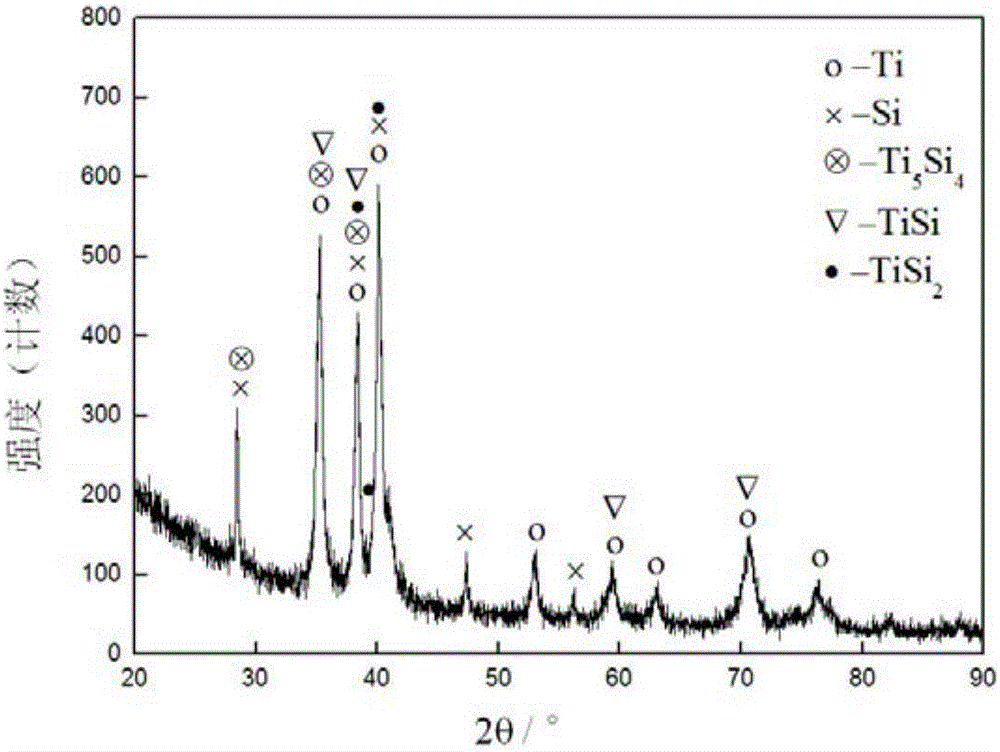

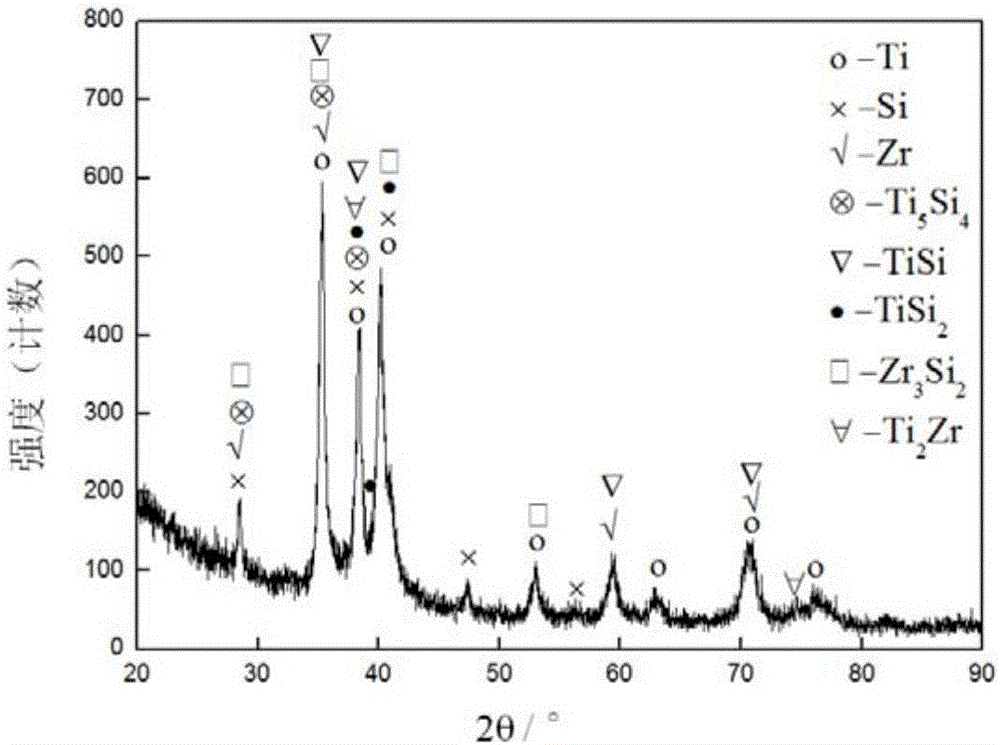

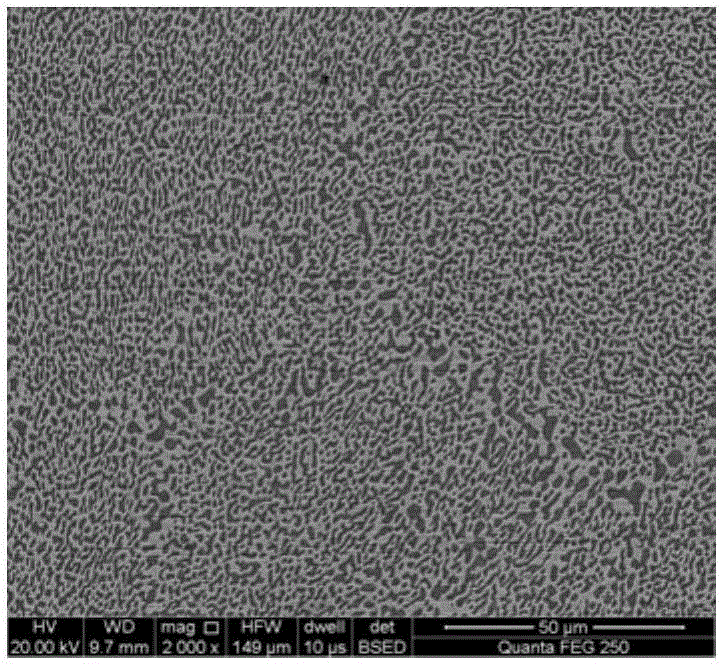

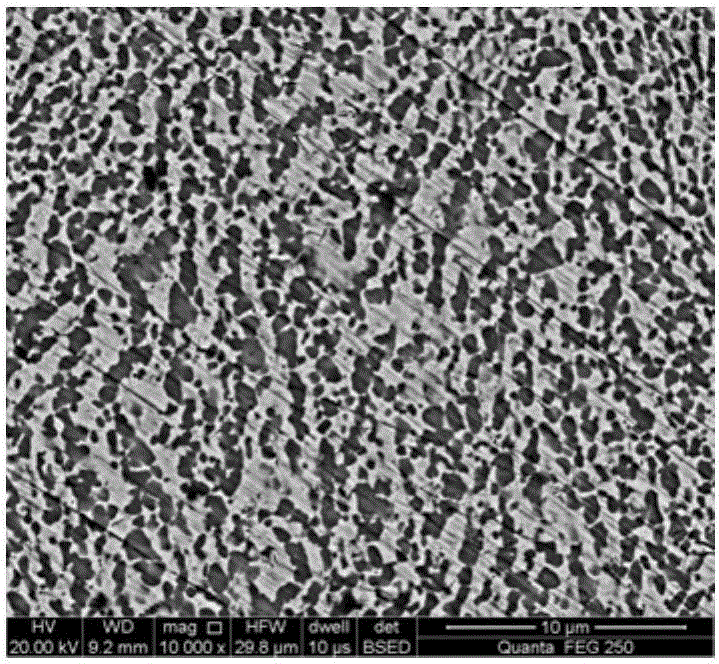

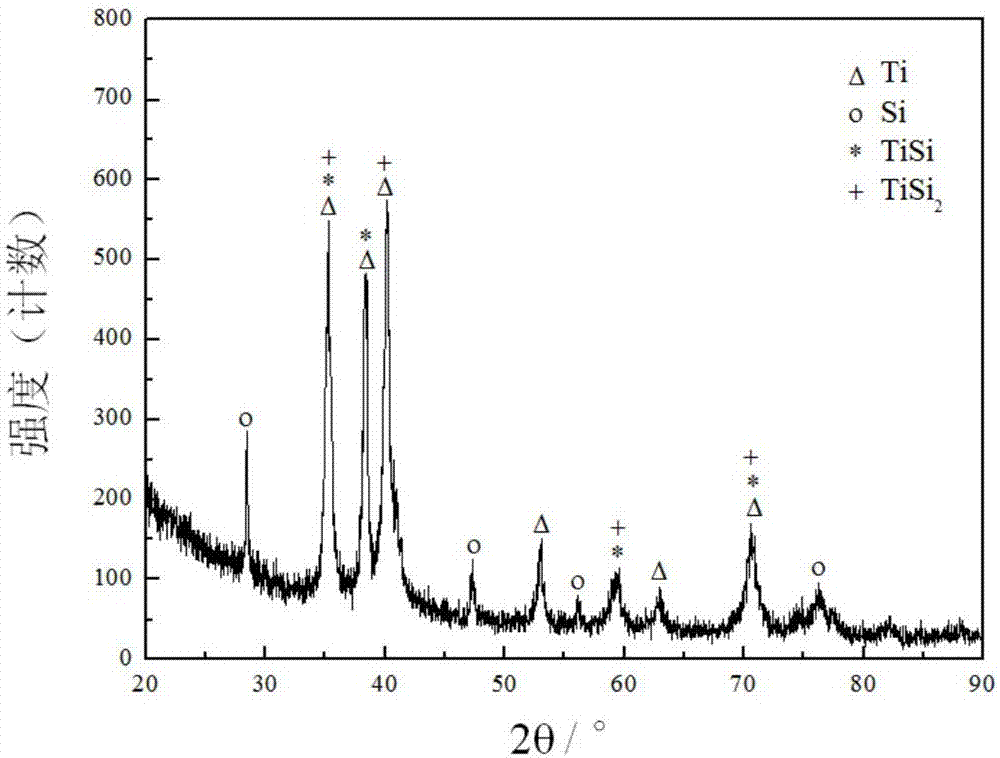

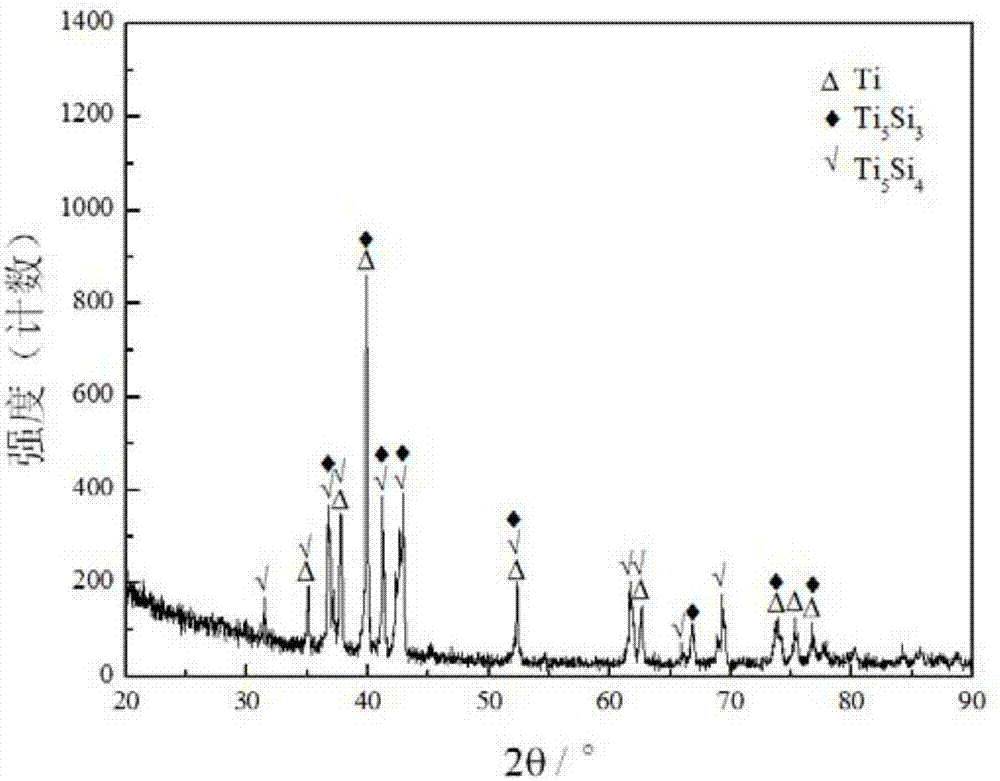

Zr alloying Ti-8Si alloy and preparing method thereof

The invention relates to a Zr alloying Ti-8Si alloy and a preparing method thereof. The Zr alloying Ti-8Si alloy is characterized in that preparation raw materials comprise Ti powder, Si powder and Zr powder. The preparing method includes the steps that firstly, the Ti powder, the Si powder and the Zr powder are evenly mixed to be subject to high energy ball milling, and partial alloying is carried out on the raw materials; secondly, powder obtained after ball milling is screened and dried; thirdly, the dried powder is prepared into press cakes through compression molding forming; and finally, vacuum pressureless sintering is carried out so that sufficient alloying can be achieved. According to the Zr alloying Ti-8Si alloy and the preparing method, the Ti-8Si-xZr alloy face is uniform in component, the compactness, the inoxidizability, the abrasive resistance and the like are improved to a certain degree, and the Zr alloying Ti-8Si alloy and the preparing method have a wide application prospect in the fields of aerospace, traffic and weaponry.

