Patents

Literature

165 results about "Antimony pentoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimony pentoxide (molecular formula: Sb₂O₅) is a chemical compound of antimony and oxygen. It always occurs in hydrated form, Sb₂O₅·nH₂O. It contains antimony in the +5 oxidation state.

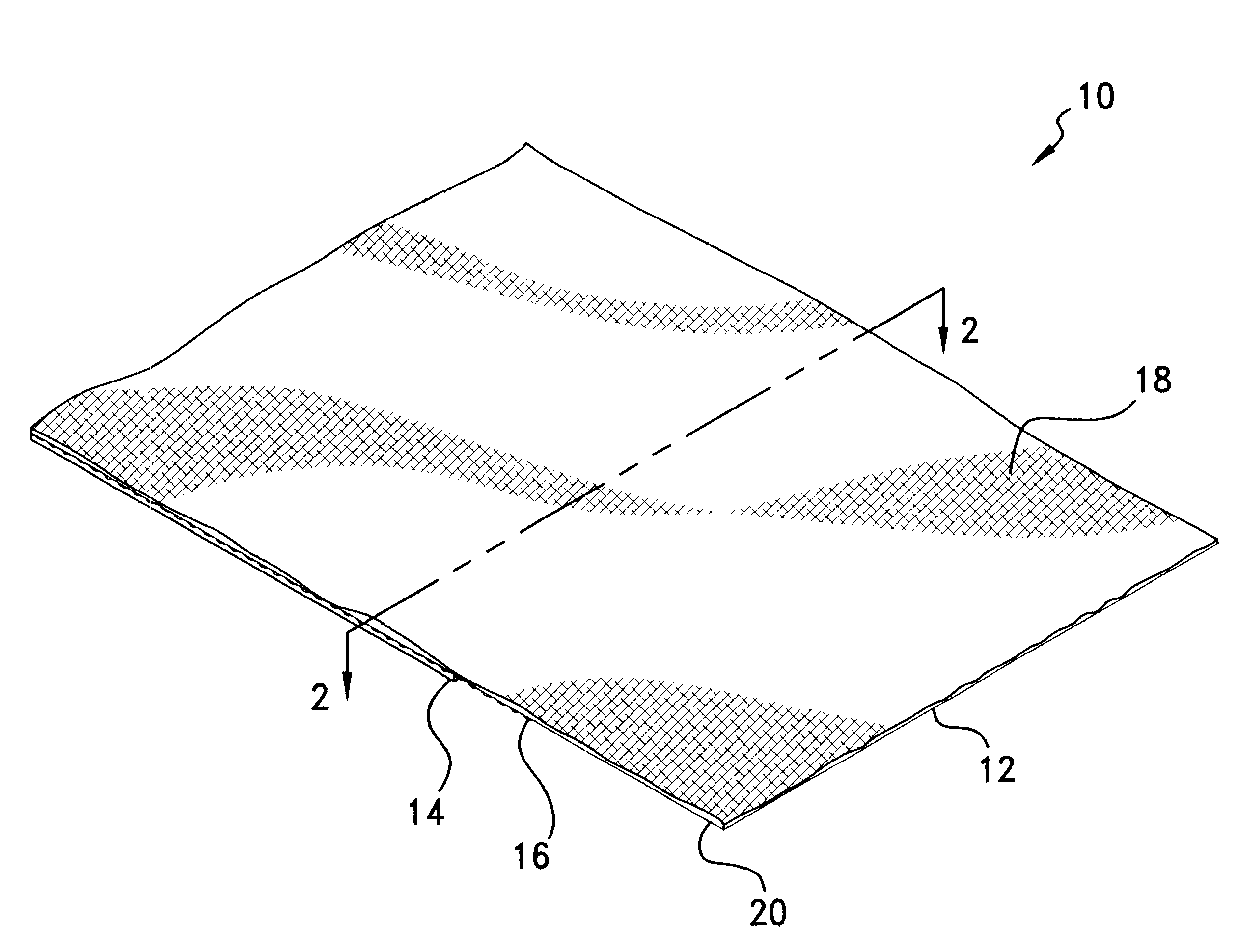

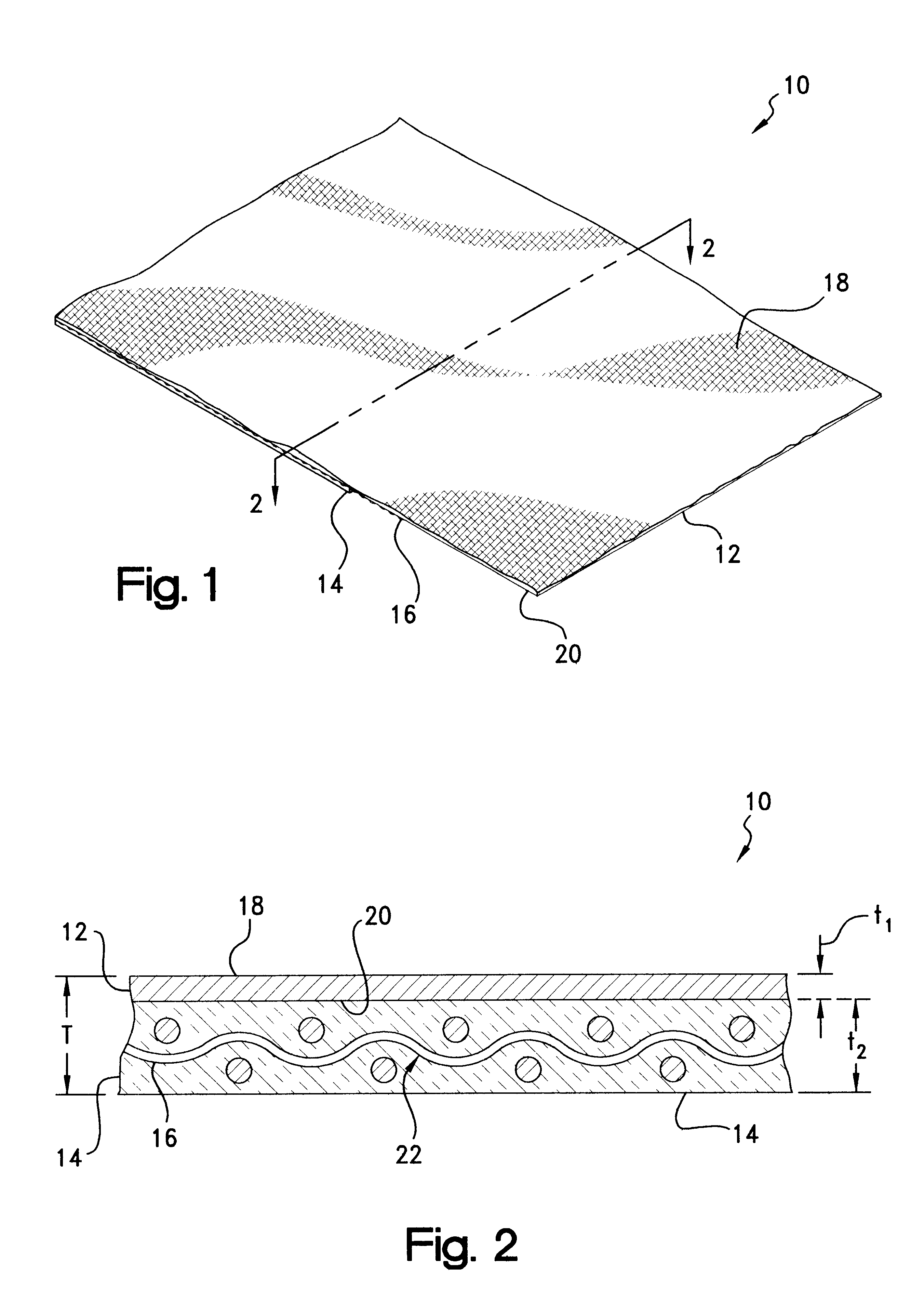

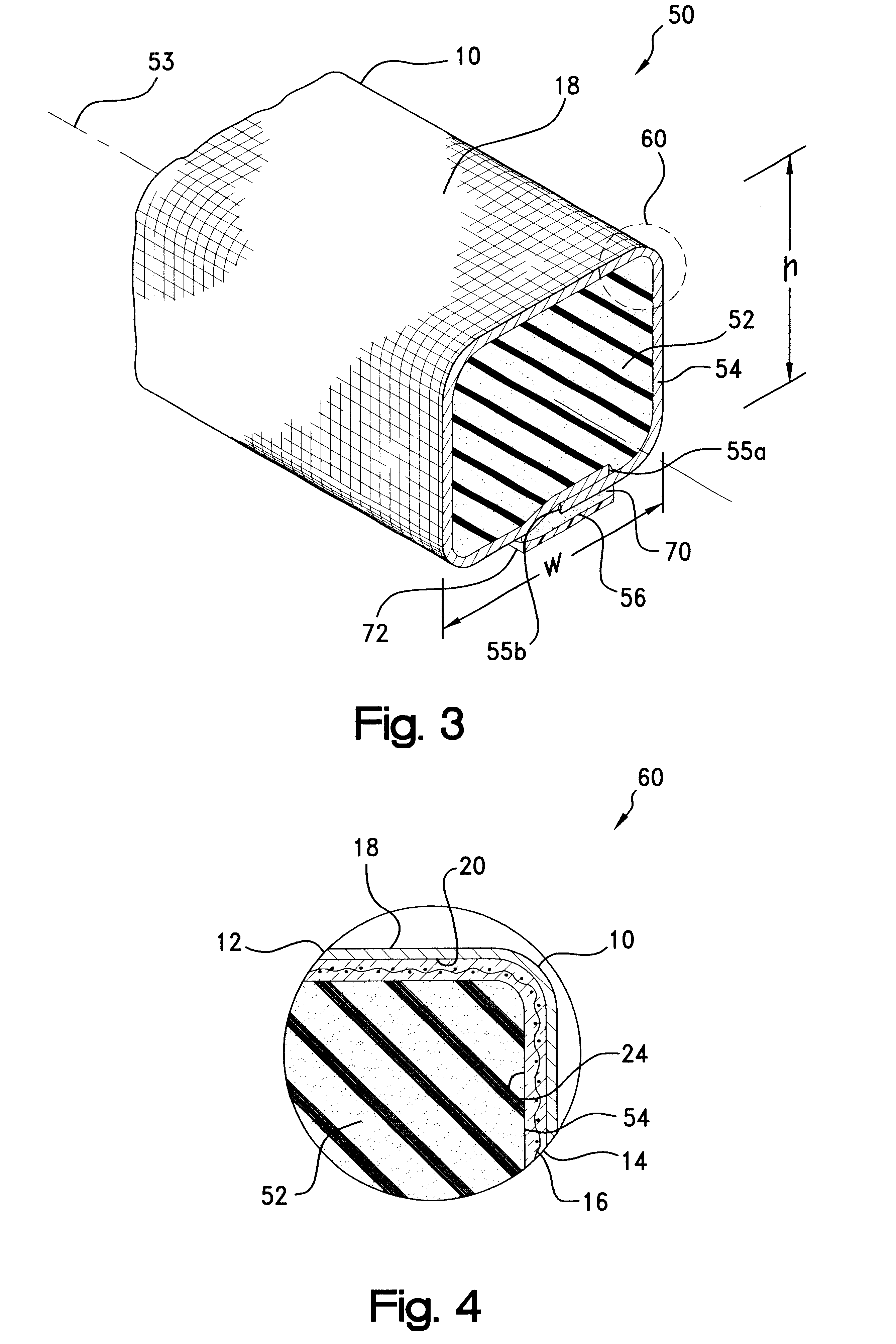

Intumescent, flame retardant pressure sensitive adhesive composition for EMI shielding applications

InactiveUS6410137B1Readily apparentGood physical propertiesScreening gaskets/sealsSynthetic resin layered productsDecabromodiphenyl etherPolybrominated Biphenyls

A flame retardant, intumescent pressure sensitive adhesive (PSA) composition for EMI shielding gaskets, tapes, wraps, and the like. The composition is formulated as an admixture of: (a) a PSA component; (b) a halogenated first flame retardant component; (c) a metal-based second flame retardant component; and (d) a filler component of expandable, intercalated graphite particles. In a representative embodiment the PSA component (a) is acrylic-based, the halogenated first flame retardant component (b) is a polybrominated diphenyl compound such as decabromodiphenyl oxide or decabromodiphenyl ether, the metal oxide-based second flame retardant component (c) is antimony oxide, antimony trioxide, or antimony pentoxide, and the filler component (d) is graphite flake.

Owner:PARKER INTANGIBLES LLC

Novel anti-flaming anti-static electricity polypropylene dedicated material and preparation method thereof

InactiveCN101735516AImprove flame retardant performanceHigh mechanical strengthBromocyclohexaneAluminium hydroxide

The invention discloses a novel anti-flaming anti-static electricity polypropylene dedicated material and a preparation method thereof; the dedicated material is prepared by the following raw materials by mass percentage: 40-70 percent of polypropylene resin or polypropylene / nylon alloy or polypropylene / nylon / PP-g-MAH, 20-40 percent of formulated fire retardant, 4-10 percent of electric-conduction fillers, and 6-15 percent of inorganic fillers; the formulated fire retardant is formulated by several kinds of compound A, compound B, ammonium polyphosphate, tetramethylolmethane, magnesium hydroxide, aluminium hydroxide and tripolycyanamide, the compound A is bromocyclohexane or hexabromocyclododecane, the compound B is antimony trioxide or antimony pentoxide; the inorganic filler adopts montmorillonoid, hydrotalcite, talcum powder or attapulgite clay. The novel anti-flaming anti-static electricity polypropylene dedicated material prepared by the invention has good flame retardant property and good anti-static electricity performance, the mechanical intensity of the material is further improved after the alloy is prepared by adding the nylon, the used raw material has low cost and is environment-protection, and no melt body drops in the anti-flaming process.

Owner:ZHEJIANG UNIV OF TECH

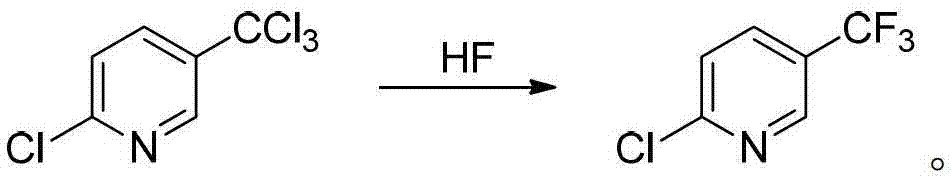

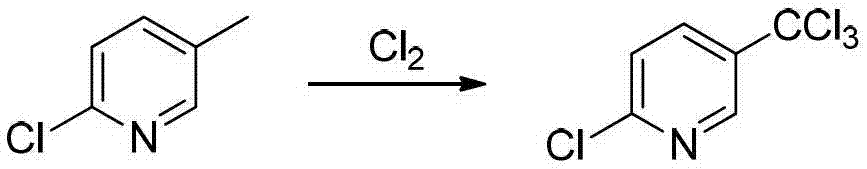

Preparation method of 2-chloro-5-tirfluoromethylpyridine

ActiveCN103288718AReduce manufacturing costReduce solid wasteOrganic compound preparationCarboxylic acid amides preparationHydrogen fluorideAntimony trioxide

The invention discloses a preparation method of 2-chloro-5-tirfluoromethylpyridine. The invention provides a preparation method of 2-chloro-5-tirfluoromethylpyridine, and the preparation method comprises the following steps of: reacting 2-chloro-5-trichloromethylpyridine with hydrogen fluoride in a closed system in the presence of a catalyst to obtain the 2-chloro-5-tirfluoromethylpyridine, wherein the catalyst is antimony trioxide and / or antimony pentoxide. The invention further provides a preparation method of a compound 2, and the preparation method comprises the following steps of: reacting a compound 3 with ammonia in the presence of alkali to obtain the compound 2. The preparation method provided by the invention is cheap and liable to obtain raw materials, low in cost, few in reaction by-products, simple in post treatment, safe to operate, environment-friendly and suitable for large-scale industrial production.

