Tray type hydraulic weight-hoisting device suitable for small space

A hydraulic lifting device, technology in narrow spaces, applied in the direction of vehicles with swing arms, etc., to achieve the effect of simple structure of slide rail, strong bearing capacity, and reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

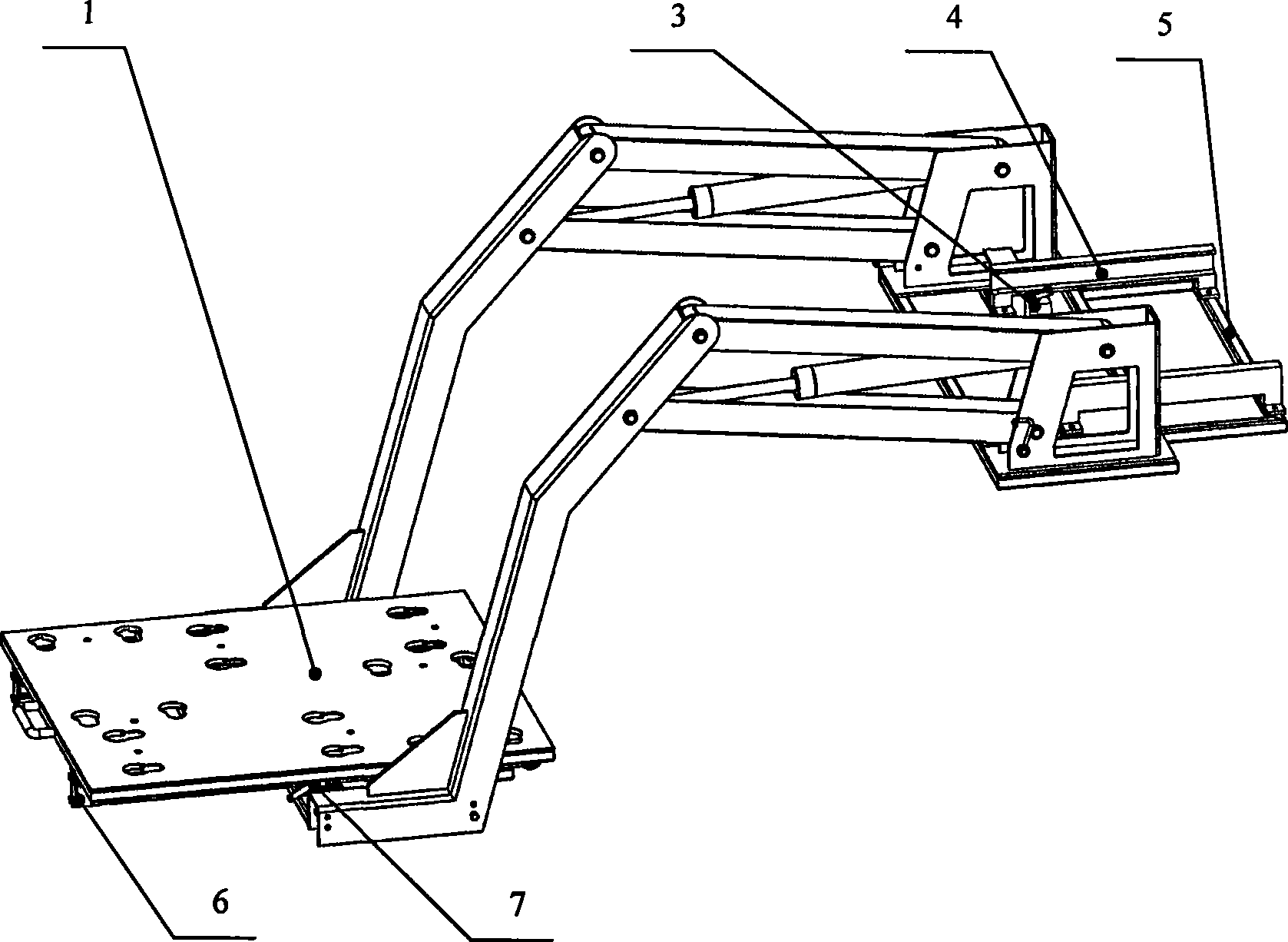

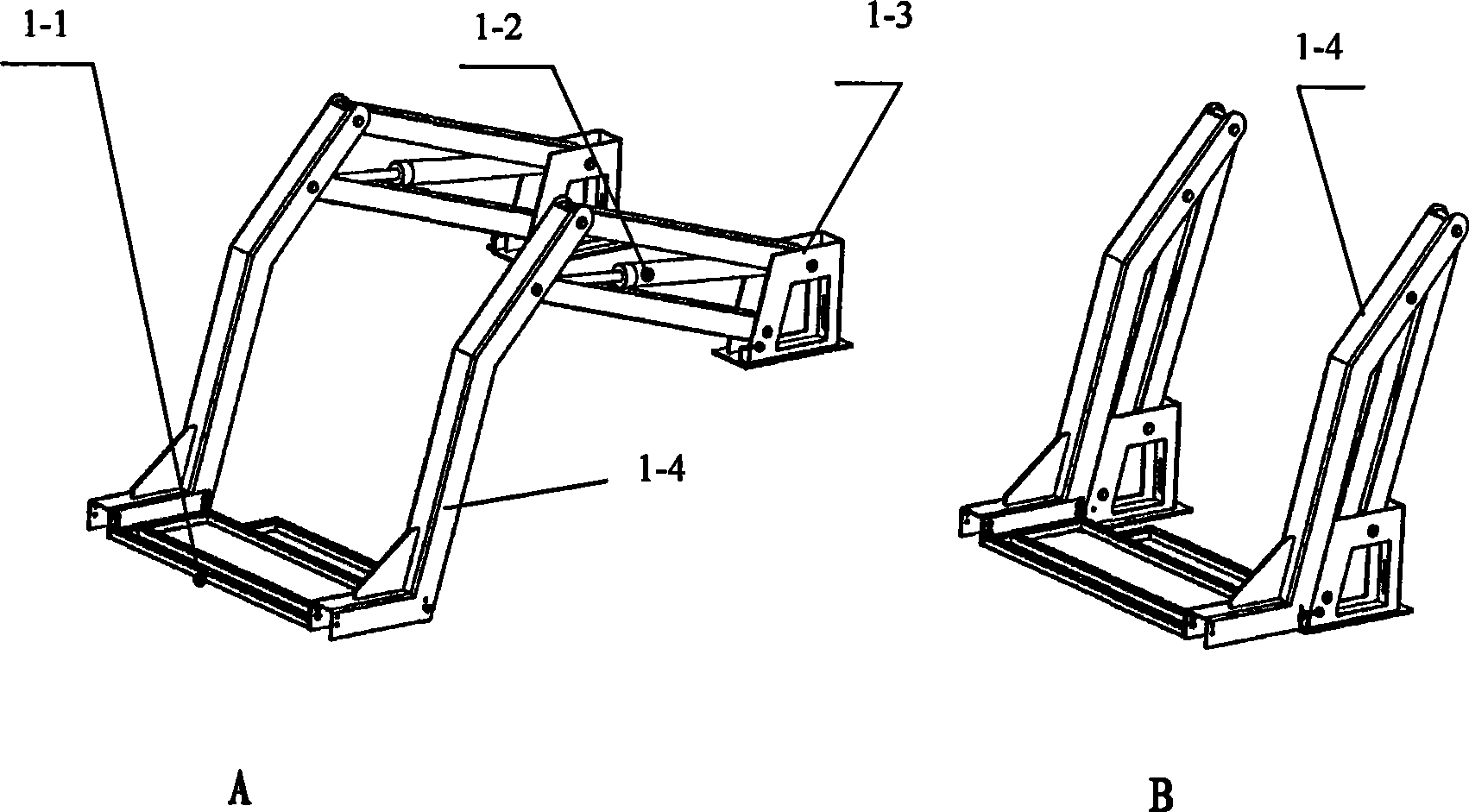

[0025] Referring to the accompanying drawings, the heavy object hydraulic lifting device in the figure includes a heavy object tray 1, a pair of parallelogram mechanism 2, and is characterized in that:

[0026] 1), one end of a pair of parallel arms of the parallelogram mechanism 2 is hinged to the fixing seat 1-3, the other end is hinged to the upper end of the bracket arm, and the lower end of the bracket arm is bent at an angle and fixed with the bracket 1-1 , can always maintain the horizontal state of the bracket when the quadrilateral mechanism moves; the hydraulic cylinder 1-2 provides power for the parallelogram mechanism, driven by the hydraulic cylinder, the parallelogram mechanism unfolds forward around the hinge point of the fixed seat and falls, or to raised and folded;

