Patents

Literature

148results about How to "Flexible sliding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

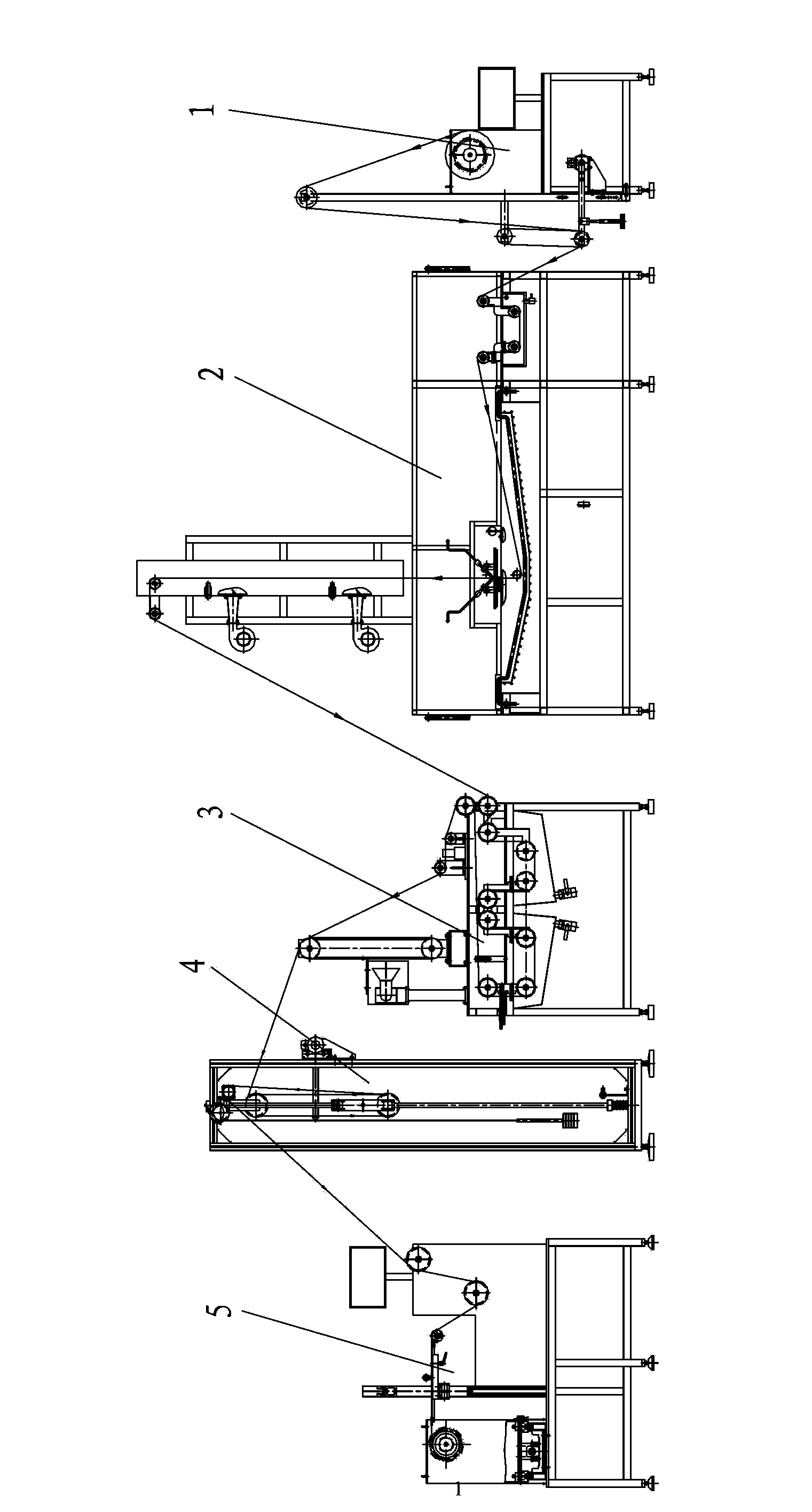

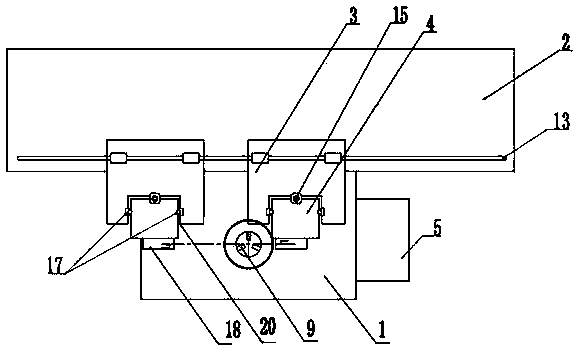

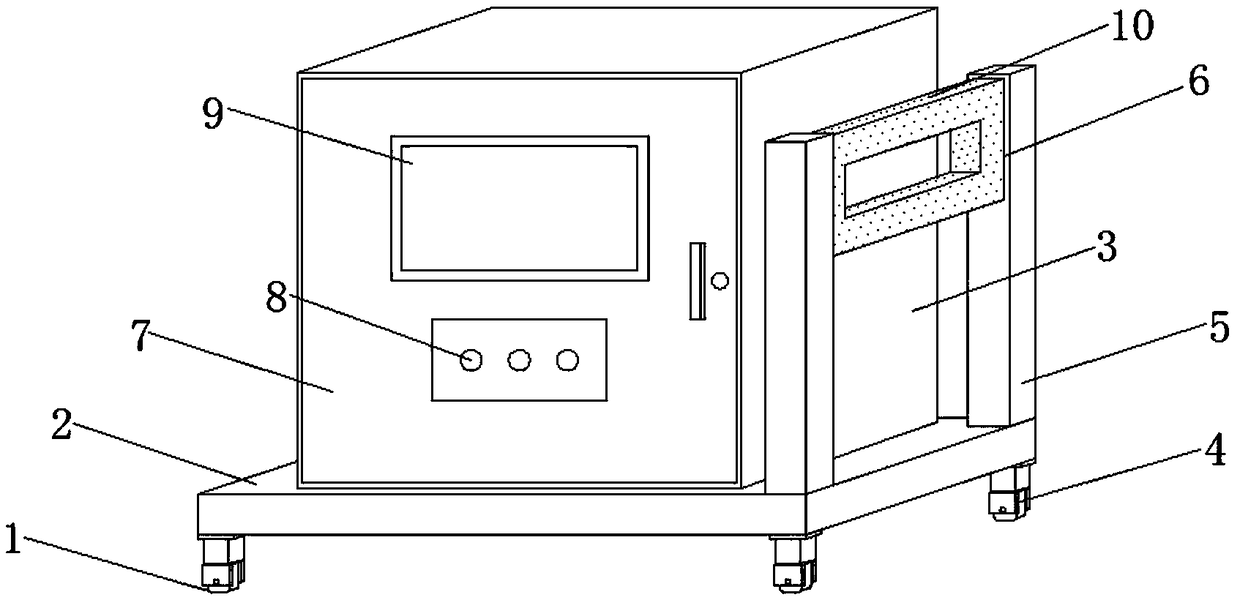

High speed automatic tin-plating machine

InactiveCN103834891ACompact structureNovel and reasonable designHot-dipping/immersion processesControl systemTin plating

The invention discloses a high speed automatic tin-plating machine which comprises an unreeling mechanism, a tin-plating mechanism, a driving and cleaning mechanism, a storage mechanism, a reeling mechanism and a control system sequentially arranged, wherein the unreeling mechanism comprises an unreeling frame, a paying off swing rod, an unreeling transitional wheel, an unreeling belt wheel, a tension adjusting wheel and an unreeling motor; the tin-plating mechanism comprises a tin-plating frame, an acidifying box, an acidifying transitional wheel frame, a solder machine, a pinch roller, a wind knife assembly and an air flue frame; the driving and cleaning mechanism comprises a cleaning frame, a cleaning agent groove, a cleaning transitional wheel bracket, a thickness measuring assembly and a traction assembly; the storage mechanism comprises a storage frame, a fixed wire storage wheel set, a mobile wire storage wheel set and a tension detection mechanism; the reeling mechanism comprises a reeling frame, a reeling guide rail bracket, a vertical wiring device and a horizontal wiring device. The high speed automatic tin-plating machine disclosed by the invention is novel and reasonable in design, ensures the quality and efficient production of tin-plating welding strips, is high in working reliability, better realizes continuous, efficient, high-quality and low-cost tin plating, and is convenient to popularize and use.

Owner:THE NORTHWEST MACHINE

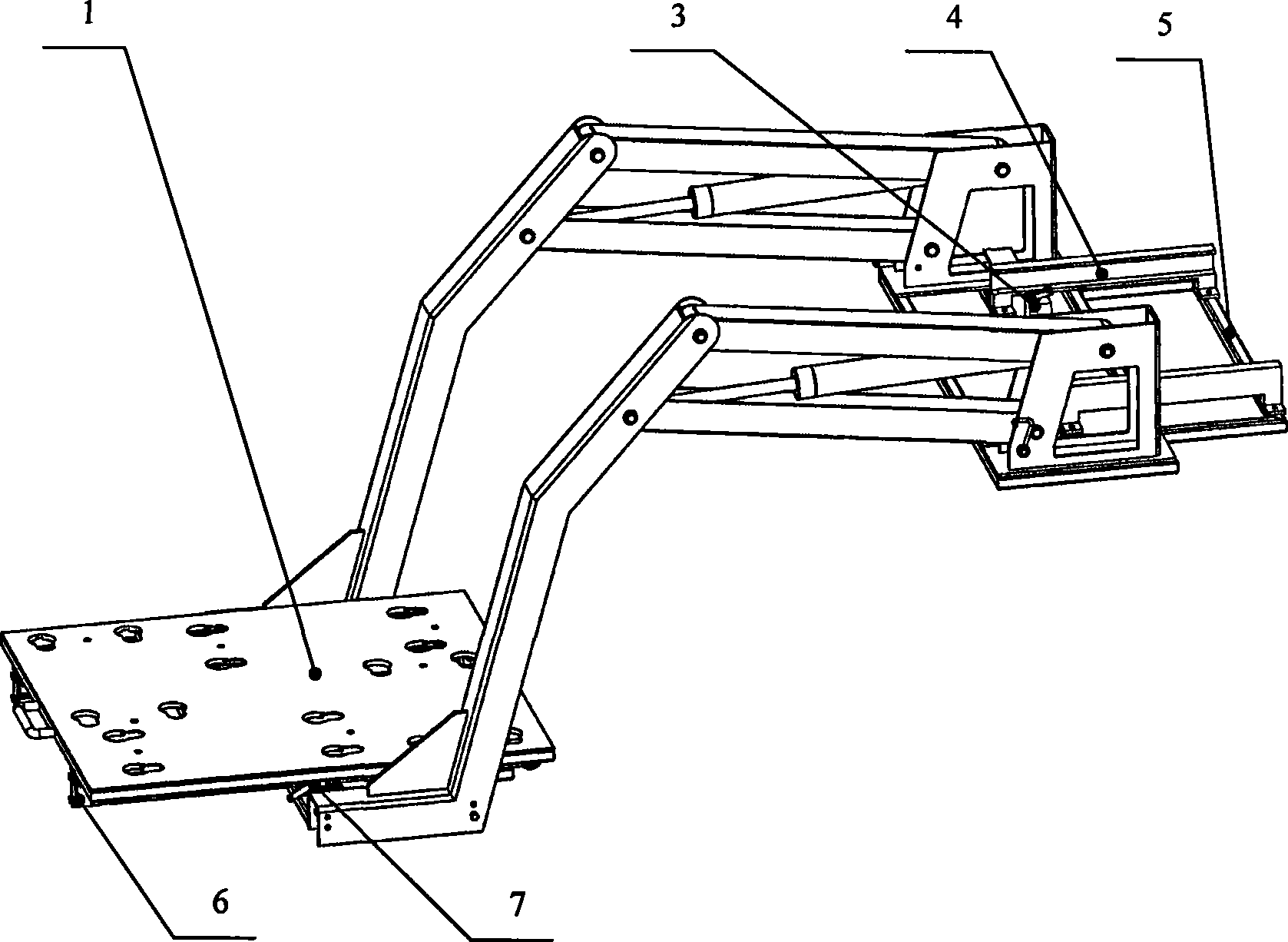

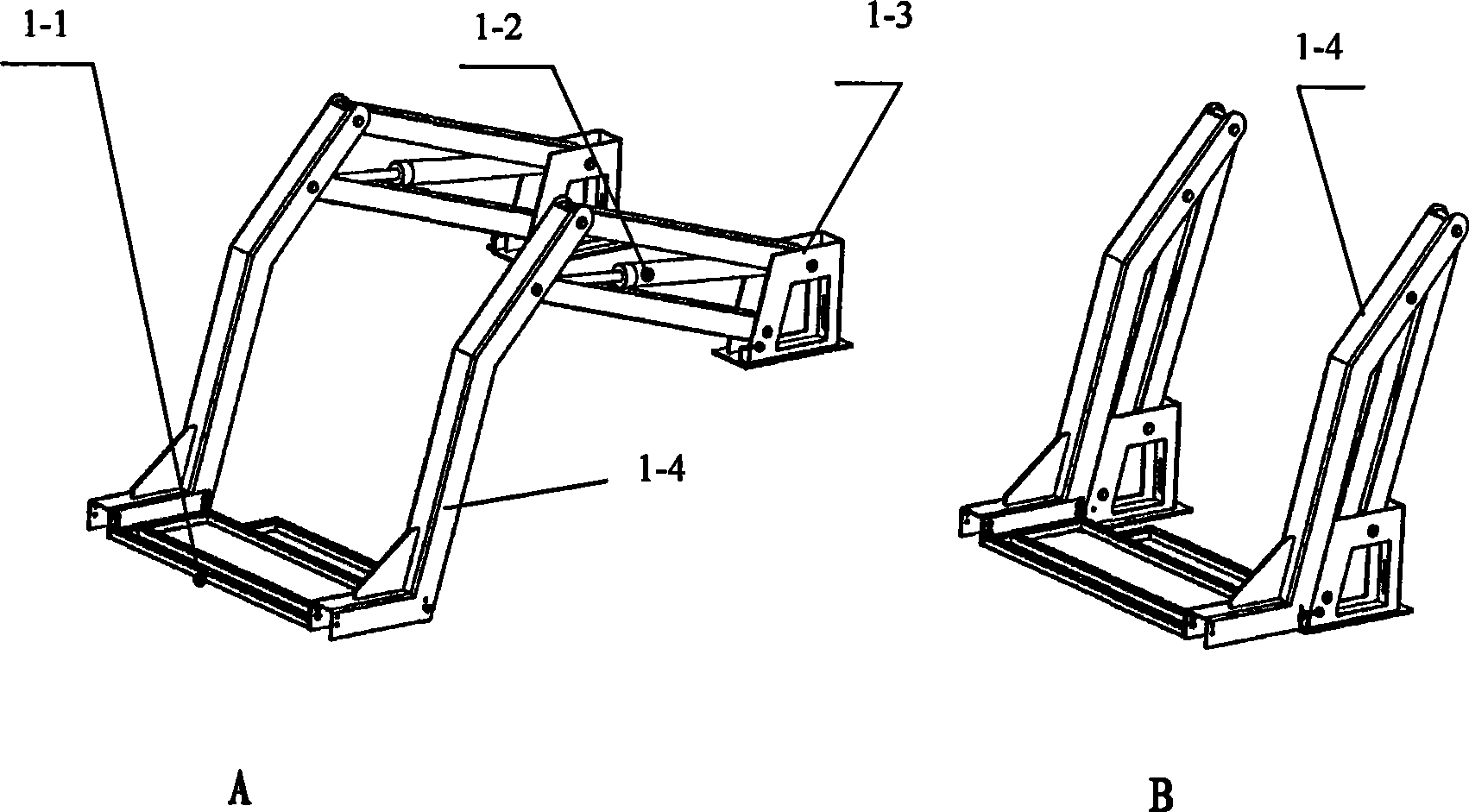

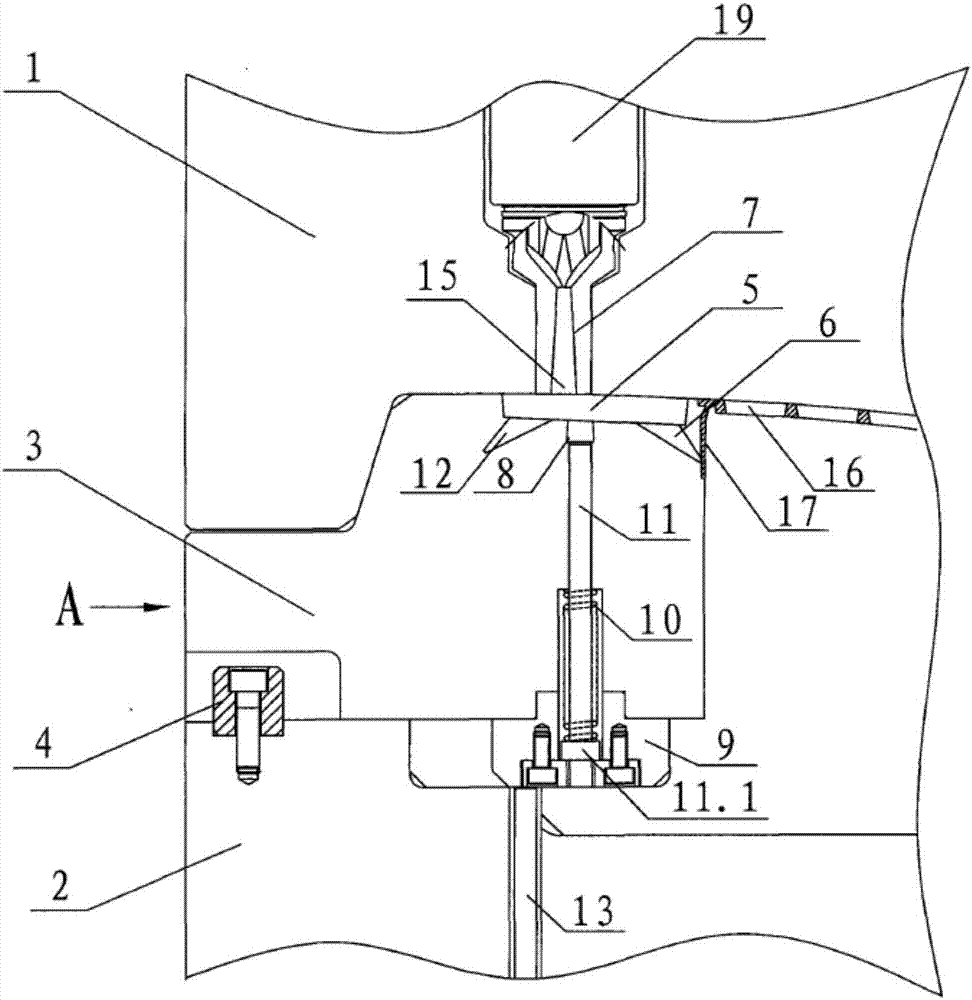

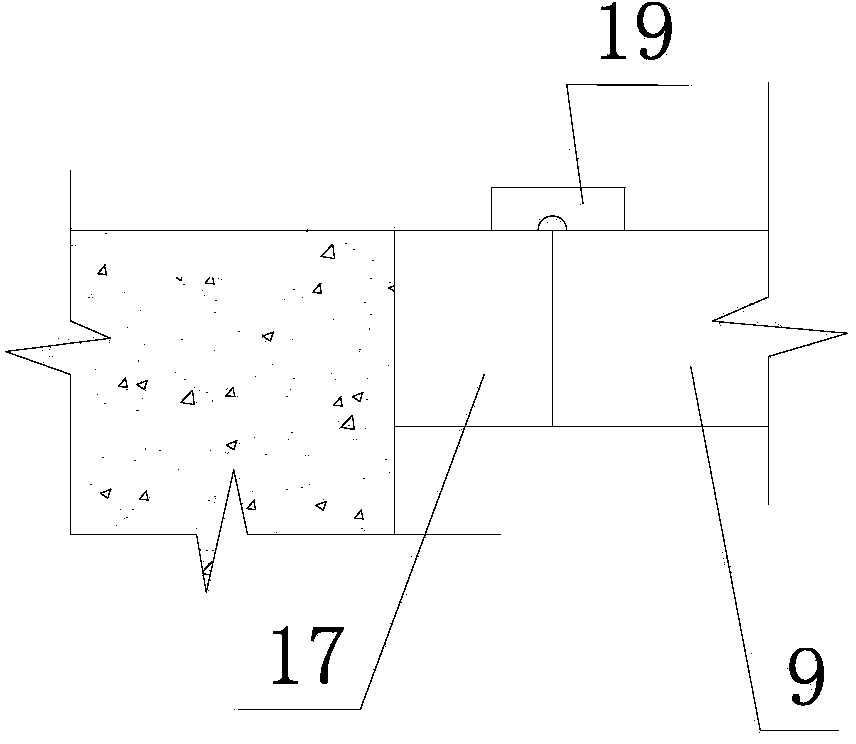

Tray type hydraulic weight-hoisting device suitable for small space

InactiveCN101480933ASolve the problem of frequent loading and unloadingSimple structureVehicle with pivoted armsHydraulic cylinderHeavy load

The invention relates to a hydraulic pallet type load lifting device applicable to small space. The device comprises a load pallet and a pair of parallelogrammic mechanisms and is characterized in that one end of each of the parallel arms of each parallelogrammic mechanism is hinged on a fixed seat, the other end is articulated with the upper end of a bracket arm, and the lower end of the bracket arm is angularly bent and fixed with a bracket; under the drive of a hydraulic cylinder, the parallelogrammic mechanisms are expanded forwards and descend, or are folded by ascending backwards, around a hinging point of each fixed seat; the load pallet is arranged on the bracket of the parallelogrammic mechanisms by sliding rails; and auxiliary supporting rollers on the sliding rails are matched with fixed sliding grooves so as to support the load pallet kept between the two fixing seats. The invention solves the problem of frequent loading and unloading of loads in a narrow operating space, and has the advantages of simple structure, high working reliability and convenient operation and maintenance.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

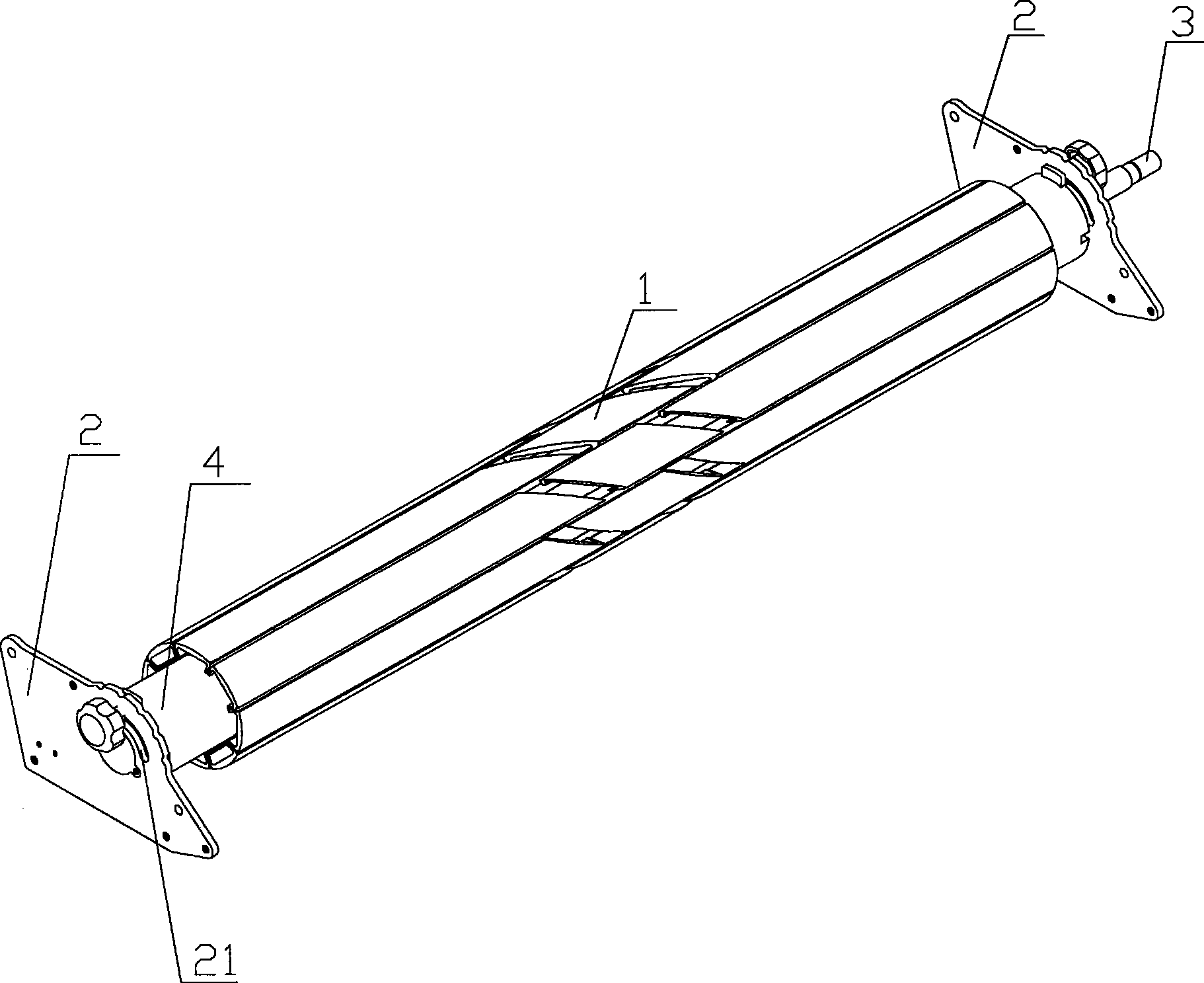

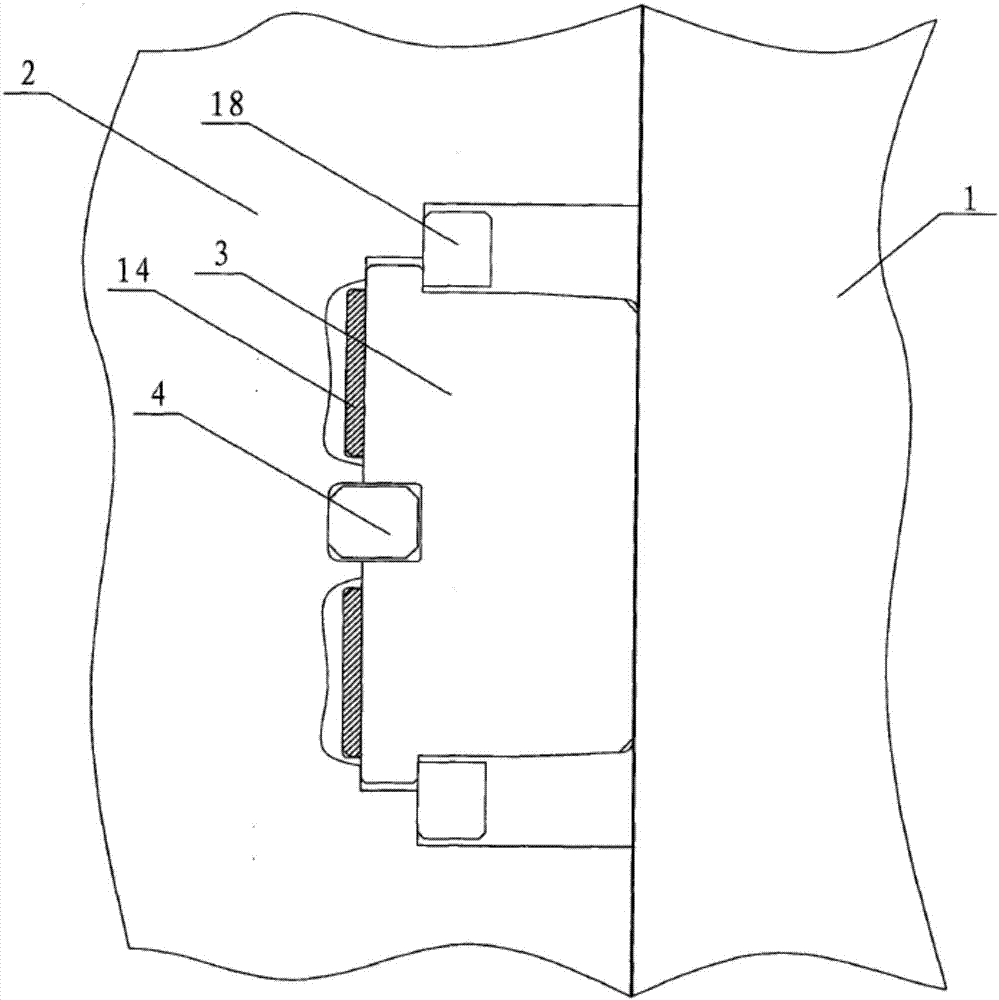

Spreading roller for spreader

InactiveCN101446011AIncrease frictionExquisite structureTextile treatment machine partsStretchingPulleyEngineering

The invention relates to a spreading roller for a spreader, comprising the rotary roller. The roller is arranged on a roller frame; one end of the roller is provided with a power input shaft; a plurality of blades which can slide left and right, are symmetric left and right and are used for spreading are arranged on the roller; and grooved pulleys for driving the blades to slide left and right are arranged at the two ends of the roller. The spreading roller is characterized in that a slide rail is arranged on the roller; the blades are connected with the slide rail; the end part of the blade is provided with a grooved pulley contact; the outer surface of the blade is provided with blade skin; the grooved pulleys are fixedly connected on a roller frame at the two sides; the grooved pulley is provided with an annular skewed slot; the contact is embedded in the skewed slot in a sliding way; and the grooved pulleys are fixed on the roller frame by a locking bolt. During the spreading, the roller rotates, and the grooved pulleys do not move; the grooved pulleys drive the blades to slide left and right. During the adjusting of the spreading range, the locking positions of the grooved pulleys are adjusted for changing the spreading range of the blades. When the spreading function is not required, the locking bolt is cancelled, and the grooved pulleys are fixed on a rotary shaft by a fixing pin, so that the blades cannot slide left and right.

