PCB testing device

A technology for testing devices and PCB boards, applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the problems of not being able to see the real problems of PCB boards, low detection efficiency, and high labor intensity, so as to improve work efficiency and test Accuracy, high degree of automation, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

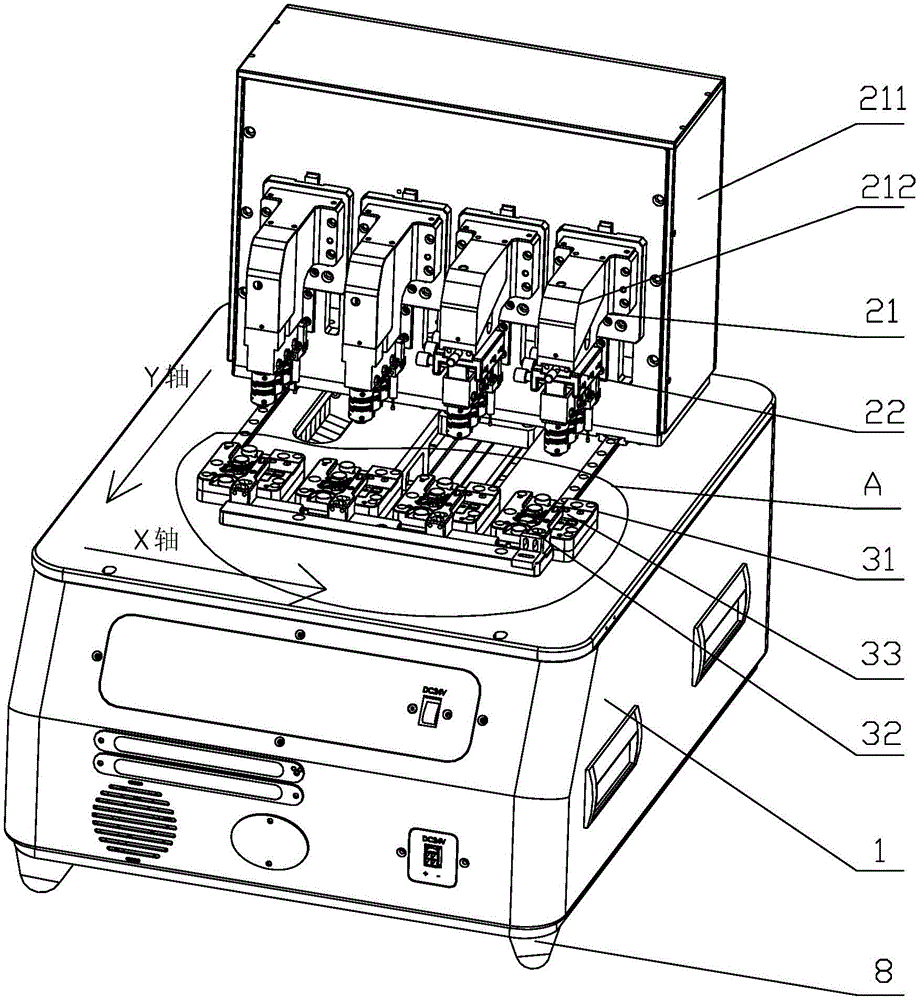

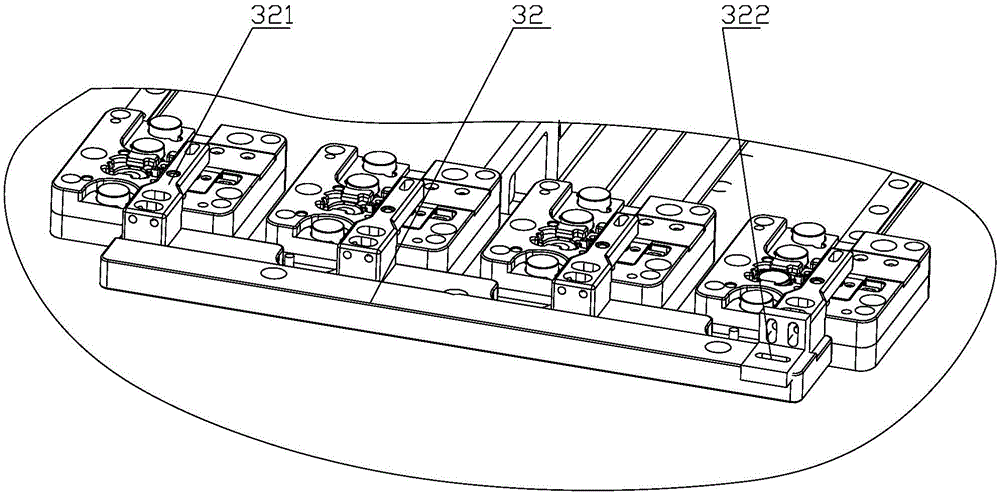

[0034] The present embodiment provides a kind of test device of PCB board, the structure of the test device of this PCB board is as follows Figure 1-Figure 8 As shown, it includes an electric control box 1, an upper mold assembly arranged above the electric control box 1 and a lower mold assembly arranged on the upper panel of the electric control box.