Owner:LIAONING TIANYU CHEM +3

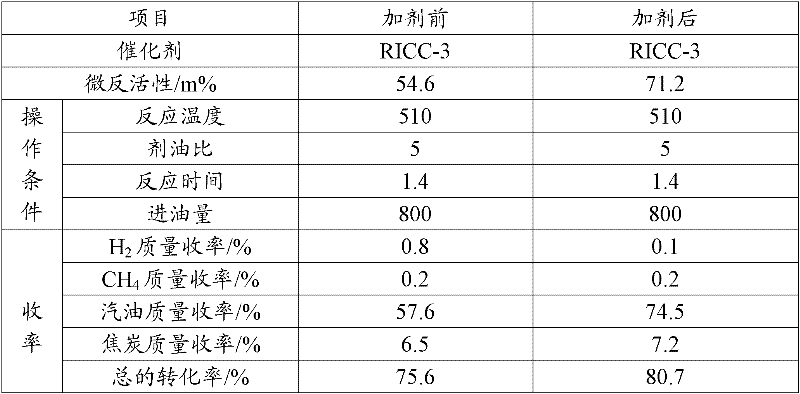

Water-soluble catalytic cracking metal passivator and preparation method thereof

The invention relates to a catalytic cracking metal passivator and a preparation method thereof, in particular to a water-soluble catalytic cracking metal passivator and a preparation method thereof. The metal passivator comprises a nickel passivator and a vanadium passivator, wherein the nickle passivator is antimony pentoxide hydrosol; the vanadium passivator is an organic acid salt aqueous solution of lanthanum or cerium; and in the passivator, the antimony content is 8-30 percent, the lanthanum or cerium content is 0-7 percent, and the rest is water. In the invention, a preparation process of hydrogen peroxide is adopted, so that reaction time is short, external heating is not required, energy is saved, consumption is lowered, and the prepared passivator is convenient to use, has stable property, and can be dissolved mutually and infinitely with water.