Owner:JIANGSU UNIV

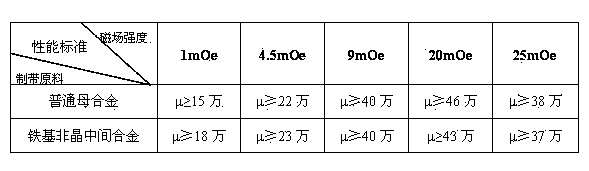

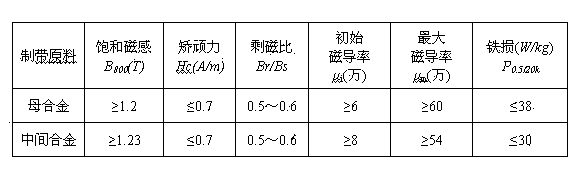

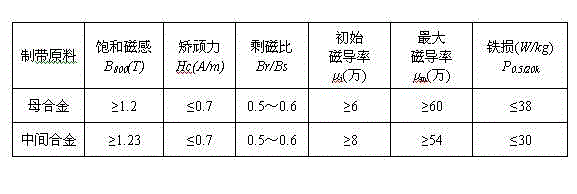

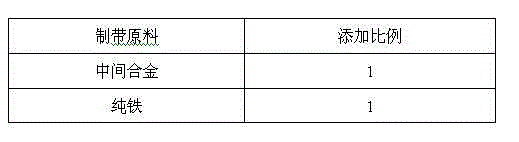

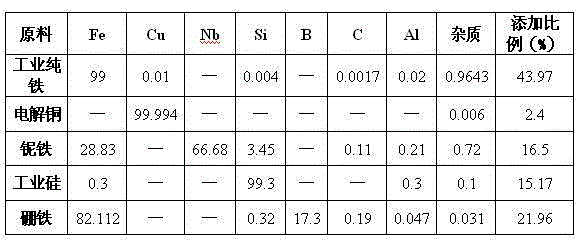

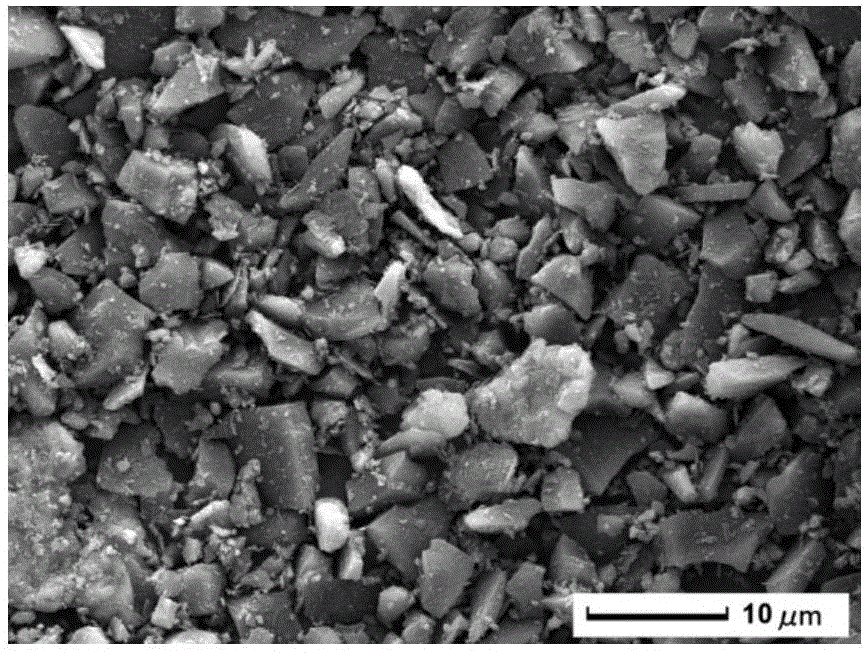

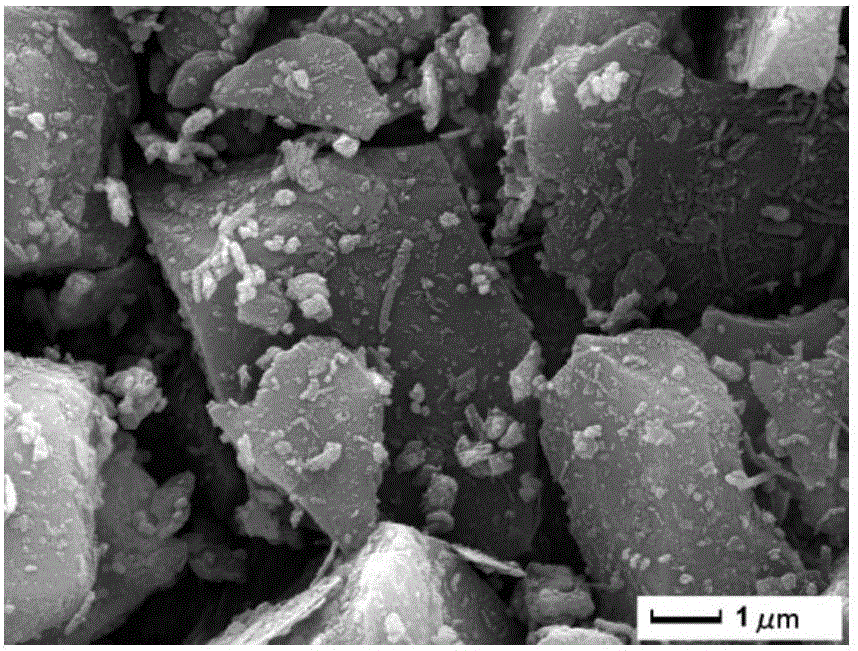

Special intermediate alloy for iron base amorphous nanocrystalline alloy and smelting method thereof

Special intermediate alloy for iron base amorphous nanocrystalline alloy belongs to the field of metallurgy. The alloy comprises the following chemical components: 15.7 wt% of Si, 3.8 wt% of B, 11 wt% of Nb, 2.4 wt% of Cu and the balance of Fe. A smelting method is as below: successively adding industrial pure iron, niobium iron, industrial silicon and electrolytic copper ferroboron into an intermediate frequency smelting furnace; (2) preheating with a small power and heating with high power; (3) completely fusing the raw materials, stirring alternatively with high and low power, at the same time carrying out furnace rocking with small to middle amplitude; and heating to 1400 DEG C and insulating for 5 min; and (4) finally carrying out dedrossing and tapping. The invention solves the problems of raw material burning loss and hard fusion of high-melting-point alloy. The amorphous nanocrystalline alloy strip produced from the intermediate alloy has multiple advantages including uniform composition, good toughness, significantly improved magnetic property and the reduced manufacturing cost.

Owner:太原钢铁(集团)有限公司

Spark plasma sintering (SPS) titanium-base composite and preparing method thereof

The invention discloses a spark plasma sintering (SPS) titanium-base composite and a preparing method thereof. The SPS titanium-base composite is characterized by being prepared from Ti-6Al-4Sn-9Zr-1.21Nb-1.6Mo-0.3Si powder and GNP nanopowder through compounding and sintering; firstly, absolute ethyl alcohol is added for sufficiently dispersing the GNP nanopowder, so that the GNP powder is free ofagglomeration phenomenon in subsequent operation, then, Ti-6Al-4Sn-9Zr-1.21Nb-1.6Mo-0.3Si powder is added to be wet-ground and then dried to be dry-ground, powder with uniform granularity is obtainedafter being sieved to be dried again, and then the mixed powder is poured into a graphite mold for plasma sintering, so that Ti-6Al-4Sn-9Zr-1.21Nb-1.6Mo-0.3Si powder and the GNP nanopowder are further alloyed. The composite obtained through the method has excellent performance, and the component uniformity and inoxidizability of the material are greatly improved.

Owner:JIANGSU UNIV

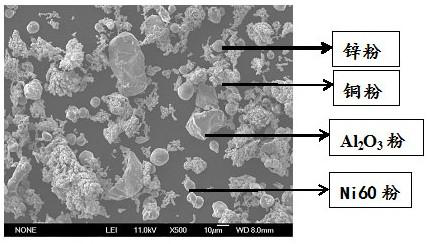

Cold spraying reinforcing material repairing material and repairing method of worn Roots blower cover plate

InactiveCN109439960AImprove wear resistanceHigh hardnessAdditive manufacturing apparatusPretreated surfacesRestorative materialSand blasting

The invention provides a cold spraying reinforcing material repairing material and a repairing method of a a worn Roots blower cover plate. The material comprises, by weight, 55%-65% of Ni60, 24%-32%of Cu powder, 6%-8% of Zn powder, 3%-5% of Al2O3 powder, and the sum of the weight percentages of the components is 100%. The method comprises the following steps: (1) pre-treatment is carried out before the cold spraying of the Roots blower cover plate is worn, performing surface sand blasting treatment on the worn roots blower cover plate by using brown fused alumina; and (2) the cold spraying repair parameters of the worn Roots blower cover plate are as follows: the preheating temperature of the cold spraying base body is 100 DEG C, the temperature of spraying gas is 300-500 DEG C, the pressure is 0.6-0.8 MPa, the spraying distance is 25 mm, the powder feeding amount is 0.4g to 0.6g / s; and (3) the heat treatment parameters are as follows: the heat treatment temperature is 500-600 DEG C,the heating speed is 3 DEG C / min, the heat preservation time is 2 hours, and the mixture is cooled along with a furnace.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

