New process for producing colloid antimonic oxide

A technology of antimony pentoxide and antimony trioxide, which is applied in inorganic chemistry, antimony compounds, chemical instruments and methods, etc., can solve the problem of difficulty in providing large-scale antimonate industrial products, difficult to realize industrialization, and difficult to industrialize transformation, etc. problems, to achieve the effect of easy promotion, stable process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

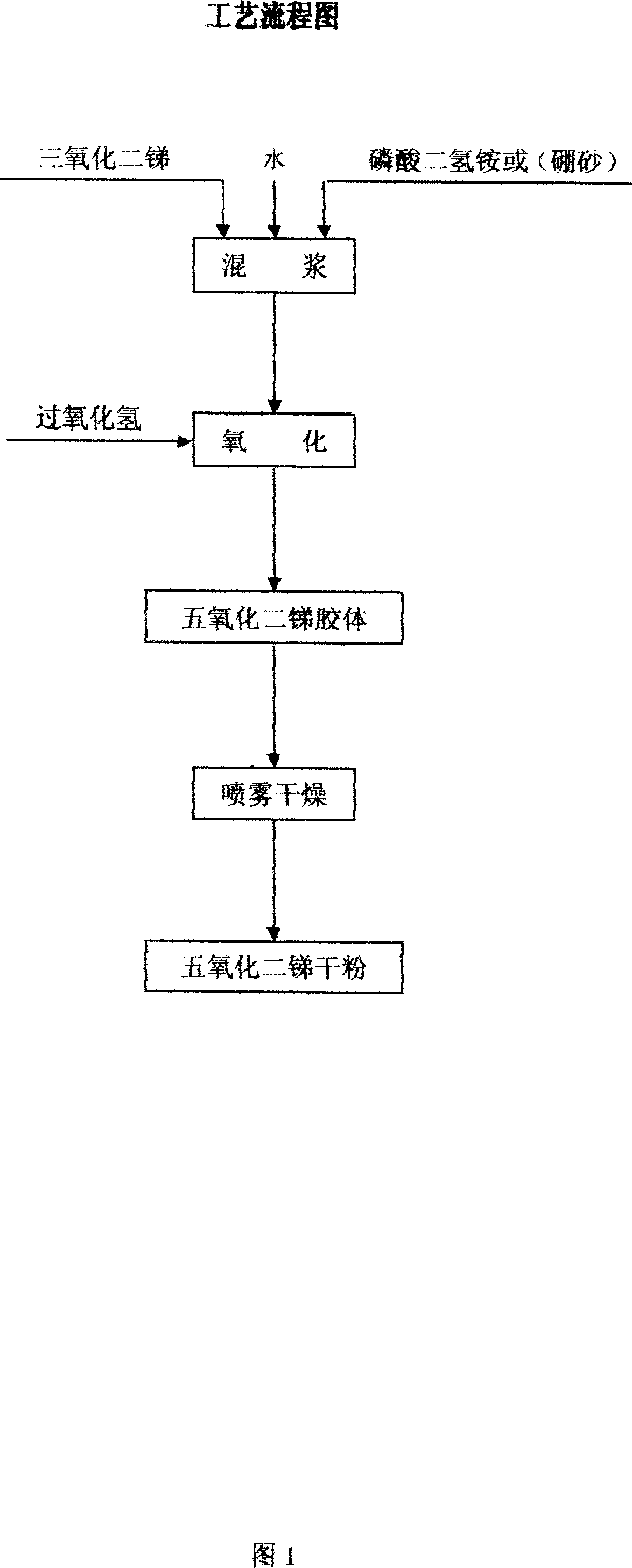

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, choose 10kg of antimony trioxide, the amount of water is 3o~45L, ammonium dihydrogen phosphate 1.5~2.5kg, before oxidation reaction, add and mix vigorously and stir evenly, then add 30% hydrogen peroxide to be 9~15L, with over Hydrogen oxide refluxes to oxidize antimony trioxide, the reaction time is 100-140 minutes, and the reaction temperature is 80-100°C, and colloidal antimony pentoxide with uniform dispersion and long stable period can be prepared. If spray drying method can be used Colloidal antimony pentoxide is further made into colloidal antimony pentoxide dry powder. The white translucent colloid can still be uniformly dispersed and dispersed in series after redissolving the dry powder into water, that is, the colloid and dry powder of the present invention are reversible and stable.

Embodiment 2

[0015] Embodiment 2, choose antimony trioxide 35~45kg, water yield is 0.6~1.2L, borax is 0.9kg, before oxidation reaction, add and mix vigorously and stir evenly, then add 30% hydrogen peroxide to be 8~14L, with peroxidation Hydrogen reflux oxidizes antimony trioxide, the reaction time is 80-100 minutes, the reaction temperature is 80-100 degrees, and the colloidal antimony pentoxide with uniform dispersion and long stable period can be prepared. Antimony pentoxide is further made into colloidal antimony pentoxide dry powder, and the dry powder-colloid is reversible and stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com