Method of using solution atomization method to prepare superfine Sb oxide

An antimony oxide, solution atomization technology, applied in chemical instruments and methods, antimony compounds, antimony oxide / antimony hydroxide / antimony oxyacid and other directions, can solve the problems of large equipment investment, long preparation process flow, etc. The effect of simple requirements, uniform and fine particles, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A kind of method that the solution atomization method of the present invention prepares superfine antimony oxide, its process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0059] (1) Weigh 50.00g SbCl 3 Solid, add 4.5mol / L hydrochloric acid solution diluted with pure water to prepare 0.55mol / L SbCl 3 solution;

[0060] (2) utilize ozone gas to above-mentioned SbCl 3 The solution is oxidized and the potential of the solution is detected. When the potential of the solution is about 0.75V, the ozone is stopped;

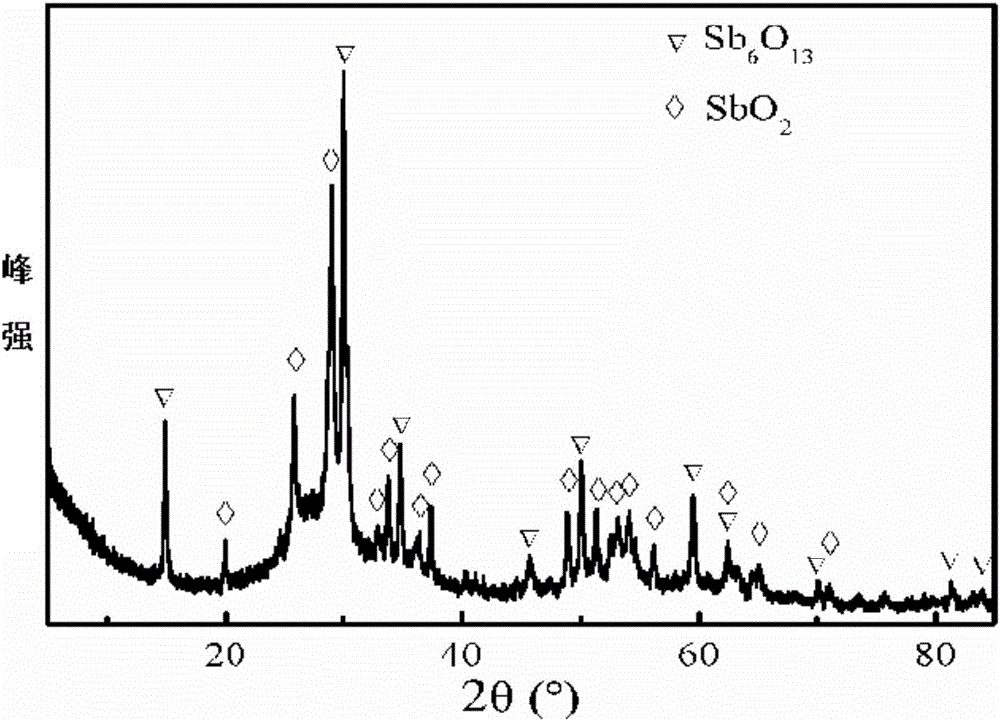

[0061] (3) Use an ultrasonic atomizer to atomize the above-mentioned oxidized solution and control the atomization flow rate to 30mL / h, and use a vacuum pump to draw negative pressure on the reaction device, so that the atomized solution enters the vertical tubular resistance furnace, Thermal decomposition reaction is carried out at a temperature of 500°C to obtain antimony oxide powder;

[0062] (4) The antimony ...

Embodiment 2

[0066] A kind of method that the solution atomization method of the present invention prepares superfine antimony oxide, its process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0067] (1) Prepare 400mL of 5.0mol / L hydrochloric acid in a beaker, heat it in a water bath to the set temperature, then weigh 40.00g of stibnite and add it to the beaker. During the experiment, use a magnetic stirrer to stir and control the stirring speed to extract During the process, continuously feed ozone gas into the solution, react for 4 hours, and filter to obtain the leachate after the reaction is completed;

[0068] (2) Utilize ozone gas to carry out oxidation operation to above-mentioned leaching liquid solution and detect solution potential, when solution potential is about 0.75V, stop feeding ozone;

