Replaceable disc tension adjustment mechanism for copper strip tinning machine

A tension adjustment mechanism and tin plating machine technology, applied in hot dip plating process, coating, metal material coating process, etc., can solve the problems of low production efficiency, unstable tension, small footprint, etc., and achieve production efficiency High, reduced friction, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

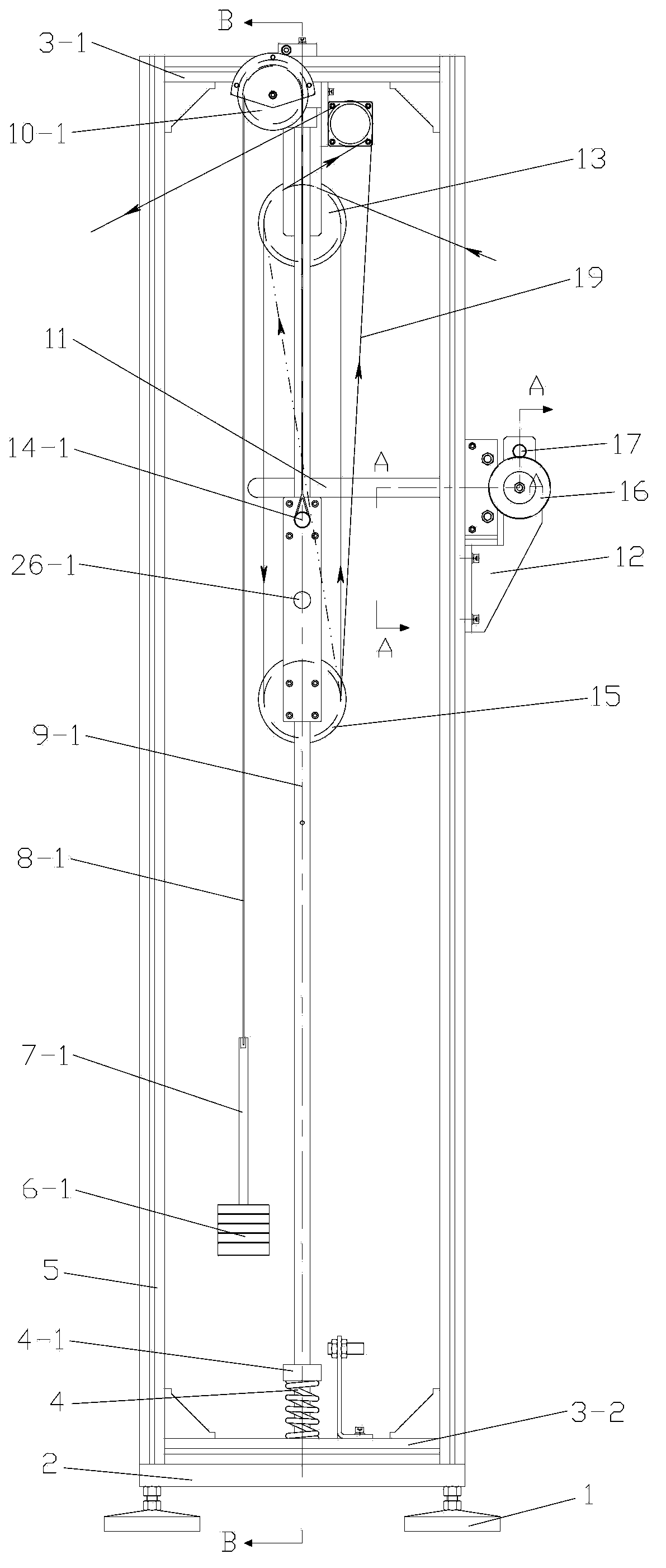

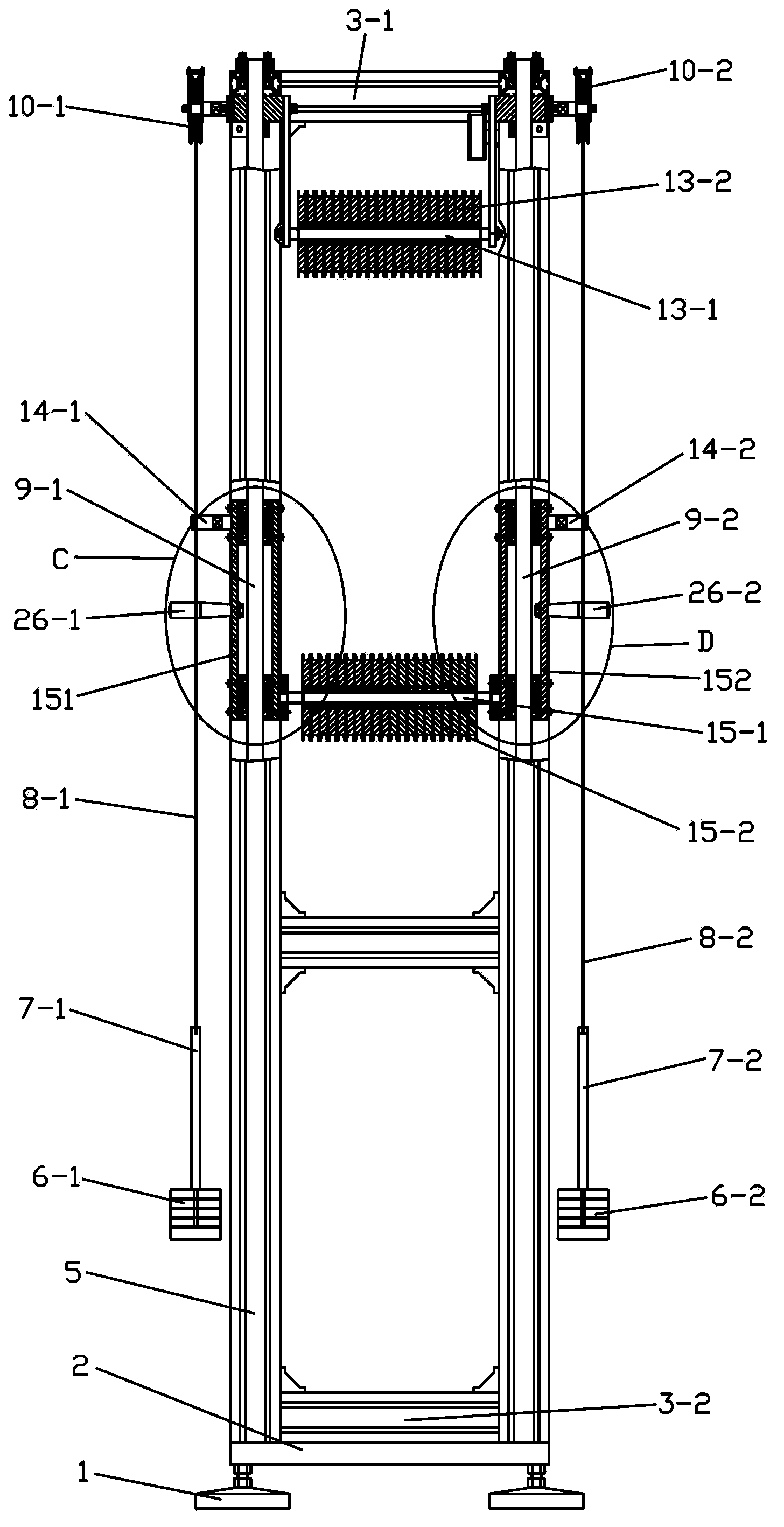