Owner:SPEEDFLY ZHEJIANG AUTOMATION TECH

A kind of counterweight mobile device of crawler crane and crane including the device

Owner:ZHEJIANG SANY EQUIP

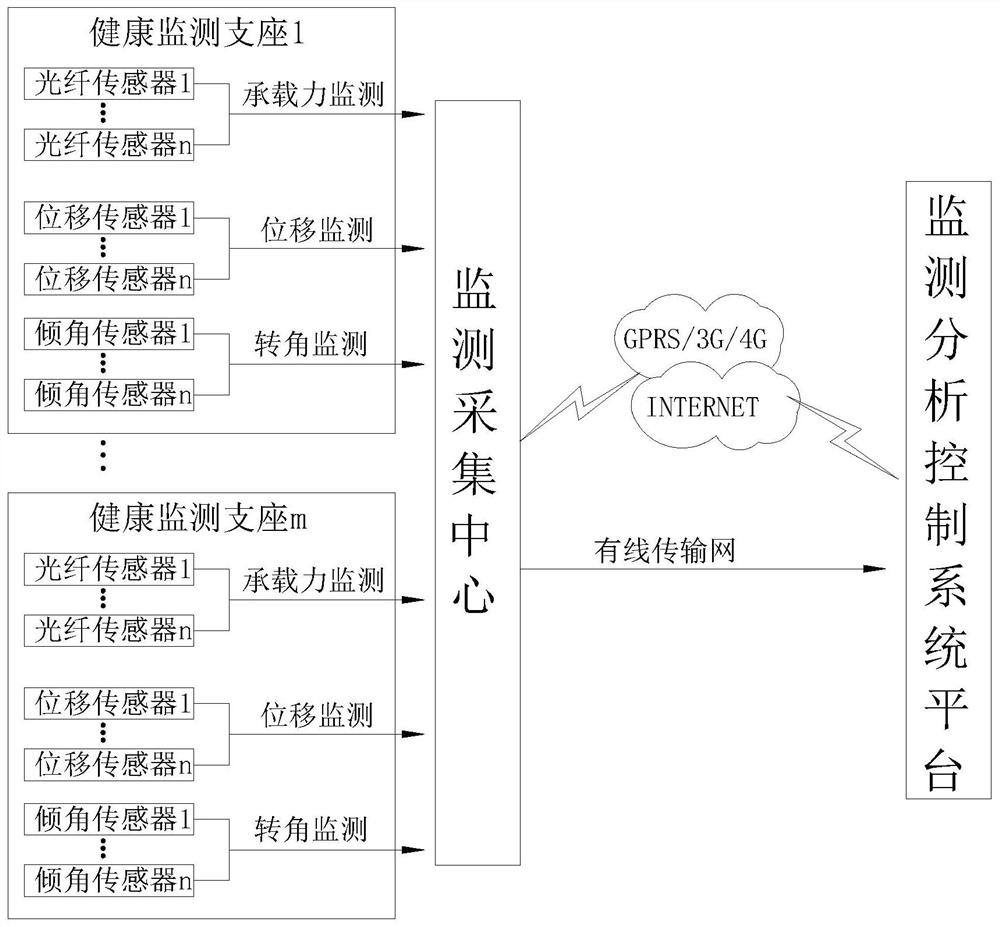

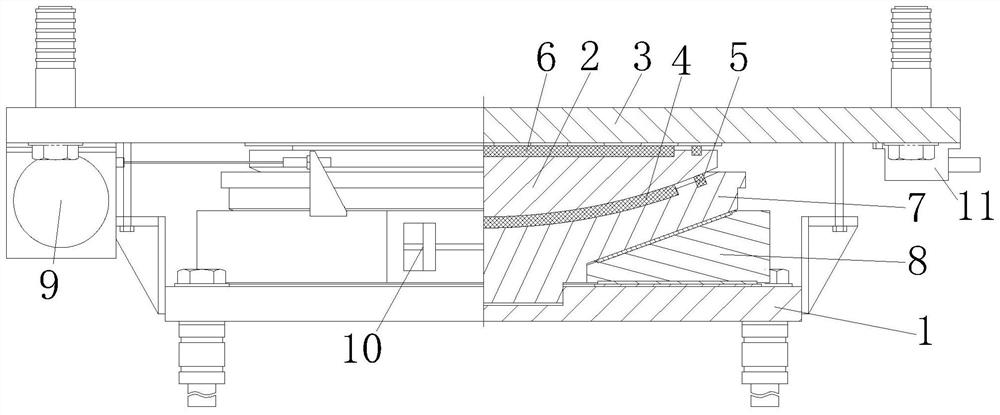

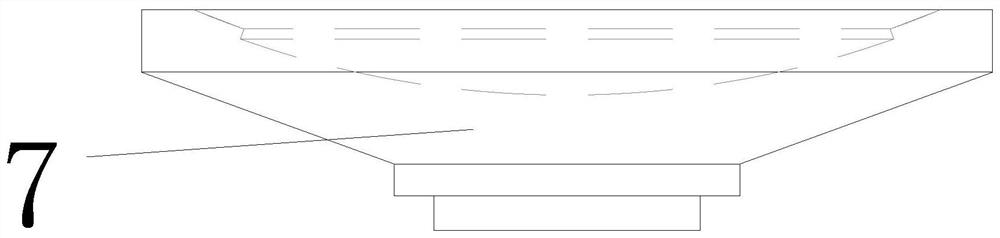

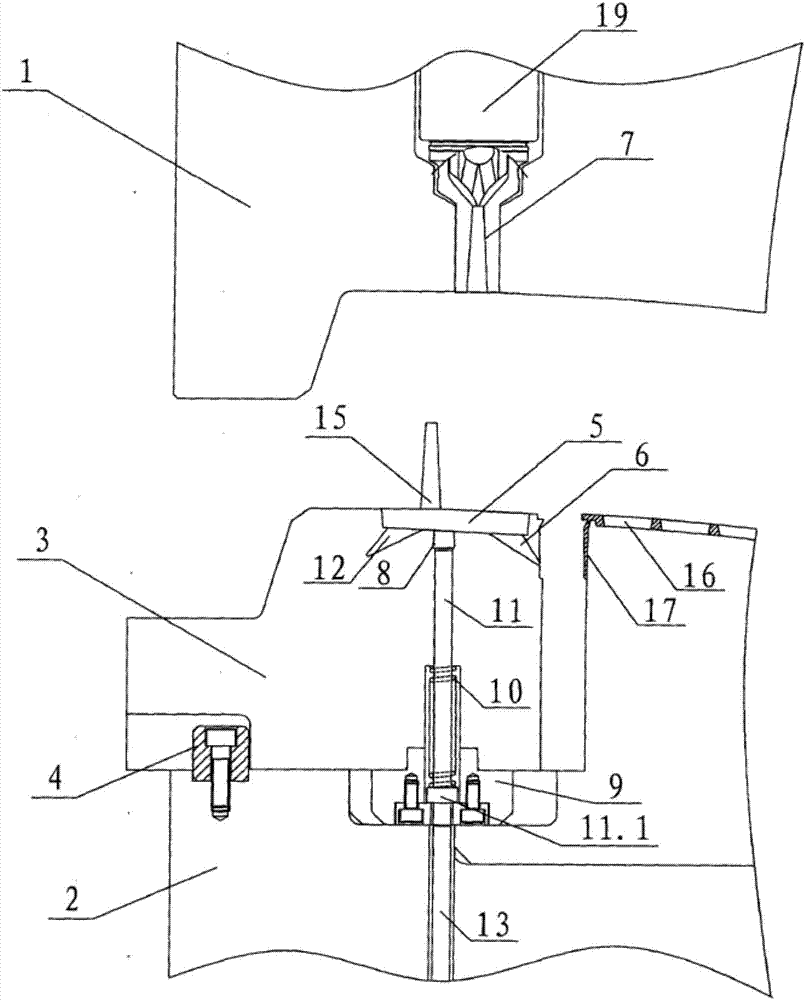

Bridge health monitoring support and monitoring system

PendingCN111855045AFacilitated releaseAchieve releaseForce measurement by measuring optical property variationBridge structural detailsMonitoring systemMechanical engineering

The invention discloses a bridge health monitoring support and a monitoring system, which are used to solve the problems that manual detection of a bridge support located in a hidden and severe engineering environment is inconvenient, all-weather monitoring cannot be achieved by manual periodic detection, meanwhile, the number of bridge supports is large, the manual detection period is long, and the safety problem of the bridge is difficult to judge. A health monitoring support group is composed of a plurality of health monitoring supports. The health monitoring support is composed of a functional part, an optical fiber force measuring sensor, a displacement sensor and an inclination angle sensor. The functional part is composed of a lower support plate, a spherical crown lining plate, anupper support plate, a plane sliding plate, a sealing ring, a plane sliding plate, a middle plate, a wedge-shaped ring, an upper support plate, a middle plate, a wedge-shaped ring and a lower supportplate. The displacement sensor and the inclination angle sensor are in transmission and connection with a monitoring and collecting center through optical fibers.

Owner:ANHUI SHOULDER TECH

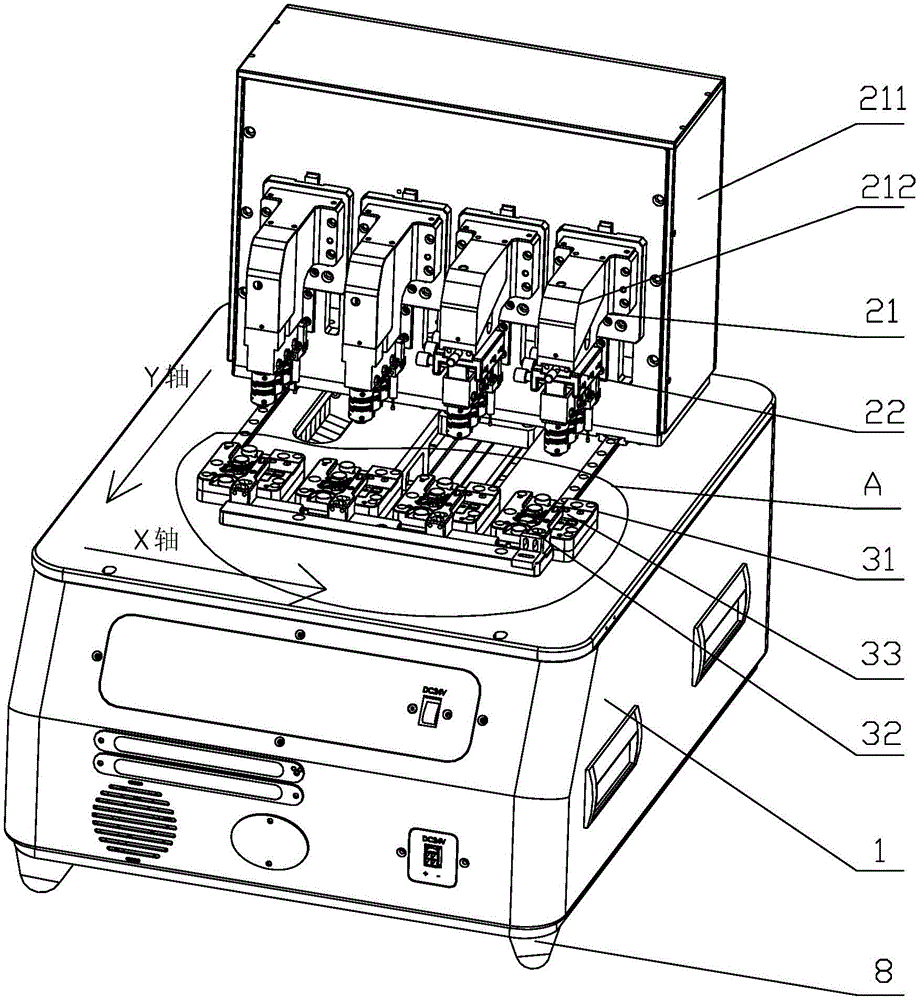

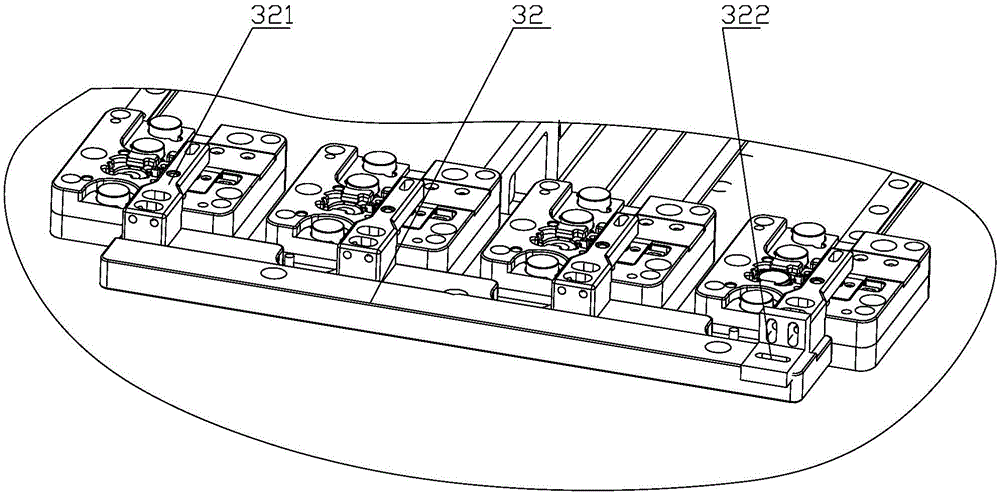

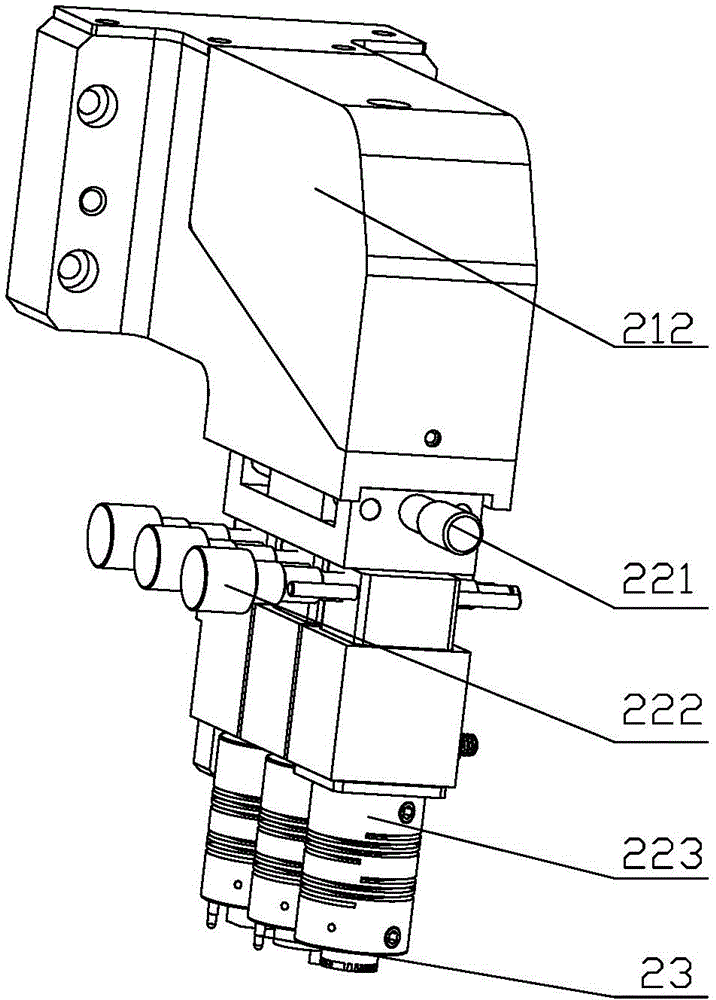

PCB testing device

The invention discloses a PCB testing device and belongs to the technical field of testing devices. The problems that a traditional PCB debugging method is low in detection efficiency, large in labor intensity, low in precision and the like are solved. The PCB testing device comprises an upper mold assembly and a lower mold assembly, wherein the upper mold assembly is arranged above an electric control box, and the lower mold assembly is arranged on an upper panel of the electric control box. Under the effect of a lifting mechanism and an XY axis moving mechanism of the upper mold assembly, a probe on the upper mold assembly is made to penetrate through a probe hole in a probe board of the lower mold assembly, so that the probe makes contact with a product to be tested on a product carrier board for testing the situations such as lack of weld and open-short circuits of main elements of the PCB. The PCB testing device is easy to operate and high in automation degree, simplifies manual operation, reduces labor intensity and improves working efficiency and testing accuracy.

Owner:KUSN MAIZHI FIXTURE TECH

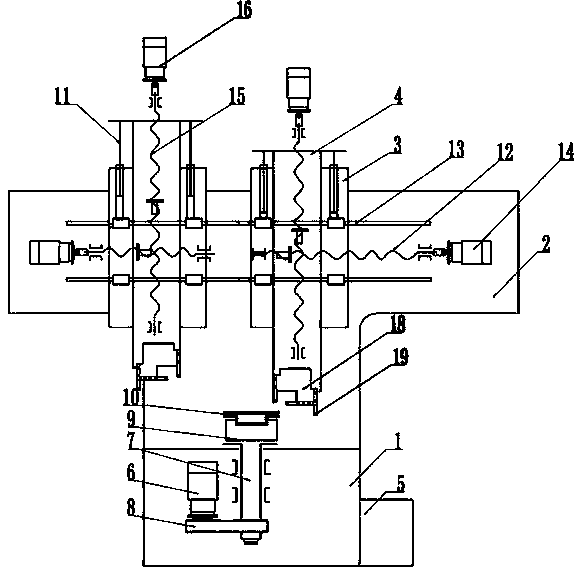

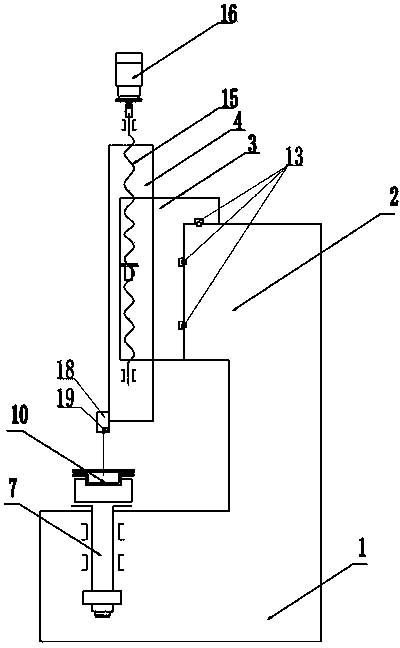

Vertical lathe for machining disc type workpieces and brake disc machining method

ActiveCN104139190ASave setup and adjustment timeImprove processing efficiencyFeeding apparatusTool holdersBall screwMechanical engineering

The invention relates to the technical field of machining, in particular to a vertical lathe for machining disc type workpieces and a brake disc machining method. The vertical lathe comprises a lathe bed, the lathe bed comprises a base and a cross beam, a workpiece rotating clamping device is arranged on the base, and the vertical lathe is characterized in that an X-direction linear guide rail is arranged on the cross beam, left and right rams are arranged on the X-direction linear guide rail, X-direction ball screw pairs and X-direction servo motors are respectively arranged between the X-direction linear guide rail and the left and right rams, Z-direction linear guide rails are arranged on the left and right rams respectively, stand columns are arranged on the Z-direction linear guide rails, Z-direction ball lead screw pairs and Z-direction servo motors are arranged between the Z-direction linear guide rails and the stand columns, and tool mounting bases are arranged at the lower ends of the stand columns. The invention further relates to the brake disc machining method. The method comprises the steps that a left tool and a right tool respectively and independently machine different faces, the workpieces are clamped and mounted by being turned, and the other faces are machined. Compared with the prior art, the vertical lathe and the brake disc machining method have the advantages of saving clamping adjusting time and improving the machining efficiency.

Owner:YANTAI LUCHEN SEAWOO CNC MACHINERY

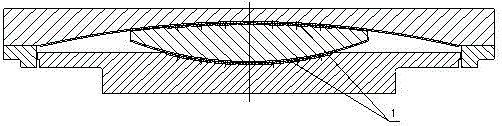

Injection mould

The invention discloses an injection mold which has no injection point on the outer surface of the product and does not need to manually trim the product. It includes a static mold and a moving mold, and the moving mold is provided with a slider and a limit block for limiting the sliding distance of the slider. , the slider is provided with runners, gate 1, and an ejector for ejecting the material handle; the slider is slidably connected with the movable mold, and the limiting block is fixedly connected with the movable mold; the runner It communicates with the gate I, and the runner also communicates with the main channel of the static mold; the gate I communicates with the core wall; the ejector device is installed in the slider, and the ejector port of the ejector device is connected to the The runners are connected.

Owner:HUANGSHI HONGXING PLASTIC MOLD

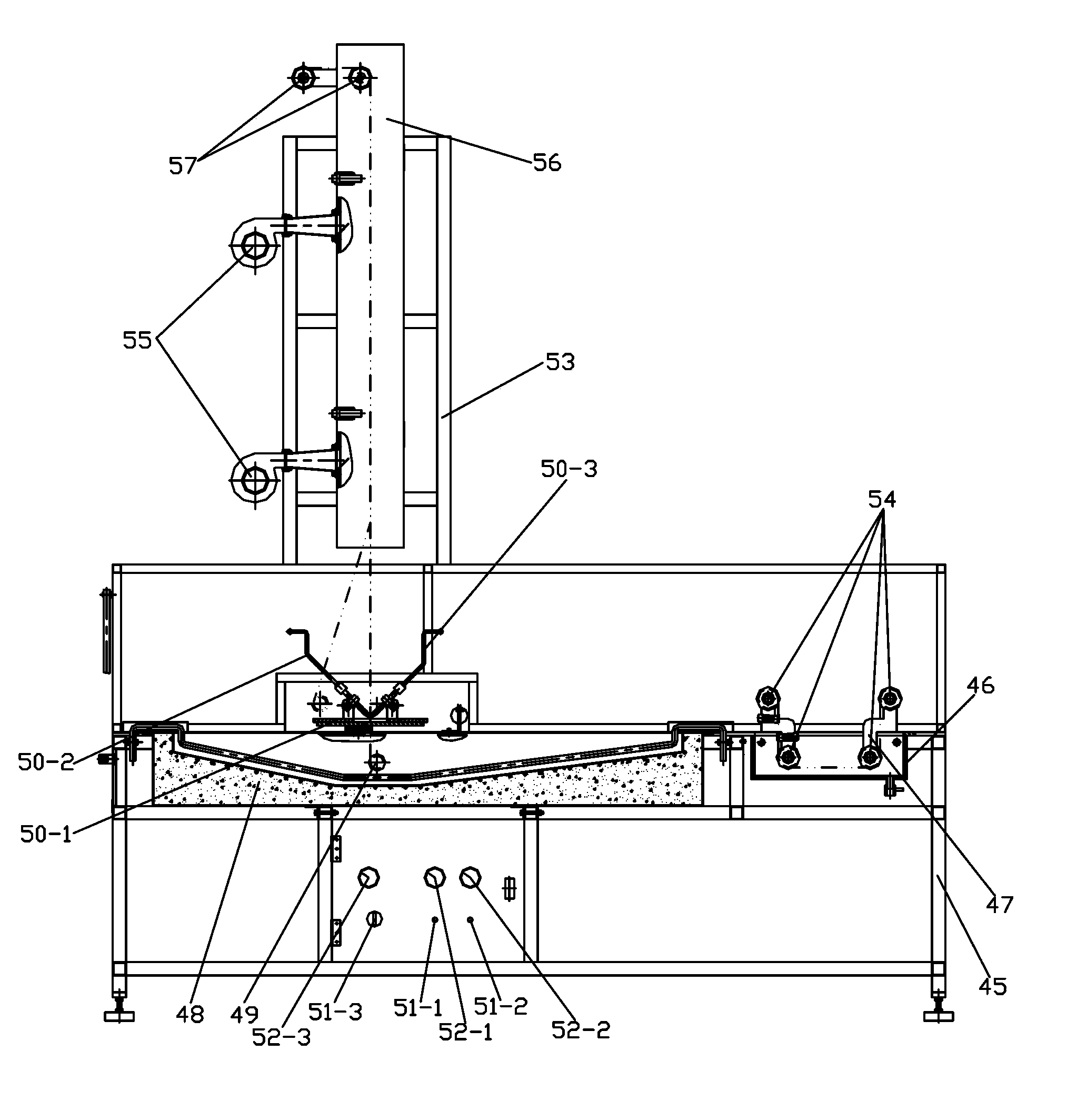

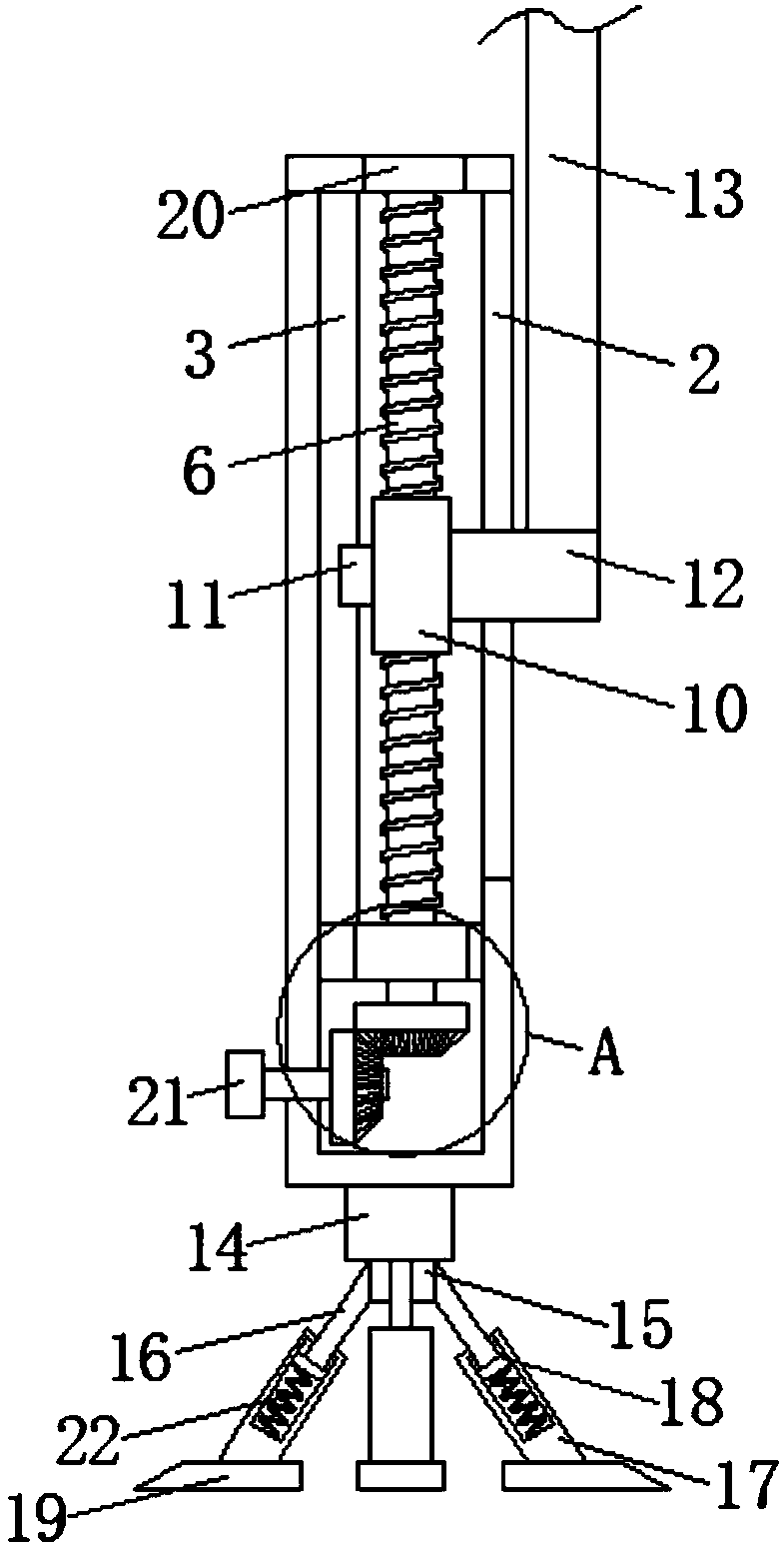

Coaxial type medical test tube cleaning device

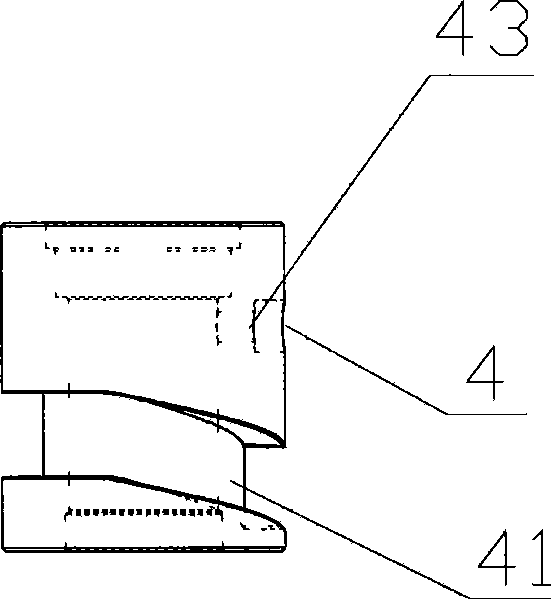

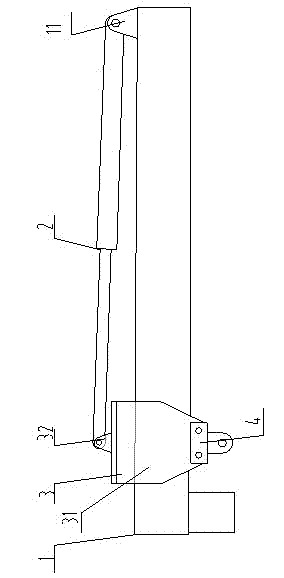

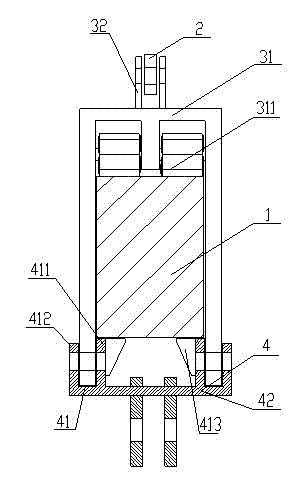

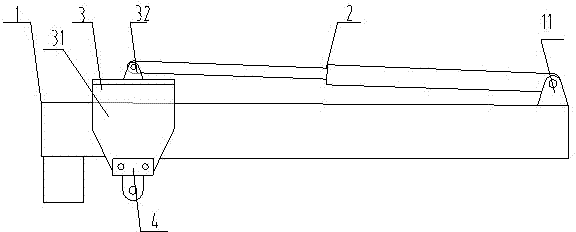

InactiveCN106513395AAvoid breakingInefficient scrubbingHollow article cleaningMotor driveSlide plate

