Patents

Literature

86results about How to "Uniform and stable tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature resistant turbine blade and production process thereof

ActiveCN104099516AImprove performanceImprove impact toughnessBlade accessoriesSolid state diffusion coatingChemical compositionSteam turbine blade

The invention discloses a high-temperature resistant turbine blade. The turbine blade comprises the following chemical components in percentage by weight: 0.19-0.21% of C, 0.55-0.57% of Mn, 0.20-0.22% of Si, 0.38-0.40% of Al, 0.30-0.32% of V, 0.40-0.42% of Ti, 0.12-0.14% of Ni, 0.06-0.08% of Sn, 0.25-0.27% of Zr, no more than 0.025% of S, no more than 0.025% of P, no more than 0.20% of Cu, 0.20-0.22% of lanthanide serial rare earth, and the balance Fe. The invention further designs a production process of the turbine blade. The production process has the advantages of simplicity and low cost, helps to largely improve the impact toughness of the blade, enhance the high temperature resistance of the blade and prolong the service life of the blade through the nitridation surface treatment.

Owner:南京赛达科技有限公司

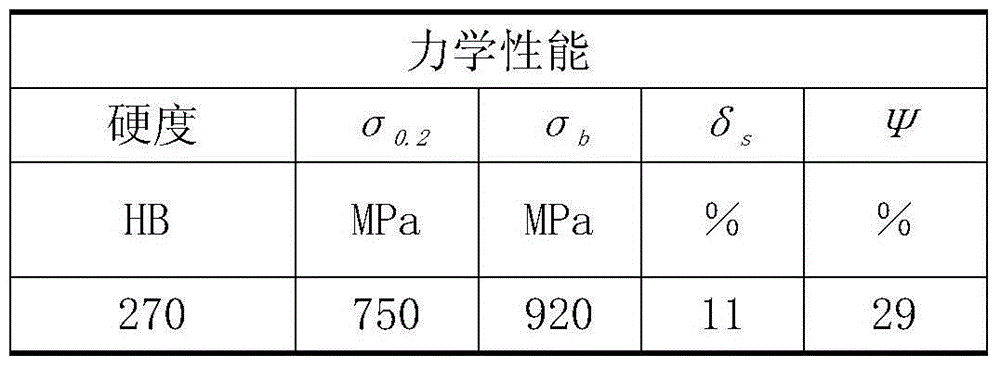

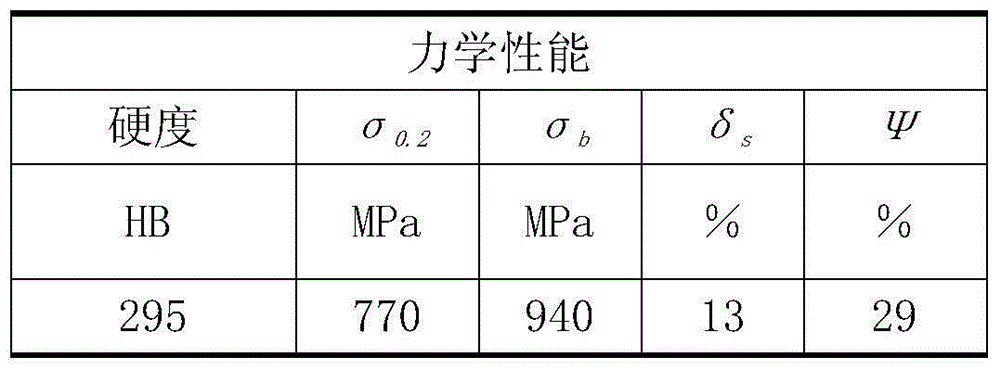

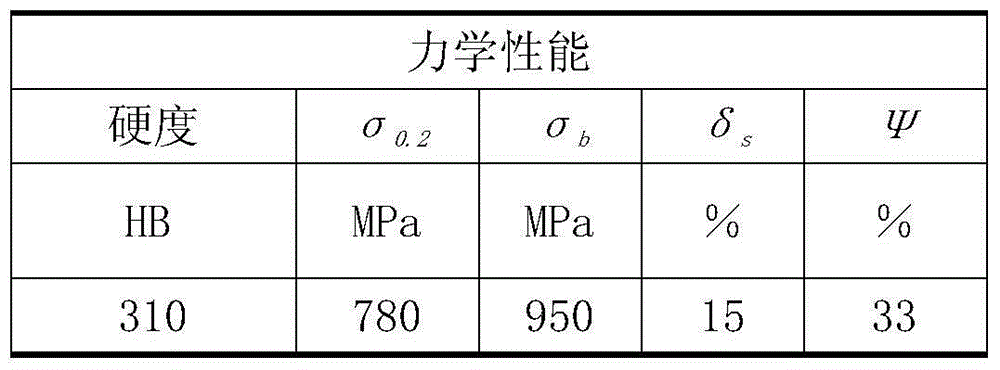

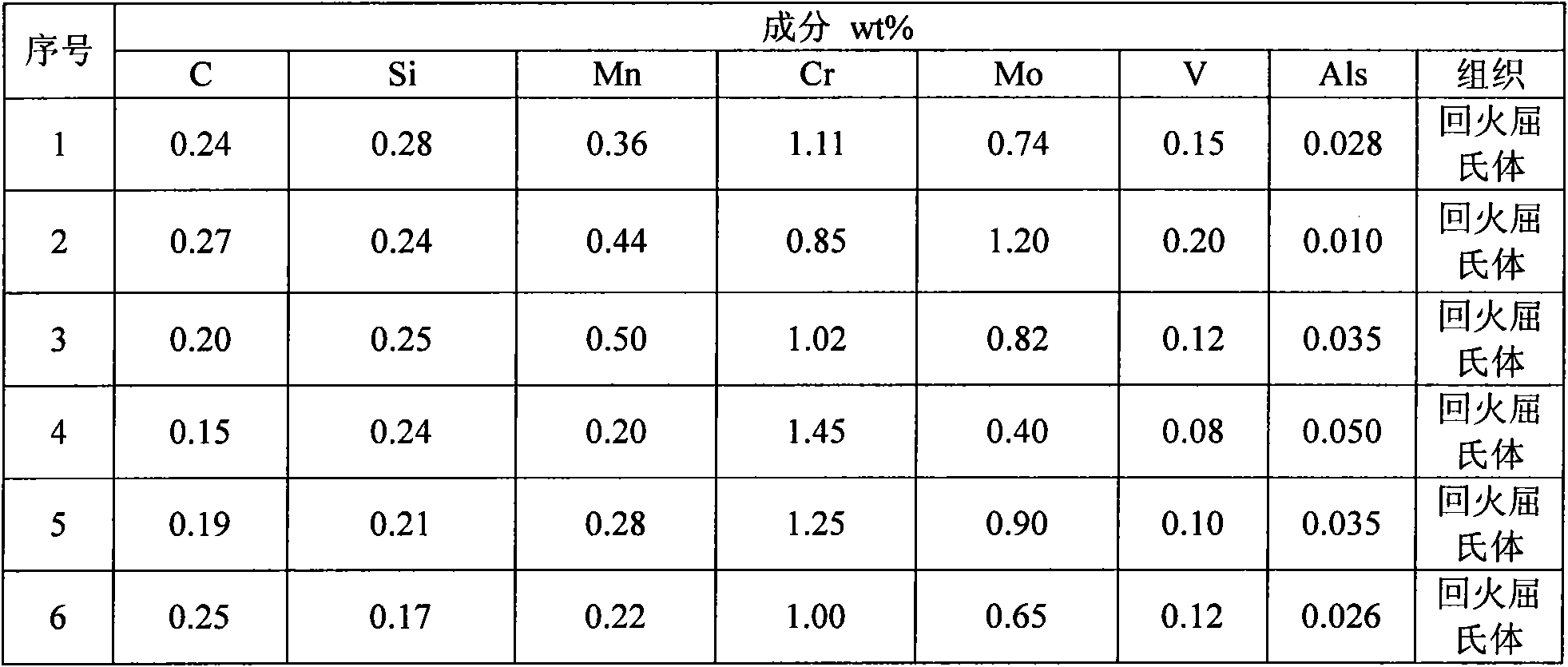

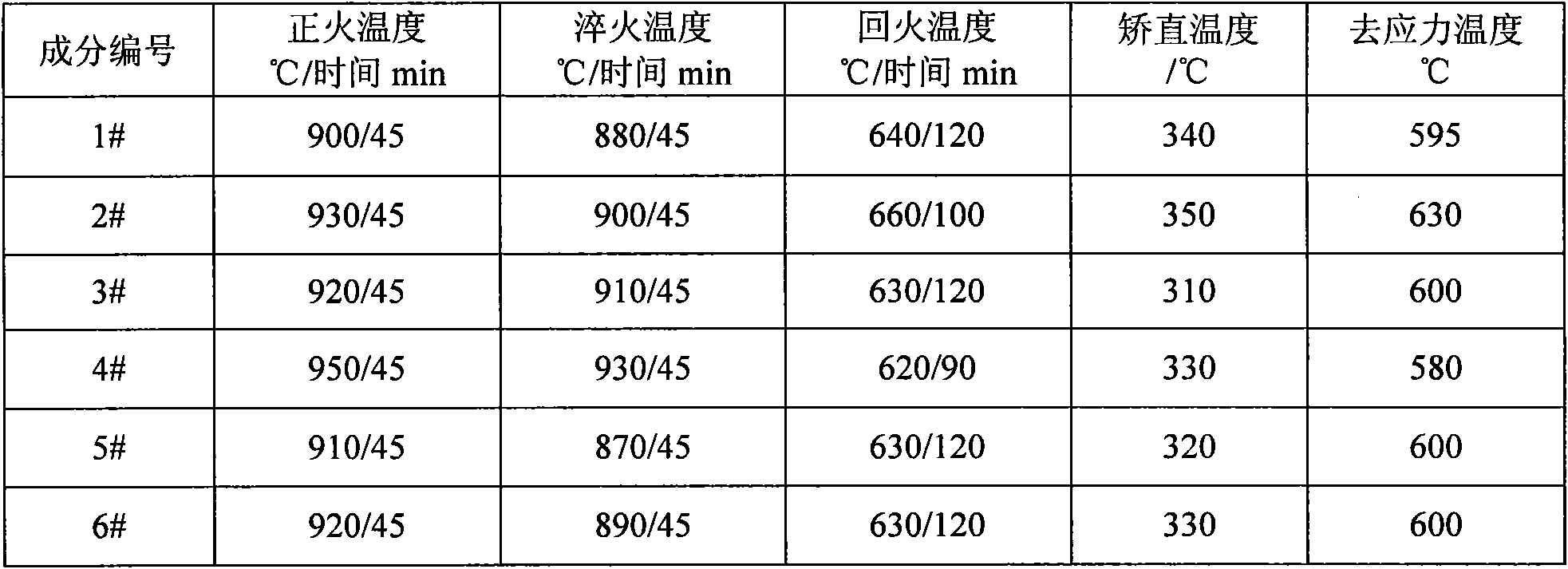

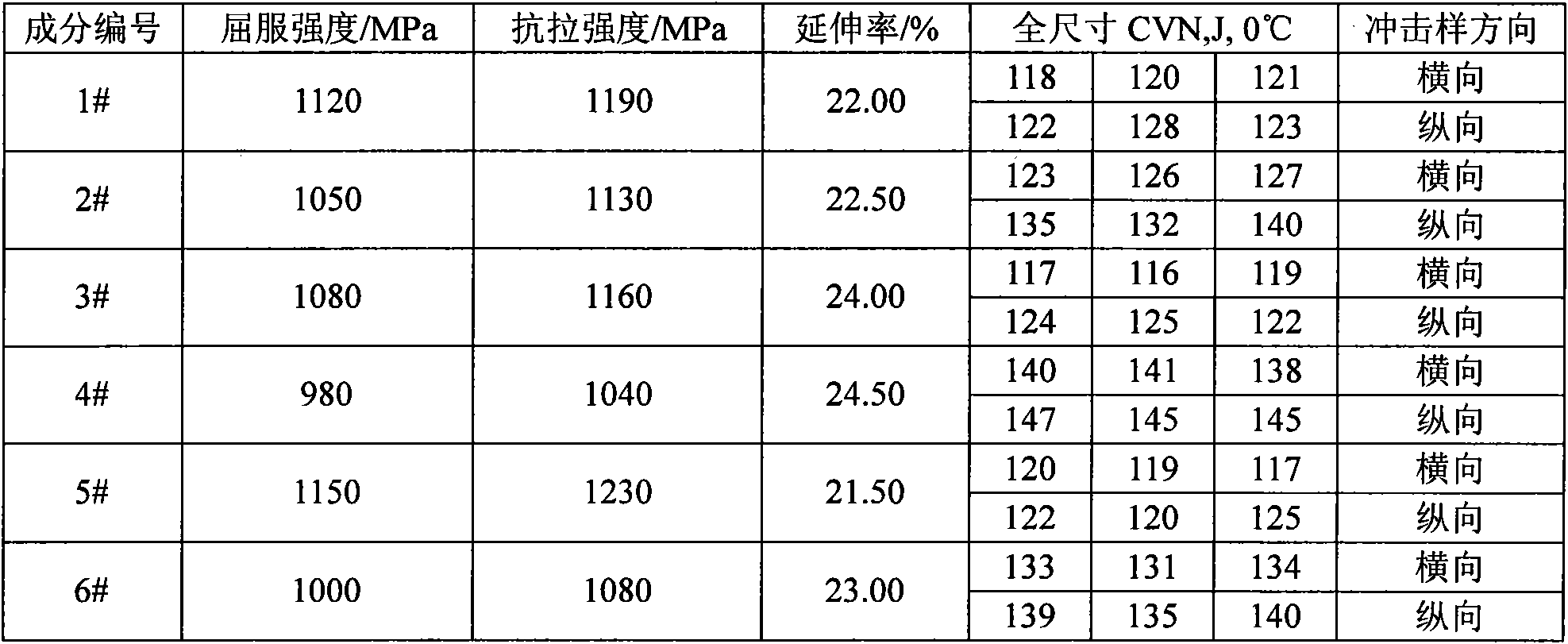

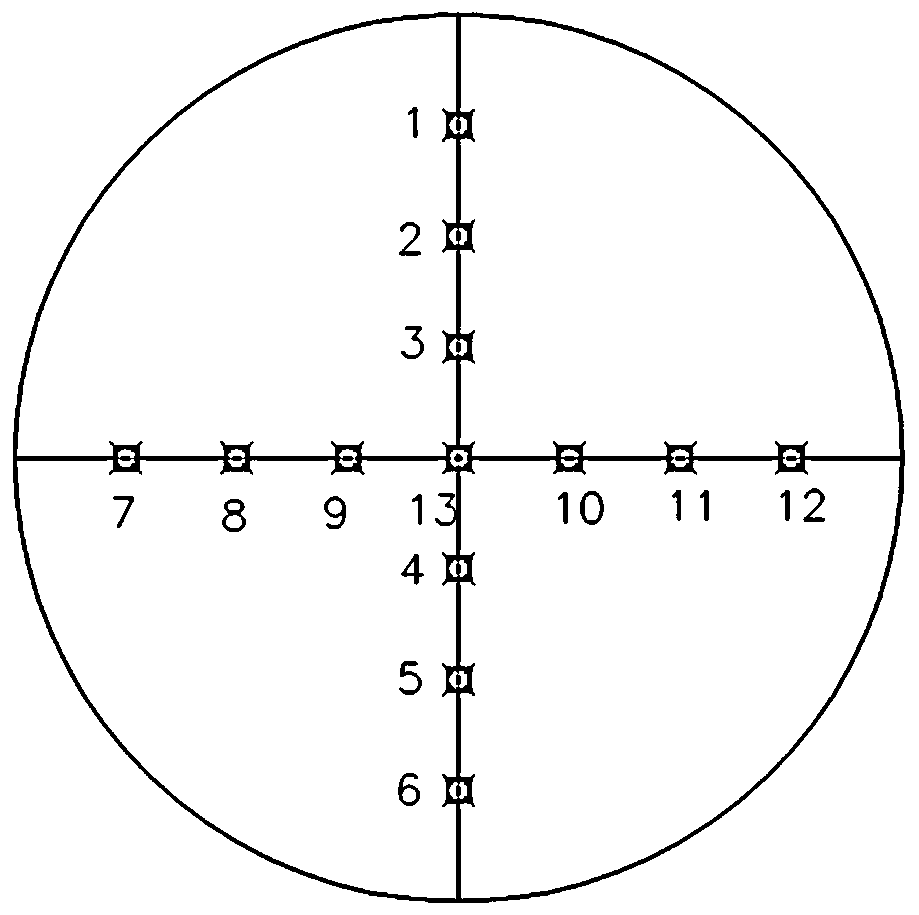

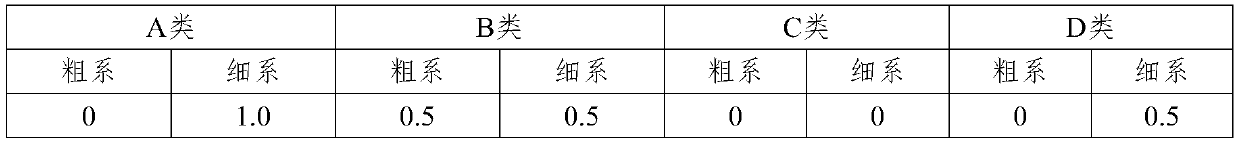

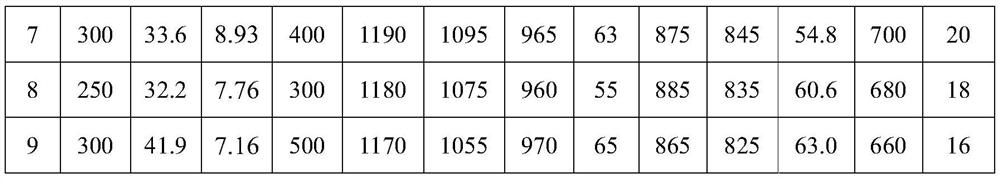

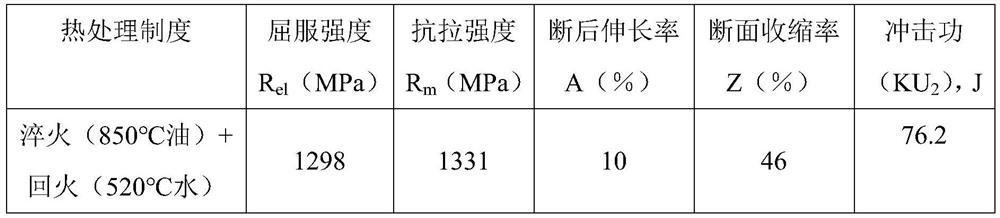

High-toughness and ultra-high strength seamless steel pipe for oil well and manufacturing method thereof

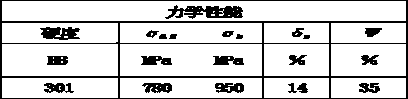

InactiveCN102400065AImprove the safety of useLow costFurnace typesHeat treatment furnacesChemical compositionUltimate tensile strength

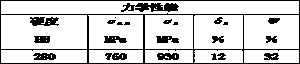

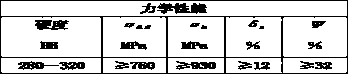

The invention discloses a high-toughness and ultra-high strength seamless steel pipe for oil well and a manufacturing method thereof. The steel contains the following chemical components of: by weight, 0.15-0.27% of C; Si being less than or equal to 0.30%; 0.20-0.50% of Mn; 0.85-1.45% of Cr; 0.40-1.2% of Mo; 0.08-0.20% of V; 0.01-0.05% of Als; P being less than or equal to 0.012%; S being less than or equal to 0.005%; H being less than or equal to 0.00015%; N being less than or equal to 0.0050%; O being less than or equal to 0.0040%; As+Sn+Pb+Sb+Bi being less than or equal to 0.0080%; and the balance being Fe. By a specific manufacturing process, the low alloy steel provided by the invention is prepared into a steel pipe, which is characterized by a mechanical property that the ratio of transverse notch CVN to yield strength is greater than or equal to 0.1, therefore raising the security of applying the ultra-high strength oil-well pipe with strength level of more than Q125 in deep wells and ultra-deep wells.

Owner:ANGANG STEEL CO LTD

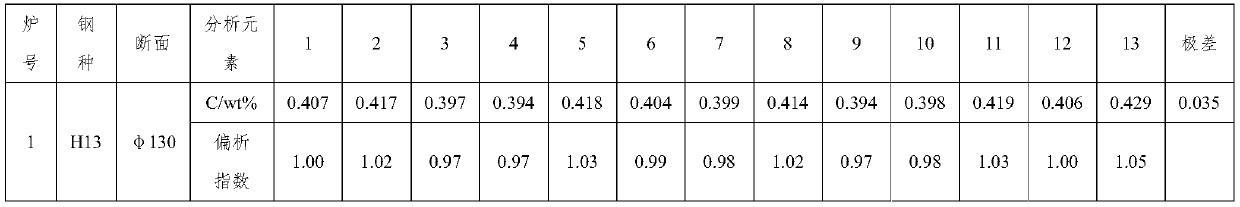