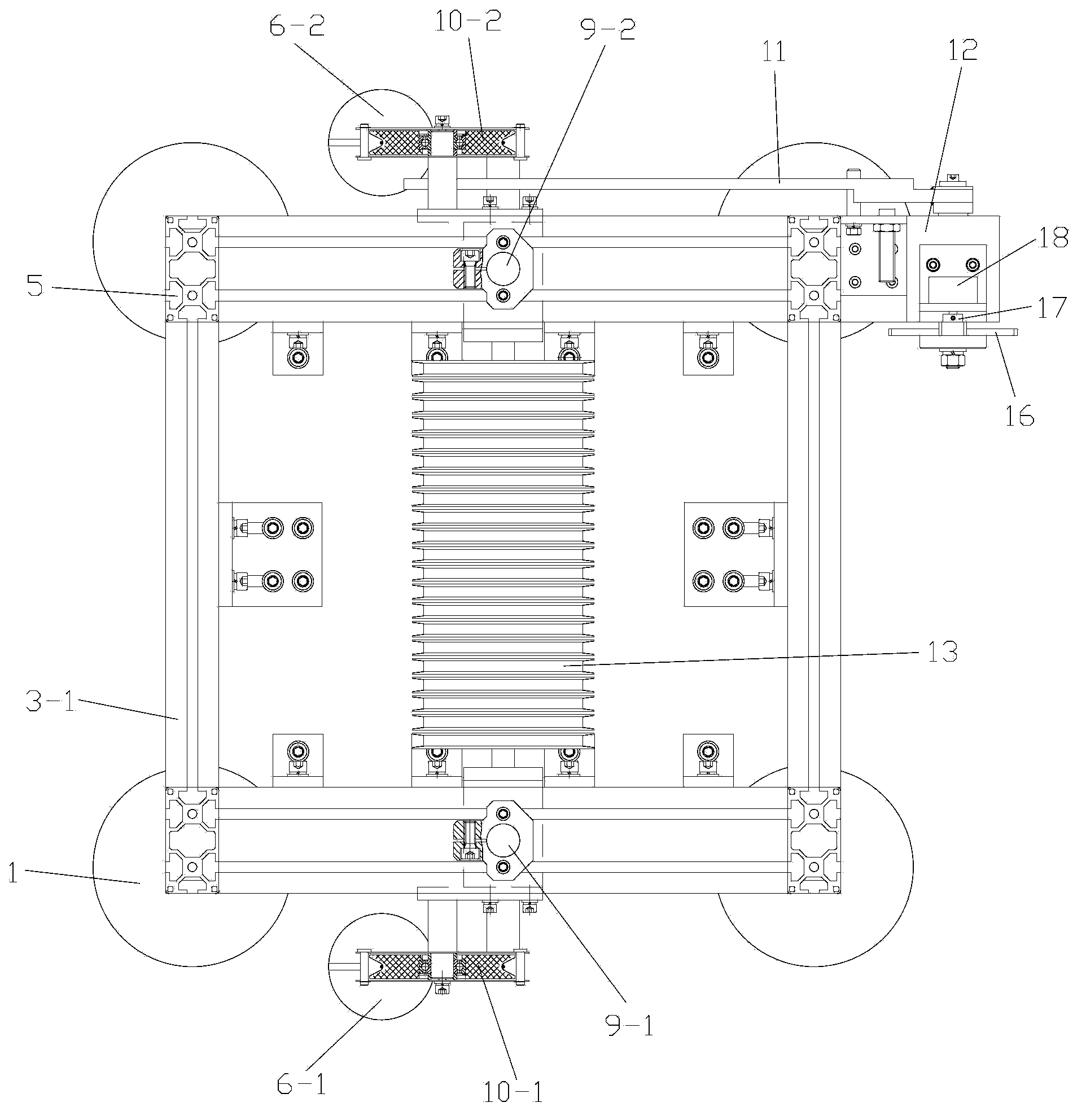

[0045] Such as Figure 1 to Figure 6 Shown, the present invention comprises frame, guide rod one 9-1, guide rod two 9-2, counterweight one 6-1, counterweight two 6-2, connecting rod one 7-1, connecting rod two 7 -2, steel wire rope one 8-1, steel wire rope two 8-2, passing wheel one 10-1, passing wheel two 10-2, stop bar one 14-1, stop bar two 14-2, fixed guide wheel group 13 and move Guide wheel set 15, and a tension detection mechanism for detecting the tension of the winding strip 19 wound between the fixed guide wheel set 13 and the moving guide wheel set 15, the guide rod one 9-1 is installed on the frame The front part of the guide rod two 9-2 is installed at the rear of the frame, the first guide rod 9-1 and the second guide rod 9-2 are symmetrically arranged, and the fixed guide wheel group 13 is fixedly installed on Between guide rod one 9-1 and guide rod two 9-2, described moving guide wheel group 15 is installed on guide rod one 9-1 and guide rod two through guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com