Device for testing dynamic friction coefficient

A dynamic friction and coefficient technology, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of high work intensity in dynamic friction coefficient testing, achieve the effects of low work intensity, good reliability, and improved compaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

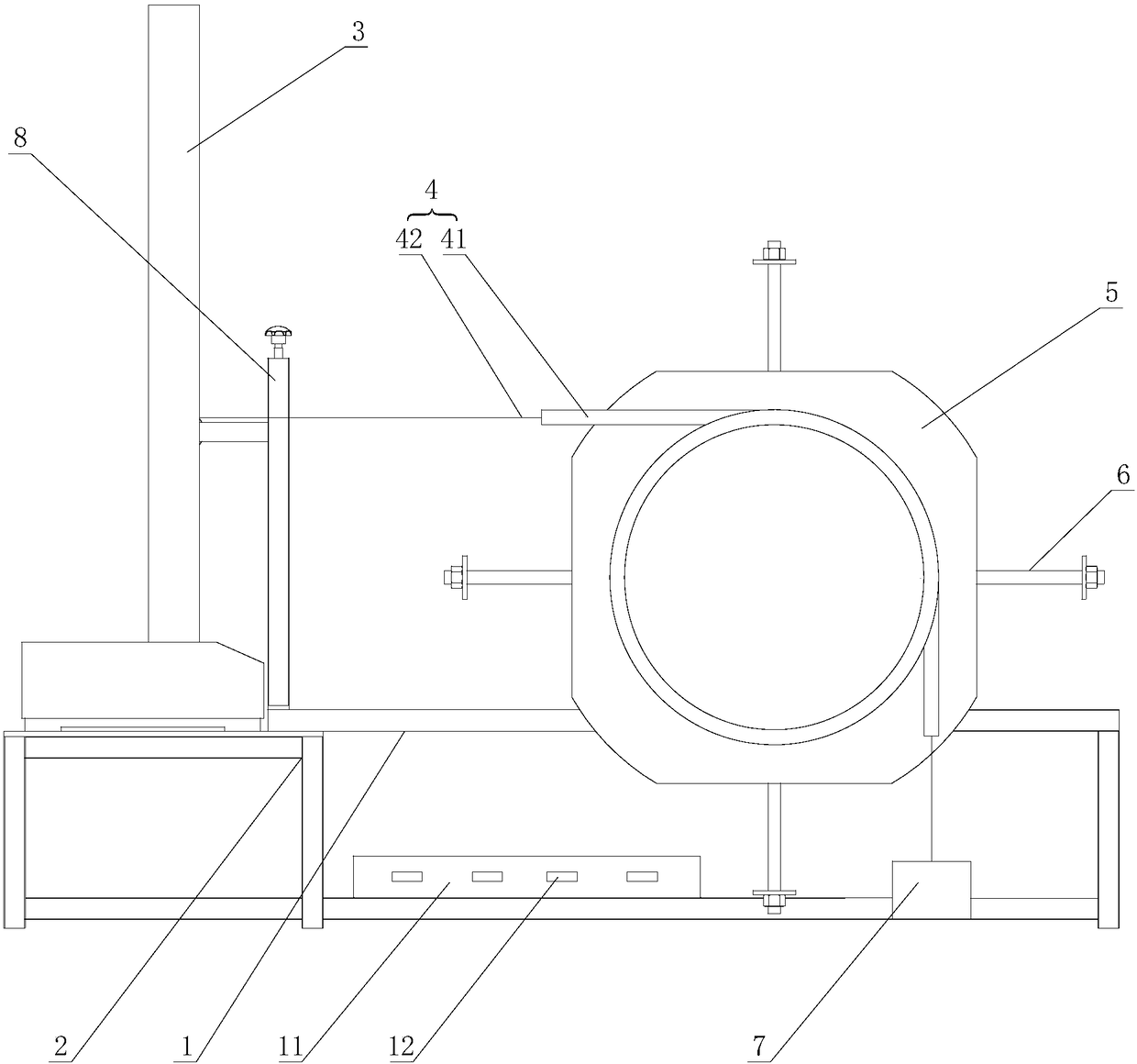

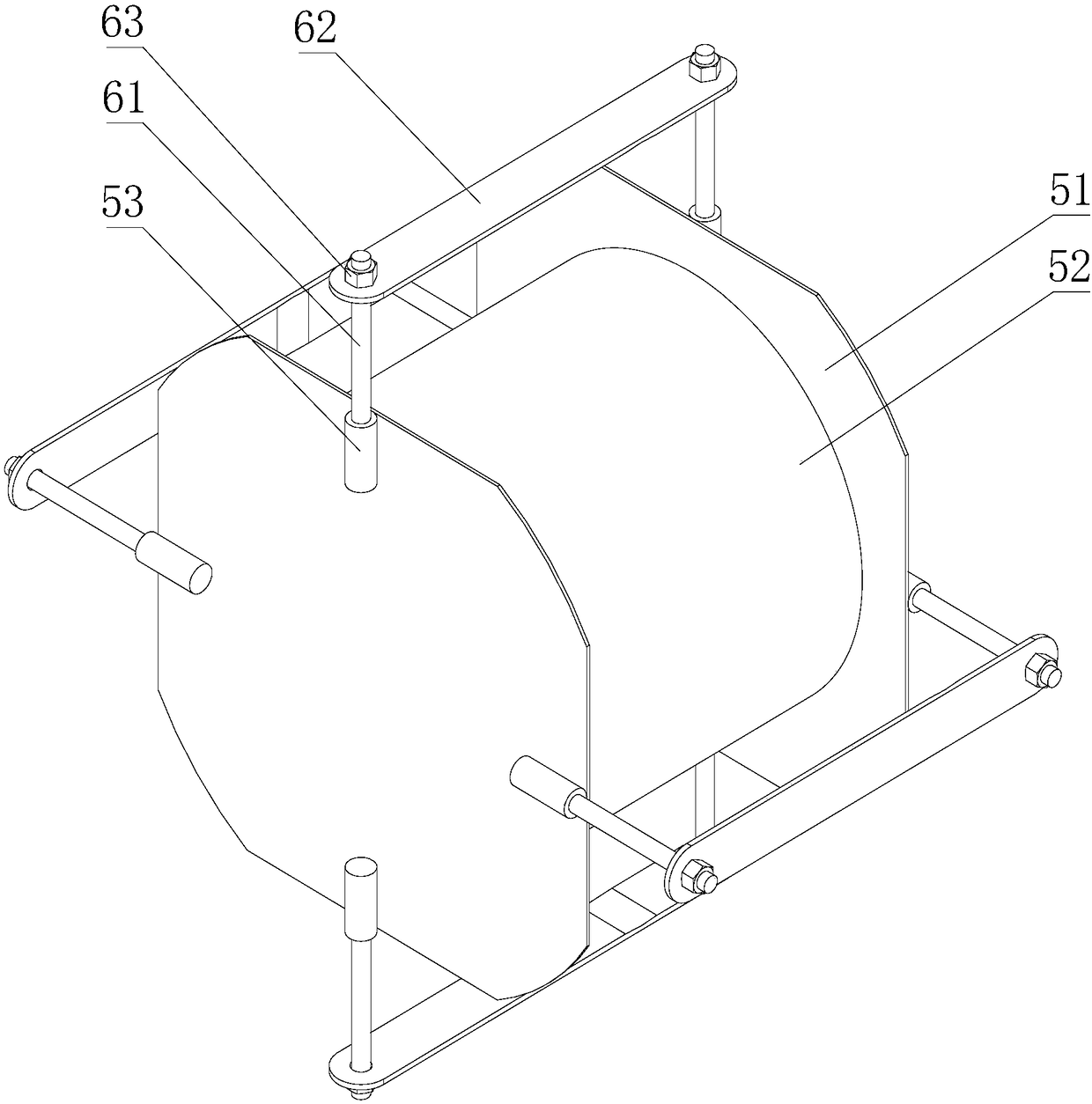

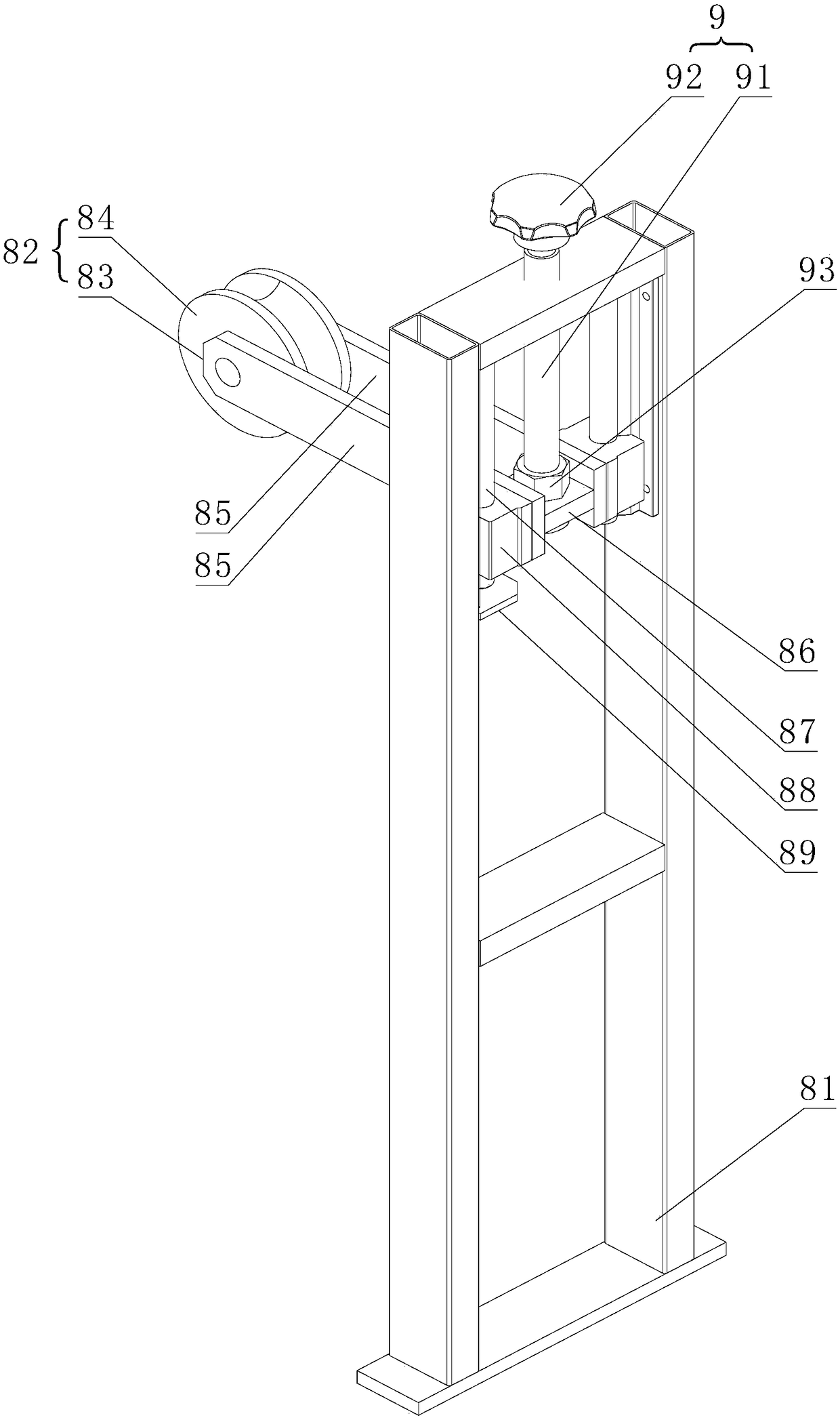

[0031] Such as figure 1 , figure 2 , image 3 As shown, a device for testing the coefficient of dynamic friction includes a fixed frame 1, a workbench 2, a tensile testing machine 3 and a sample 4, and the sample 4 includes a fixed part 41 and a movable part arranged in the fixed part 41 42. The tensile testing machine 3 is fixedly connected to the worktable 2, and one end of the fixed frame 1 is also fixed on the workbench, which can optimize the overall structure and reduce the floor space of the device. The fixed frame 1 is provided with a fixing part 41 winding drum mechanism 5, the drum mechanism 5 is provided with a compression assembly 6 that compresses the fixed part 41 on the drum mechanism 5, and the fixed frame 1 is provided with a weight 7 connected to one end of the movable part 42, The other end of movable part 42 links to each other with tensile testing machine 3, is provided with collet on the other end of movable part 42 in the present embodiment, and colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com