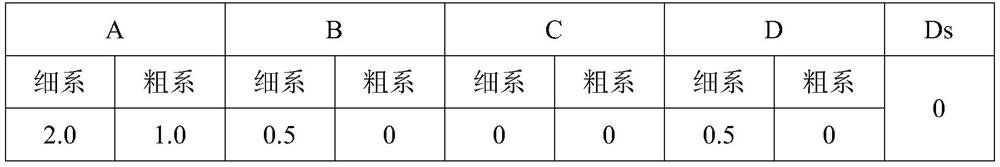

H13 die steel and production method thereof

The invention belongs to the technical field of die steel and particularly relates to H13 die steel and a production method of the H13 die steel. The H13 die steel comprises chemical components including, by weight, 0.32%-0.45% of C, 0.80%-1.20% of Si, 0.20%-0.50% of Mn, 4.75%-5.50% of Cr, 1.10%-1.75 of Mo, 0.80%-1.20 of V, not larger than 0.25% of Cu, not larger than 0.25% of Ni, larger than andequal to the sum of 2.726 C and 0.183 Si and smaller than or equal to the sum of 3.283 C and 0.179 Si of the sum of Mo, Nb and Ti and the balance Fe and inevitable impurities. By the adoption of the H13 die steel and the production method, the content of harmful elements in the steel is strictly controlled, the content of inclusions in the steel is reduced through a reasonable refining process, and it is ensured that the die steel has good cleanliness; with large compression ratio rolling, the compression ratio is larger than or equal to 15, and the internal structure of an H13 rolled materialis dense; and the transverse and longitudinal unnotched impact of the steel are both larger than or equal to 280 J, and the ratio of the transverse unnotched impact energy to the longitudinal unnotched impact energy is larger than 0.8.

Owner:SHANDONG IRON & STEEL CO LTD

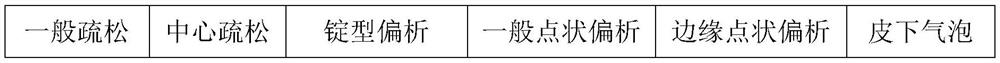

Steel ring billet casting technique based on casting and rolling combined forming

ActiveCN104439219AReduce heating timesSave blankingMolten metal pouring equipmentsFurnace typesTemperingCasting mold

The invention discloses a steel ring billet casting technique based on casting and rolling combined forming. The steel ring billet casting technique based on casting and rolling combined forming comprises the steps that firstly, a casting mold is manufactured by means of water glass sand, the casting mold is dried and sprayed with painting, casting raw materials of a steel ring are smelted and are poured into the casting mold, and normalizing, tempering and quenching-tempering heat treatment are conducted on a steel ring billet formed through pouring; secondly, the steel ring billet is cooled to the room temperature, and polishing and machining are conducted on the cooled steel ring billet; finally, the steel ring billet which can be directly used for casting and rolling combined forming is obtained. According to the steel ring billet cast according to the technique, the defects, such as shrinkage cavities, shrinkage porosity and segregation, appearing in the steel ring billet casting process can be reduced, grains are refined to the maximum extent, and the high-quality steel ring billet capable of meeting the requirement for the ring rolling performance is manufactured; due to the fact that the processes of the casting and rolling combined forming technique are simplified, the quality and performance of the ring rolling technique and a ring workpiece are guaranteed.