The invention relates to the field of medical facilities, in particular to a coaxial type medical test tube cleaning device. The coaxial type medical test tube cleaning device comprises a frame body assembly, a clamping mechanism, a cleaning mechanism and a supply mechanism. The cleaning mechanism and the supply mechanism are mounted on a rack of the frame body assembly. The supply mechanism slides on the rack. The cleaning mechanism is arranged below the supply mechanism. A lead-screw-nut pair is arranged between the supply mechanism and the cleaning mechanism. A stepping motor drives a lead screw of the lead-screw-nut pair to rotate. A plurality of guiding rods are arranged between the supply mechanism and the cleaning mechanism. The clamping mechanism is arranged on a bottom plate. A clamping part sliding plate is mounted on the clamping mechanism. A test tube rack is placed on the clamping part sliding plate. Test tubes are placed in the test tube rack. Through the coaxial type medical test tube cleaning device, the phenomena that the washing efficiency is low, and test tubes are broken due to trembles of a whole device caused by rotation of a motor in the cleaning process of the medical test tubes can be avoided.

Owner:谷新运

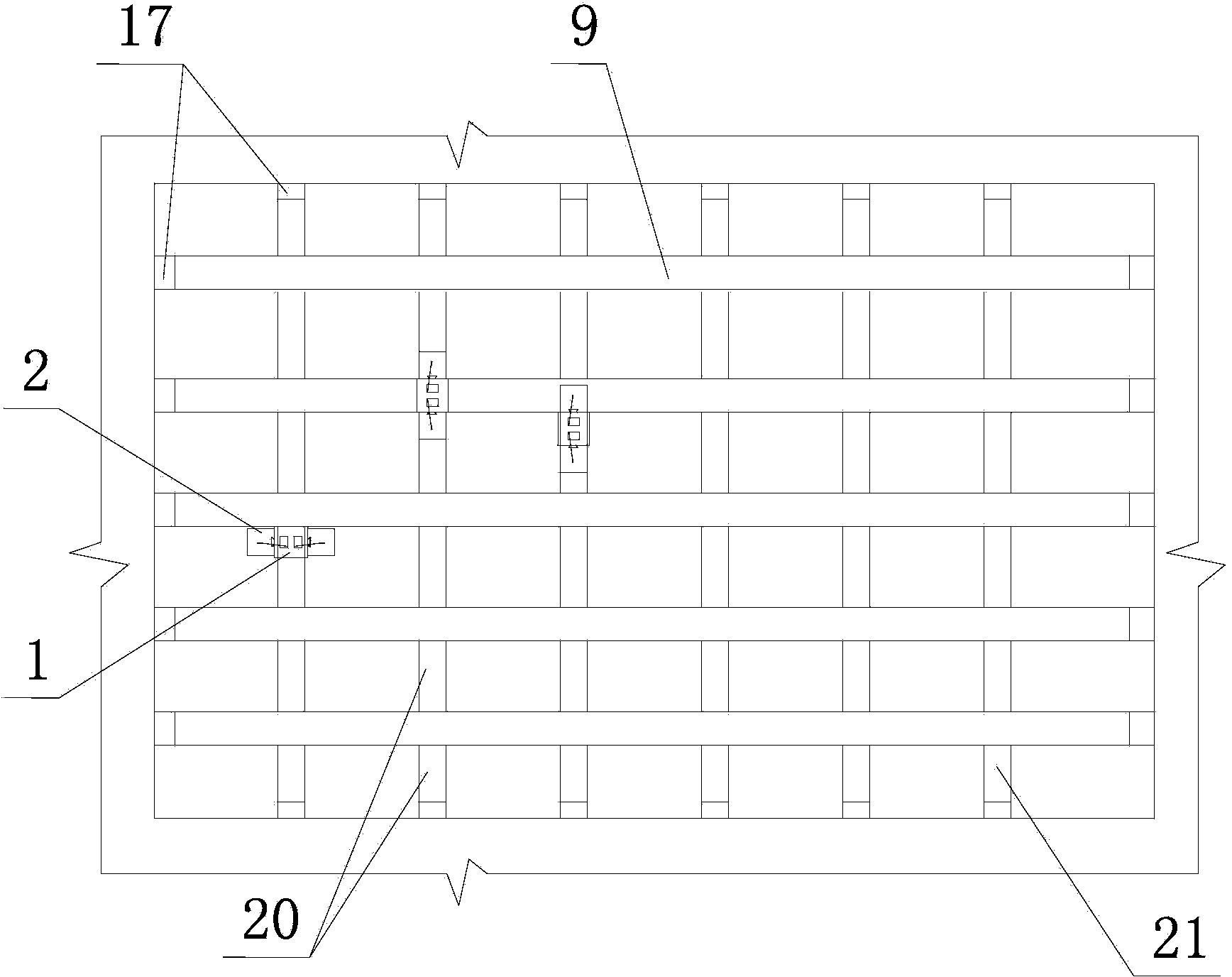

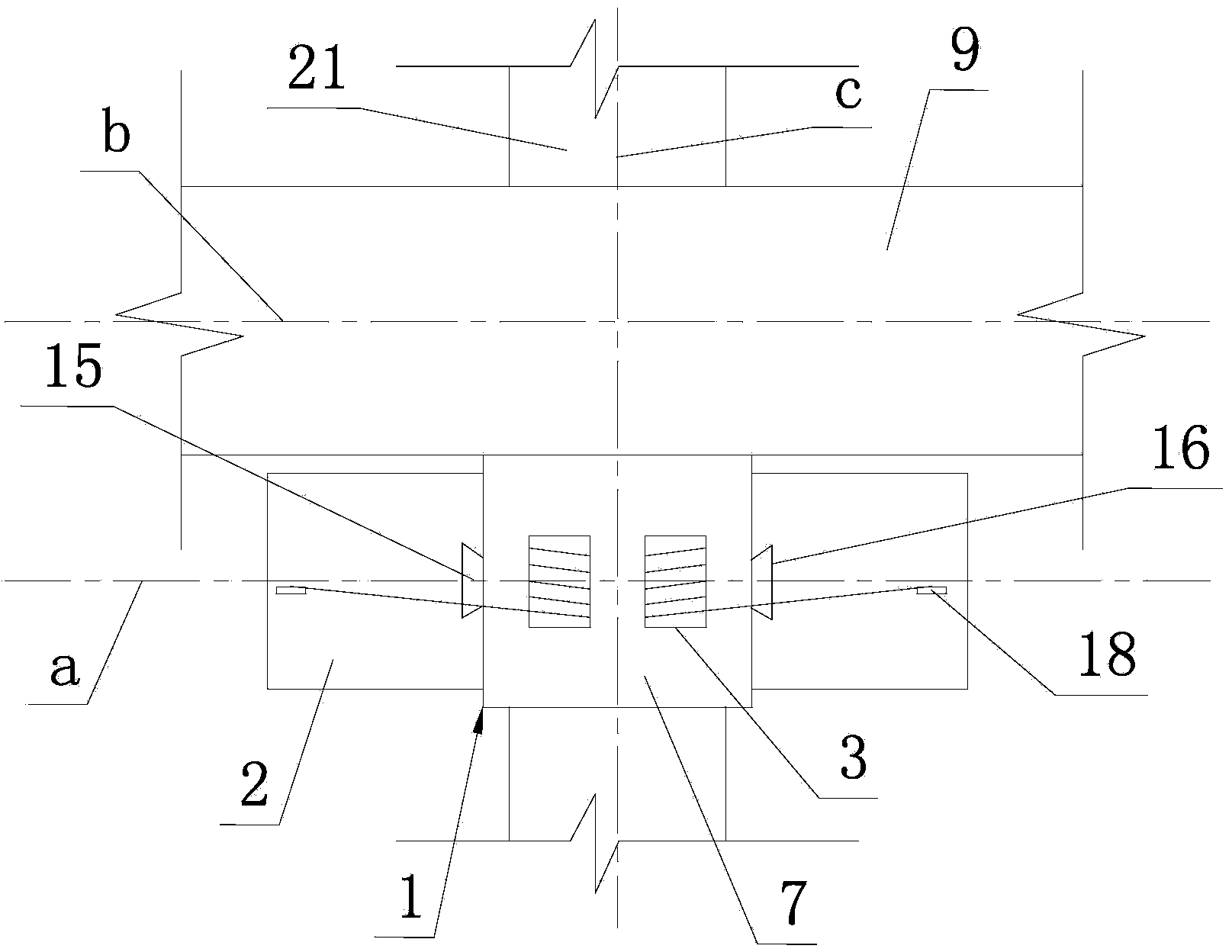

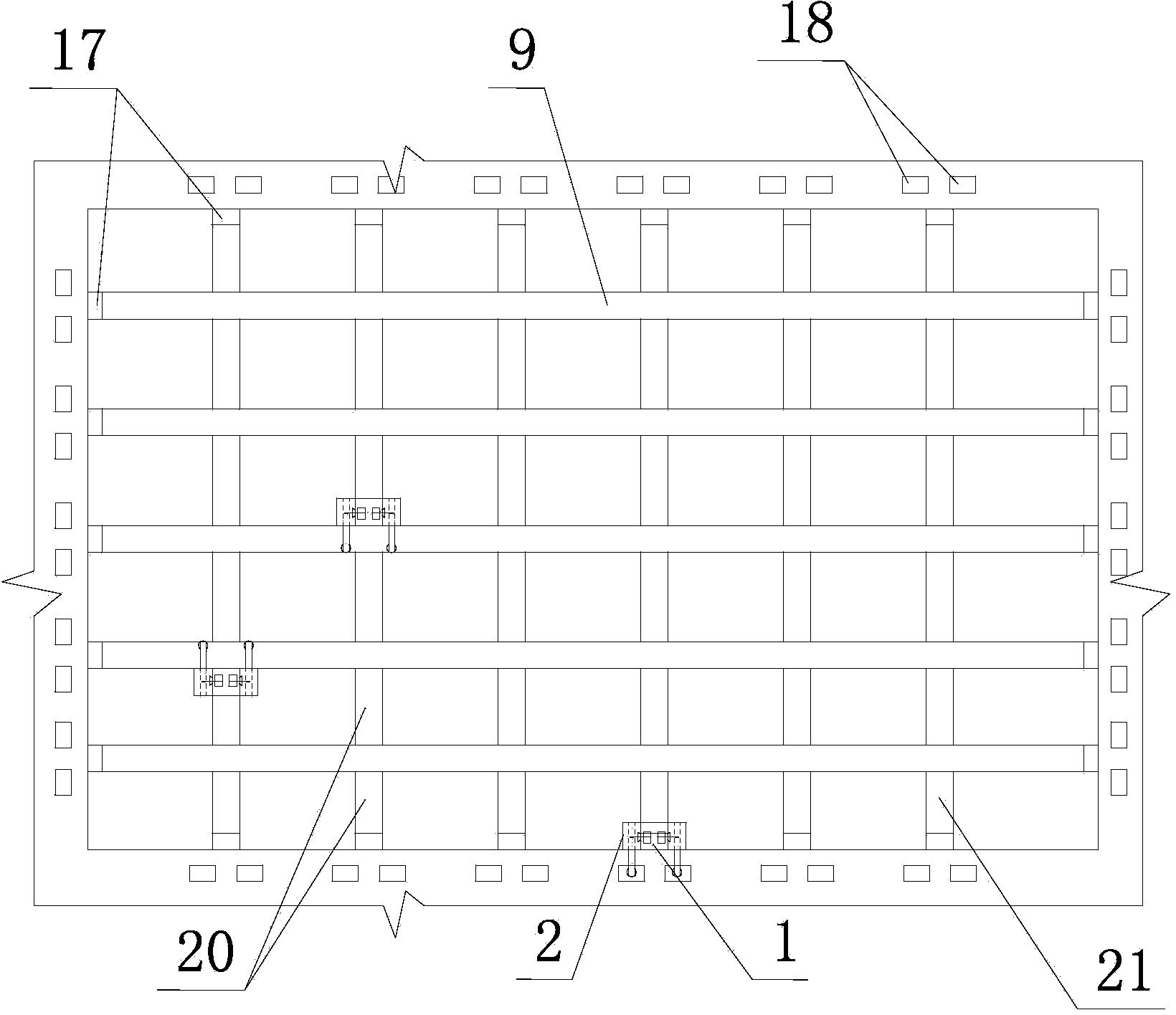

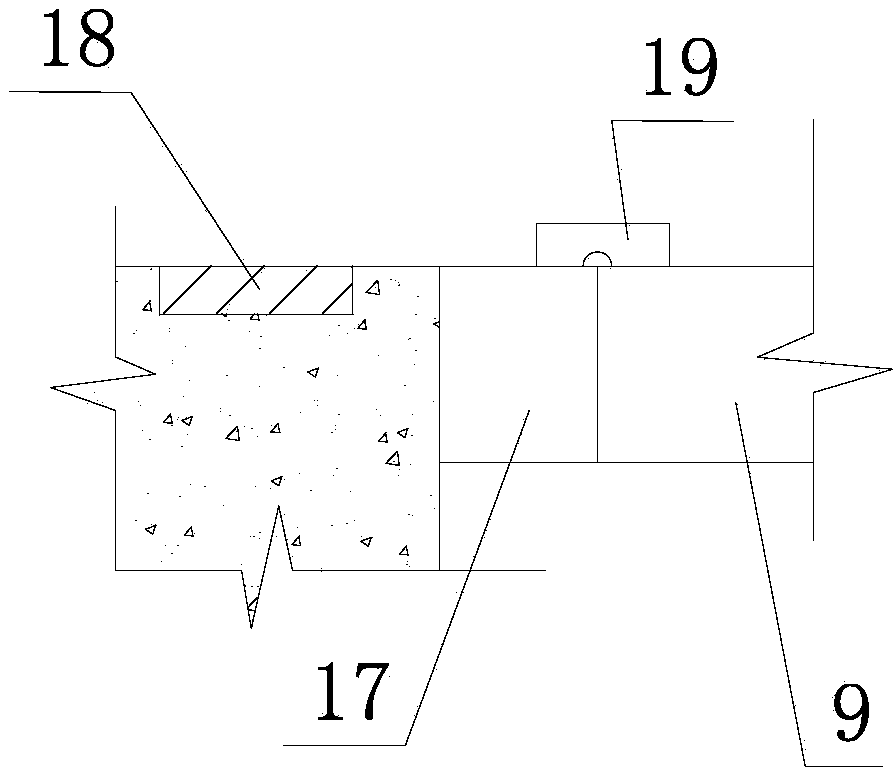

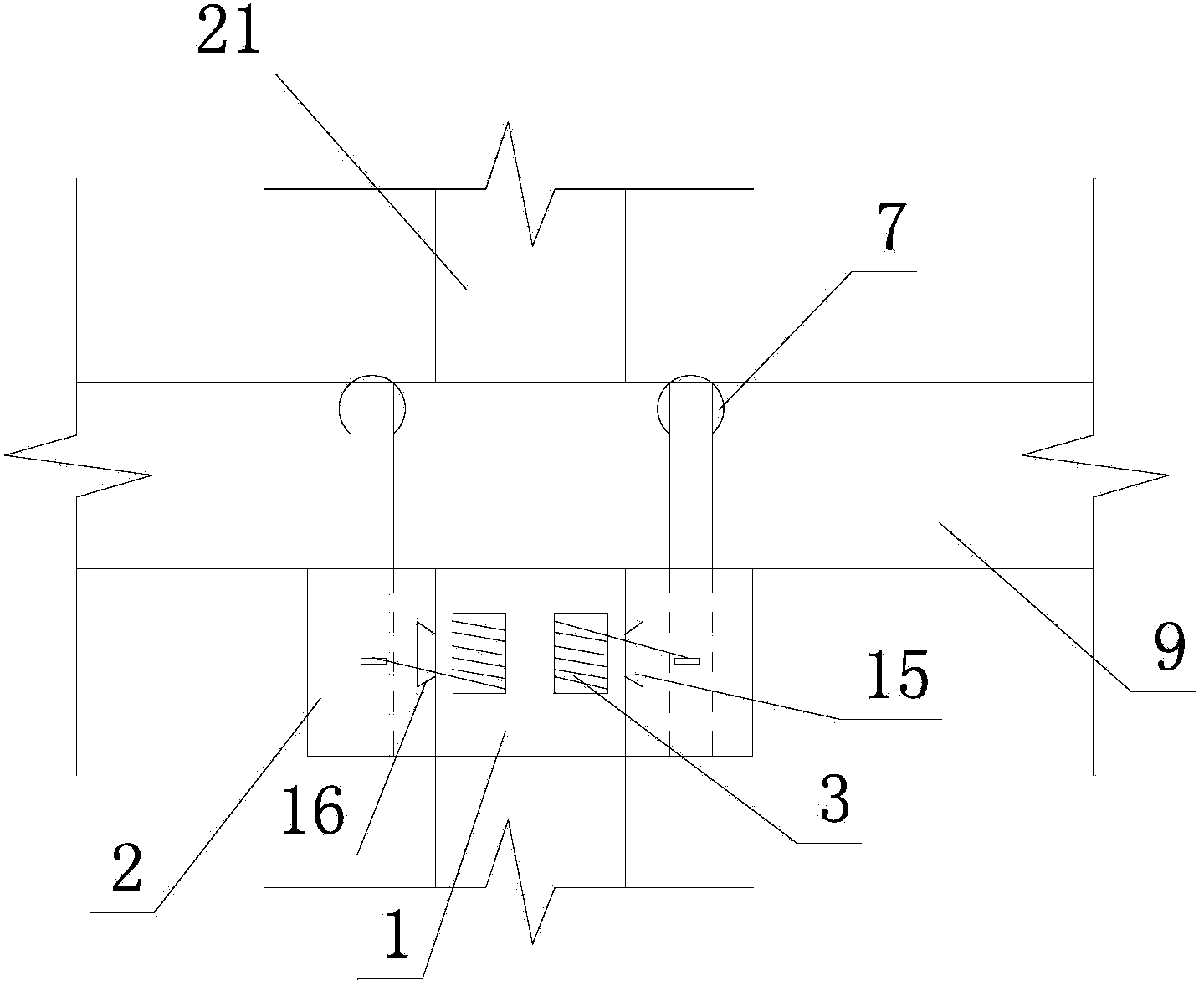

Construction device and construction method for steel beam connection platform

ActiveCN104060846APass smoothlyEasy to weldBuilding material handlingMaterial consumptionUltimate tensile strength

The invention discloses a construction device and a construction method for a steel beam connection platform. The construction device comprises a trolley (1) and two operation car baskets (2), wherein the trolley (1) comprises a chassis and a rotary part (7), a transmission gear is fixedly arranged on the lower end of the rotary part (7), and a motor output gear of the chassis is meshed with the transmission gear; the top of the rotary part (7) and the tops of the operation car baskets (2) are fixed through a winch (3); an electromagnet is arranged on the chassis of the trolley (1); the method comprises the key points that at the normal section position of a main beam (9) or a secondary beam unit (21), the trolley (1) and two operation car baskets (2) move in a manner of clamping the main beam (9) or the secondary beam unit (21) in the triangular structure, when the trolley (1) reaches each node and then lifts the operation car basket (2) through the winch (3), so that the operation car baskets (2) are enabled to be flush with the bottom surface of the trolley (1), so as to pass the node. With the construction device and the construction method, the material consumption is saved, the working intensity is reduced, and the operation is convenient and quick.

Owner:ZHEJIANG ERJIAN STEEL STRUCTURE

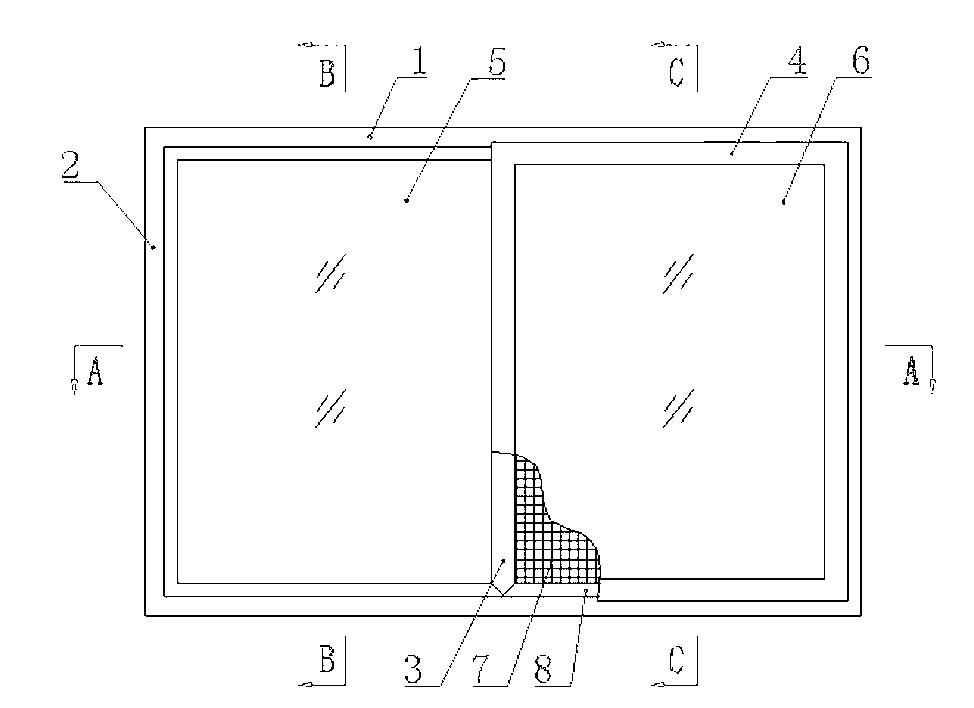

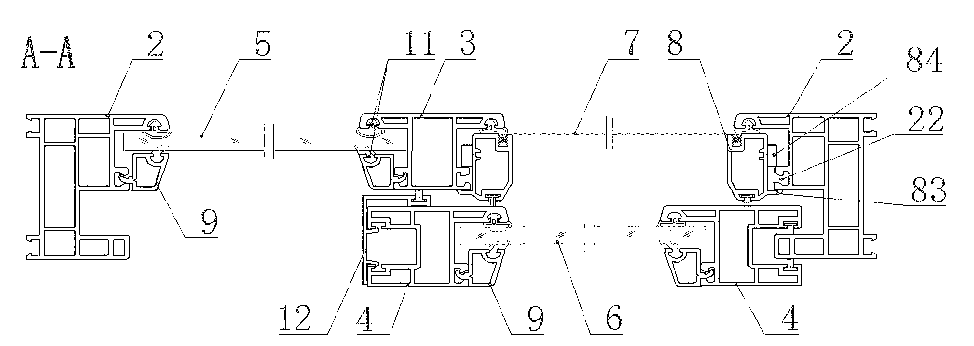

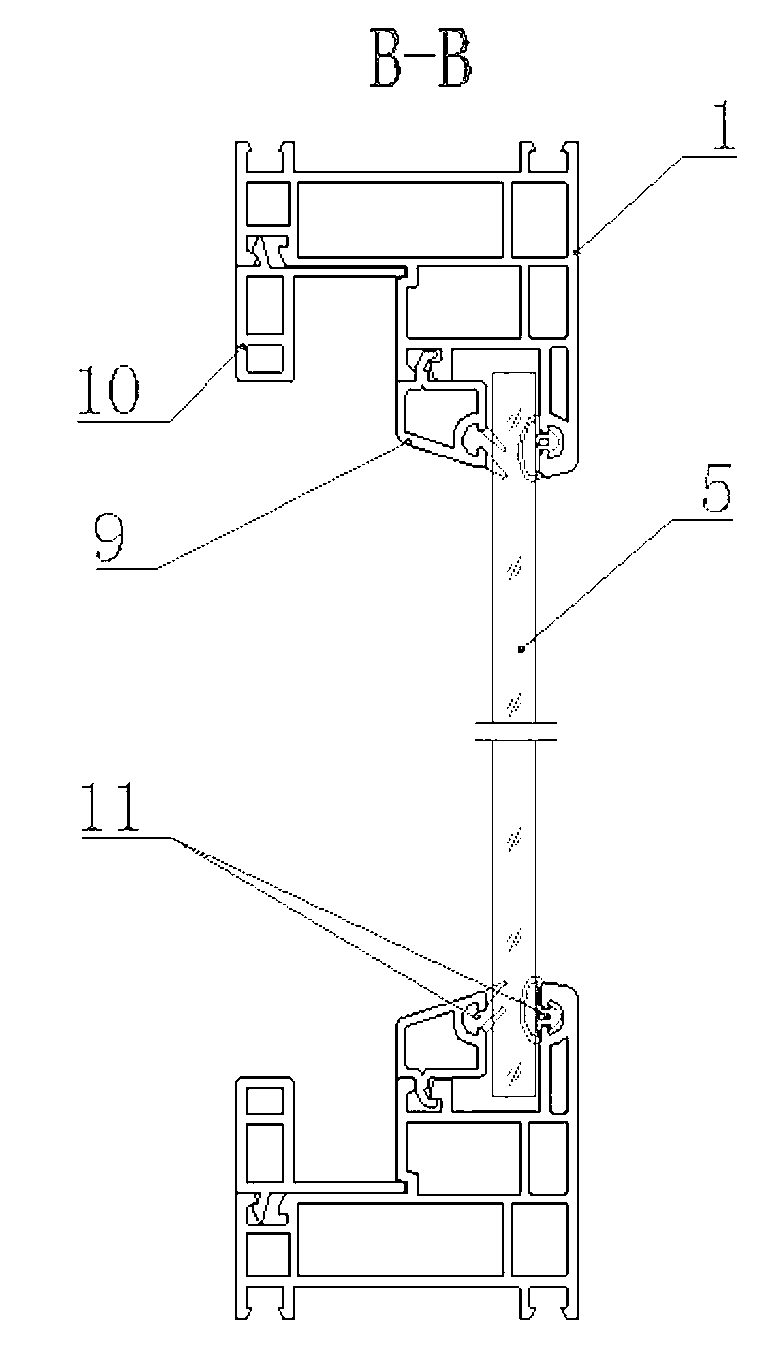

Novel single-leaf push-pull sealing window with welded mullion and manufacturing method of novel single-leaf push-pull sealing window

ActiveCN102704802APrevent insertionDoes not affect push and pull movementInsect protectionWindow/door framesPush pullEngineering

The invention discloses a novel single-leaf push-pull sealing window with a welded mullion and a manufacturing method of the novel single-leaf push-pull sealing window. The novel single-leaf push-pull sealing window is characterized in that the mullion is welded with cross frames which are welded with vertical frames so as to form two rectangular grids; the outer half parts of the inner circumferential surfaces of the two rectangular grids are provided with fixed layers, and are respectively and fixedly provided with glass and screen sashes; the inner half parts of the two cross frames are provided with split sash rails, and the inner half parts of the two vertical frames are provided with convex rails which are correspondingly consistent to the sash rails and are integrated with the vertical frames; the sash rails and the convex rails are combined and butted to form a square-shaped grid which is internally provided with a push-pull sash, so that a push-pull layer is formed; and a sealing wool strip is respectively arranged between the outer side of the push-pull sash and the upper and the lower fan rails and between the outer side of the push-pull sash and the convex rails of one vertical frame adjacent to the vertical frame provided with the screen sashes. The invention has the advantage that the defects that the gaps formed between the sash and the sash and at the connecting positions of the upper-lower opposite parts and the frames are difficultly sealed, the parallel sizes of the upper and the lower horizontal frames are difficultly guaranteed to be consistent due to no support, the thicknesses and the shapes of the sashes are larger, the quantity of the sashes is more, the raw materials are wasted and the cost is high are overcome.

