Heat-resistant alloy carburizing steel and preparation method thereof

A heat-resistant alloy and carburizing steel technology, applied in the field of carburizing steel, can solve the problems of cracking tendency and poor process performance, and achieve the effects of fine grain, long service life and uniform and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

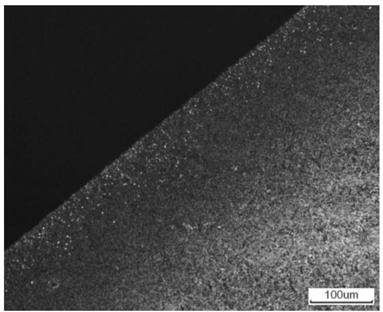

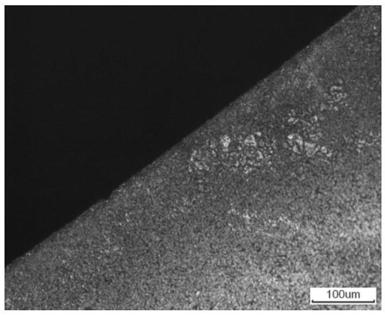

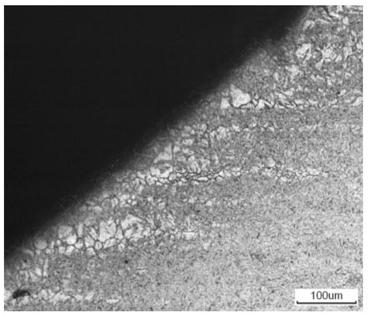

[0045] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0046]Carburized steel is processed into workpieces and generally undergoes carburizing, quenching, cryogenic treatment (to reduce paralysis), tempering, aging and other processes, and finally obtains a tempered martensite structure. Among them, the temperature range of carburizing is about 890-930°C; the quenching temperature is 850-880°C, after quenching, martensite, martensite plus parasite or martensite plus parasite plus undissolved carbides are obtained; The fire temperature is about 200°C, that is, from room temperature to the tempering temperature, both martensite and parasite undergo structural transformation, including the decomposition of martensite, the transformation of parasite, the precipitation and change of carbides, and the recovery and recovery of α phase. re-crystallize. Its organization still maintains a fine lath martens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com