Continuous friction stir extrusion production method and production device for ultra-fine grain material

A friction stir and production method technology, applied in the direction of metal extrusion dies, etc., can solve the problems of high strength, low plasticity, and no ideal solution for wire rods, and achieve the effect of excellent mechanical properties and uniform and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

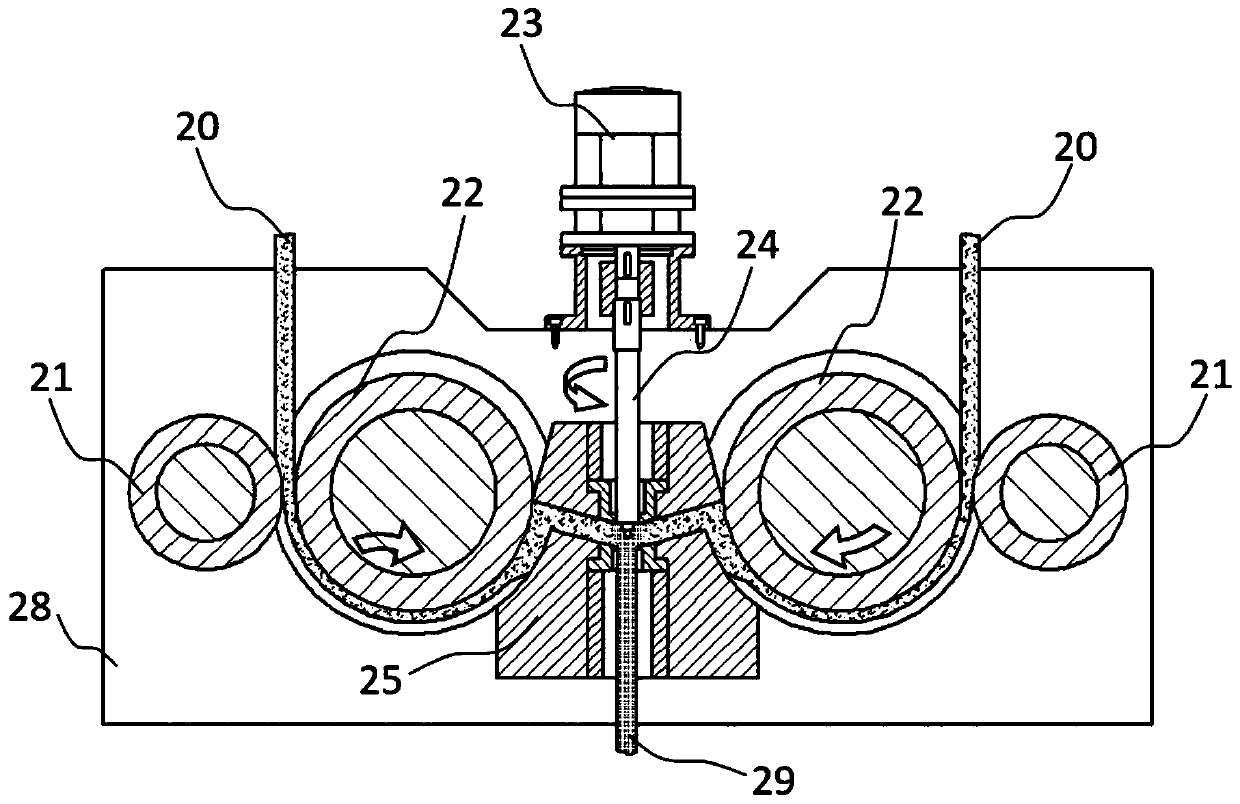

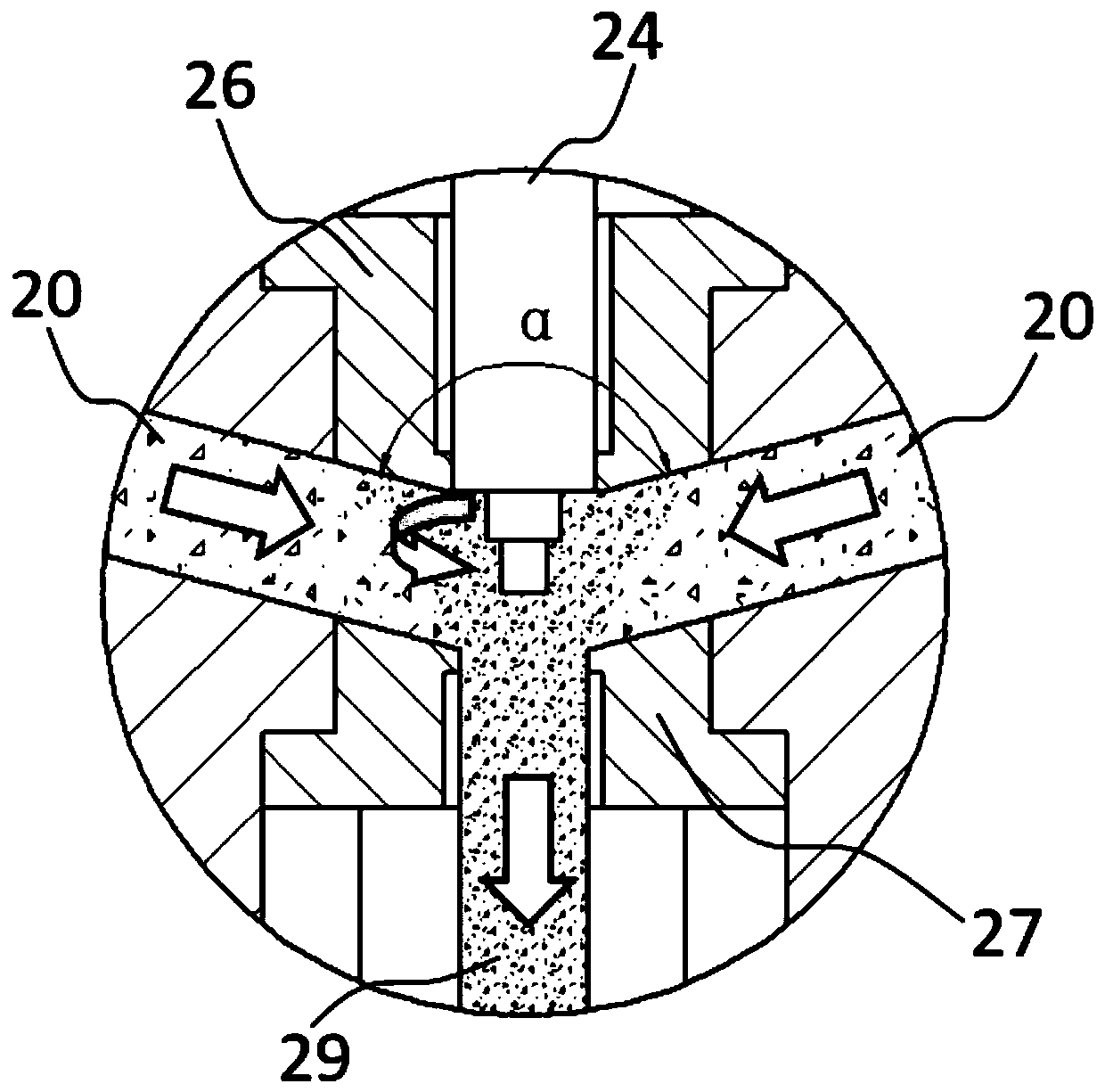