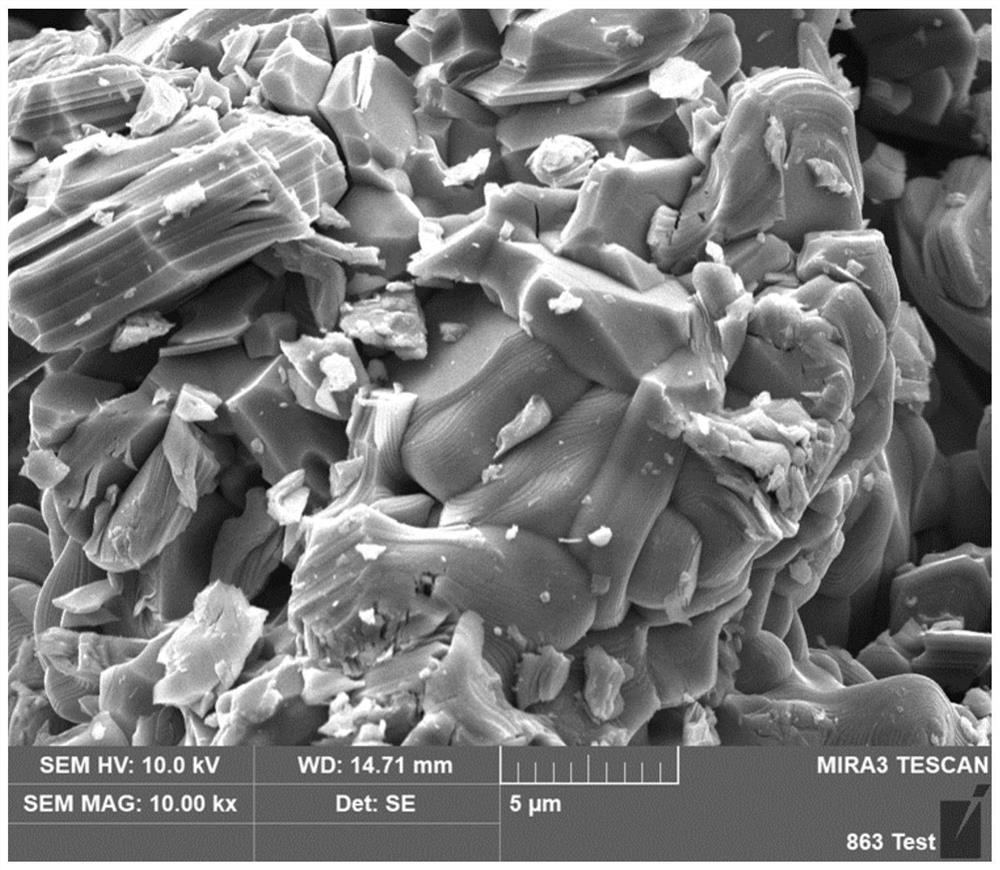

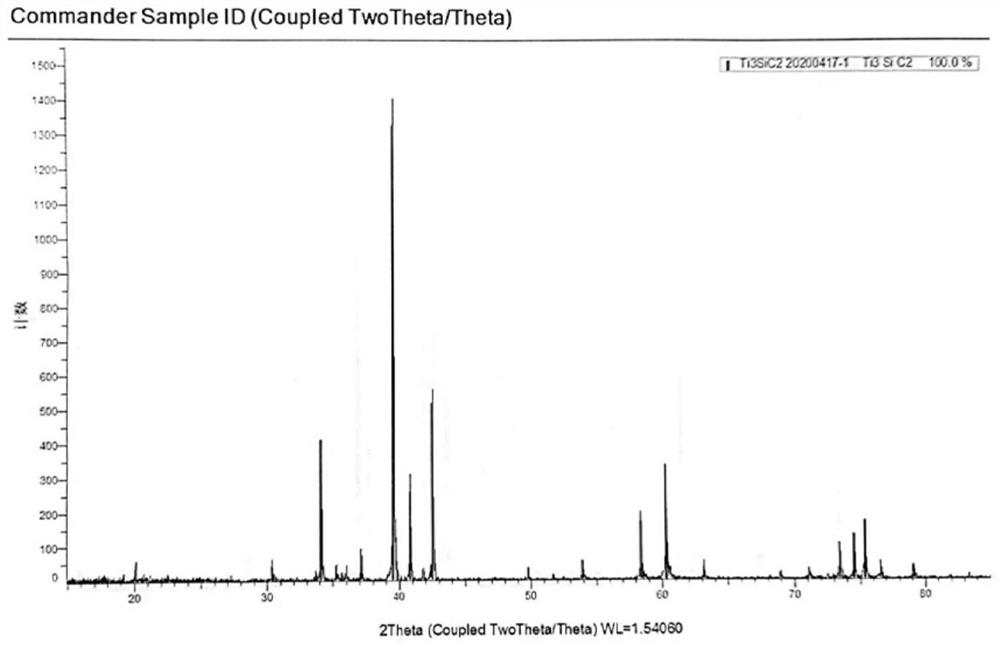

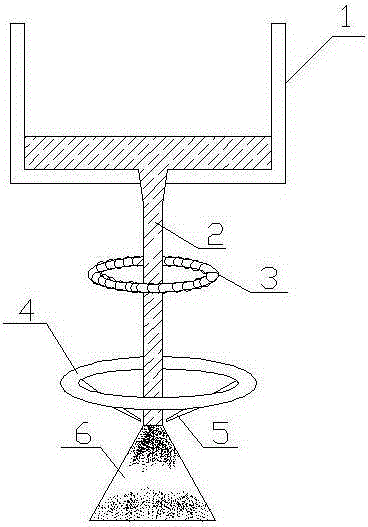

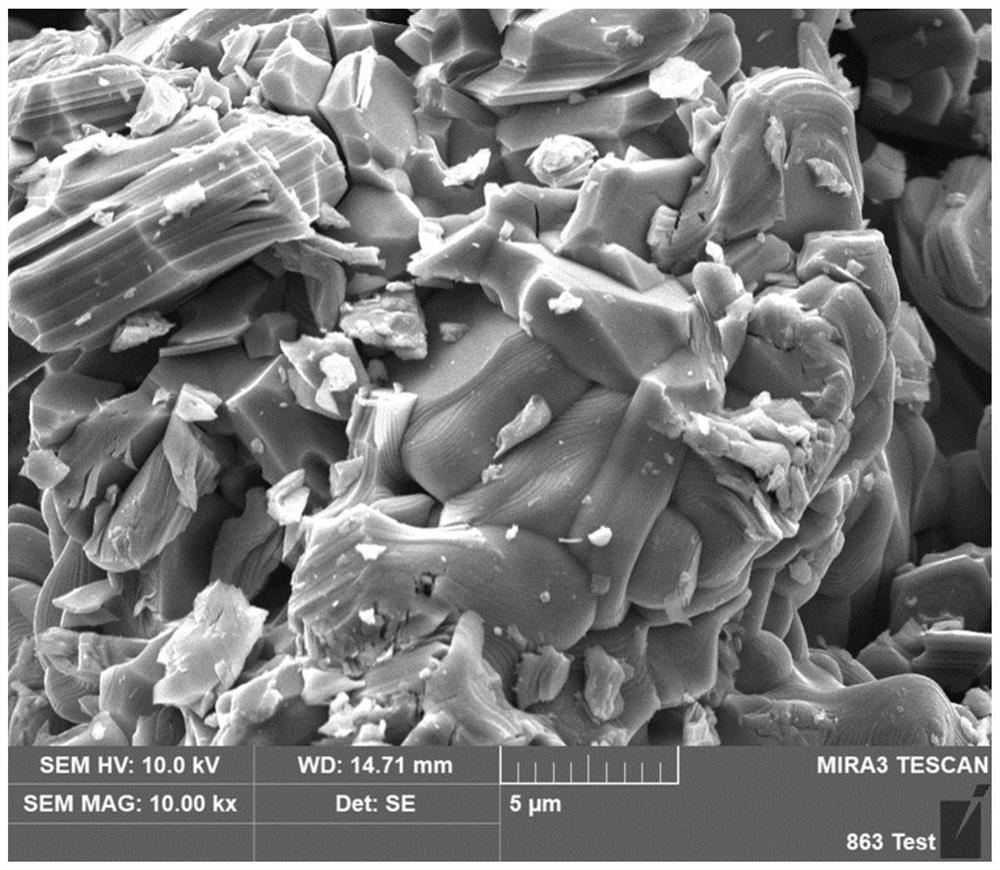

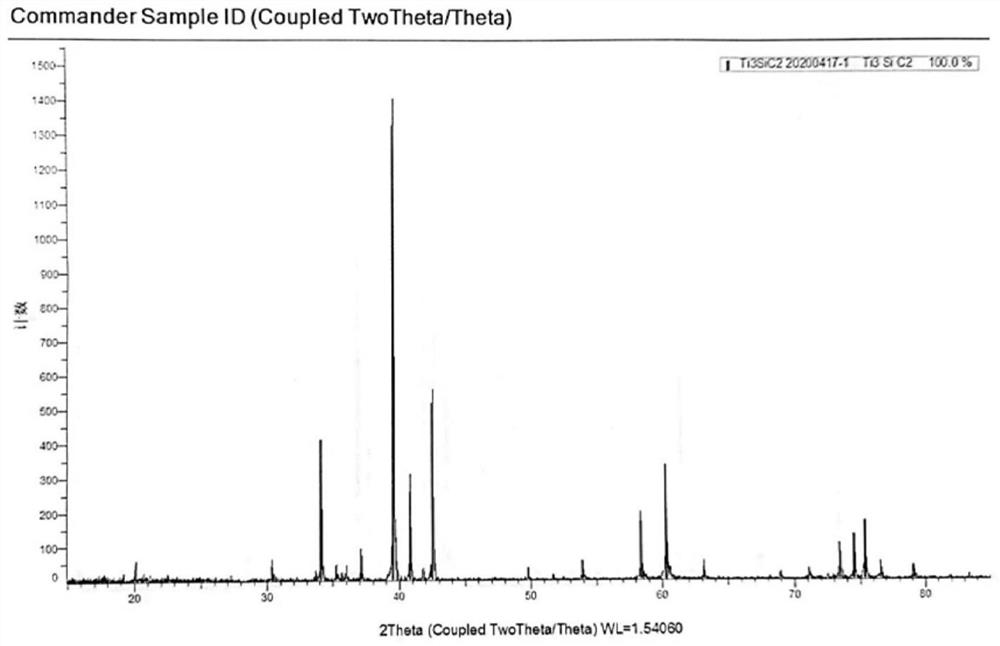

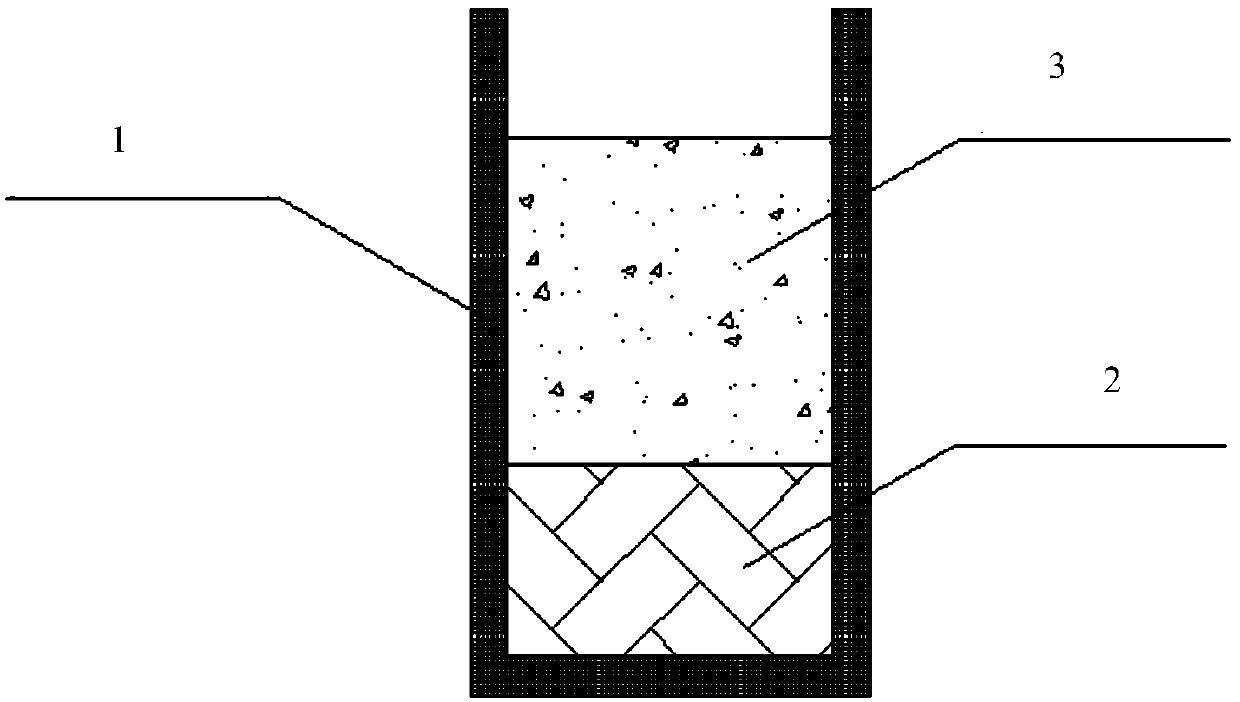

Production process of silicon carbide titanium

ActiveCN112919470AFully alloyedRaw materials are easy to getCarbon compoundsChemical industrySilicon alloyAdhesive

The invention relates to a production process of silicon carbide titanium, which comprises the following steps of filling sponge titanium and monocrystalline silicon into a vacuum induction melting furnace, continuously heating until the sponge titanium and the monocrystalline silicon are remelted, and stopping vacuumizing, after argon is filled, conducting stirring, pouring and mold fixing, and acquiring a titanium-silicon alloy ingot, processing the titanium-silicon alloy ingot into titanium-silicon alloy powder, filling titanium-silicon alloy powder and graphite powder into a vacuum ball mill, adding an adhesive, ball-milling and mixing for 24 hours under the protection of argon, pressing into a round cake by using a press, filling into a crucible of a vacuum resistance furnace, vacuumizing, heating to 1100 DEG C, keeping the vacuum degree to 25 Pa, preserving the heat for 3.5 hours, continuously heating to 1350 DEG C, keeping the vacuum degree to 25-350 Pa, preserving the heat, fully alloying, filling argon, continuously heating to 1520 DEG C, and preserving heat for 3 hours to obtain a Ti3SiC2 block material. The method has the advantages of primary raw material taking, low cost, no need of deep processing, low temperature requirement in the whole reaction process, good product purity, and realization of large-scale industrial production.

