Drug breaking and grinding device

A grinding device and medicine technology, which is applied in the field of medical equipment, can solve the problems of wasting manpower and material resources, energy waste, etc., and achieve the effect of increasing the grinding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

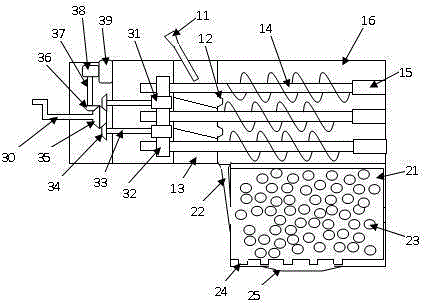

[0028] Such as figure 1 shown.

[0029] A drug crushing and grinding device includes a crushing system, a grinding system, a power and a transmission system.

[0030] The crushing system includes a crushing system preparation chamber and a crushing chamber. The preparation chamber of the crushing system is provided with a drug raw material inlet obliquely. Three crushing rollers are arranged side by side through the preparation chamber of the crushing system and the crushing chamber. The crushing chamber wall between the rollers is provided with a crushing system inlet, which is used to transport the drug raw materials from the crushing system preparation chamber to between every two crushing rollers of the crushing system. The plate is used to obliquely roll the pharmaceutical raw materials into the crushing system inlet. There are multiple medicine baffles, all arranged obliquely, the bottom one is sealed, and the upper ones are arranged in random order, so that both the e...

Embodiment 2

[0043] A drug crushing and grinding device includes a crushing system, a grinding system, a power and a transmission system.

[0044] The crushing system includes a crushing system preparation chamber and a crushing chamber. The preparation chamber of the crushing system is provided with a drug raw material inlet obliquely. Three crushing rollers are arranged side by side through the preparation chamber of the crushing system and the crushing chamber. The crushing chamber wall between the rollers is provided with a crushing system inlet, which is used to transport the drug raw materials from the crushing system preparation chamber to between every two crushing rollers of the crushing system. The plate is used to obliquely roll the pharmaceutical raw materials into the crushing system inlet. There are three drug baffles, and the upper two are arranged obliquely and randomly, so that both the entrances of the crushing system can accept the drug raw materials.

[0045] One end o...

Embodiment 3

[0053] When in use, put the solid tablet (or traditional Chinese medicine solid raw material) through the drug raw material inlet, through the obliquely set baffle, the drug flows into the crushing roller, and the tablet (or other raw material) is broken into pieces by the crushing of the crushing roller. Small medicines are rolled into the grinding system through the medicine transmission groove, and the internal grinding balls are driven to collide with each other through the rotation of the inner cylinder, so that the small medicines are ground into powder, and the powdered medicines that meet the requirements are rotated to the grinding system through the outlet due to the centrifugal force of the inner cylinder. Between the inner cylinder and the outer cylinder, it slides to the lower end of the outer cylinder according to gravity, and flows out through the outlet of the outer cylinder to complete the crushing and grinding of solid medicine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com