Owner:盐城市大丰区生产力促进中心

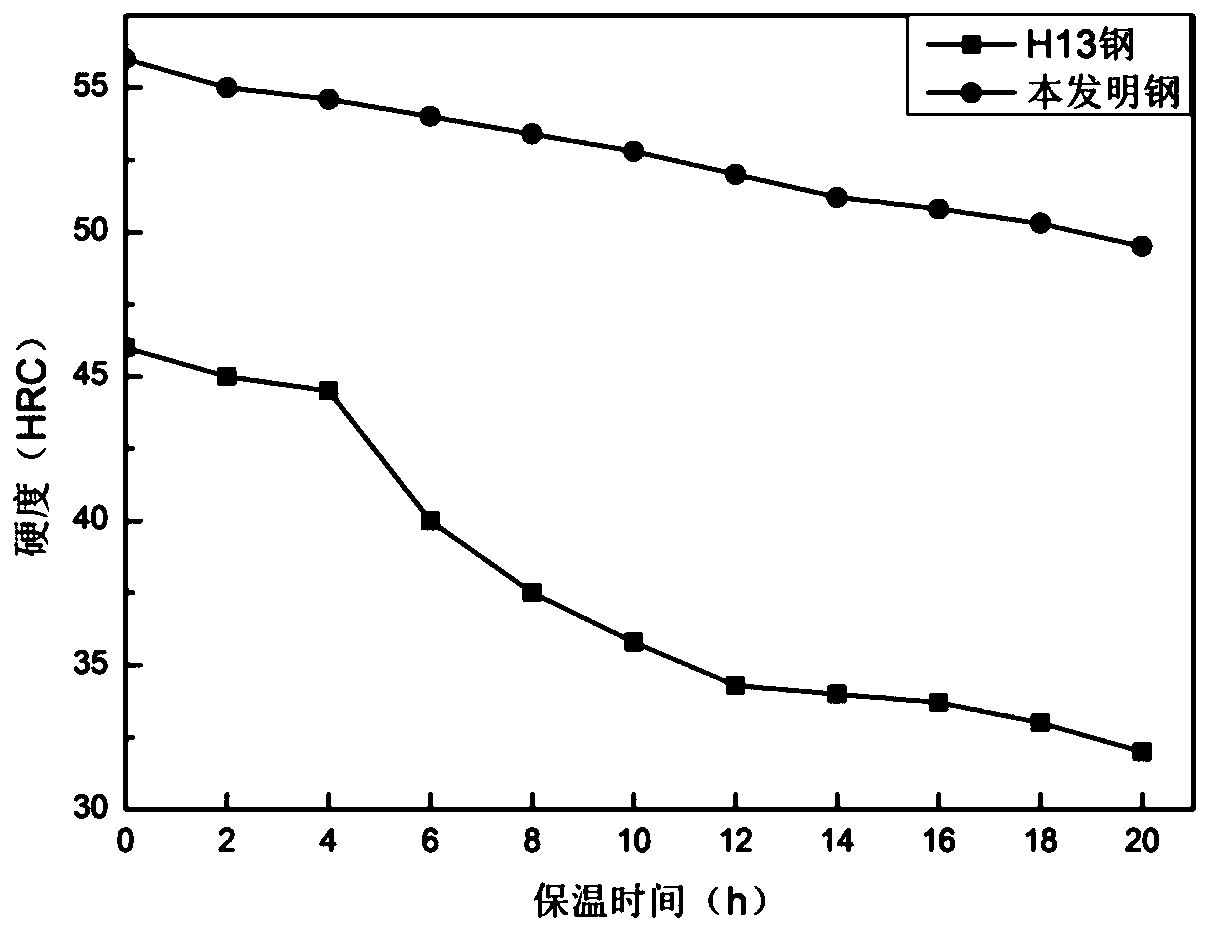

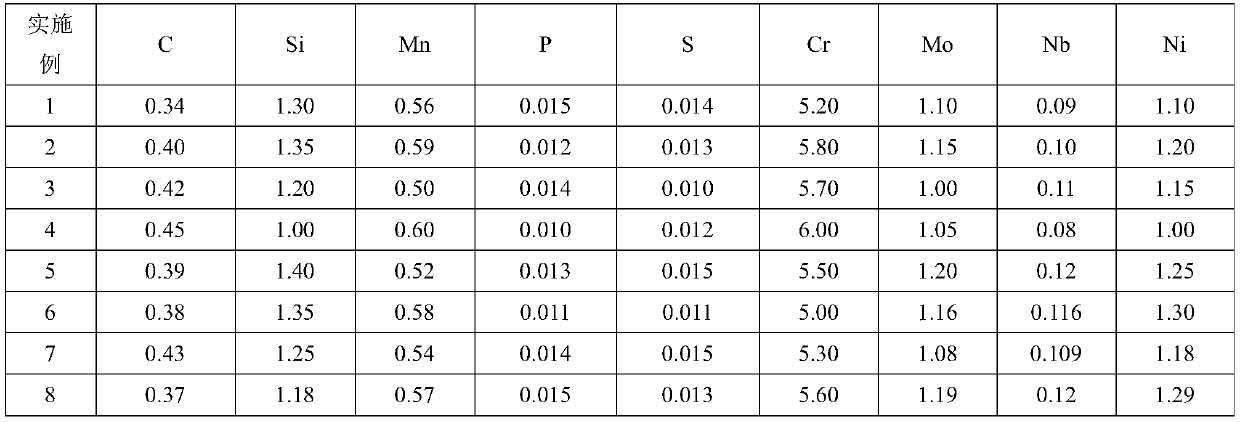

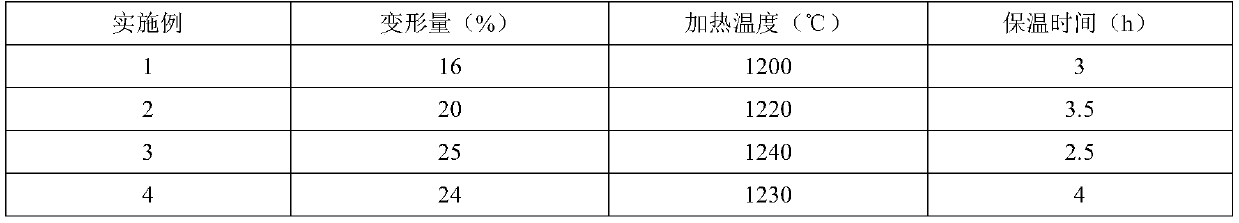

Hot-working die steel and efficient preparation method thereof

The invention relates to hot-working die steel and an efficient preparation method thereof. The hot-working die steel comprises, by weight, 0.34%-0.45% of C, 1.00%-1.40% of Si, 0.50%-0.60% of Mn, lessthan or equal to 0.015% of P, less than or equal to 0.015% of S, 5.00%-6.00% of Cr, 1.00%-1.20% of Mo, 0.08%-0.12% of Nb, 1.00%-1.30% of Ni, and the balance Fe and inevitable impurities. The preparation method has the advantages that the alloy components are optimized, and mechanical diffusion and thermal diffusion are adopted to jointly act, so that the components of the hot-working die steel are homogenized, the time required for homogenization of the alloy elements is shortened, the production efficiency is improved, the production cost is reduced, the produced hot-working die has the Rockwell hardness of 55-57 HRC, the isotropic performance is good, and the thermal stability is good.

Owner:ANGANG STEEL CO LTD

Turbine blade capable of enhancing impact toughness and production technique thereof

ActiveCN104060191AAvoid formingPrevent early brittle crackingFurnace typesHeat treatment furnacesMischmetalChemical composition

The invention provides a turbine blade capable of enhancing impact toughness, which comprises the following chemical components in percentage by mass: 0.13-0.15% of C, 0.8-0.9% of Si, 0.5-0.8% of Mn, 14-16% of Cr, 0.1-0.3% of Ni, 1.3-1.5% of Cu, 0.6-1.1% of Mo, 0.1-0.15% of W, 0.36-0.45% of V, 0.5-0.8% of Nb, 0.28-0.30% of Al, 0.16-0.18% of Ti, 0.08-0.10% of B, 0.45-0.48% of Na, at most 0.02% of S, at most 0.03% of P, 0.3-0.6% of rare-earth metal and the balance of Fe. The invention also provides a production technique of the turbine blade capable of enhancing impact toughness. The production technique can greatly enhance the impact toughness of the blade and prolong the service life of the blade.

Owner:南京赛达科技有限公司

Medium-strength nitric acid corrosion-resistant titanium alloy

The invention discloses a medium-strength nitric acid corrosion-resistant titanium alloy. The titanium alloy is composed of the following components of, in percentage by mass, 5.0-7.0% of Ta, 0.7-1.5%of Al, 0.2-2% of Zr, 0.6-1.5% of Mo, 0.2-2% of Nb, and the balance Ti and inevitable impurities. The tensile strength of the annealed titanium alloy subjected to annealing treatment is 670-750 MPa, the yield strength of the annealed titanium alloy is 520-650 MPa, and the corrosion rate of the annealed titanium alloy in a boiling nitric acid solution with the concentration of 6 mol / L is not higherthan 0.08 mm / a. According to the medium-strength nitric acid corrosion-resistant titanium alloy, through adjusting the content of each element in the titanium alloy, the medium-strength nitric acid corrosion-resistant titanium alloy has excellent tensile strength, yield strength, corrosion resistance and impact toughness, also has excellent cold and hot processing properties, can be prepared intovarious processed products, and is suitable for manufacturing related equipment in the fields of nuclear industry and chemical industry.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Flange for wind power drum and manufacturing technique thereof

ActiveCN103045960APrevent precipitationGuaranteed corrosion resistanceFlanged jointsTemperingChemical composition

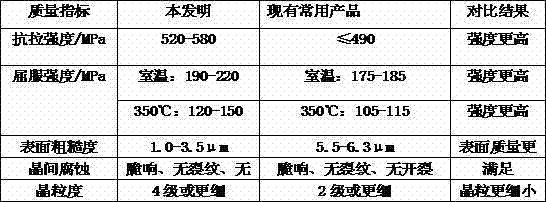

The invention provides a flange for a wind power drum, and a manufacturing technique thereof. The flange comprises the chemical compositions in percentage by weight: 0.15-0.22 percent of C, 0.55-0.65 percent of Si, 0.65-0.75 percent of Mn, 5-8 percent of Ni, 4-6 percent of Cr, 0.65-0.85 percent of Nb, 0.25-0.45 percent of Cu, 0.05-0.07 percent of N, 0.05-0.07 percent of Mo, 0.7-0.9 percent of Al, 0.02-0.03 percent of S, 0.08-0.09 percent of Ti, 0.01-0.04 percent of V, 0.002-0.003 percent of B, 1-2 percent of rare earth lanthanide series and the balance of Fe. According to the invention, with the heating processing procedures of two-time normalization and two-time tempering, the excellent corrosion resistance of the flange is ensured, and meanwhile, high tensile strength and high yield strength are achieved; and the flange is ensured to have smaller surface roughness, more uniform and stable tissue, and less air holes and sand holes.

