Bending lower die for bending machine and manufacturing method for bending lower die

A manufacturing method and bending machine technology, applied in the field of bending machines, can solve problems such as workpiece damage, low precision, and difficulty in unloading workpieces, and achieve the effects of prolonging life, improving processing accuracy, and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

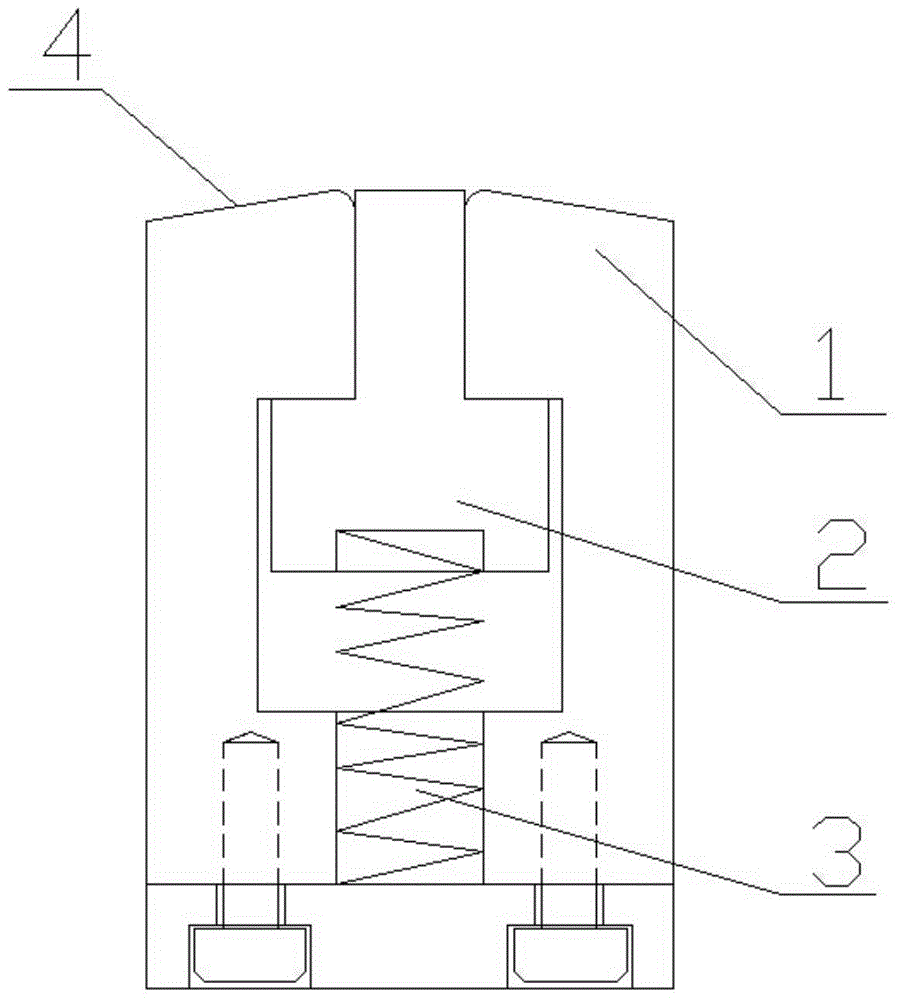

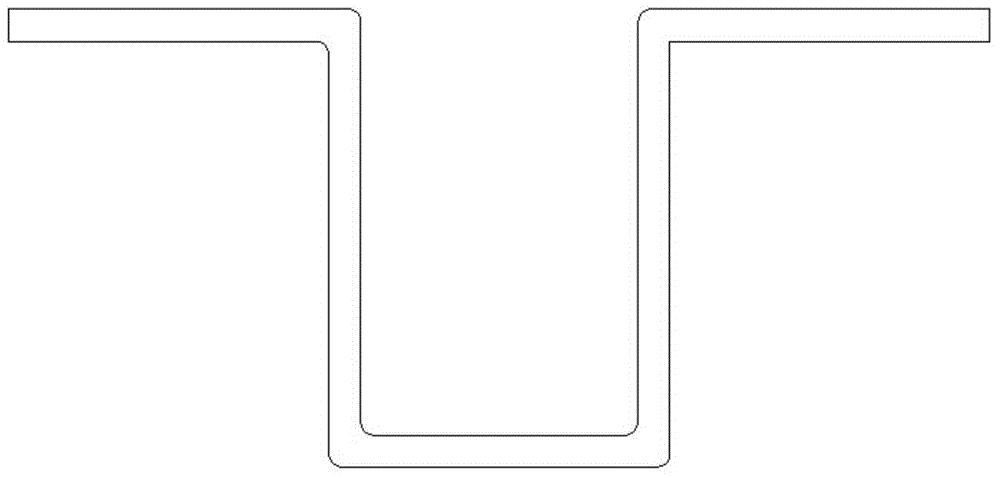

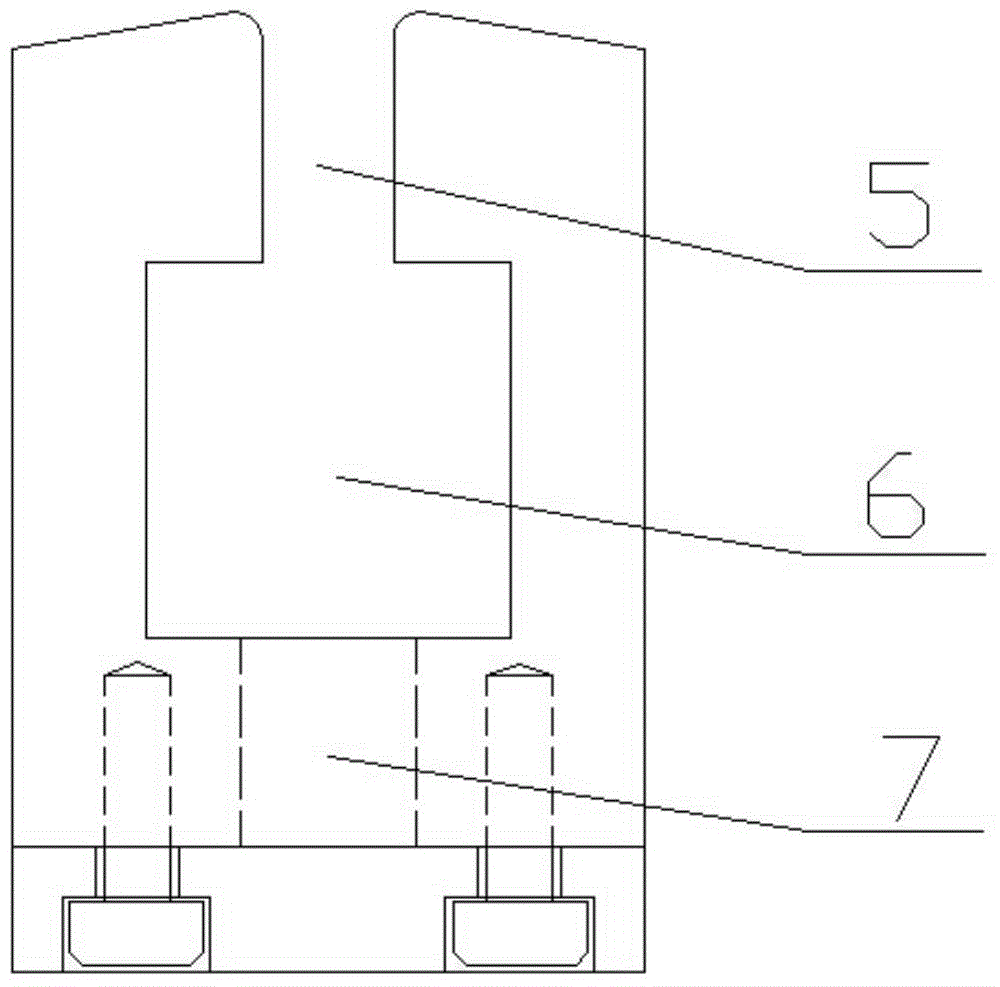

[0059] Such as figure 1 , figure 2 with image 3 As shown, a lower mold for bending a U-shaped workpiece with a processing depth of 400 mm and a width of 100 mm includes a lower mold base 1, a top block 2 at the bottom of the mold, and a discharge spring 3. The lower mold base 1 is sequentially provided with a first cavity Cavity 5, second cavity 6 and spring cavity 7; the inner surface of the first cavity 5 is provided with a wear-resistant layer, the roughness Ra of the inner surface of the first cavity 5 is 0.8, the width of the first cavity 5 is 100 mm, and the depth is 440mm; the width of the second cavity 6 is 300mm; the spring chamber 7 is arranged on the bottom surface of the second cavity 6, the quantity of the spring chamber 7 is 2, and its shape is a cylinder, and the longitudinal section width of the spring chamber 7 is 150mm The material of the top block 2 at the bottom of the mold is 40SiMn2, and the top block 2 at the bottom of the mold is an inverted T shape...

Embodiment 2