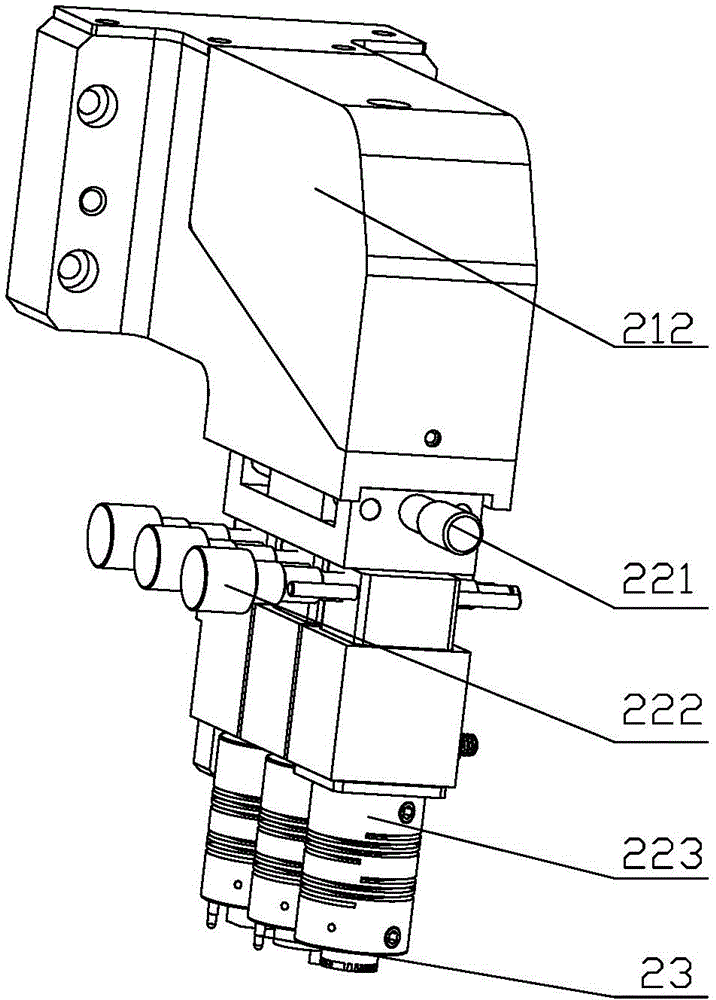

[0035] The upper mold assembly includes four sets of lifting mechanisms 21 , four sets of XY axis moving mechanisms 22 and four sets of probes 23 corresponding to the lifting mechanisms 21 and XY axis moving mechanisms 22 , and each set of probes 23 includes three probes 23 . The lifting mechanism 21 is used to drive the probe 23 to move up and down. It includes a fixed seat 211 and a lifting cantilever 212 slidingly connected with the fixed seat 211. The fixed seat 211 is provided with a linear guide rail. The linear guide rail is arranged perpendicular to the upper panel of the electric control box. The cantilever 212 can s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com