Owner:WUXI HUAERTAI MACHINERY MFG

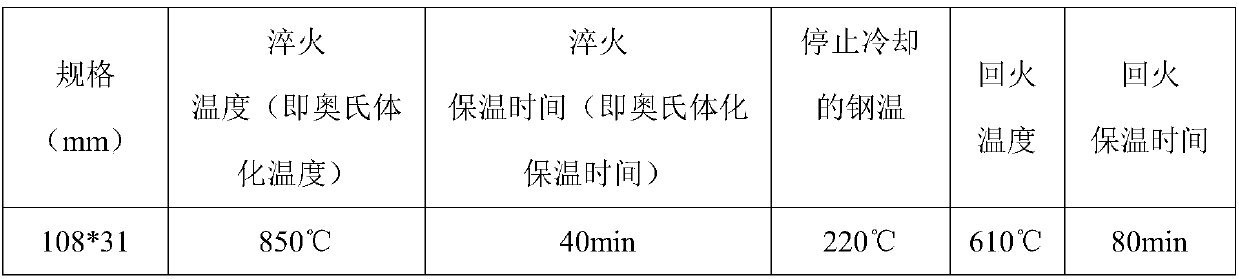

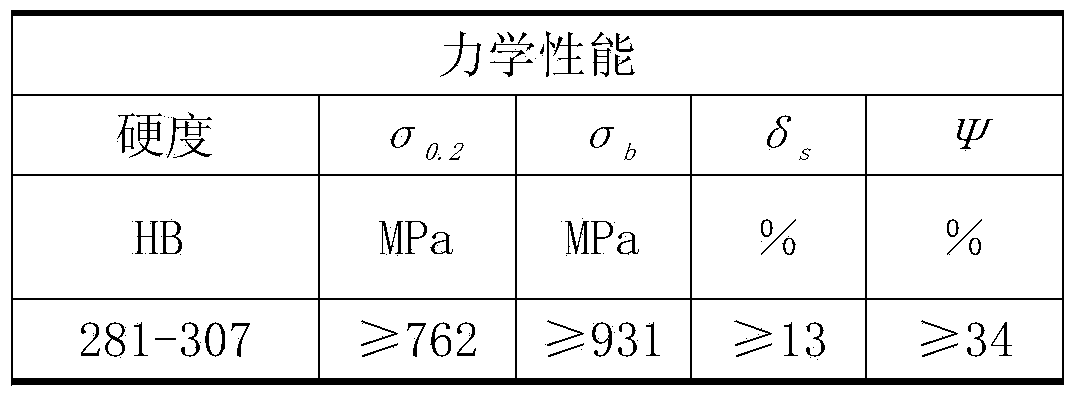

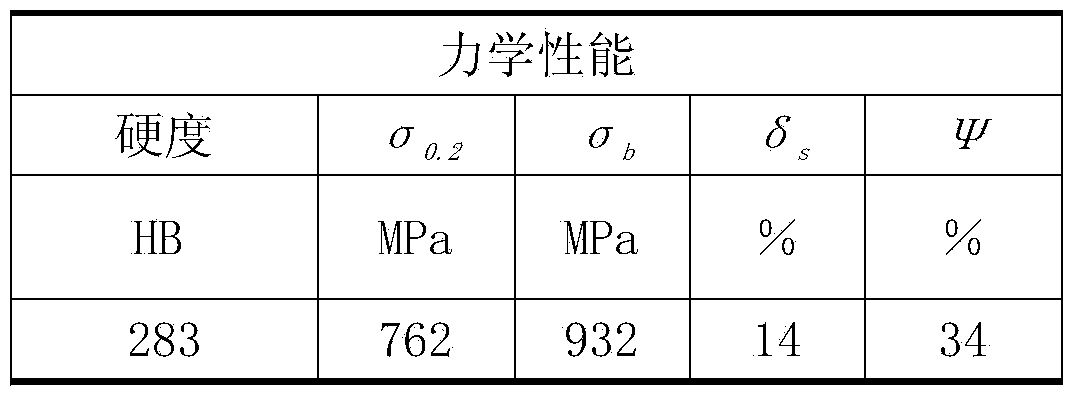

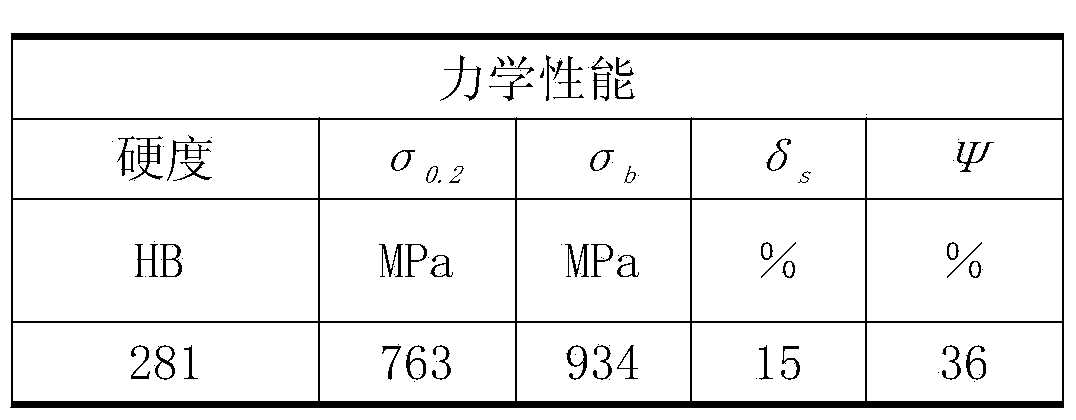

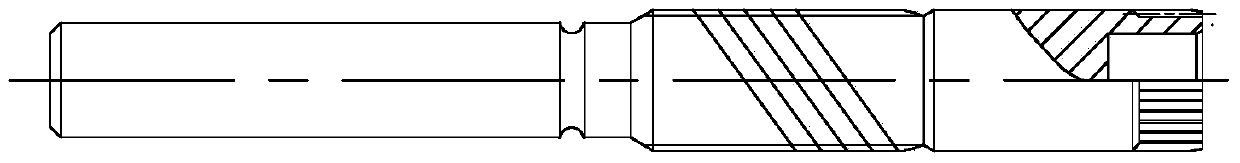

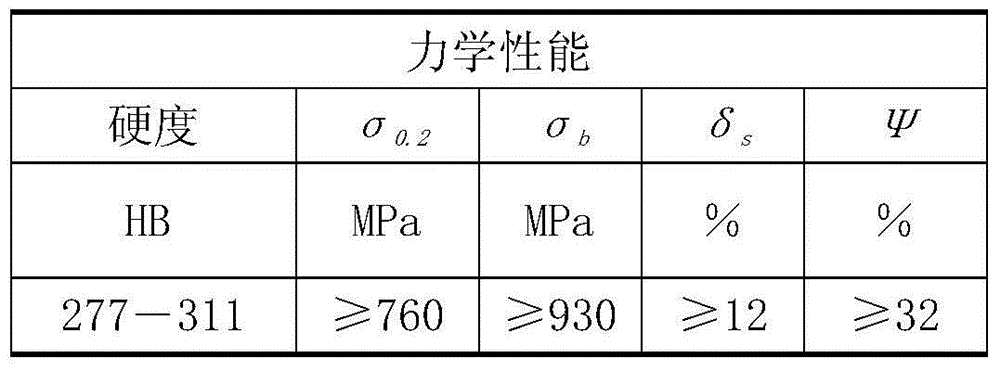

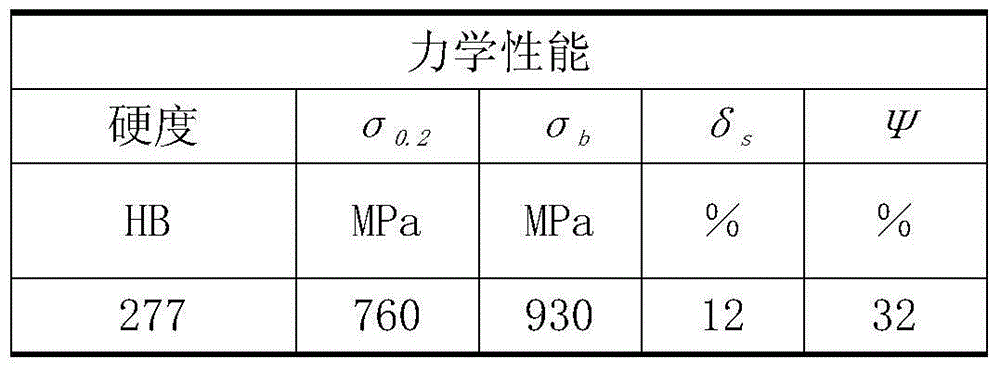

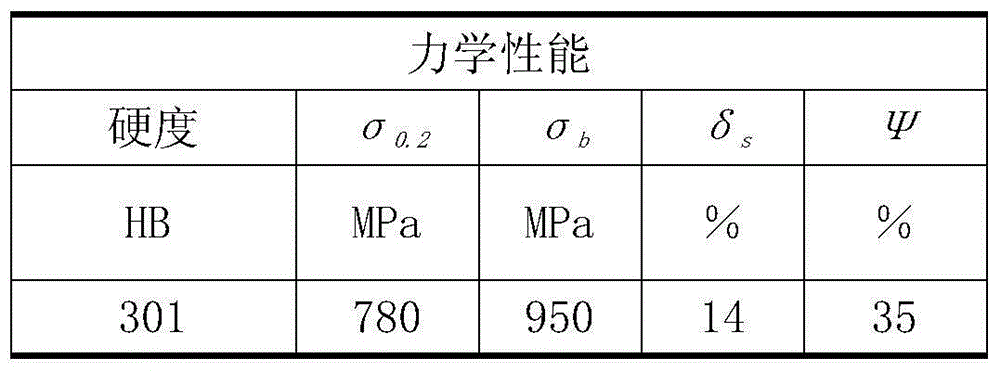

Manufacturing method for producing drill stem joint form seamless steel tube

ActiveCN110538874AGood effectIncrease productivityFurnace typesMetal rolling arrangementsRoom temperatureHardness

The invention provides a manufacturing method for producing a drill stem joint from a seamless steel tube. The manufacturing method comprises the following steps: preparing continuously cast circulartube blank through processes of smelting, external refining, vacuum degassing and casting in sequence; performing heating treatment on the prepared continuously cast circular tube blank; performing hole-piercing, tube-rolling and reducing and sizing treatment on the tube blank obtained by heating treatment, and cooling the tube blank to the room temperature, thereby obtaining a seamless steel tube; performing tempering treatment on the stainless steel tube; performing ultrasonic flaw detection on the tempered seamless steel tube on automatic flaw detecting lines, and ensuring that the surfaceand internal quality of the stainless steel tube is free of defects; unloading the qualified seamless steel tube subjected to ultrasonic flaw detection, turning and processing to define the finished product drill stem joint. The manufactured drill stem is uniform and stable in integral structure and mechanical property. The manufactured drill stem joint has section hardness fluctuation within 3HRC(25HBW), and can control strength fluctuation within 70 Mpa.

Owner:DAYE SPECIAL STEEL CO LTD

Preparation method for magnesium alloy profile material for automobile oil tank

InactiveCN106591658AReduce heat sensitivityImprove solderabilityUnderstructuresFuel supplyRare-earth elementFuel tank

The invention discloses a magnesium alloy profile material for an automobile oil tank. The magnesium alloy profile material comprises the following components of, by mass, 8%-15% of Al, 2%-4% of Mn, 10%-13% of Zn, 1%-3% of Ni, 7%-9% of Ca, 1%-3% of Cu, 1%-3% of Sc, 0.2%-0.3% of P, 1%-3% of Zr, 2%-4% of B, 0.1%-0.4% of V, 0.002%-0.004% of Nb, 2%-5% of So, 0.01%-0.03% of C, 2%-4% of Co, 0.2%-0.5% of Fe, 0.5%-0.8% of rare earth elements, and the balance Mg. The invention further relates to a preparation method for the magnesium alloy profile material for the automobile oil tank. The preparation method is simple and easy to operate, the prepared oil tank has good corrosion resistance, the service life is long, and the cost is low.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

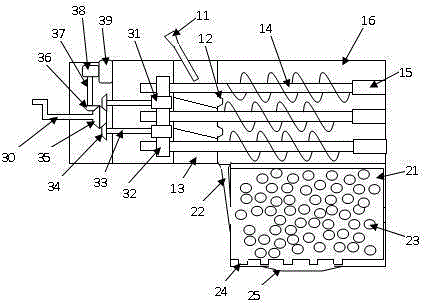

Drug breaking and grinding device

InactiveCN106733109AIncrease grinding rateImprove grinding effectFurnace typesGrain treatmentsDrugTransmission system

The invention relates to a drug breaking and grinding device which comprises a breaking system, a grinding system and a power and transmission system. Through the improvement and reasonable arrangement of the various components, breaking and grinding are separated, so that the working efficiency is improved. In addition, with the creative adoption of the grinding system in which grinding balls are matched with a grinding internal barrel and a grinding external barrel, the grinding efficiency and the product quality are improved.

Owner:王宝林

Material for magnesium alloy doors and windows and production method of material

The invention discloses a material for magnesium alloy doors and windows. The material for the magnesium alloy doors and windows is composed of Mg, Al, Mn, Zn, Cu, Ni, Sc, P, Zr, Y, Ca, Sr, B, Co and a rare earth element, wherein the rare earth element is composed of Ce, Nd, Gd, Pr, Dy, Yb, La and Sm; the invention further discloses a production method of the material for the magnesium alloy doors and windows, and the method comprises the following steps: smelting, heat treatment, forging, quenching and tempering heat treatment, cooling, checking and storing, the production method is simple and easy, the manufacturing cost is low, and the produced material for the magnesium alloy doors and windows is excellent in corrosion resistance, can resist high temperature, is solderable, and has a prolonged service life.

Owner:SUZHOU CITY WUZHONG DISTRICT XUKOU FENGSHOU MACHINERY PARTS FACTORY

Turbine blade capable of improving thermal cracking resistance and production process thereof

ActiveCN104032236AReduced impact toughnessImprove impact toughnessBlade accessoriesMachines/enginesMischmetalChemical composition

The invention discloses a turbine blade capable of improving the thermal cracking resistance. The turbine blade comprises the following chemical components in percentage by mass: 0.31-0.35% of C, 0.10-0.12% of Si, 0.75-0.77% of Mn, 0.63-0.65% of Ni, 11.2-11.7% of Cr, 0.65-0.68% of Mo, 0.16-0.18% of V, 0.85-0.88% of Sr, 0.15-0.17% of Nb, 0.05-0.07% of Cu, 0.27-0.29% of Al, 0.13-0.15% of Ti, 0.06-0.08% of B, less than or equal to 0.02% of S, 0.21-0.35% of rare earth metal and the balance of Fe. By adopting the turbine blade, the impact toughness of a blade is greatly improved, the thermal cracking resistance of the blade is improved, and the service life of the blade is prolonged.

Owner:南京赛达科技有限公司

CrCuNiMoV high-entropy alloy material and preparation method thereof

The invention discloses a CrCuNiMoV high-entropy alloy material and a preparation method thereof, and belongs to the field of alloy material preparation. The CrCuNiMoV high-entropy alloy is prepared from the elements such as Cr, Cu, Ni, Mo and V. The preparation method comprises the following steps of (1) weighing materials: weighing various metal materials according to the equal molar ratio; and(2) melting the alloy: using a non-self-consumed vacuum arc melting furnace for repetitively melting the weighed materials for more than four times. The CrCuNiMoV high-entropy alloy prepared through the invention is provided with main composition phases: an FCC phase and a small number of Laves phase, has the advantages of wear resistance and corrosion resistance, and has a good application prospect in the fields of wear resistance and corrosion resistance.