Owner:SHANDONG CHAMBROAD HLDG GRP CO LTD +1

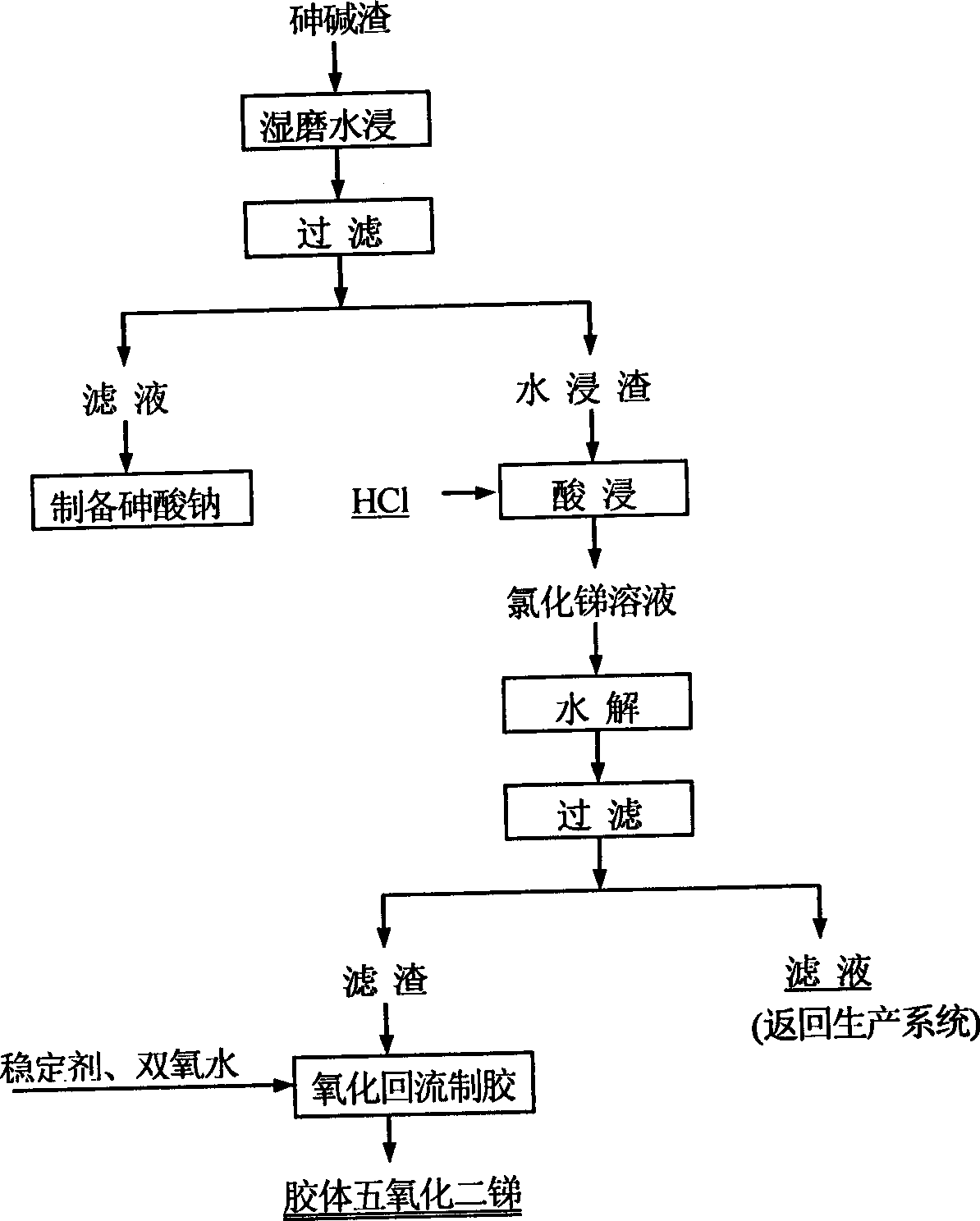

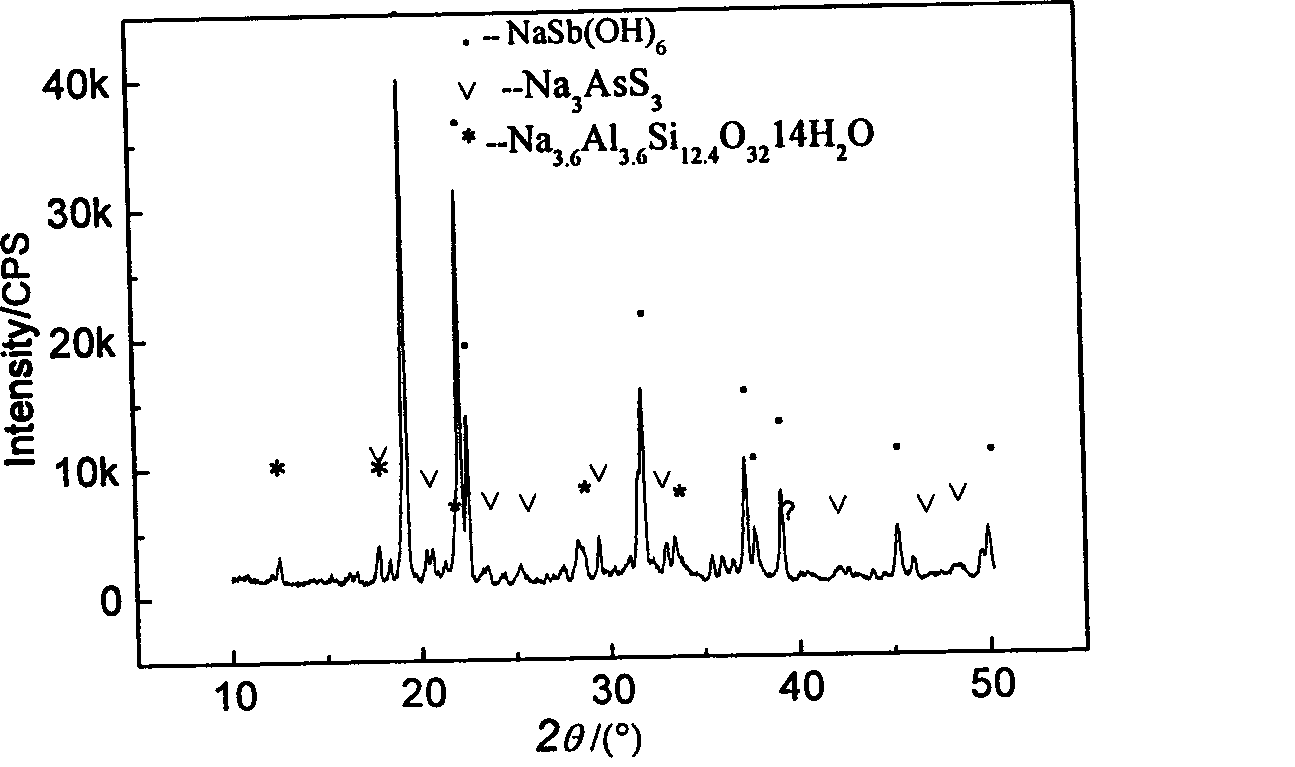

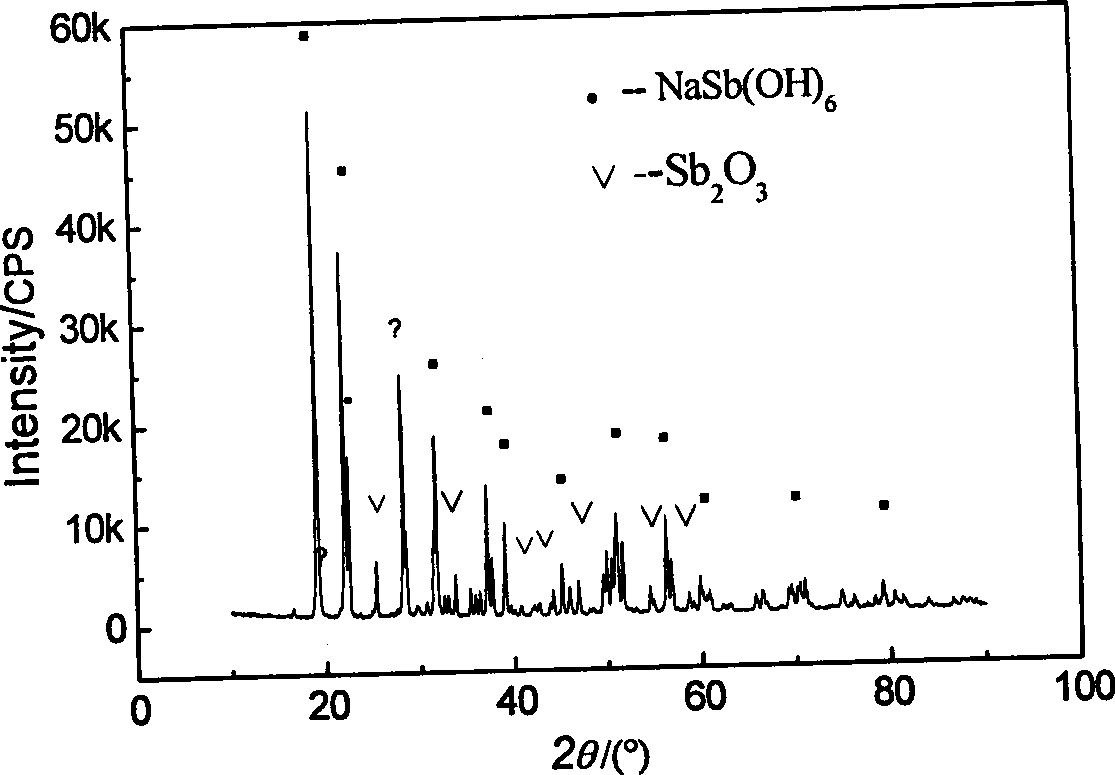

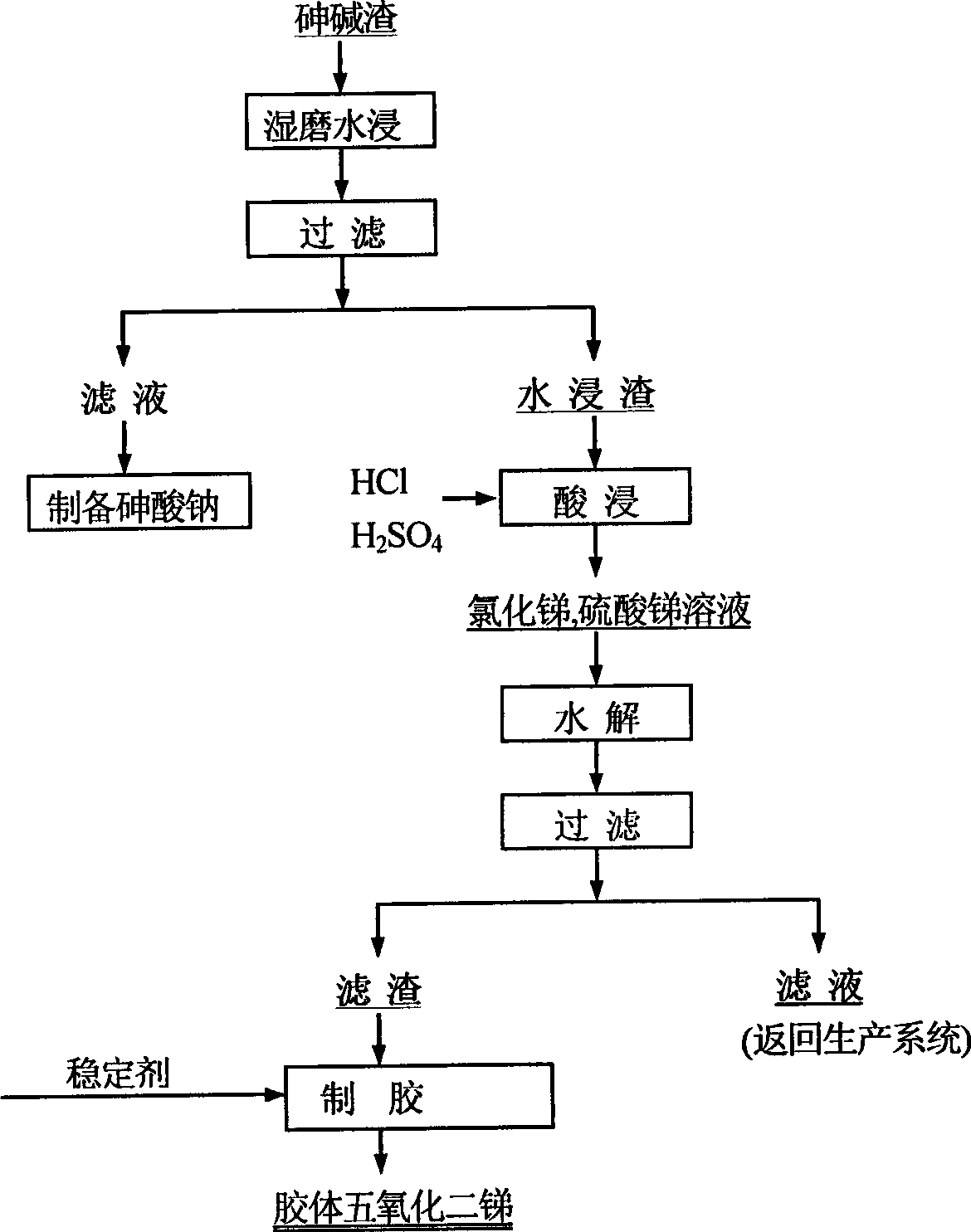

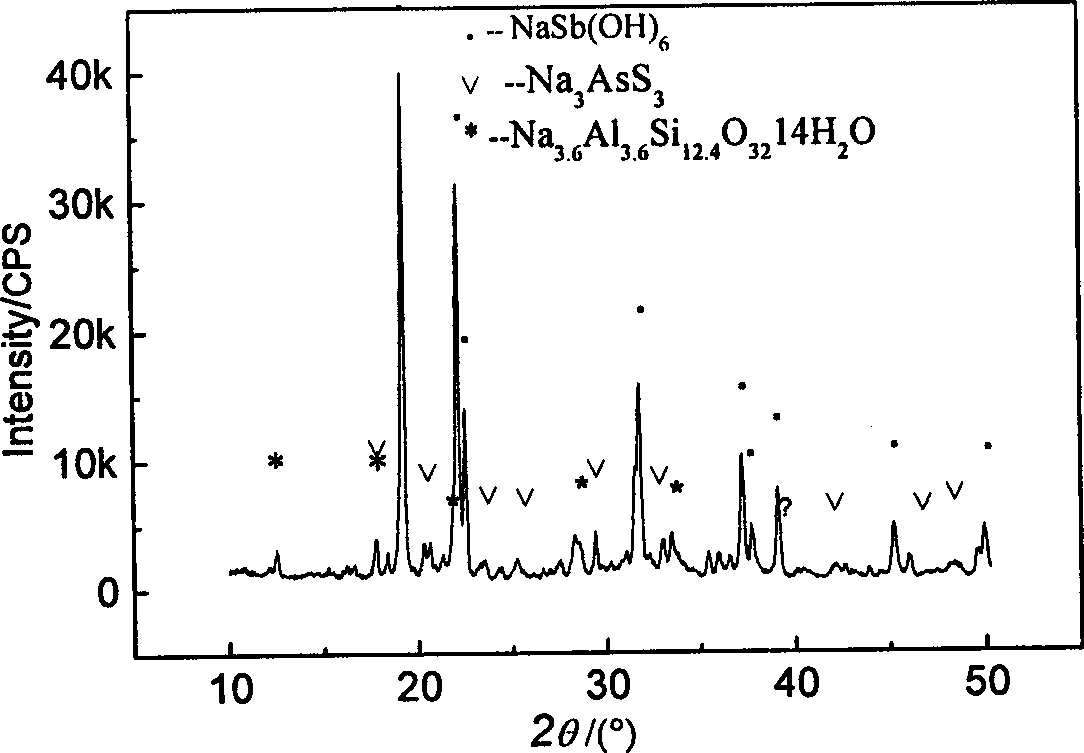

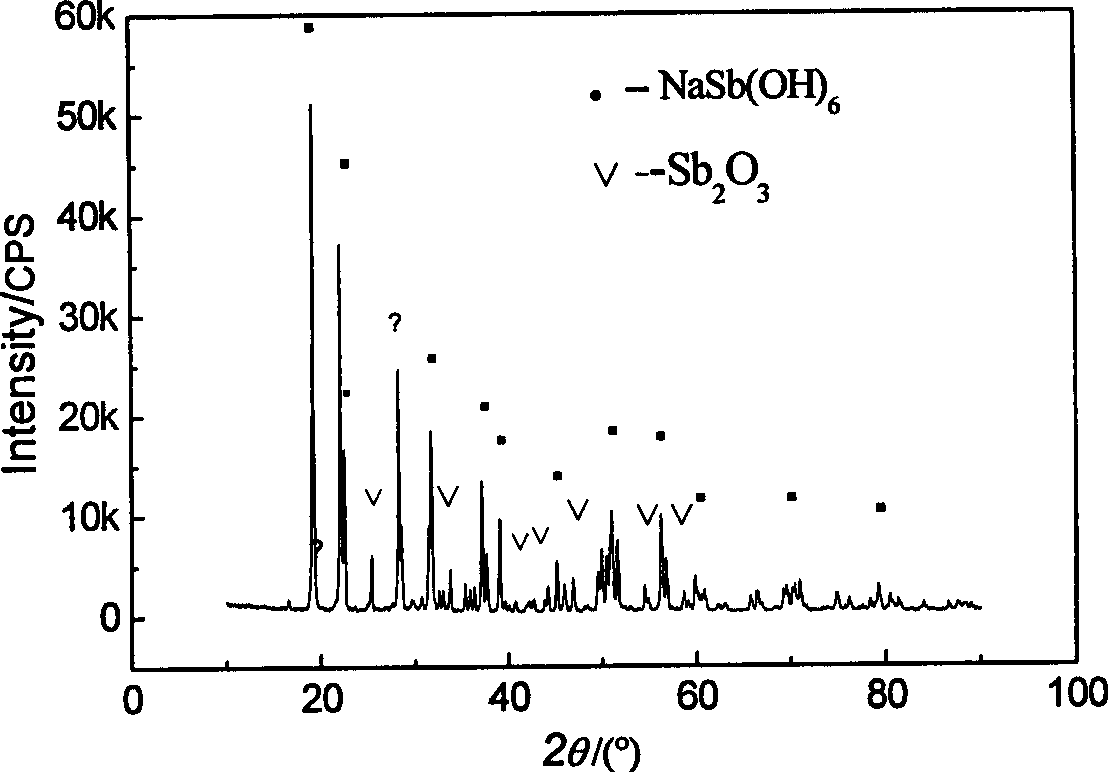

Method for comprehensively processing stibium smelt arsenic alkaline residue and producing colloid antimony peroxide

The invention relates to a method for processing antimony smelting slag, in particular to a method for comprehensively processing antimony smelting arsenic-alkali slag and preparing colloidal antimony pentoxide. The method mainly comprises four processes including water leaching, acid leaching, hydrolysis and colloid making. The antimony oxide obtained from hydrochloric acid leaching and hydrolyzing adopts the oxidation reflux process to prepare the colloidal antimony pentoxide. In the method, the arsenic-alkali slag is subjected to wet processing, antimony resources are recovered while treating the antimony pollution and the colloidal antimony pentoxide is prepared, thereby realizing the recycling of the resources.

Owner:CENT SOUTH UNIV

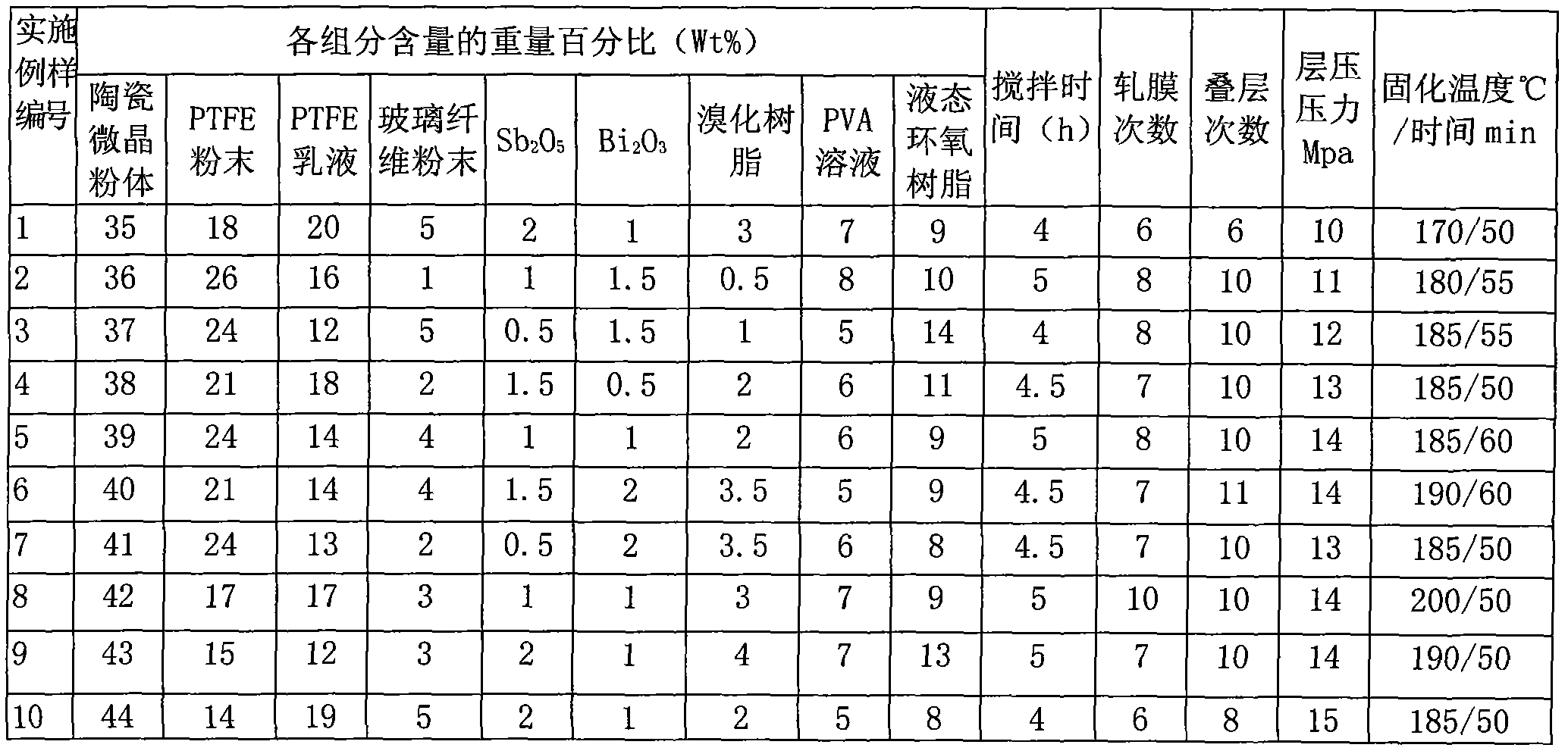

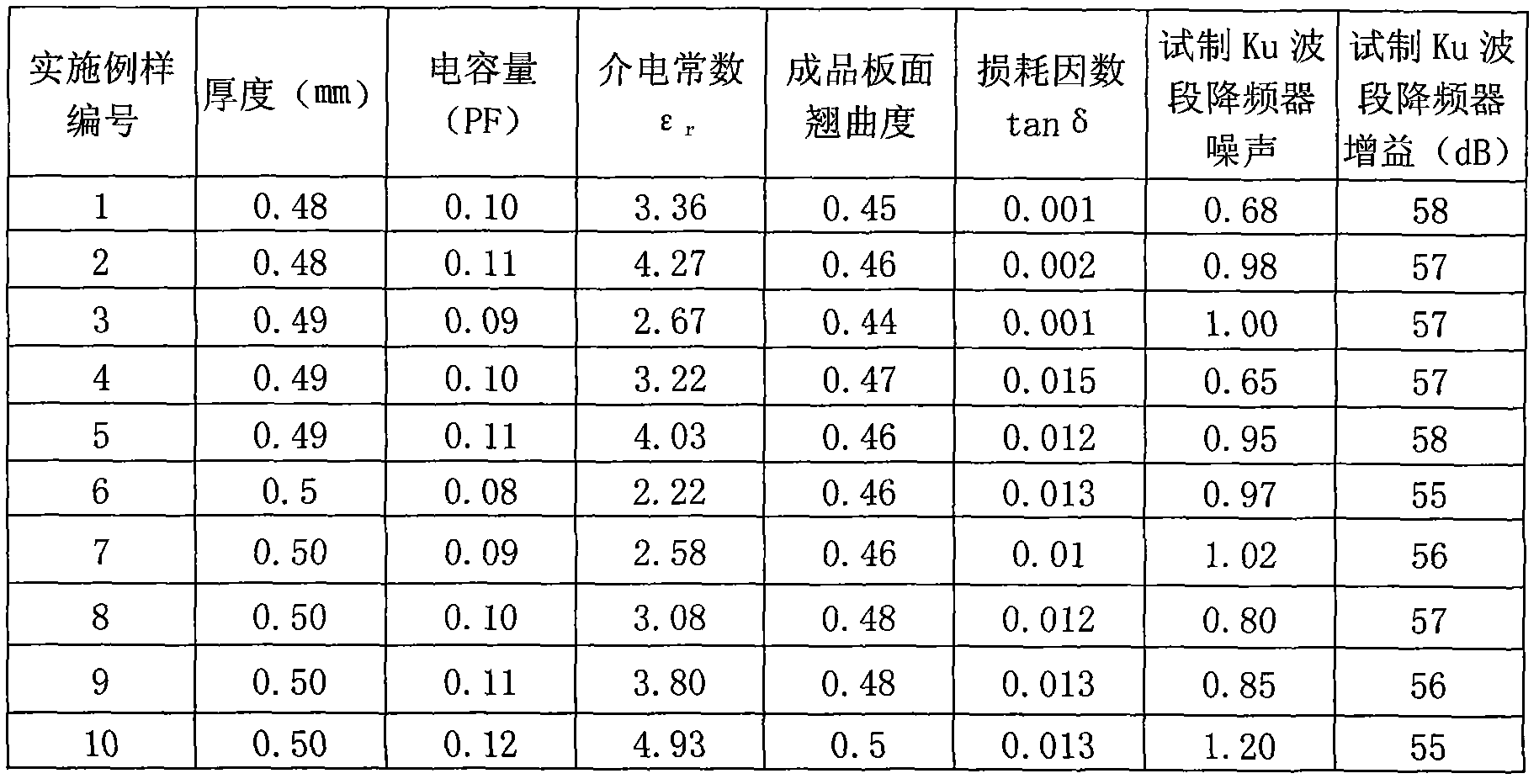

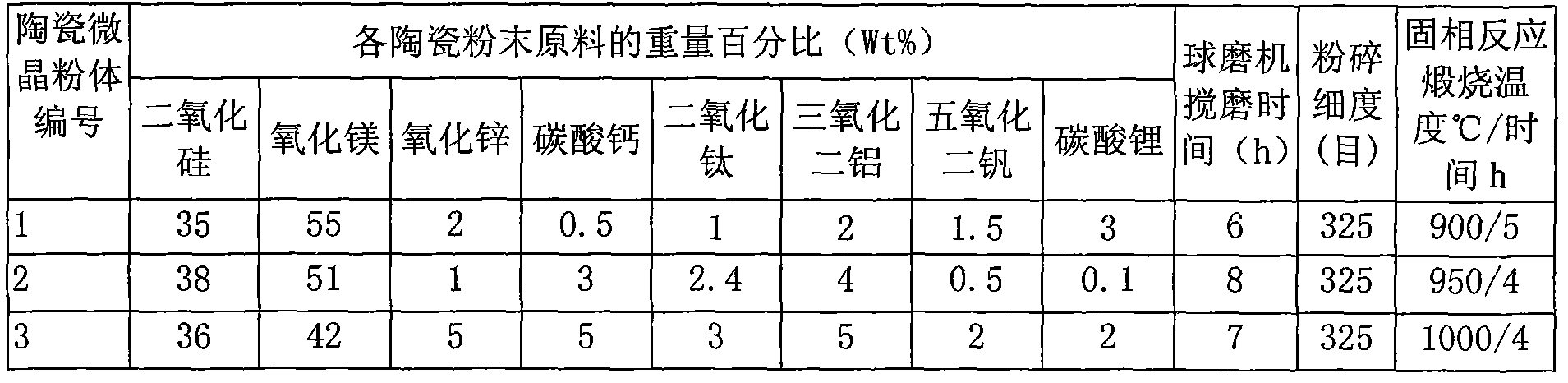

Environment friendly microwave medium ceramic substrate

The invention relates to an environment friendly microwave medium ceramic substrate which is mainly used for the circuits of microwave and millimeter wave satellite communication products, military radar products, electronic navigation products, microwave safety monitoring products, and the like. The substrate is prepared by adopting the following steps of: directly mixing ceramic microcrystal powder with polytetrafluoroethylene (PTFE) powder, PTFE emulsion, glass fiber powder, liquid-state epoxy resin and PVA (Polyvinylalcohol) solution raw material and micro flame-retardant additive raw materials: brominated resin, antimony pentoxide (Sb2O5) and bismuth trioxide (Bi2O3); carrying out blooming, primary drying, laminating, finish rolling, two-surface or two-way continuous sizing, redrying, two-surface or two-way continuous copper foil coating, tailoring and high-pressure lamination; then vacuumizing and curing for 50-60min at low temperature of 170-200 DEG C. The invention does not contain Nb heavy metal components and has good properties of microwave high frequency band low dielectric Epsilonr, low loss tan delta, high signal transmission efficiency and high stability and the advantages of simple process and low sintering temperature and can be cofired with a silver electrode.

Owner:CHENZHOU GONGTIAN ELECTRONICS CERAMICS TECH

Antimony peroxide ethanol dispersion preparation method

InactiveCN1544338AGood dispersionDisruption of regularityAntimony compoundsPigment physical treatmentAlcoholSolvent

The invention provides a process for preparing antimony pentoxide ethanol dispersion comprising, charging antimony trioxide and dispersion stabilizer into ethanol, oxidizing antimony trioxide into antimony pentoxide by hydrogen dioxide, preparing the outcome yield with content of antimony pentoxide over 5% through reaction solution concentration and dewatering. The dispersion stabilizer is tertiary amine formed by straight chain groups, and anhydrous alcohol is used as dewatering agent.