Owner:辽宁中色新材科技有限公司

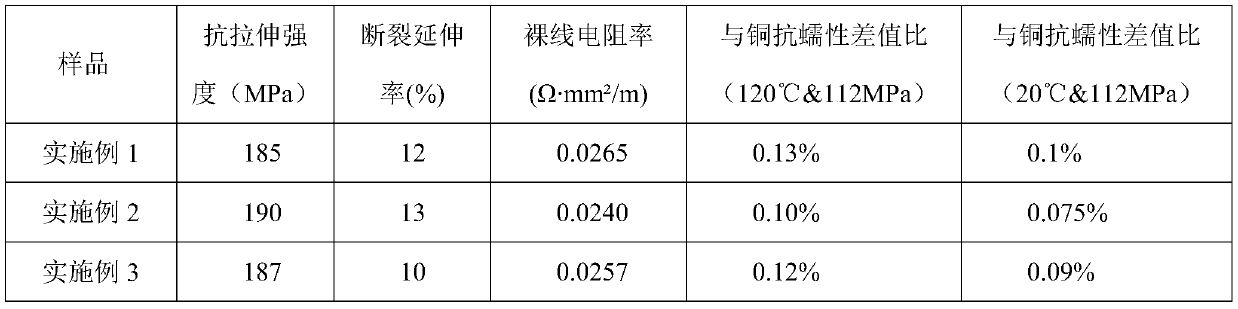

Creep-resistant high-conductive copper-clad aluminum alloy conductor and preparation method thereof

InactiveCN109903889AImproved compressive creep performanceImprove conductivitySingle bars/rods/wires/strips conductorsInsulated cablesElectrical conductorCerium

The invention relates to the technical field of electric wires, and in particular relates to a creep-resistant high-conductive copper-clad aluminum alloy conductor and preparation method thereof. Thecreep-resistant high-conductive copper-clad aluminum alloy conductor comprises an aluminum alloy rod and a copper layer; the copper layer uniformly and centrically coats the surface of the aluminum alloy rod; the aluminum alloy rod comprises the following materials in percentage by weight: 0.05-3.00% of iron, 0.005-0.60% of copper, 0.005-0.50% of magnesium, 0.005-0.50% of cerium, 0.005-0.05% of boron and the balance of aluminum and inevitable impurities. The preparation method of the creep-resistant high-conductive copper-clad aluminum alloy conductor comprises the following steps of smelting,continuous casting and rolling, coating and welding, annealing and wiredrawing. The creep-resistant high-conductive copper-clad aluminum alloy conductor provided by the invention is high in electricconductivity and good in mechanical strength, has the extension strength capable of being up to 185MPa, and can be applied to electric wire conductors.

Owner:SHENZHEN SHENZHOU CABLE

Nanometer copper oxide in-situ reduction wood composite material and preparation method thereof

ActiveCN109176773AEasy to prepareHigh activityWood treatment detailsCane mechanical workingFiberThermal compression

The invention discloses a nanometer copper oxide in-situ reduction wood composite material and a preparation method thereof. The nanometer copper oxide in-situ reduction wood composite material is made of five components, and the components include, by mass, 40%-50% of Chinese pennisetum micro powder, 20%-30% of wheat straw middlings, 10%-20% of reed fiber, 10%-15% of nanometer copper oxide powderand 0.5%-3% of polyethylene glycol 400. The preparation method comprises eight steps including preparation of the Chinese pennisetum micro powder, preparation of the wheat straw middlings, preparation of the reed fiber, matching, preparation of wood alloy, material mixing, thermal compression moulding forming and subzero treatment. According to the preparation method, material forming theories ofthe interdisciplines including powder metallurgy and powder engineering, composite material and engineering, wood science and technology and the like are comprehensively applied, and the wood composite material forming technology and method are innovated.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

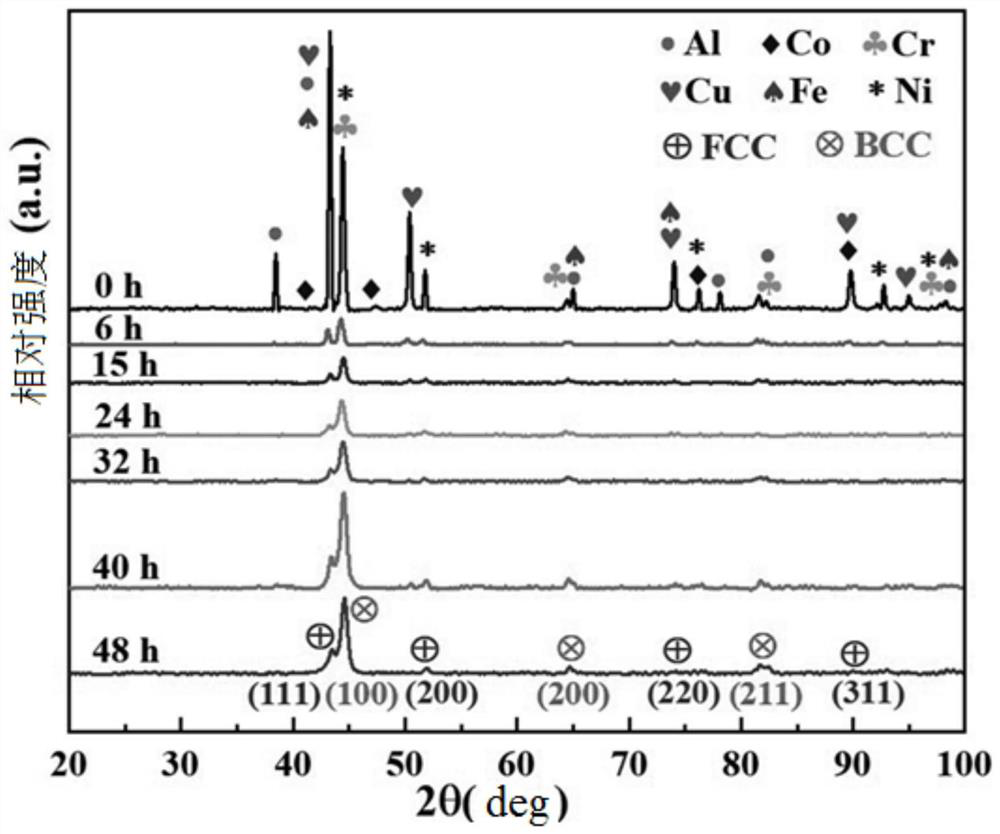

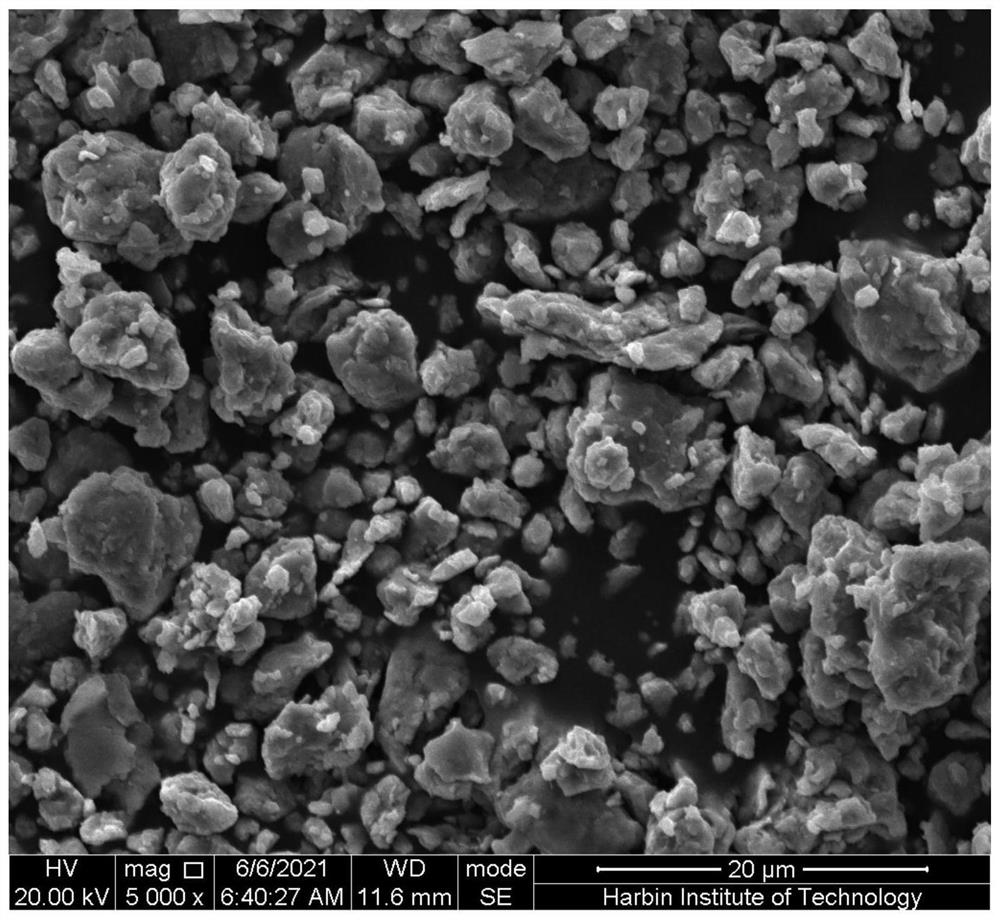

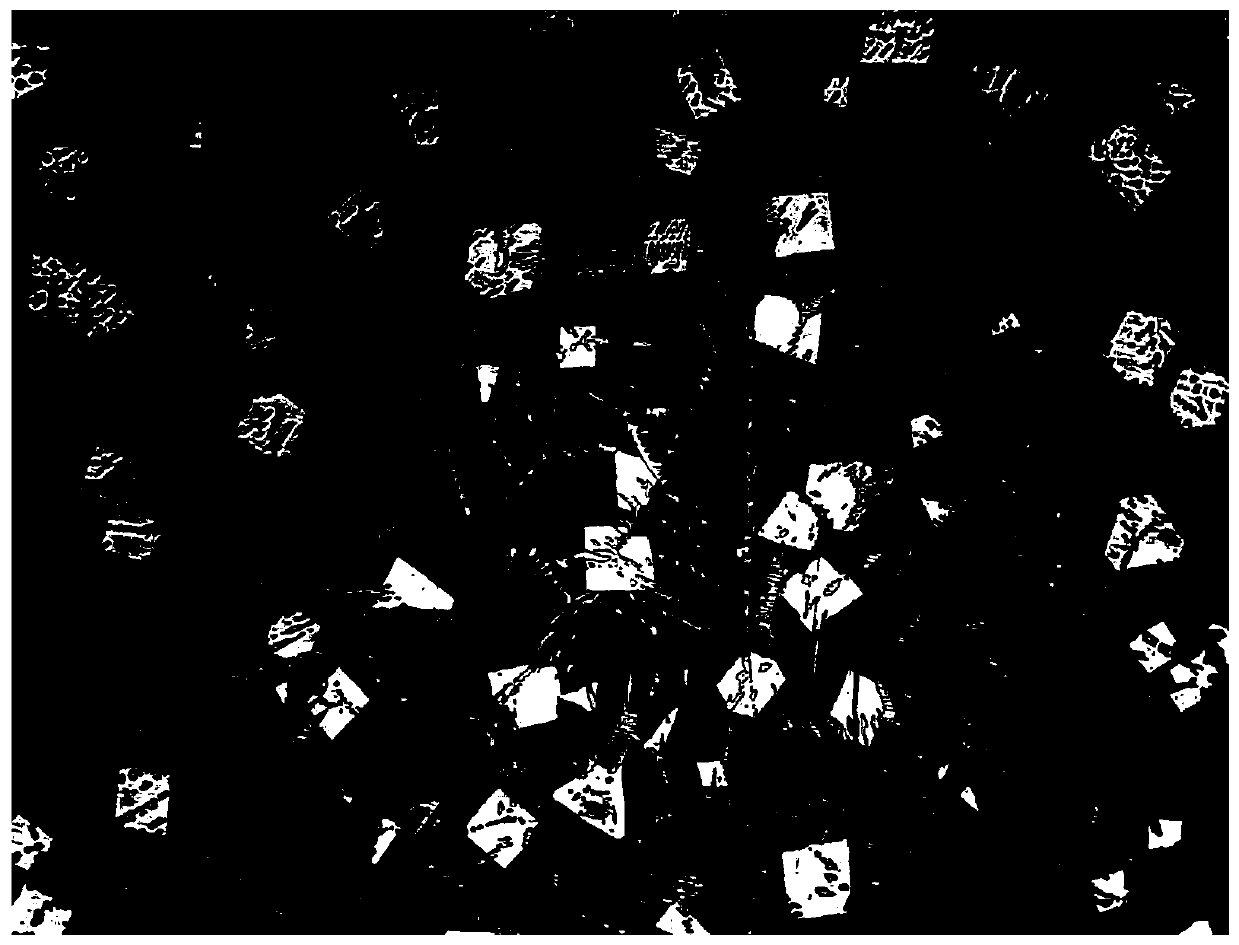

High-powder-yield mechanical alloying and sintering forming method for high-entropy alloy