Owner:长治市悦弘门窗型材有限公司

Guide rail photographing device

The invention relates to a guide rail photographing device. The guide rail photographing device comprises a support. A rotating plate is connected to the support through a first sliding mechanism in aleft-right or front-back sliding mode. A case is connected to the rotating plate rotationally. An operating platform is fixedly connected to the case. A fine adjustment mechanism for mounting a camera is connected to the upper end face of the operating platform through a second sliding mechanism in a left-right or front-back sliding mode. A photographing hole is formed in the support. A combinedlight source is arranged on each of two sides of the photographing hole. The guide rail photographing device has the advantages that the regional guide rail space design is adopted, and three-dimensional accurate adjustment and positioning can be achieved through guide rail sliding during 360-degree rotation, so that accurate photographing is guaranteed, photographed pictures are not deflected anddeformed, and vignetting is avoided.

Owner:JIANGXI HOLITECH TECH

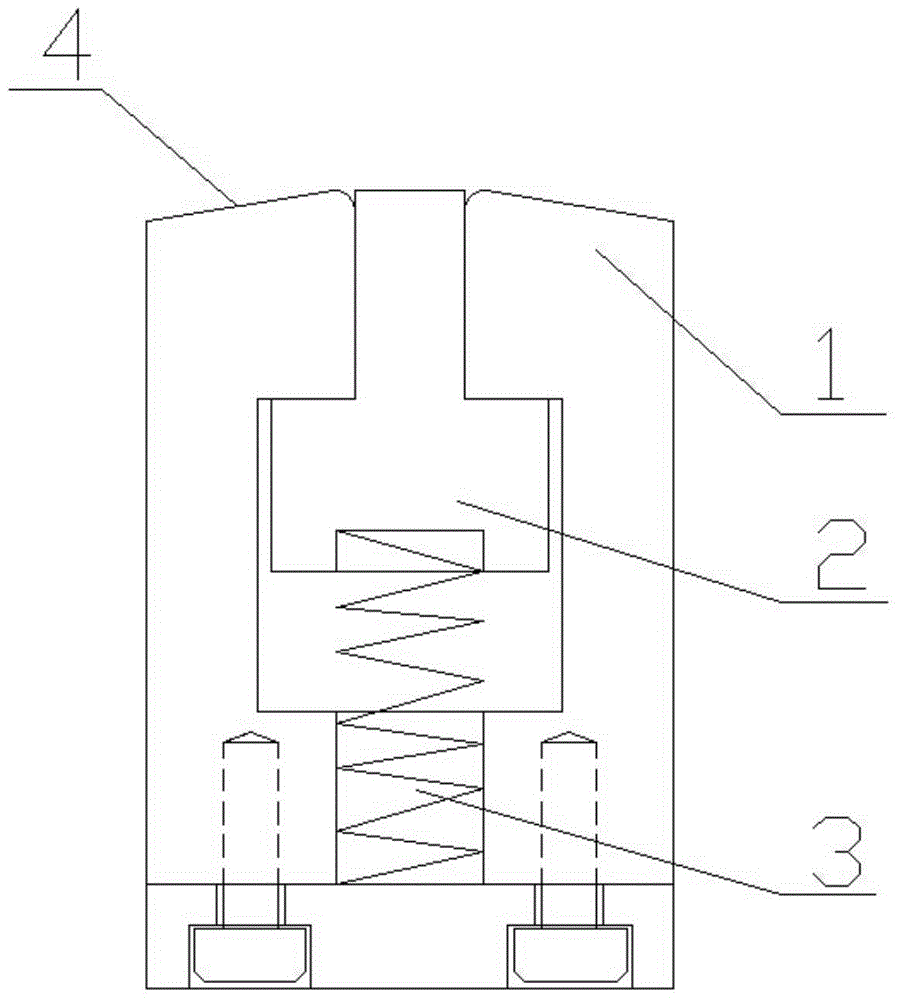

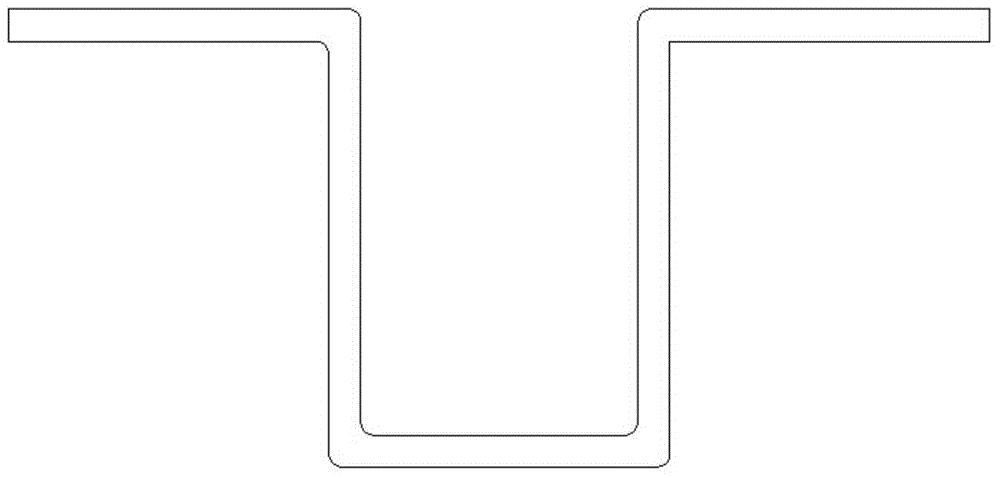

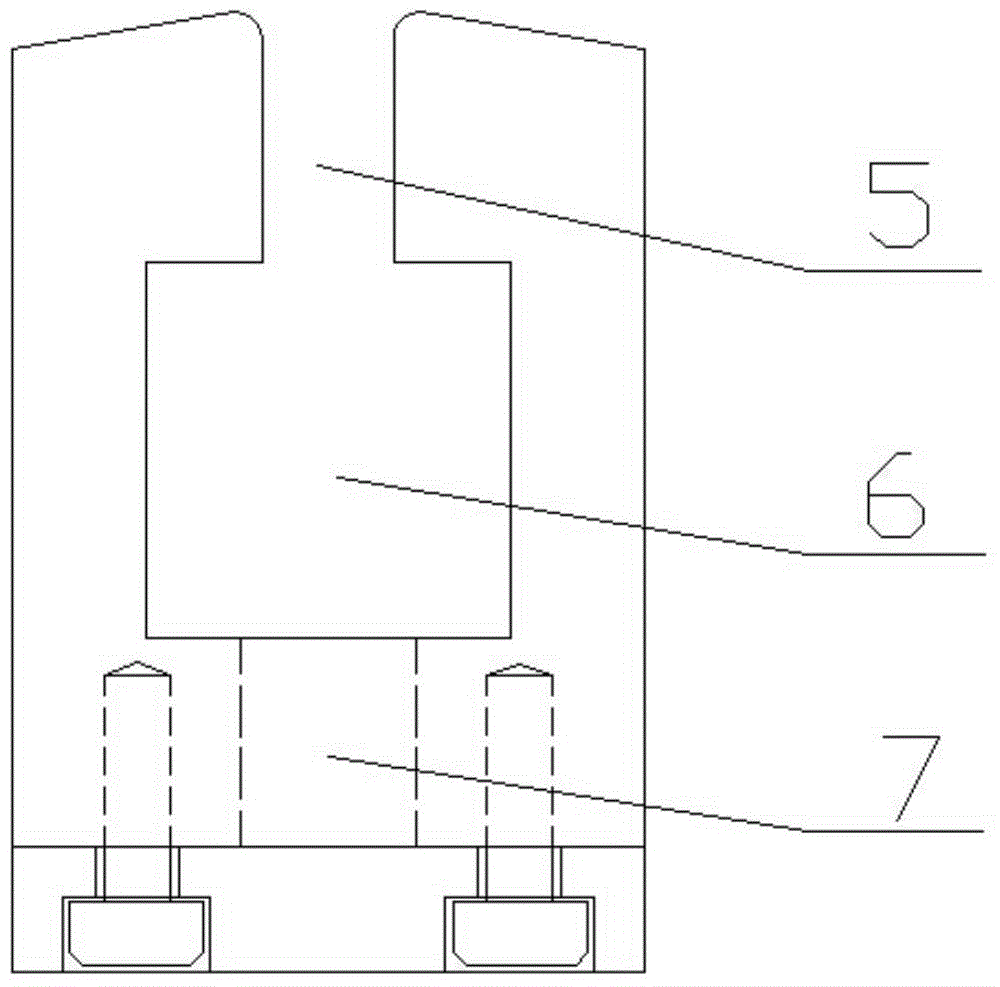

Bending lower die for bending machine and manufacturing method for bending lower die

ActiveCN104475582ACause some damagesNo deformationShaping toolsEjection devicesEngineeringInverted-T shape

The invention discloses a bending lower die for a bending machine and a manufacturing method for the bending lower die and belongs to the field of bending machines. The invention solves the problems that the precision is low when a large-depth U-shaped workpiece with a planar bottom surface is machined and the workpiece after machining is difficultly disassembled and taken and is easy to damage in the prior art. The bending lower die comprises a lower die base, a die bottom convex piece and an unloading spring; the lower die base is sequentially provided with a first cavity, a second cavity and a spring cavity from top to bottom; the spring cavity is formed on the bottom surface of the second cavity; the cross section of the die bottom convex piece is an inverted T shape; the die bottom convex piece is arranged in the second cavity; one end of the die bottom convex piece extends into the first cavity, and the other end of the die bottom convex piece is connected with the unloading spring; the unloading spring is arranged in the spring cavity. The U-shaped workpiece with the planar bottom surface can be machined at high precision by the bending lower die, and the bending lower die has the advantages of simple structure, reasonable design and easy manufacture.

Owner:ANHUI LIYUAN NUMERICAL CONTROL CUTTING TOOL & PATTERNS MFG

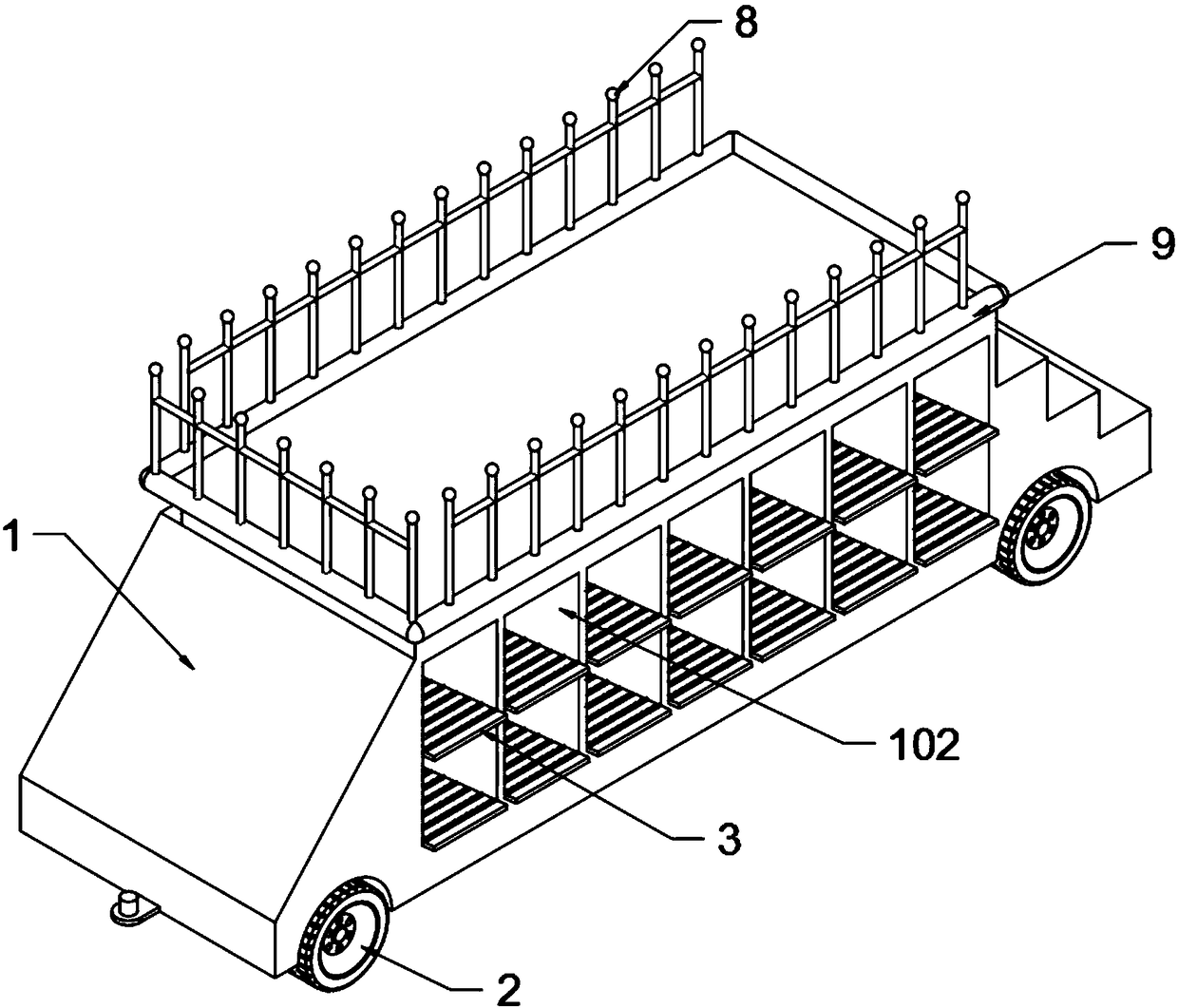

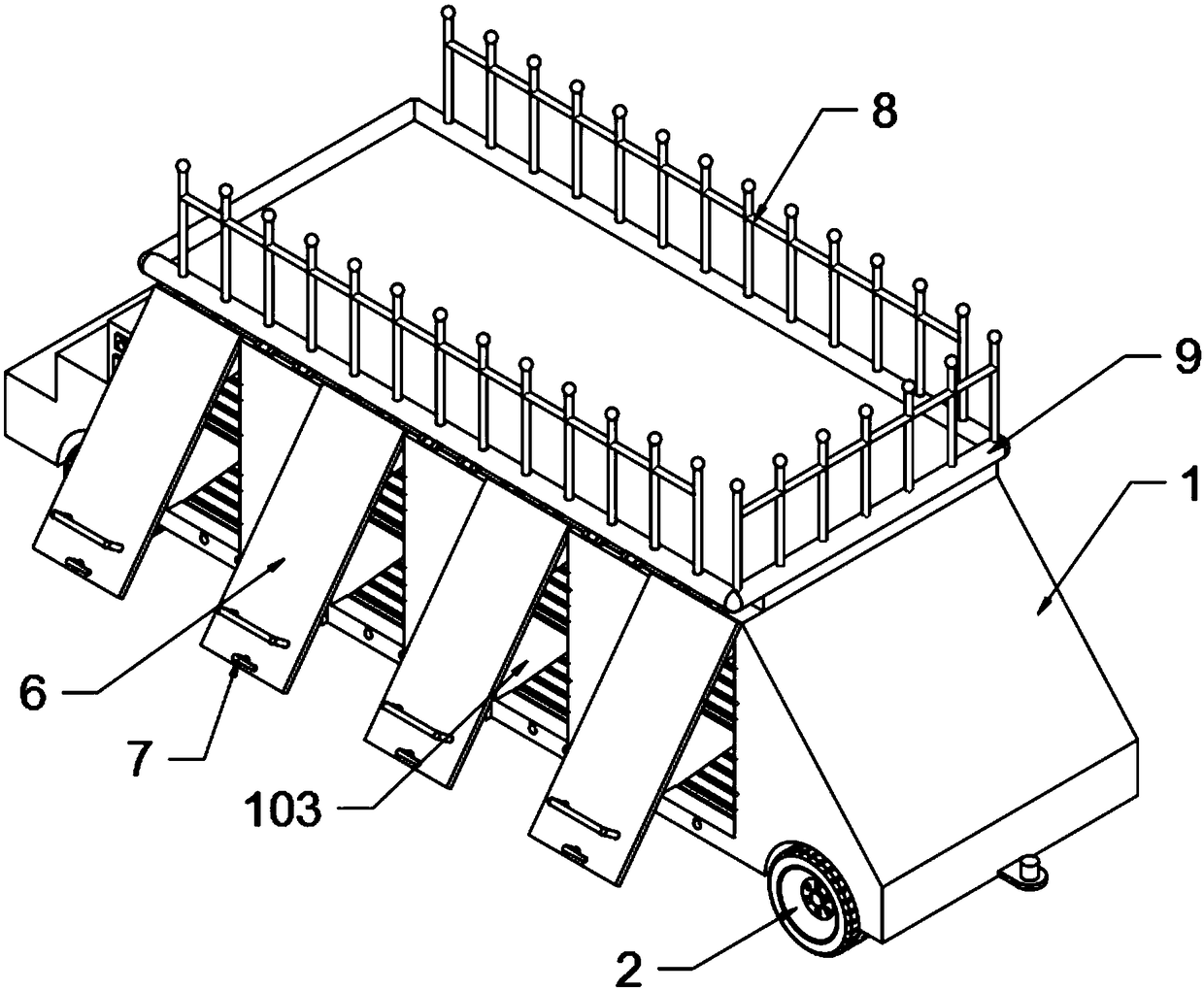

Mobile luggage carrying device for air transportation

InactiveCN109229416AGuaranteed RegularityAffect the protective effectVehicle with rollersFreight handling installationsPulp and paper industryAir transport

The invention provides a mobile luggage carrying device for air transportation, which comprises a lighting switch and a battery; The vehicle body is of a hollow structure, and seven storage openings are arranged on the left end face of the vehicle body, and seven unloading openings are arranged on the right end face of the vehicle body; 7 loc holes are arrange at that bottom of the end face of theright end of the vehicle body, and one end of the handle is inserted into the inside of the locking hole; The wheels are arranged in two groups, and the wheels are respectively arranged at the frontand rear ends of the bottom ends of the vehicle body; A load plate is arrange inside that vehicle body, and ten supporting shaft are distributed on the top end face of the load plate; The ball is arranged on the support shaft, and the top of the ball is higher than the top end face of the bearing plate; 7 door are arranged in total, and that door is arrange on the right end face of the vehicle body, and the handle is rotatably connected with the bottom of the vehicle door; The invention is advantageous in partitioning the luggage boxes stored in the device, separating the luggage boxes in thedevice from each other, ensuring the regularity between the luggage boxes, and facilitating the post-unloading operation of the personnel.

Owner:杨佳魏

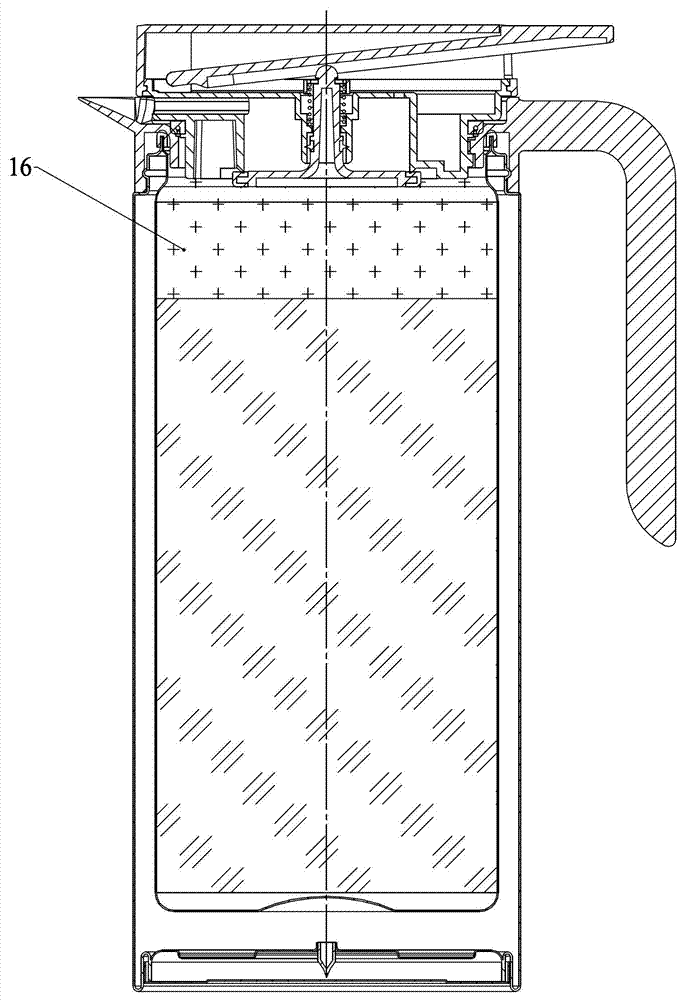

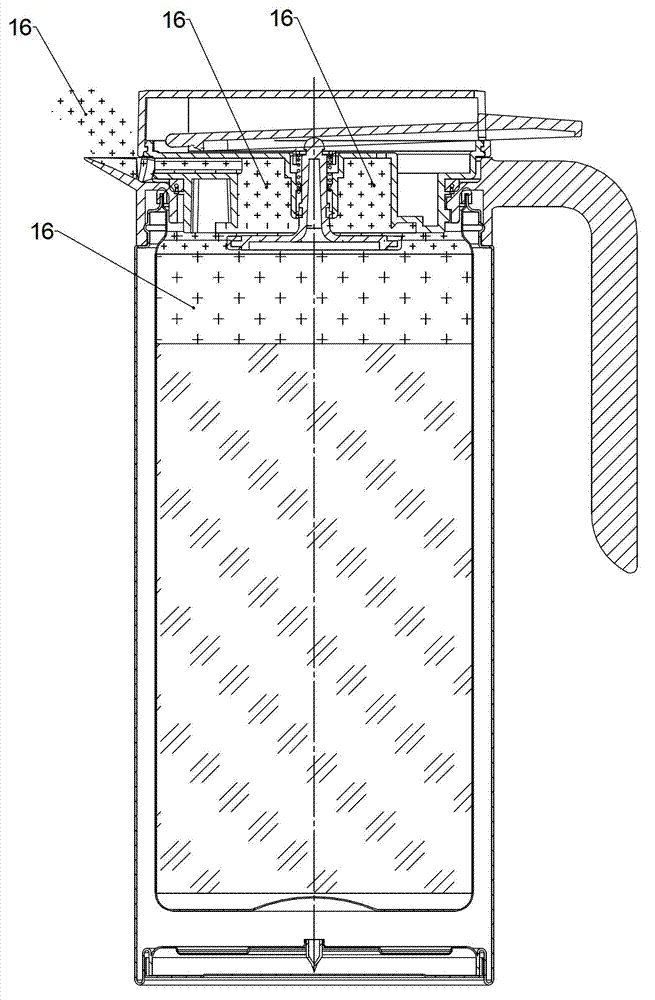

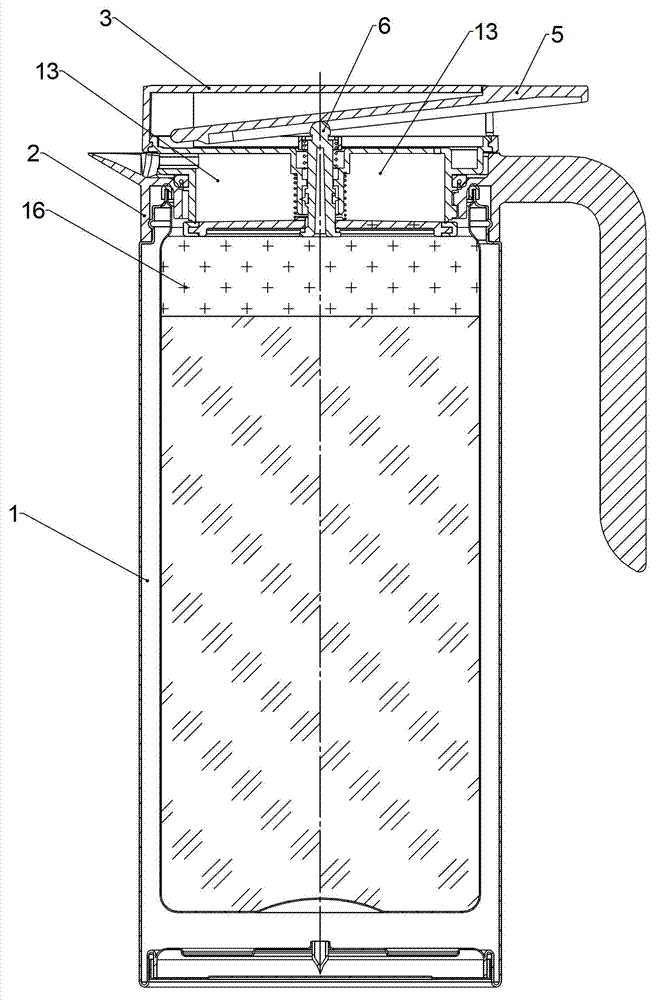

Steam-proof vacuum pot and pot lid thereof

The invention relates to a steam-proof vacuum pot and a pot lid thereof. The steam-proof vacuum pot comprises a pot body and a pot lid, wherein an water outlet control plug of the pot lid comprise a plug body, a mandrel control unit and a button; a main spring of the mandrel control unit is sleeved at the upper part of a mandrel and is limited between an inner limiting barrel of a core barrel and a spring end cover which is arranged on the upper end of the mandrel; the lower end of the mandrel is provided with a gap and a sealing ring; when the mandrel slips downward along a sealing end cover through the elasticity of the main spring, the sealing ring is separated from the sealing end cover and the steam in the port is communicated with a steam release chamber through the gap, so that a steam release structure is formed; a buffer spring is sleeved outside the barrel body of the core barrel and is arranged between a limiting shoulder outside the barrel body of the core barrel and the upper side of the sealing end cover; the mandrel control unit drives the sealing end cover to move downward through the elasticity of the buffer spring so as to form a water outlet control structure. The steam-proof vacuum pot and the pot lid have the advantages of saving labour in control, safety and scald protection.