Owner:TSINGHUA UNIV

EVA (ethylene-vinyl acetate) elastomer sheath material for wind power generation torsion-resistant flexible cables and preparation method thereof

ActiveCN103122098AGood dispersionImprove heat aging resistancePlastic/resin/waxes insulatorsInsulated cablesElastomerEngineering

The invention discloses an EVA (ethylene-vinyl acetate) elastomer sheath material for wind power generation torsion-resistant flexible cables and a preparation method thereof. The EVA elastomer sheath material for wind power generation torsion-resistant flexible cables comprises the following components in parts by weight: 60-70 parts of EVA, 30-40 parts of CPE (chlorinated polyethylene), 20-25 parts of acetylene smoke, 10-15 parts of modified nano SiO2, 30-50 parts of talcum powder, 5-10 parts of antimony pentoxide, 1-2 parts of polytrimethyldihydroquinoline, 10-15 parts of dicyclohexyl phthalate, 2-3 parts of lead stearate, 3-5 parts of disalt-base lead phthalate, 1-2 parts of vinyltriethoxysilane and 6-8 parts of DCP (dicumyl peroxide). The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, favorable flame retardancy, low smoke, high flexibility, torsion resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for wind power generation flexible cables.

Owner:ANHUI HUAJIN CABLE GROUP

Method for comprehensively processing stibium smelt arsenic alkaline residue and producing colloid antimony peroxide

The invention relates to a method for processing antimony smelting slag, in particular to a method for comprehensively processing antimony smelting arsenic-alkali slag and preparing colloidal antimony pentoxide. The method mainly comprises three processes including water leaching, acid leaching and hydrolysis. The colloidal antimony pentoxide is prepared by an oxidation-hydrolysis method. In the method, the arsenic-alkali slag is subjected to wet processing, antimony resources are recovered while treating the antimony pollution and the colloidal antimony pentoxide is prepared, thereby realizing the recycling of the resources.

Owner:CENT SOUTH UNIV

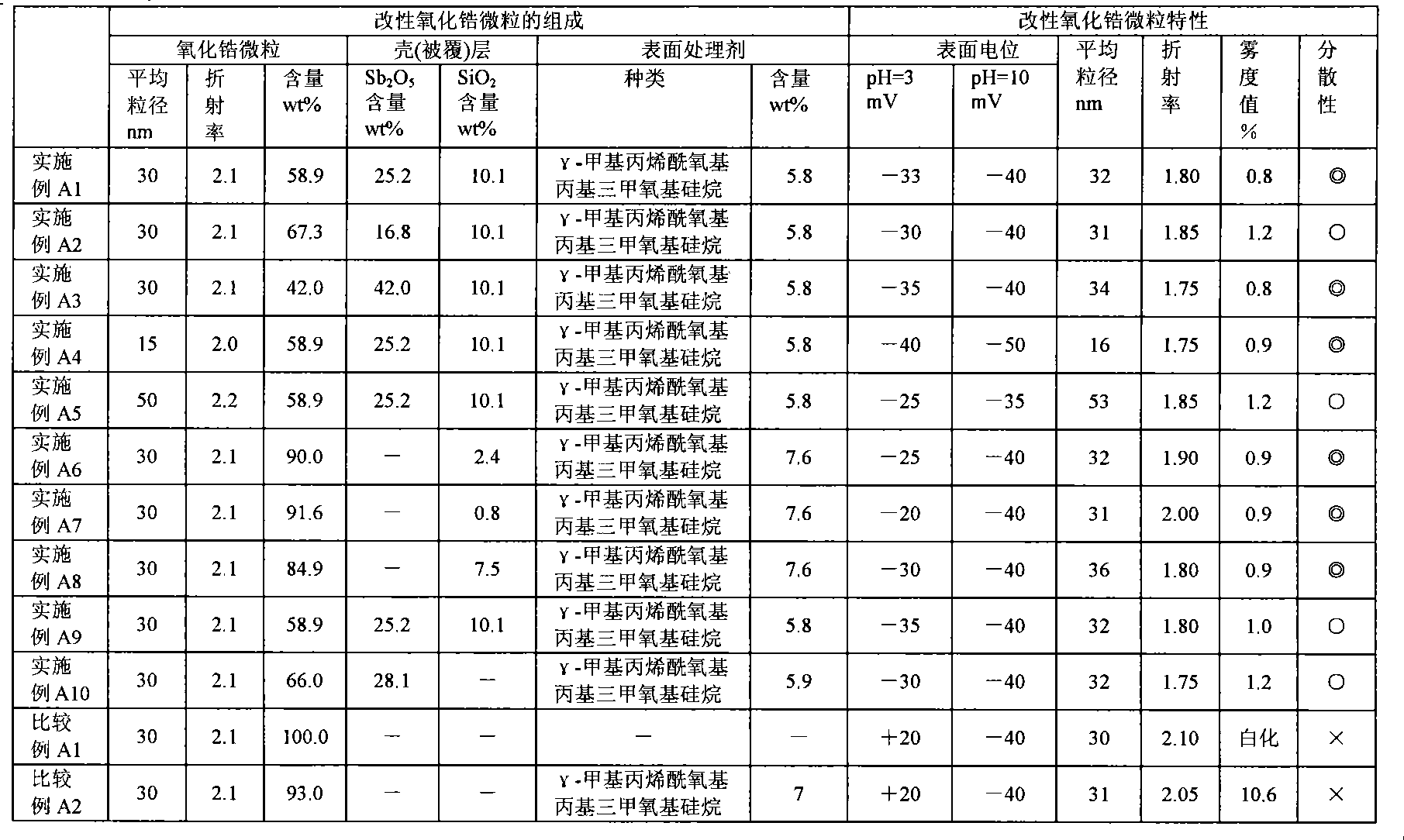

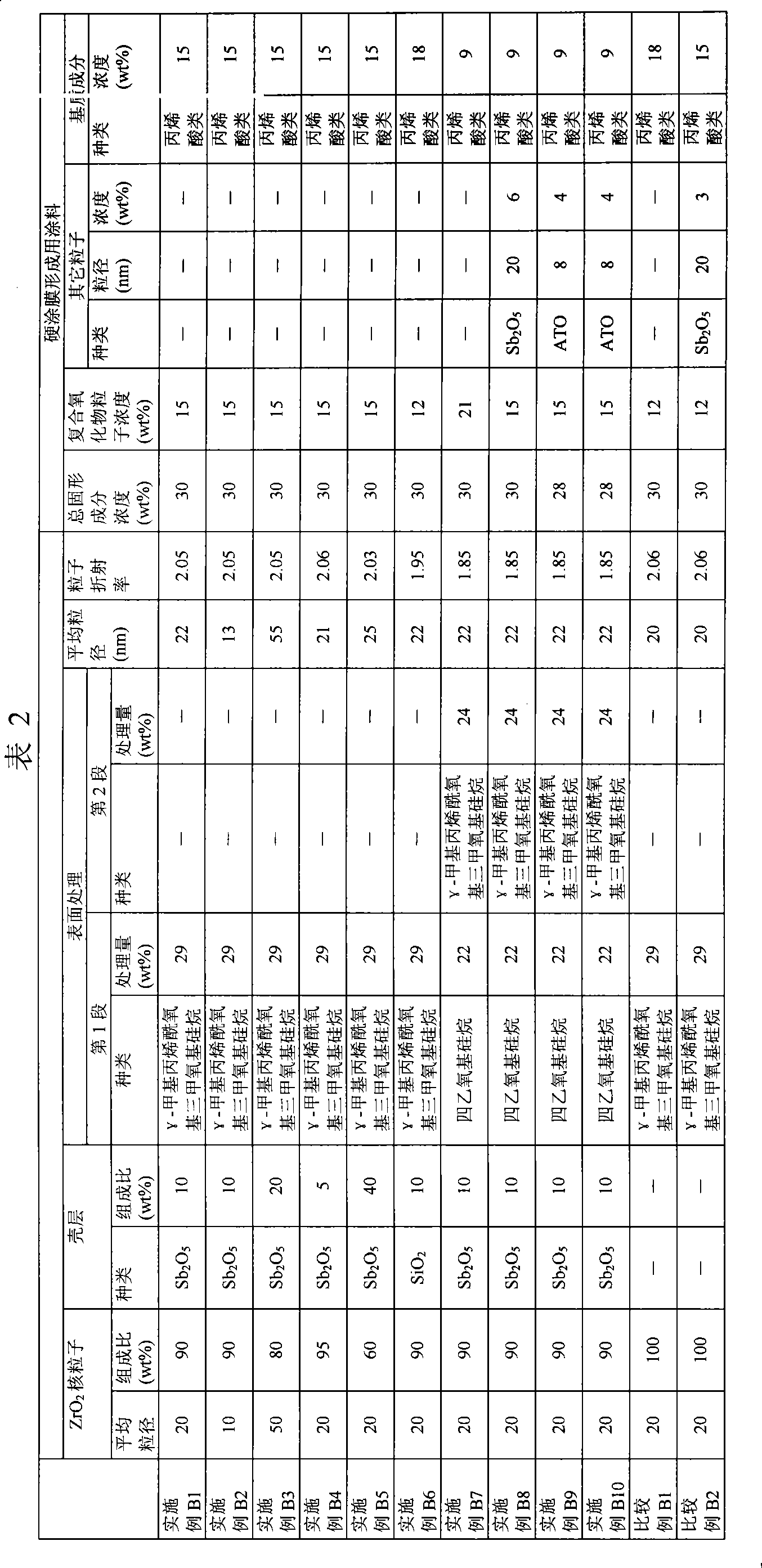

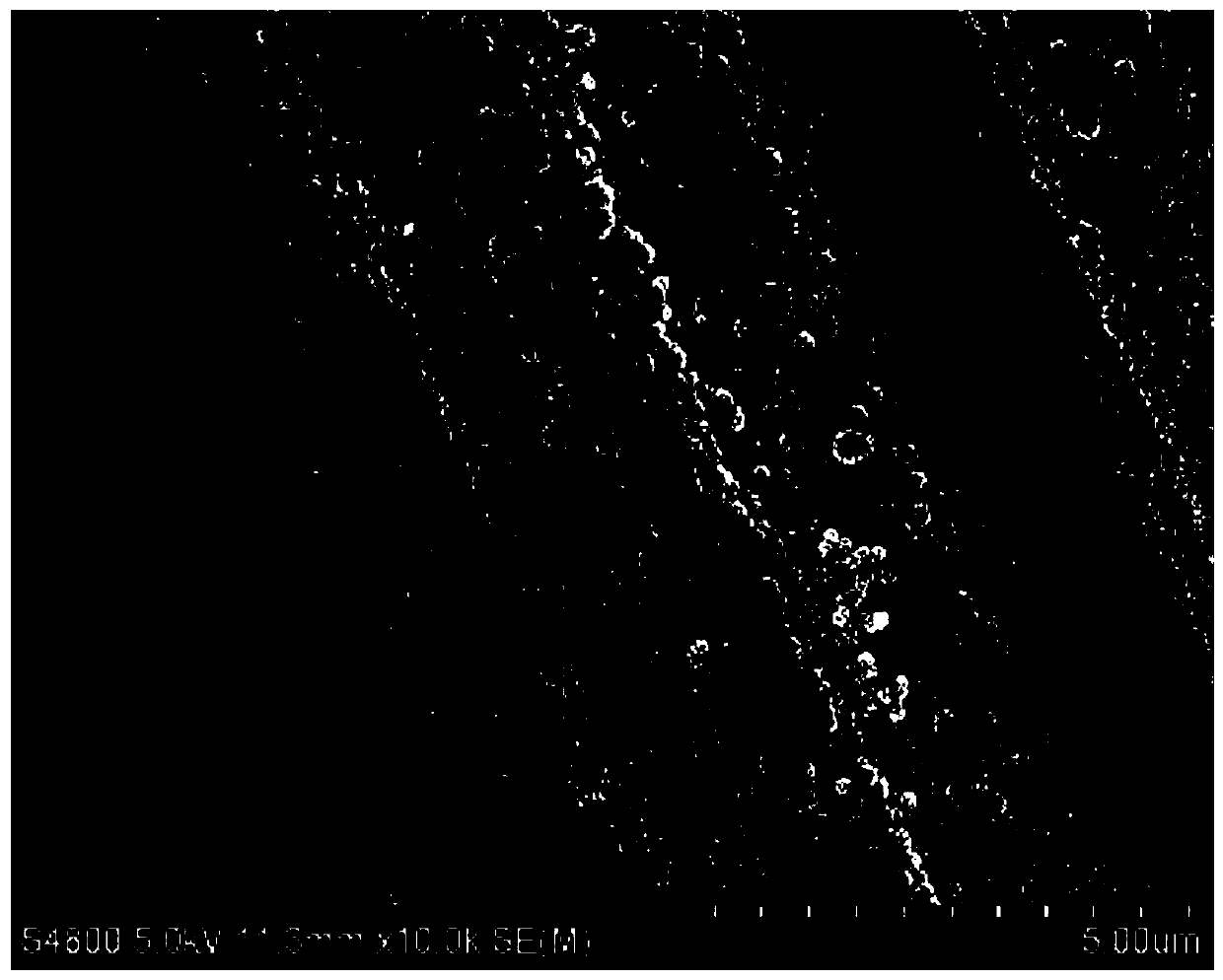

Substrate with Hard Coat Film and Coating Solution for Forming Hard Coat Film

ActiveUS20090061183A1Improve stabilityEasily adjusted in refractive indexMaterial nanotechnologyMixing methodsRefractive indexHardness

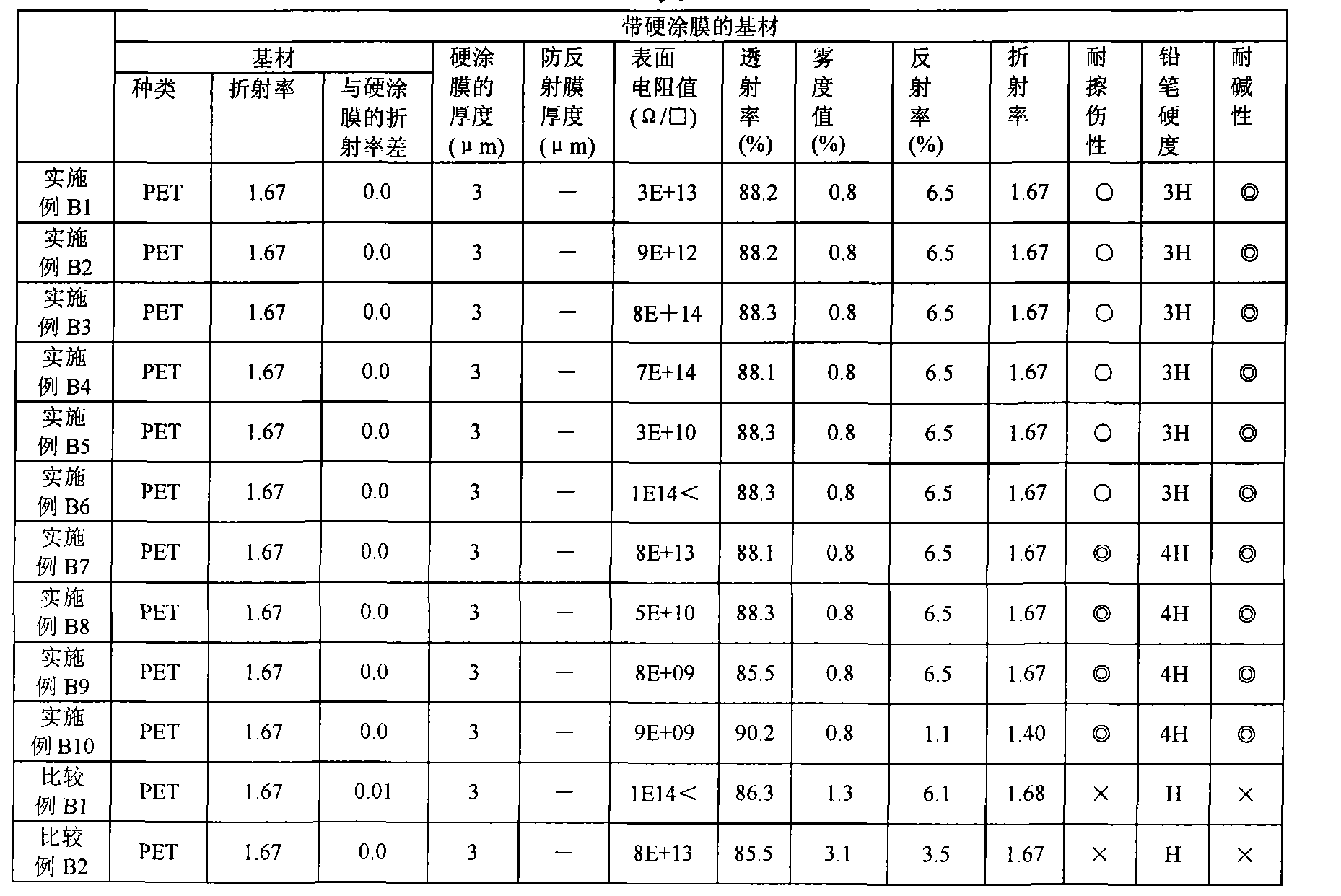

The present invention provides modified zirconia fine particles which are stable in an acidic region as well as in an alkaline region, and which may be readily adjusted in refractive index in a predetermined range. The present invention further provides a substrate with a hard coat film excellent in adhesiveness with the substrate, abrasion resistance, scratch strength, pencil hardness and the like without interference fringes and a coating solution which may form the hard coat film.The substrate with a hard coat film is composed of composite oxide particles formed on at least one surface of the substrate and a matrix component, wherein the composite oxide particles are composite oxide particles having a core-shell structure composed of a core formed from zirconium oxide and a shell formed from antimony pentoxide and / or silica.

