Tooth engaged power-off brake

A de-energized brake, tooth-clamping technology, applied in the direction of brake type, brake components, brake parts, etc., can solve the problems of large heat generation, high requirements for use environment, long braking stroke, etc., and achieve convenient maintenance. , Fast assembly, ensure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

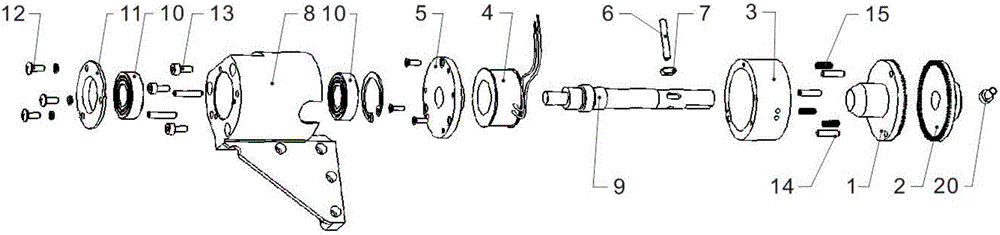

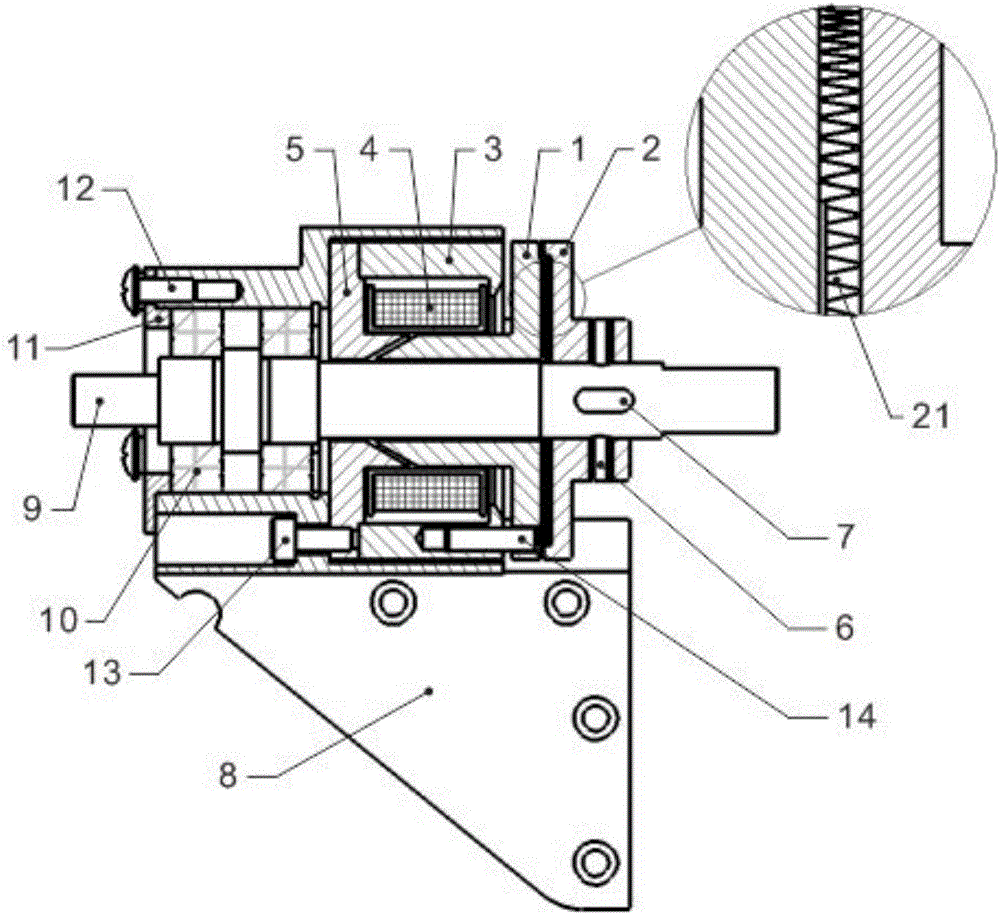

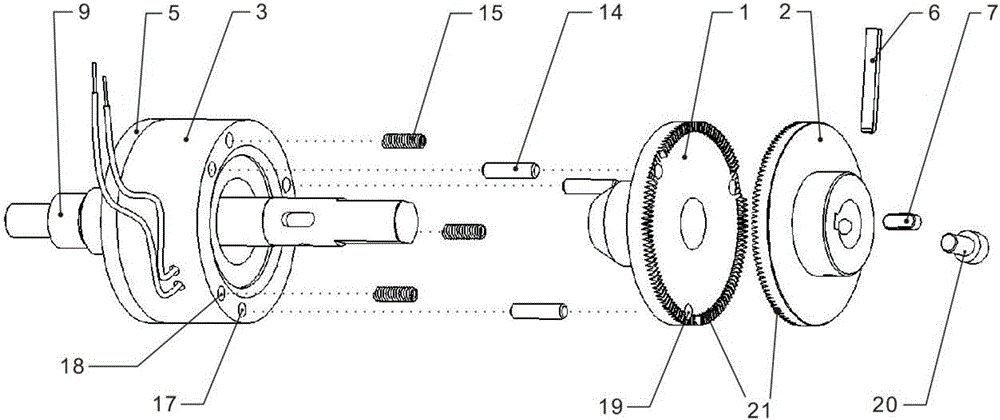

[0016] Such as Figure 1 to Figure 5 As shown, the jaw-type power-off brake includes a mounting seat 8 with a built-in transmission shaft 9, a housing 3 containing an excitation coil 4 placed in the mounting seat 8, an inner gear plate 1 placed on the end face of the housing 3, and the inner gear The outer toothed disc 2 corresponding to the disc 1 is characterized in that one end of the housing 3 is connected with a cover plate 5, and the end surface of the housing 3 close to the inner toothed disc 1 is provided with a plurality of spring seats 18 and spring pin seats 17, A separation spring 15 is installed in the spring seat 18 , a spring pin 14 is installed in the spring pin seat 17 , and a spring pin hole 19 corresponding to the spring pin seat 17 is provided on the inner gear plate 1 .

[0017] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com