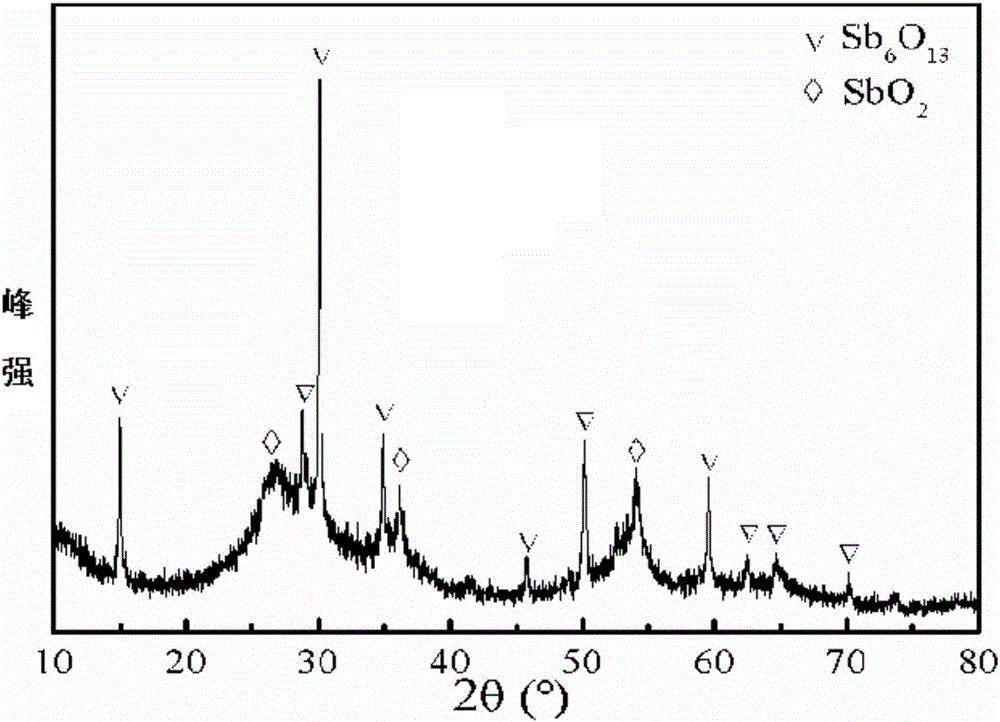

[0069] (3) Use an ultrasonic atomizer to atomize the above-mentioned oxidized solution and control the atomization flow rate to be 50mL / h, and ...

Embodiment 3

[0074] A kind of method that the solution atomization method of the present invention prepares superfine antimony oxide, its process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0075] (1) Weigh 50.00g SbCl 3 Solid, added to the 4.5mol / L hydrochloric acid solution diluted with pure water to prepare 0.55mol / L SbCl 3 solution;

[0076] (2) Use oxygen gas to treat the above-mentioned SbCl 3 The solution is oxidized and the potential of the solution is detected. When the potential of the solution is about 0.75V, stop feeding oxygen;

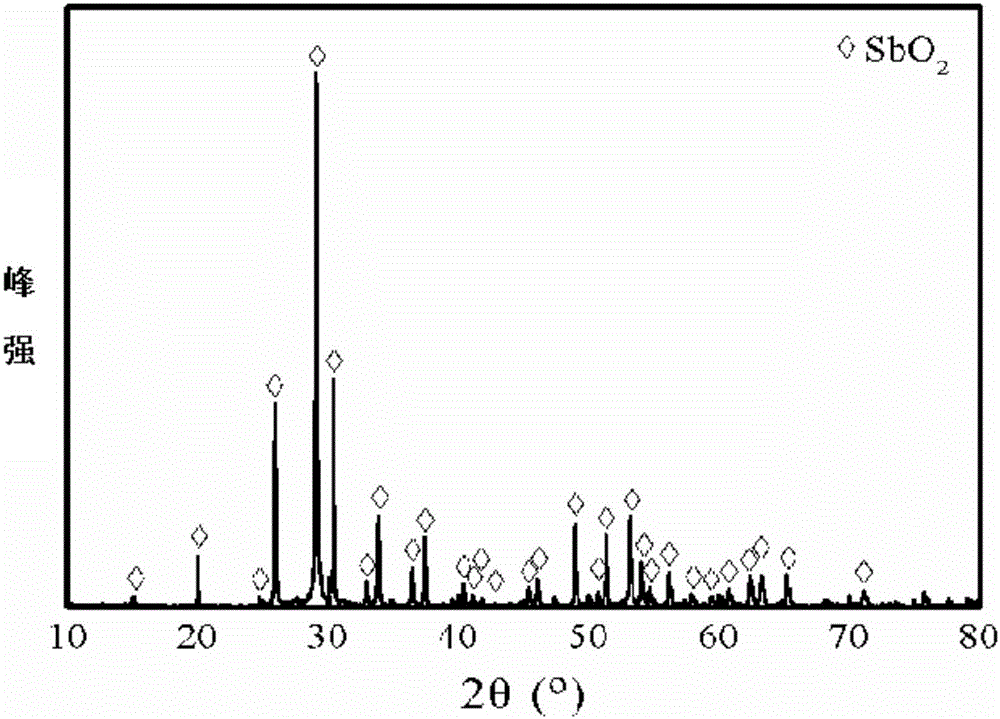

[0077] (3) Use an ultrasonic atomizer to atomize the above-mentioned oxidized solution and control the atomization flow rate to be 50mL / h, and use a vacuum pump to draw negative pressure on the reaction device so that the atomized solution enters the vertical tubular resistance furnace. Perform thermal decomposition reaction at a temperature of 900°C to obtain antimony oxide powder;

[0078](4) The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com