Owner:JGC CATALYSTS & CHEM LTD

Process for Producing Antimony Pentaoxide

InactiveUS20080038187A1Increase concentrationMaterial nanotechnologyOther chemical processesReaction temperatureAntimony trioxide

The invention relates to a process for producing diantimony pentoxide having a high oxidation purity. A process for producing an aqueous sol of diantimony pentoxide, which comprises mixing diantimony trioxide (Sb2O3) and an aqueous hydrogen peroxide solution in an aqueous medium, and after the temperature has reached from 50 to 80° C., reacting the diantimony trioxide with the aqueous hydrogen peroxide solution while keeping the reaction temperature at a level not higher by at least 10° C. than a desired set temperature in the temperature range, to thereby obtain a sol having dispersed in the aqueous medium diantimony pentoxide particles which have a primary particle size of from 2 to 50 nm and which have a diantimony trioxide / diantimony pentoxide weight ratio of not higher than 5 wt %.

Owner:NISSAN CHEM IND LTD

High energy type zinc oxide piezoresistor material and preparation method thereof

InactiveCN102515740AReduce the residual pressure ratioReduce leakage currentVaristor coresOvervoltage protection resistorsTin dioxideHigh energy

The invention relates to a high energy type zinc oxide piezoresistor material and a preparation method thereof, which belong to the technical field of piezoresistor material preparation. The preparation method comprises (1) enabling manganese carbonate, barium carbonate and strontium carbonate to be mixed, ball-milled and calcined to obtain mixture A; (2) enabling titanium oxide, antimony pentoxide, bismuth trioxide, cobalt oxide, nickel oxide, silica and stannic oxide to be mixed in submicron-sized zinc oxide powder to obtain mixture B which is mixed and ball-milled with the mixture A to obtain mixture C; and (3) adding aluminum nitrate, silver nitrate, magnesium nitrate, a dispersing agent and an antifoaming agent in the mixture C, ball-milling and drying to obtain high energy type zinc oxide piezoresistor composite powders which are formed in a pressing mode and sintered to obtain a high energy type zinc oxide piezoresistor. The high energy type zinc oxide piezoresistor material is simple in preparation method, prepared zinc oxide piezoresistor has high energy density, low leakage current and residual voltage ratio, batch of products is stable, acceptability is high, and the high energy type zinc oxide piezoresistor material is applicable to scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

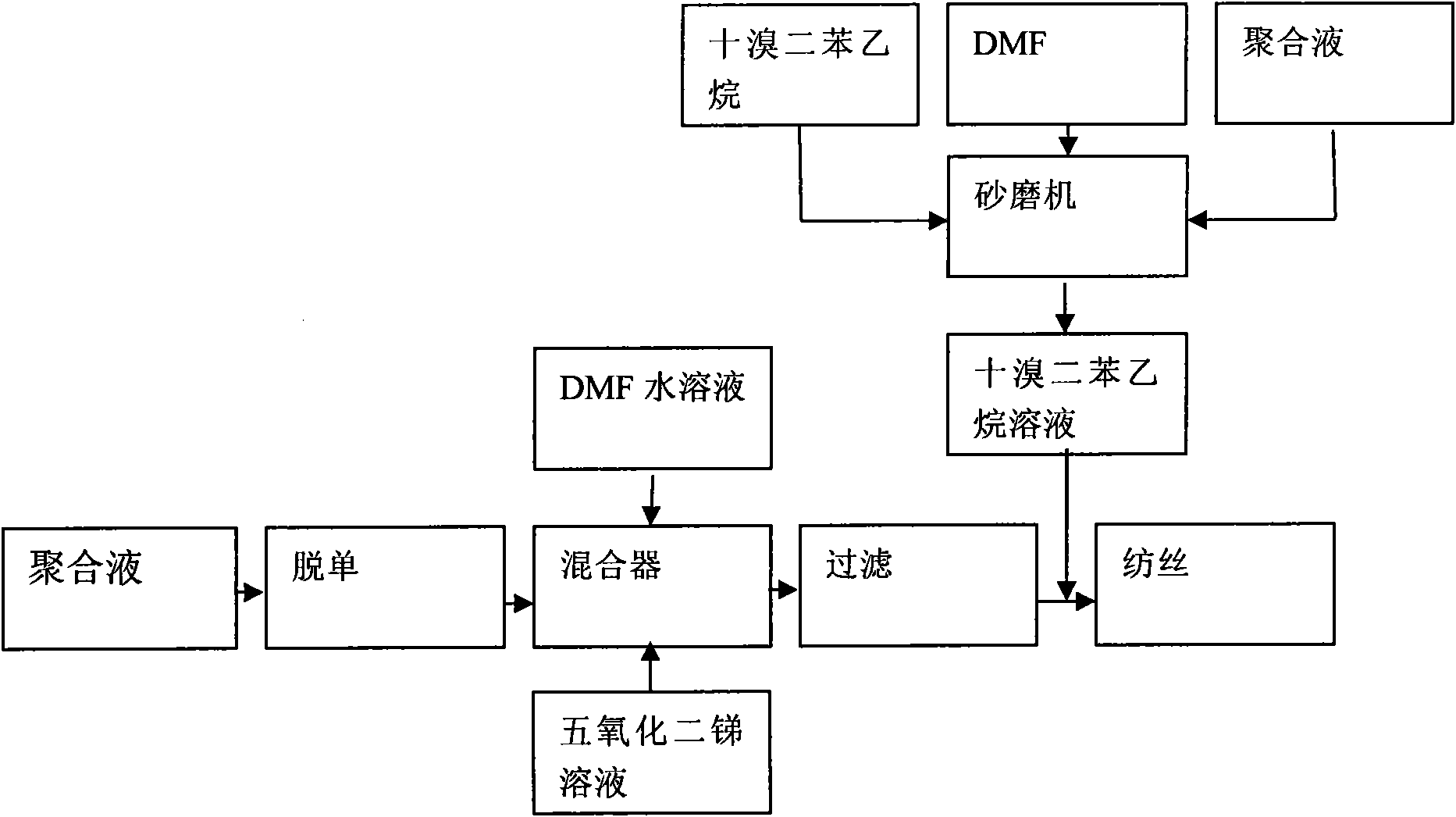

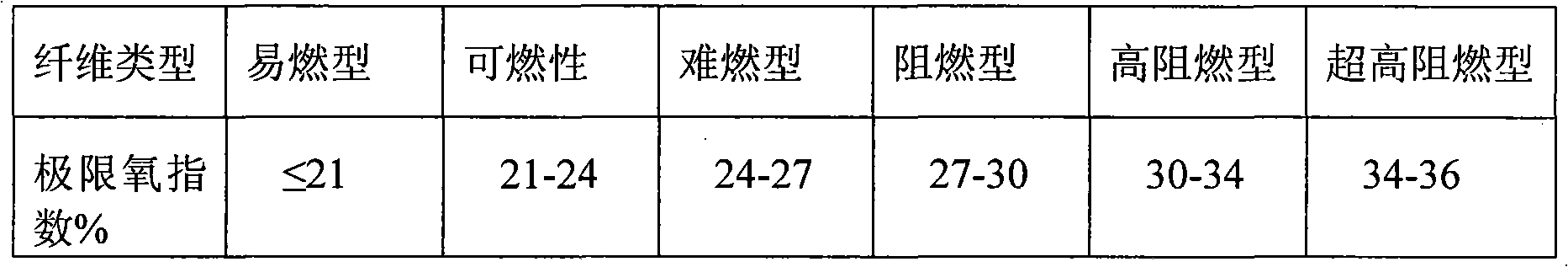

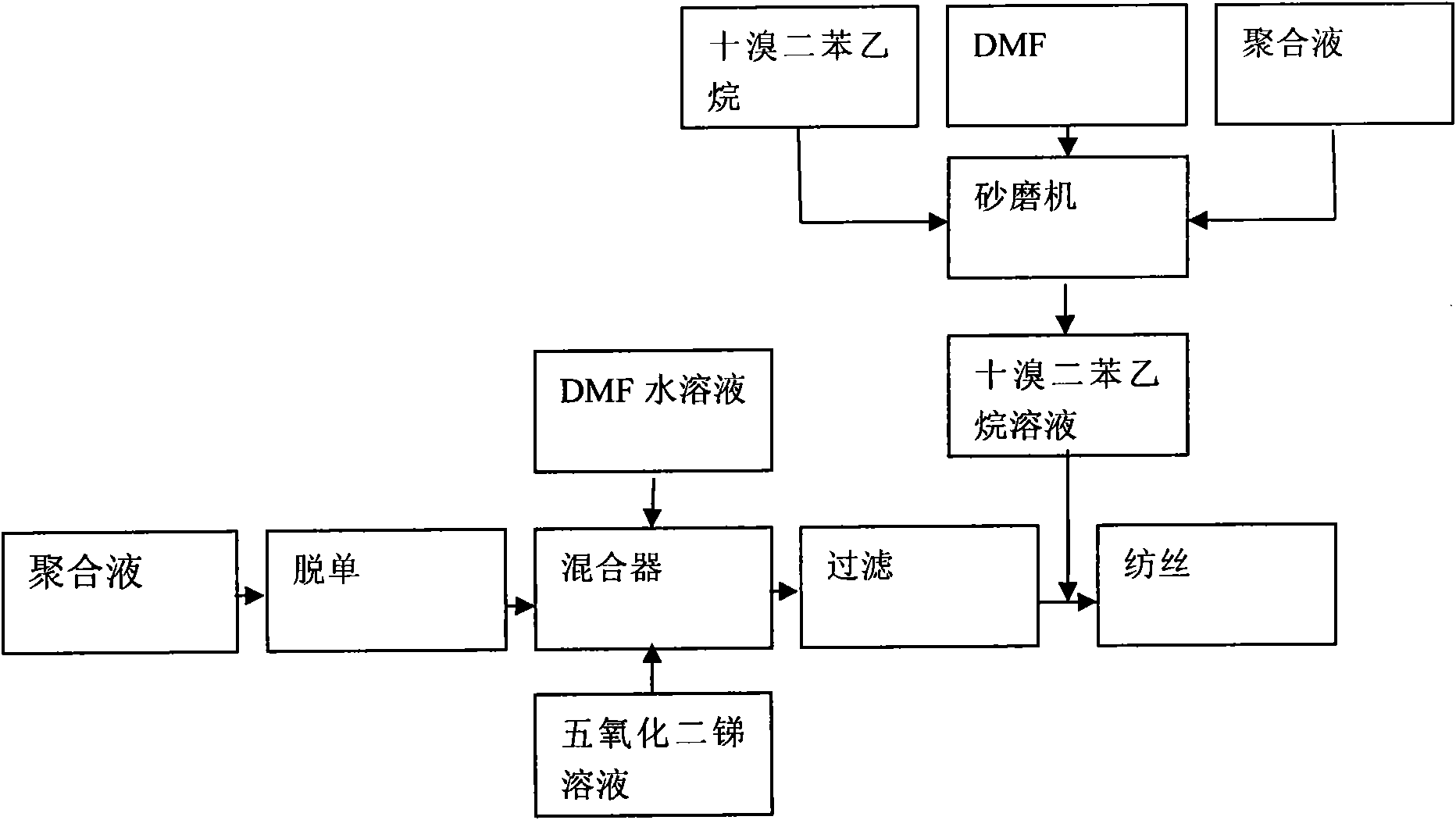

Ultrahigh flame-retardant AN-VDC copolymer fiber and production method thereof

InactiveCN102154725APermanent ultra-high flame retardant performanceEvenly distributedFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentFiberAcrylonitrile

The invention discloses an ultrahigh flame-retardant AN-VDC copolymer fiber and a production method thereof. Chemical compositions of the copolymer fiber contain acrylonitrile, vinylidene chloride, acrylamide methyl propane sodium sulfonate, antimony peroxide and decabromdiphenylethane, wherein the weight ratio of the antimony peroxide in the fiber is 6.5 to 10%, and the weight ratio of the decabromdiphenylethane in the fiber is 5.5 to 10%. The production method of the fiber comprises the following steps of: fully mixing the decabromdiphenylethane, a polymerizing liquid and dimethyl fomamide which are ground and filtered to be prepared into a decabromdiphenylethane solution; adding an antimony peroxide colloidal solution and a dimethyl fomamide aqueous solution into polymerizing liquid undegoing demonomerisation, filtering the mixed liquor after being fully mixed, and then continuously adding the prepared decabromdiphenylethane solution on line to the mixed liquor, and finally sending the mixed liquor to a spinning working procedure. As the ultrahigh flame-retardant AN-VDC copolymer fiber has excellent fire resistance, environmental protection and combination properties, the fiber is increasingly and widely applied in various fields, in particular to the field of a specific flame-retardant fabric.

Owner:FUSHUN RAYVA FIBER

Laser carving powder applied to laser marking and preparation process thereof

The invention discloses laser carving powder applied to laser marking. The laser carving powder comprises the following raw materials in parts by weight: polypropylene resin, C5 petroleum resin, barium sulfate, a nucleating agent, an antioxidant, toner, a lubricant, silicon oxide, titanium dioxide, zinc sulfide, chromium sesquioxide, neodymium oxide, bismuth oxide, tin oxide, zinc molybdate, ammonium molybdate, basic copper phosphate, copper oxide, copper chromite black, copper carbonate, copper sulfate, copper chloride, copper chromite, copper thiocyanate, spinel, tin dioxide, tin ash, sodiumstannate, potassium stannate, zinc sulfate, antimony trioxide, antimony pentoxide, sodium antimonate, potassium carbonate, syndiotactic polystyrene and polyhexamethylene adipamide; according to the preparation process of the laser carving powder applied to laser marking, the laser carving powder applied to laser marking is prepared, and the preparation process comprises the following steps: S1, grinding; S2, performing crushing; S3, performing mixing; S4, adding a chemical agent; S5, drying; and S6, crushing.

Owner:东莞市烁康新材料科技有限公司

Substrate with hard coat film and coating solution for forming hard coat film

The invention relates to modified zirconia fine particles, substrate with hard coat film and coating solution for forming hard coat film. The modified zirconia fine particles are zirconia fine particles having their surfaces coated with antimony pentoxide and / or silica, and having their surface potentials in a range of -120 to -10 mV, as measured by the following conditions: condition (1): a solid content concentration of 1% by weight in a dispersion solution of the modified zirconia fine particles; and conditions (2): a pH in a range of 2 to 13 in a dispersion solution of the modified zirconia fine particles.

