Preparation method of tantalum-doped hydrated antimony pentoxide adsorbing material

A technology of antimony pentoxide and adsorption materials, which is applied in the direction of chemical instruments and methods, separation methods, cation exchange materials, etc., can solve problems such as no patent literature and non-patent literature reports, and achieve improved adsorption capacity and process flow simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

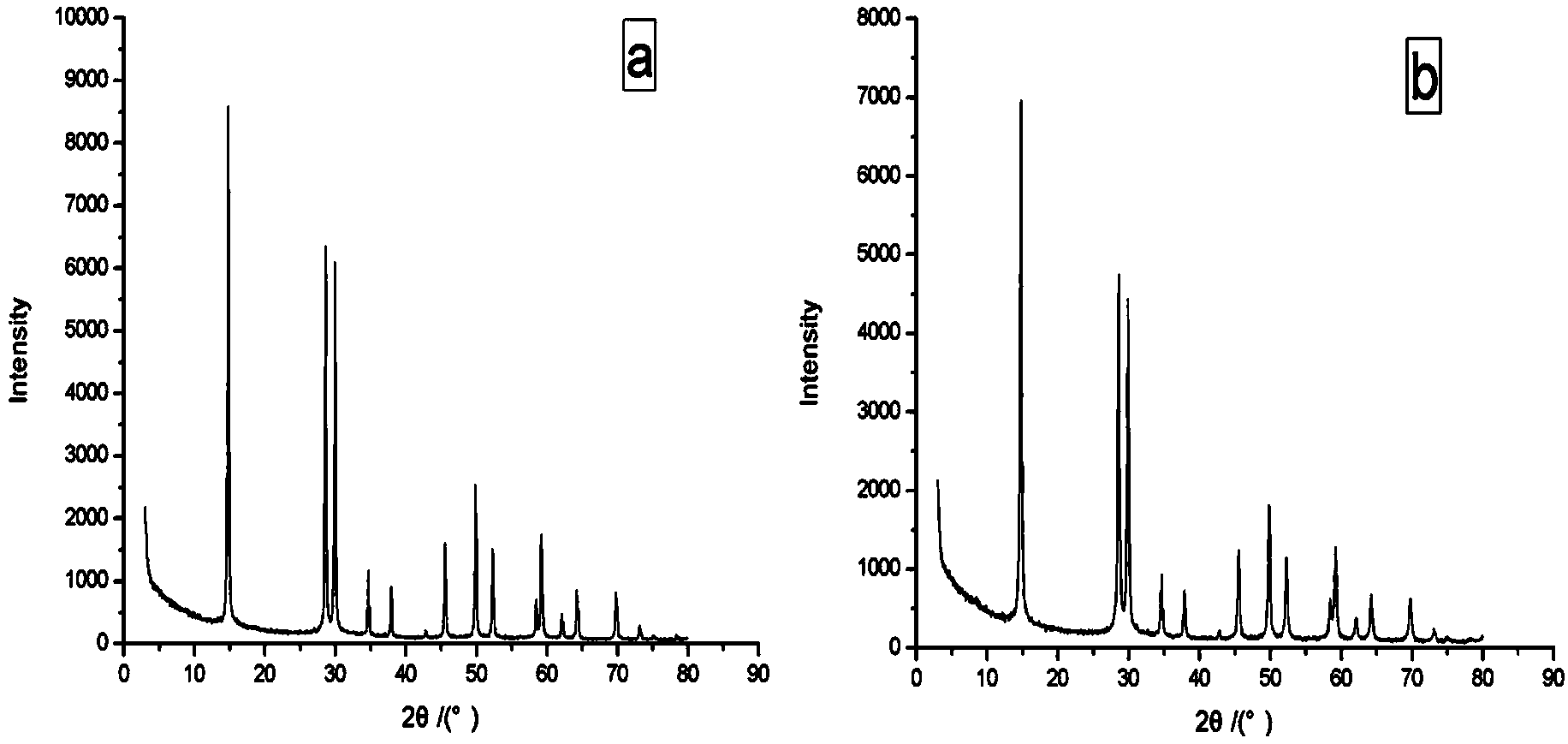

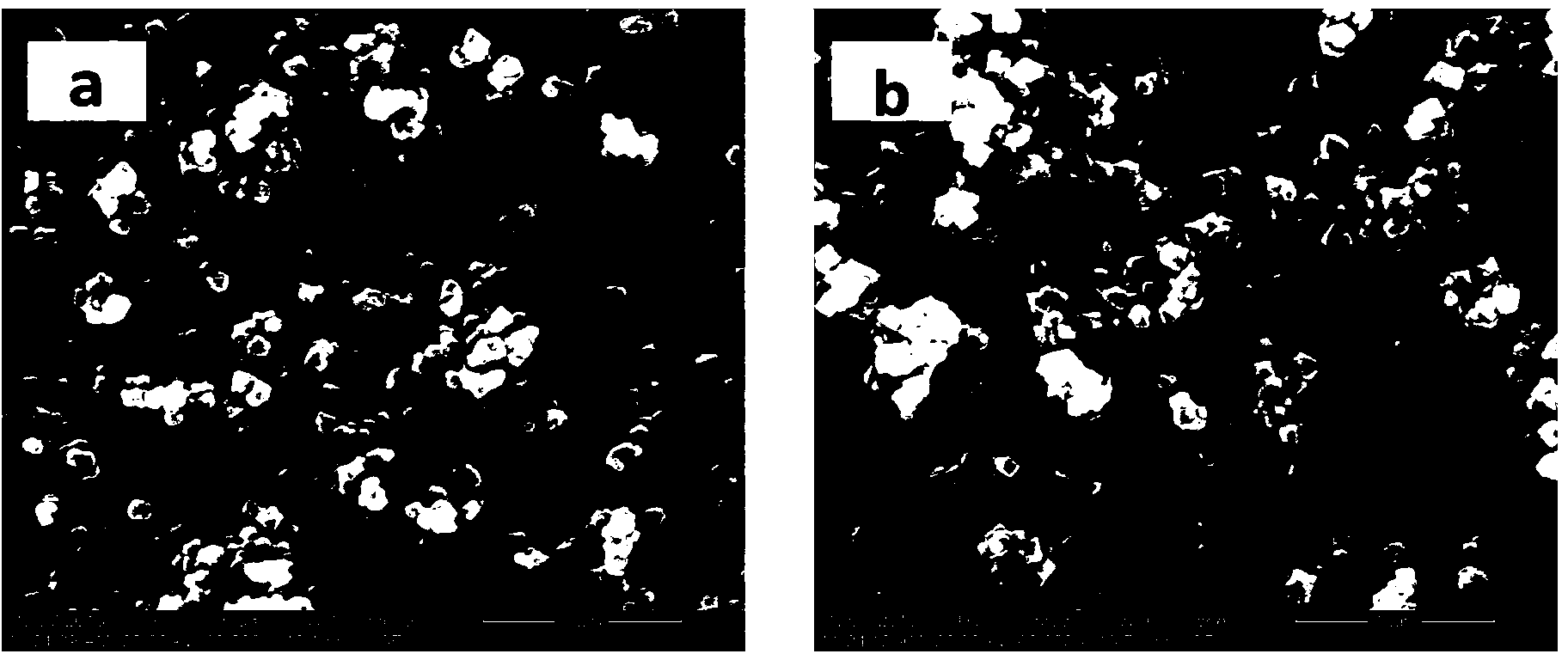

Embodiment 1

[0040] Take 0.7mol / L of SbCl 5 Put 18 parts of hydrochloric acid solution in a polytetrafluoroethylene reactor, add 18 parts of double distilled water, stir to make it fully mixed, then add 19 parts of ammonia water with a concentration of 8mol / L to the above solution, and adjust the pH value to 1.43. Stir for 0.5h, seal the polytetrafluoroethylene reactor, place it in a programmed oven, set the heating and cooling rate to 1°C / min, and conduct hydrothermal treatment at a temperature of 160°C for 48h. After the reaction is completed, take out the reactor and cool to room temperature . The reaction product is washed with distilled water until it becomes neutral, and then placed in a freeze dryer at a temperature of -40° C. to freeze-dry to obtain a hydrated antimony pentoxide material.