The invention discloses a high-powder-yield mechanical alloying and sintering forming method for a high-entropy alloy, and relates to a mechanical alloying and sintering forming method for the high-entropy alloy. The invention aims to solve the technical problem of low powder yield of an existing mechanical alloying method for preparing the high-entropy alloy. In the step 3, high-speed ball milling is conducted without adding a process control agent, then stearic acid is added, and ball milling is continued, so that the phenomenon that powder adheres to balls and a tank is basically avoided, the powder yield is greatly improved and can reach 99.2%, the powder is completely alloyed, and the powder is fine. The prepared powder is subjected to vacuum hot press sintering to form the block Al<0.8>Co<0.5>Cr<1.5>FeNiCu high-entropy alloy, and the alloy structure is fine and uniform.

Owner:HARBIN INST OF TECH

High-antimony tin-based babbitt metal material and preparation method thereof

The invention provides a high-antimony tin-based babbitt metal material and a preparation method thereof. The high-antimony tin-based babbitt metal material comprises the following components in percentage by weight: 10-12% of antimony, 5-7% of copper, 0.003-0.01% of tellurium, 0.01-0.015% of germanium and the balance of tin. The invention further provides the preparation method of the high-antimony tin-based babbitt metal material. According to the high-antimony tin-based babbitt metal material and the preparation method thereof, the components and the proportion of the high-antimony tin-based babbitt metal material are improved, the strength and the mechanical property of the high-antimony tin-based babbitt metal material are improved, the preparation method of the high-antimony tin-based babbitt metal material is improved, the full alloying of alloy elements is guaranteed, various impurities are removed, and the problems of tedious operation, high labor intensity, relatively low alloy quality and the like are effectively solved.