[0088] Such as figure 1 , figure 2 with image 3 As shown, a lower mold for bending a U-shaped workpiece with a processing depth of 300mm and a width of 80mm includes a lower mold base 1, a top block 2 at the bottom of the mold, and a discharge spring 3. The lower mold base 1 is sequentially provided with a first cavity Cavity 5, second cavity 6 and spring cavity 7; the inner surface of the first cavity 5 is provided with a wear-resistant layer, the roughness Ra of the inner surface of the first cavity 5 is 0.8, the width of the first cavity 5 is 80mm, and the depth is 340mm; the width of the second cavity 6 is 240mm; the spring chamber 7 is arranged on the bottom surface of the second cavity 6, the quantity of the spring chamber 7 is 8, and its shape is a cylinder, and the longitudinal section width of the spring chamber 7 is 120mm The material of the top block 2 at the bottom of the mold is 40SiMn2, and the top block 2 at the bottom of the mold is an inverted T shape. The...

Embodiment 3

[0116] Such as figure 1 , figure 2 with image 3 As shown, a lower mold for bending U-shaped workpieces with a processing depth of 200 mm and a width of 50 mm includes a lower mold base 1, a mold bottom top block 2 and a discharge spring 3, and the lower mold base 1 is sequentially provided with first hollows from top to bottom Cavity 5, second cavity 6 and spring cavity 7; the inner surface of the first cavity 5 is provided with a wear-resistant layer, the roughness Ra of the inner surface of the first cavity 5 is 0.8, the width of the first cavity 5 is 50 mm, and the depth is 240mm; the width of the second cavity 6 is 150mm; the spring chamber 7 is arranged on the bottom surface of the second cavity 6, the quantity of the spring chamber 7 is 6, and its shape is a cuboid, and the longitudinal section width of the spring chamber 7 is 75mm The material of the top block 2 at the bottom of the mold is 40SiMn2, and the top block 2 at the bottom of the mold is an inverted T shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com