Steam-proof vacuum pot and pot lid thereof

A vacuum pot and steam technology, used in non-pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of scalding people, laborious, large control of sealing end caps, etc., to achieve labor-saving control, good sealing effect, sliding flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

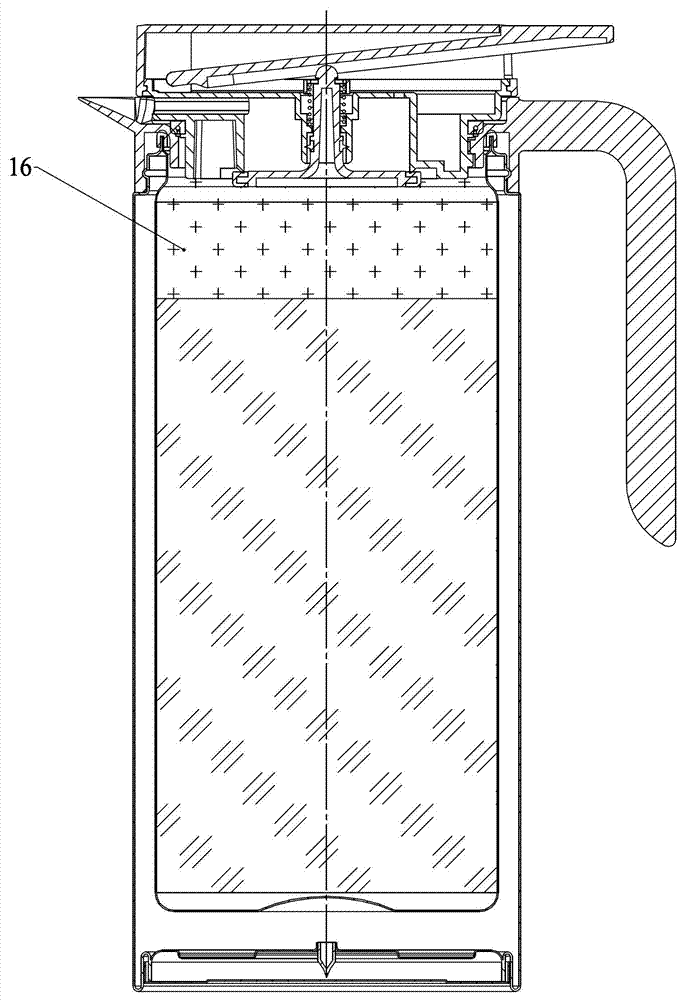

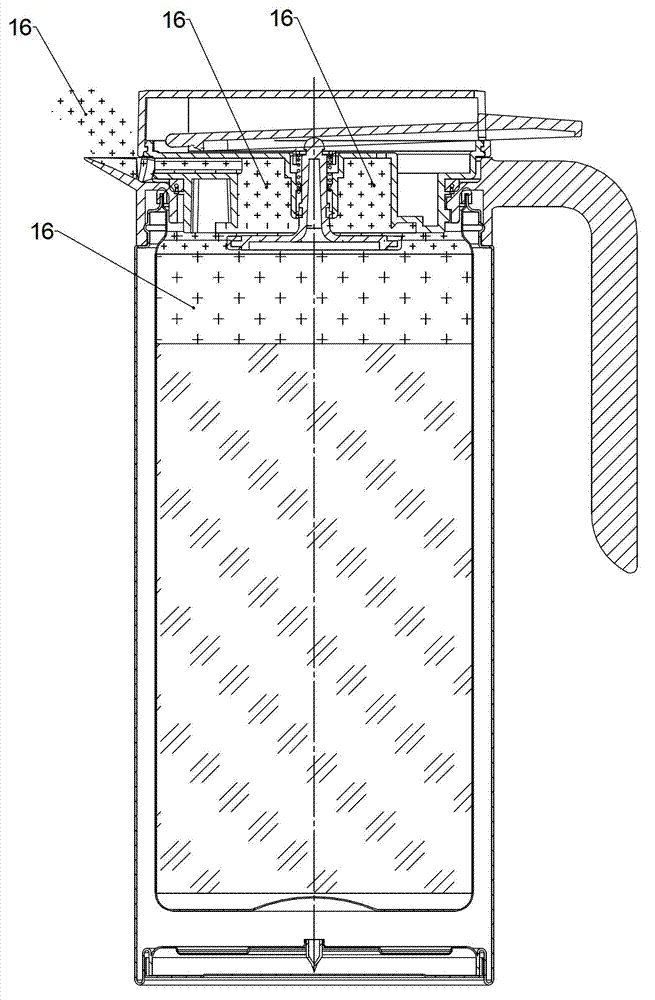

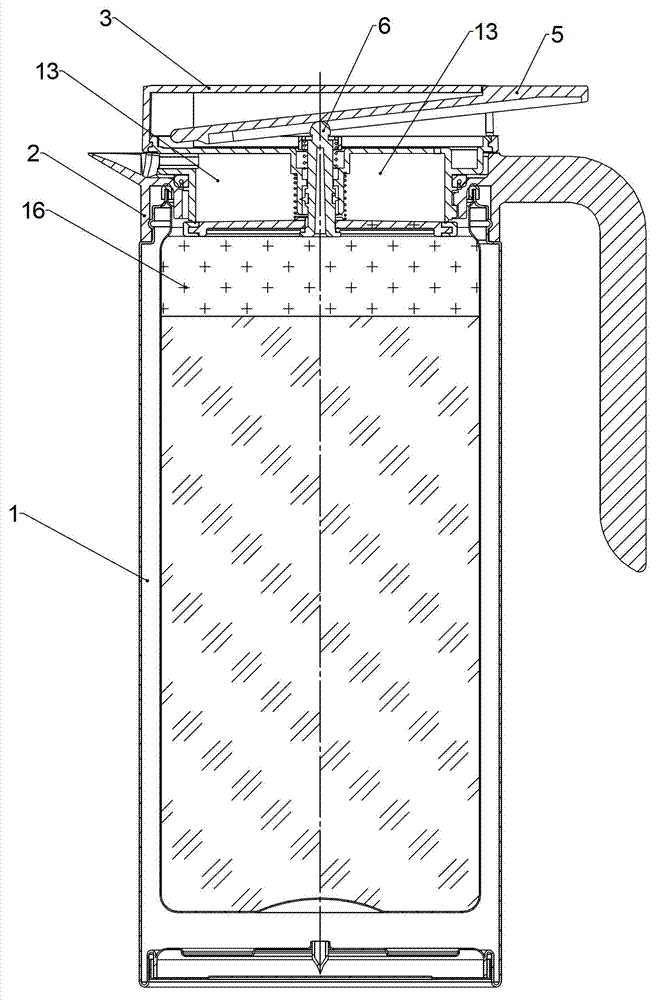

[0017] refer to Figure 3 to Figure 6 , this embodiment is a vacuum pot, including a pot body 1 and a pot cover, the pot cover includes a main cover 2 connected with the pot body, the main cover is provided with a water outlet control plug, and the upper part of the water outlet control plug is connected with an upper cover 3 The water outlet control plug includes a plug body 4, a mandrel control part and a button 5; the mandrel control part includes a mandrel 6, a main spring 7, a buffer spring 8 and a sealing end cover 9; the plug body is provided with a mandrel for installing the mandrel 10. The main spring is set on the upper part of the mandrel and is limited between the inner limit cylinder 11 of the mandrel and the spring end cover 12 arranged on the upper end of the mandrel; the sealing end cover is set on the lower end of the mandrel, and the plug body and A steam release chamber 13 is enclosed between the sealing end caps. The lower end of the mandrel is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com