Owner:揭阳市兴财实业有限公司

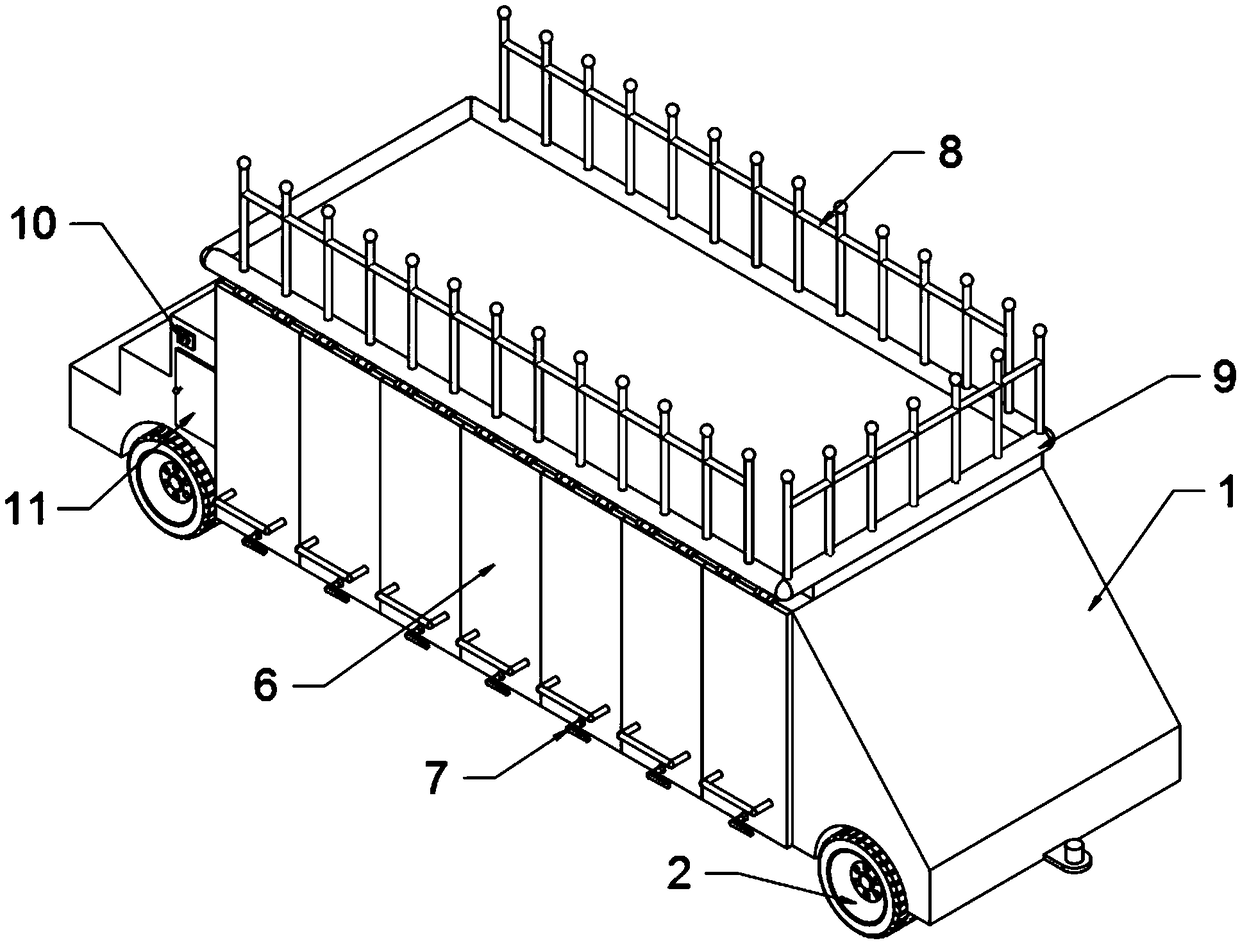

Construction device and method for large-span steel girder frame connection platform

The invention discloses a construction device and method for a large-span steel girder frame connection platform. The device comprises a trolley (1) and operation baskets (2), wherein the top of the trolley (1) is connected with the tops of the operation baskets (2) through a winch (3); a guide rail (6) is arranged at the bottom of each operation basket (2); each guide rail (6) is provided with a second electromagnet and a third electromagnet (8). The method is characterized in that the trolley (1) and the two operation baskets (2) form a tripod-like structure and clamp a main girder (9) or a secondary girder unit to move at a normal section of the main girder (9) or the secondary girder unit; when the trolley (1) arrives at each node, the operation baskets (2) are lifted through the winch (3) so that the operation baskets (2) can be flush with the bottom face of the trolley (1) and pass through the node. By means of the construction device and method, consumption of steel tubes and fasteners can be reduced, construction cost and labor intensity can be lowered, operation is convenient and fast, the construction period is shortened, the construction space below the platform is not occupied, and potential safety hazards are eradicated.

Owner:浙江浙建钢结构有限公司

Travel sunshade umbrella bracket convenient to carry

The invention relates to the technical field of travel goods, and discloses a travel sunshade umbrella bracket convenient to carry. The bracket comprises a fixing pipe, a sliding groove is formed in the right side of the fixing pipe, a sliding rail is fixedly installed on the inner wall of the fixing pipe, the inner wall of the fixing pipe is fixedly connected with a fixing plate, and a first bearing is embedded in the inner wall of the fixing plate. According to the travel sunshade umbrella bracket convenient to carry, by arranging a threaded sleeve, under the function of a threaded rod, an umbrella frame can be adjusted up and down and effectively extended or retracted, the size is smaller, the occupied area is small, and a user can carry the bracket conveniently; by arranging a fixationbase, a support rod can be extended or retracted under the function of a spring, the falling speed of the fixing pipe is effectively reduced, it is ensured that a sunshade umbrella keeps stable underthe condition of air blowing or external force, the travel comfort degree of the user is improved, and the good mood of the user is ensured.

Owner:镇江市华铖旅游用品有限公司

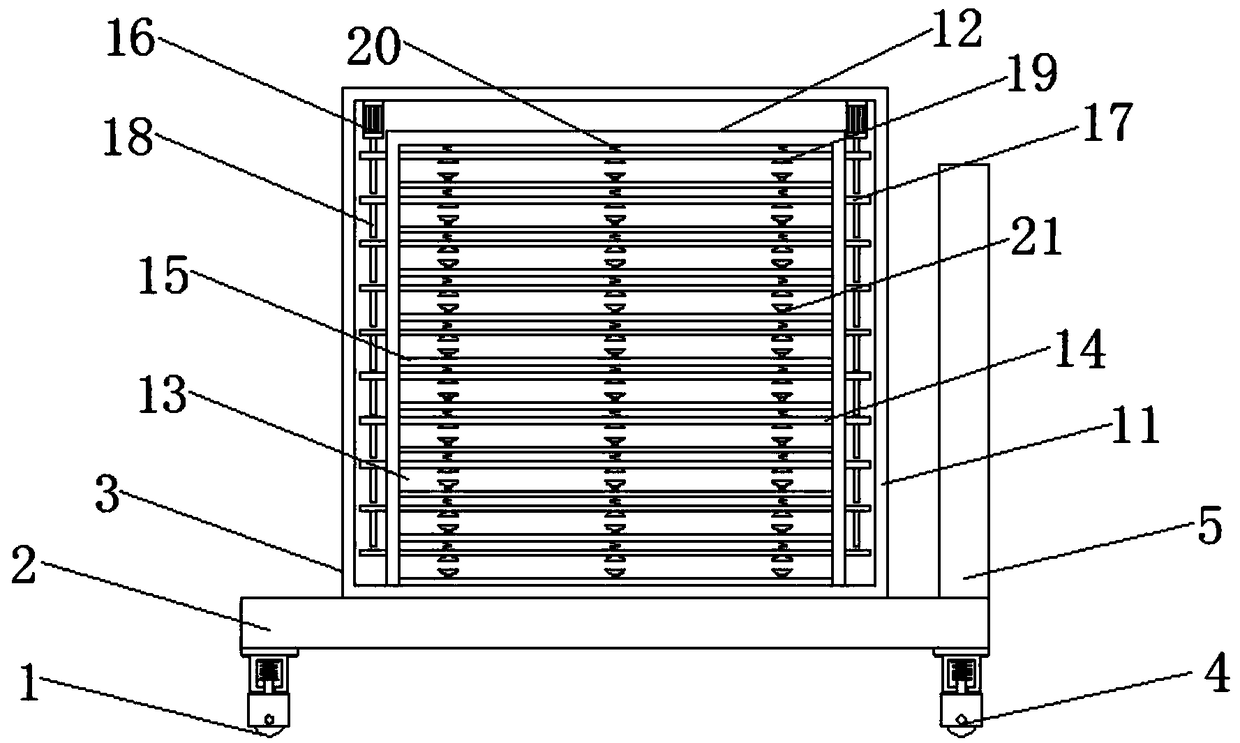

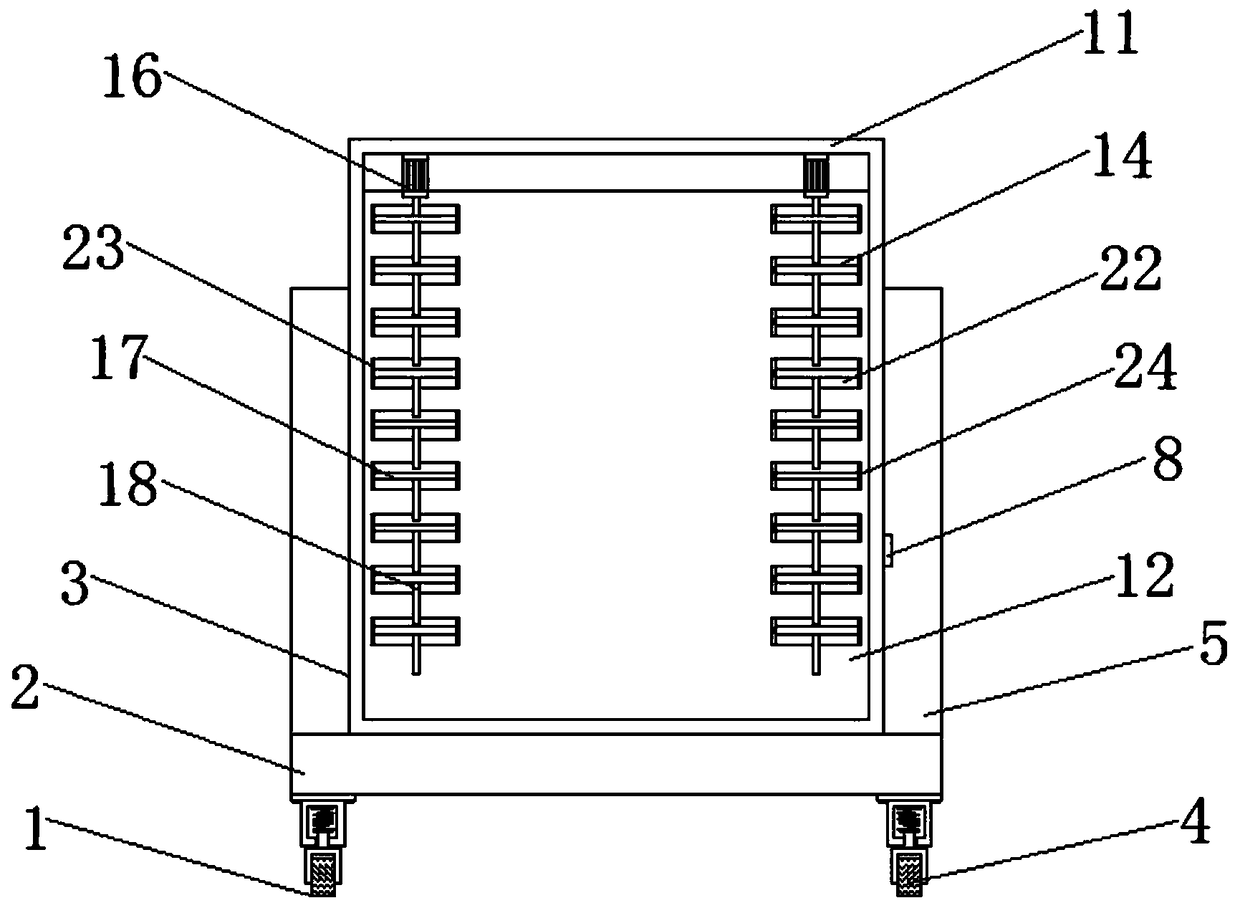

Energy-saving material stacking and carrying device

ActiveCN109229166AEasy to observeEasy to adjust freelyHand carts with multiple axesHand cart accessoriesCasterEnergy analysis

An energy-saving material stacking and carrying device is disclosed. A base is arranged at the bottom of the device body, A carrier tank is mounted on the top of the base, A tank door is mounted on the front side of the tank, the outer side of the carrier tank is provided with a housing, At both end of that top end of the housing are mount electric pushrods, A placement chamber is mounted on the inner side of the housing, a receiving groove is provided inside the placing chamber, A moving plate is mounted on the top end of the receiving groove, a first suction cup is mounted on the bottom endof the moving plate, both ends of the moving plate are provided with convex plates, a fixing plate is mounted on the bottom end of the receiving groove, A cushion is mounted on the top end of the fixing plate, Support rods are mounted on both sides of one end of the base, the top end of the strut is hinged with a folding handle, The bottom of the base is provided with a shock-absorbing caster wheel, and the top of the moving plate is provided with a plurality of expansion springs, which are flexible in expansion and contraction, convenient for moving the moving plate, and convenient for free adjustment of the space of the accommodating groove to install energy-saving glass with different thicknesses, thus widening the applicable range of the device body and improving its practicability.

Owner:诸暨市众创机械设备厂

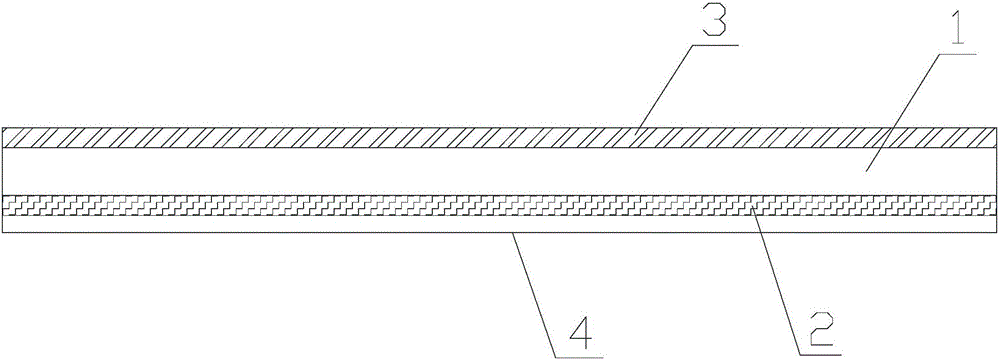

Polytetrafluoroethylene foot pad for computer mouse and preparation method thereof

ActiveCN106183280ALow sliding resistanceFlexible slidingLamination ancillary operationsSynthetic resin layered productsWater contactRoughcast

The invention relates to a polytetrafluoroethylene foot pad for a computer mouse and a preparation method thereof. A foot pad body is made of a polytetrafluoroethylene sheet, an activating treatment layer is arranged at the surface of the foot pad body, and an adhering layer is arranged at the surface of the activating treatment layer; a PE (polyethylene) protective film is arranged at the lower surface of the polytetrafluoroethylene sheet. The preparation method of the polytetrafluoroethylene foot pad comprises the following steps of (1) material fixing, color matching, and screening; (2) manufacturing of a blank; (3) sintering; (4) turning; (5) surface activating treatment; (6) flattening; (7) film coating. The water contact angle of the activating treatment layer is greater than 15 degrees and is smaller than 45 degrees. The polytetrafluoroethylene foot pad for the mouse prepared by the preparation method has the advantages that the sliding resistance is small, the abrasion-resistant property is realized, and the mouse can be flexibly, quickly and smoothly slide at the surface of any object; the moving speed higher than 4.19m / s can be reached at the surface of common cushion pad, each action can be accurately recorded, the comfortability in use is realized, and the control is accurate.

Owner:JIANGSU TAIFULONG TECH

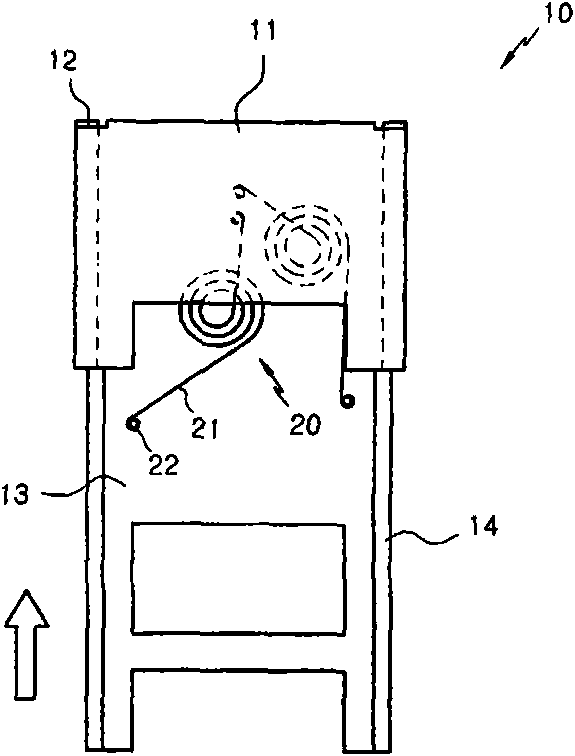

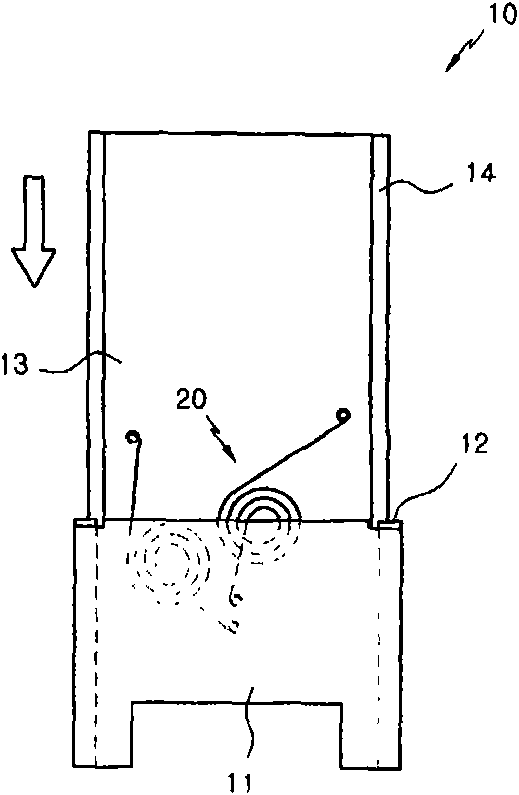

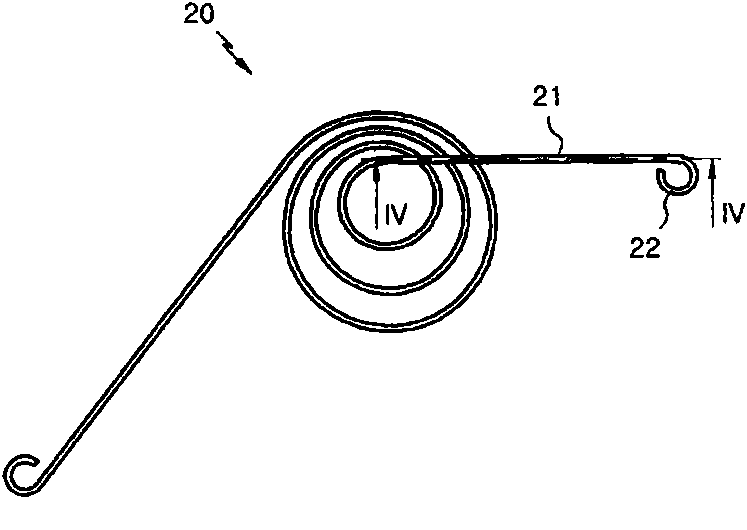

Spring for a slide module, and slide module using same

InactiveCN101854405AFlexible use of swipe operationStability and durabilityTorsion springsTransmissionLine segmentStructural stability

The present invention relates to a spring for a slide module, which is applied to a small terminal having a slide module and a electrical line such as a data line or a power line penetrating therethrough, such as a portable communication terminal operating in a sliding system, to reduce the thickness of the terminal employing the spring, and wherein said spring has a structural stability to maintain the elasticity or shape thereof in a good condition, and to thus smoothly assist in the sliding motion of the terminal over a long period of time. The spring for a slide module according to the present invention couples units of a slide-type portable terminal operating when supplied with power such that the units are slidable relative to one another, and comprises a coil unit and a pair of leg units. The coil unit includes an interconnection portion, and a first coil and a second coil which are stacked into layers, in such a manner that at least a portion of the first coil and at least a portion of the second coil are out of line when viewed from the front of the circle of the layer to enable the circle of the layer of the first coil and the circle of the layer of the second coil to have different centers. The leg units are extended in opposite directions, from each end of the first coil and the second coil, and the extended ends of the leg units are rotatably coupled to the slide module. The coil unit and the leg units are formed into a shape in which two sides facing each other are parallel to each other, and the segment perpendicularly interconnecting said two sides has a length shorter than that of any one of said two sides in the cross-section in the thickness direction of the shape.

Owner:郑义先

Medical test tube cleaning device

InactiveCN106733983AAvoid breakingInefficient scrubbingHollow article cleaningMotor driveMedical equipment

The invention provides a medical test tube cleaning device and relates to the field of medical equipment. The cleaning device comprises a frame assembly, a spacing adjusting mechanism, a cleaning mechanism and a supply mechanism, the cleaning mechanism and the supply mechanism are mounted on a frame of the frame assembly, the supply mechanism slides on the frame, the cleaning mechanism is arranged under the supply mechanism, a screw-nut pair is arranged between the supply mechanism and the cleaning mechanism, and a stepping motor drives a screw on the screw-nut pair to rotate. A plurality of guide rods are arranged between the supply mechanism and the cleaning mechanism, and the spacing adjusting mechanism is arranged on a baseplate. A test tube holding plate is mounted on the spacing adjusting mechanism, a test tube holder is arranged on the test tube holding plate, and a test tube is placed in the test tube holder. Through the cleaning device, the problems that scrubbing efficiency is low in the medical test tube cleaning process and the motor rotates to drive the whole device to shake resulting in test tube breakage can be solved.

Owner:谷新运

Sewage purification equipment convenient for disassembly and assembly

InactiveCN107758764AEasy to assemble and disassembleFlexible slidingTreatment involving filtrationWater/sewage treatment apparatusSewageFresh water

The invention discloses a sewage purification equipment which is easy to disassemble and assemble, which comprises a purification equipment body, two purification boxes are placed inside the purification equipment body, and fixing plates are placed on the front and back of each purification box, and each fixing plate The side of the plate away from the purification box is fixedly connected with the inner wall of the purification equipment body, and the side of each fixed plate close to the purification box is provided with a clamping groove. The sewage purification equipment that is easy to disassemble can fix the clean water tank by setting a purification box inside the sewage purification equipment body, and setting locking rods and connecting rods on both sides of the clean water tank. Under the action of the groove and the clamping block, the clean water tank can be flexibly slid inside the water purification equipment body, which can make the water purification equipment body easy to disassemble and improve work efficiency. Equidistantly arranged drainage holes are provided at the bottom of the clean water tank, which facilitates the purification and treatment of sewage.

