Ni-Mn-Ti-based multi-element alloy target material, preparation method thereof and film

An alloy target and thin film technology, which is applied in the coating process of metal materials, electrical components, magnetic properties of inorganic materials, etc., can solve the deviation of the photon absorption ability of charge mobility from the theoretical prediction value, being susceptible to surface dielectric state modulation, two-dimensional Problems such as application limitations of transition metal dichalcogenide materials, to achieve the effect of simplifying the heat treatment process, good mechanical properties, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

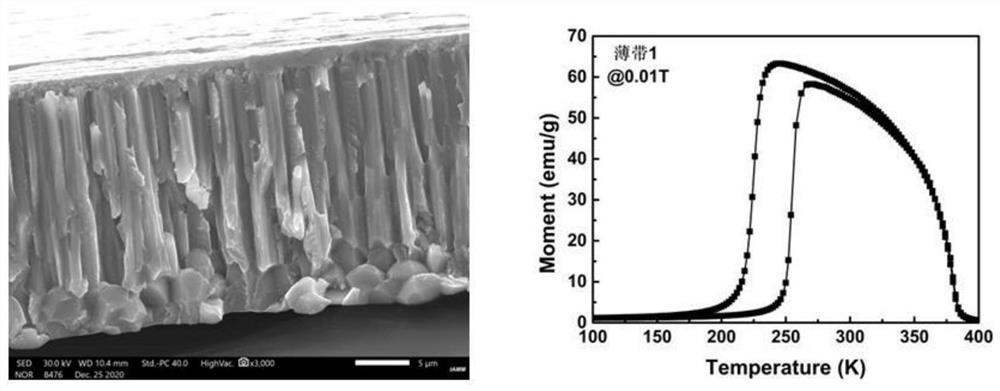

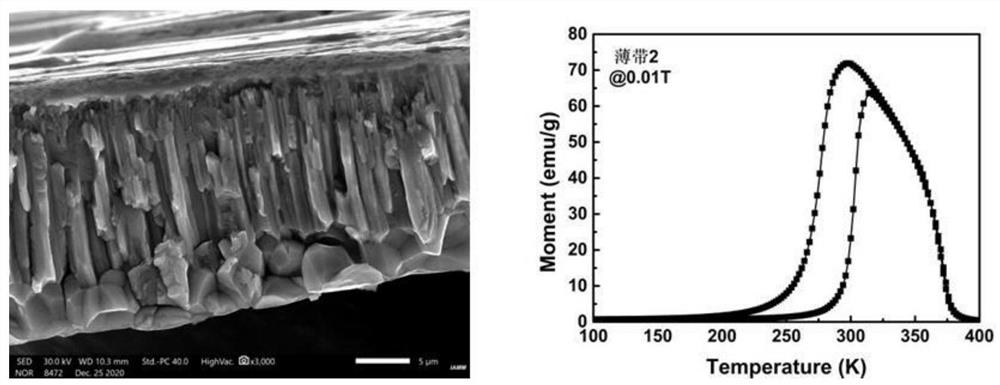

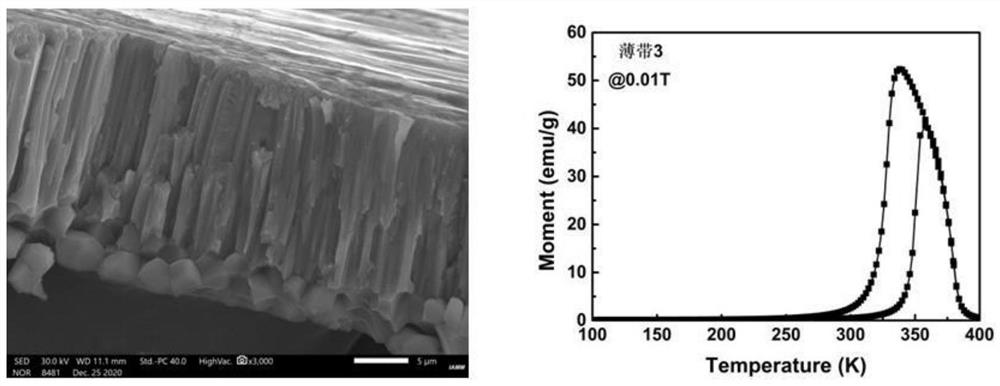

[0039] A method for preparing a Ni-Mn-Ti-based multi-component alloy target, wherein the chemical formulas of the materials are respectively Ni 35 co 15 mn 35 Ti 15 (sample 1), Ni 35.5 co 14.5 mn 35 Ti 15 (sample 2), Ni 36 co 14 mn 35 Ti 15 (sample 3), described material preparation method comprises the following steps:

[0040] (1) Ingredients: Weigh high-purity raw materials Ni, Mn, Co, and Ti according to the ratio in the chemical formula, and carefully polish off the oxide layer on the surface of the required transition metal elements before ingredients.

[0041] Taking Mn element as an example, it needs to be cleaned and smelted to ensure the purity of the raw material. The specific steps are as follows: 1) Put a certain amount of Mn element in the beaker, and then pour it into the beaker diluted with water at a volume ratio of about 1:1. Dilute hydrochloric acid solution to make it chemically react, and stir it quickly with a glass rod during the reaction; 2) ...

Embodiment 2

[0052] The difference between embodiment 2 and embodiment 1 is that step (5) is different, and all the other processes are identical.

[0053] High-temperature hot pressing: the prepared mixed powder is used as raw material, and the Ni-Co-Mn-Ti target is prepared by vacuum hot pressing powder metallurgy. The prepared alloy mixed powder is placed in a mold for sintering, and then the mold is put into a sintering furnace for vacuuming and hot pressing; during the hot pressing process, the background vacuum in the furnace is ≤3*10 -7 Pa, under the pressure of 35MPa, the temperature is raised to 1200 ° C in stages, and each stage is kept for 30 minutes. It is divided into 6 stages. 1 is equivalent and will not be repeated here.

Embodiment 3

[0054] The difference between embodiment 3 and embodiment 1 is that step (3) is different from step (5), and all the other processes are identical.

[0055] Melt quick quenching: Put the alloy ingot melted in the electric arc furnace into a water-cooled copper crucible, melt it by induction melting, then tilt the copper crucible, and blow the molten alloy out of the bottom of the quartz tube through the Ar gas. Mouth, it is rapidly cooled on a rotating copper wheel with a speed of 30m / s, solidified, and made into a thin strip.

[0056] High-temperature hot pressing: the prepared mixed powder is used as raw material, and the Ni-Co-Mn-Ti target is prepared by vacuum hot pressing powder metallurgy. The prepared alloy mixed powder is installed in the mold for sintering, and then the mold is put into the sintering furnace for vacuuming and hot pressing; during the hot pressing process, the background vacuum in the furnace is ≤3*10-7Pa, under the pressure of 28MPa Raise the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com