Seismic absorption and isolation support with variable friction coefficient

A technology of friction coefficient and vibration reduction and isolation, which is applied in the field of variable friction coefficient vibration reduction and isolation bearings, can solve the problems of high friction coefficient of bearings, achieve excellent bearing capacity, good compatibility, and improve the effect of limit PV value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

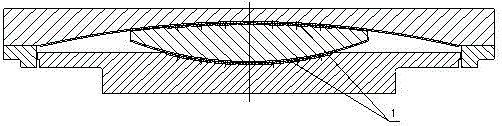

[0024] Such as figure 1 As shown, a variable friction coefficient shock-absorbing and isolating bearing of the present invention, the sliding friction pair 1 adopts a speed-dependent friction material as the core sliding part.

[0025] The composition and mass percentage of the friction material are: polytetrafluoroethylene 60%, composite wear-resistant filler 30%, friction coefficient modifier 10%, wherein the composite wear-resistant filler accounted for the mass percentage of the total friction material is composed of: polyphenylene ester 25%, nano silicon dioxide 2%, molybdenum disulfide 3%. Firstly, polyphenylene, nano silicon dioxide and molybdenum disulfide were weighed according to the mass ratio, mixed and dried at 300°C for 1.5h. Weigh the components of polytetrafluoroethylene, composite wear-resistant filler and friction coefficient modifier according to the proportion, put them into a high-speed mixer and mix them evenly; after sieving, pour them into a mold for m...

Embodiment 2

[0028] Such as figure 1 As shown, a variable friction coefficient shock-absorbing and isolating bearing of the present invention, the sliding friction pair 1 adopts a speed-dependent friction material.

[0029] The composition and mass percentage of the friction material are 88% polytetrafluoroethylene, 10% composite wear-resistant filler, and 2% friction coefficient modifier. The composition of the composite wear-resistant filler is: polyether ether ketone 9%, graphite 1% . First, weigh polyether ether ketone and graphite according to the mass ratio, mix them and dry them at 250° C. for 2.5 hours. Weigh the components of polytetrafluoroethylene, composite wear-resistant filler and friction coefficient modifier according to the proportion, put them into a high-speed mixer and mix them evenly; after sieving, pour them into a mold for molding at a pressure of 45MPa, keep the pressure for 1min, and release the mold The blank was obtained; after the blank was parked at room temp...

Embodiment 3

[0032] Such as figure 1 As shown, a variable friction coefficient shock-absorbing and isolating bearing of the present invention, the sliding friction pair 1 adopts a speed-dependent friction material.

[0033] The composition and mass percentage of the friction material are: ultra-high molecular weight polyethylene 75%, composite wear-resistant filler 20%, friction coefficient modifier 5%, wherein the composite wear-resistant filler is composed of: polyphenylene ester 15%, nano-alumina 3%, molybdenum disulfide 1.5%. Firstly, polyphenylene, nano-alumina, and molybdenum disulfide were weighed according to the mass ratio, mixed and dried at 330° C. for 2 hours. Weigh the components of ultra-high molecular weight polyethylene, composite wear-resistant filler and friction coefficient modifier according to the proportion, put them into a high-speed mixer and mix them evenly; after sieving, pour them into a mold for molding at a pressure of 20MPa and a molding temperature of 220°C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com