Owner:XIANGTAN UNIV +1

High-strength titanium alloy steam turbine blade

InactiveCN108624783ALow costDoes not affect the chemical compositionAntifouling/underwater paintsBlade accessoriesEpoxyTitanium alloy

The invention discloses a high-strength titanium alloy steam turbine blade. The surface of the steam turbine blade is further provided with a protection layer, and the protection layer is prepared from, by mass, 10-15 parts of modified ethylene-propylene-diene monomer rubber, 15-20 parts of methyl phenyl silicone resin, 8-11 parts of organosilicon-modified epoxy resin, 5-7 parts of nanometer SiC powder, 13-15 parts of filler and pigment, 3-5 parts of dispersing agent, 10-15 parts of coupling agent, 13-15 parts of curing agent, 7-9 parts of defoaming agent and 1-3 parts of anti-mildew bactericide. The high-strength titanium alloy steam turbine blade has good strength, and is good in corrosion resistance, simple in preparation process, low in cost and long in service life.

Owner:南京赛达科技有限公司

Heat-resistant alloy carburizing steel and preparation method thereof

The invention discloses heat-resistant alloy carburizing steel. The heat-resistant alloy carburizing steel comprises the following components of, by weight percentage, 0.16-0.22% of C, less than or equal to 0.15% of Si, less than or equal to 0.60% of Mn, 0.10-0.25% of Cu, 1.80-1.90% of Cr, 1.80-1.90% of Ni, 0.50-1.10% of Mo, 0.015-0.030% of S, less than or equal to 0.015% of P, 0.010-0.025% of Al,0.013-0.018% of N, 0.020-0.040% of Nb, less than or equal to 0.00015% of H, less than or equal to 0.0012% of O, and the balance Fe and impurity elements. The invention further discloses a preparationmethod of the heat-resistant alloy carburizing steel. According to the heat-resistant alloy carburizing steel and the preparation method thereof, the heat-resisting alloy carburizing steel with 300-500 DEG C working temperature resistance, fine crystal grains, high purity and excellent strength and toughness performance can be obtained.

Owner:宝钢特钢长材有限公司

Corrosion-resistant turbine blade and production process thereof

ActiveCN104032239AReduced impact toughnessImprove impact toughnessBlade accessoriesFurnace typesTurbine bladeRare earth

The invention discloses a corrosion-resistant turbine blade which comprises the following chemical components in percentage by mass: 0.29-0.31 percent of C, 0.11-0.13 percent of Si, 0.69-0.73 percent of Mn, 0.60-0.62 percent of Ni, 9.5-9.7 percent of Cr, 0.15-0.17 percent of V, 0.16-0.18 percent of Nb, 0.05-0.07 percent of Cu, 0.21-0.23 percent of Al, 0.13-0.15 percent of Ti, 0.75-0.77 percent of Sb, 0.82-0.88 percent of Co, less than or equal to 0.03 percent of S, less than or equal to 0.02 percent of P, 0.09-0.12 percent of rare earth metals and the balance of Fe. The water erosion resistance and corrosion resistance of the blade can be improved, so that the service life of the blade is prolonged.