Owner:JGC CATALYSTS & CHEM LTD

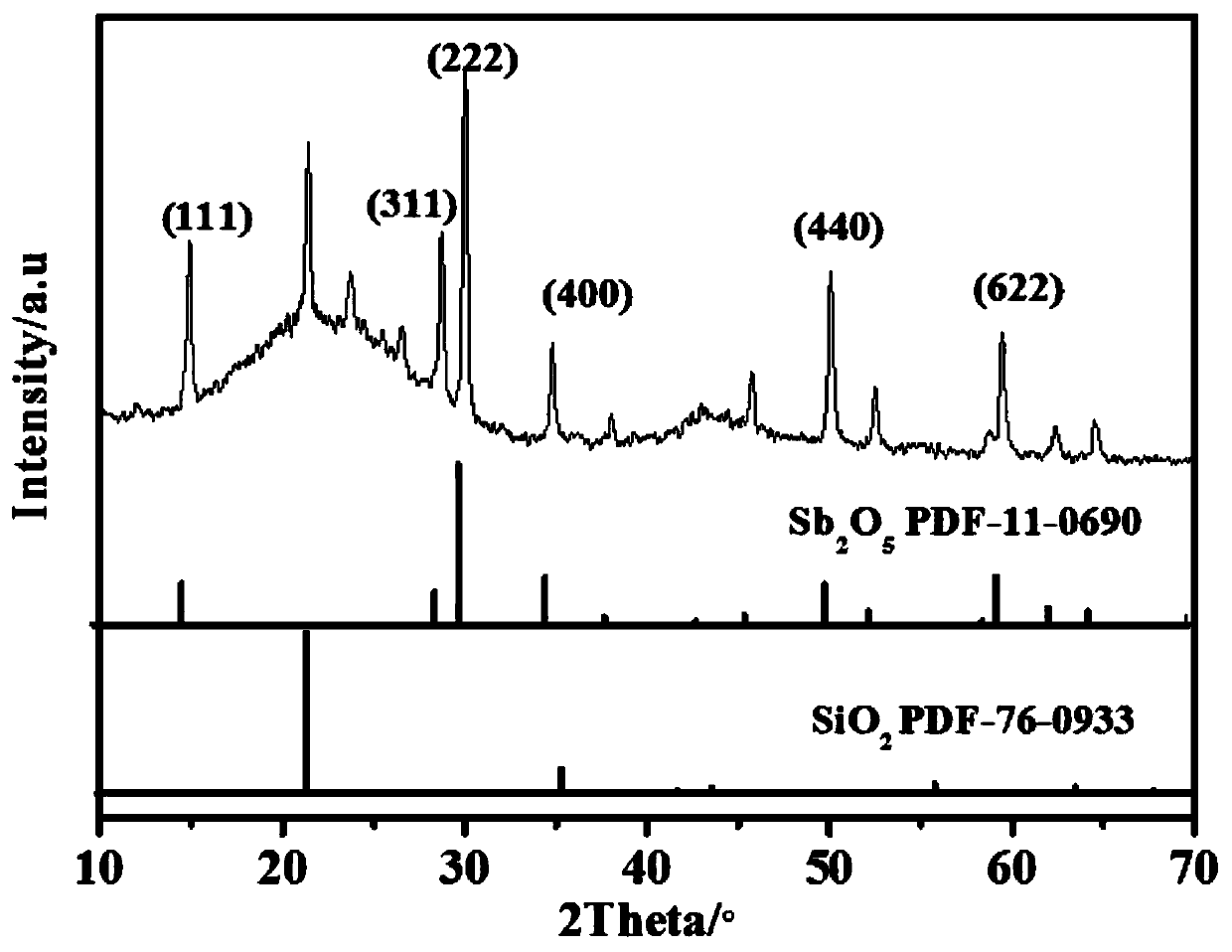

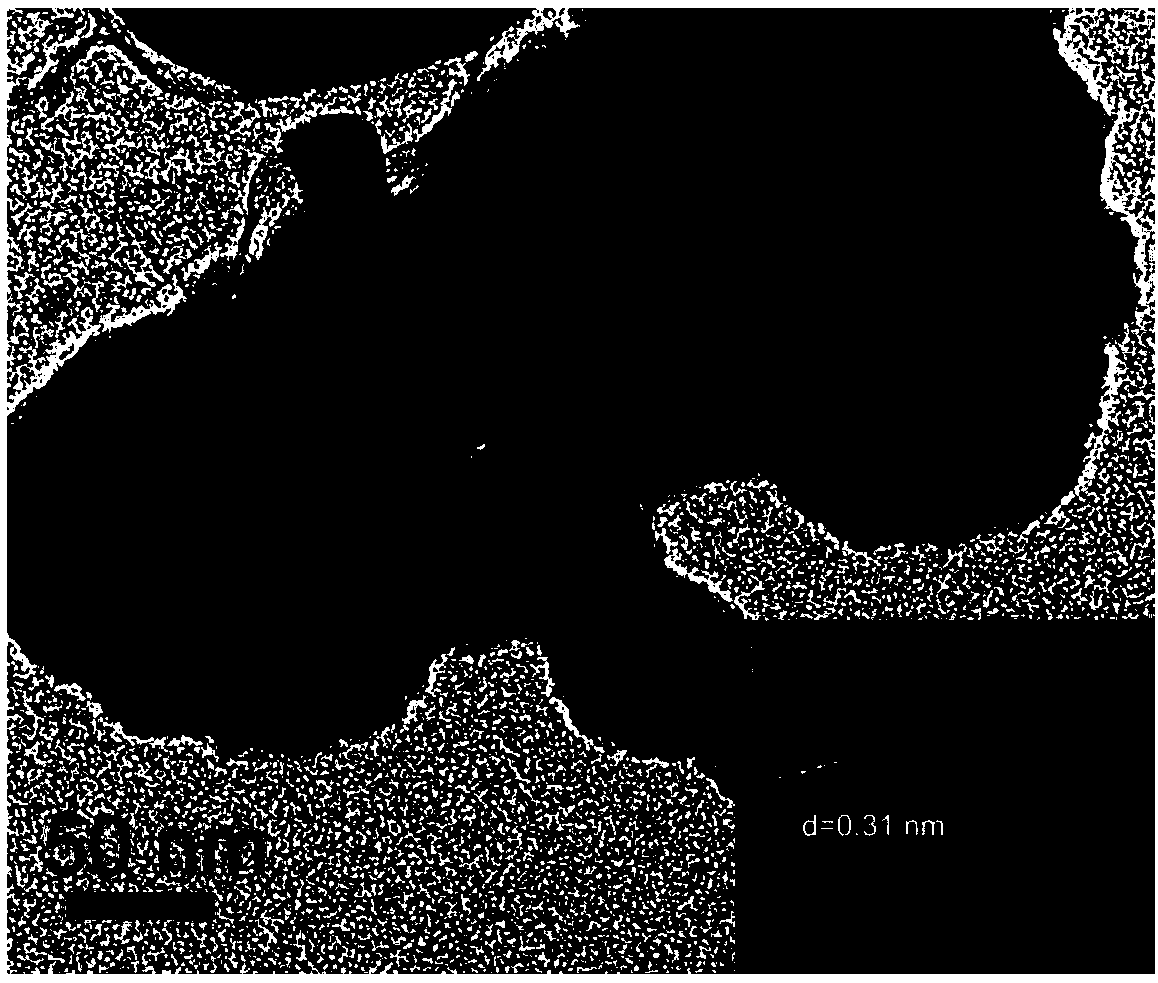

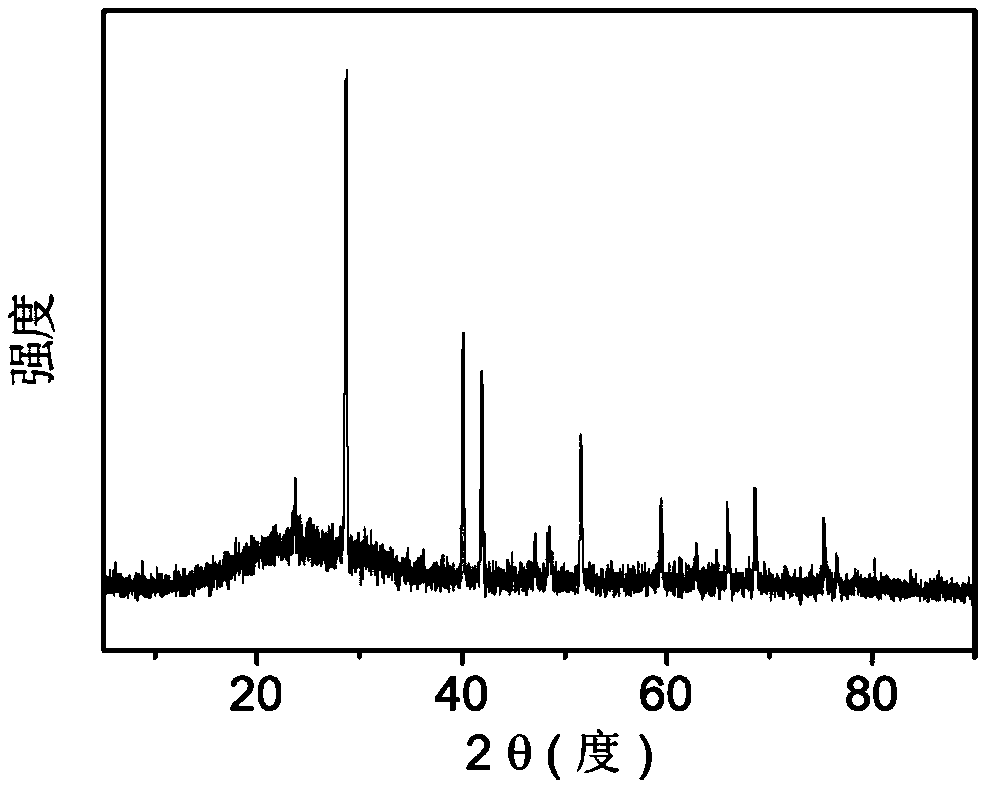

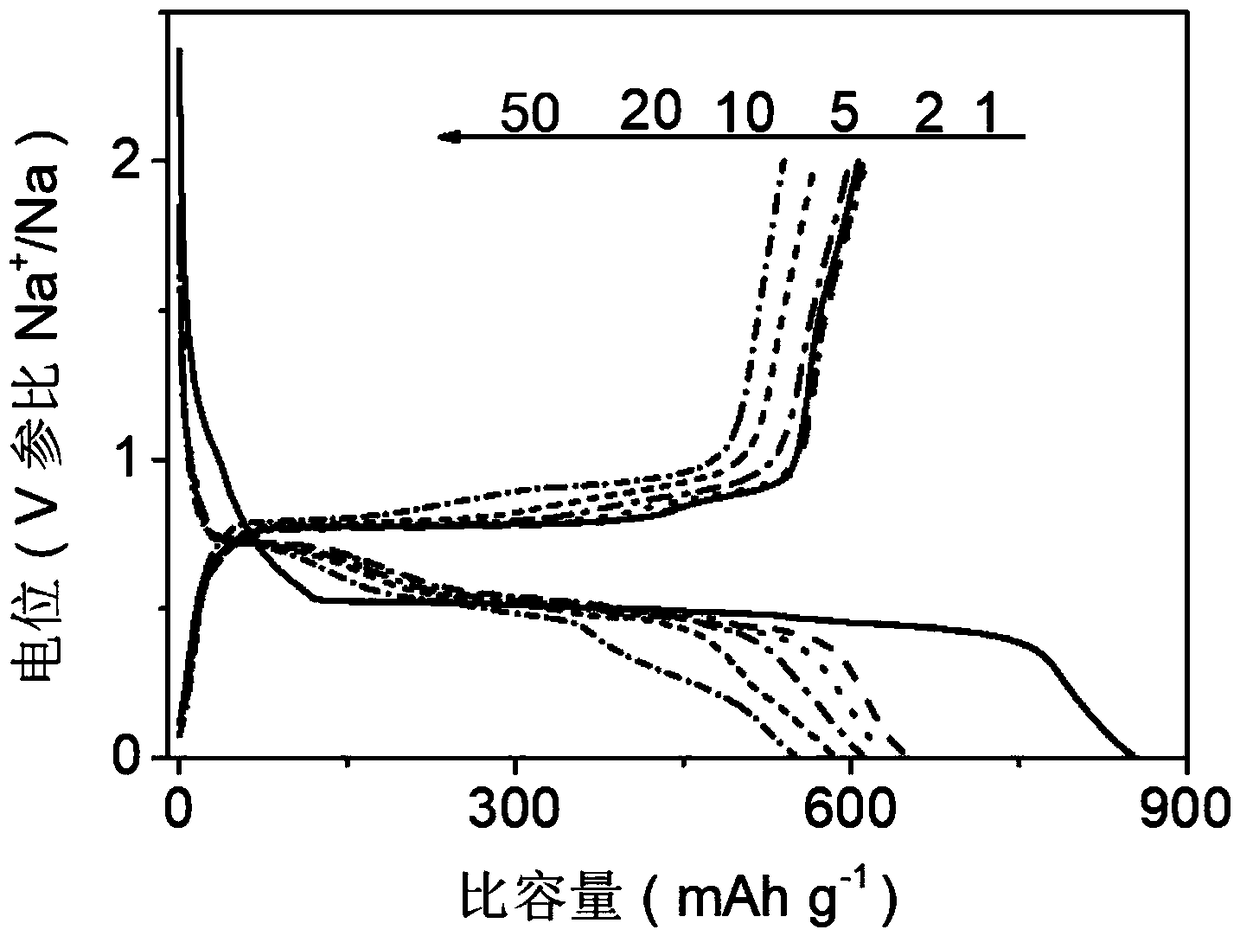

Preparation of antimony pentoxide/silicon dioxide/carbon cloth flexible material and application thereof as negative electrode of sodium-ion battery

The invention discloses preparation of an antimony pentoxide / silicon dioxide / carbon cloth flexible material and an application thereof as a negative electrode of a sodium-ion battery, which comprisesthe following steps: grinding silicon dioxide, adding the silicon dioxide into deionized water for dissolution to obtain a solution A; adding antimony trichloride into the ethanol solution for dissolution to obtain an antimony trichloride solution, and adding a sodium hydroxide aqueous solution into the antimony trichloride solution to adjust the pH value of the antimony trichloride solution to obtain a solution B; adding the solution A into the solution B and stirring to obtain a solution C; impregnating the activated carbon cloth in the solution C, transferring the solution C and the carboncloth into a reaction kettle for hydrothermal reaction, cooling the carbon cloth to room temperature, moving out the carbon cloth, and cleaning and drying the carbon cloth to obtain the antimony pentoxide / silicon dioxide / carbon cloth flexible sodium ion battery negative electrode material. The method is simple to operate and low in cost, and the silicon material can be applied to the negative electrode material of the sodium-ion battery.

Owner:SHAANXI UNIV OF SCI & TECH

Method of Producing Glass

InactiveUS20090266111A1Reduce the presence of air bubblesImprove refining effectGlass furnace apparatusNitrateSulfate

Provided is a method of producing a glass, including, in order to obtain an excellent refining effect: preparing a raw glass batch including: an antimony compound containing pentavalent antimony; and an oxidizing agent (a cerium oxide, a sulfate, a nitrate); and melting the raw glass batch. In preparing the raw glass batch, it is preferable that the antimony compound be premixed with the oxidizing agent. When the nitrate is used as the oxidizing agent, the raw glass batch is prepared so as to include the antimony compound in an amount of more than 0.5 parts by mass and at most 3 parts by mass, in terms of an amount of antimony pentoxide, per 100 parts by mass of a base glass composition expressed in terms of an amount of an oxide.

Owner:AVANSTRATE INC

Colloidal antimony oxide powder low in volatility at high temperature and preparing method thereof

ActiveCN104828866AExcellent high temperature heating performanceStable white appearanceAntimony compoundsIon exchangeColloid

The invention relates to colloidal antimony oxide powder low in volatility at high temperature and a preparing method thereof. The colloidal antimony oxide powder is made by 1, performing reduction, to be specific, adjusting pH value of antimony pentoxide hydrosol to 7.0 to 8.0 via alkali metal hydroxide, and adding reducing agent to allow partial reduction to obtain antimony oxide sol; 2, removing alkali metal ions, to be specific, removing the alkali metal ions in the antimony oxide sol by ion exchange; 3, performing drying, to be specific, drying the antimony oxide sol with the alkali metal ions removed, to obtain the colloidal antimony oxide powder low in volatility at high temperature. The colloidal antimony oxide powder has lower crystal water content than common colloidal antimony pentoxide powder, the high-temperature burning loss rate of the colloidal antimony pentoxide powder made by the conventional methods is decreased from 16% to 6% below, and high-temperature heating performance is excellent; when heated to 400 DEG C, the colloidal antimony oxide powder never carbonizes or blackens and has stable white appearance; the preparation process is easy to control and has no three wastes.