Owner:江苏天康光电缆仪表有限公司

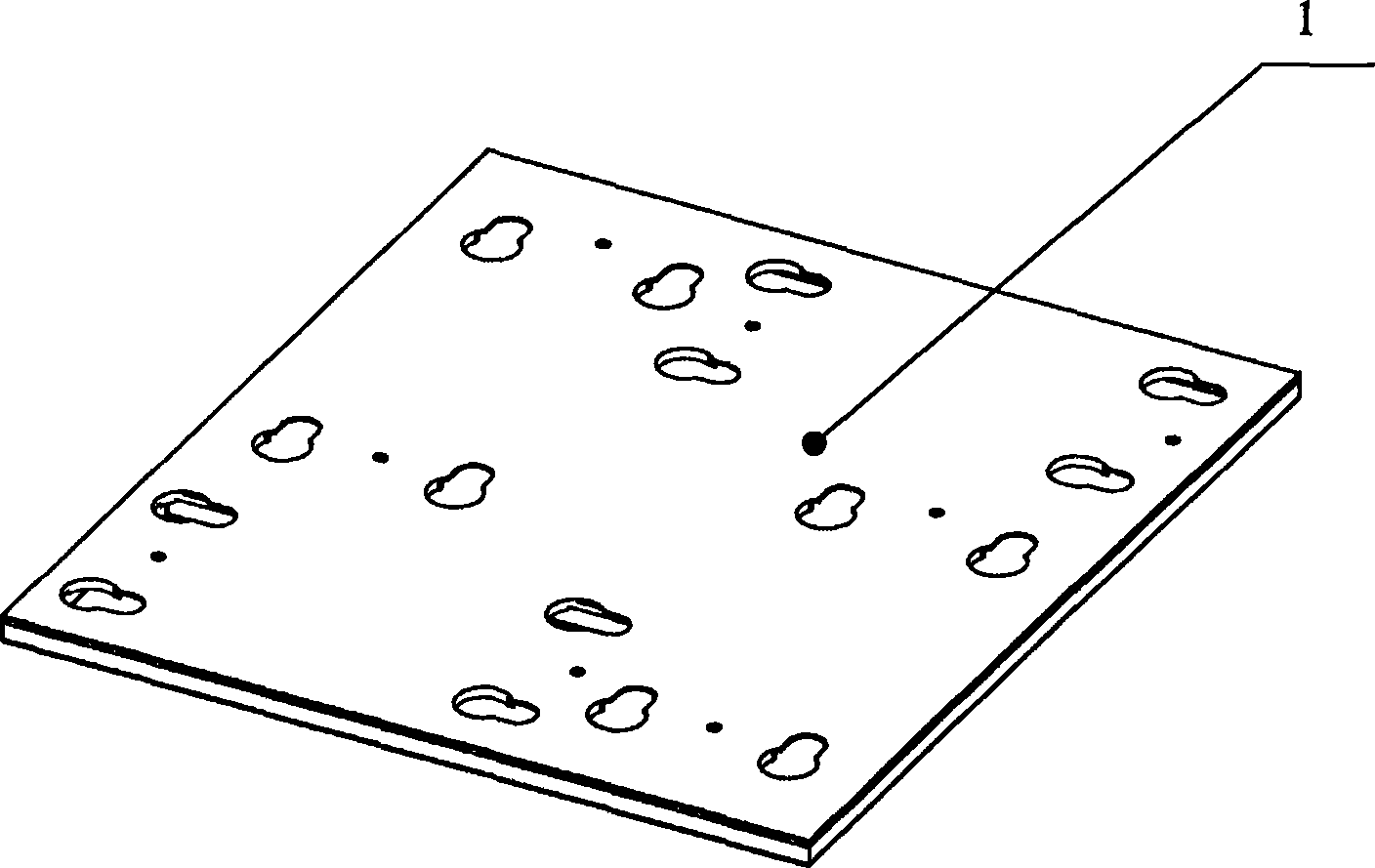

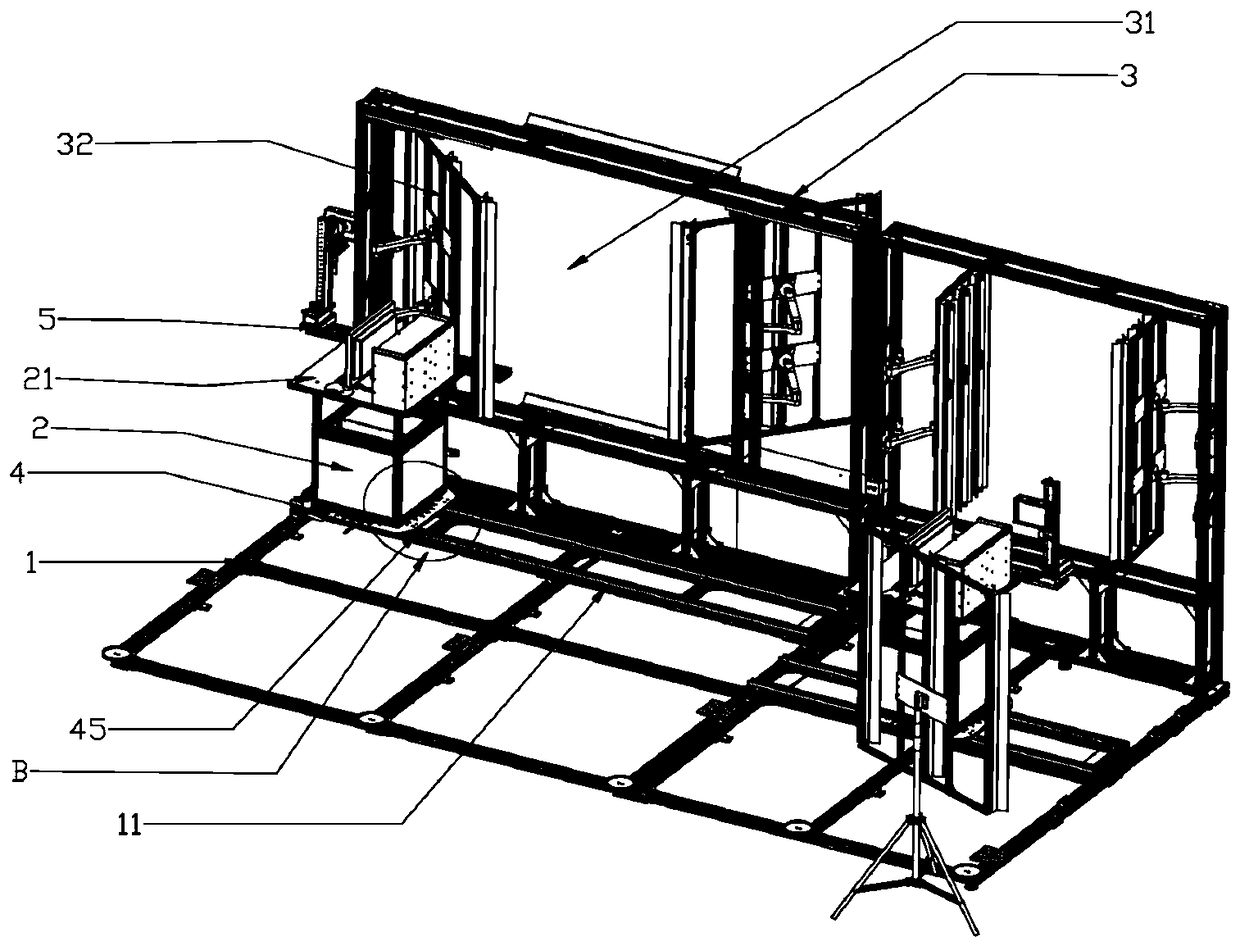

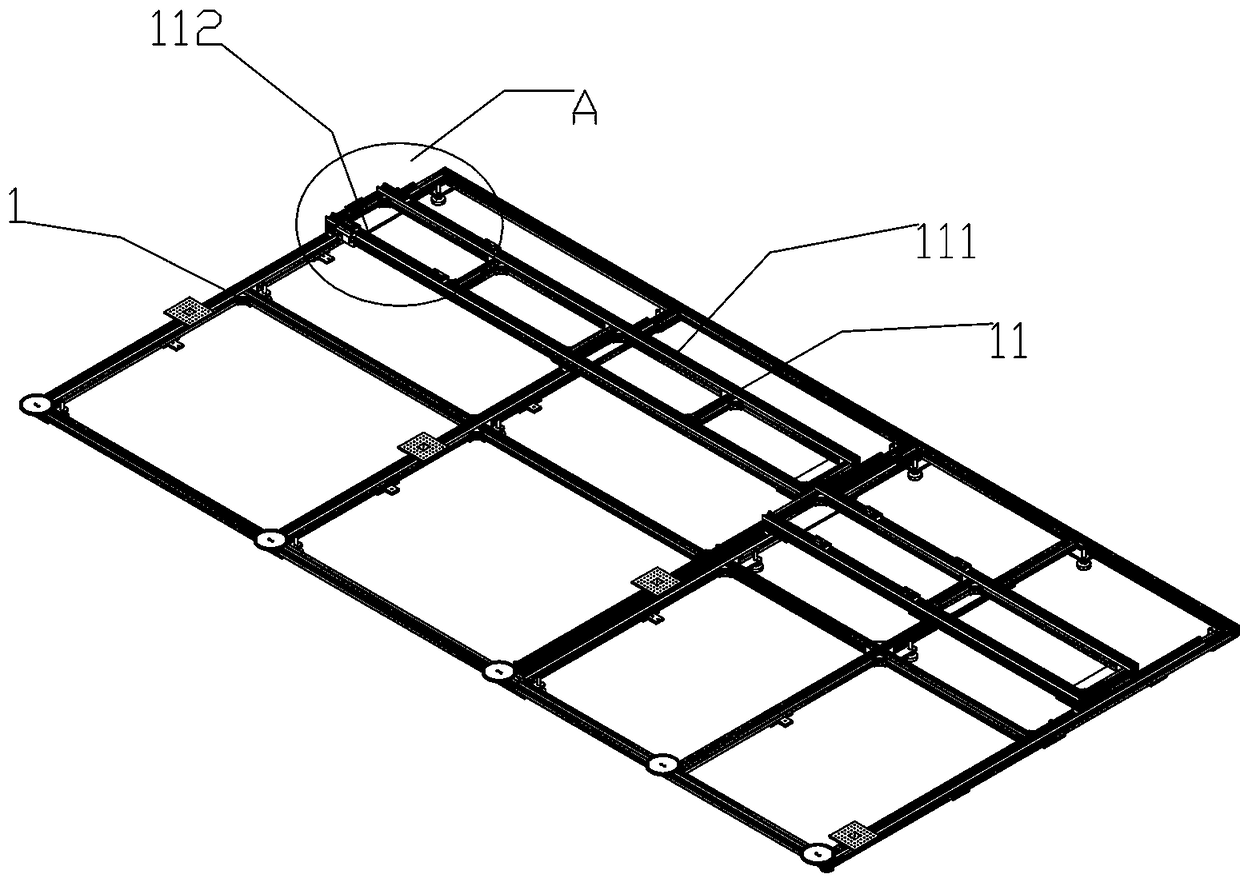

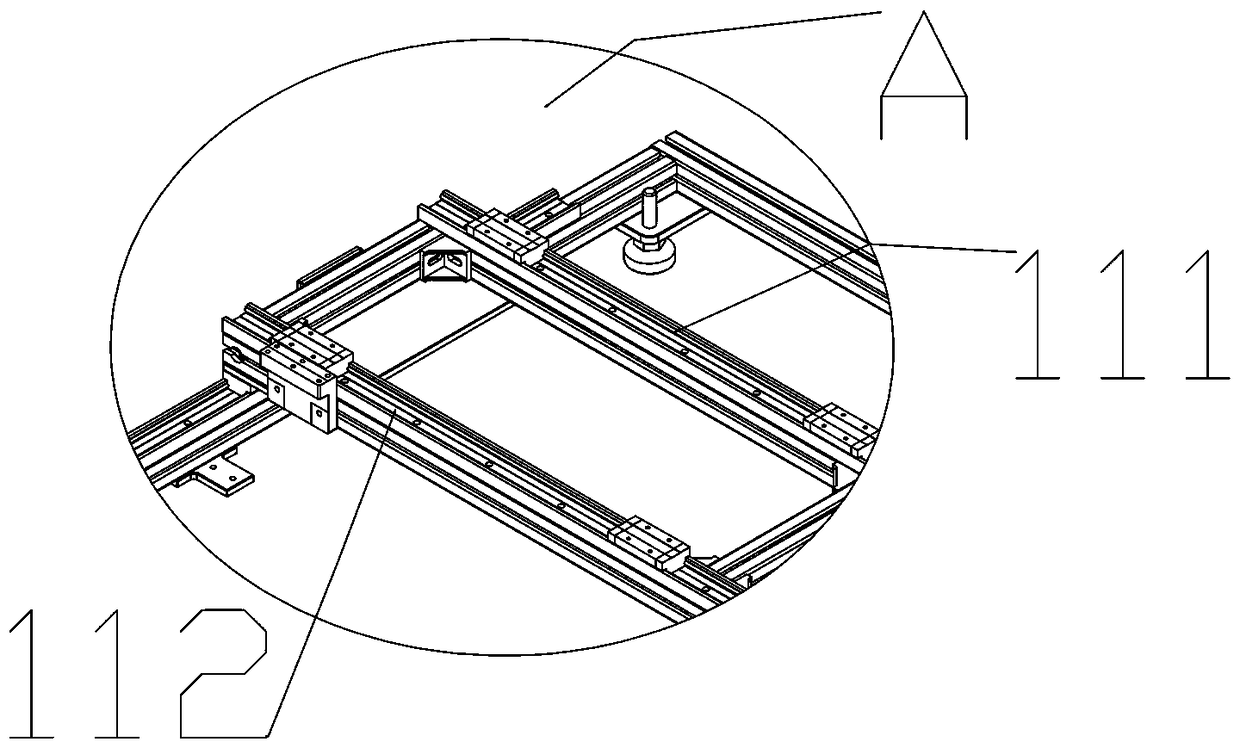

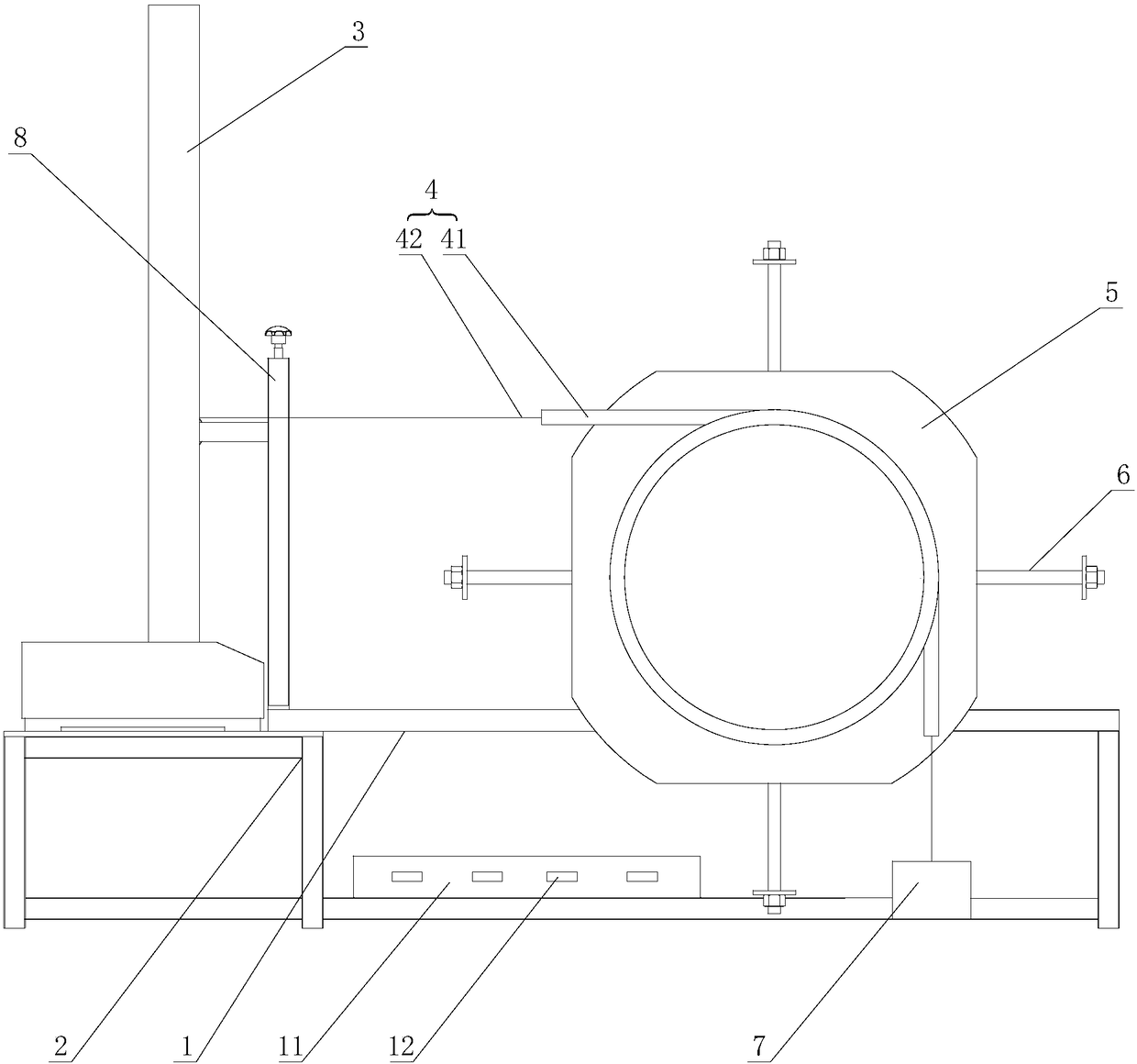

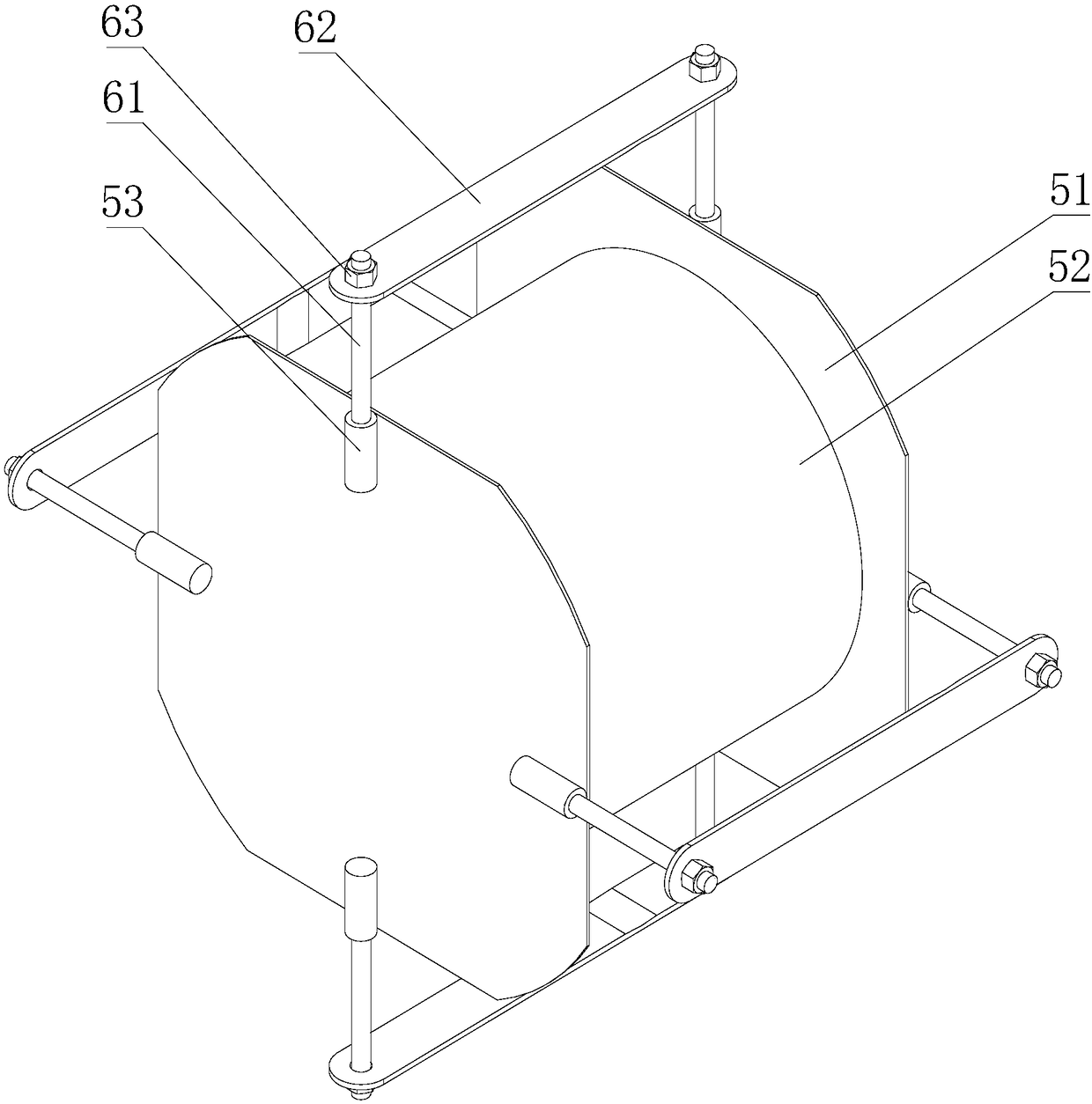

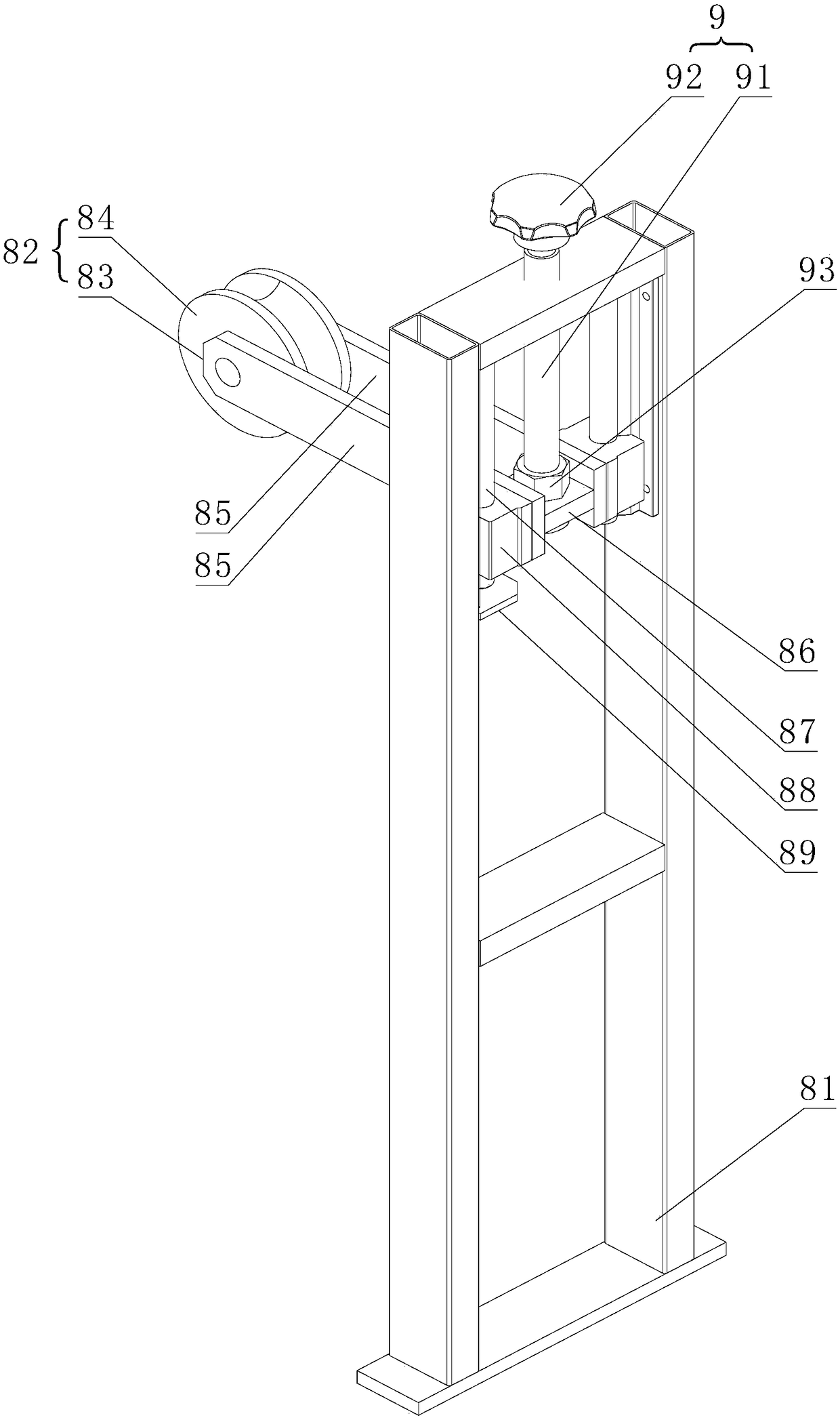

Device for testing dynamic friction coefficient

PendingCN108120669AReduce work intensityGood reliabilityUsing mechanical meansMaterial analysisDynamical frictionFixed frame

The invention relates to a device for testing a dynamic friction coefficient. The device comprises a fixed frame, a worktable, a tensile testing machine and a sample, wherein the sample comprises a fixed part and a movable part, a round drum mechanism for being wound with the fixed part is arranged on the fixed frame, a compression assembly is arranged on the round drum mechanism, a weight connected with one end of the movable part is arranged on the fixed frame, and the other end of the movable part is connected with the tensile testing machine. The device has the advantages that the round drum mechanism is wound with the fixed part in the sample, the movable part is pulled to move in the fixed part through the tensile testing machine, and the dynamic friction coefficient between the movable part and the fixed part is calculated according to an average tensile load measured in a tensile testing process, the gravity of the weight connected to one end of the movable part and the windingangle of the fixed part on the round drum mechanism, and the dynamic friction coefficient among samples can be accurately calculated; and the working intensity is low, the reliability of a sample testing result is good, and the sample testing efficiency can be increased.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST +2

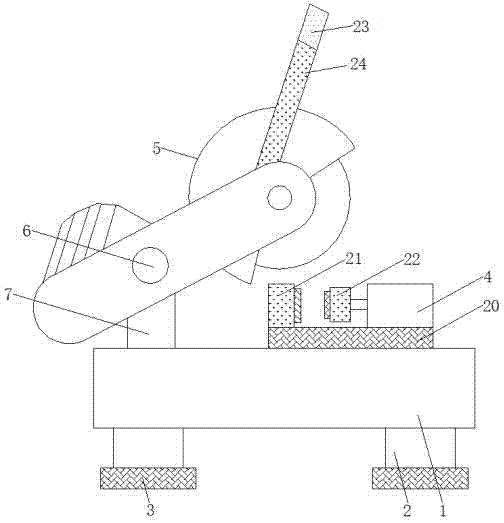

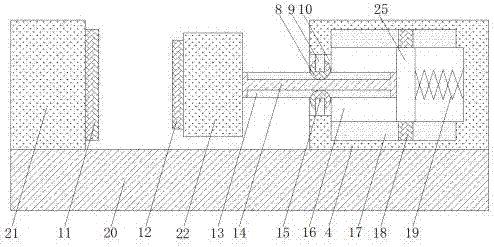

Automobile component processing cutting equipment with clamping function

InactiveCN107442841AAvoid shaking or droppingGood clamping performanceShearing machinesShearing machine accessoriesPulleyEngineering

The invention discloses a cutting device for processing automobile parts with a clamping function, comprising a base, a support rod is fixedly connected to the left side of the upper surface of the base, and the top end of the support rod is fixed and hinged to a cutting machine body through a first pin shaft . The cutting equipment for automobile parts processing with clamping function is provided with a strong spring and a connecting rod inside the cavity, and under the action of the clamping groove and the clamping block, the connecting rod and the connecting rod can be pushed by the elastic force of the strong spring. The second fixed block presses against the first fixed block, which can clamp and fix the auto parts, effectively avoid the shaking and falling of the auto parts, and have good clamping performance. groove, and a pulley matching the chute is set inside the through hole, which can make the connecting rod slide flexibly inside the through hole, thus ensuring the clamping of the first fixed block and the second fixed block to the automobile parts, effectively It guarantees the processing quality of auto parts.