Owner:四川朗峰电子材料有限公司

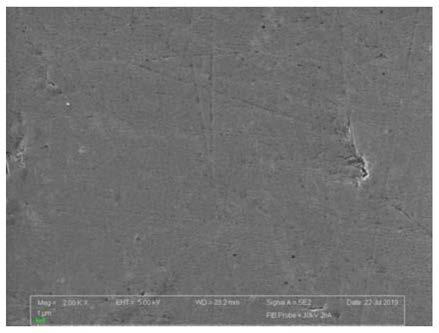

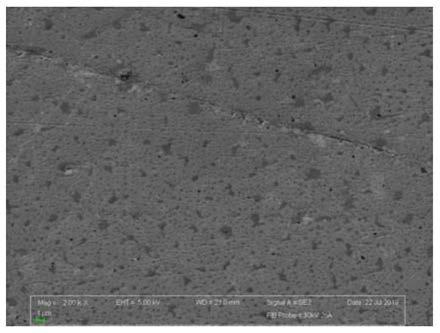

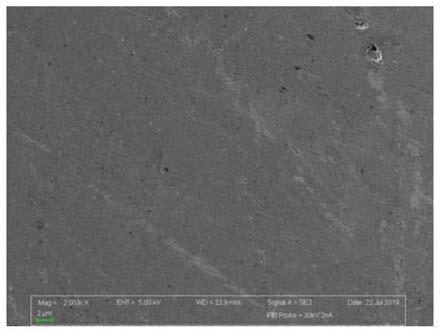

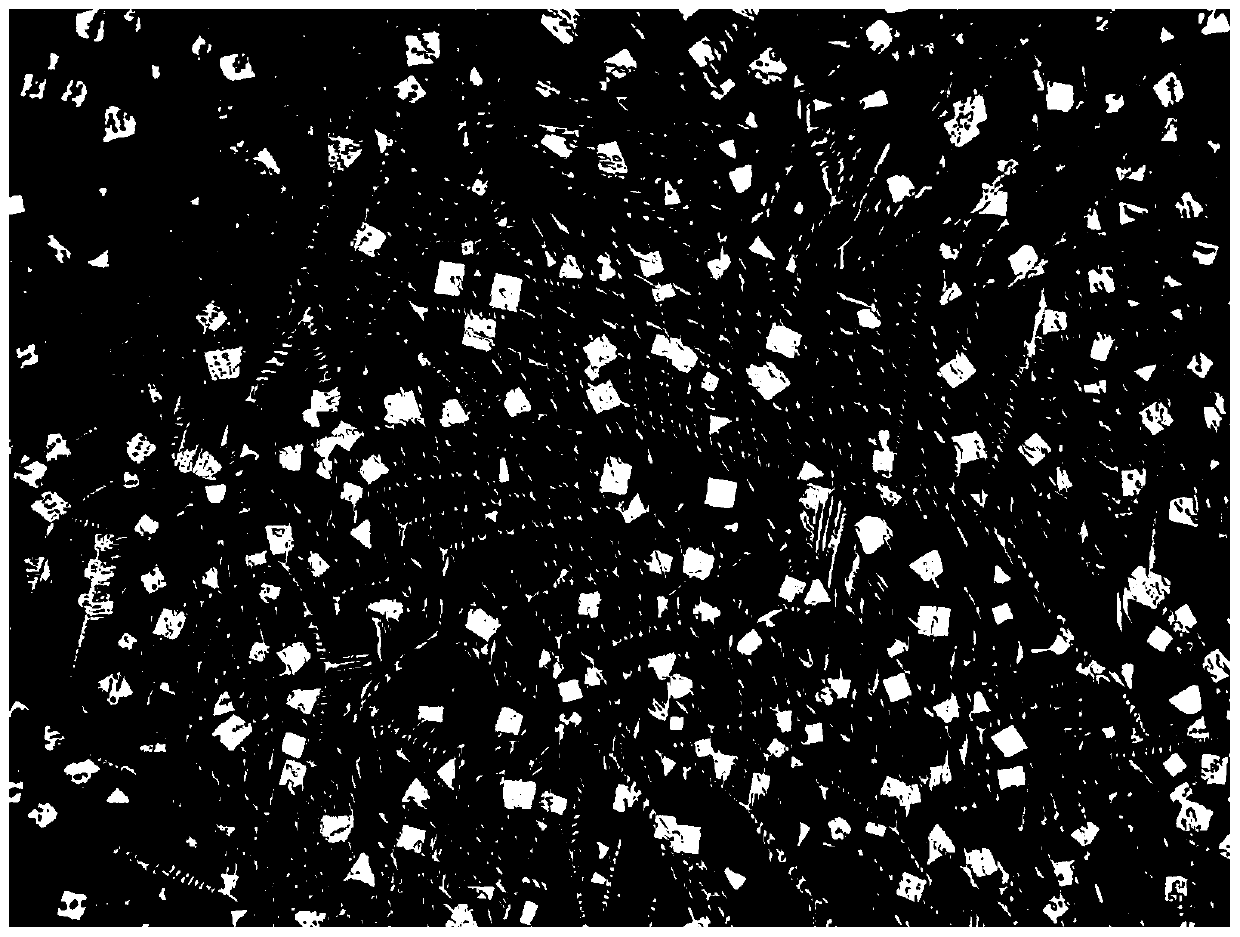

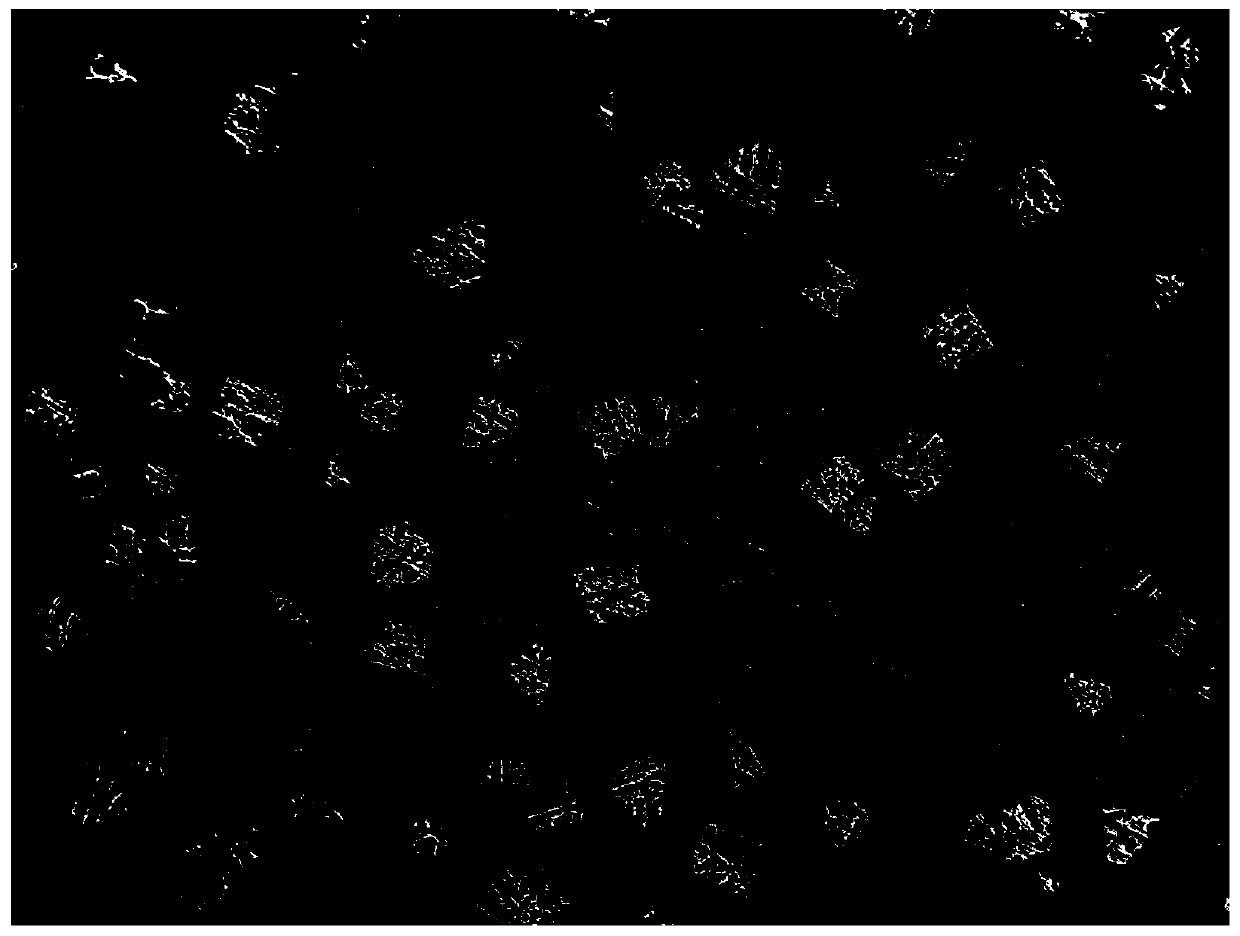

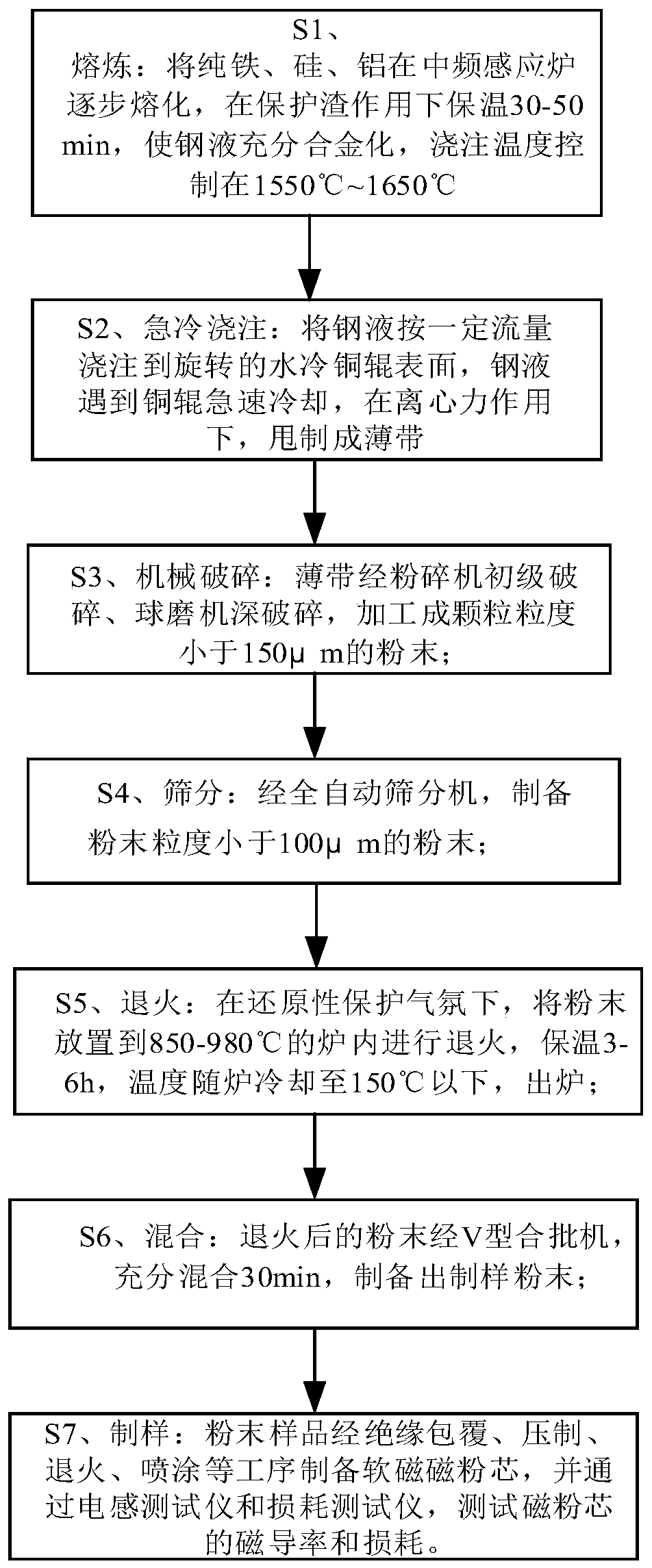

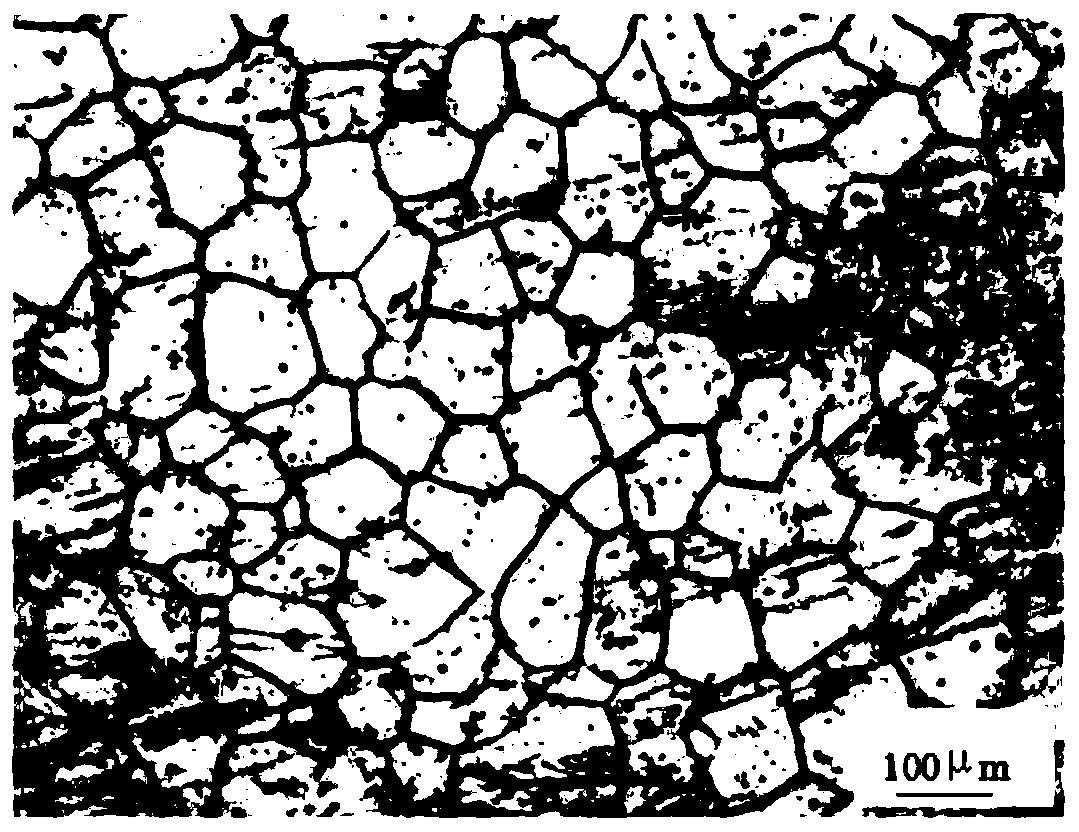

Preparation method of iron-silicon-aluminum alloy powder with high magnetic conductivity

InactiveCN110534282AFully alloyedImprove purityInductances/transformers/magnets manufactureMagnetic materialsMagnetic powderCopper

The invention provides a preparation method of iron-silicon-aluminum alloy powder with high magnetic conductivity, relates to the soft magnetic material field and a rapid cooling pouring technology, and is an improvement of an iron-silicon-aluminum soft magnetic powder manufacturing process. The preparation method of the iron-silicon-aluminum alloy powder with high magnetic conductivity comprisesthe following steps of smelting, quenching and pouring, mechanical crushing, screening, annealing, mixing and sample preparation testing. In a quenching and pouring process, molten steel is poured toa surface of a rotated water-cooled copper roller according to a preset flow, and the molten steel is rapidly cooled when encountering the copper roller and is swung into a thin band under a centrifugal force effect. According to the preparation method, complex equipment is not needed, purity of the smelted molten steel is greatly improved, an oxygen content of the powder is low, a grain size is fine, the magnetic conductivity of a prepared magnetic powder core can reach more than 150 mu, and losses are low.

Owner:山东汇嘉磁电科技有限公司

A kind of preparation method of uniform gold-tin eutectic alloy foil

The invention relates to a preparation method for a gold-tin eutectic alloy foil having a uniform structure. The preparation method comprises: accurately preparing a gold-tin alloy raw material with a tin mass percentage of 20% and a gold mass percentage of 80%; in a non-consumable electrical arc smelting furnace, under a vacuum degree of 10<-3> Pa, repeatedly carrying out smelting, electromagnetic stirring and cooling at least three times to obtain a gold-tin alloy casting ingot; and carrying out homogenization annealing on the casting ingot, and then carrying out multi-pass thermal compression to obtain the gold-tin eutectic foil. According to the present invention, the vacuum electrical arc smelting, the circular electromagnetic stirring and the cyclic thermal compression to prepare the whole lamellar eutectic structure, wherein the eutectic point component does not have the primary phase; and compared with the preparation method in the prior art, the preparation method of the prevent invention has the following characteristics that: the complete alloying is achieved, the strength is high, the weldability is good, other components are not added or the gold-to-tin ratio is not adjusted, the welding temperature and the welding performance are stable, the welding piece deformation and the force on the welding piece are uniform, the welding piece cracking condition is not easily generated, the yield is high, the production efficiency is much higher than the production efficiency of the electroplating method for preparing the gold-tin welding piece, the production cost is reduced, and the preparation method is suitable for mass production.

Owner:CENT SOUTH UNIV

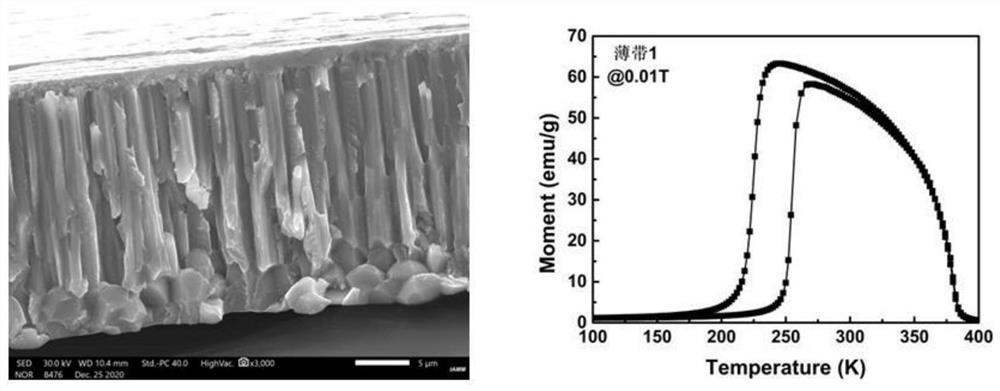

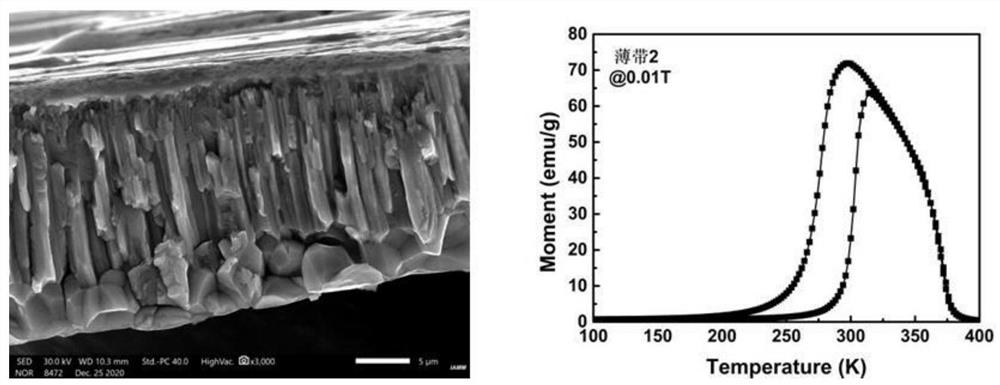

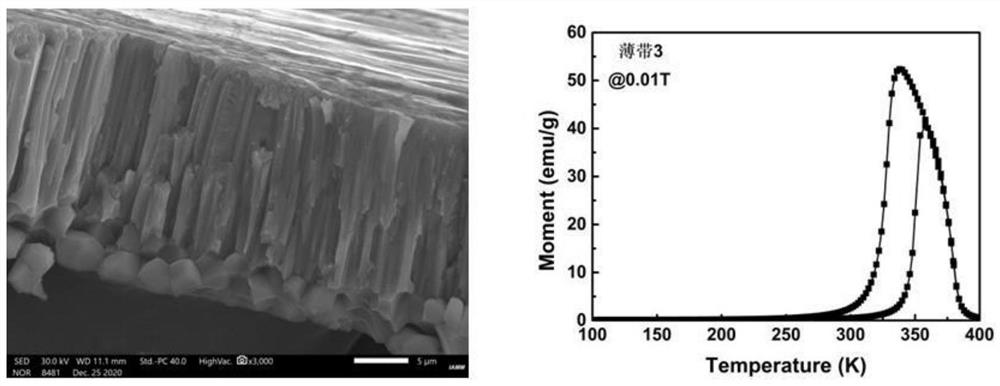

Ni-Mn-Ti-based multi-element alloy target material, preparation method thereof and film

PendingCN113235055AHigh purityGood mechanical propertiesVacuum evaporation coatingSputtering coatingThin membraneQuenching

The invention relates to a Ni-Mn-Ti-based multi-element alloy target material, a preparation method thereof and a film. Firstly, an alloy ingot is prepared through electric arc melting, the purity and compactness of the alloy are improved, and multiple elements are fully alloyed; subsequently, a thin strip is thrown out at a certain wheel speed through rapid quenching for a melt, the porosity in the material is reduced, a subsequent heat treatment process is simplified, grains are refined, and element distribution tends to be more uniform; then, the thin strip is ground into alloy powder, the problem of non-uniform components caused by a too low melting point or a too high melting point of a single element is effectively solved, and the phase change temperature span is widened under the condition that the original magnetism is ensured; and finally, the quaternary alloy target material is prepared through hot pressing. According to the invention, the advantages of electric arc melting and high-temperature hot pressing preparation are integrated, and the rapid quenching for the melt is combined, so that the target material which is uniform in component, low in porosity, high in purity, small in grain size and wide in phase change temperature zone span can be prepared; and NiMnTi-based alloy is adopted as the target material, and the prepared film has good mechanical performance, so that subsequent stress regulation and control are facilitated, and the multifunctional film is obtained.