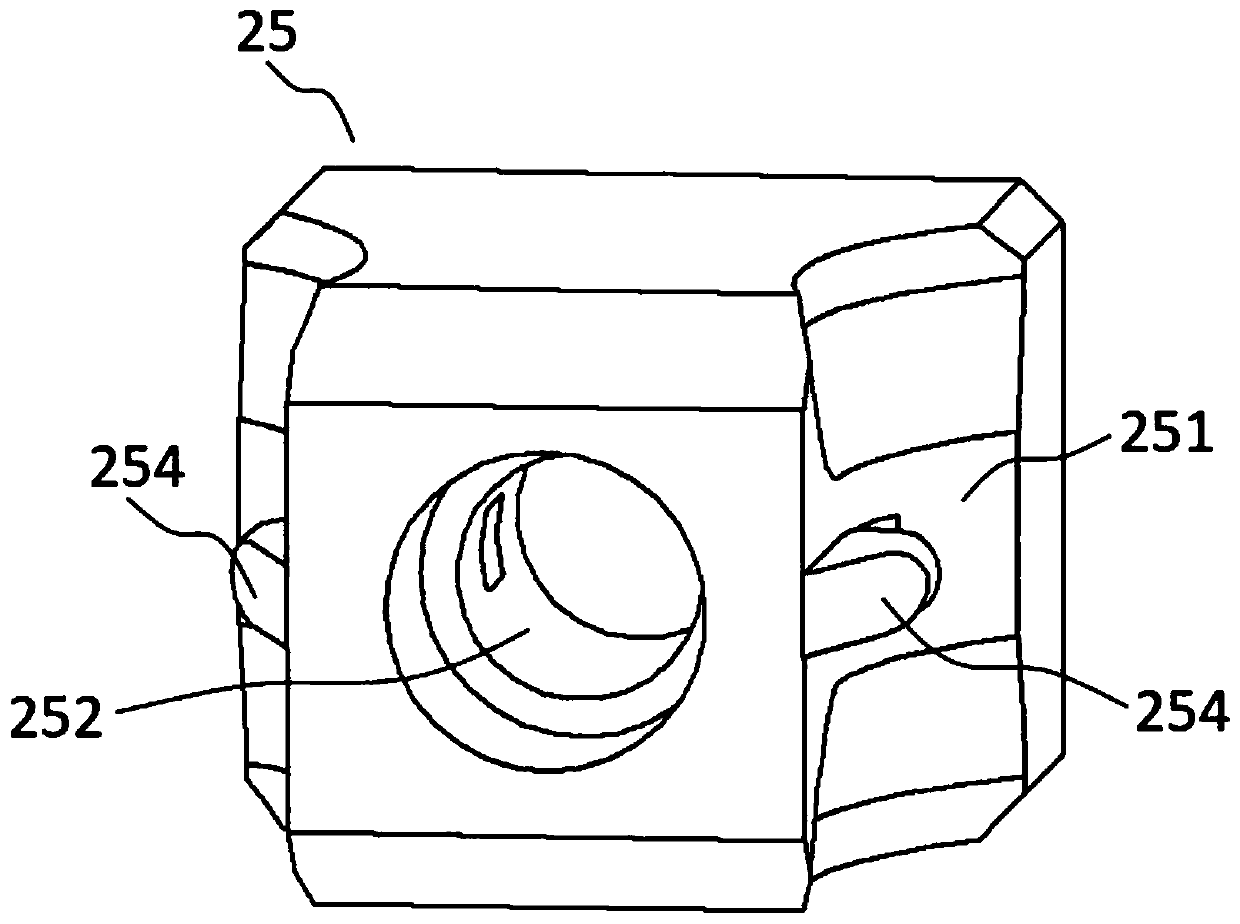

[0068] The diameter of the extrusion wheel 22 is 250 mm, and the center distance is 400 mm. There is an annular groove on the peripheral surface of the extrusion wheel with a width of 8 mm. , the symmetry plane passes through the midpoint of the shortest line connecting the axes of the two extrusion wheels, and the angle between the centerlines of the feed hole 255 is 90°.

[0069] During work, the guide die 26 and the extrusion die 27 are first installed in the die cavity 25, and locked with nuts, the die cavity is installed in the middle of the two extrusion wheels 22 and fixed; the stirring rod 24 is stretched into the guide die, to the shaft shoulder The end face is flush with the end face of the guide die, start the stirring device 23, and make the stirring rod 24 rotate; start the main shaft, make the extrusion wheel 22 rotate synchronously, and feed the billet 20 through the hole between the extrusion wheel 22 and the pressing wheel 21, After the product is extruded fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com