Owner:JIANGYIN YONGCHANG TRAFFIC MACHINERY PARTS

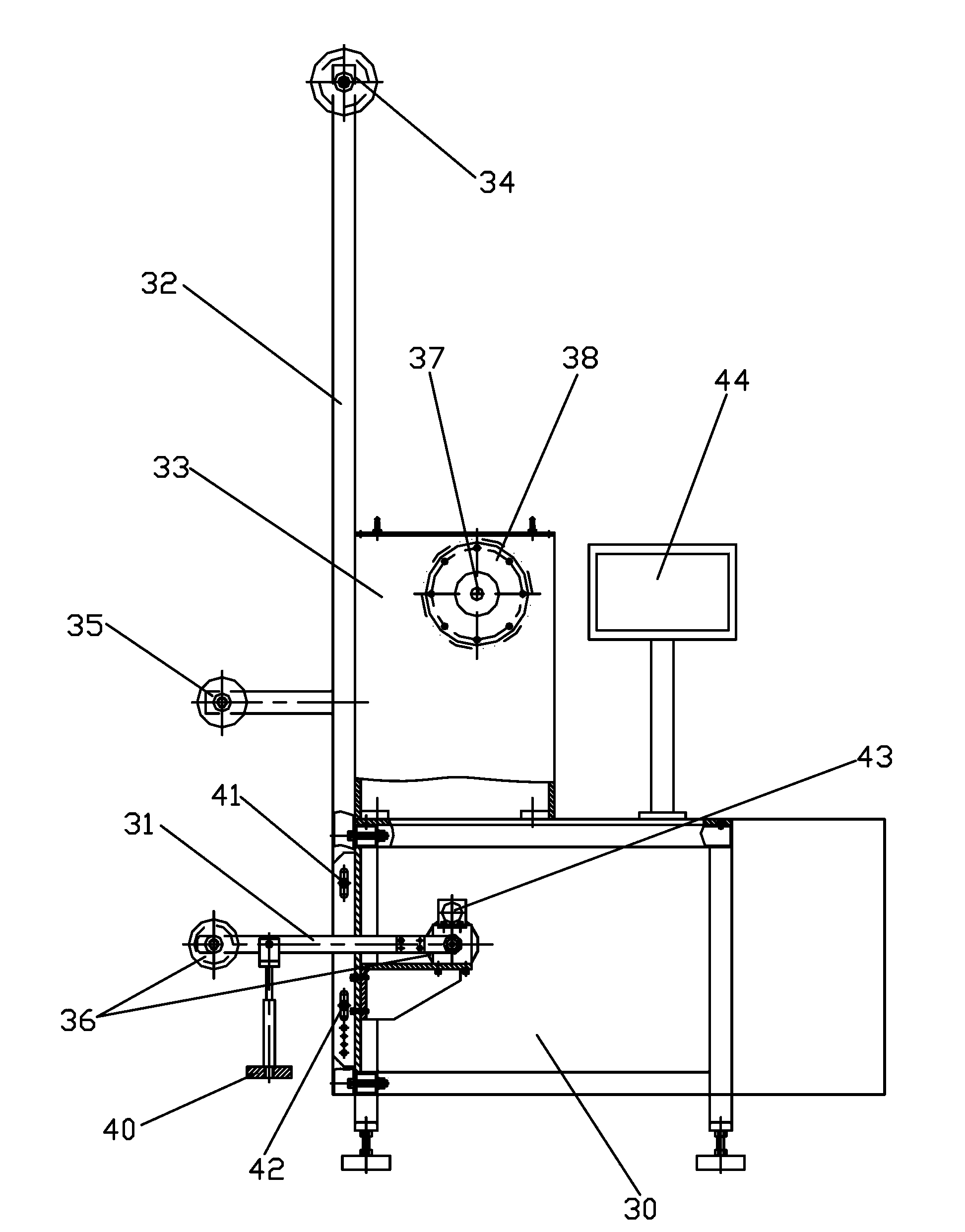

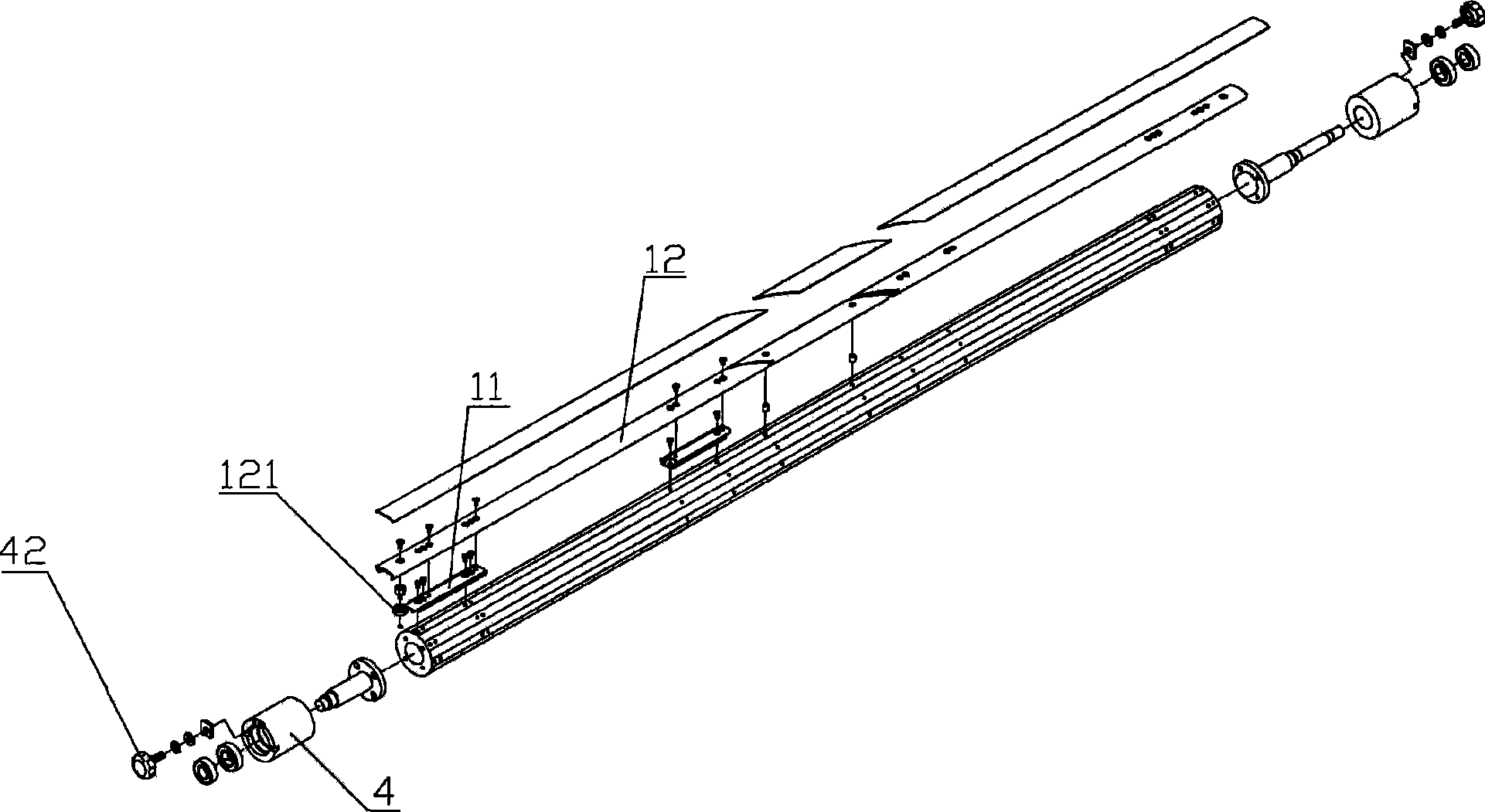

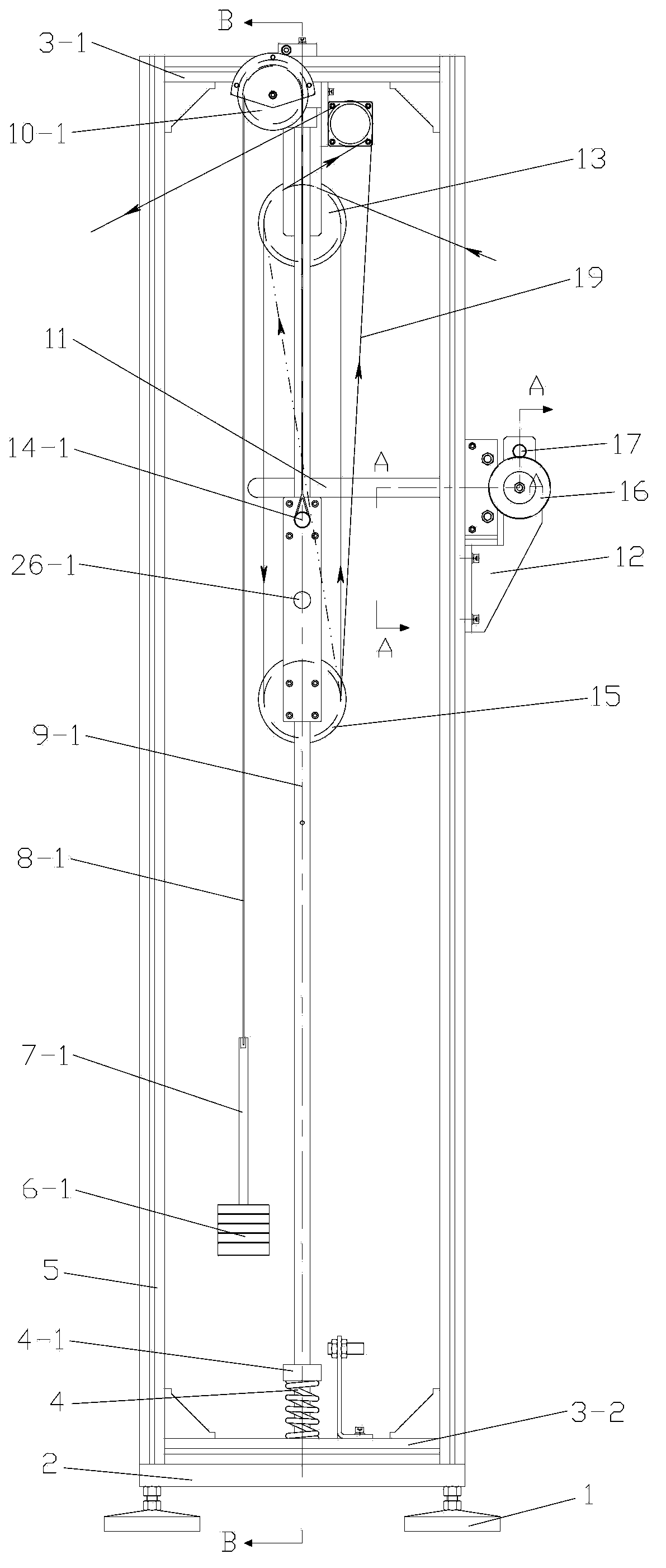

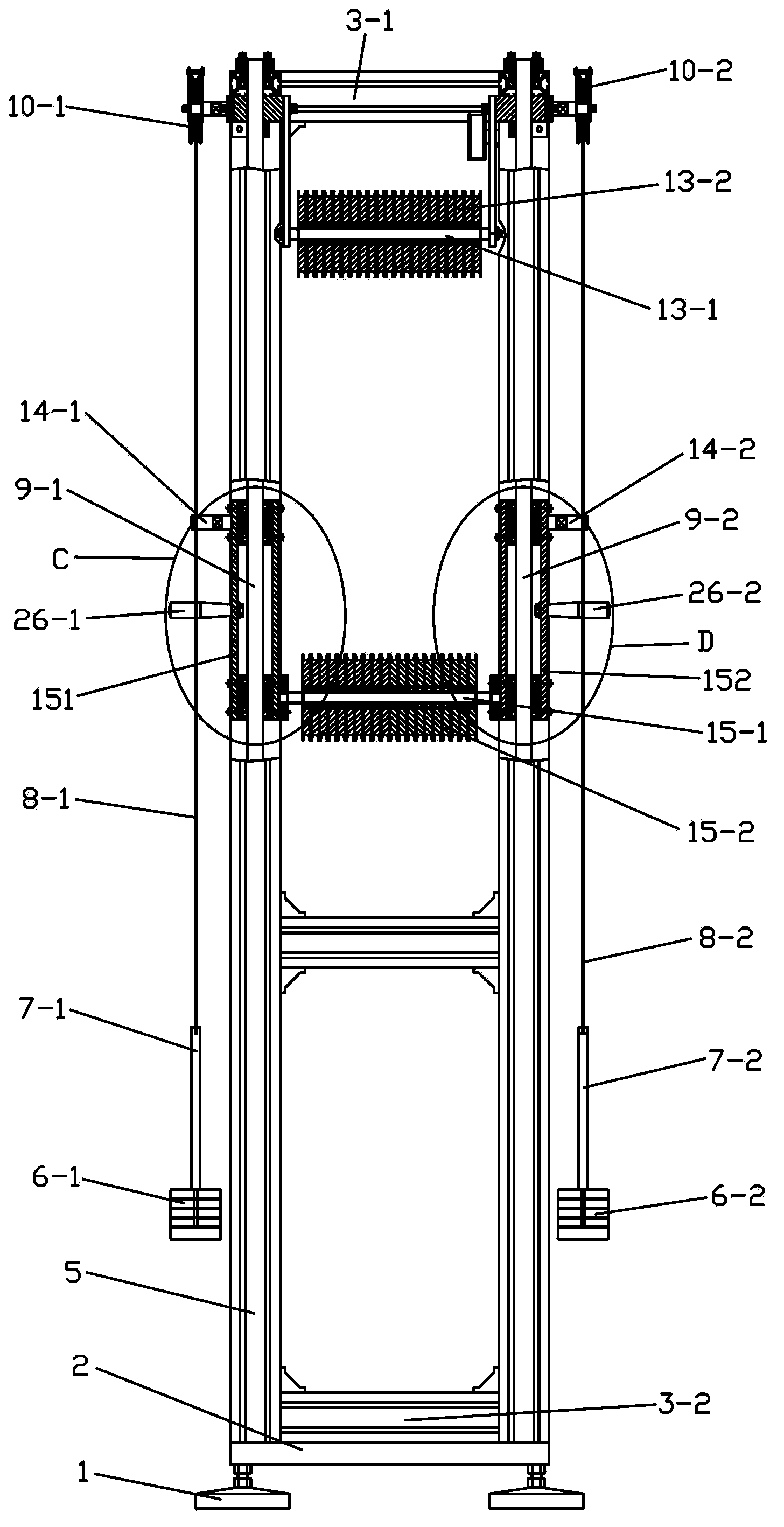

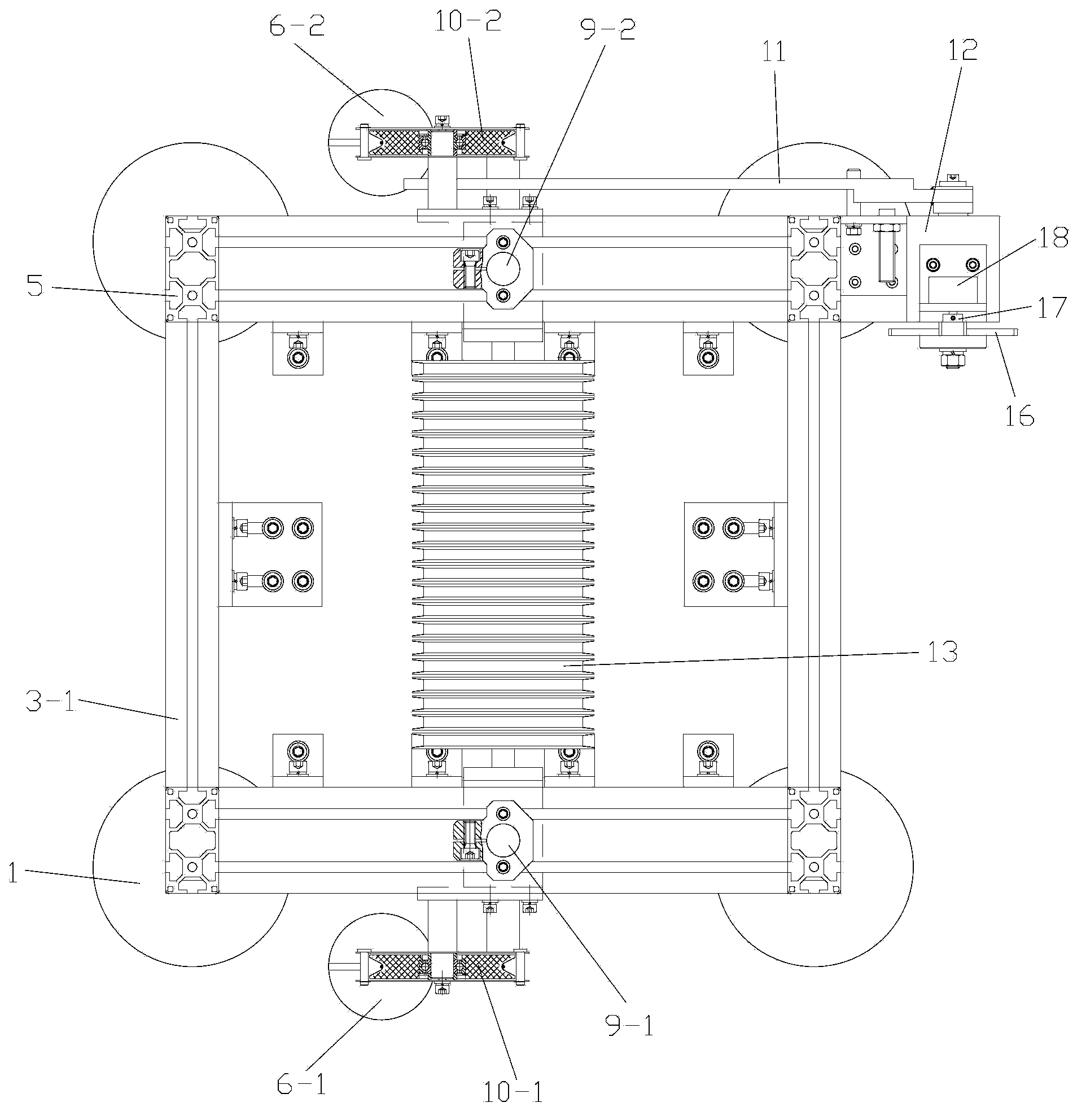

Replaceable disc tension adjustment mechanism for copper strip tinning machine

InactiveCN103805933ASimple structureReasonable designHot-dipping/immersion processesSmall footprintEngineering

The invention discloses a replaceable disc tension adjustment mechanism for a copper strip tinning machine. The replaceable disc tension adjustment mechanism comprises a rack, a guide bar I, a guide bar II, a balancing weight I, a balancing weight II, a connecting rod I, a connecting rod II, a steel wire rope I, a steel wire rope II, an idler wheel I, a third wheel II, a stop lever I, a stop lever II, a fixed guide wheel group, a movable guide wheel group and a tension detection mechanism, wherein the guide bar I and the guide bar II are arranged on the rack, the fixed guide wheel group is arranged between the guide bar I and the guide bar II, and the movable guide wheel group is slidably arranged between the guide bar I and the guide bar II; the balancing weight I is arranged at the lower end of the connecting rod I, the upper end of the connecting rod I is connected to one end of the steel wire rope I, the other end of the steel wire rope I bypasses the third wheel I and is connected to the stop lever I, the balancing weight II is arranged at the lower end of the connecting rod II, the upper end of the connecting rod II is connected to one end of the steel wire rope II, and the other end of the steel wire rope II bypasses the idler wheel II and is connected to the stop lever II. The replaceable disc tension adjustment mechanism can realize disc replacement without machine halt, is time-saving and labor-saving, convenient to use and operate and high in production efficiency and occupies a small area.

Owner:THE NORTHWEST MACHINE

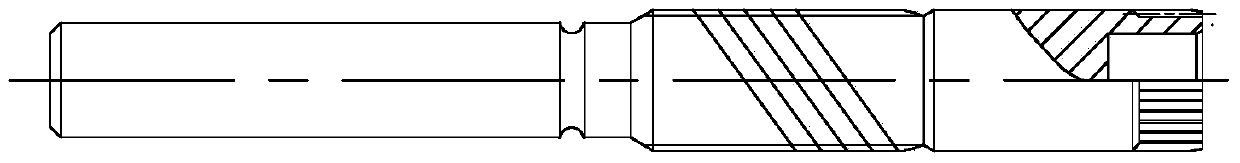

Non-magnetic planet shaft and machining process thereof

ActiveCN104002105AUniform and stable tissueFlexible slidingSolid state diffusion coatingFurnace typesSolution treatmentFlexural strength

The invention relates to a non-magnetic planet shaft and a machining process thereof. The non-magnetic planet shaft is made of a stainless steel 0Cr18Ni9 material. The machining process of the non-magnetic planet shaft includes feeding, solution treatment, surface oxalate treatment, spline extruding and heading, machining, inclined spline rolling, straightening, grinding, nitrocarburizing and deoiling washing. The planet shaft manufactured through the process is table and even in organization, not easy to magnetize even in long-time use, flexible in sliding and capable of meeting the requirement for bending strength.

Owner:无锡市神力齿轮冷挤有限公司

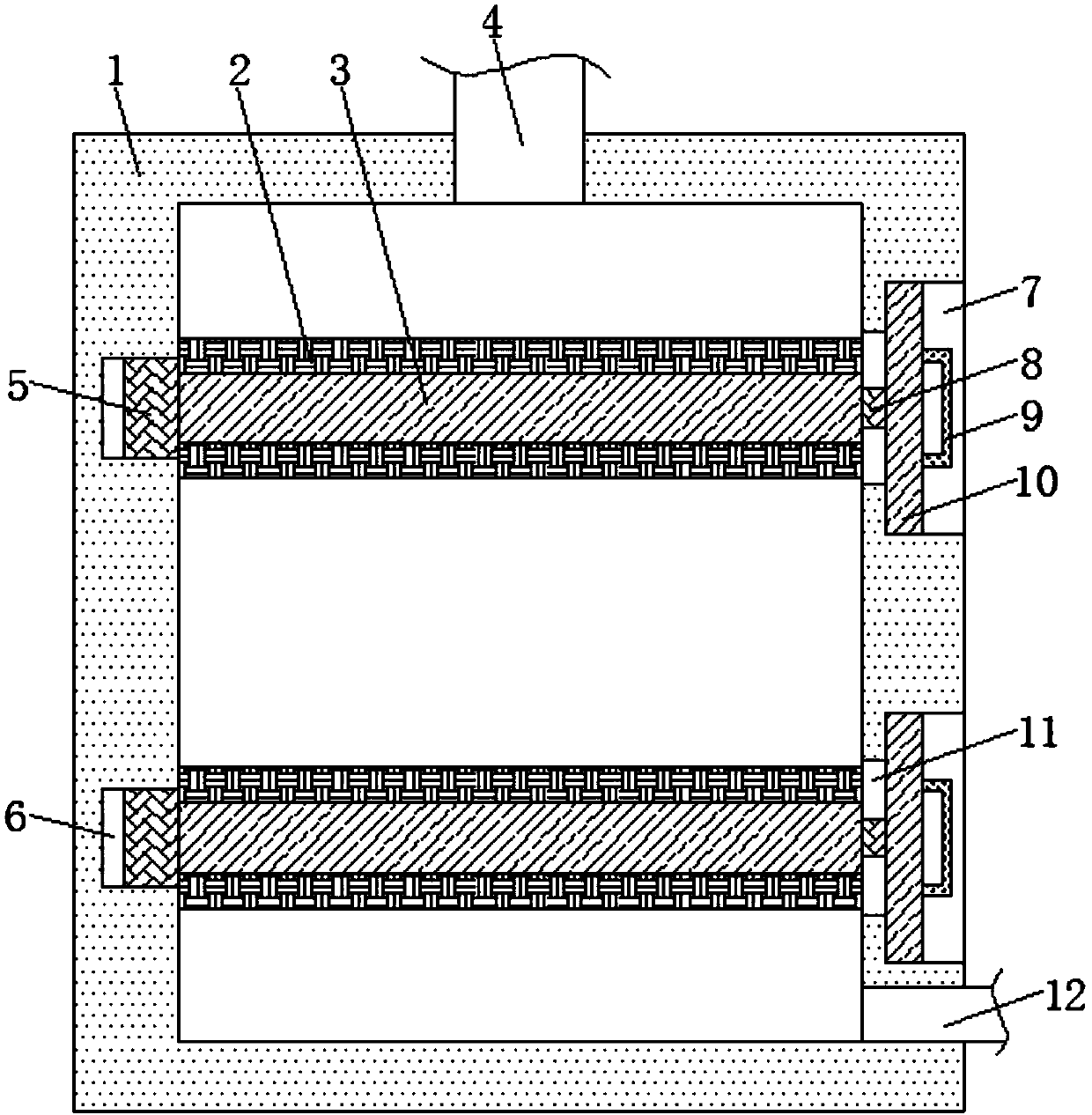

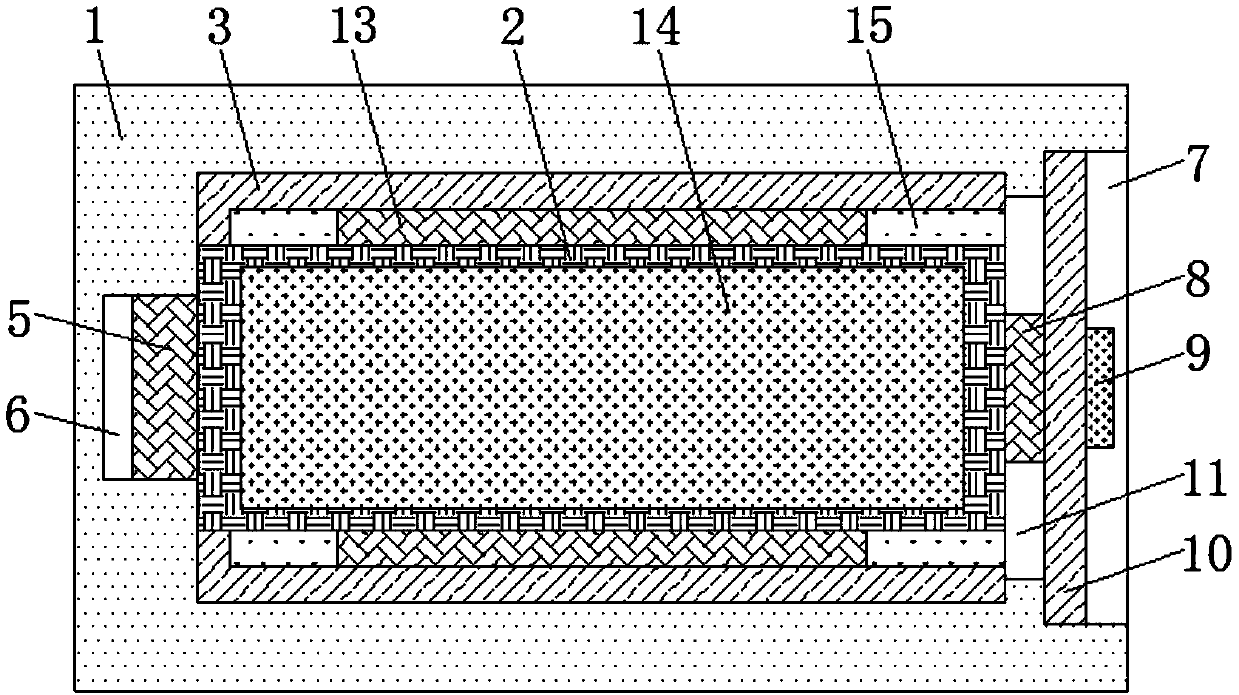

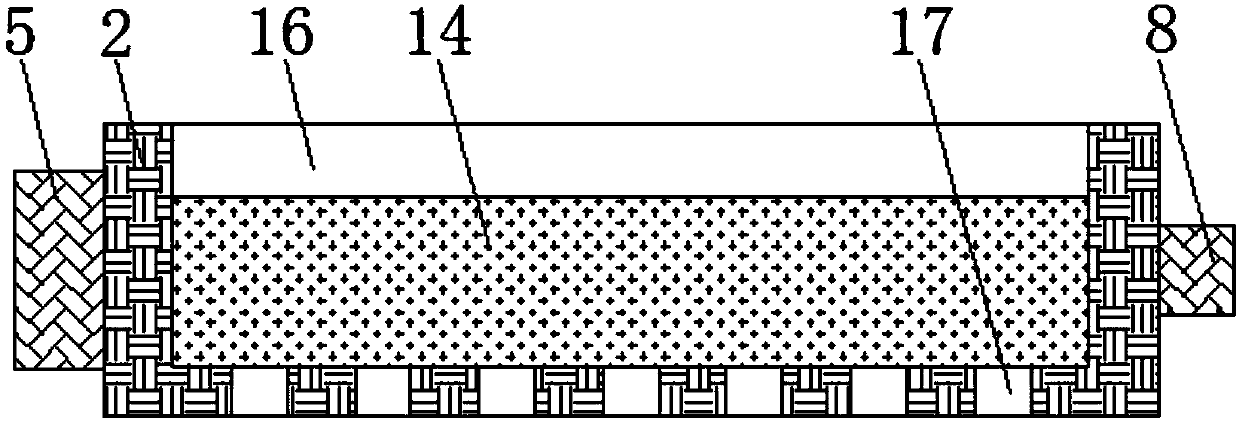

Seismic absorption and isolation support with variable friction coefficient

The invention provides a seismic absorption and isolation support with a variable friction coefficient to balance the contradiction between the daily function and the energy consumption capacity due to the friction coefficient of the seismic absorption and isolation support. When the speed is lower than or equal to 15 mm / s, the friction coefficient of the support is smaller than or equal to 0.02; when the speed is higher than or equal to 100 mm / s, the friction coefficient of the support is larger than or equal to 0.05.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