Owner:南京赛达科技有限公司

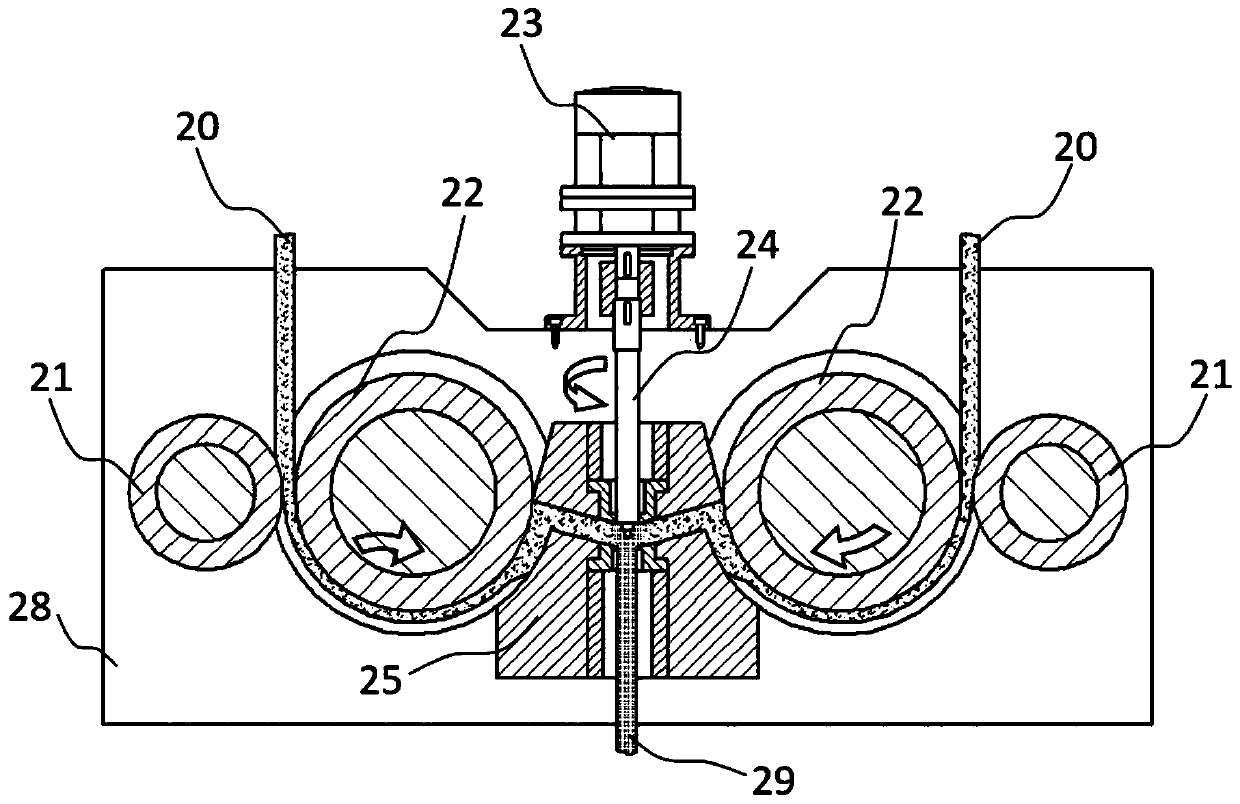

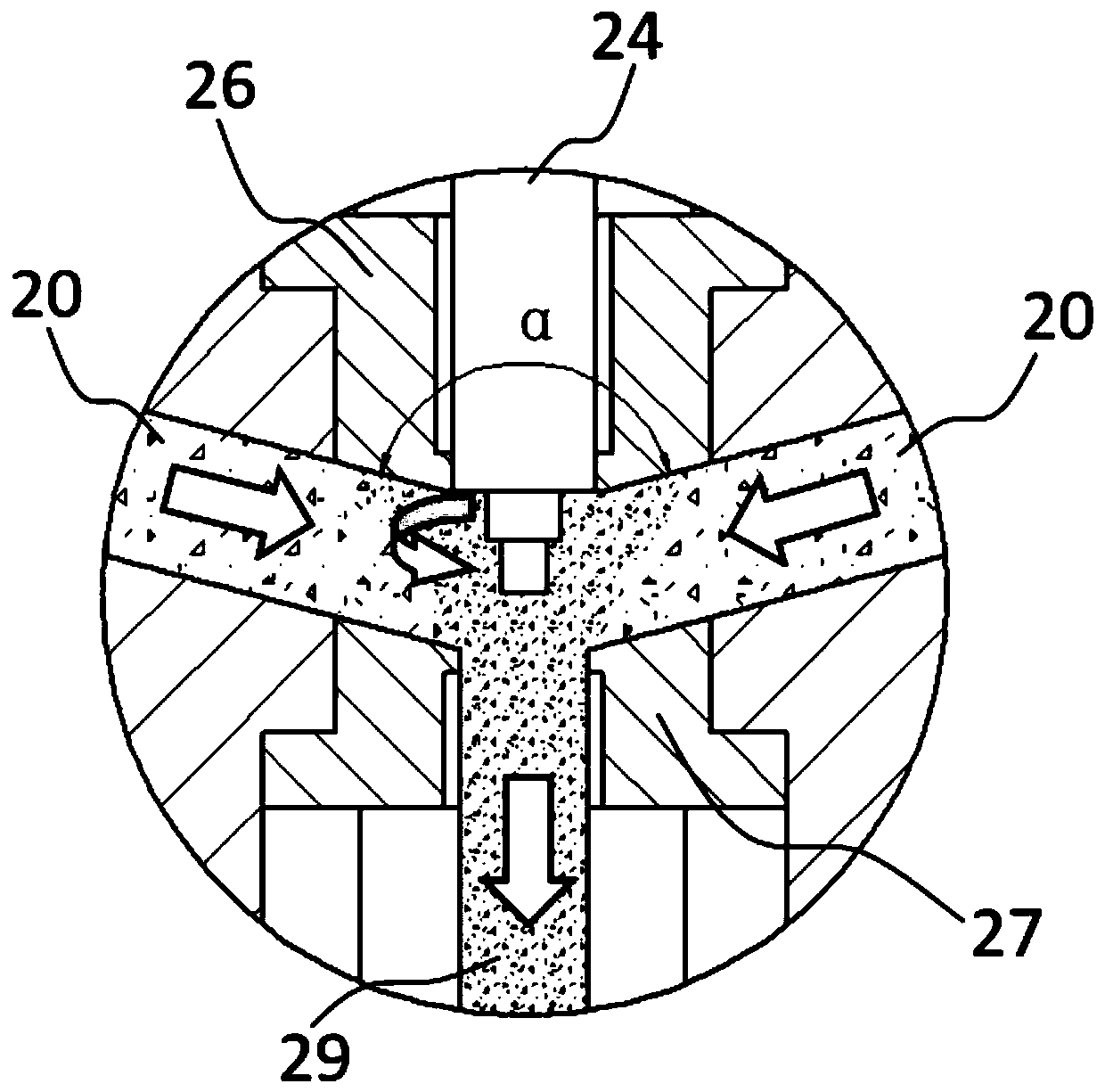

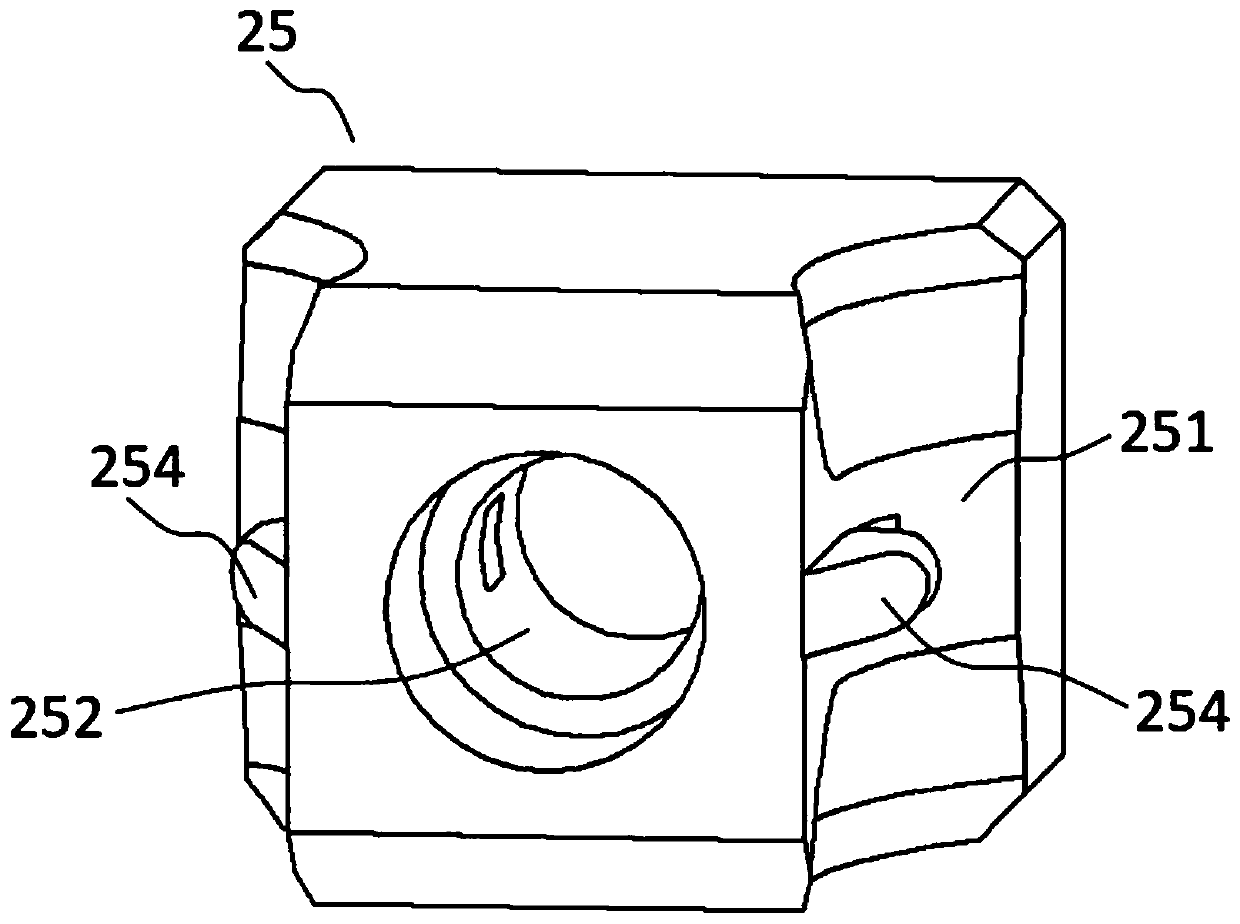

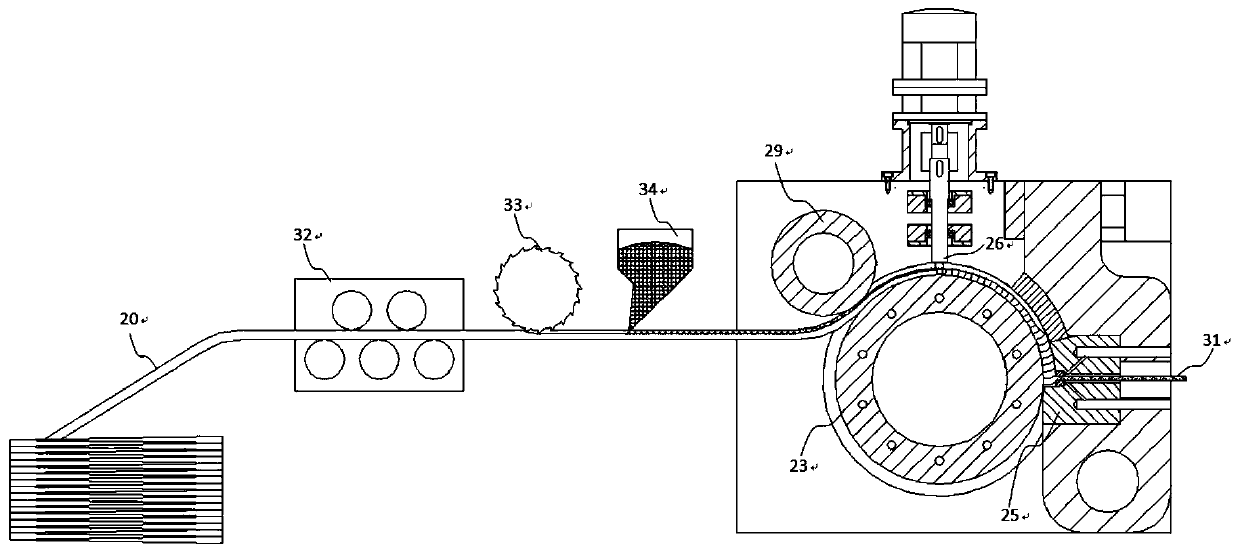

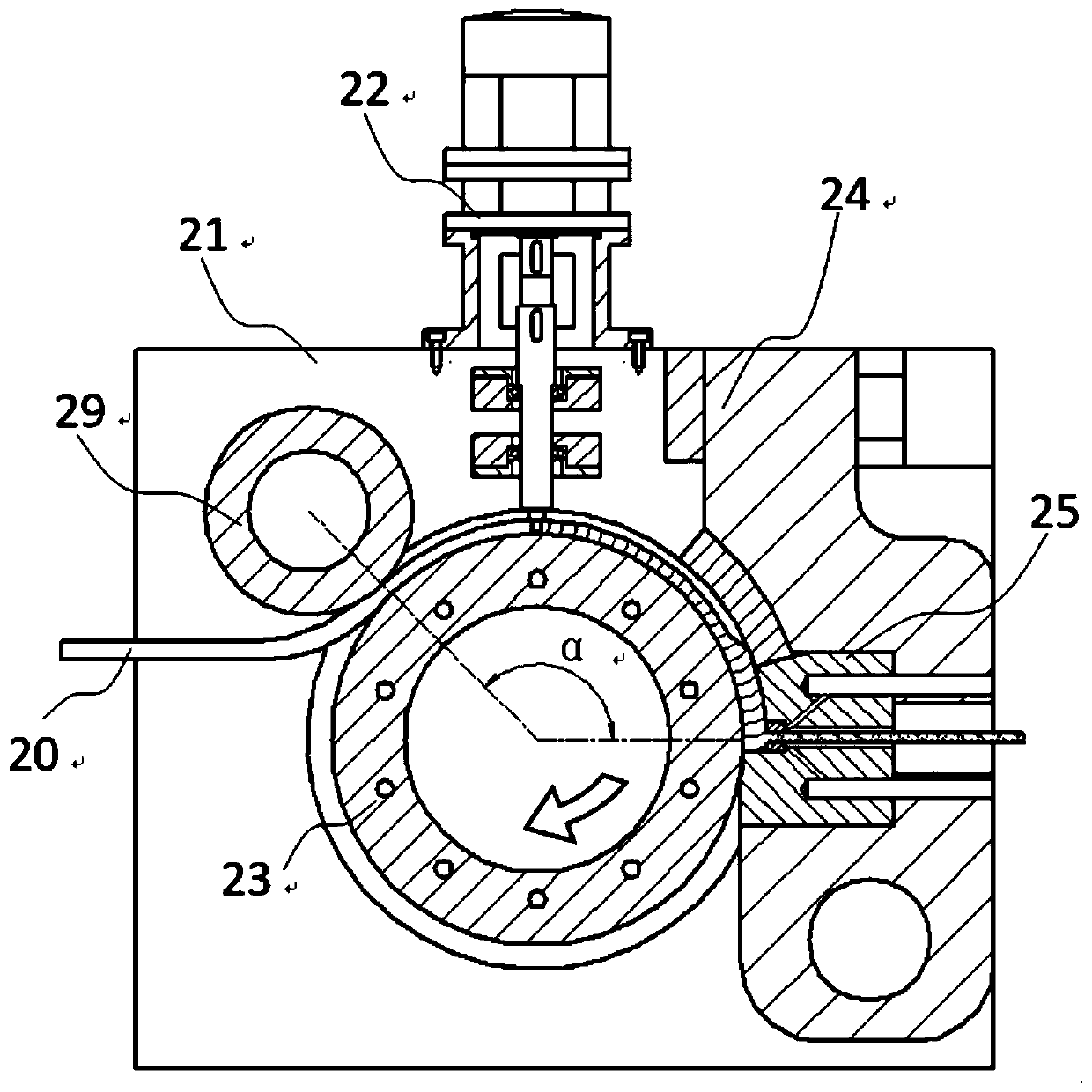

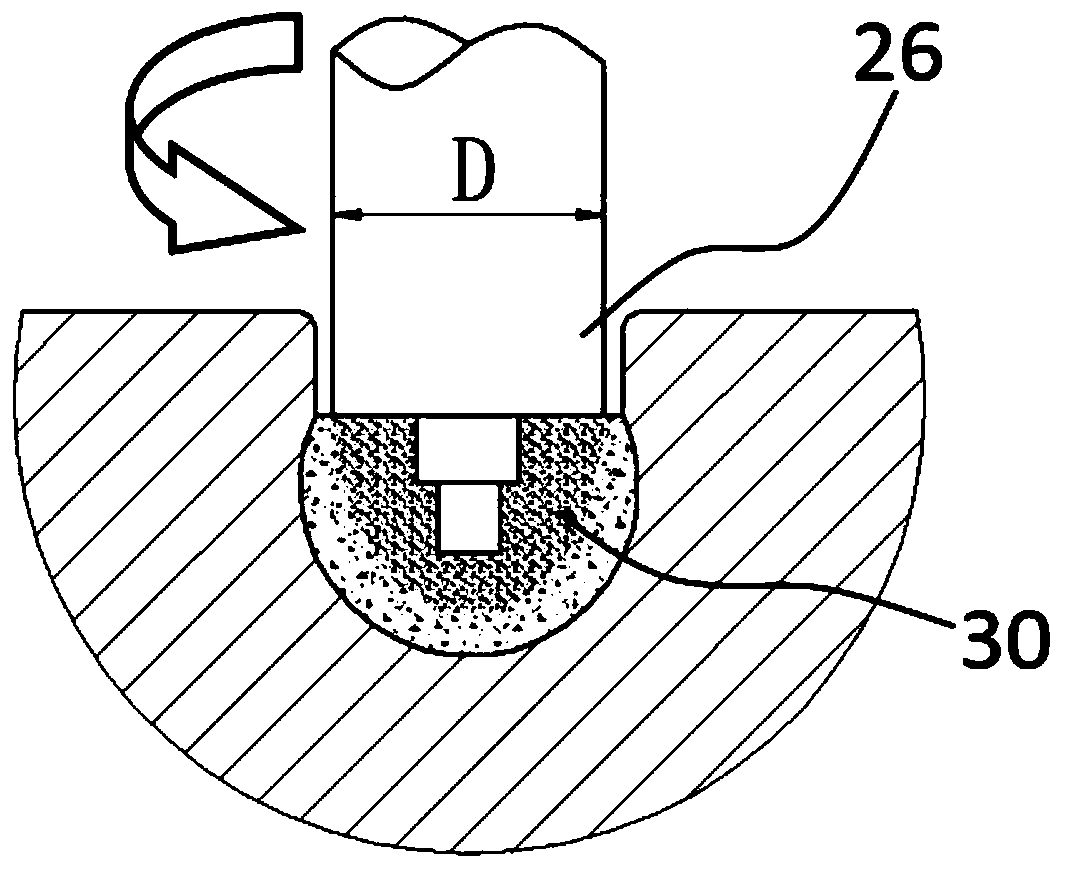

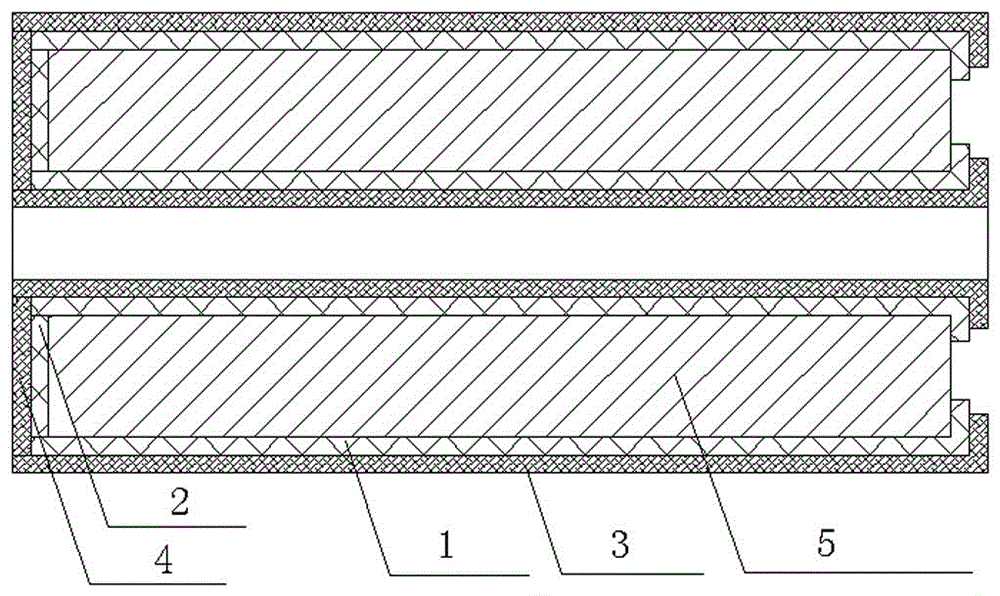

Continuous friction stir extrusion production method and production device for ultra-fine grain material

PendingCN110605307AGood mechanical propertiesWith ultra-fine grainExtrusion diesEngineeringFriction stir processing

The invention provides a continuous friction stir extrusion production method and production device for an ultra-fine grain material. A pair of extrusion wheels is symmetrically arranged, and synchronously rotates in opposite directions to drive at least two blank materials to enter a die cavity from the two sides; a stir bar extends into the die cavity via a center hole of the die cavity to directly reach a converging zone of the at least two blank materials; friction stir processing of the blank materials is realized by rotation of the stir bar; the metal blank materials are fed into a stirzone continuously through rotation of the extrusion wheels; finished product blank materials are rapidly cooled after being extruded by an opening of an extrusion die to form continuous large-length ultra-fine grain type wire products; and forced cooling is performed on the interior of the stir bar through a cooling medium in an operation course.