Owner:锡矿山闪星锑业有限责任公司

Antimony carbon negative electrode material of sodium ion battery, preparation therefor and application method thereof

InactiveCN108878820AReduce the problem of large volume changesUniform diameterCell electrodesCarbon layerSodium-ion battery

The invention discloses an antimony carbon negative electrode material of a sodium ion battery, a preparation therefor and an application method thereof, and relates to the technical field of sodium ion battery negative electrode materials. The preparation method comprises the following steps: dissolving a carbon source in a methanol solution, adding nano antimony pentoxide colloidal solution, anduniformly stirring; spray drying at a high temperature and collecting powder to obtain a precursor material; and performing high-temperature calcination on the precursor material in a 5% of mixture of argon and hydrogen to obtain a carbon layer coated antimony carbon negative electrode material. The preparation method of the antimony negative electrode material of a sodium ion battery is simple,rapid and safe, and meets a requirement of green synthesis. Electrochemical test shows that the new carbon layer coated antimony carbon negative electrode material can effectively alleviate the problem of volume of the electrode material getting bigger during a charging and discharging process of the battery, so that the sodium ion battery can maintain a high specific capacity. In particular, theantimony negative electrode material is extremely useful for sodium ion batteries. According to the antimony carbon negative electrode material of a sodium ion battery, the preparation therefor and the application method thereof, a solid technical material basis for developing an energy storage battery system with abundant resources and low cost, and high capacity and high stability is provided.

Owner:SHANGHAI NORMAL UNIVERSITY

Electric heating paint

InactiveCN104327554AHigh electrothermal conversion efficiencyFast heatingElectrically-conductive paintsTin dioxideLithium oxide

The invention relates to the field of paint compositions and particularly relates to electric heating paint. The electric heating paint is prepared from the following raw materials in percentage by weight: 40-60% of metal oxides, 5-2% of nonmetal oxides, 5-20% of organic semiconductor materials and 5-20% of high-molecular polymer; the metal oxides consist of the following raw materials in percentage by weight: 20-40% of tin dioxide, 5-20% of antimony pentoxide, 5-10% of cobaltosic oxide, 5-35% of aluminium oxide, 5-15% of zinc oxide, 5-10% of barium oxide, 5-10% of yttrium oxide, 0-20% of zirconium oxide and 5-10% of lithium oxide; the nonmetal oxides consist of the following raw materials in percentage by weight: 10-30% of boron oxide, 30-50% of silicon dioxide and 20-40% of tellurium dioxide; the organic semiconductor materials consist of the following raw materials in percentage by weight: 10-90% of polyaniline and 10-90% of polypyrrole; and the high-molecular polymer consists of the following raw materials in percentage by weight: 10-90% of poly(propionitrile) and 10-90% of polyamide.

Owner:WEIHAI EAST RED NEW MATERIAL

Antimony pentoxide dispersion preparation method

InactiveCN1544339AReduce polarityGood dispersionAntimony compoundsPigment physical treatmentOrganic acidFiber

The invention provides a process for preparing antimony pentoxide ethanol dispersion which can be used as special flame retardant, catalyst and surface processing agent, comprising the steps of, dissolving organic acid and dispersion stabilizer into water, charging antimony trioxide, mixing for dispersion, oxidizing antimony trioxide into antimony pentoxide by hydrogen dioxide, carrying out concentration, ageing and concentration to the reaction liquid for producing antimony pentoxide content of over 50%, whose grain size is between 1-20 nm, viscosity is less than 10mPaS, pH=6.0-7.0.

Owner:TSINGHUA UNIV

Method for preparing antimony pentoxide dry powder

The invention relates to a method for preparing antimony pentoxide dry powder, which comprises the following steps of: mixing antimonous oxide, an oxidizing agent and water in a certain ratio for stirring, reflux and cooling, adding an inertia porous material in the reaction process, and filtering and drying a product after a reaction is finished to obtain a white antimony pentoxide solid with a core-shell structure. The method overcomes the defects of high energy consumption of atomizing drying, harmful to health of operating personnel due to superfine powder and the like in the process of producing the antimony pentoxide, so the invention provides a method for preparing the core-shell antimony pentoxide dry powder, which has the advantages of low cost and high utilization rate of rare materials.

Owner:广东宇星阻燃新材股份有限公司

High-transparency organosilicon heat-conduction pouring sealant for electronic products and preparation method of pouring sealant

InactiveCN107880843AImprove thermal conductivityHigh transparencyNon-macromolecular adhesive additivesMacromolecular adhesive additivesTransformerSealant

The invention discloses a high-transparency organosilicon heat-conduction pouring sealant for electronic products. The pouring sealant is prepared from a component A and a component B, wherein the component A comprises raw materials in parts by weight as follows: 100 parts of vinyl silicone oil, 8-12 parts of hydrogen-containing silicone oil, 20-40 parts of liquid coumarone-indene resin, 0.3-0.6 parts of 1-methyl-1-butynol, 30-50 parts of inorganic and transparent heat-conduction modified filler, 0.5-1.5 parts of antimony pentoxide and 0.5-1.5 parts of a silane coupling agent; the component Bcomprises raw materials in parts by weight as follows: 15-25 parts of vinyl silicone oil and 0.5-1 part of a platinum catalyst. The pouring sealant is applicable to electronic product machining such as transparent heat-insulation and heat-condition encapsulation of electronic products such as power modules, high-frequency transformers, connectors, sensors, electric heating parts, circuit boards and the like; the pouring sealant has good heat conductivity, transparency and flame retardance, is in a soft rubber form after being cured, is good in impact resistance and high in adhesion force and has excellent insulating, shockproof, dampproof, corona-resistant, electric-leakage-resistant and chemical-media-resistant properties.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

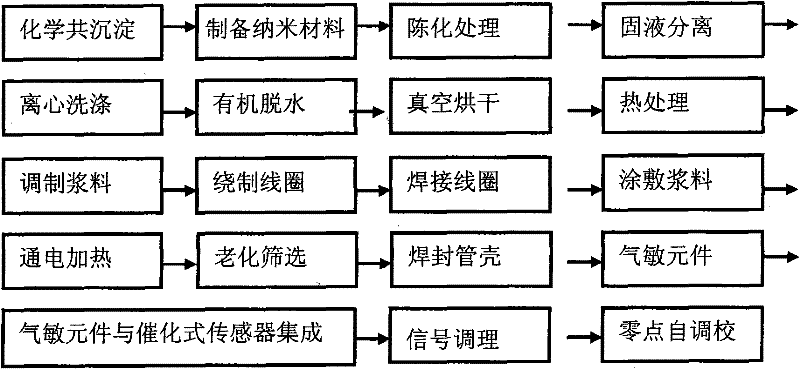

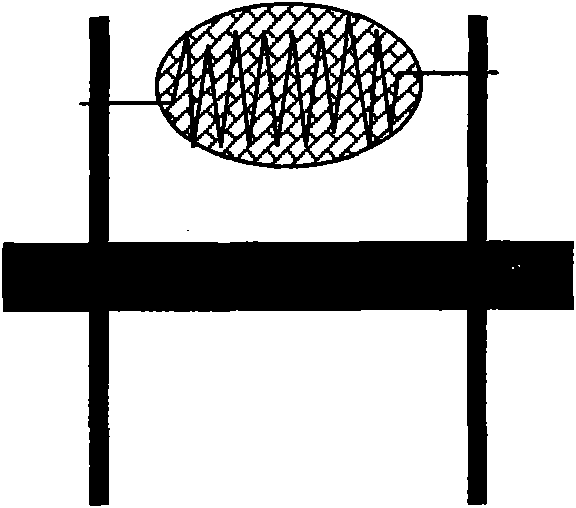

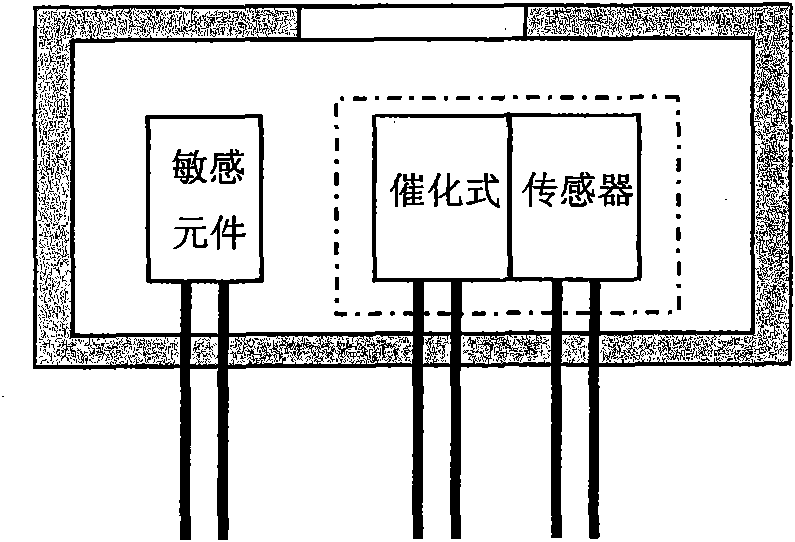

Zero point self adjustment and calibration method for catalytic gas sensor

InactiveCN102235989AStandard school period is shortEliminate distractionsMaterial resistanceMicrocontrollerSlurry

The invention provides a zero point self adjustment and calibration method for a catalytic gas sensor. A nano-semiconductor tin dioxide, antimony pentoxide and cerium oxide composite sensitive material is prepared by a chemical coprecipitation method; the sensitive material is formed by aging, solid-liquid separation by centrifugation, deionizing washing, dehydration by organic solvents, vacuum drying, and heat treatment; and the sensitive material is prepared into slurry by glycerin. By coiling technology, a coil with a diameter of 0.2 mm is coiled by a wire with a diameter of 0.018 mm, and is suspendedly welded on a standard two-feet socket. The sensitive slurry is coated on the coil; the coil is heated by ohmic heating to allow the slurry to be burned into a small ball with certain strength; a shell with holes is sealed on the socket by capacitor discharge welding; and a gas sensitive element with a full scale being less than the volume fraction of 10*10-6v / V for liquefied petroleum gas (natural liquefied gas, hydrogen, organic gas) is produced. The gas sensitive element is integrated with the catalytic gas sensor; with the characteristic that the lowest detection limit of the catalytic gas sensor (a volume fraction of 50*10-6 v / V) is much higher than the full scale of the gas sensitive element, when the detection limit of the gas sensitive element is lower than the full scale, the concentration of ambient detected gas is considered to be nearly zero, and the zero point of the sensor is adjusted by a one-chip microcomputer of a conditioning circuit of the catalytic gas sensor; therefore the function of zero point self adjustment and calibration of the catalytic gas sensor is realized; the invention solves the problem of zero point drift during long-term use of the catalytic gas sensor, realizes the self adjustment and calibration function of the self adjustment and calibration, prolongs the alignment calibration period of the self adjustment and calibration.

Owner:HARBIN ENG UNIV

Manufacturing method of white acrylic conductive fiber

InactiveCN103789863AHigh whitenessImprove antioxidant capacityElectroconductive/antistatic filament manufactureWet spinning methodsTin dioxidePolymer science

The invention relates to a manufacturing method of white acrylic conductive fiber. The method comprises the following processing steps: (1) drying polyacrylonitrile powder, titanium dioxide, tin dioxide and antimony pentoxide; (2) mixing the titanium dioxide, the tin dioxide, the antimony pentoxide, a coupling reagent, a dispersing agent and the polyacrylonitrile powder to obtain a mixture; (3) mixing the mixture obtained in the step (2) and dimethyl formamide (DMF) in a stirring tank to obtain spinning mixed liquid; (4) carrying out pressurization on the spinning mixed liquid to enable the spinning mixed liquid to be pressed into a spinning kettle from the stirring tank through an intermediate filtering device, adding negative pressure for the spinning mixed liquid in the spinning kettle, and defoaming; (5) carrying out pressurization on the spinning kettle, spinning the spinning mixed liquid by a spinning nozzle, enabling the product to pass through coagulating bath for three times, a stretching device, a drying roller and a winding roller, and finally drying by a drying oven to obtain the white acrylic conductive fiber. The acrylic conductive fiber is good in conductivity (with the volume resistivity of 105-109 omega cm) and light in color, so that the application scope of the acrylic conductive fiber is expanded.

Owner:JIANGNAN UNIV

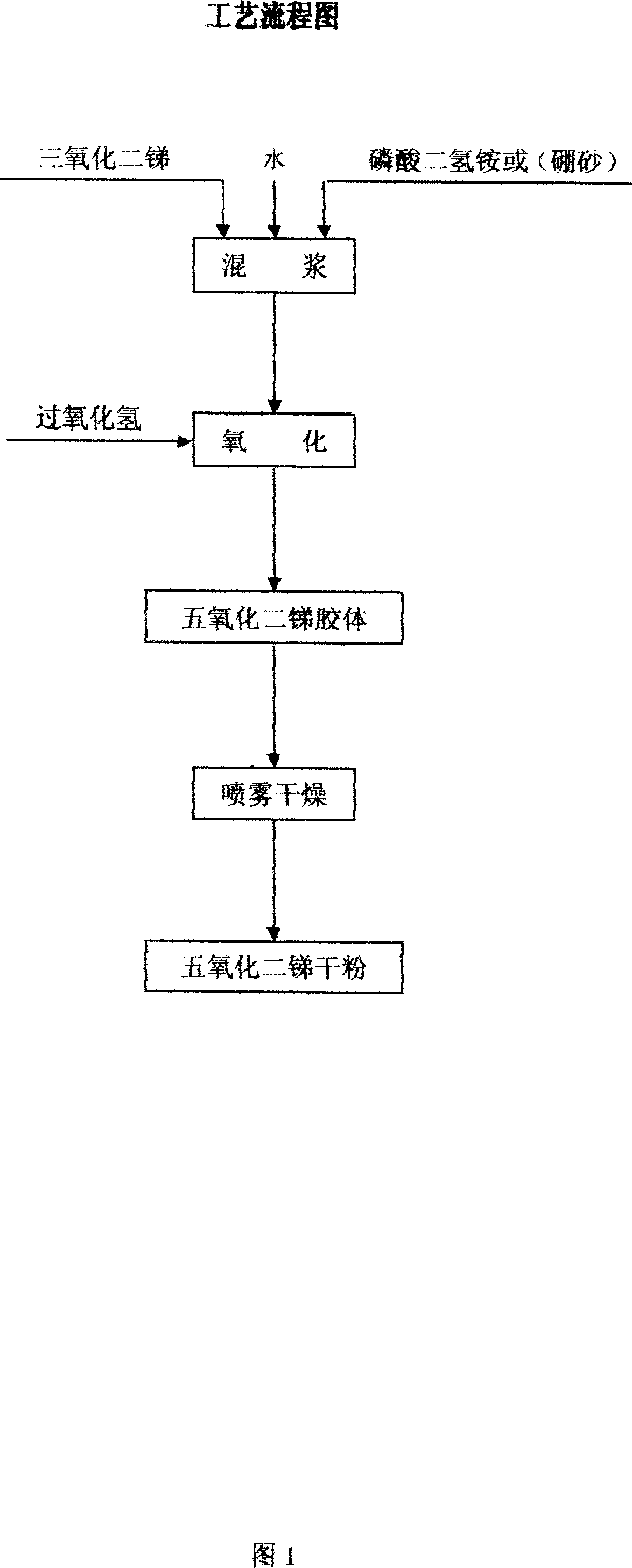

New process for producing colloid antimonic oxide

The invention relates to a method to produce colloid antimony pentoxide that adds water, stabilizer ammonium dihydrogen phosphate or borax, and 30% hydrogen peroxide into antimony oxide, heating to 80-95 degree centigrade, taking reaction for 90-140 minutes to gain colloid antimony pentoxide. Using spraying drying method, the colloid antimony pentoxide could be made into colloid antimony pentoxide powder. It has the advantages of reversible, stable, simple device, reliable quality, etc.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of polyantimonic acid ion-exchanger

InactiveCN101007290AImprove adsorption capacityAvoid contactCation exchangersHydration reactionIon exchange

The invention discloses a preparation method of poly-antimonic acid ion exchanger. The method of the invention includes the following steps: 1) antimony trioxide oxidation: antimony trioxide is oxygenated under the presence of oxidants and prepares hydrated antimony pentoxide sol; 2) Oxide aging: aging the prepared hydrated antimony pentoxide sol 1- 30 days under constant temperature of 0 ~ 70 degreeC; 3) drying and exploring in order to form particles: drying the aged hydrated antimony pentoxide sol to poly-antimonic acid solid, putting it into thin nitric acid solution to explore particles and prepares poly-antimonic acid ion exchanger. The invention method has the following advantages: 1. mild preparation conditions and short reaction time; 2. simple installations, low requirements to equipment and easy operation process; 3. preparation process avoids the touch of toxic chemicals; 4. low-cost preparation process, less art operating cost and good adsorption properties of ion exchanger; 5. high selective adsorption capacity of the prepared poly-antimonic acid inorganic ion exchanger to Sr2+.