Owner:HANGZHOU DIANZI UNIV

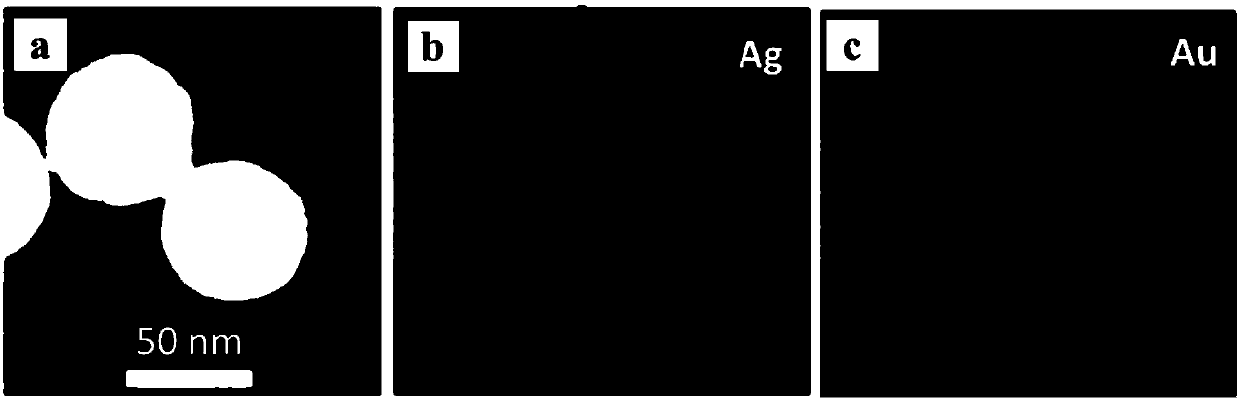

A method for rapid preparation of three-dimensional porous gold-silver alloy nanomaterials

ActiveCN107584135BShorten alloying timeShort manufacturing timeMaterial nanotechnologyRoom temperatureAlloy

The invention discloses a method for rapidly preparing a three-dimensional porous gold-silver alloy nanometer material, which comprises the following steps: adding silver nitrate and ascorbic acid into a gold nano octahedral colloidal solution and reacting for 30 minutes under the condition of 50-80 DEG C so as to prepare a gold@silver nano cubic colloidal solution; uniformly mixing the gold@silver nano cube cubic colloidal solution with deionized water under the action of stirring and irradiating with a laser with a power of 670-680 volts for 60 -90 seconds so as to prepare a gold-silver alloy nanosphere colloidal solution; adding nitric acid into the gold-silver alloy nanosphere colloidal solution and reacting for 0.5-hours to obtain the three-dimensional porous gold-silver alloy nanometer material. The method not only can rapidly prepare the three-dimensional porous gold-silver alloy nanomaterial at room temperature and greatly shorten the preparation time, but also realizes the complete alloying of gold and silver elements; the three-dimensional porous gold-silver alloy nanomaterial has uniform size, large specific surface area, and good monodispersity; the preparation processis simple and easy to operate.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Special intermediate alloy for iron base amorphous nanocrystalline alloy and smelting method thereof

The iron-based amorphous nano master alloy belongs to the field of metallurgy, and its chemical composition mass percentage is: Si is 15.7, B is 3.8, Nb is 11, Cu is 2.4, and the balance is Fe. The smelting method is: add industrial pure iron - ferroniobium - industrial silicon - electrolytic copper boron iron into the intermediate frequency smelting furnace in sequence; (2) preheat with low power first, and then heat with high power; (3) wait After the raw materials are completely melted, carry out alternating stirring with large and small power, and at the same time cooperate with the shaking furnace with medium and small range; when the temperature rises to 1400 ° C, keep it warm for 5 minutes; (4) Finally, slag and tap. The invention solves the problems of burning loss of raw materials, difficulty of melting high-melting point alloys and the like. The amorphous and nanocrystalline strips produced by using the master alloy have multiple advantages such as uniform composition, good toughness, significantly improved magnetic properties, and reduced manufacturing costs.

Owner:太原钢铁(集团)有限公司

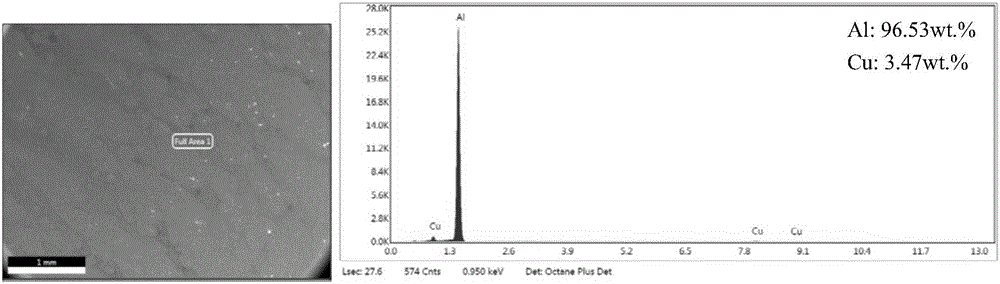

High hardness, high thermal conductivity and low expansion coefficient Al-Cu-CNT material and preparation method thereof

A high hardness, high thermal conductivity and low expansion coefficient Al-Cu-CNT material and a preparation method thereof are disclosed, the high hardness, high thermal conductivity and low expansion coefficient Al-Cu-CNT material is characterized in that: the high hardness, high thermal conductivity and low expansion coefficient Al-Cu-CNT material is prepared from Al powder, Cu powder and CNT; the preparation method is as follows: first, the Al powder, the Cu powder and the CNT are uniformly mixed and dried for high-energy ball milling for mechanical alloying, ball-milled powder is pressed into blocks, a graphite-powder-coated sample is sintered for further fully mechanical alloying, and finally solution and aging treatment of the sintered sample is performed. The Al-Cu-CNT material has the advantages of uniform composition, high hardness, greatly-improved elastic modulus and thermal conductivity, low thermal expansion coefficient, and wide application prospect in the field of electronic packaging.

Owner:JIANGSU UNIV

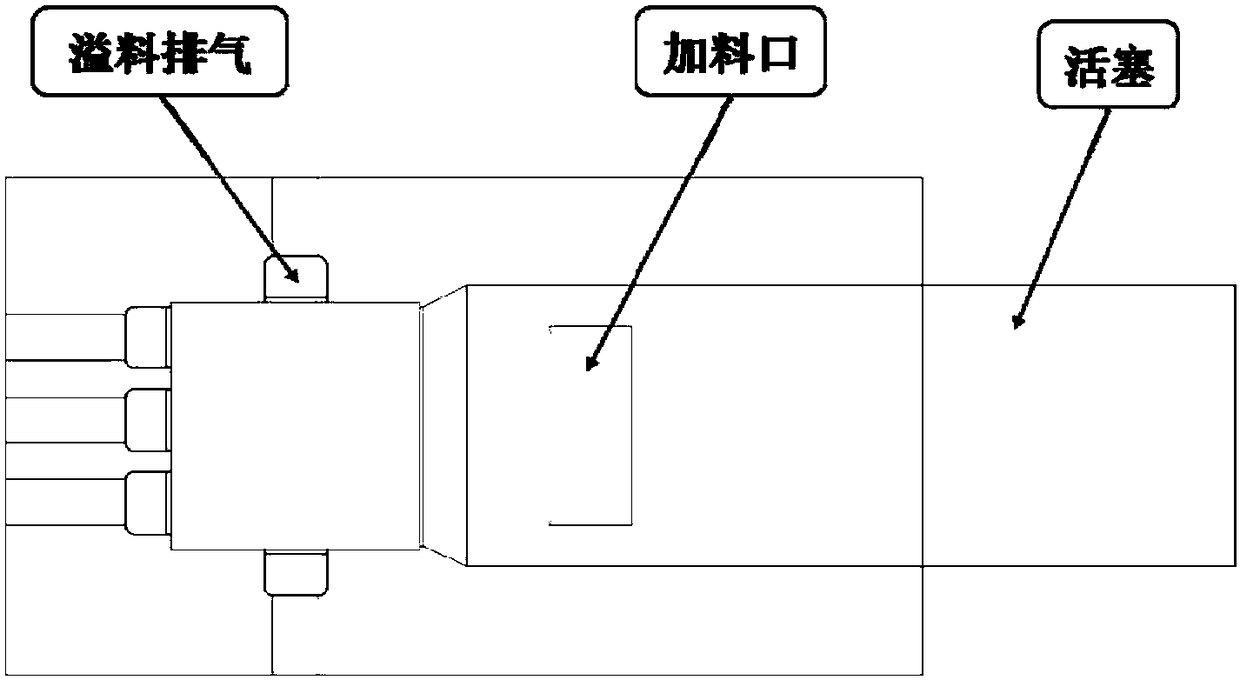

A high-efficiency die-casting preparation method of ultra-thin gold-tin eutectic material

The invention relates to an efficient die-casting preparation method for an ultrathin Au-Sn eutectic material, and belongs to the technical field of metal material preparation. The preparation method includes the following steps that an Au-Sn eutectic alloy raw material with the mass percent of Sn being 20% and the mass percent of Au being 80% is accurately prepared; the Au-Sn raw material is subjected to vacuum electric arc smelting under the condition that the vacuum degree reaches 6*10<-4>Pa, and electromagnetic stirring is further added to obtain an Au-Sn alloy die-casting ingot of the regular eutectic structure without a primary phase; the die-casting ingot is subjected to die-casting formation in a hot chamber die-casting machine; and a die-casting sheet is subjected to homogenizing annealing, and accordingly the ultrathin Au-Sn eutectic material can be obtained. According to the efficient die-casting preparation method, a mother alloy vacuum electric arc smelting one-step die-casting sheet formation technology is adopted to successfully obtain the ultrathin Au-Sn eutectic material of the uniform eutectic point component structure, the prepared product achieves complete alloying, the rate of finished products is high, components are stable, strength is high and welding performance is good. The designed preparation method is high in preparation efficiency, short in preparation process, low in cost and suitable for batch production.

Owner:CENT SOUTH UNIV

A kind of pre-alloyed powder for diamond sawing tool

The invention discloses prealloyed powder for diamond sawing tools. The prealloyed powder, disclosed by the invention, comprises the following components in percentage by weight: 20-25% of Cu, 5-10% of Co, 1-3% of Ni, 3-6% of Cr, and the rest amount of Fe. As raw materials of carcasses for the diamond sawing tools, the prealloyed powder has the advantages of low oxygen content, fine granularity, uniform and segregation-free components, irregular particle morphology, difficult secondary oxidation, difficult agglomeration and full alloying; and the obtained carcasses are uniform in structure, high in hardness and impact strength, and are good in mechanical control of diamond.