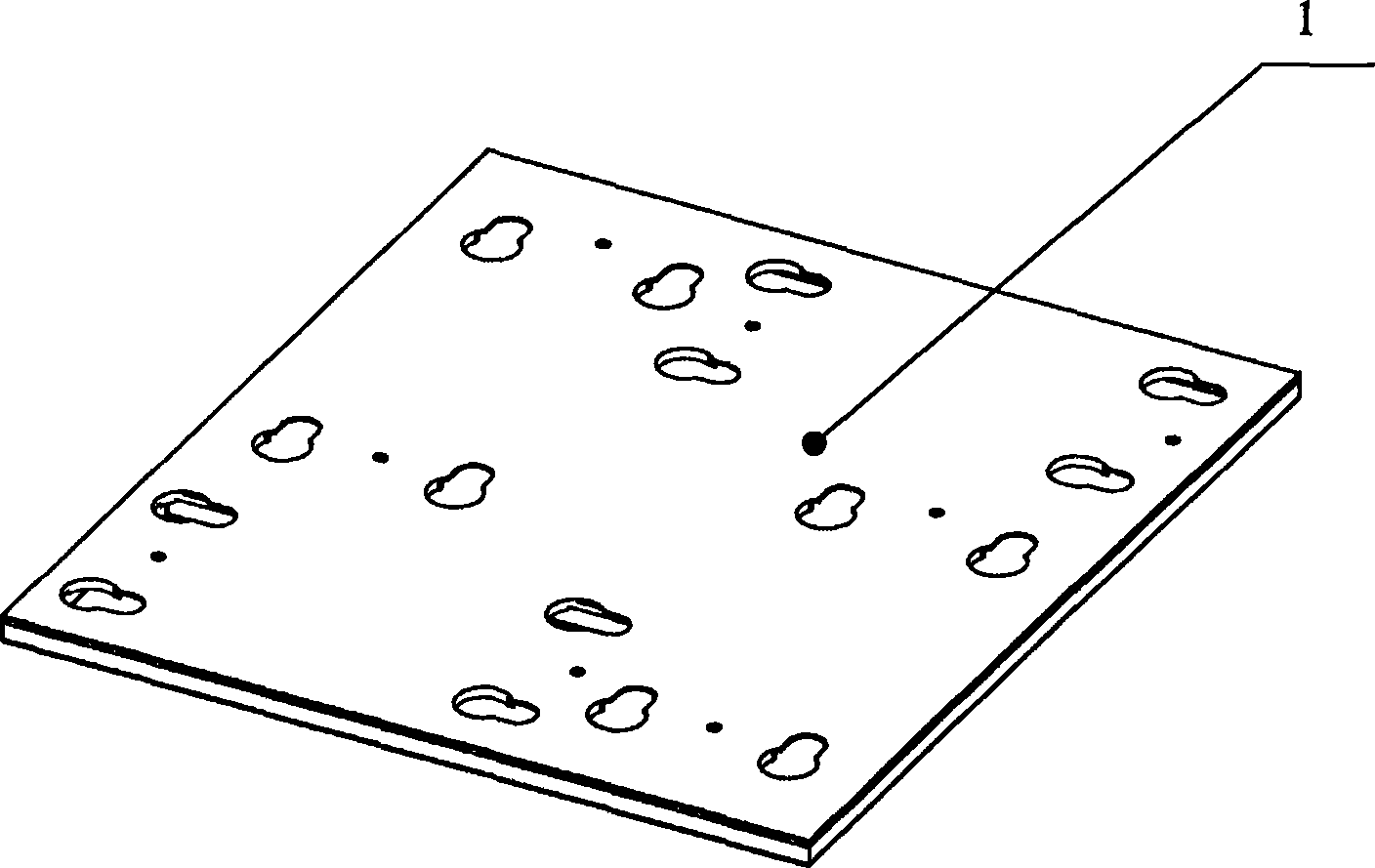

[0027] 2), the heavy object tray 1 is installed on the bracket 1-1 of the parallelogram mechanism through the slide rail 6, wherein the heavy object tray 1 is fixed with the upper bracket 6-1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com