Owner:DALIAN JIAOTONG UNIVERSITY

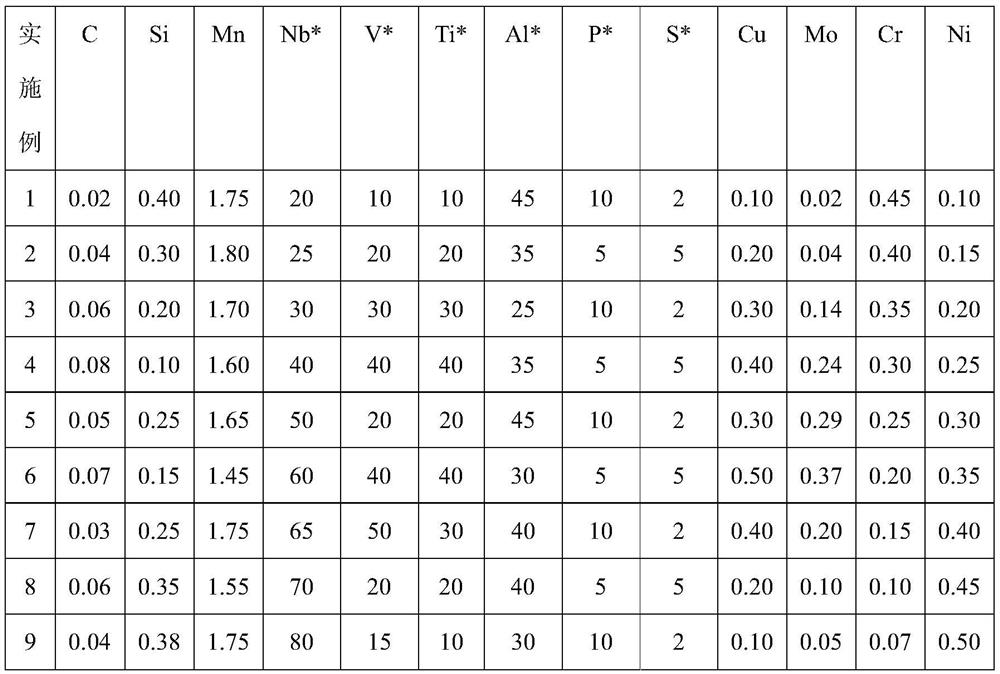

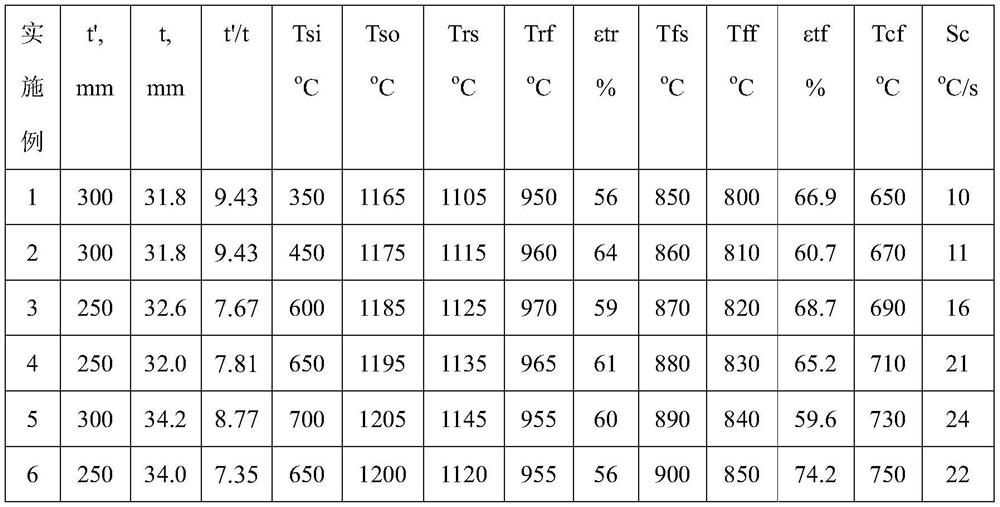

A high-strain steel plate for high-homogeneity l485 marine line pipe and its manufacturing method

Owner:ANGANG STEEL CO LTD

Continuous friction stir and extrusion production method for metal matrix composite and production device thereof

PendingCN110576069AGrain refinementUniform and stable tissueExtrusion diesWire rodMetal matrix composite

The invention provides a continuous friction stir and extrusion production method for a metal matrix composite and a production device thereof. According to the method and the device, a concave grooveis processed on a straightened matrix metal bar, a reinforcement is added into the concave groove, a composite blank is pressed into an annular groove of an extrusion wheel through a material pressing wheel and is clamped, the blank is driven to move towards a stirring head through rotation of the extrusion wheel, friction stir processing is carried out on the blank in the annular groove betweenthe material pressing wheel and a mold cavity at least once through rotation of the stirring head, the flowing direction is changed after the stirred blank is blocked by a material blocking block, theblank is extruded out from an inner hole of a mold, and therefore a continuous large-length metal matrix composite wire product is formed.

Owner:DALIAN JIAOTONG UNIVERSITY

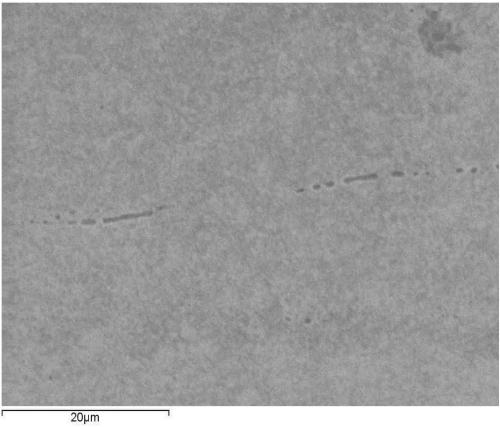

A kind of high-performance tc11 tube and its preparation method

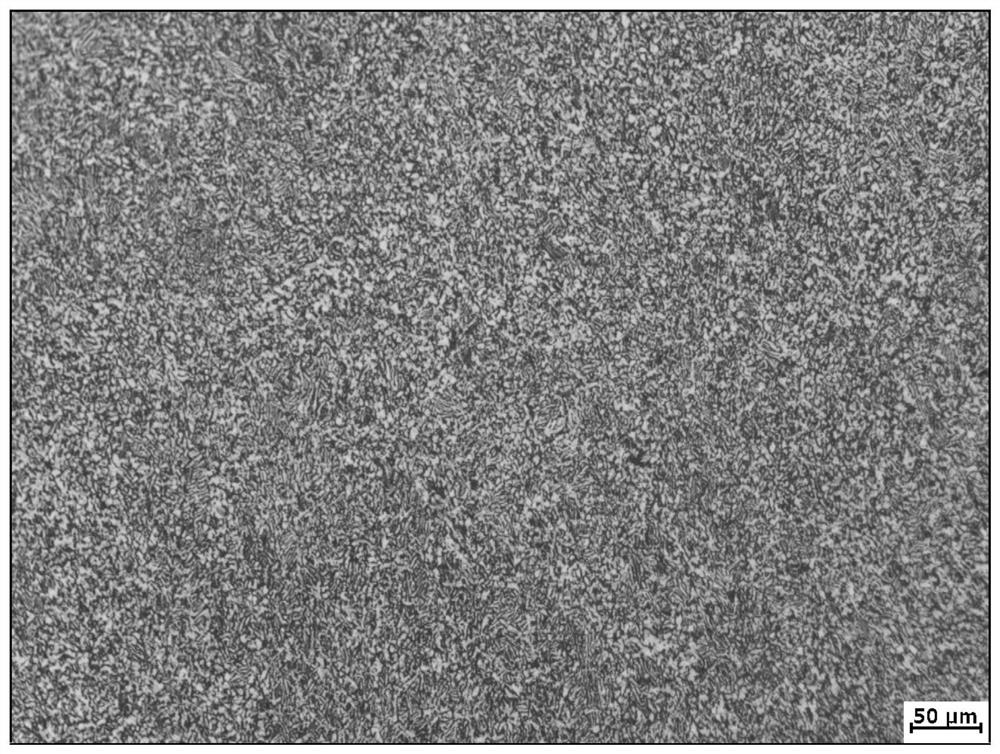

The invention relates to a high-performance TC11 tube and a preparation thereof. According to the preparation method, the finished product TC11 tube is prepared by firstly preparing a TC11 titanium alloy cast ingot from a first-class titanium sponge, an aluminum-vanadium alloy, an aluminum-zirconium alloy and scrap zirconium by virtue of strict control of materials and the melting process, forging the cast ingot to obtain a black-rust sheared billet, then machining and carrying out surface grinding to obtain a extruded ingot billet, drilling the ingot billet, sheathing, heating and extruding to obtain a tube billet, then carrying out hot straightening, surface treatment and heat treatment and finally machining, such as boring and turning to obtain the finished product TC11 tube. The TC11 titanium alloy tube prepared by the preparation method disclosed by the invention has the characteristics that (1) the TC11 titanium alloy tube has very high strength, ductility and impact properties; (2) the tube having relatively high tolerance level can be obtained; (3) the microstructure of the TC11 titanium alloy tube is uniform and stable; and (4) the TC11 titanium alloy tube has excellent corrosion performance. The TC11 titanium alloy tube can meet the high-standard application requirement in the petroleum industry.

Owner:NINGXIA ORIENT TANTALUM IND

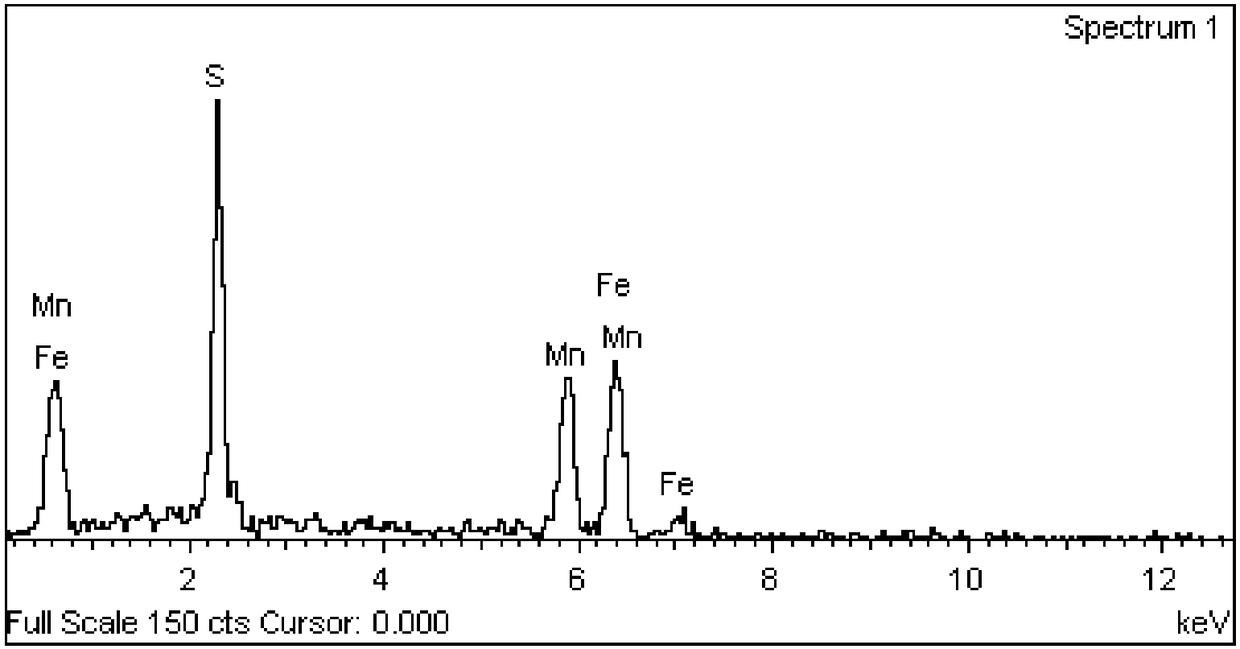

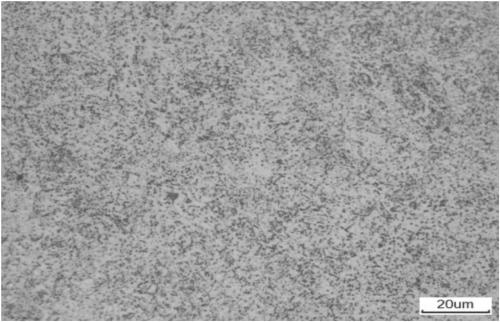

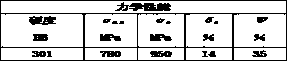

Carburizing steel for oil nozzle valve body and preparation method of carburizing steel

InactiveCN109321837AEasy to cutEasy to drill holesFurnace typesHeat treatment furnacesNiobiumManganese

The invention provides carburizing steel for an oil nozzle valve body and a preparation method of the carburizing steel. The carburizing steel mainly comprises carbon, manganese, copper, chromium, nickel, sulphur, aluminum, nitrogen and niobium. The preparation method of the carburizing steel comprises the following steps of conducting preliminary smelting; conducting steel ladle refining; conducting continuous pouring; rolling a bar material or a wire material; and drawing the bar material or the wire material till the surface is glossy. The carburizing steel and the preparation method thereof have the beneficial effects that after annealing is conducted on the steel for the oil nozzle valve body, a nodulizing pearlitic structure is obtained; hardness carbide particles are fine and uniform in size, and the hardness ranges from 185 HBW to 210 HBW; cutting and trepanning machining of the oil nozzle valve body can be conducted conveniently; and meanwhile, a prepared structure is providedfor subsequent carburization and quenching heat treatment.

