Creep-resistant high-conductive copper-clad aluminum alloy conductor and preparation method thereof

A technology of copper-clad aluminum alloy and aluminum alloy melt, which is applied in the direction of cable/conductor manufacturing, conductor, insulated conductor, etc., can solve the problems of high cost of copper wire and cable, increased contact resistance, poor bending performance, etc., and achieves improvement Compressive creep performance, recovery plasticity, and the effect of improving creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

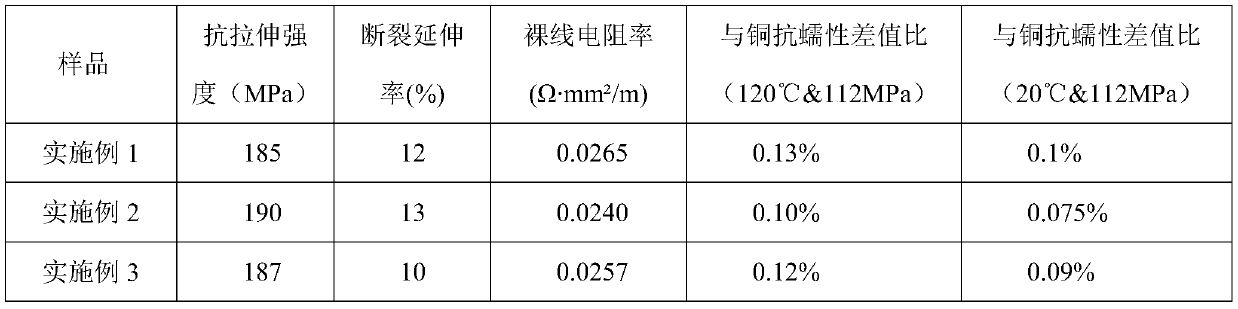

[0036] The creep-resistant high-conductivity copper-clad aluminum alloy conductor of Example 1 in Table 1 was prepared according to the following steps:

[0037] (1) Smelting treatment: Melt the aluminum alloy raw material at 750°C to form a melt, then carry out degassing and refining, and the furnace temperature is 740°C;

[0038] (2) Continuous casting and rolling treatment: using the full two-roller continuous casting and rolling production process, the melt obtained in step (1) is poured into a continuous casting machine for casting, and is continuously cooled with cooling water during casting to obtain a cast The billet is continuously fed into the continuous rolling mill. The continuous rolling mill is lubricated by emulsion and rolled into an aluminum alloy rod. The casting temperature is 700°C, the cooling water temperature is 30°C, the rolling temperature is 500°C, and the final rolling temperature is 500°C. 300°C, the temperature of the emulsion is below 32°C; cast a...

Embodiment 2

[0042] The creep-resistant high-conductivity copper-clad aluminum alloy conductor of Example 2 in Table 1 was prepared according to the following steps:

[0043] (1) Smelting treatment: Melt the aluminum alloy raw material at 730°C to form a melt, then carry out degassing and refining, and then release it at 720°C;

[0044](2) Continuous casting and rolling treatment: using the full two-roller continuous casting and rolling production process, the melt obtained in step (1) is poured into a continuous casting machine for casting, and is continuously cooled with cooling water during casting to obtain a cast The billet is continuously fed into the continuous rolling mill. The continuous rolling mill is lubricated by emulsion and rolled into an aluminum alloy rod. The casting temperature is 720°C, the cooling water temperature is 25°C, the rolling temperature is 500°C, and the final rolling temperature is 300°C, the temperature of the emulsion is below 35°C; casting an aluminum al...

Embodiment 3

[0048] The creep-resistant high-conductivity copper-clad aluminum alloy conductor of Example 3 in Table 1 was prepared according to the following steps:

[0049] (1) Smelting treatment: Melt the aluminum alloy raw material at 730°C to form a melt, then carry out degassing and refining, and then release it at 700°C;

[0050] (2) Continuous casting and rolling treatment: using the full two-roller continuous casting and rolling production process, the melt obtained in step (1) is poured into a continuous casting machine for casting, and is continuously cooled with cooling water during casting to obtain a cast The billet is continuously fed into the continuous rolling mill. The continuous rolling mill is lubricated by emulsion and rolled into an aluminum alloy rod. The casting temperature is 720°C, the cooling water temperature is 25°C, the rolling temperature is 180°C, and the final rolling temperature is 180°C. 260°C, the temperature of the emulsion is below 25°C; cast an alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com