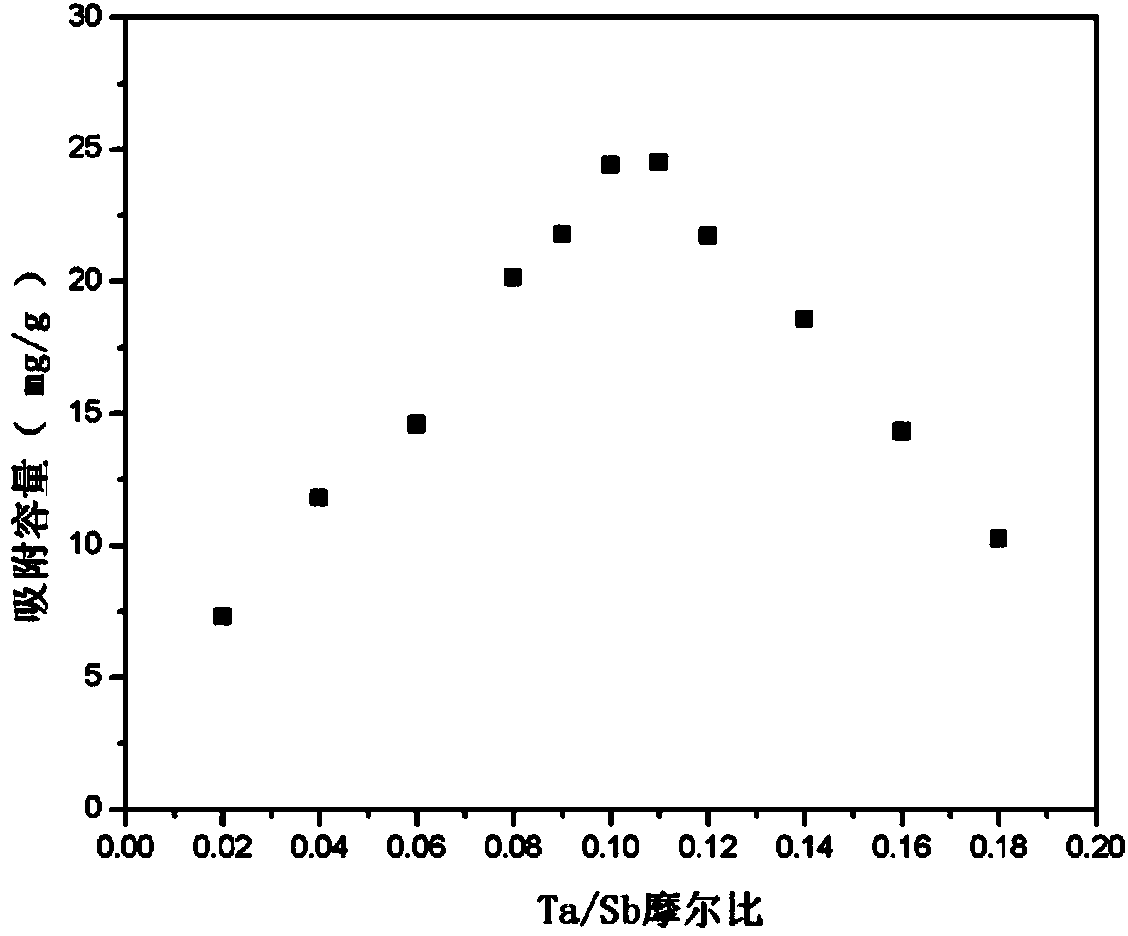

Embodiment 2

[0042] Take 0.8mol / L of SbCl 5 Put 15 parts of hydrochloric acid solution in a polytetrafluoroethylene reactor, add 16 parts of double distilled water, stir to make it fully mixed, and then add 0.11mol / L TaCl to the above solution 5 2 parts of ethanol solution, so that the molar ratio of Ta / Sb in the solution is 0.02, stir to make it fully mixed, then add 19 parts of ammonia water with a concentration of 8mol / L to the above solution, adjust the pH value to 1.35, stir the solution for 0.5h, seal The polytetrafluoroethylene reaction kettle is placed in a programmed oven, and the heating and cooling rate is set to 1°C / min. At a temperature of 160°C, hydrothermal treatment is carried out for 48 hours. After the reaction is completed, the reaction kettle is taken out and cooled to room temperature. The reaction product is used Washing with distilled water until neutral, and then freeze-drying in a freeze dryer at a temperature of -40°C, to obtain a tantalum-doped antimony pentoxide h...

Embodiment 3

[0044] Take 0.8mol / L of SbCl 5 Put 15 parts of hydrochloric acid solution in a polytetrafluoroethylene reactor, add 14 parts of twice distilled water, stir to make it fully mixed, and then add 0.11mol / L TaCl to the above solution 5 4 parts of ethanol solution, so that the molar ratio of Ta / Sb in the solution is 0.04, stir to make it fully mixed, then add 19 parts of ammonia water with a concentration of 8mol / L to the above solution, adjust the pH value to 1.29, stir the solution for 0.5h, seal The polytetrafluoroethylene reaction kettle is placed in a programmed oven, and the heating and cooling rate is set to 1°C / min. At a temperature of 160°C, hydrothermal treatment is carried out for 48 hours. After the reaction is completed, the reaction kettle is taken out and cooled to room temperature. The reaction products are respectively Washing with distilled water until neutral, and then freeze-drying in a freeze dryer at a temperature of -40°C to obtain a tantalum-doped antimony p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com