Manufacturing method for producing drill stem joint form seamless steel tube

A manufacturing method and technology for seamless steel pipes, which are applied in manufacturing tools, metal rolling, furnaces, etc., can solve the problems of low performance stability, serious environmental pollution, low finishing efficiency, etc., and achieve uniform and stable mechanical properties. The effect of high overall efficiency and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

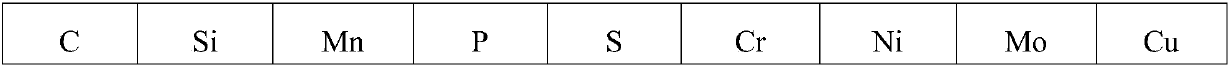

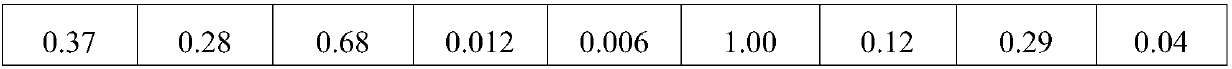

[0074] Using electric furnace smelting, refining outside the furnace and vacuum degassing, it is continuously cast into a continuous casting round tube billet with a diameter of 155 mm. The chemical composition is shown in Table 1. It is then heated in a ring-shaped heating furnace at 1240 ° C. After heating for 4 hours, it is released from the furnace. Piercing is carried out on a conical piercer with a feed angle of 12°, a rolling angle of 15°, and a reduction of 12%, and then the pipe is rolled by an ASSEL pipe rolling machine with a feed angle of 8° and a rolling angle of 6 °, the diameter reduction is 15mm, the wall reduction is 4.8mm, and then the reduction and sizing is carried out on the twelve-stand sizing machine. The deformation of the sizing machine is 11.5%, and the specification of the hot-rolled seamless steel pipe is 108 *31mm (outer diameter*wall thickness), treated according to the quenching and tempering method of this embodiment, the specific quenching and t...

Embodiment 2

[0085] The continuous casting round tube billet with a diameter of 155 mm is used. The chemical composition of the steel grade is specifically shown in Table 4. The process of smelting, heating and rolling the seamless steel pipe is shown in Example 1. The specification of the hot-rolled seamless steel pipe is 116*35mm (outer diameter* wall thickness), using a heat treatment system of 840°C quenching heating and 590°C tempering heating, and processing according to the quenching and tempering method of this embodiment. The specific quenching and tempering process is shown in Table 5. The comparison of the mechanical properties of steel pipes produced in Example 1) is shown in Table 6, wherein the tensile test is tested according to ASTM A370, the impact test is tested according to ASTM E23, and the hardness is tested according to ASTM E18.

[0086] Table 4 Chemical composition of seamless steel pipes (mass fraction%, the balance is Fe and unavoidable impurities)

[0087] ...

Embodiment 3

[0094] The continuous casting round billet with a diameter of 155 mm is used. The chemical composition of the steel grade is shown in Table 7. The process of smelting, heating and rolling the seamless steel pipe is shown in Example 1. The specification of the hot-rolled seamless steel pipe is 116*35mm (outer diameter* wall thickness), using the heat treatment system of quenching heating at 850°C and tempering heating at 598°C, and processing according to the quenching and tempering method of this embodiment. The specific quenching and tempering process is shown in Table 8. The comparison of the mechanical properties of steel pipes produced in Example 1) is shown in Table 9, wherein the tensile test is tested according to ASTM A370, the impact test is tested according to ASTM E23, and the hardness is tested according to ASTM E18.

[0095]Table 7 Chemical composition of seamless steel tube steel (mass fraction%, the balance is Fe and unavoidable impurities)

[0096] C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com