Owner:宝钢特钢长材有限公司

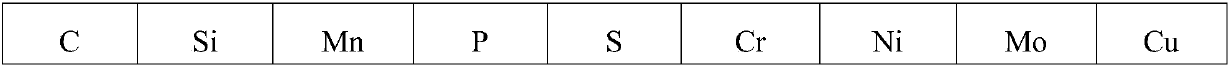

Steel for front axle of medium-sized truck and production method of steel

ActiveCN113201689AStable room temperature impact performanceStability Control RatioMetal rolling arrangementsMetallurgyTruck

The invention discloses steel for a front axle of a medium-sized truck and a production method of the steel. The steel comprises the following chemical components including, by weight, 0.39% to 0.43% of C, 0.20% to 0.37% of Si, 0.65% to 0.80% of Mn, 0.95% to 1.10% of Cr, 0.01% to 0.05% of Mo, 0.02% to 0.03% of Ni, 0.02% to 0.05% of Cu, less than or equal to 0.020% of P, 0.010% to 0.025% of S, 0.010% to 0.040% of Alt and the balance Fe and other inevitable impurities, so that the contents of Mo, Ni and Cu in the steel meet the condition that the sum of Mo, Ni and Cu is more than or equal to the sum of 0.013C, 0.033Mn and 0.034Cr and less than or equal to the sum of 0.018C, 0.026Mn and 0.065 Cr. According to the steel for the front axle of the medium-sized truck and the production method of the steel, the contents of Mo, Ni, Cu and other elements in the steel are accurately controlled, steel grains are refined, the impact toughness of the steel is improved, and the fatigue life of the automobile front axle is prolonged.

Owner:SHANDONG IRON & STEEL CO LTD

Long-life steam turbine blade and production process thereof

ActiveCN104046919AReduced impact toughnessImprove impact toughnessBlade accessoriesFurnace typesMaterials scienceIndustrial engineering

The invention discloses a long-life steam turbine blade. The long-life steam turbine blade consists of the following chemical components in percentage by weight: 0.29-0.31% of C, 0.16-0.19% of Si, 0.75-0.77% of Mn, 0.73-0.85% of Ni, 9.5-10.1% of Cr, 0.55-0.64% of Mo, 0.15-0.17% of Sn, 0.11-0.15% of V, 0.82-0.84% of Sr, 0.15-0.17% of Nb, 0.02%-0.03% of Cu, 0.13%-0.15% of T, 0.06-0.08% of B, not greater than 0.01% of Ca, not greater than 0.03% of S, not greater than 0.03% of P, 0.16%-0.18% of rear-earth metal, and the balance of Fe. The production process disclosed by the invention is carried out by hot-forging, annealing, blade mechanical machining, distressing thermal treatment, tempering thermal treatment, cooling, surface-enhanced thermal treatment, physical and chemical inspecting, ultrasonic-wave flaw detecting, and cleaning-packaging. The production process disclosed by the invention can greatly improve impact toughness of the blade, can improve water erosion resistance and corrosion resistance of the blade, and can prolong the service life of the blade.

Owner:南京赛达科技有限公司

Processing technology of corrosion-resistant butterfly valve flap

InactiveCN106591634AUniform and stable tissueGuaranteed corrosion resistanceCorrosion resistantRaw material

The invention discloses a processing technology of a corrosion-resistant butterfly valve flap. The processing technology comprises the steps of raw material preparation, compression, sintering molding, heat treatment, phosphating treatment, inspection and warehousing. The processing technology is simple and easy to operate, the processed butterfly valve flap has good corrosion resistance, the service life is prolonged and the cost is reduced.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

Preparation technology of graphene oxide toughened alumina-based ceramic cutter

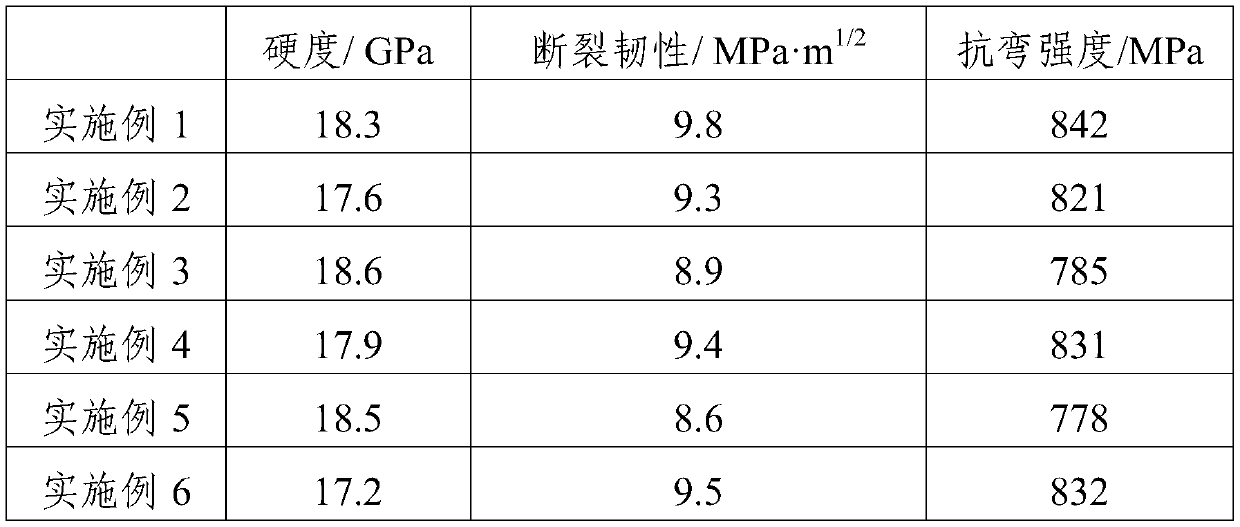

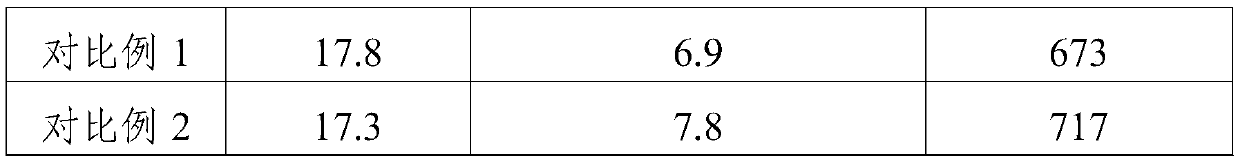

The invention provides a preparation technology of a graphene oxide toughened alumina-based ceramic cutter, and relates to the technical field of ceramic cutters. The preparation technology comprisesthe following steps: (1) adding graphene oxide into anhydrous ethanol, and adding polyethylene glycol and alumina powder to obtain a powder slurry I; (2) mixing anhydrous ethanol with polyethylene glycol, and adding beta-SiC nanoparticles, TiC whiskers and a sintering aid to obtain a powder slurry II; (3) performing ball milling to obtain a composite slurry; (4) drying and sieving the composite slurry to obtain a composite powder; (5) carrying out pre-pressing forming; and (6) carrying out vacuum hot-pressing sintering on the obtained pre-pressed green body. The graphene, TiC whiskers and beta-SiC nano-particles have synergistic effects, so the reinforcing and toughening effects are good, the dispersity of all the raw materials in the preparation process is high, and the prepared ceramic cutter has excellent mechanical properties, high toughness and strength and good wear resistance.

Owner:安徽予初网络科技有限公司

Non-magnetic planet shaft and machining process thereof

ActiveCN104002105AUniform and stable tissueFlexible slidingSolid state diffusion coatingFurnace typesSolution treatmentFlexural strength

The invention relates to a non-magnetic planet shaft and a machining process thereof. The non-magnetic planet shaft is made of a stainless steel 0Cr18Ni9 material. The machining process of the non-magnetic planet shaft includes feeding, solution treatment, surface oxalate treatment, spline extruding and heading, machining, inclined spline rolling, straightening, grinding, nitrocarburizing and deoiling washing. The planet shaft manufactured through the process is table and even in organization, not easy to magnetize even in long-time use, flexible in sliding and capable of meeting the requirement for bending strength.

Owner:无锡市神力齿轮冷挤有限公司

Turbine blade capable of enhancing water corrosion resistance and production technique thereof

ActiveCN104060192AThe segregation of alloying elements is weakenedImprove impact toughnessFurnace typesHeat treatment furnacesCorrosionSteam turbine blade

Owner:南京赛达科技有限公司

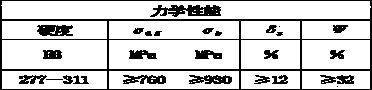

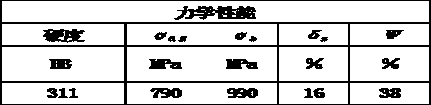

Special steel and processing technique of high-wear-resistance bearing

ActiveCN104195456AReduce segregationReduced impact toughnessFurnace typesHeat treatment furnacesLutetiumTempering

The invention discloses a special steel of a high-wear-resistance bearing. The blank comprises the following chemical components in percentage by mass: 0.21-0.23% of C, 0.07-0.09% of Si, 0.66-0.68% of Mn, 0.83-0.85% of Ni, 9.1-9.3% of Cr, 0.55-0.57% of Mo, 0.13-0.15% of V, 0.11-0.13% of Nb, 0.01-0.03% of Cu, 0.19-0.21% of Ti, 0.05-0.07% of B, at most 0.025% of S, at most 0.015% of P, 0.12-0.14% of rare-earth metal and the balance of Fe. The rare-earth metal comprises the following chemical components in percentage by mass: 2-4% of cerium, 11-13% of neodymium, 3-5% of gadolinium, 4-6% of lutetium, 5-7% of dysprosium, 1-3% of europium, 8-10% of erbium and the balance of lanthanum. The invention also discloses a processing technique of the high-wear-resistance bearing, which comprises the following steps: forging, annealing, tempering, turning, carburizing and heat treatment. The product has the characteristics of high working size precision, stable inherent quality, excellent properties, long service life and high reliability.

Owner:南京创贝高速传动机械有限公司

Special steel material for high-strength bearing and machining process of high-strength bearing

ActiveCN104213040AReduce segregationReduced impact toughnessSolid state diffusion coatingMischmetalTempering

The invention discloses a special steel material for a high-strength bearing and a machining process of the high-strength bearing. A blank comprises the following chemical components in percentage by mass: 0.24-0.26% of C, 0.10-0.12% of Si, 0.95-0.97% of Mn, 0.45-0.47% of Ni, 6.3-6.5% of Cr, 0.26-0.28% of Mo, 0.32-0.34% of Sr, 0.08-0.10% of Nb, 0.03-0.05% of Cu, 0.17-0.19% of Al, 0.26-0.28% of Ti, not more than 0.01% of S, not more than 0.02% of P, and 0.15-0.17% of rare earth metals, the balance being Fe, wherein the rare earth metals consist of the following chemical components in percentage by mass: 3-5% of praseodymium, 11-13% of neodymium, 9-11% of promethium, 3-5% of gadolinium, 2-4% of lutecium, 6-8% of europium, 1-3% of terbium and 4-6% of holmium, the balance being erbium. The invention further discloses the machining process of the high-strength bearing; and the machining process comprises the steps of forging, annealing, tempering, turning, carburizing and heat treatment. The produced bearing has the characteristics of high machining size precision, stable inherent quality, excellent performance, long service and high reliability.

Owner:南京创贝高速传动机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com