Owner:TSINGHUA UNIV

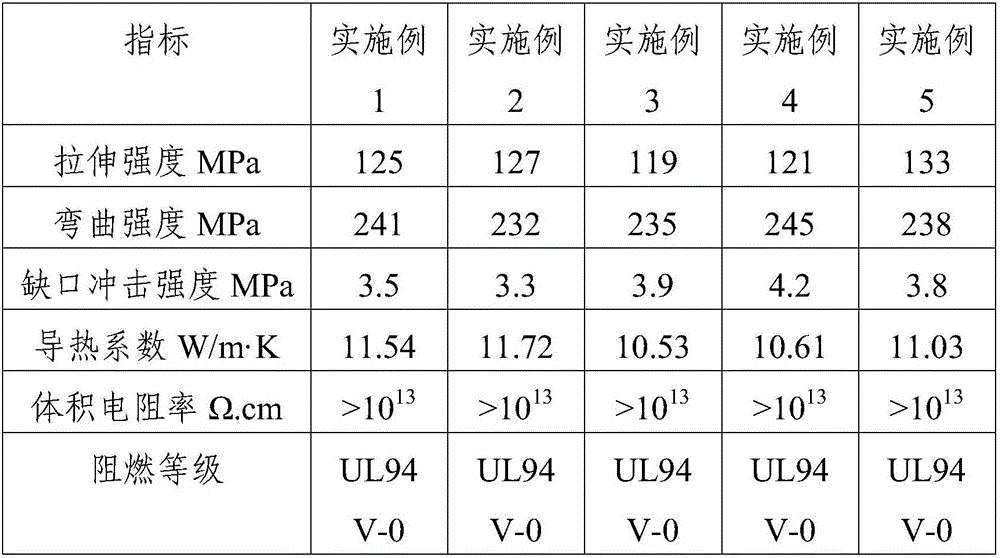

Flame-retardant PET heat-conducting material for heater and preparation method thereof

InactiveCN106147155AImprove flame retardant performanceImprove thermal stabilityHeat-exchange elementsHeat conductingEngineering plastic

The invention relates to the technical field of engineering plastics, in particular to a flame-retardant PET heat-conducting material for a heater and a preparation method thereof. The flame-retardant PET heat-conducting material for a heater consists of the following raw materials in parts by weight: 65-75 parts of PET, 15-75 parts of PBT 20 parts, 0.4-0.6 parts of talcum powder, 15-18 parts of zinc oxide, 3-6 parts of magnesium oxide, 8-10 parts of nano-boron nitride, 2-4 parts of nano-silica, 2-4 parts of hollow glass microspheres , 3‑6 parts of titanate coupling agent, 1.5‑2.5 parts of calcium stearate, 1‑2 parts of dioctyl phthalate, 3‑5 parts of colloidal antimony pentoxide, 4‑5 parts of silicone flame retardant 7 parts, 2-3 parts of polytetrafluoroethylene, 3-6 parts of stabilizer, the main steps of the preparation method of the flame-retardant PET heat-conducting material for the heater include weighing and drying, modification treatment, premixing, extrusion granulation, The flame-retardant PET heat-conducting material for heaters in the present invention has excellent thermal conductivity, good insulation, and good flame retardancy and mechanical properties, making its use in heaters safer and more reliable.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

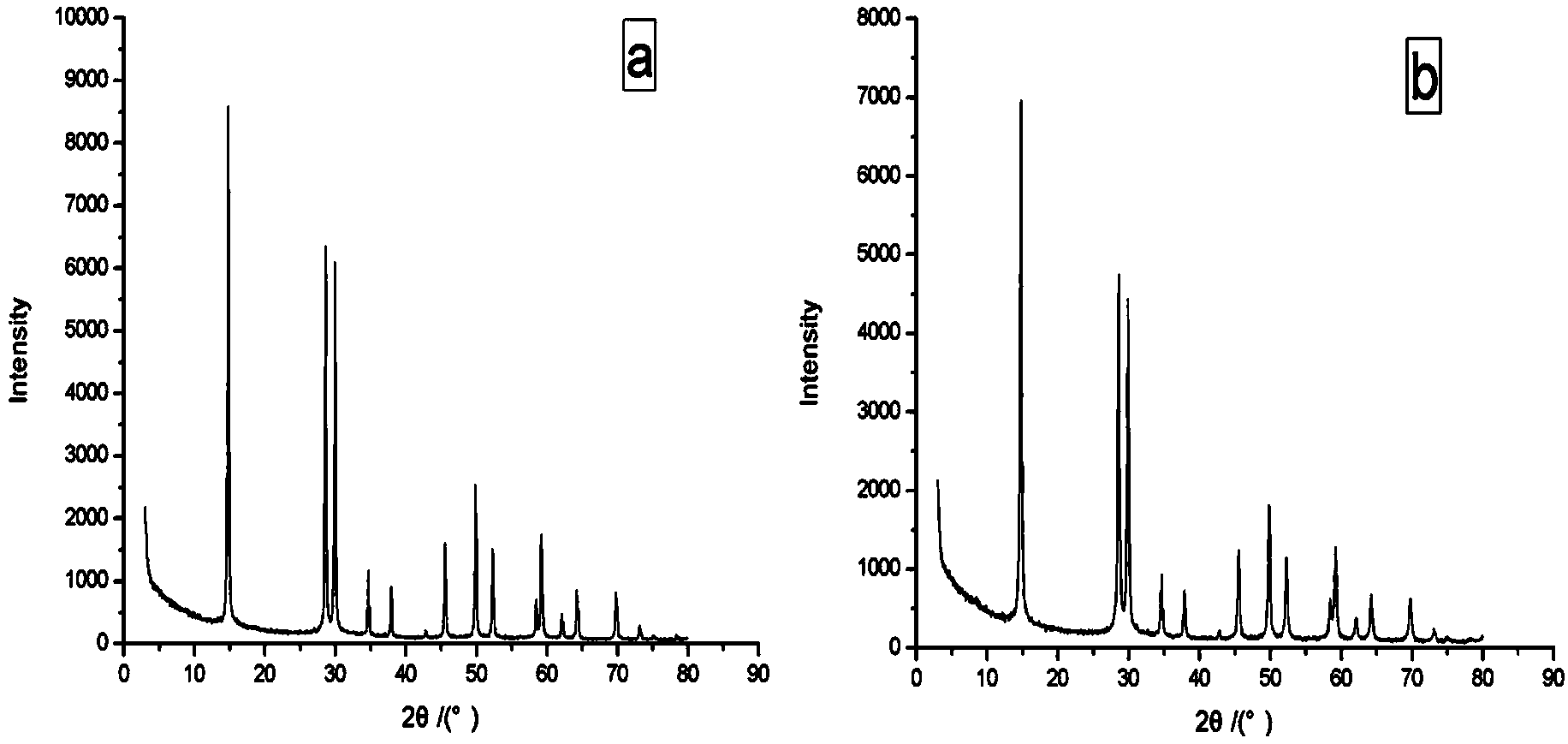

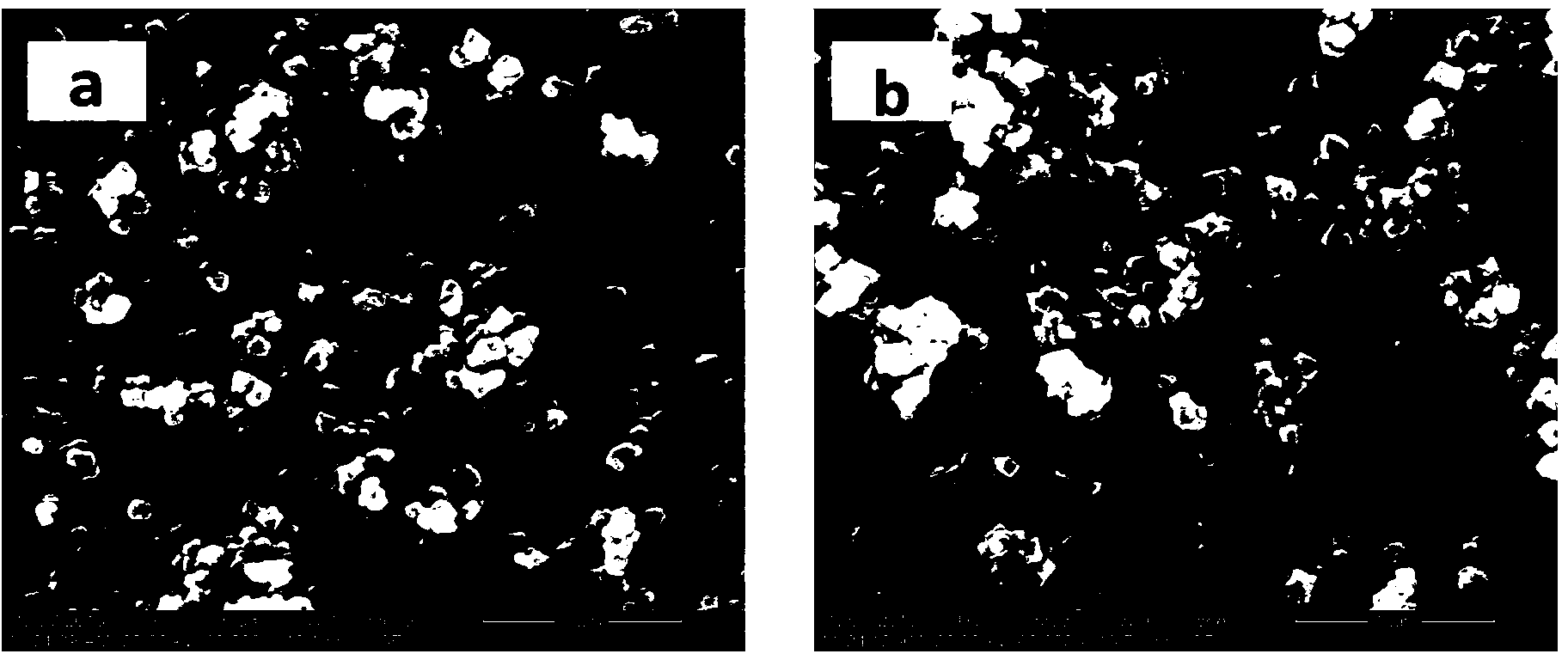

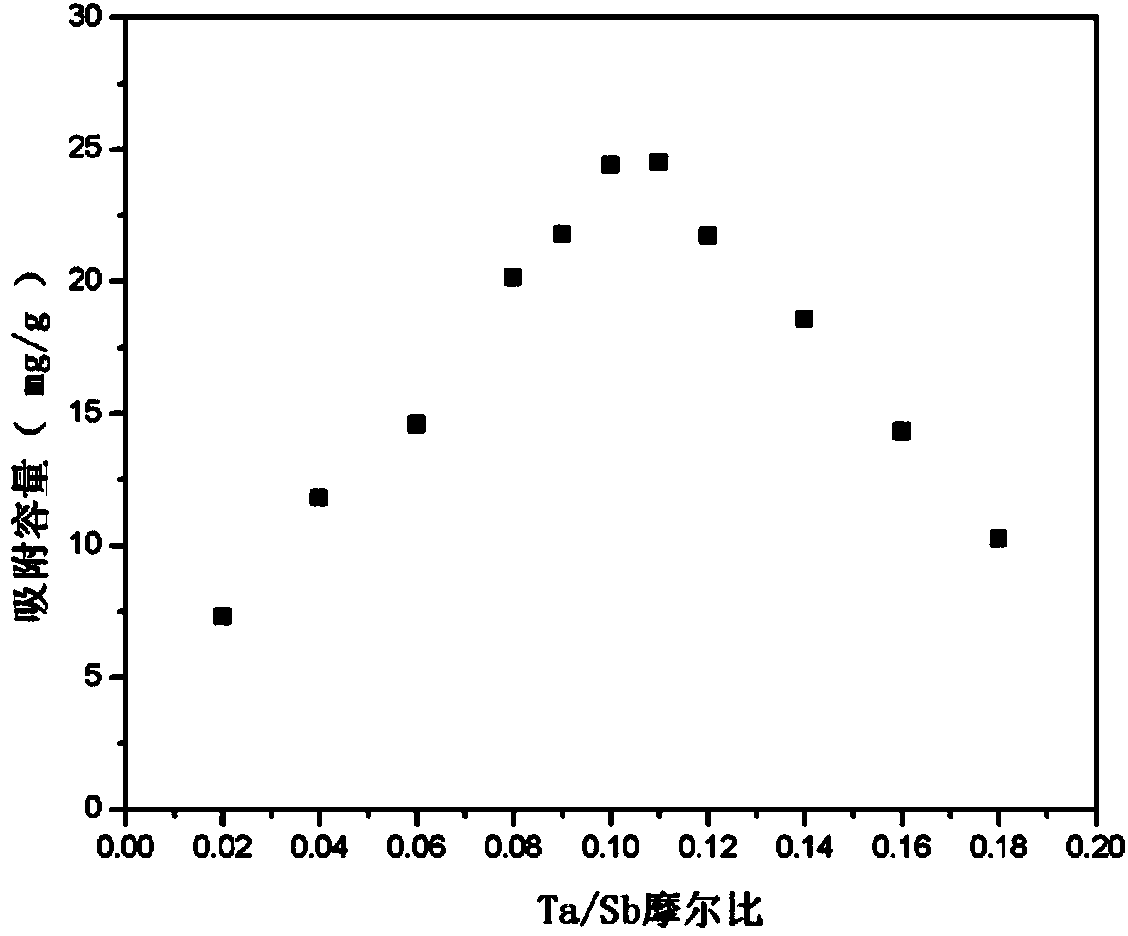

Preparation method of tantalum-doped hydrated antimony pentoxide adsorbing material

InactiveCN103977758AHigh adsorption capacitySimple processCation exchanger materialsOther chemical processesFreeze-dryingPolytetrafluoroethylene

The invention discloses a preparation method of a tantalum-doped hydrated antimony pentoxide adsorbing material. The preparation method is characterized by comprising the following steps: preparing 15-18 parts of an SbCl5 hydrochloric acid solution of which the concentration is 0.7-0.8mol / L, adding the SbCl5 hydrochloric acid solution into a polytetrafluoroethylene reaction kettle, adding 0-18 parts of redistilled water, and stirring and mixing; adding 0-18 parts of a TaCl5 ethanol solution of which the concentration is 0.09-0.11mol / L into the solution so as to regulate the molar ratio of Ta to Sb in the solution to be 0-0.18, and stirring and adequately mixing the two solutions; adding 19-21 parts of ammonia water of which the concentration is 8mol / L into the solution, regulating the pH value of the solution to be 1-2, and stirring for 0.5-1 hour; sealing the polytetrafluoroethylene reaction kettle, putting the polytetrafluoroethylene reaction kettle into a programmable drying oven, respectively setting the warming and cooling velocities to be 1 DEG C per minute, carrying out hydro-thermal treatment for 24-48 hours at 160-180 DEG C, taking out the reaction kettle and cooling to the room temperature after the reaction is finished, respectively washing reaction products to be neutral by virtue of distilled water, putting the reaction products into a freezer dryer, and carrying out freeze drying at -40 DEG C, so as to obtain the tantalum-doped hydrated antimony pentoxide adsorbing material.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Lead zirconate titanate piezoelectric ceramic and preparation method thereof

The invention discloses a lead zirconate titanate piezoelectric ceramic. The lead zirconate titanate piezoelectric ceramic is prepared from the following raw materials in parts by weight: 55 to 75 parts of lead tetroxide, 0 to 6 parts of barium sulfate, 0.2 to 8 parts of strontium carbonate, 0.1 to 0.9 part of niobium pentoxide, 0.2 to 1 part of antimony pentoxide, 15 to 25 parts of zirconium dioxide and 8 to 15 parts of titanium dioxide. According to the lead zirconate titanate piezoelectric ceramic disclosed by the invention, an excellent lead zirconate titanate piezoelectric ceramic material is prepared by adopting a two-step sintering solid-phase synthesis preparation method, so that the high-temperature sintering time is effectively shortened, and the energy, the time and the production cost are saved to a certain extent. According to the two-step sintering method, by controlling the temperature change, grain boundary migration can be restrained, grain boundary diffusion can be kept in an active state, and therefore the purpose of completing sintering on the premise that grains do not grow up is achieved.

Owner:GUANGZHOU KAILITECH ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com