Spring for a slide module, and slide module using same

A technology of sliding modules and torsion springs, applied in the direction of torsion springs, springs/shock absorbers, telephone structures, etc., to achieve the effect of durability, firmness, and flexible use of sliding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, in order to facilitate the implementation of related matters of the present invention by those skilled in the technical field of the present invention, a detailed description will be made using pictures of typical embodiments of the present invention.

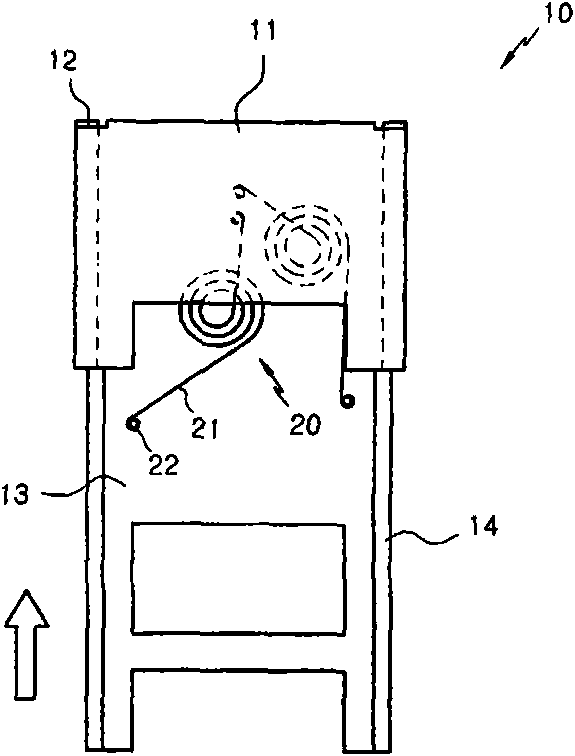

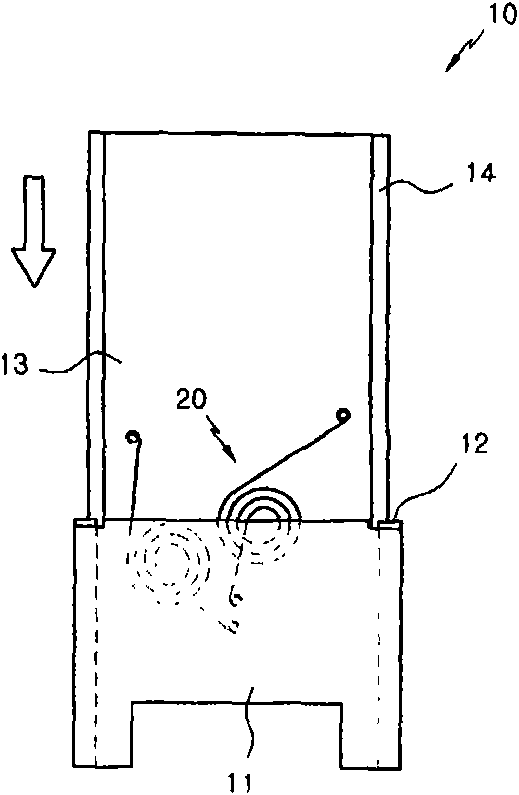

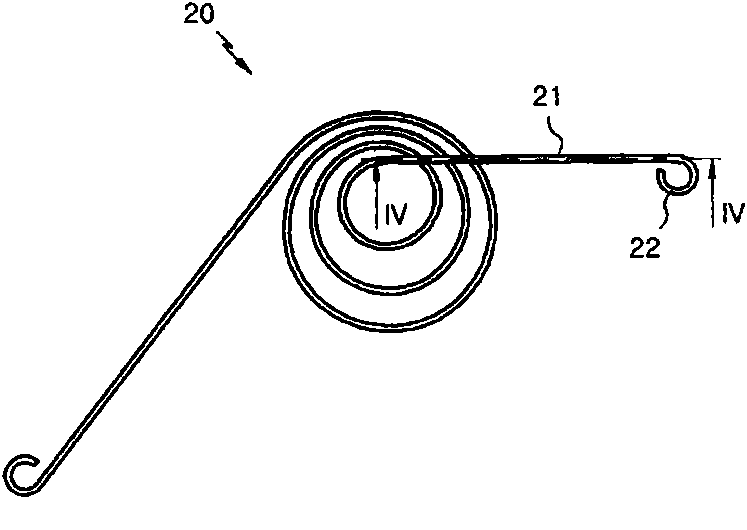

[0054] Figure 7 Is a perspective view showing a torsion spring in an embodiment of the present invention; Figure 8 Is a front view showing the torsion spring in an embodiment of the present invention; Picture 9 Is a plan view showing the torsion spring in an embodiment of the present invention; Picture 10 Yes Picture 9 A-A line cross-sectional view; Picture 11 with Picture 12 Is a front view showing the main structure of the torsion spring in an embodiment of the present invention; Figure 13a , Figure 13b It is a plan view in which the coil parts of the torsion spring form other forms in an embodiment of the present invention; Figure 14a to Figure 14c Is a plan view showing various deformed shapes of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com