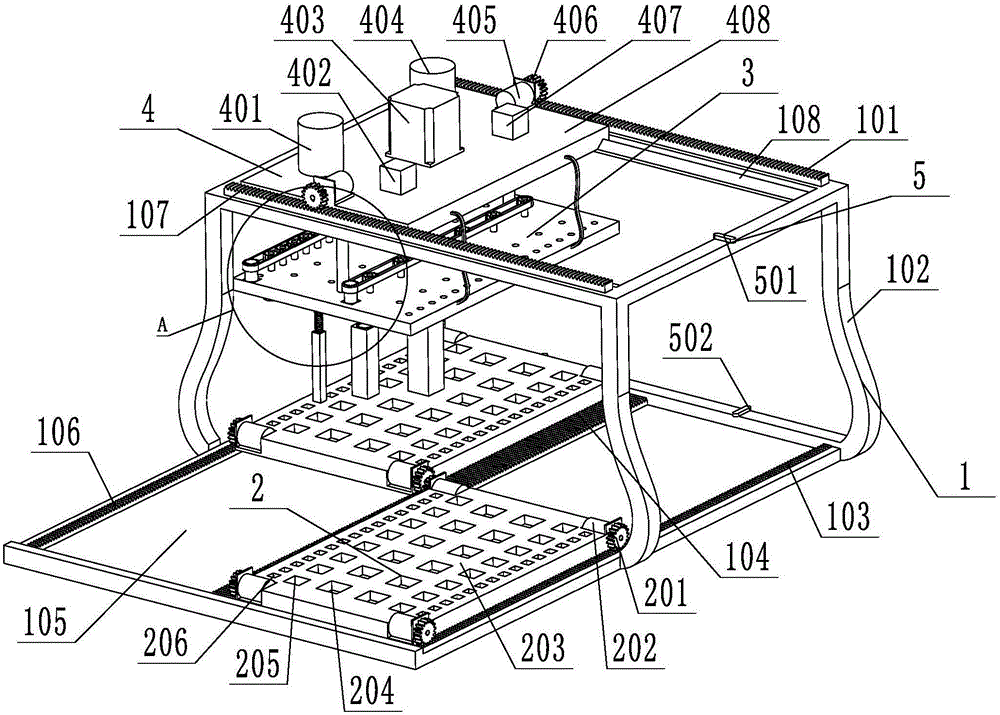

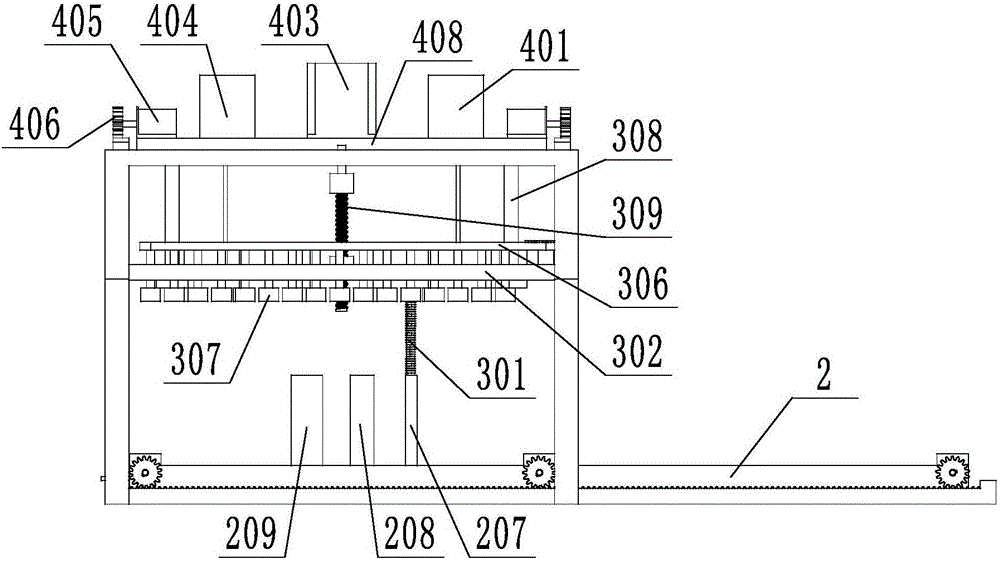

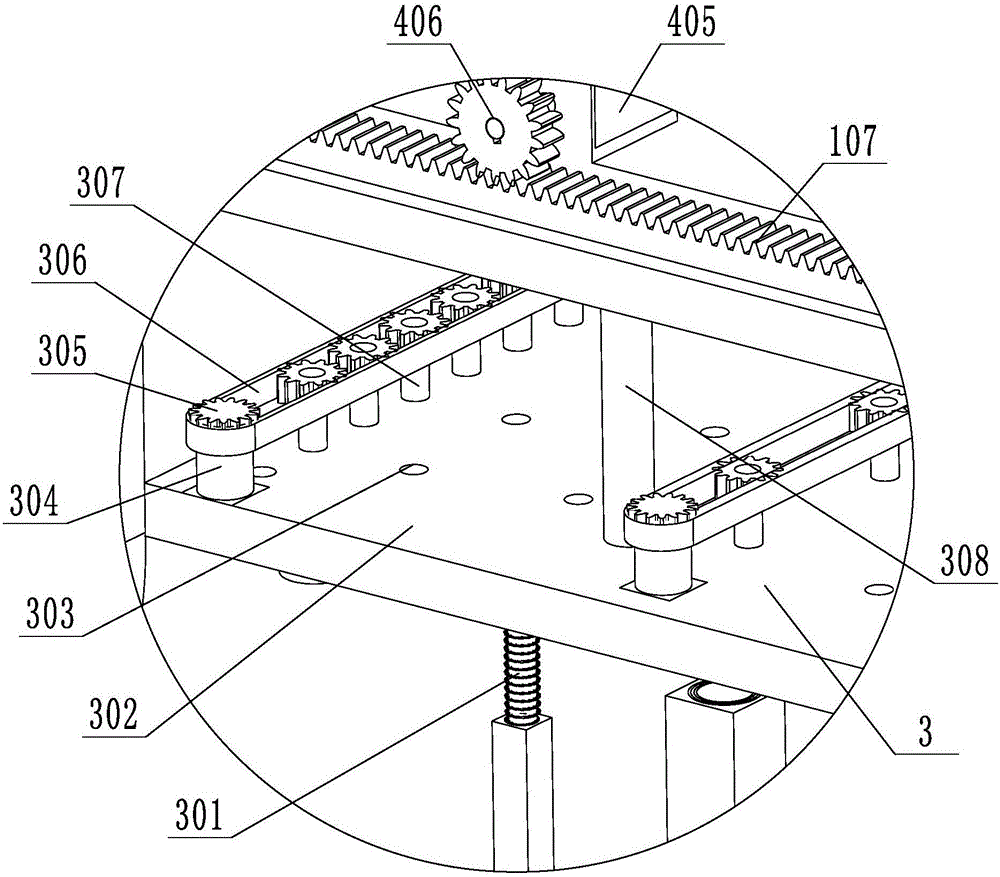

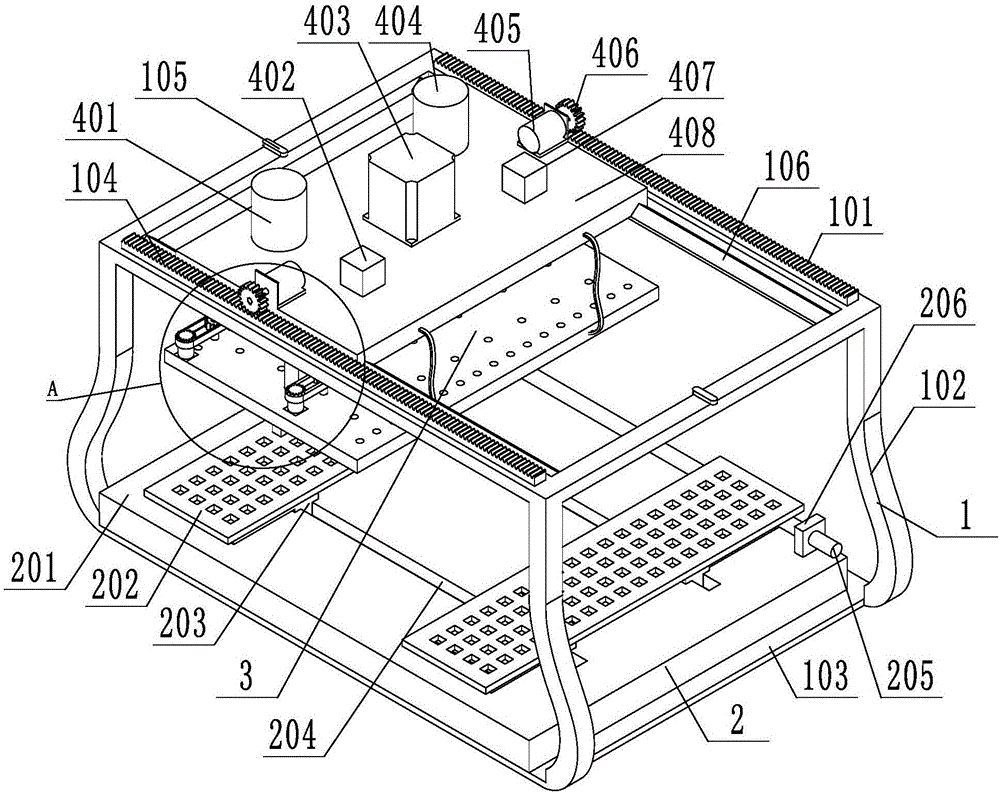

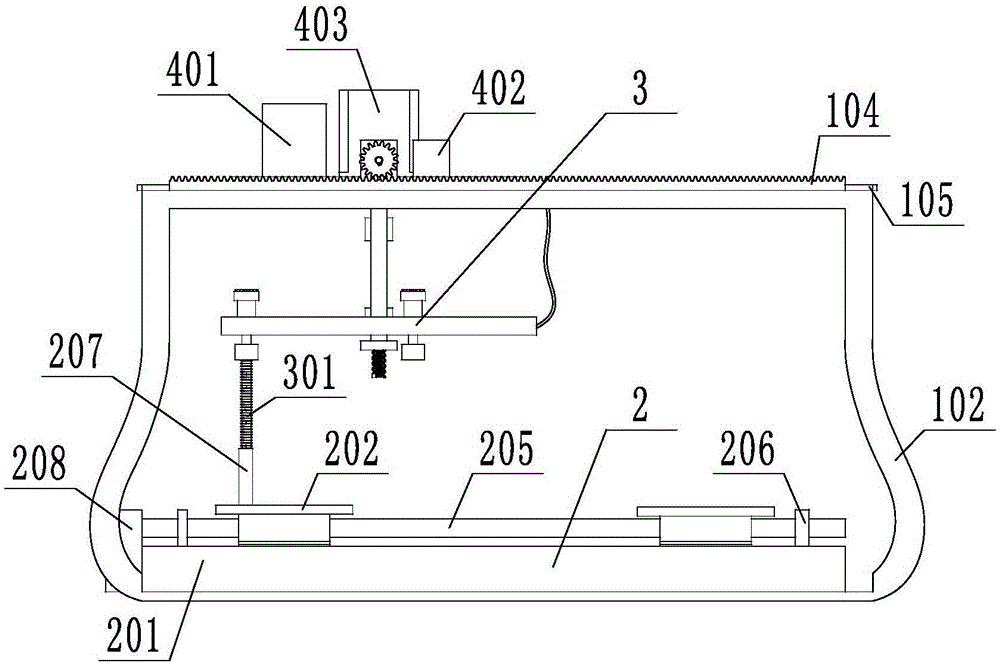

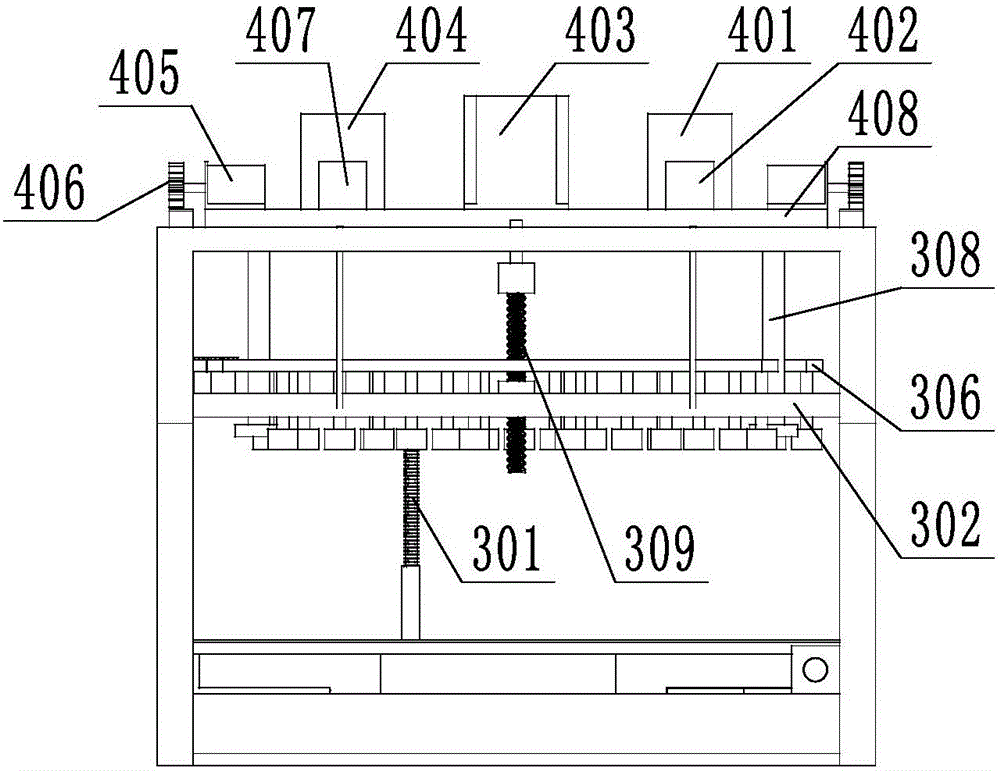

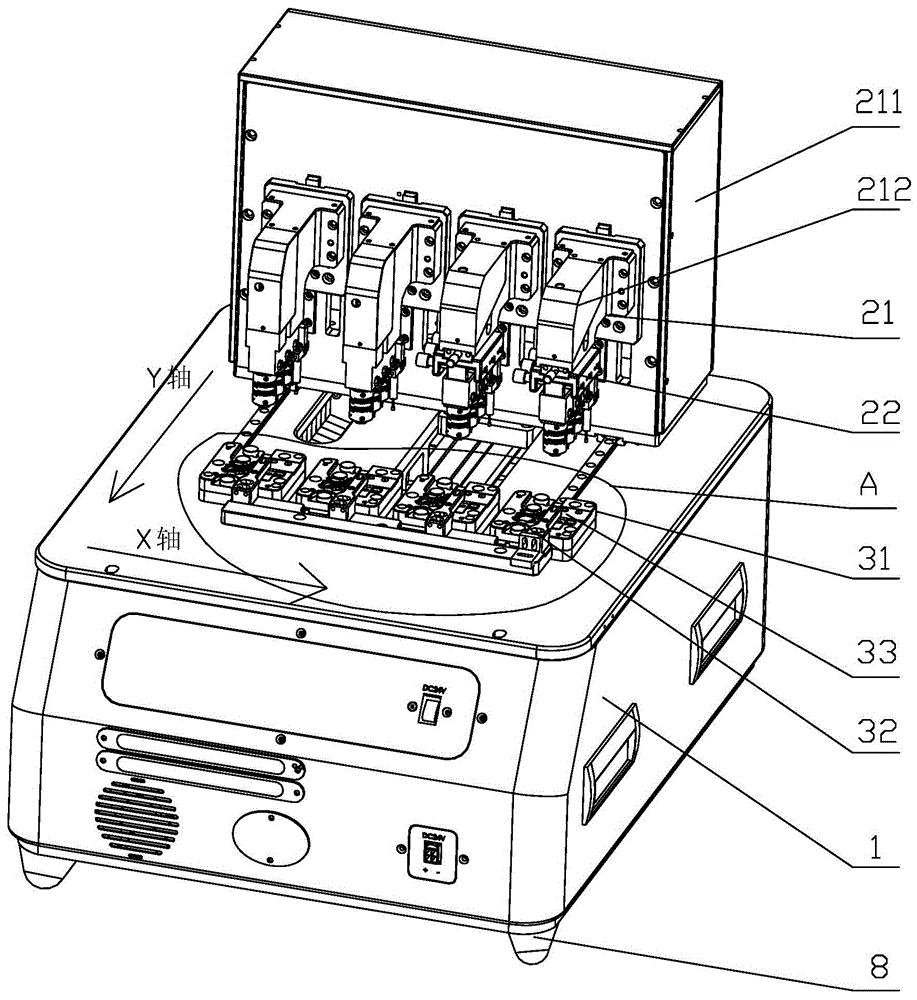

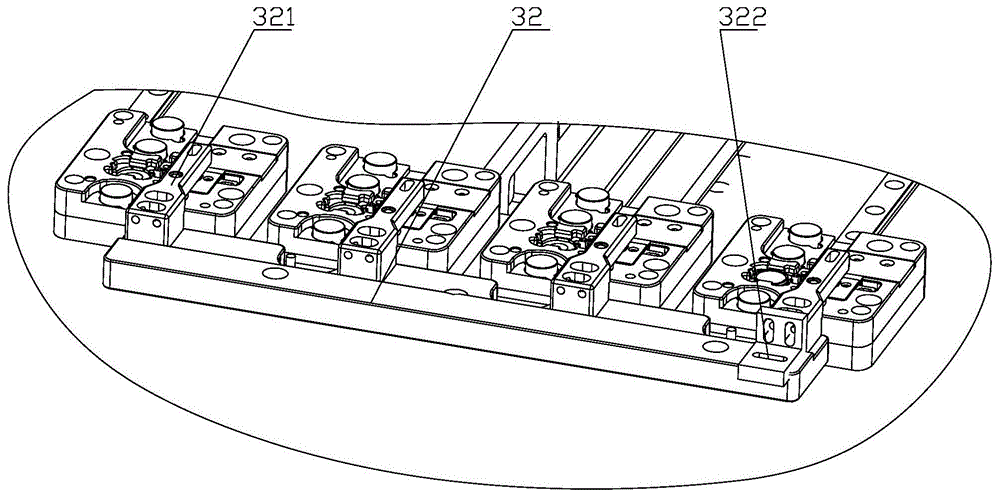

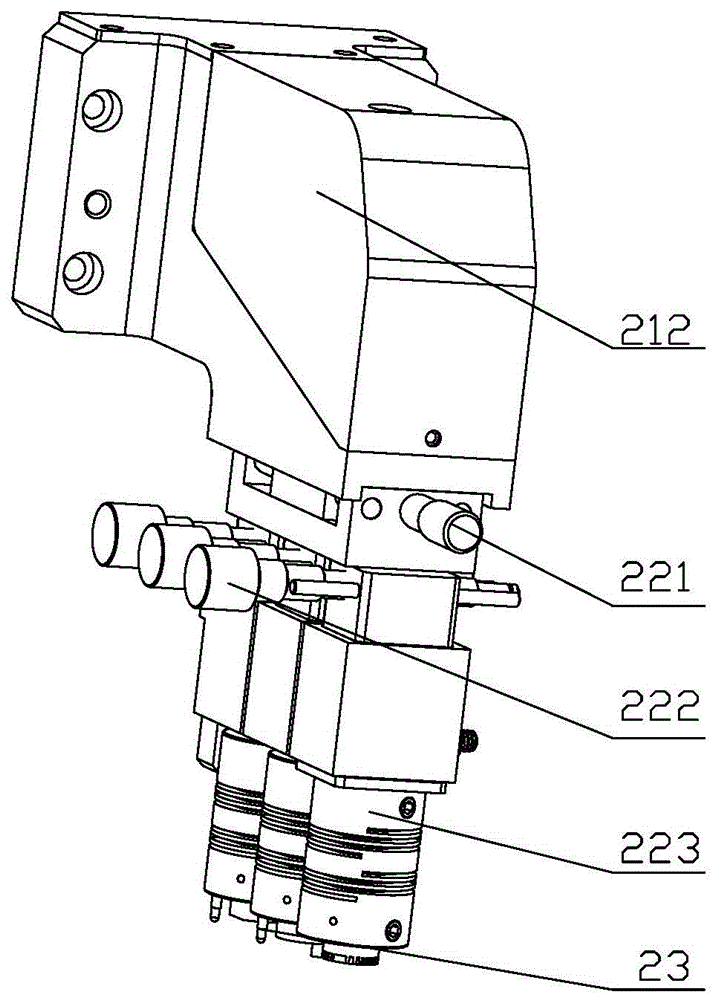

A test device for pcb board

ActiveCN104142454BEasy to operateHigh degree of automationElectrical testingProbe cardElectrical control

The invention discloses a testing device for a PCB board, which belongs to the technical field of testing devices and is designed to solve the problems of low detection efficiency, high labor intensity and low precision of the traditional PCB board debugging method. The testing device of the PCB board includes an upper mold assembly arranged above the electric control box and a lower mold assembly arranged on the upper panel of the electric control box. Under the action of the lifting mechanism and the XY axis moving mechanism of the upper mold assembly, the upper mold assembly The probes on the mold assembly are adjusted to pass through the probe holes on the probe board of the lower mold assembly, so that the probes are in contact with the product to be tested on the product carrier for testing such as missing soldering of main components on the PCB board and Circuit opening and short circuiting etc. The invention has simple operation and high degree of automation, simplifies manual operation, reduces labor intensity, and improves work efficiency and test accuracy.

Owner:KUSN MAIZHI FIXTURE TECH

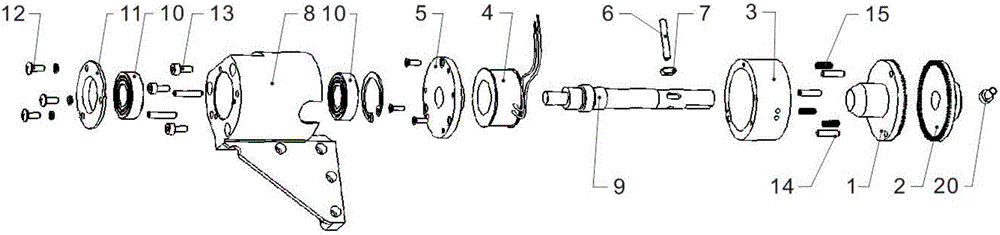

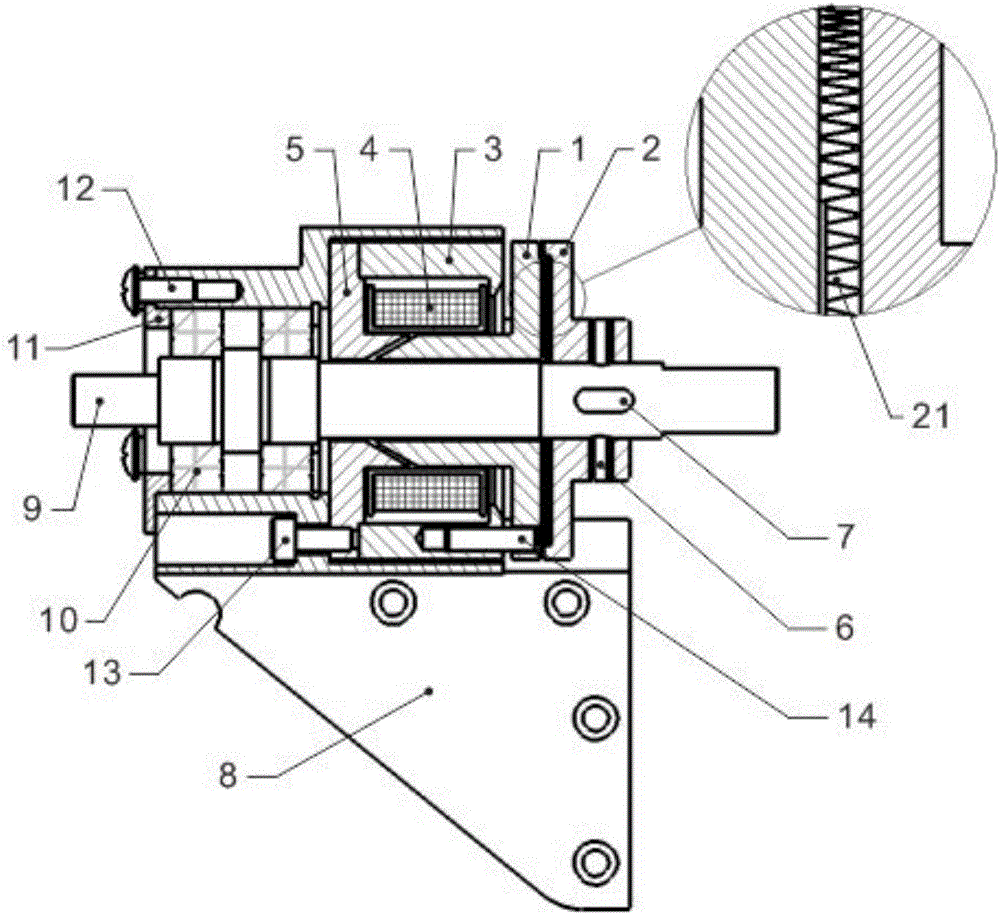

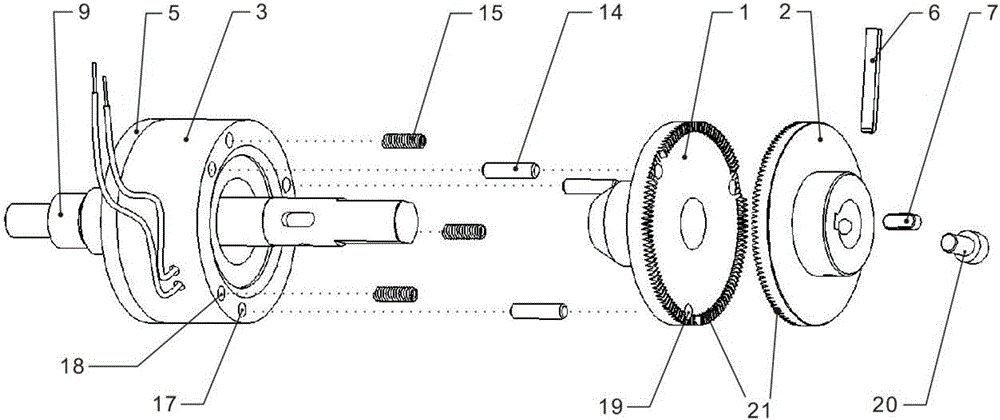

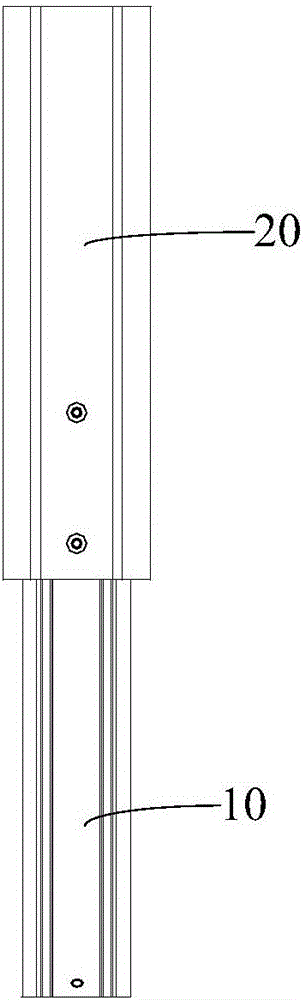

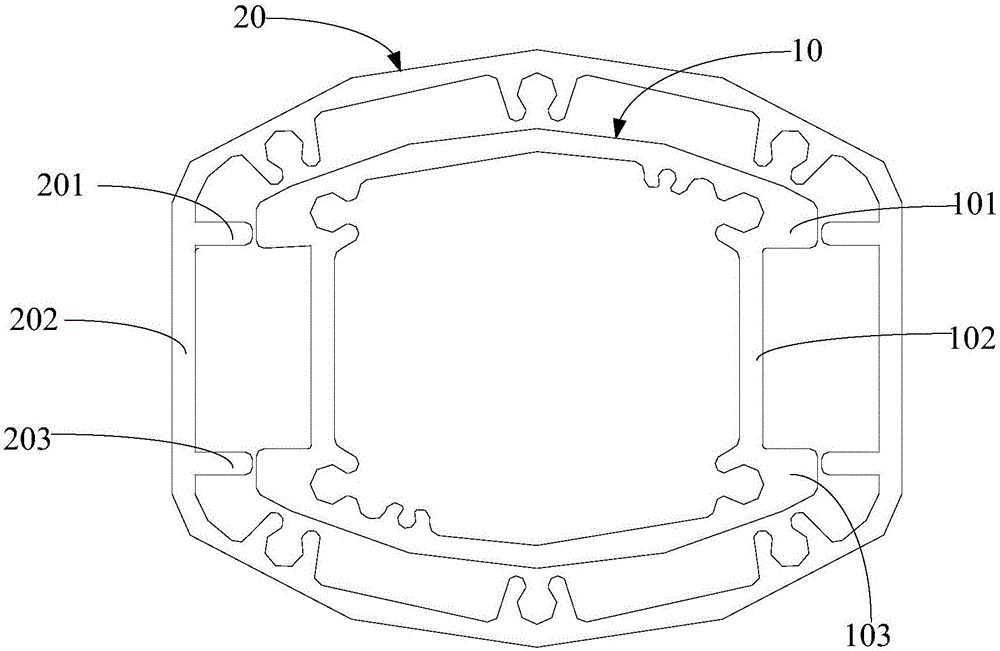

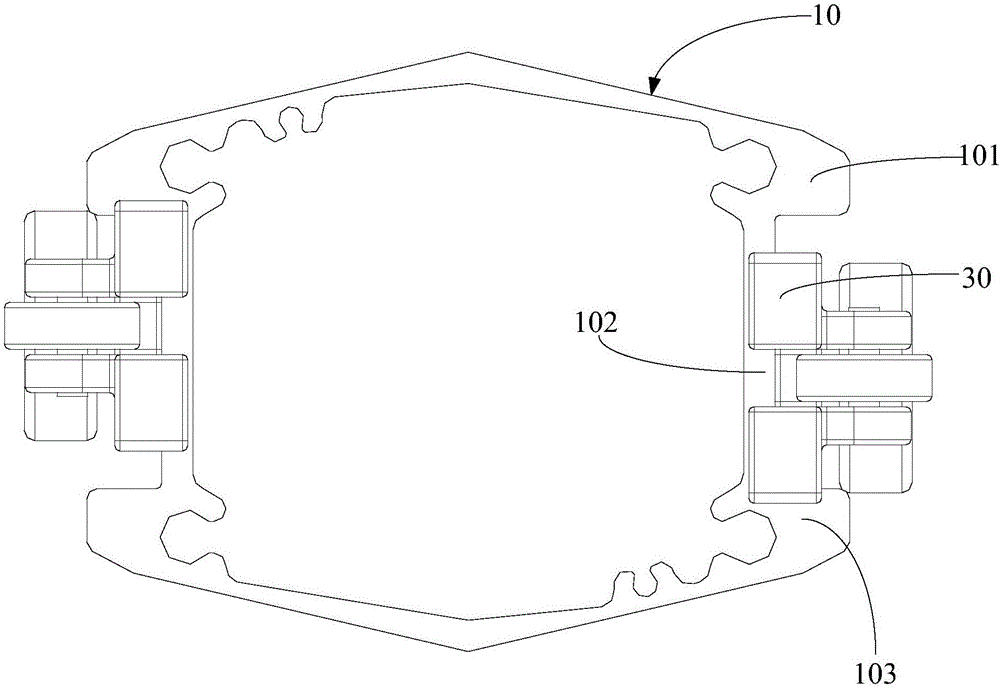

Tooth engaged power-off brake

PendingCN106402212AGuaranteed accuracyFlexible slidingBraking membersBrake actuating mechanismsDrive shaftEngineering

The invention discloses a tooth engaged power-off brake. The tooth engaged power-off brake comprises a mounting base with a transmission shaft inside, a shell positioned in the mounting base and with a magnet exciting coil, an inner tooth disc positioned on the end surface of the shell, and an outer tooth disc corresponding to the inner tooth disc; one end of the shell is connected with a cover plate; multiple spring bases and elastic pin bases are arranged on the end surface, near the inner tooth disc, of the shell; separation springs are mounted in the spring bases; elastic pins are mounted in the elastic pin bases; and the inner tooth disc is provided with elastic pin holes corresponding to the elastic pin bases. The tooth engaged power-off brake is simple in structure, small in size, reasonable in layout, excellent in brake performance and high in reliability.

Owner:SHAOXING IND SCI DESIGN & RES INST CO LTD

Upright post structure for medical vehicle

ActiveCN106236462AHeight adjustableWon't cause scratchesNursing accommodationEngineeringMedical treatment

Owner:SHENZHEN NUBOMED EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com