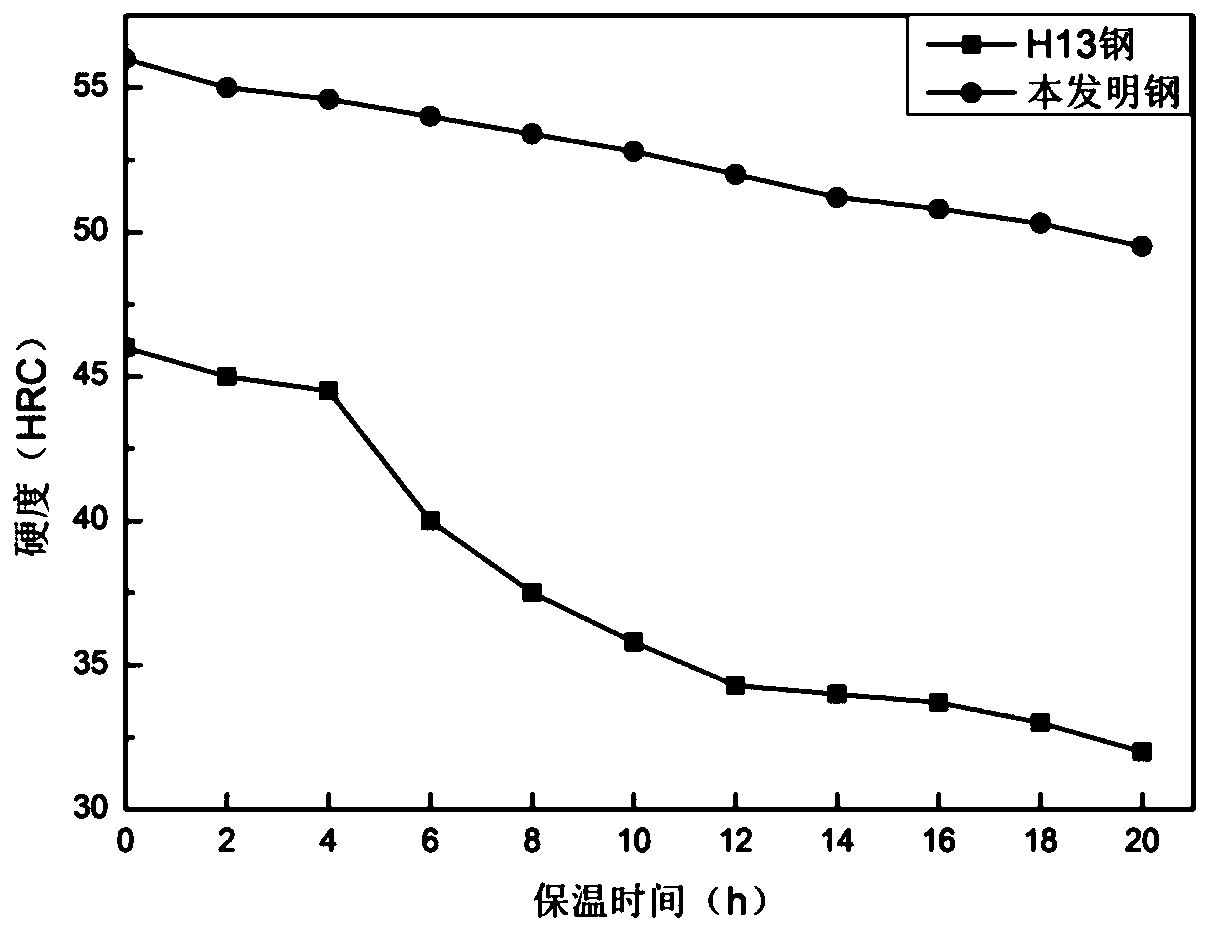

Hot-working die steel and efficient preparation method thereof

A hot work die steel and high-efficiency technology, applied in the field of hot work die steel and its efficient preparation, can solve the problems of occupying heat treatment furnaces, reducing production efficiency, increasing production costs, etc., so as to improve production efficiency, prevent component segregation, reduce The effect of small production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

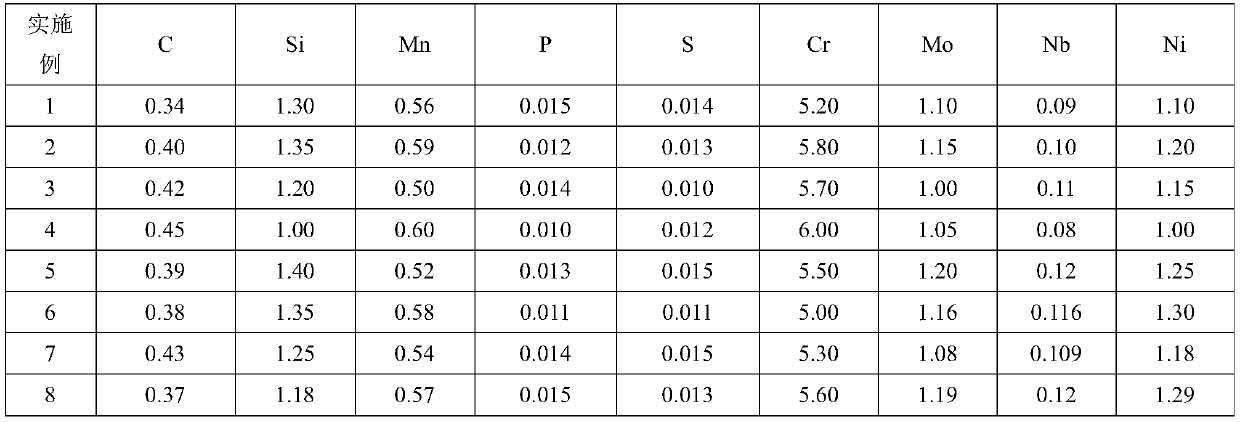

[0031] A kind of hot work die steel, the weight percentage of the chemical composition of this hot work die steel is:

[0032] C: 0.34%-0.45%, Si: 1.00%-1.40%, Mn: 0.50%-0.60%, P≤0.015%, S≤0.015%, Cr: 5.00%-6.00%, Mo: 1.00%-1.20%, Nb: 0.08%-0.12%, Ni: 1.00%-1.30%, and the balance is Fe and unavoidable impurities.

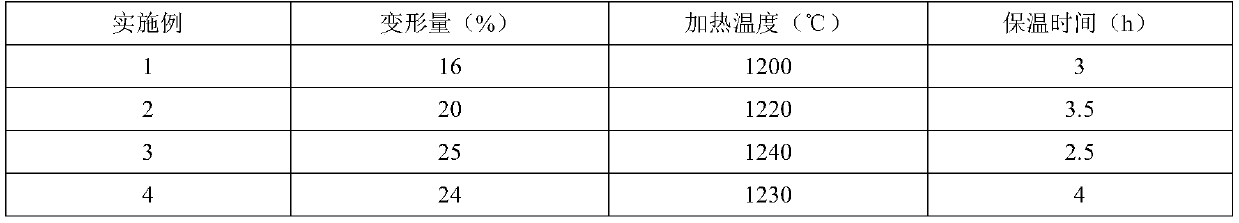

[0033] A high-efficiency preparation method for hot work die steel, comprising the following steps:

[0034] 1) The molten iron pretreatment-converter smelting-external refining (LF+RH) method is used for smelting, the slab is continuously cast to obtain a continuous casting slab, and the continuous casting slab is subjected to rolling pre-deformation, and the deformation is controlled at 15%-25% , followed by high-temperature homogeni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com