Owner:杭州屹通新材料股份有限公司

A kind of production technology of silicon carbide titanium

ActiveCN112919470BFully alloyedRaw materials are easy to getCarbon compoundsChemical industrySilicon alloyBall mill

Owner:辽宁中色新材科技有限公司

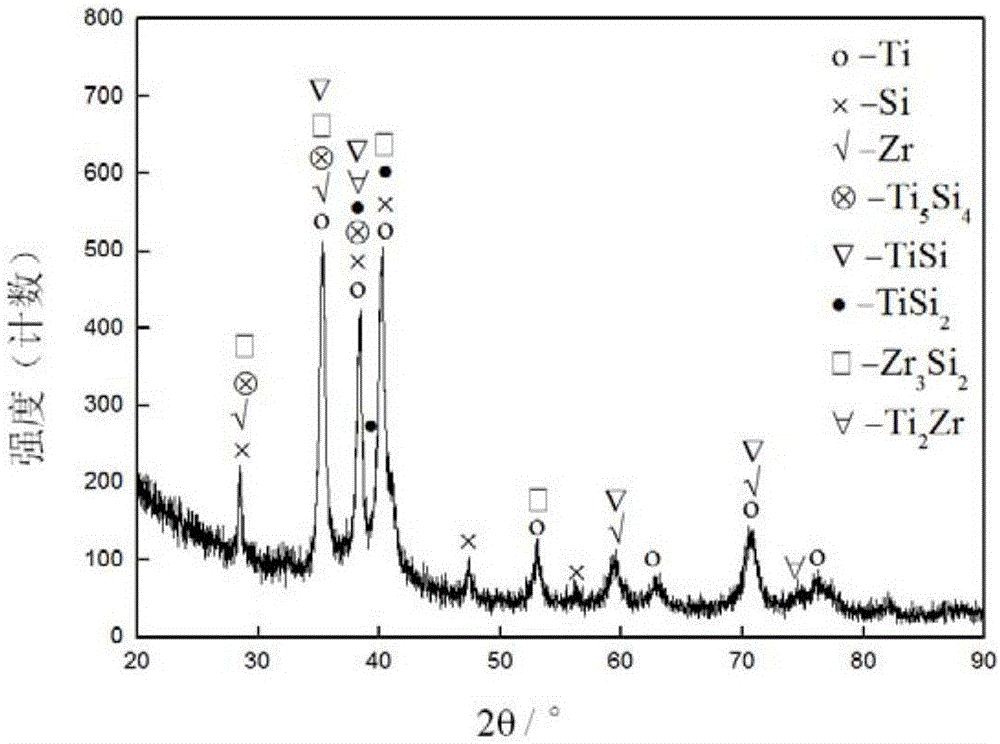

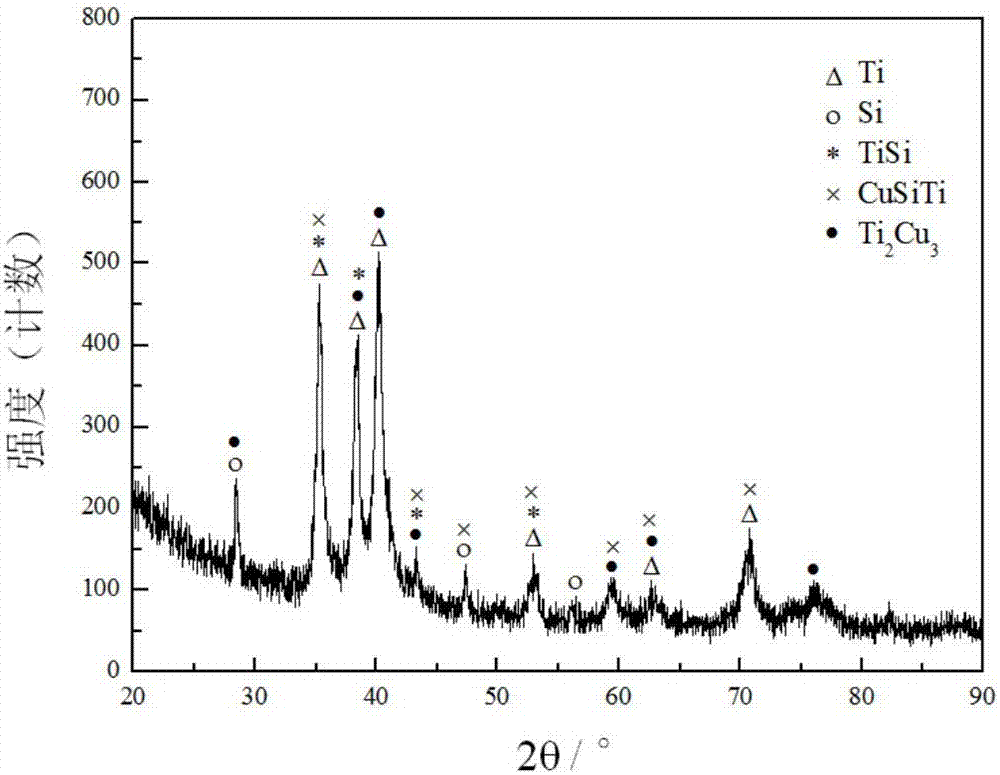

A kind of Cu-alloyed Ti-8Si alloy and preparation method thereof

A copper-alloyed Ti-8Si alloy and a preparation method thereof. The copper-alloyed Ti-8Si alloy is prepared from titanium powder, silicon powder and copper powder. The preparation method includes the steps of: uniformly mixing the titanium powder, silicon powder and copper powder and performing high-energy ball milling to partially alloy the powder material; drying and sieving the ball-milled powder material and compression-molding the dried powder material to form a briquette; and finally performing vacuum pressure-free sintering to completely alloy the briquette. The Ti-(8-0.08x)Si-xCu alloy has uniform surface component, is increased in compactness, microhardness, elasticity modulus, fracture toughness, anti-oxidizing property, corrosion resistance and frictional wear performance at certain degrees, and has a wide application prospect in the fields of aerospace, traffic transportation and weapon equipment.

Owner:JIANGSU UNIV

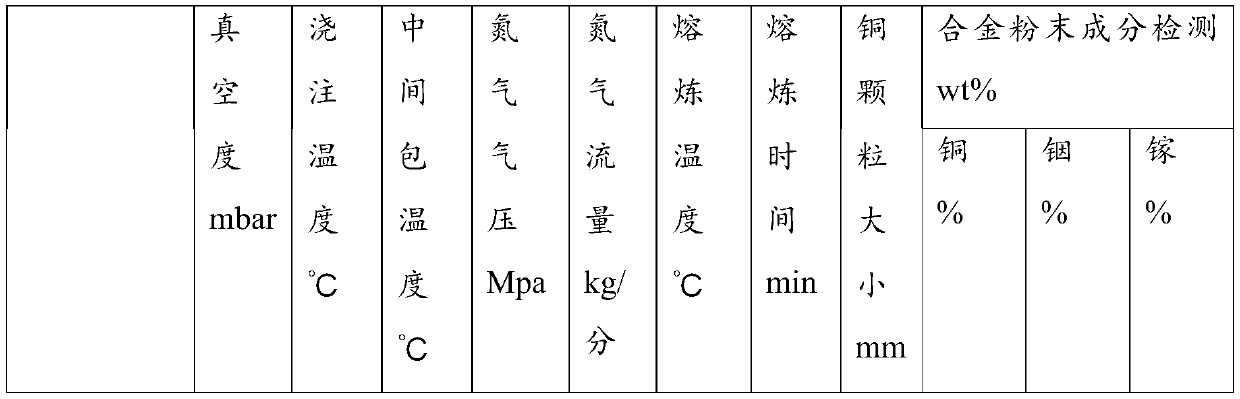

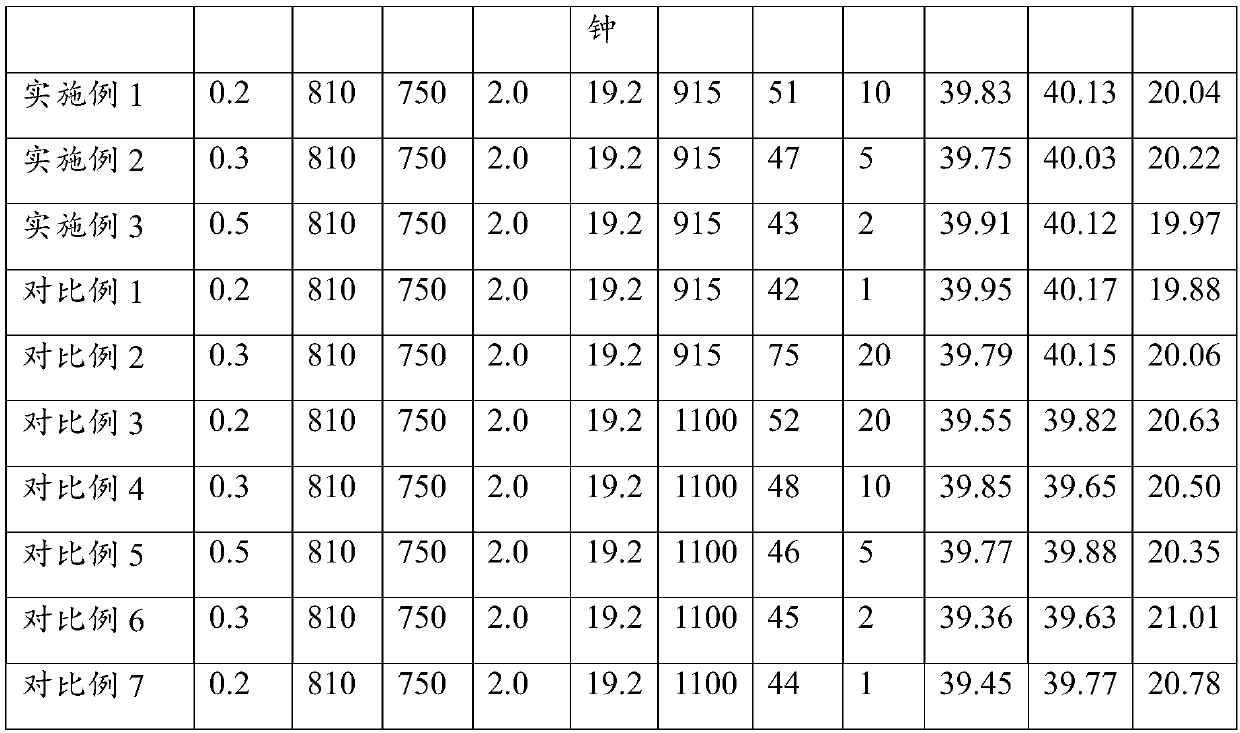

Preparation method for copper-indium-gallium alloy powder

PendingCN110605399AReduce energy costsReduce manufacturing costVacuum evaporation coatingSputtering coatingIndiumCrucible

The invention relates to a preparation method for copper-indium-gallium alloy powder. The preparation method comprises the steps that copper, indium, gallium and recovered copper-indium-gallium alloypowder with the particle size not within the set range are molten into an alloy solution in a smelting crucible; the alloy solution is atomized, cooled and screened to obtain the copper-indium-galliumalloy powder with the particle size within the set range; copper-indium-gallium alloy powder with the particle size not within the set range is recovered; and wherein in the smelting step, indium andgallium are put at the bottom of the smelting crucible, and after mixed, copper particles and the recovered copper-indium-gallium powder with the particle size not within the set range are put on theindium and gallium in the smelting crucible. Through the preparation method, the smelting temperature is lowered, thus component deviation in the copper-indium-gallium alloy powder is avoided, the preparation period of the alloy powder is shortened, and constituent stability and production efficiency of the copper-indium-gallium alloy powder are improved.

Owner:MIASOLE EQUIP INTEGRATIONFUJIANCO LTD

Melting method for magnesium alloy containing high reactivity elements

Owner:QINGHAI SUNGLOW MAGNESIUM

An SPS sintered titanium-based composite material and its preparation method

An SPS sintered titanium-based composite material and its preparation method, which is characterized in that it is prepared by composite sintering of Ti-6Al-4Sn-9Zr-1.21Nb-1.6Mo-0.3Si powder and nano-GNP powder; first, add absolute ethanol Fully disperse the nano-GNP powder so that the GNP powder will not agglomerate in subsequent operations, then add Ti-6Al-4Sn-9Zr-1.21Nb-1.6Mo-0.3Si powder for wet grinding, and then dry grind after drying. After the materials are sieved, a powder with uniform particles is obtained, which is dried again, and then the mixed powder is poured into a graphite mold for plasma sintering to obtain Ti‑6Al‑4Sn‑9Zr‑1.21Nb‑1.6Mo‑0.3Si powder and nano-GNP powder. Further alloying. The composite material obtained by the invention has excellent performance, and the composition uniformity and oxidation resistance of the material are greatly improved.

Owner:JIANGSU UNIV

Iron-hafnium-rare earth master alloy and preparation method thereof

Owner:全南晶环科技有限责任公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com